Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Conductive materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

'Electrically Conductive' means the ability of any material or object to conduct electricity through it with offering least possible resistance to the flow of electrons. Silver is found to be the most conductive material of all.

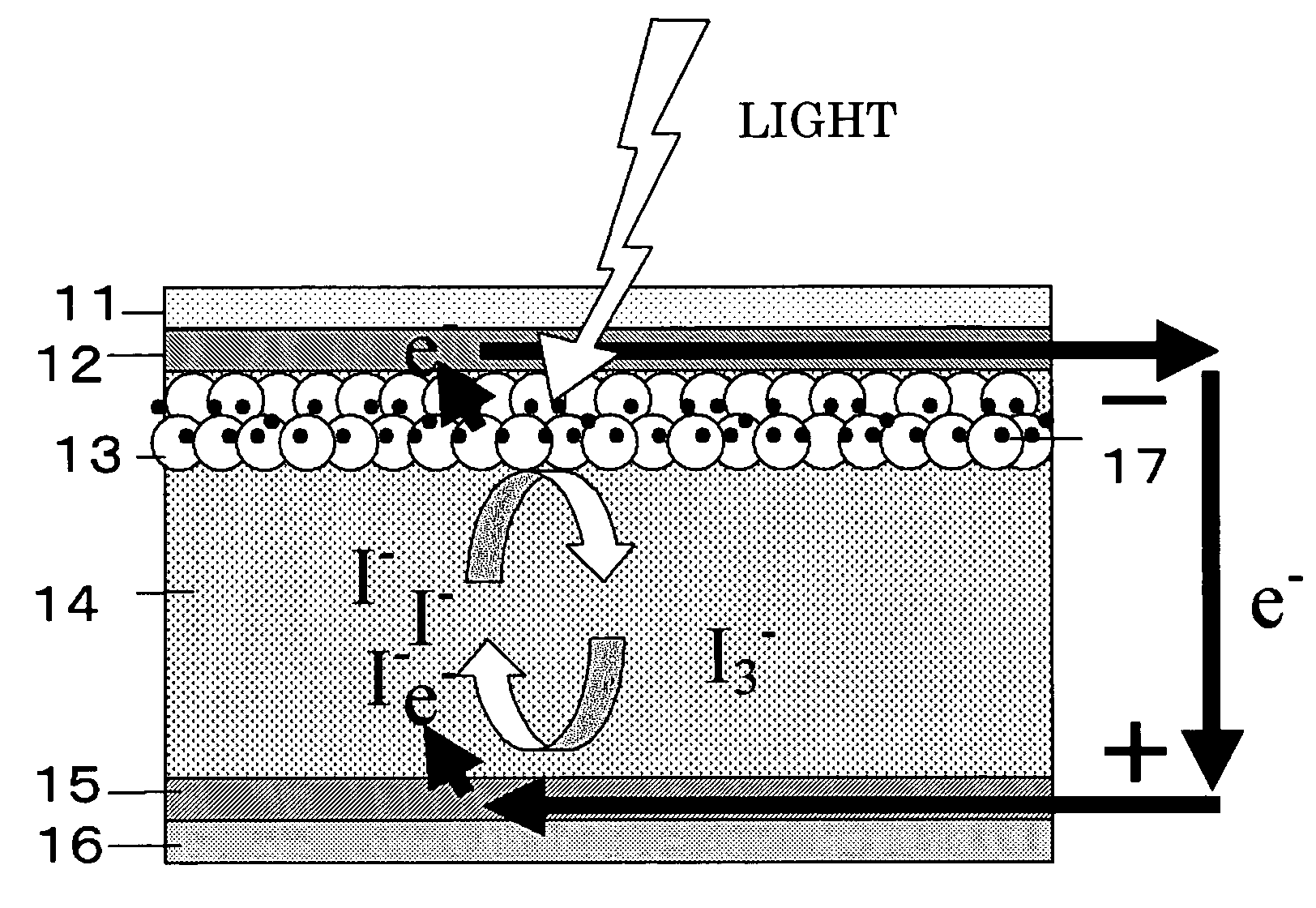

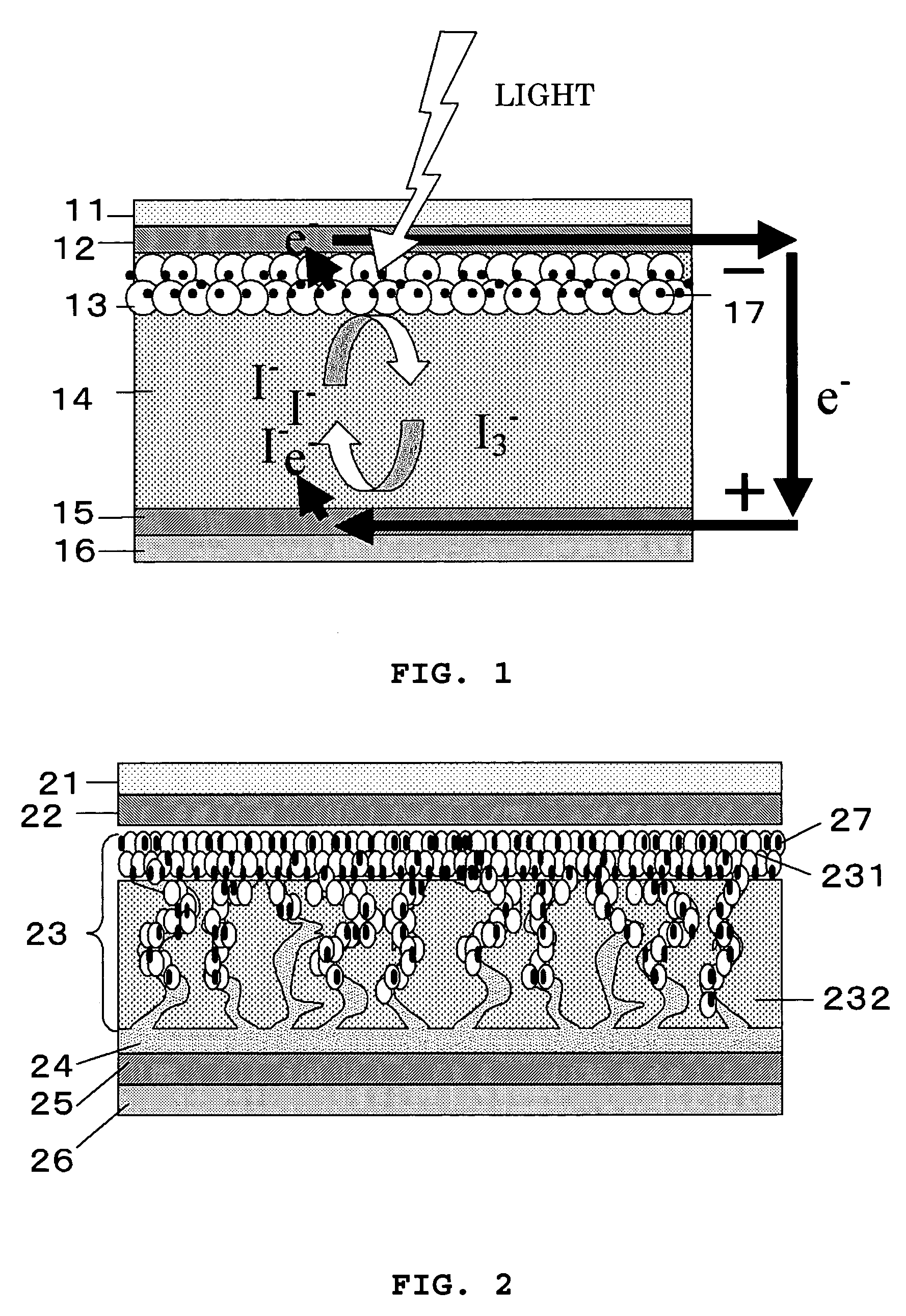

Porous electrodes, devices including the porous electrodes, and methods for their production

InactiveUS20060021649A1Improve efficiencyIncrease flexibilityElectrolytic capacitorsHybrid capacitor electrodesPore diameterConductive materials

Owner:SUMITOMO CHEM CO LTD

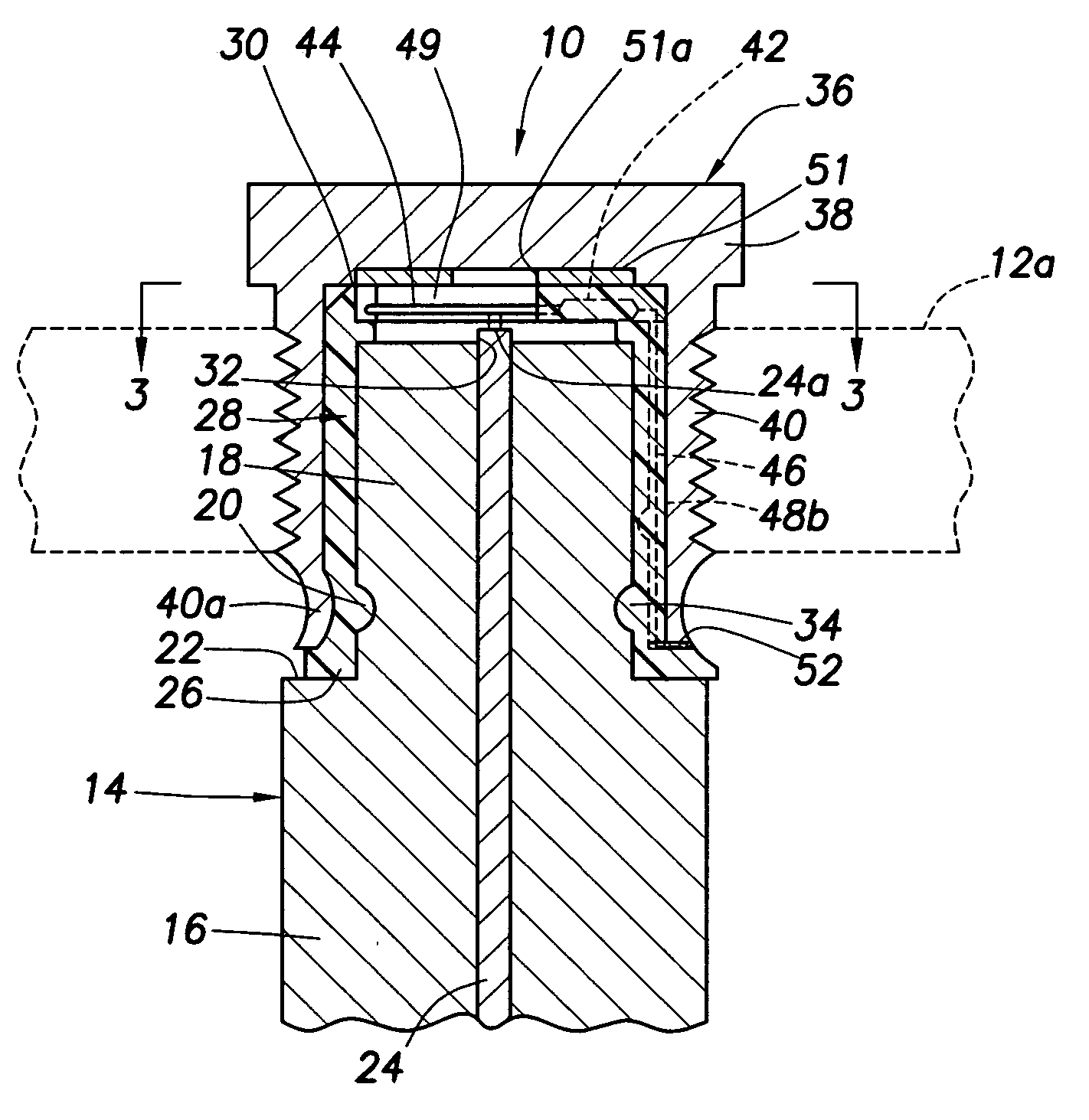

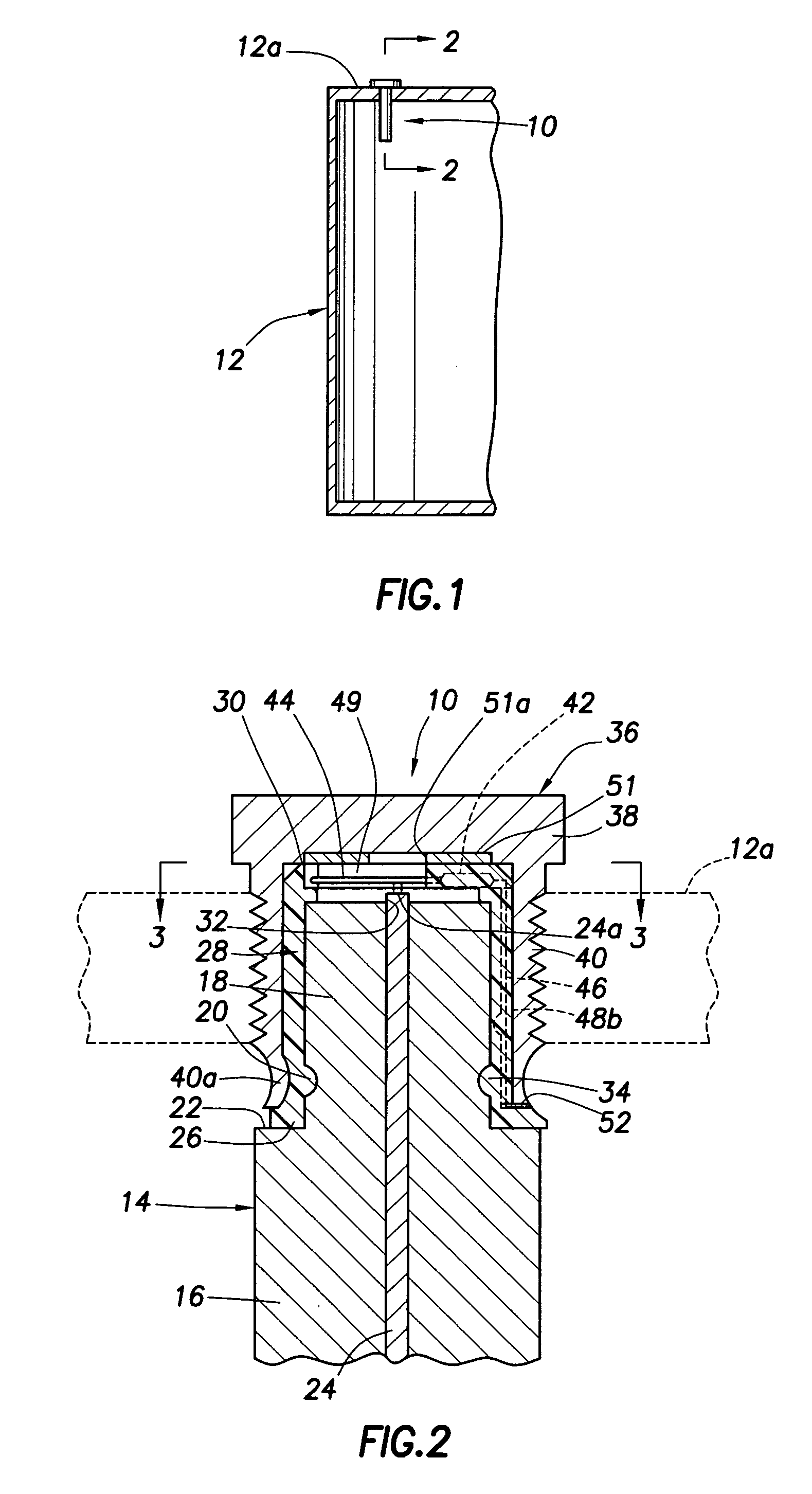

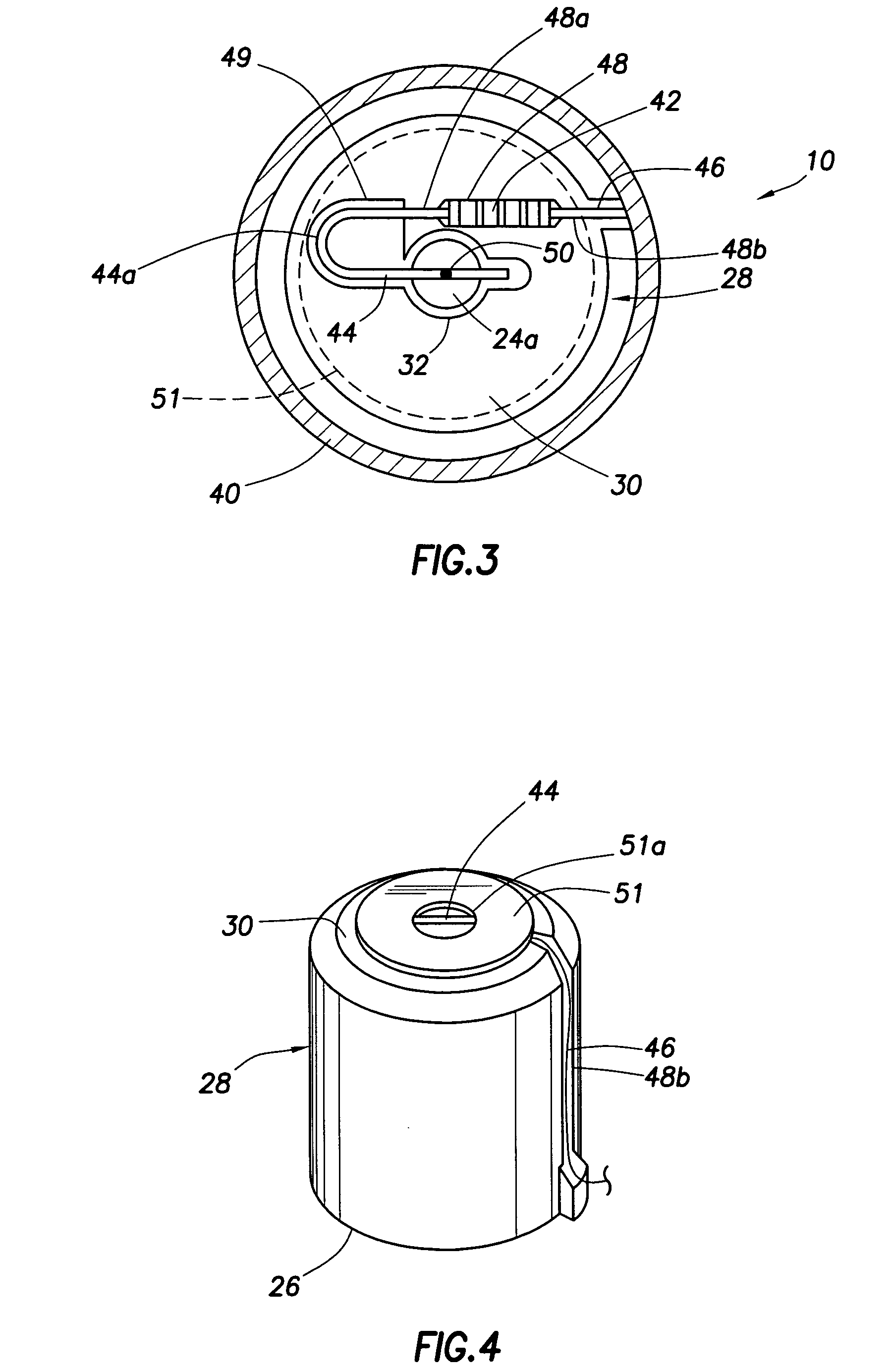

Wheel luminaire

A system for illuminating a wheel on a vehicle, the wheel having a concave area adapted for mounting around a wheel hub attached to stationary structure on the vehicle, the vehicle having an electrical power source. The system includes a contact ring that includes a circular backing ring of an electrically insulating material and a layer of electrically conductive material over the backing ring. The contact ring is flexibly supported from the concave area of the wheel where a contact brush mounted from the stationary structure of the vehicle makes contact with the layer of electrically conductive material on the contact ring. At least one electrical light emitting device is electrically connected to the layer of electrically conductive material on the contact ring, so that electrical power from the power source reaches the light emitting device through the contact brush and through the contact ring.

Owner:MARTINEZ MARVIN R +1

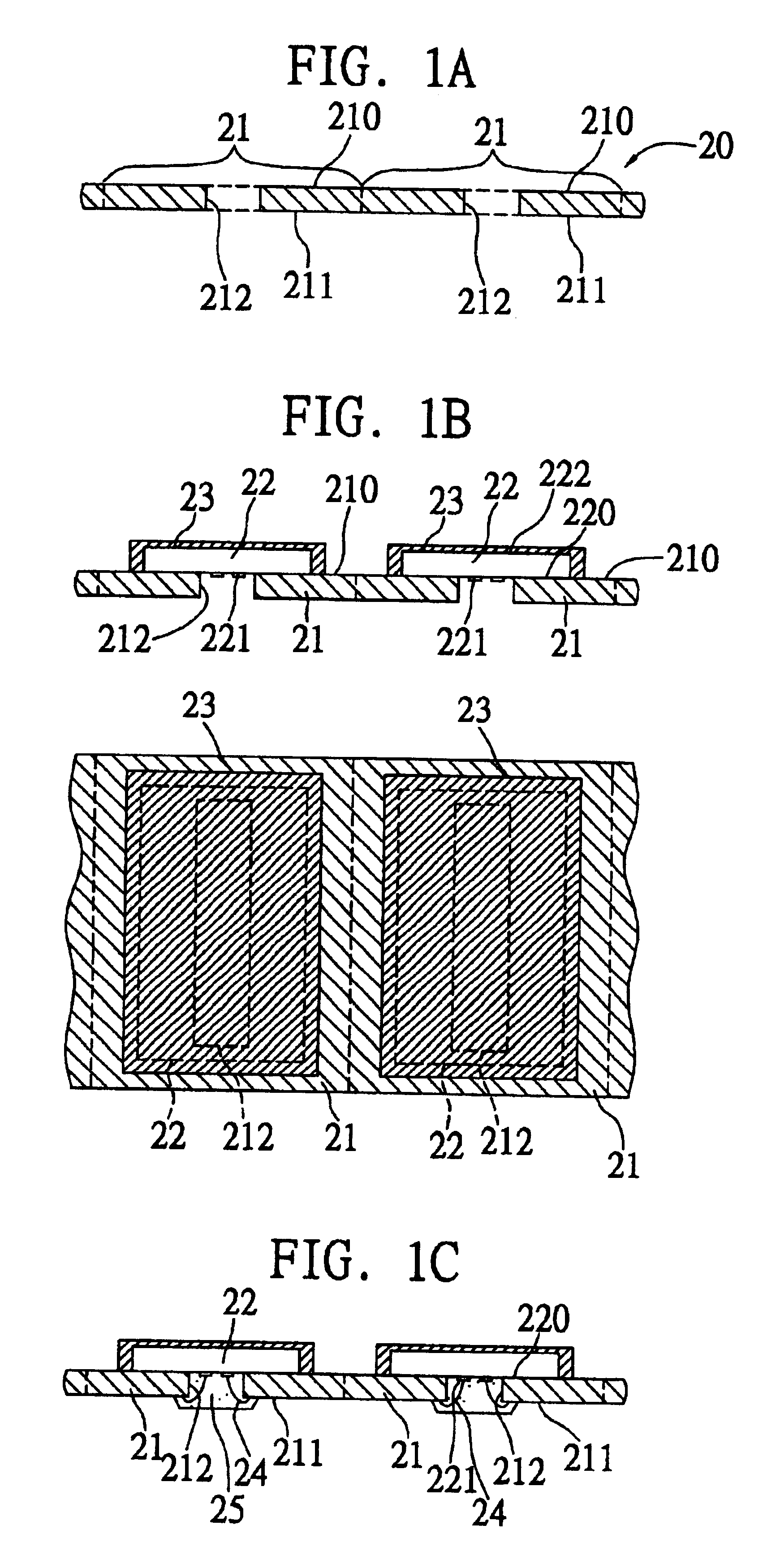

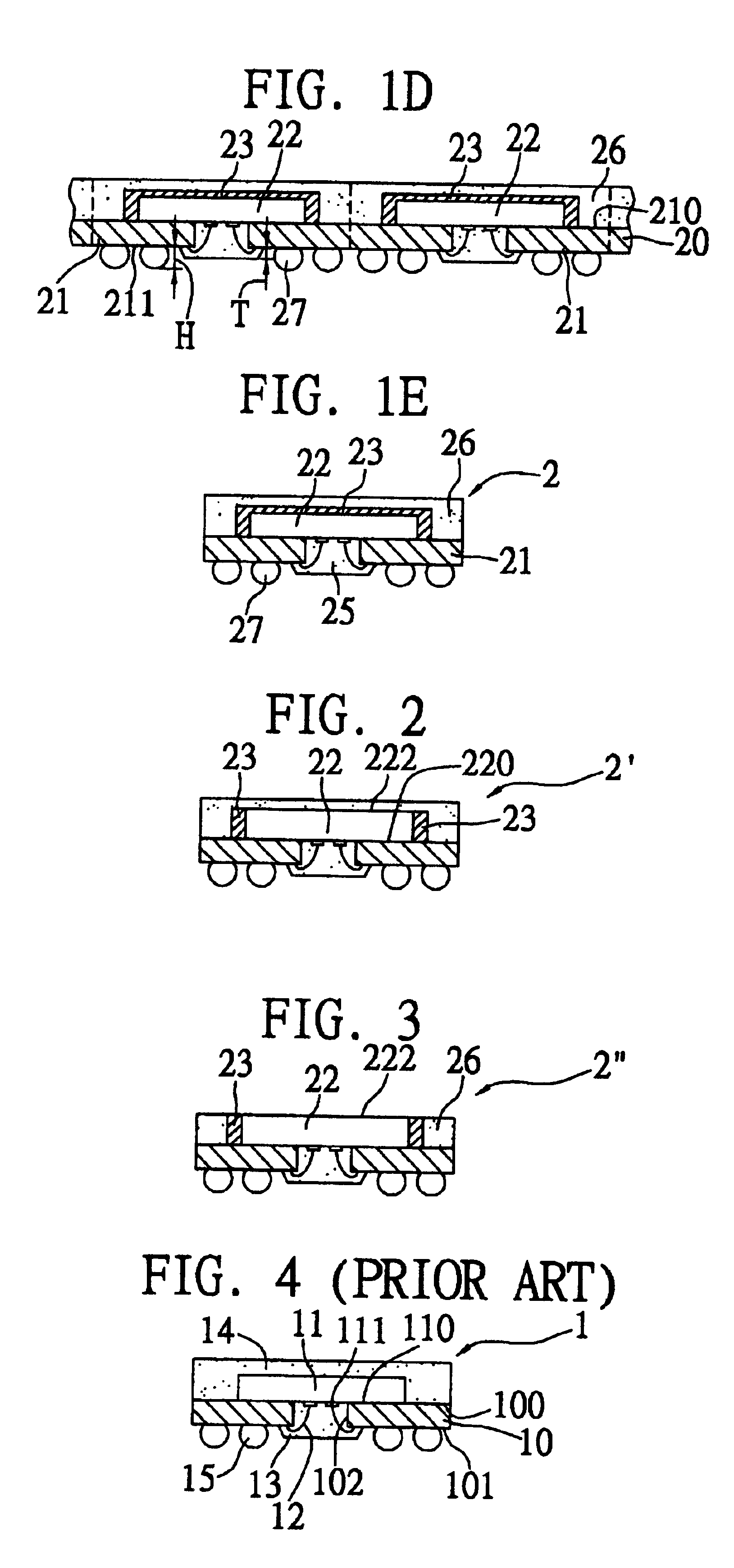

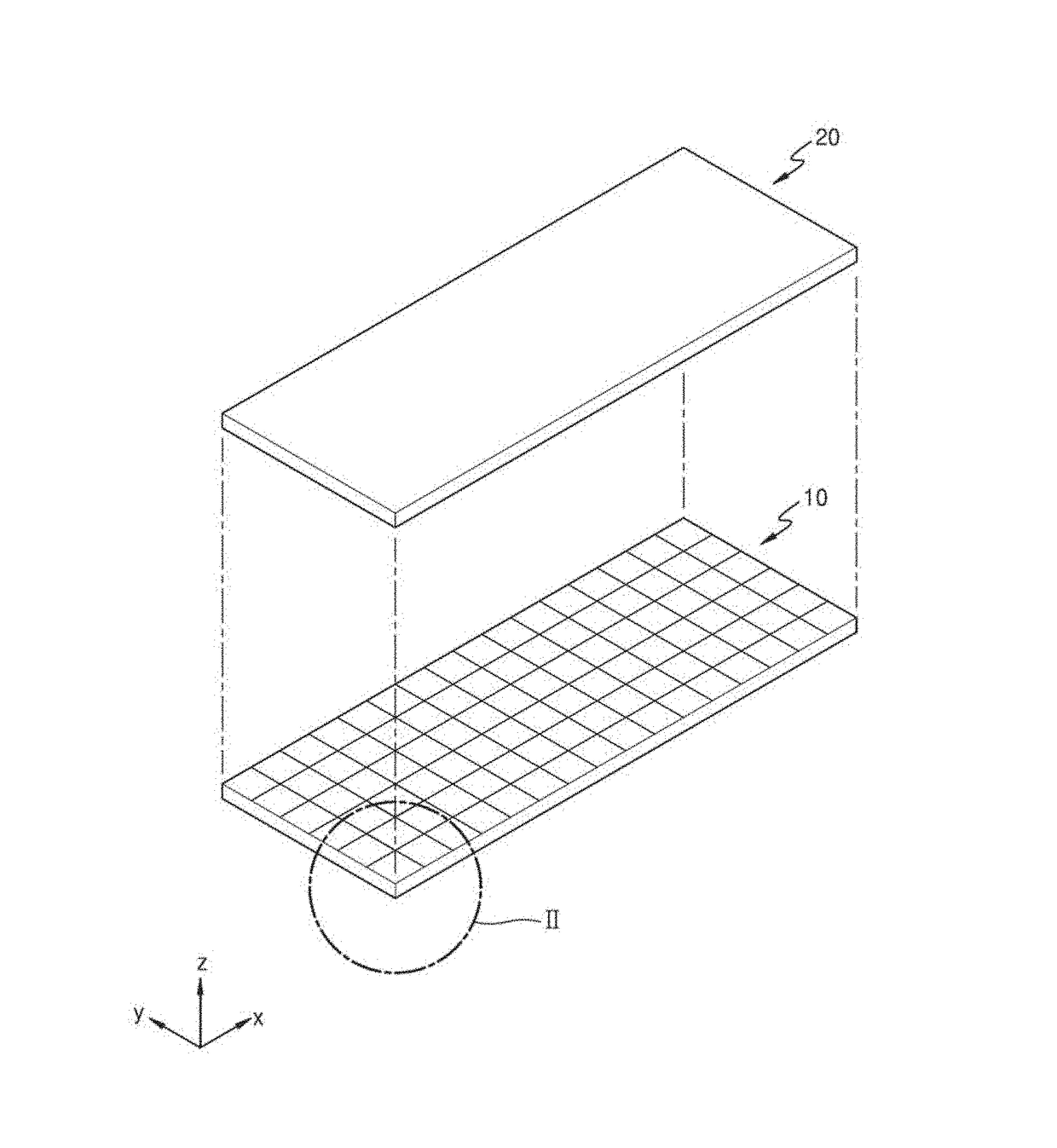

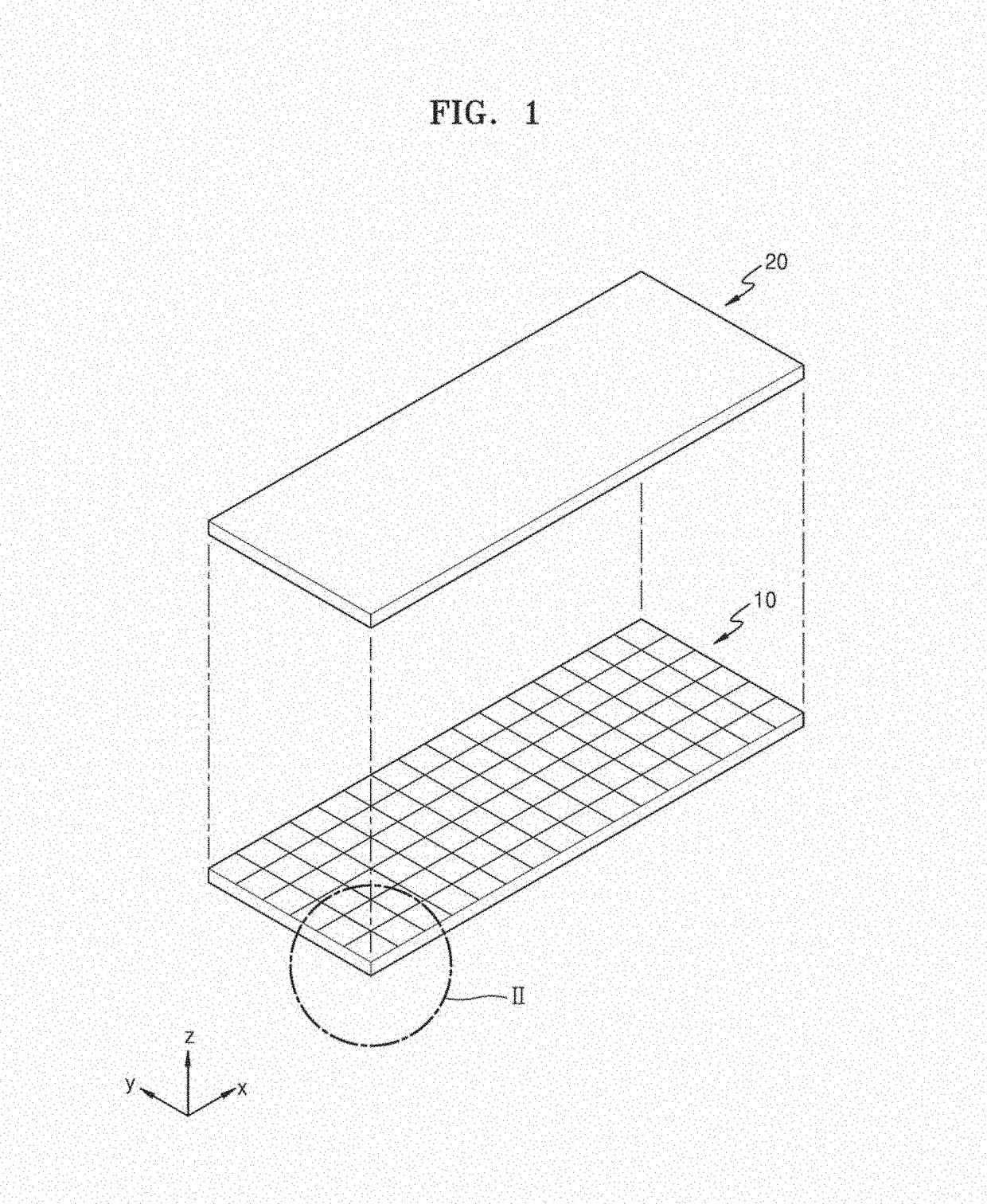

Semiconductor carrier film, and semiconductor device and liquid crystal module using the same

ActiveUS7164205B2Increase productionFine pitchSemiconductor/solid-state device detailsSolid-state devicesAlloyConductive materials

Owner:SHARP KK +1

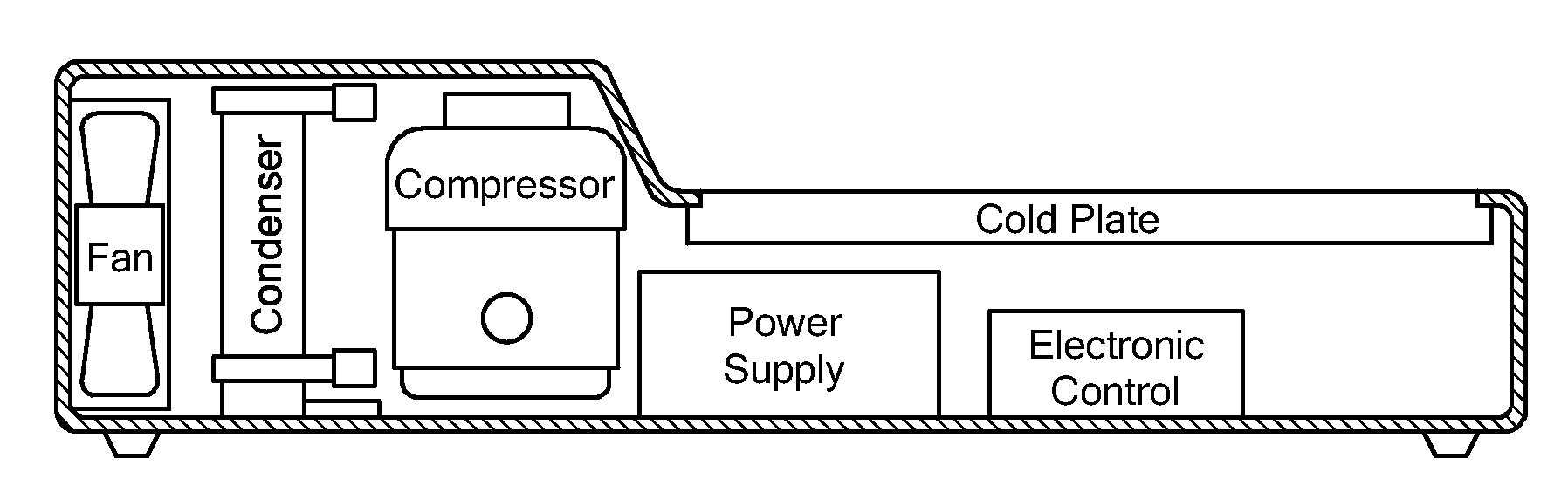

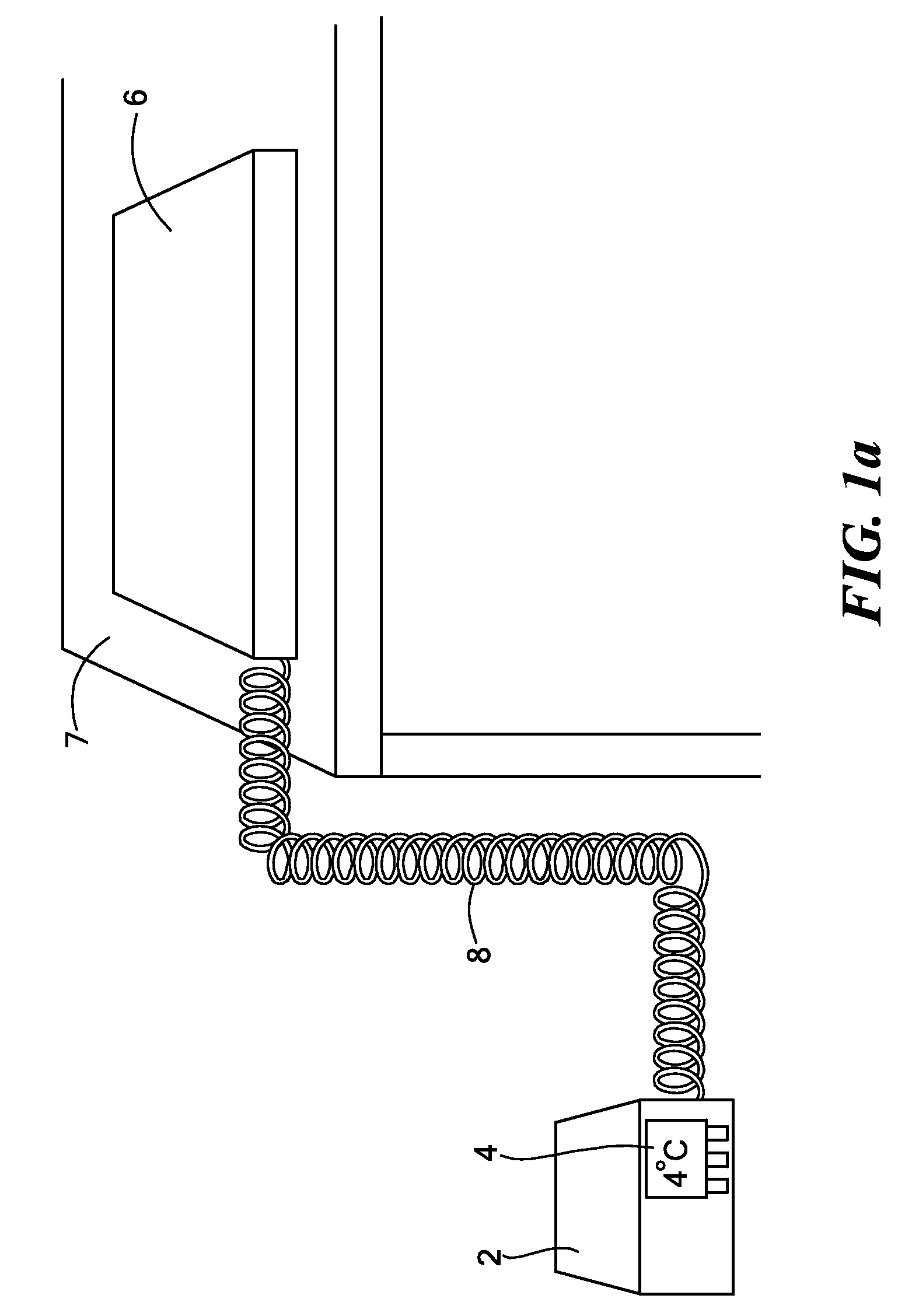

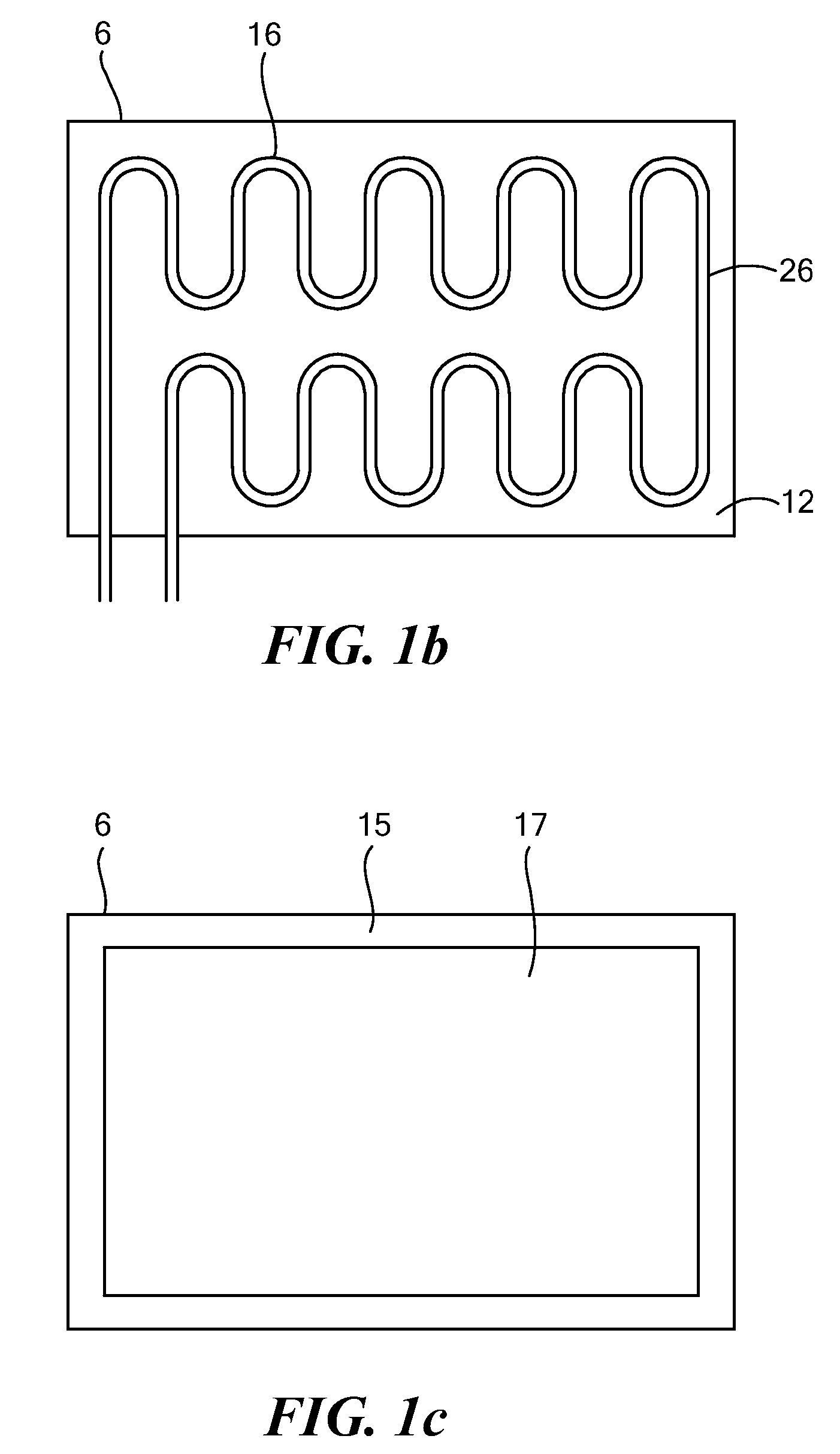

Laboratory Temperature Control With Ultra-Smooth Heat Transfer Surfaces

InactiveUS20080029248A1Decreased emissivitySludge treatmentHeating or cooling apparatusTemperature controlElectrical resistance and conductance

Owner:SAGE SCI

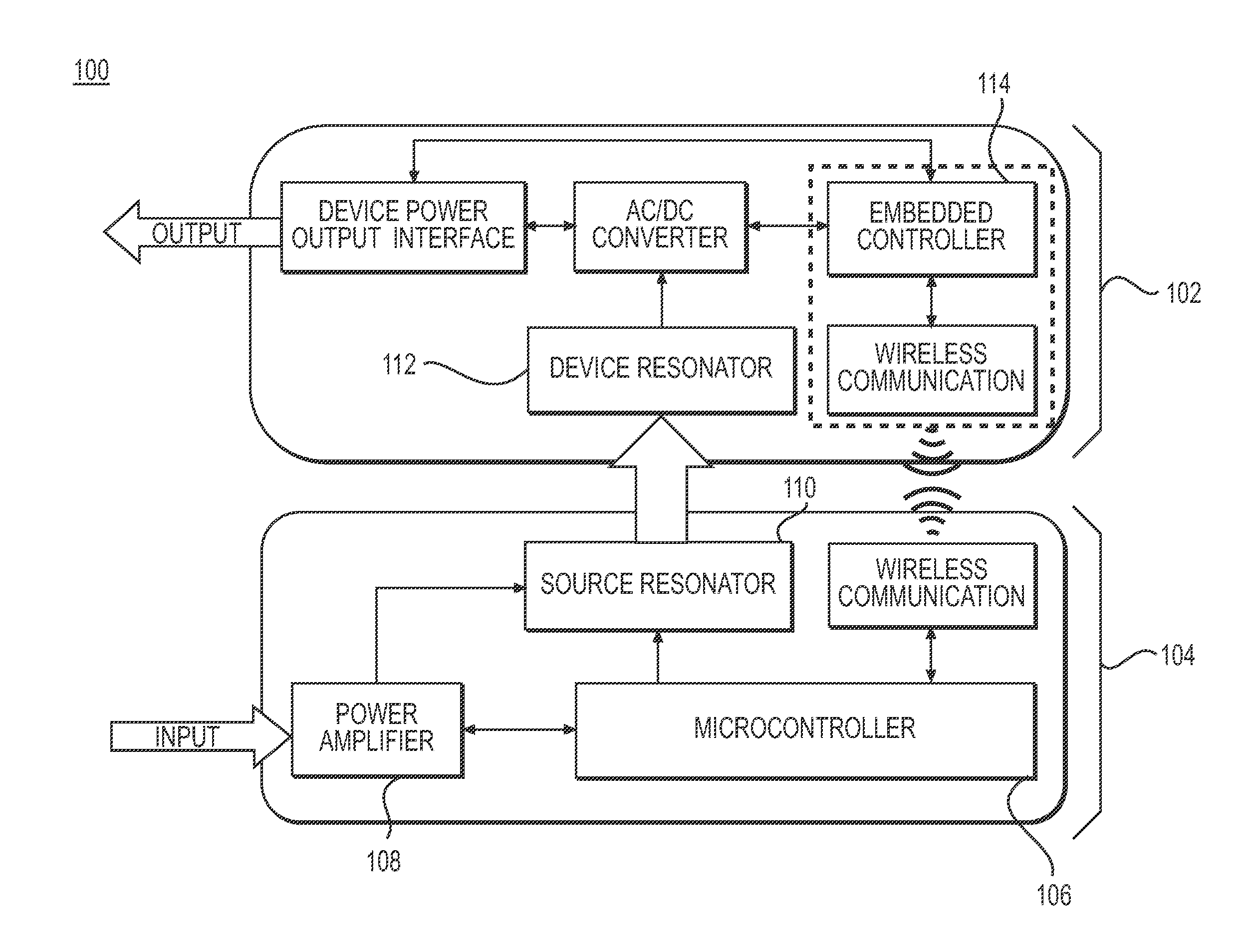

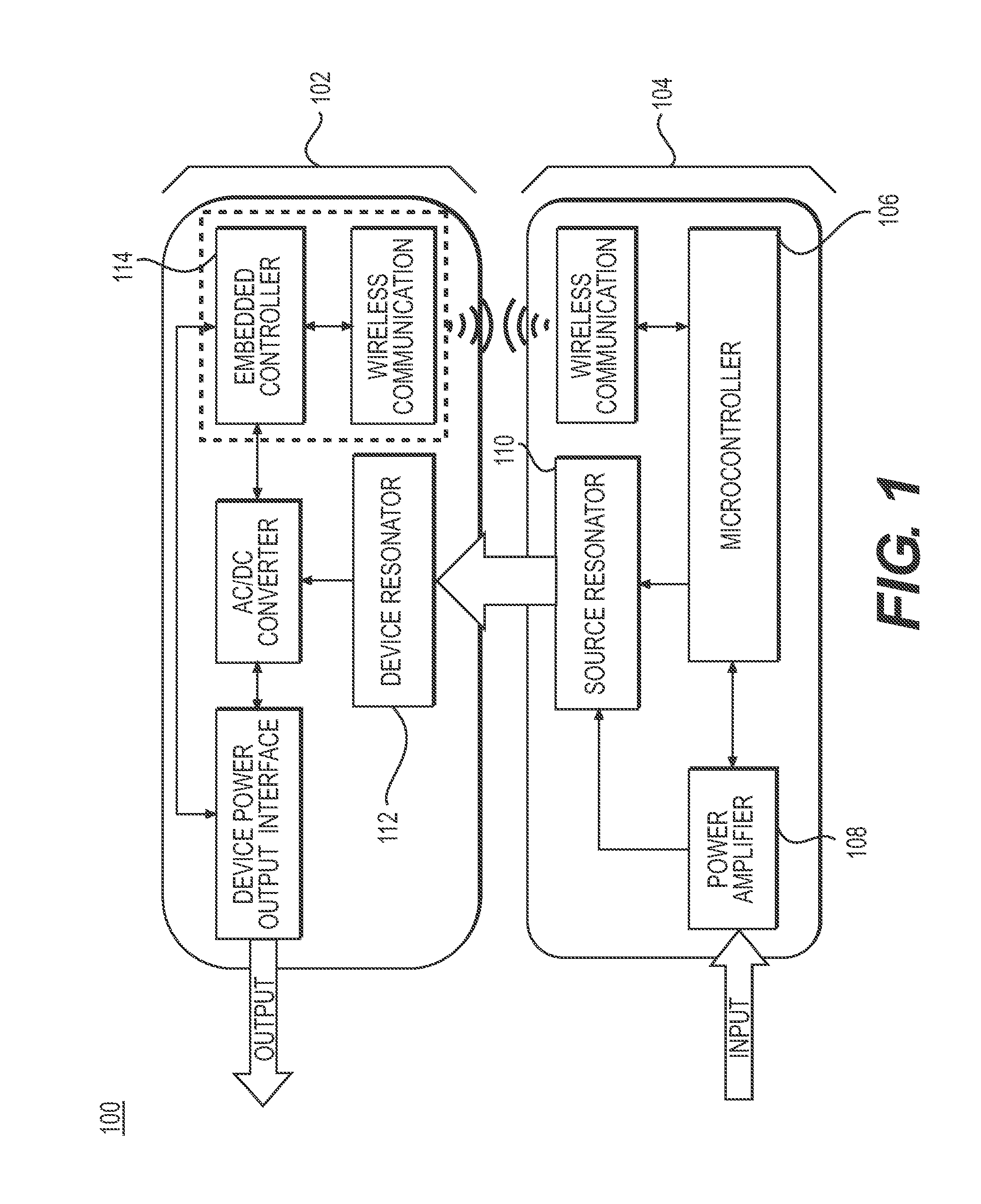

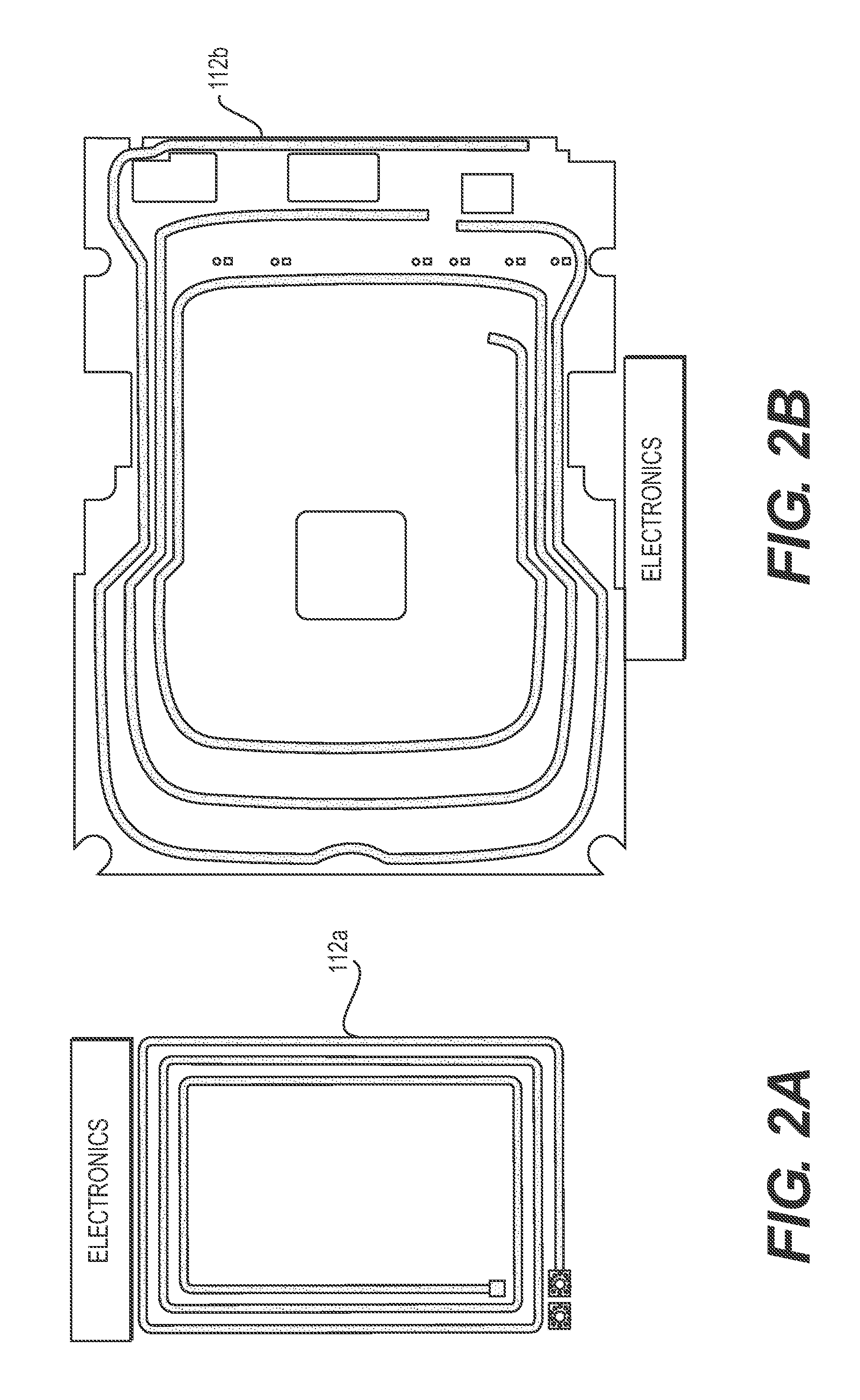

Wireless energy transfer for mobile device applications

ActiveUS20150303708A1Reduce inductance shiftingNear-field transmissionTransformersEnergy transferConductive materials

Owner:WITRICITY CORP

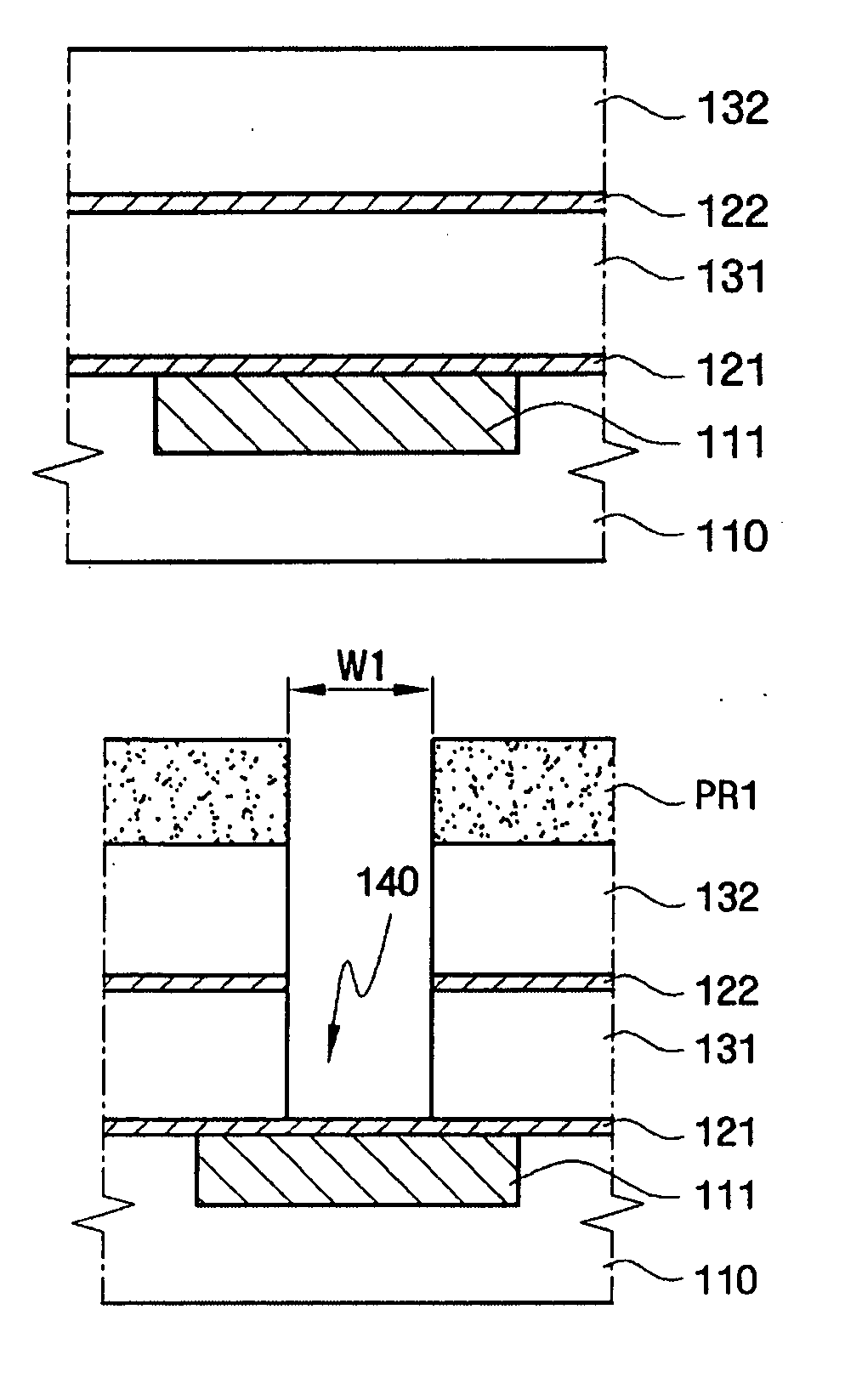

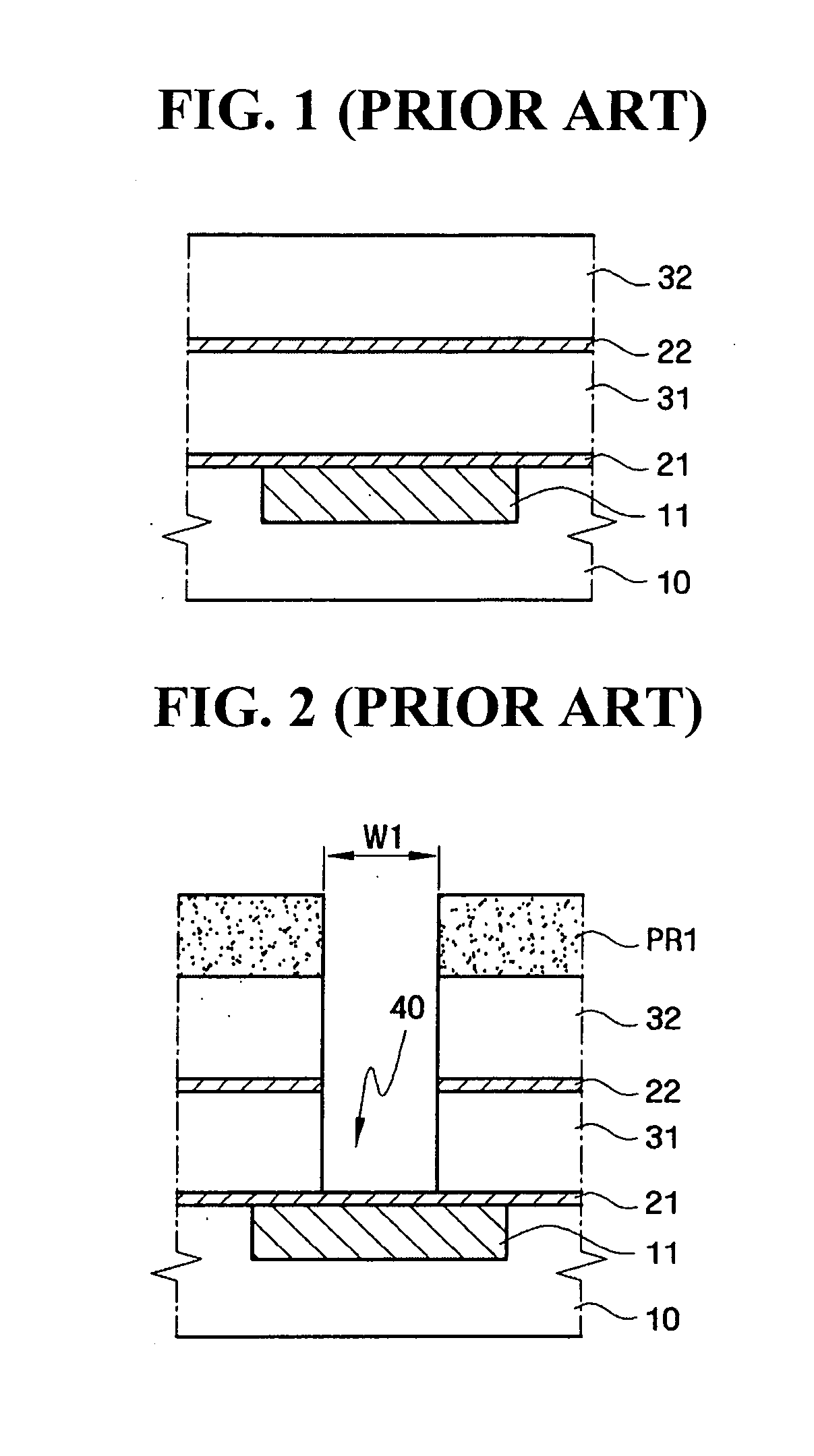

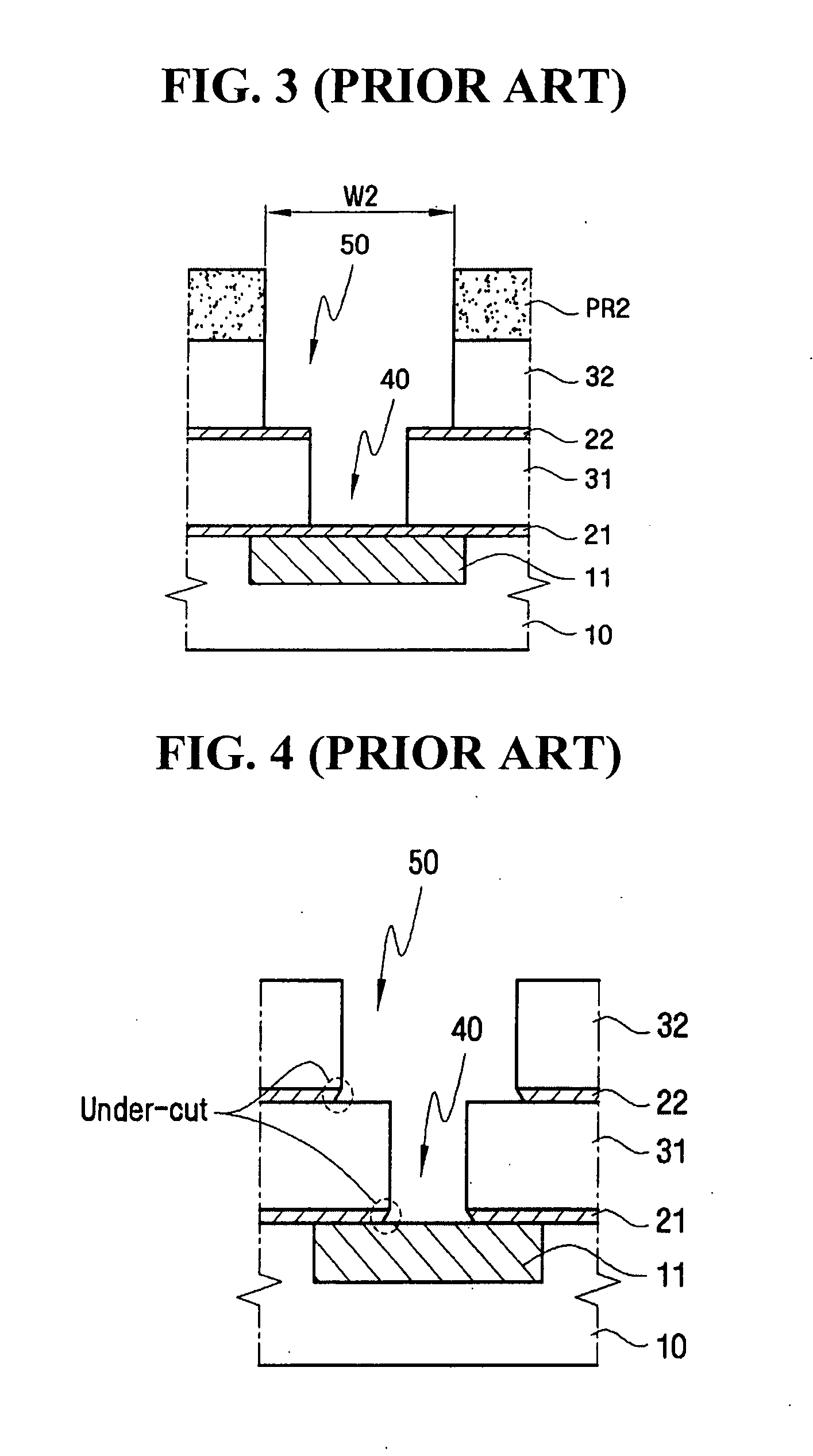

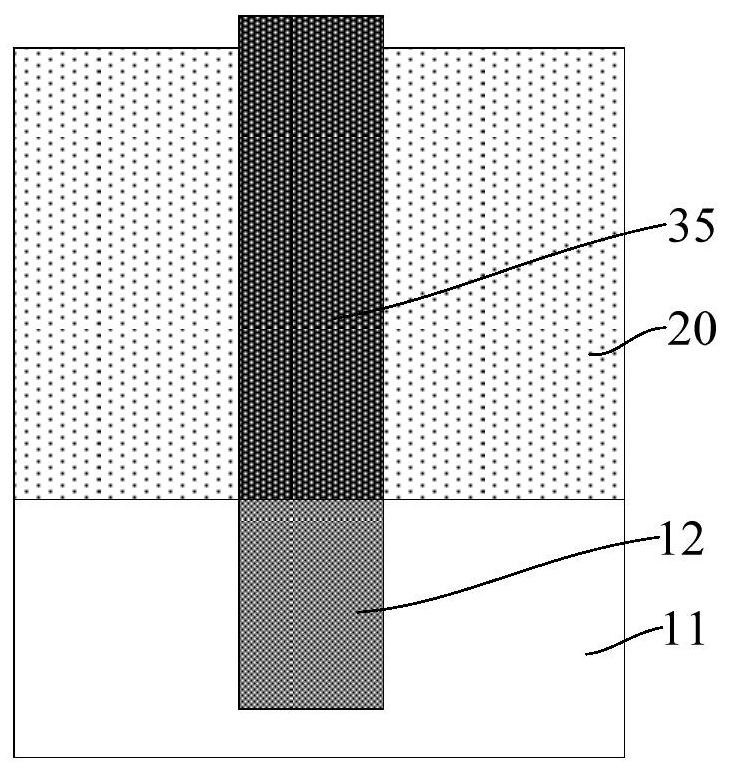

TFT array substrate manufacture method

ActiveCN105702623AReduce sizeNo short circuit problemSolid-state devicesSemiconductor/solid-state device manufacturingPixel densitySlope angle

The invention provides a TFT (Thin Film Transistor) array substrate manufacture method which comprises the following steps: coating and forming a flat layer on source electrodes and drain electrodes; instead of processing via holes, depositing and patterning a common electrode layer and a passivated protection layer; forming via holes in the passivated protection layer so as to expose the flat layer, and then ashing the flat layer so as to expose the drain electrodes. Compared with a conventional method by which the common electrode layer is deposited and patterned after the via holes are formed in the flat layer, the TFT array substrate manufacture method described in the invention is advantageous in that no electrically conductive material will be left in the via holes of the flat layer when the common electrode layer is patterned, and therefore no short circuit problem will occur in the via holes of the flat layer; the via holes are formed in the flat layer in a pixel region by a means of dry etching through ashing operation, the formed via holes are allowed to have large slope angles, and therefore the size of a TFT can be reduced to a certain extent and and pixel density can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

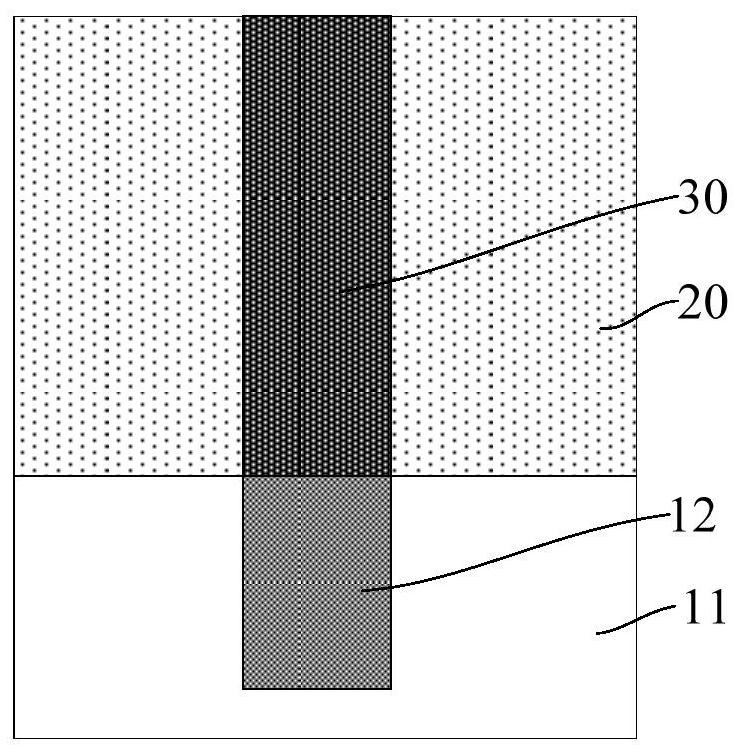

Semiconductor device and manufacturing method thereof

InactiveUS20060197230A1Increase capacityEasy to operateTransistorSemiconductor/solid-state device detailsDevice materialConductive materials

A semiconductor device comprises a first insulating film formed over a semiconductor substrate, a second insulating film formed on the first insulating film, a contact plug made of a conductive material vertically penetrating the first and second insulating films and extending on the second insulating film, and a conductor film in contact with the upper surface of the contact plug and part of the second insulating film. This construction makes it possible to form minute via-holes in a mass-production line without increasing parasitic capacity, increasing the number of manufacturing steps, and generating defects.

Owner:FUJITSU SEMICON LTD

Method of forming metal interconnect of semiconductor device

InactiveUS20060024941A1Avoid analysisSemiconductor/solid-state device manufacturingMetal interconnectDevice material

Owner:SAMSUNG ELECTRONICS CO LTD

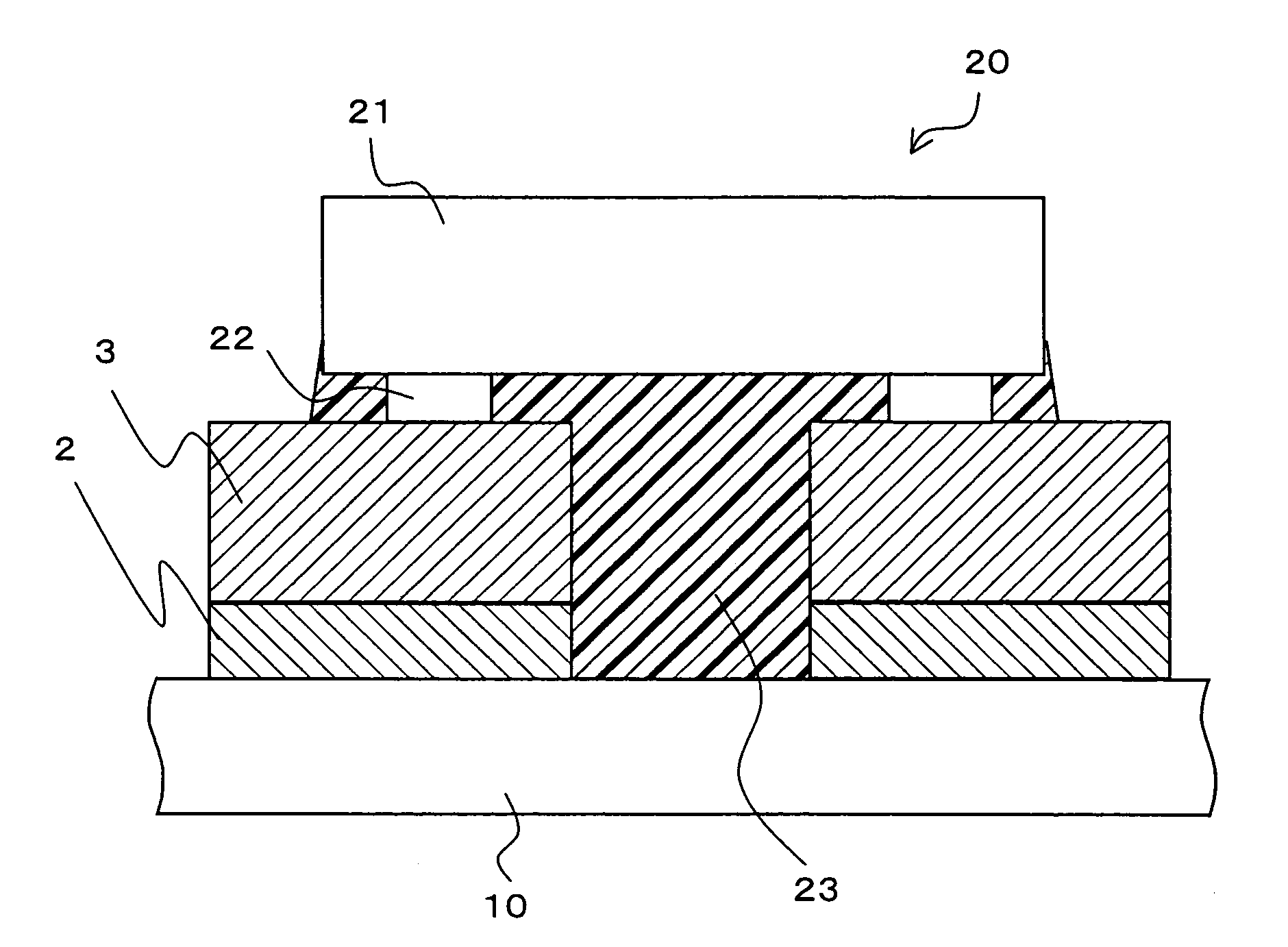

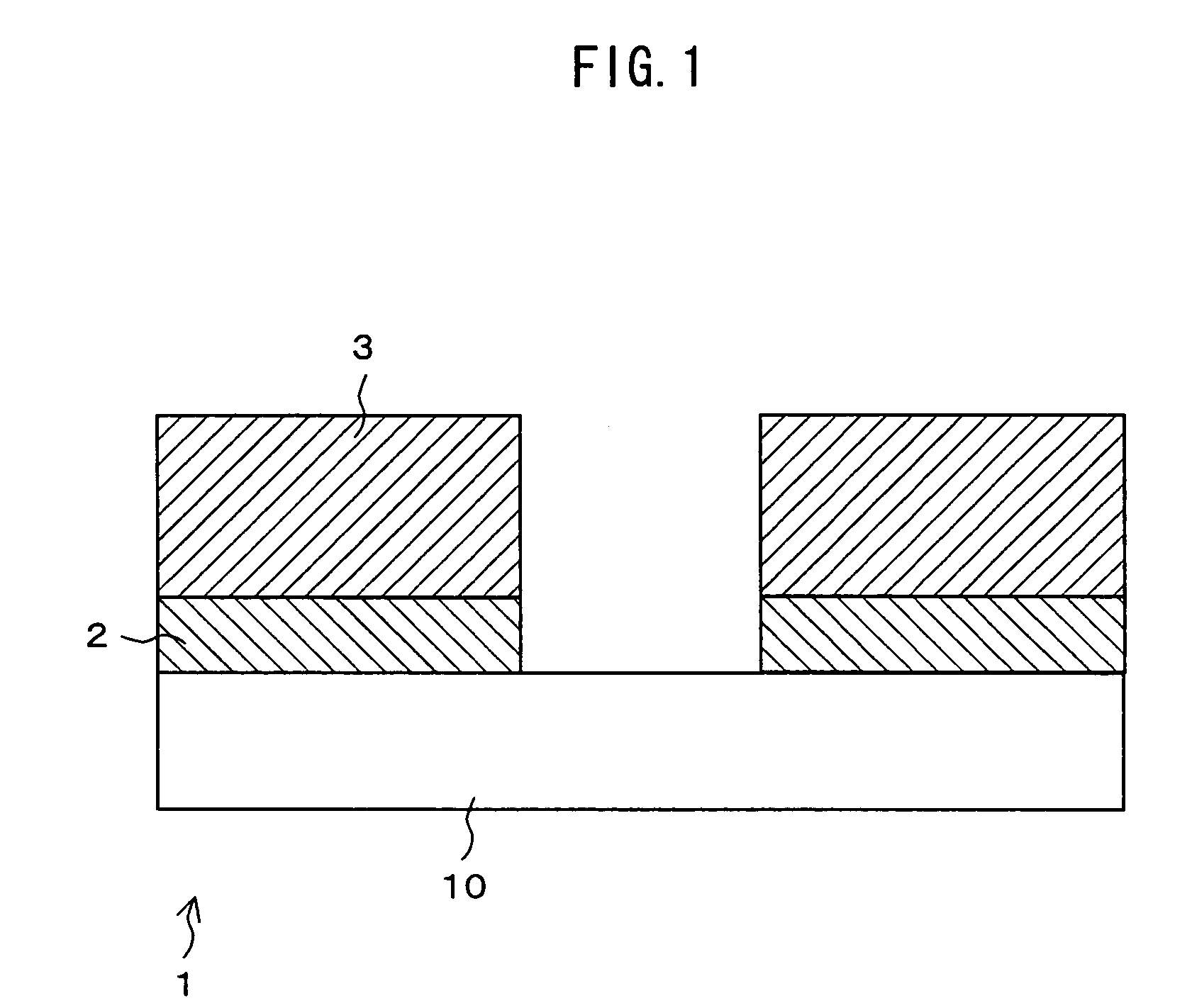

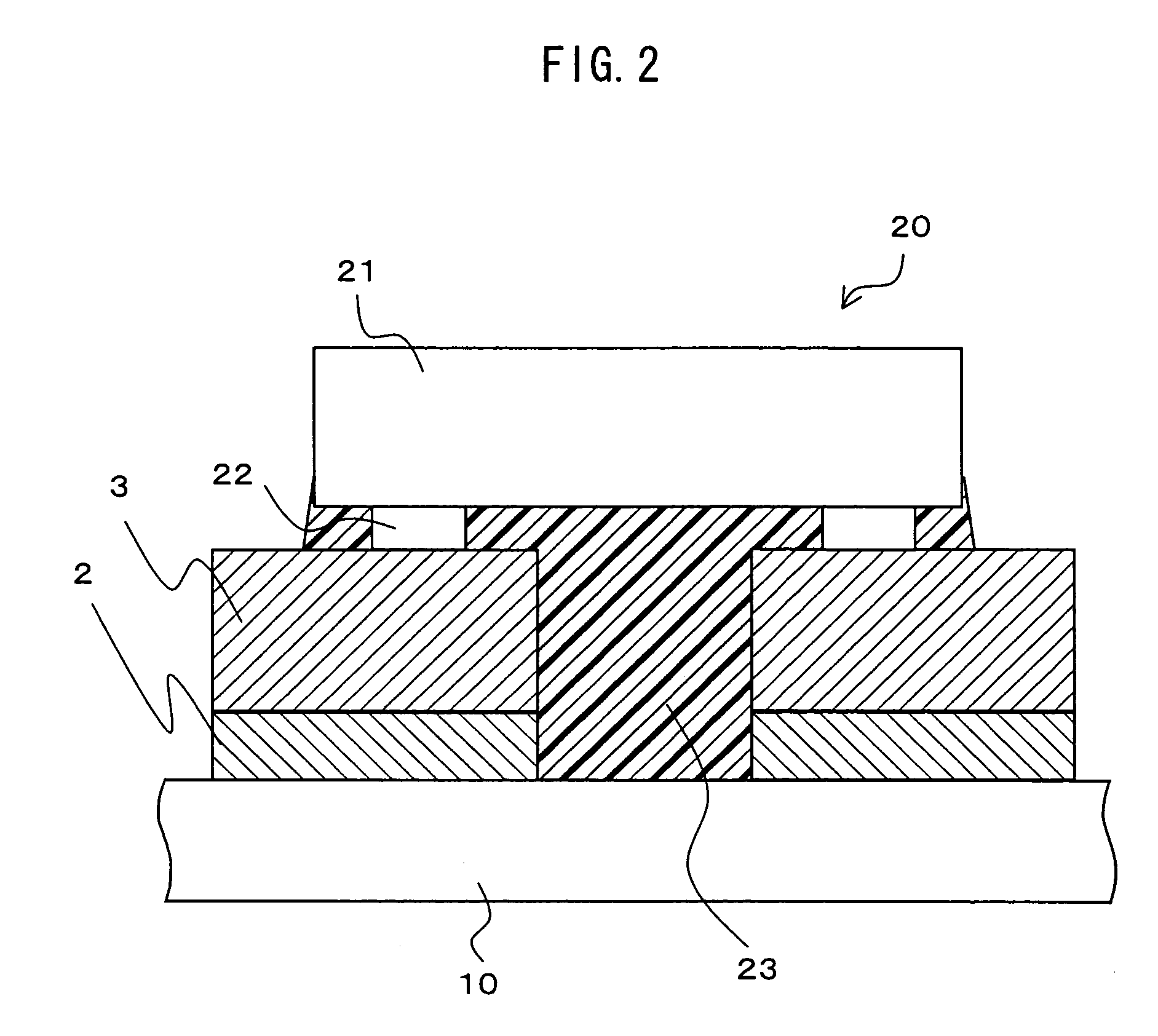

Semiconductor device manufacturing method, semiconductor device, and wiring board

InactiveUS20080174012A1Reduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device manufacturing method includes (a) bonding a first surface of a metal plate to a substrate, (b) forming a plurality of metal posts that are arranged in vertical and lateral directions in a plan view and include a first metal post and a second metal post, by partially etching the metal plate bonded to the substrate from a second surface of the metal plate, (c) fixing an integrated circuit (IC) element to the second surface of the first metal post, (d) coupling the second metal post and a pad terminal of the integrated circuit element via a conductive material, (e) resin-sealing the integrated circuit element, the metal posts, and the conductive material by providing a resin onto the substrate, and (f) removing the substrate from the resin and the first surfaces of the metal posts sealed using the resin.

Owner:SEIKO EPSON CORP

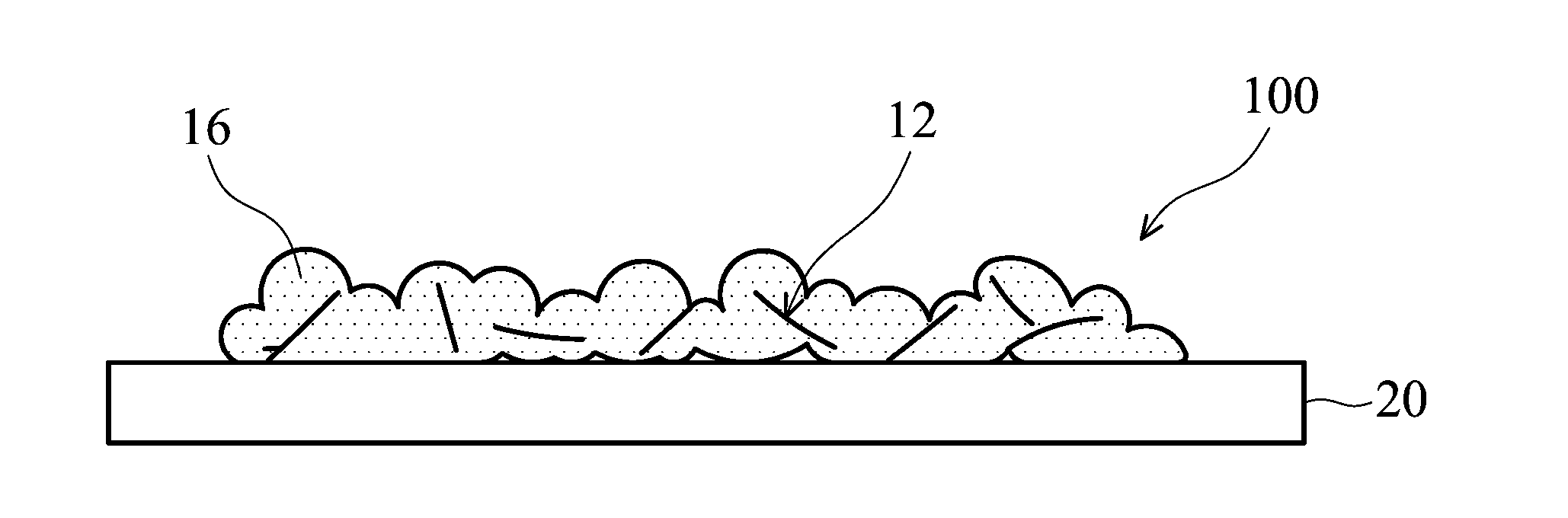

Direct oxidation fuel cells with improved cathode gas diffusion media for low air stoichiometry operation

InactiveUS20080176112A1Promote oxidationSimple methodNanotechFuel cell auxillariesFuel cellsEngineering

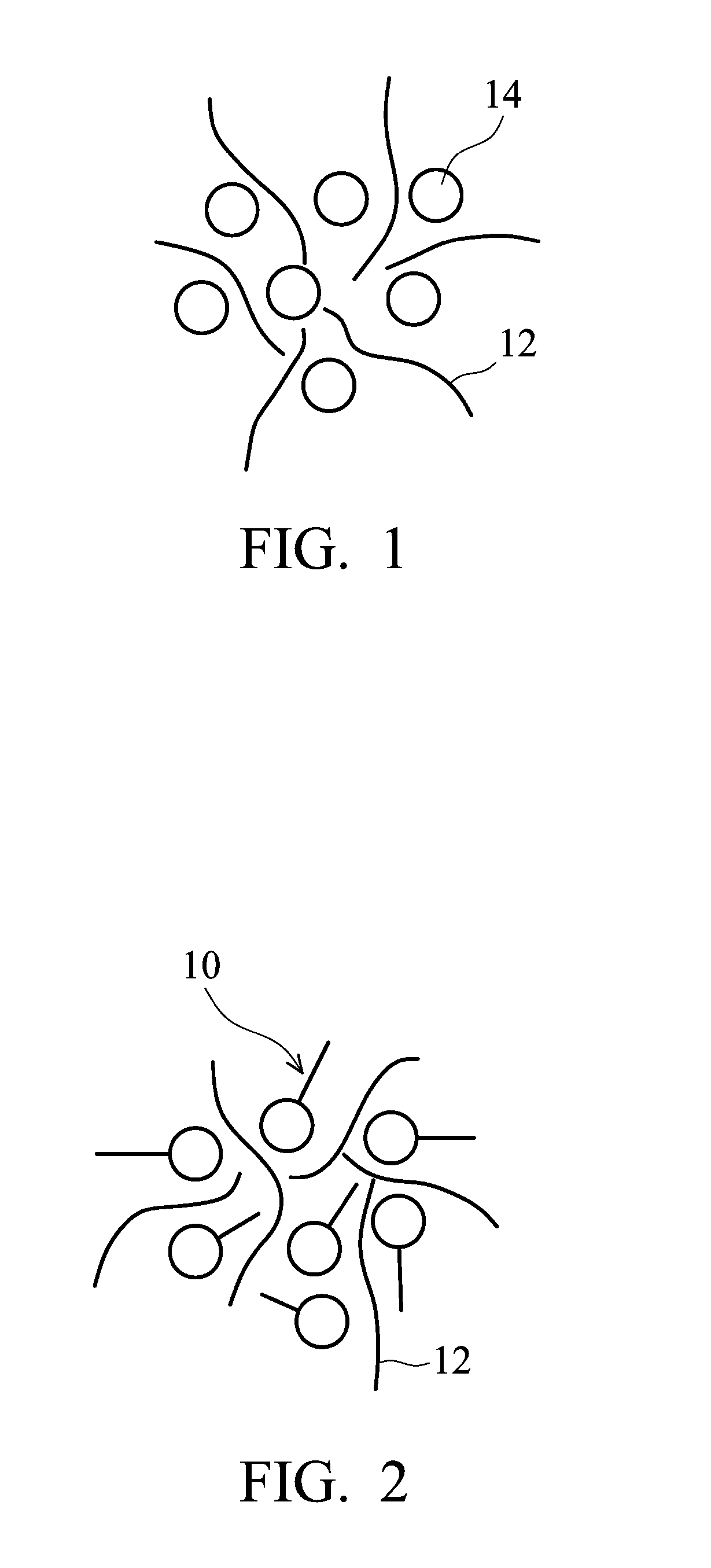

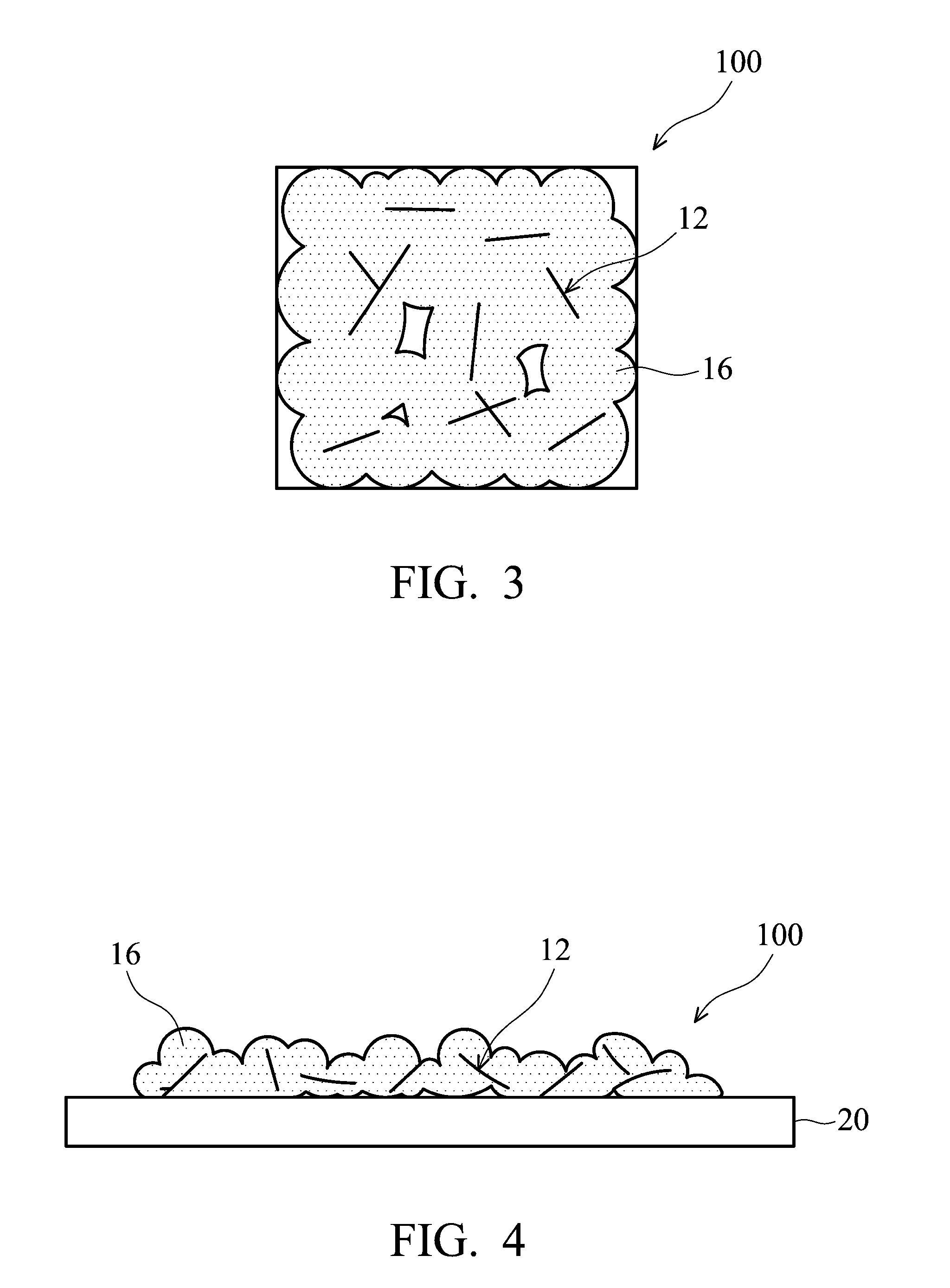

A cathode for use in a direct oxidation fuel cell (DOFC) comprises a gas diffusion medium (GDM) including a backing layer and a microporous layer comprising a fluoropolymer and an electrically conductive material, wherein loading of the fluoropolymer in the microporous layer is in the range from about 10 to about 60 wt. %. In use, a concentrated solution of a liquid fuel is supplied to an anode and an oxidant to the cathode of the fuel cell, and the fuel cell may be operated at a low oxidant stoichiometry ξc not greater than about 2.5.

Owner:PANASONIC CORP +1

Integrated thermal door component for head mounted display

InactiveUS20190104650A1Near-field for read/write/interrrogation/identification systemsDetails for portable computersDisplay deviceConductive materials

A head mounted display (HMD) device for supporting virtual reality and augmented reality includes a frame and a thermal door component between which a mobile device may be sandwiched. The thermal door component includes a first portion that is substantially planar for reversibly coupling with a portion of a back surface of the mobile device and a heat sink. The heat sink includes a substantially planar portion coupled to a surface of the first portion of the thermal door component. The heat sink may be made of magnesium or other thermally conductive material. A second portion is coupled to the back of the first portion. An opening, channel, or recess that allows access to the interior of the thermal door component by ambient air to allow the thermal door component to draw heat away from the mobile device and the HMD device.

Owner:GOOGLE LLC

Resistored anode construction

ActiveUS20070125640A1Avoid corrosionCellsImmersion heating arrangementsEngineeringConductive materials

Owner:RHEEM MFG CO

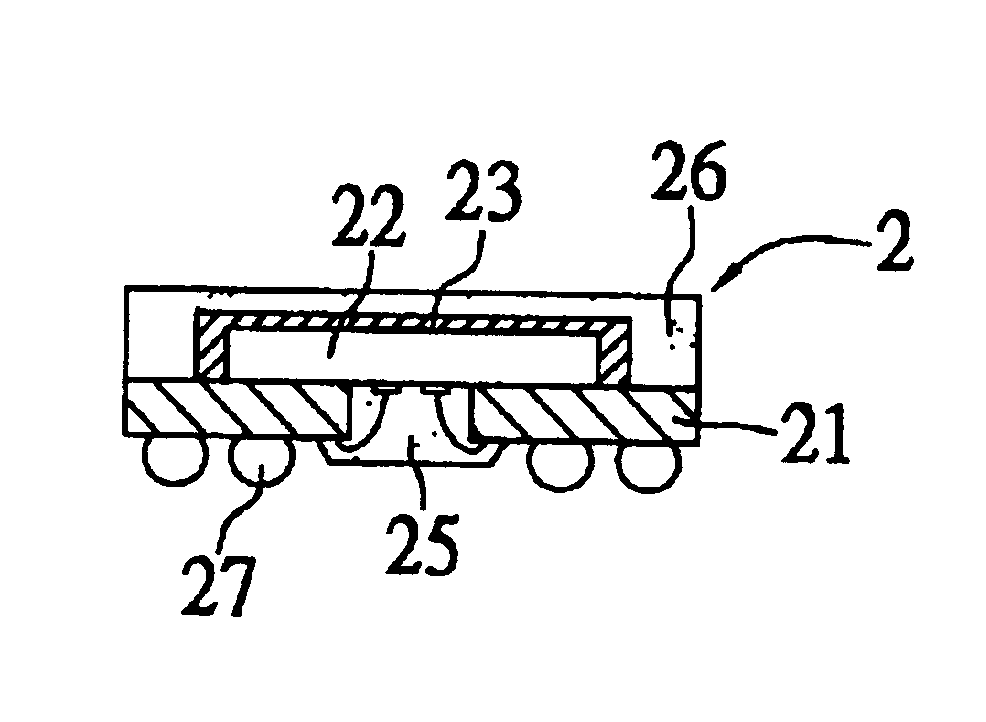

Strengthened window-type semiconductor package

InactiveUS6879030B2High mechanical strengthAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageConductive materials

Owner:SIGURD UTC CORP

Fabrication Process Using Circuit-on-Wire

ActiveUS20150221671A1Solid-state devicesSemiconductor/solid-state device manufacturingActive matrixElectrical connection

A method is provided for forming a circuit-on-wire (CoW) assembly. The method forms a flexible line with a plurality of periodic alignment marks used as a guide to place CoW devices overlying a surface of the flexible line. The CoW devices may be LEDs, capacitors, diodes, photodiodes, resistors, thin-film transistors, or combinations of the above-listed elements. The flexible line may be a conductive material, such as a metal wire, and the periodic alignment marks may be vias formed through the wire. If the flexible line is electrically conductive, an electrically conductive adhesive may be applied to the electrically conductive line, so that an electrical connection is formed between the CoW devices and the electrically conductive line. Subsequent to placing the CON devices, processes may be formed on the flexible line and CoW devices such as lithographic etching and thin-film deposition. An active matrix array using CoW devices is also presented.

Owner:SHARP KK

Manufacturing method of surface mounted device resistor

ActiveCN102082017ALow costReduce dosageResistors adapted for applying terminalsSilver pasteSputtering

Owner:UNIROYAL ELECTRONICS IND

Positive electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

ActiveUS20170187036A1InhibitionWithout deteriorating battery characteristicFinal product manufactureElectrode carriers/collectorsLithiumInorganic particle

The positive electrode as an embodiment includes a positive electrode current collector mainly composed of aluminum, a positive electrode mixture layer containing a lithium-containing transition metal oxide and disposed above the positive electrode current collector, and a protective layer disposed between the positive electrode current collector and the positive electrode mixture layer. The protective layer contains inorganic particles, an electro-conductive material, and a binding material; is mainly composed of the inorganic particles; and is disposed on the positive electrode current collector to cover the positive electrode current collector in approximately the entire area where the positive electrode mixture layer is disposed and at least a part of the exposed portion of the positive electrode current collector where the positive electrode mixture layer is not disposed on the surface of the positive electrode current collector.

Owner:PANASONIC CORP

Electrically conductive composition and fabrication method thereof

ActiveUS20110101283A1Electric discharge heatingRadiation applicationsConductive polymerConductive materials

Owner:IND TECH RES INST

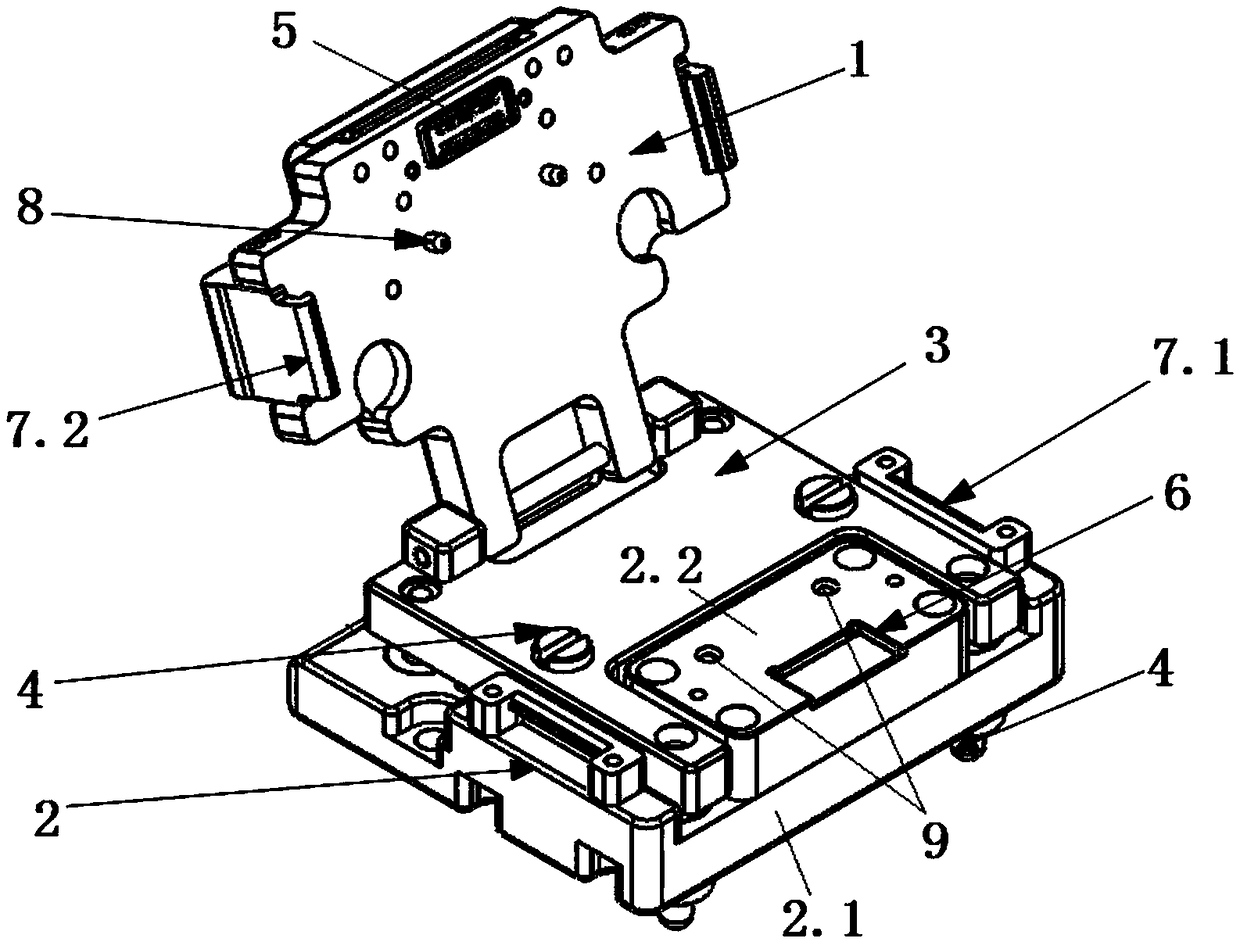

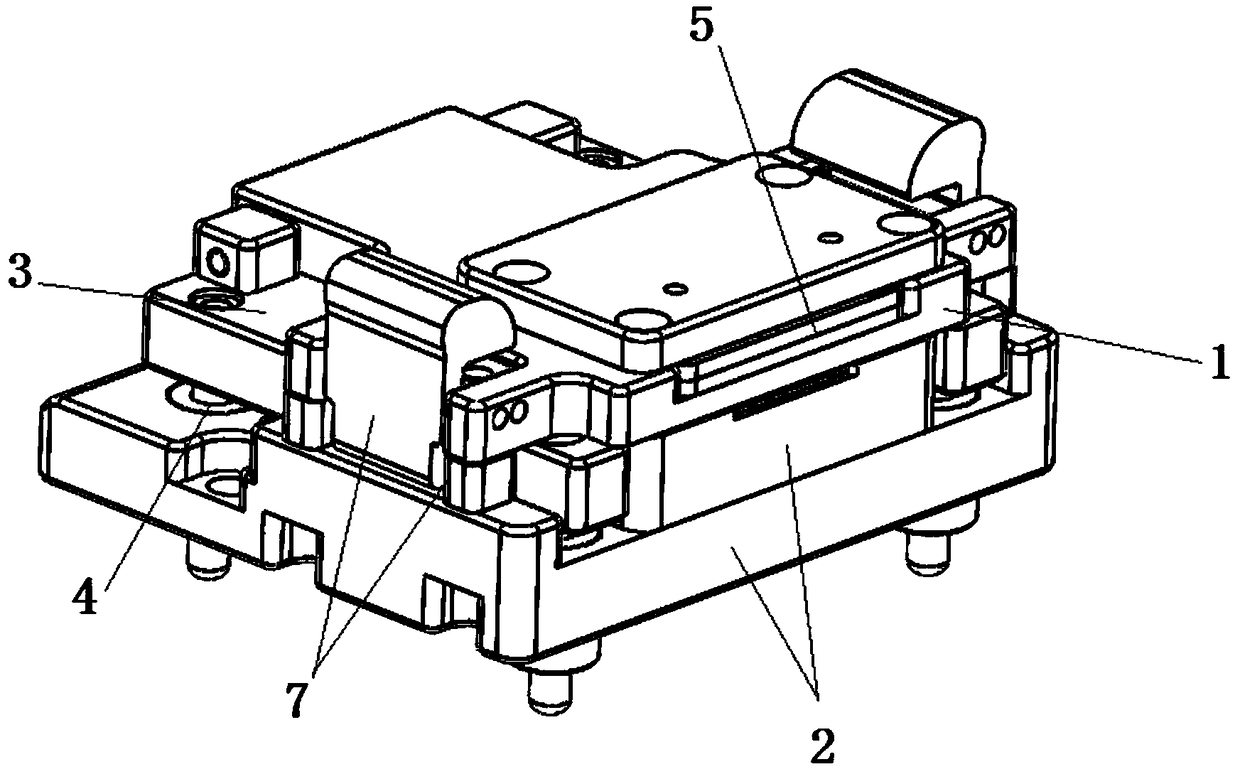

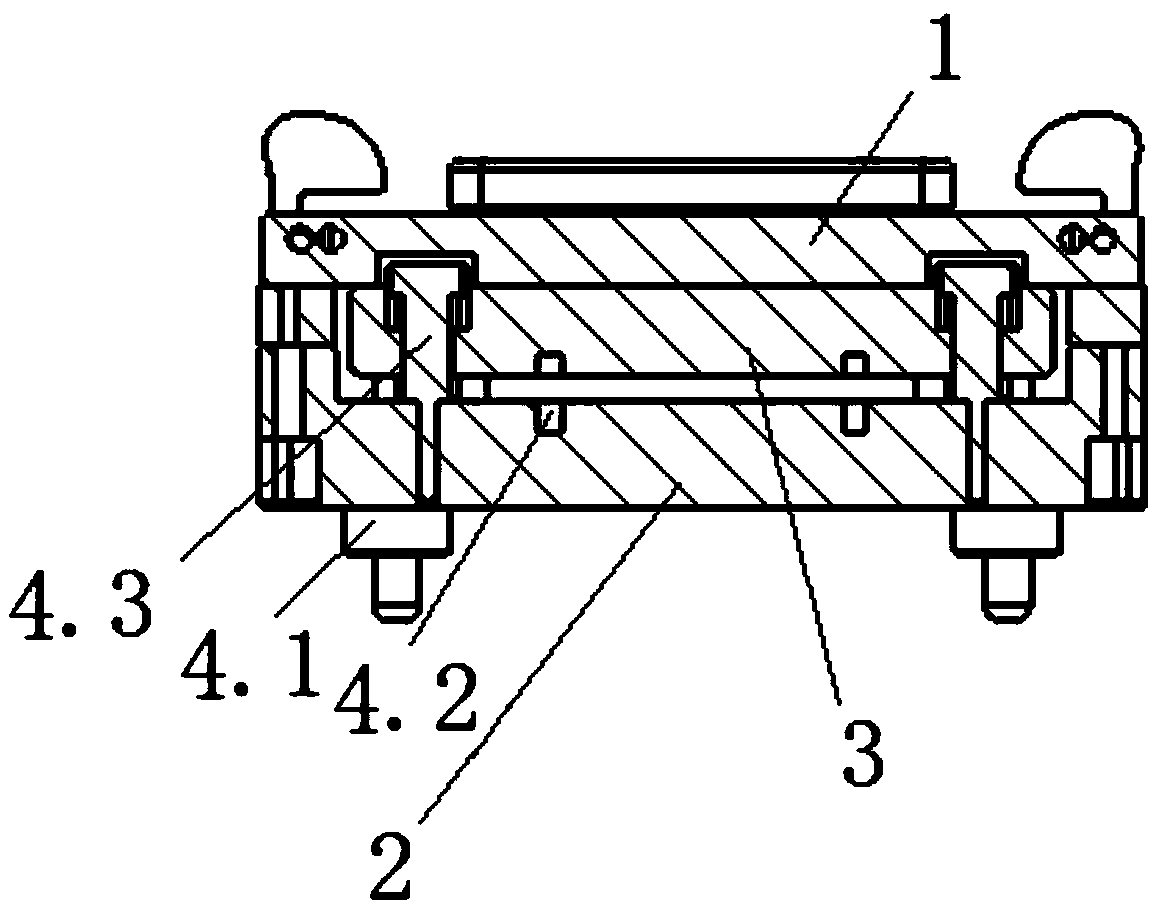

Flip type vertical pressing joint POGO conducting device

PendingCN109061238AEasy to manufactureEasy to placeCoupling contact membersMeasurement instrument housingConductive materialsElectrical and Electronics engineering

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Dielectric fluid for electric discharge machining a non electrically conductive material

InactiveCN101410214ARapid Ablation ProcessingPromote rapid formationDielectricElectric discharge

The invention relates to a dielectric fluid (5) for electrical discharge machining an electrically non-conductive material, characterised in that it is of an aqueous solution or an aqueous suspension of at least one carbonaceous substance.

Owner:SIEMENS AG

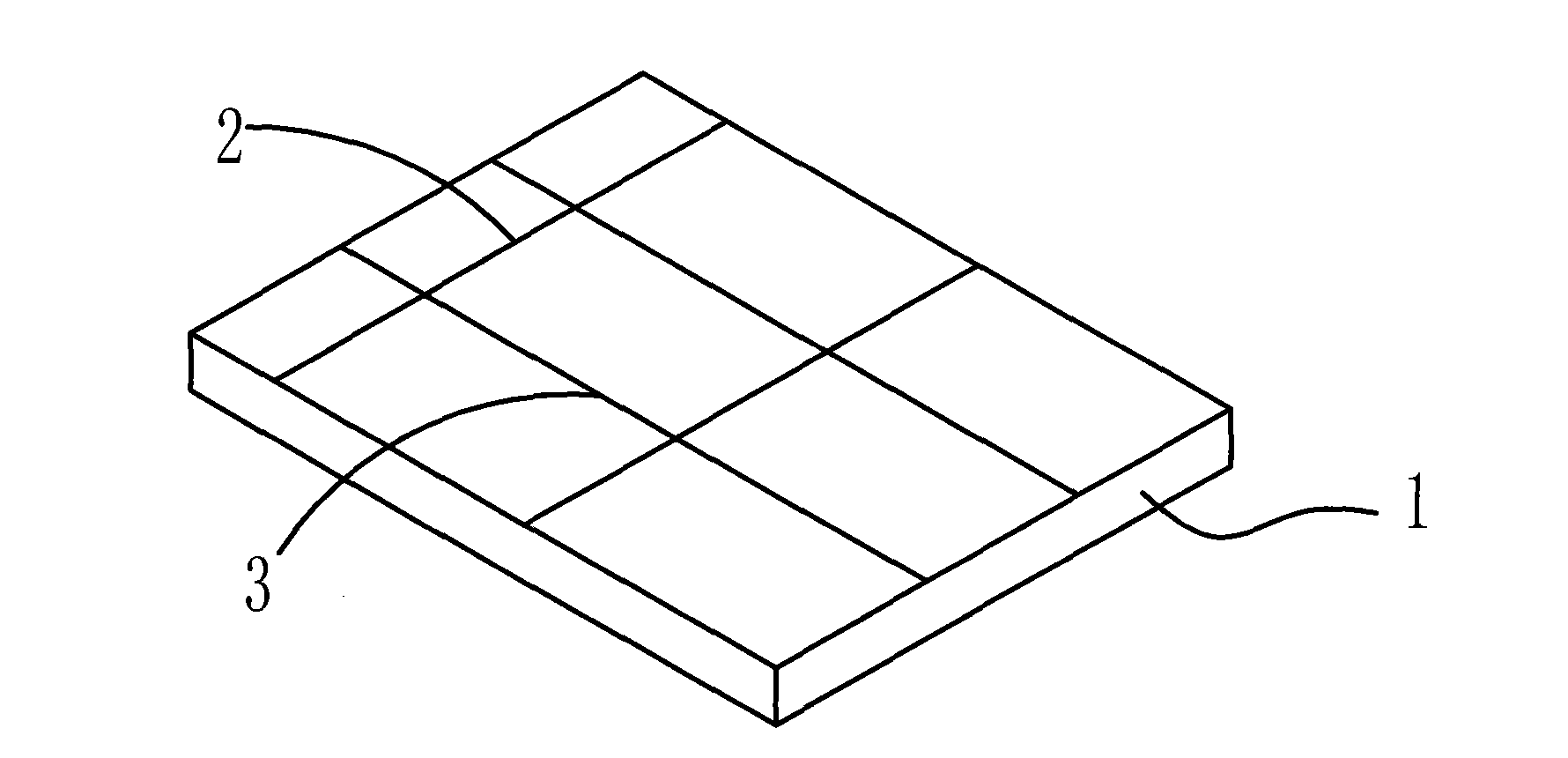

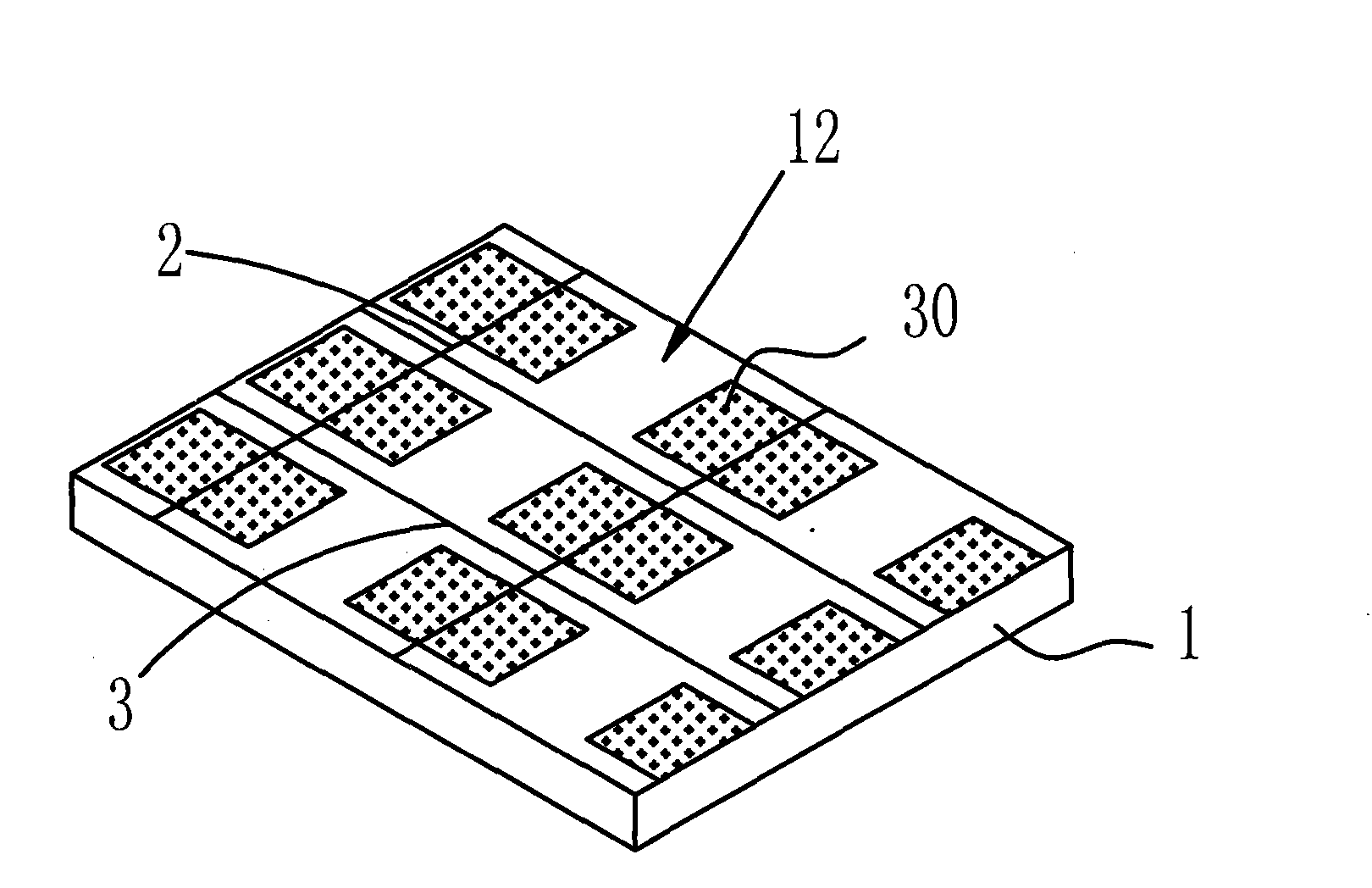

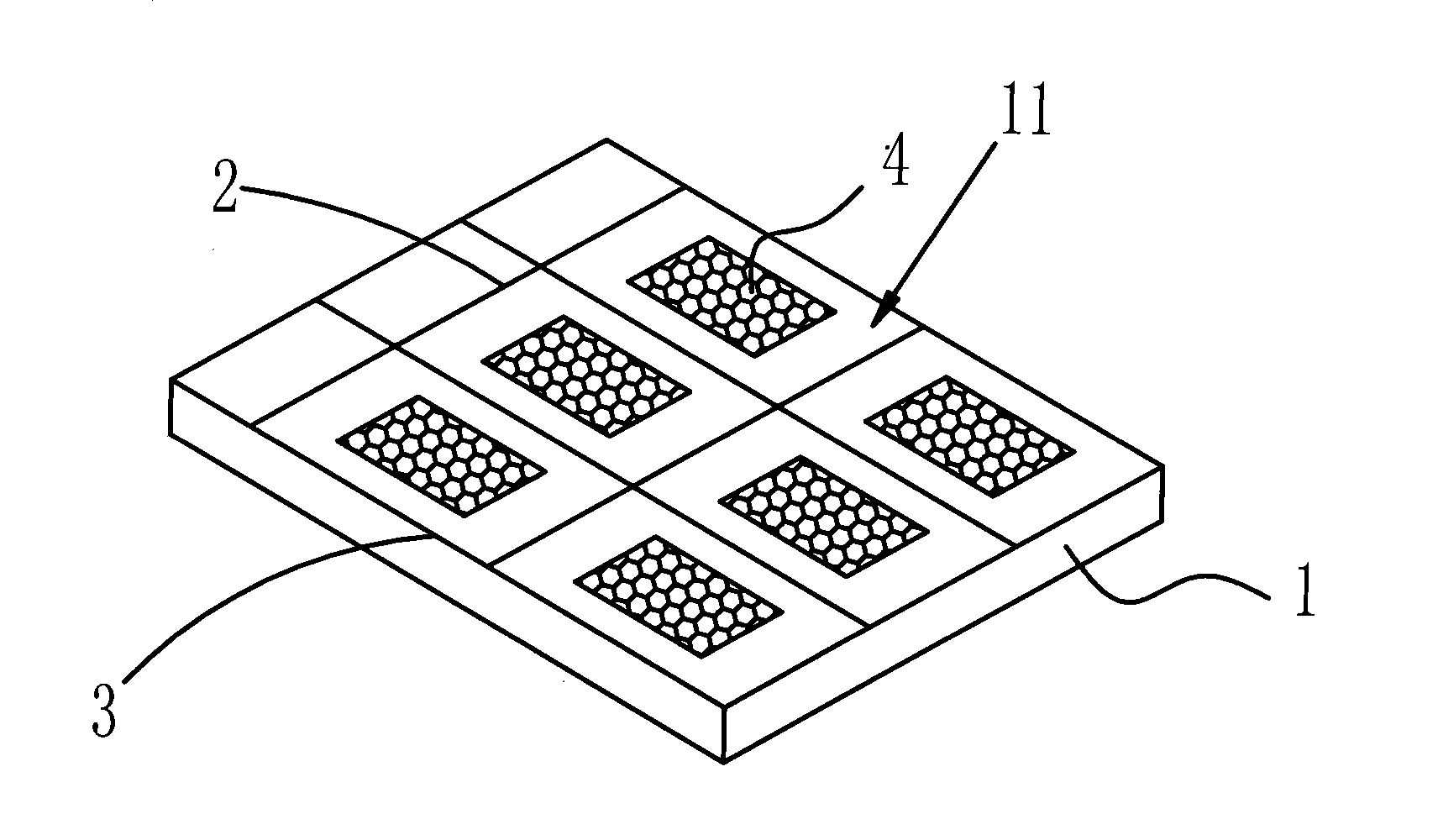

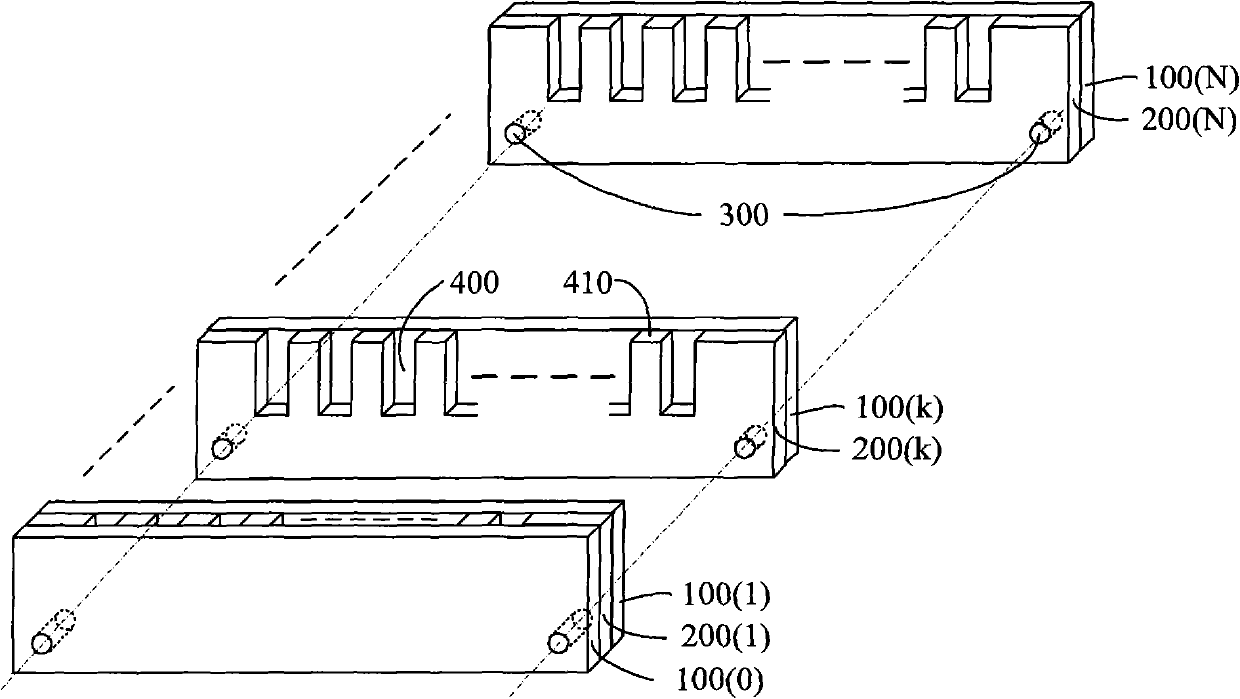

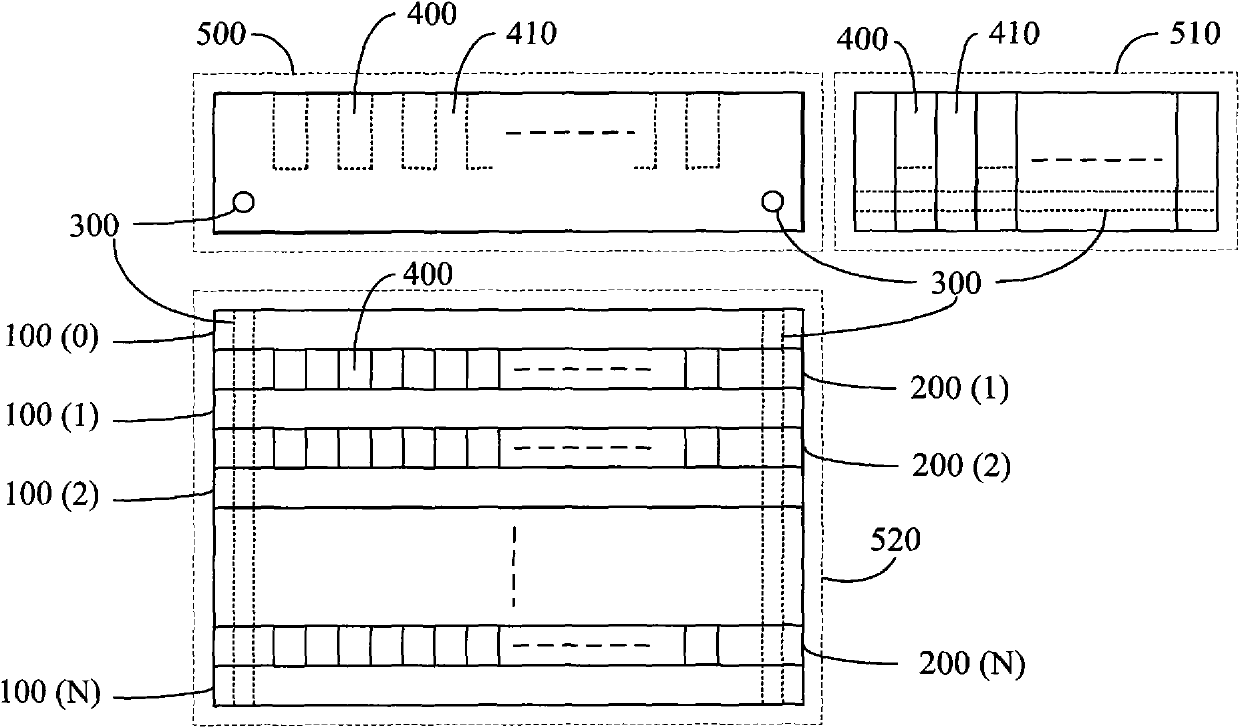

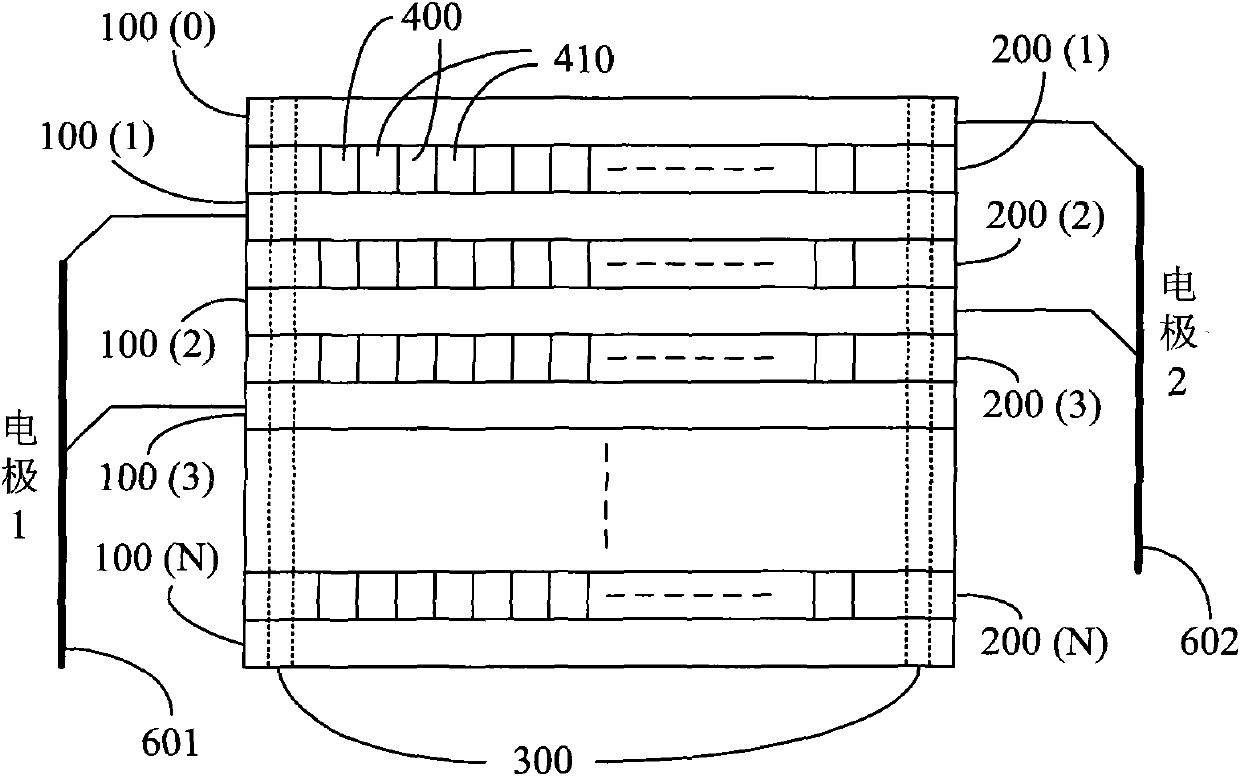

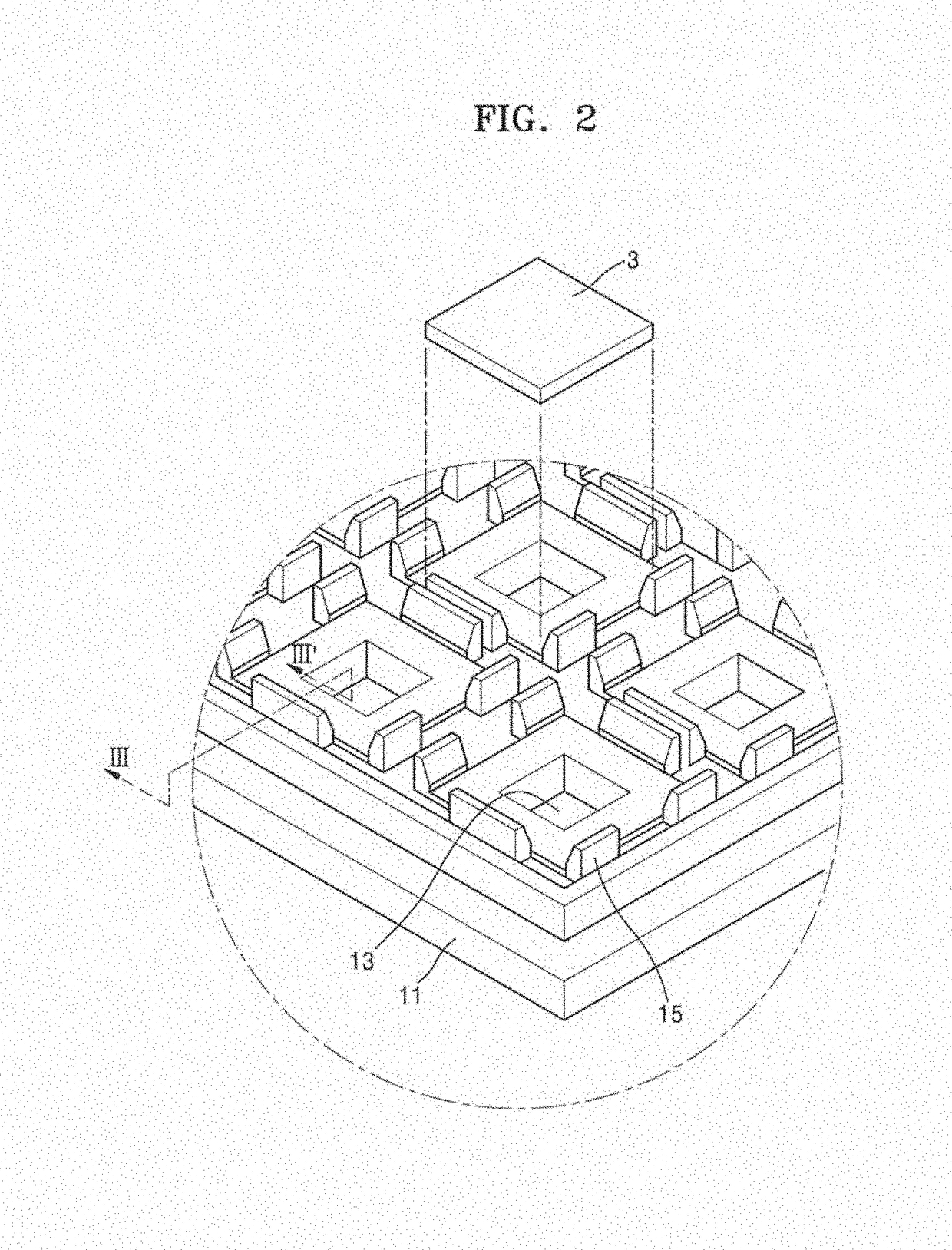

Configurable two-dimensional micro-plasma array device and preparation method thereof

InactiveCN101794699AIncreased size flexibilityIncrease array densityCold-cathode tubesCold cathode manufactureConductive materialsDielectric layer

Owner:SHANDONG UNIV

Semiconductor-accommodating tray and cover therefor

InactiveUS20170250121A1Low and uniform electric resistanceGood antistatic effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

Owner:KOSTAT

High-intensity high-speed informationization manned spacecraft manufactured by new graphene materials

InactiveCN102745344AHigh hardnessImprove conductivityArtificial satellitesSecondary cellsRe entryNew energy

Owner:WUXI TONGCHUN NEW ENERGY TECH

Thin film transistor and manufacturing method thereof and display substrate

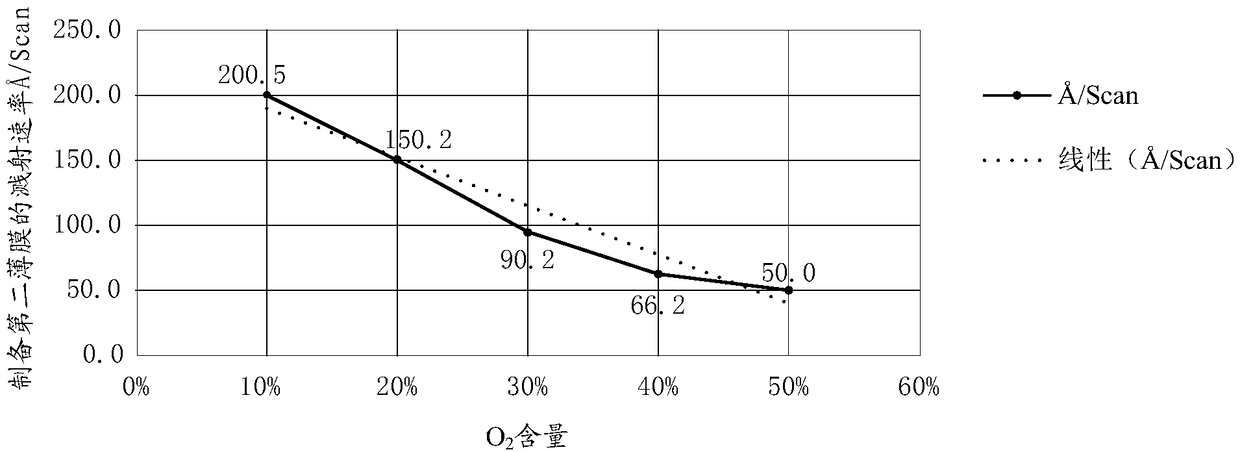

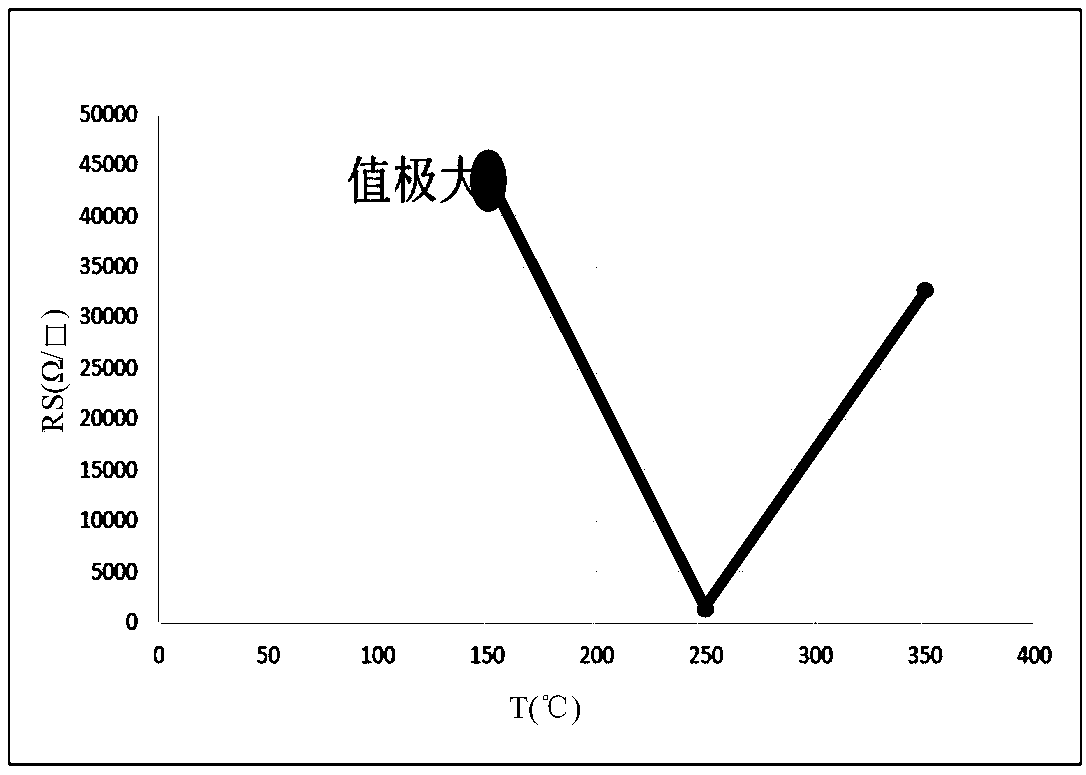

ActiveCN108766972AReduce oxygen contentReduce sheet resistivityTransistorSolid-state devicesOptoelectronicsConductive materials

Owner:BOE TECH GRP CO LTD

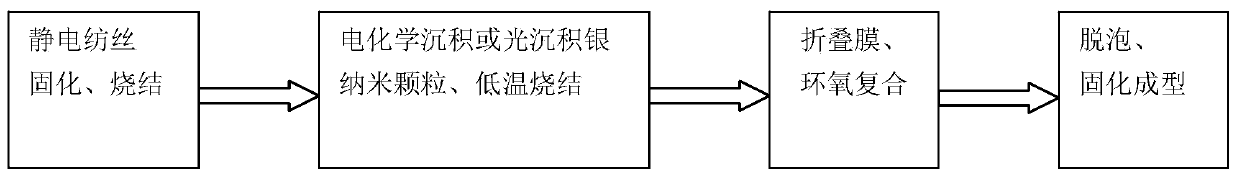

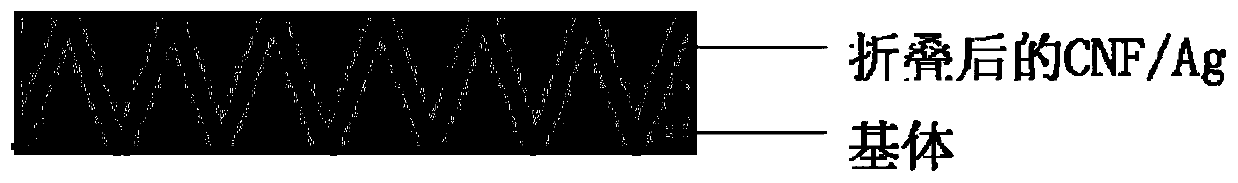

Composite heat-conductive material and preparation method thereof

ActiveCN110452494AGood general applicabilityThe experimental operation method is simpleCarbon fibresElectrospinningWave shape

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Electronic module and manufacturing method thereof

ActiveCN104103631AIncrease surface areaWill not affect normal workSemiconductor/solid-state device detailsSolid-state devicesElectromagnetic electron waveComputer module

The invention discloses an electronic module and a manufacturing method thereof. The electronic module comprises a substrate, an electronic element, a mould sealing layer and a composite electromagnetic wave mask layer. The electronic element is configured on the substrate. The mould sealing layer covers a part of bearing surface of the electronic element and the substrate. The mould sealing layer is provided with an upper surface which is provided with a three-dimensional geometric pattern. The composite electromagnetic wave mask layer covers the upper surface of the mould sealing layer with the advantage of the form so that electromagnetic wave is shielded. The composite electromagnetic wave mask layer comprises a magnetic material layer and a conductive material layer.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD +1

Remote control device with improved shielding and grounding performance

InactiveUS20070247325A1Sufficient shielding and grounding propertyElectric signal transmission systemsElectrically conductive connectionsElectricityRemote control

A remote control device (100) includes an insulated housing (2, 3) including an outer surface (20, 30) plated with a conductive material for providing a suppression of EMI, an inner surface (21, 31), and a receiving space (4) defined by the outer surface and the inner surface, a printed circuit board (51) received in the receiving space, and including at least a first conductive pad (511), and a second conductive pad electrically connected to the first conductive pad by conductive trace, a cable including at least one grounding conductor electrically connected to the second conductive pad, grounding means (22) electrically connected to the conductive material and the first conductive pad for providing a sheath for ESD generated on the remote control device.

Owner:HON HAI PRECISION IND CO LTD

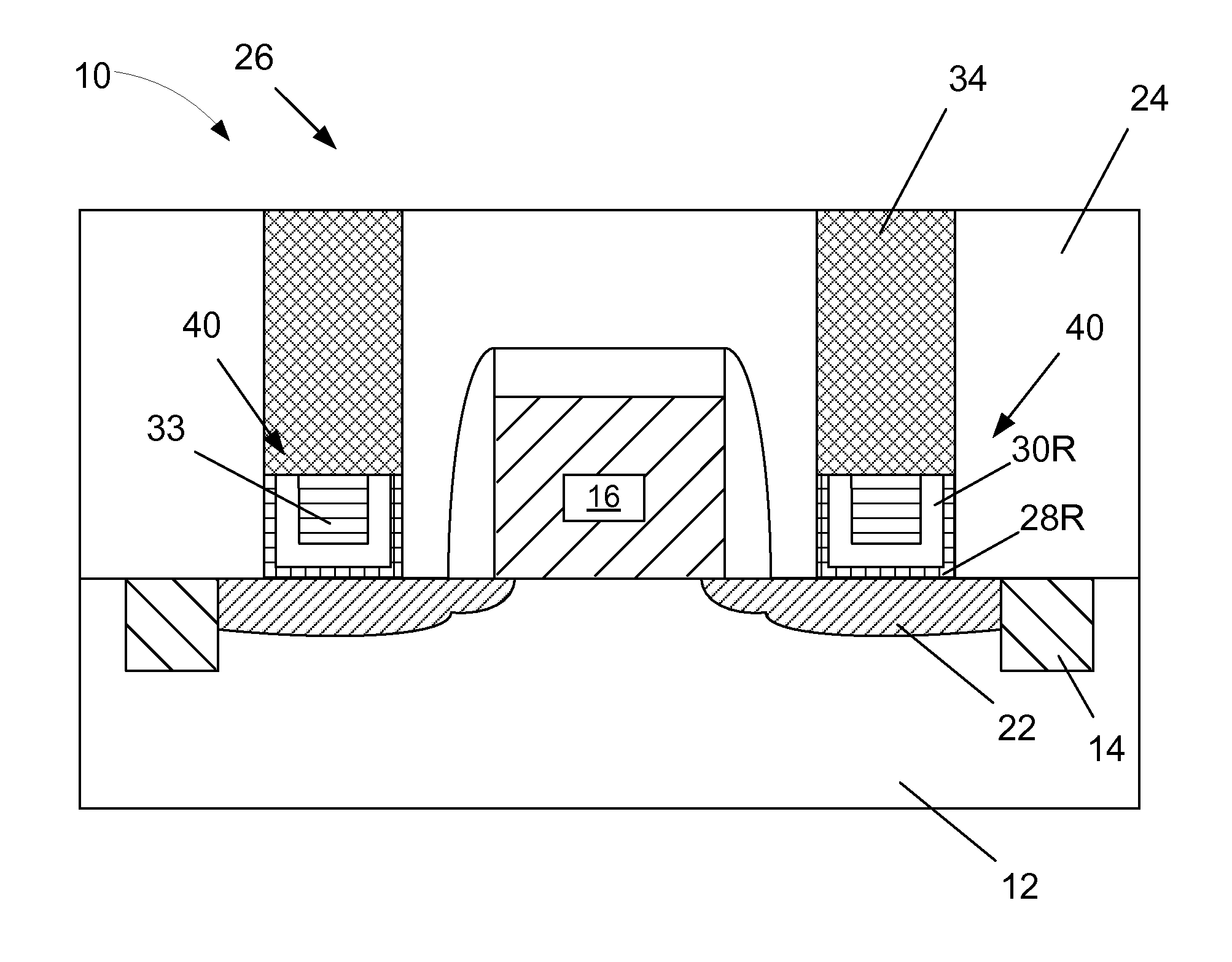

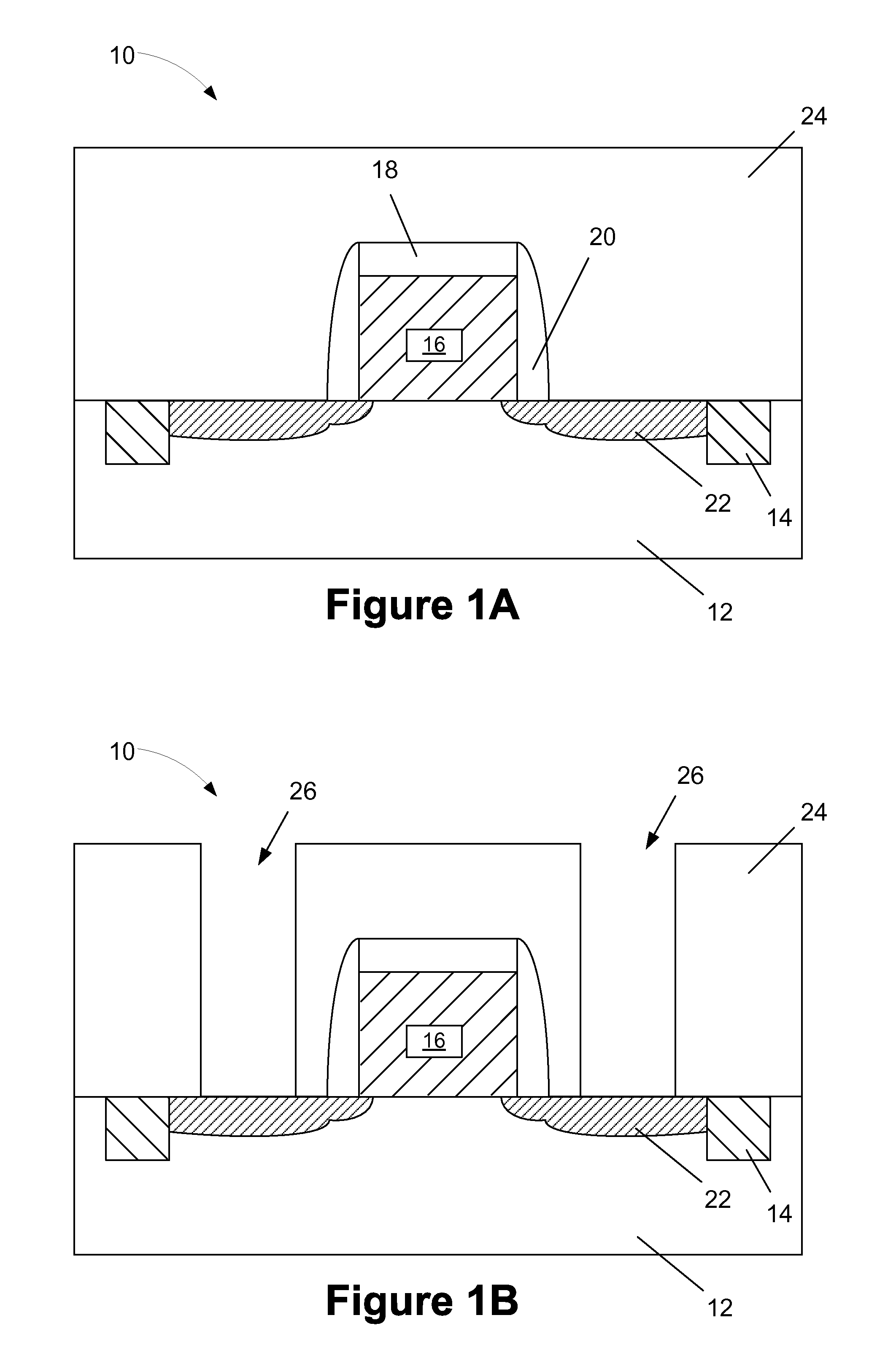

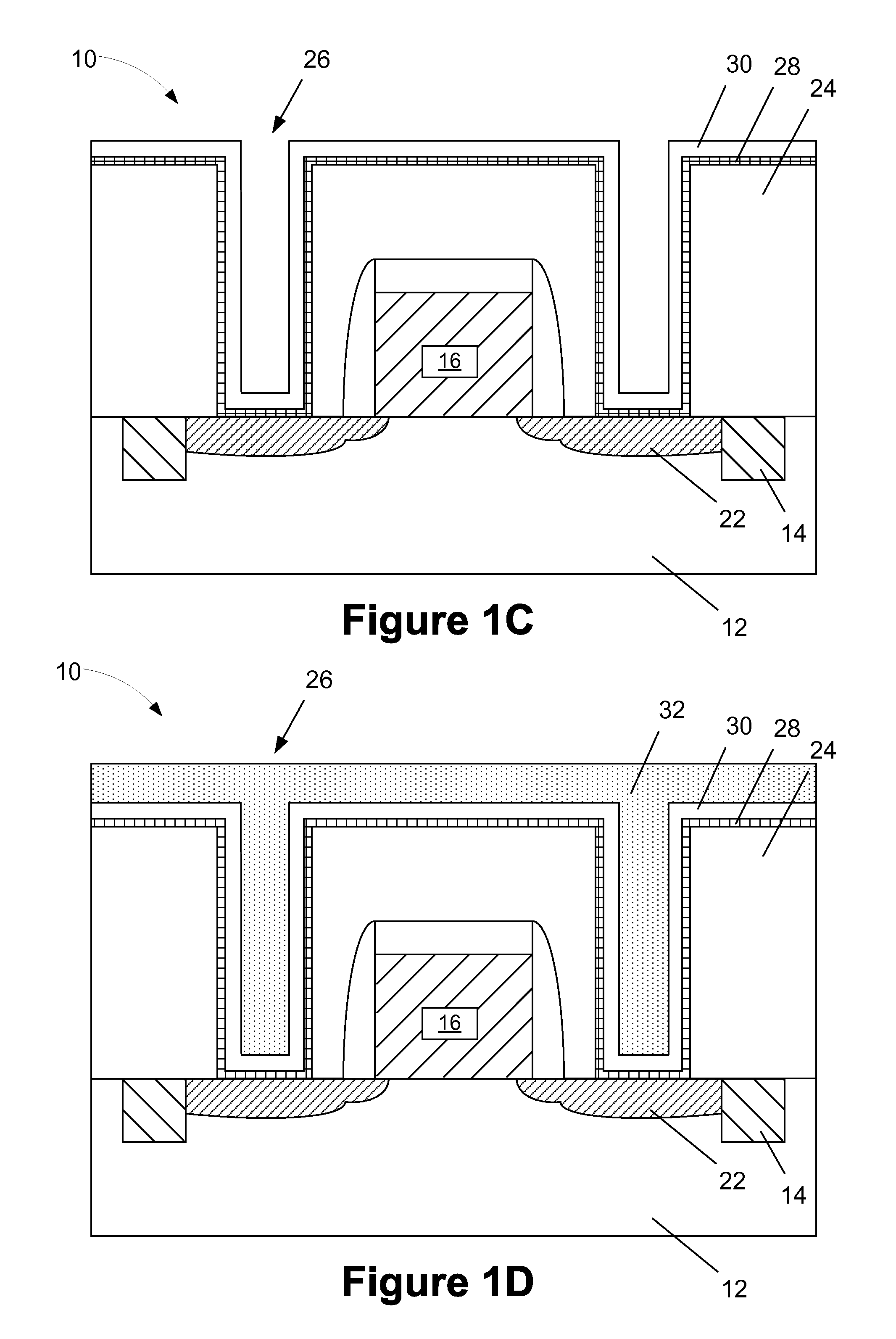

Methods of forming mis contact structures for semiconductor devices and the resulting devices

InactiveUS20150349083A1Well formedTransistorSemiconductor/solid-state device detailsConductive materialsSemiconductor

Owner:IBM CORP +1

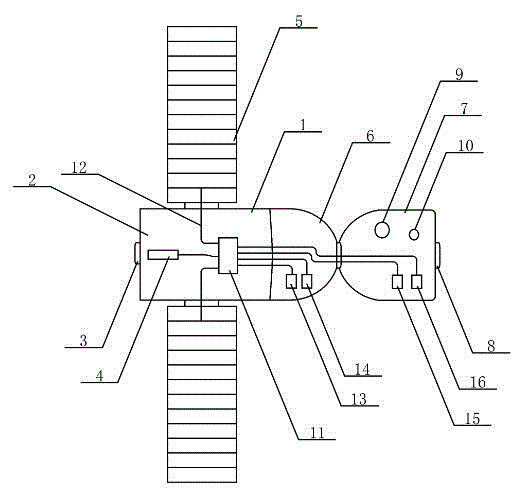

Electric arc discharge cutting head

The invention discloses an electric arc discharge cutting head which comprises a positive electrode and a negative electrode. The electric arc discharge cutting head is characterized in that the positive electrode is made of cone high temperature resisting conductive materials including an inner cone hole, the negative electrode is made of a cone bar high temperature resisting conductive materials including a circular cone head, a through hole is formed in the bottom of the cone hole of the positive electrode, high-temperature hot airflow is sprayed to a steel part through the through hole, the cone head of the negative electrode is inserted into the cone hole of the positive electrode, a metal sleeve is arranged on the outer column face of the positive electrode to prevent the positive electrode from bursting at high temperature and hurting people, a water jacket is arranged on the outer layer of the metal sleeve, a water inlet and a water outlet are formed, a high-temperature ceramic cover plate is fixedly connected to the upper end face of the positive electrode through screws, mirror face treatment is carried out on a combination face, the combination face is effectively sealed, a compressed gas inlet and a conductive column through hole of the negative electrode are formed in the high-temperature ceramic cover plate, mirror face treatment is carried out on the combination face of the upper end plane of the negative electrode and the high-temperature ceramic cover plate, a conductive column is fixed to the upper end plane of the negative electrode, and the combination face of the negative electrode and the high-temperature ceramic cover plate is effectively sealed under the traction of the conductive column.

Owner:ZHENJIANG NEW DISTRICT HUIDA ELECTROMECHANICAL TECH CO LTD

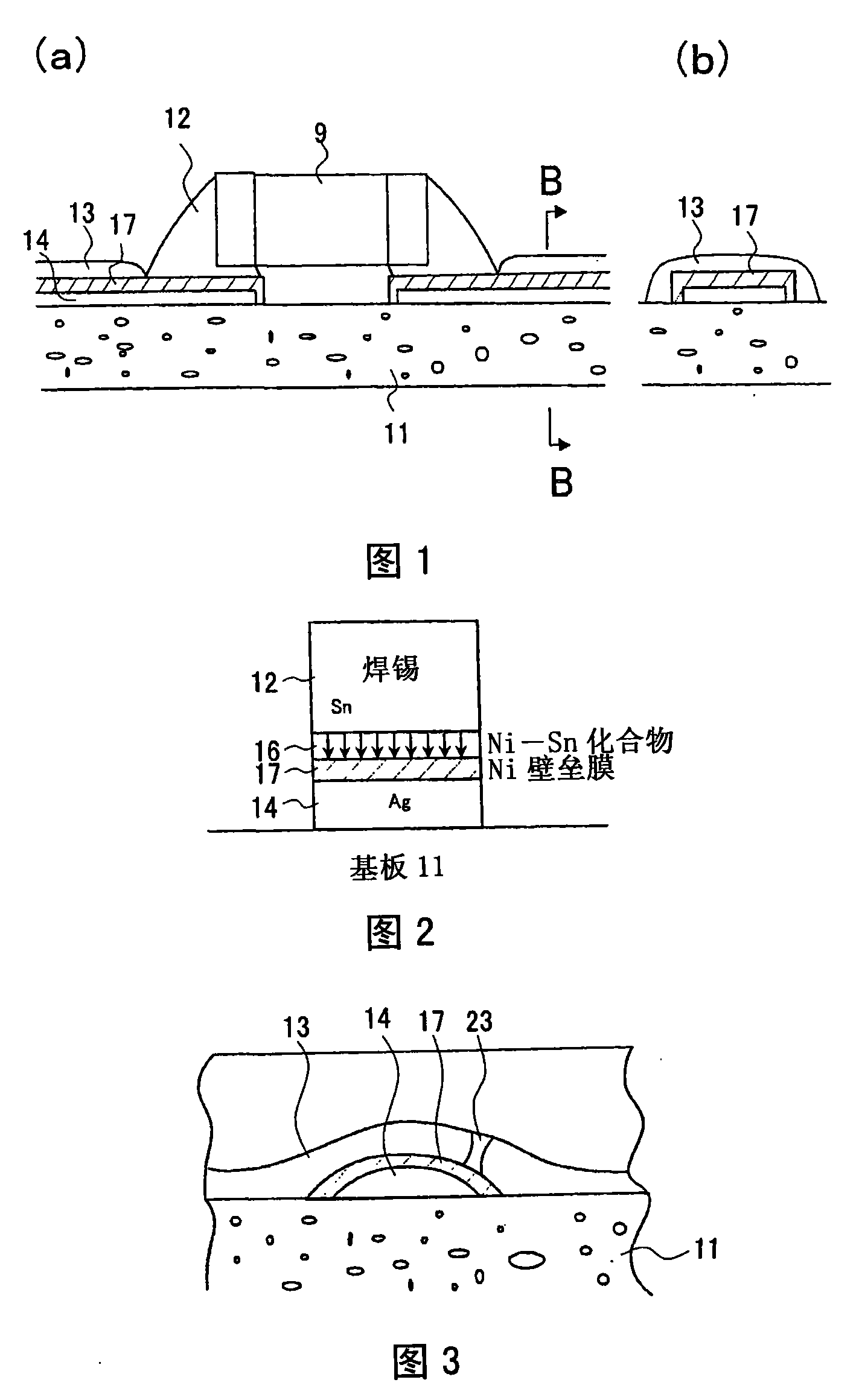

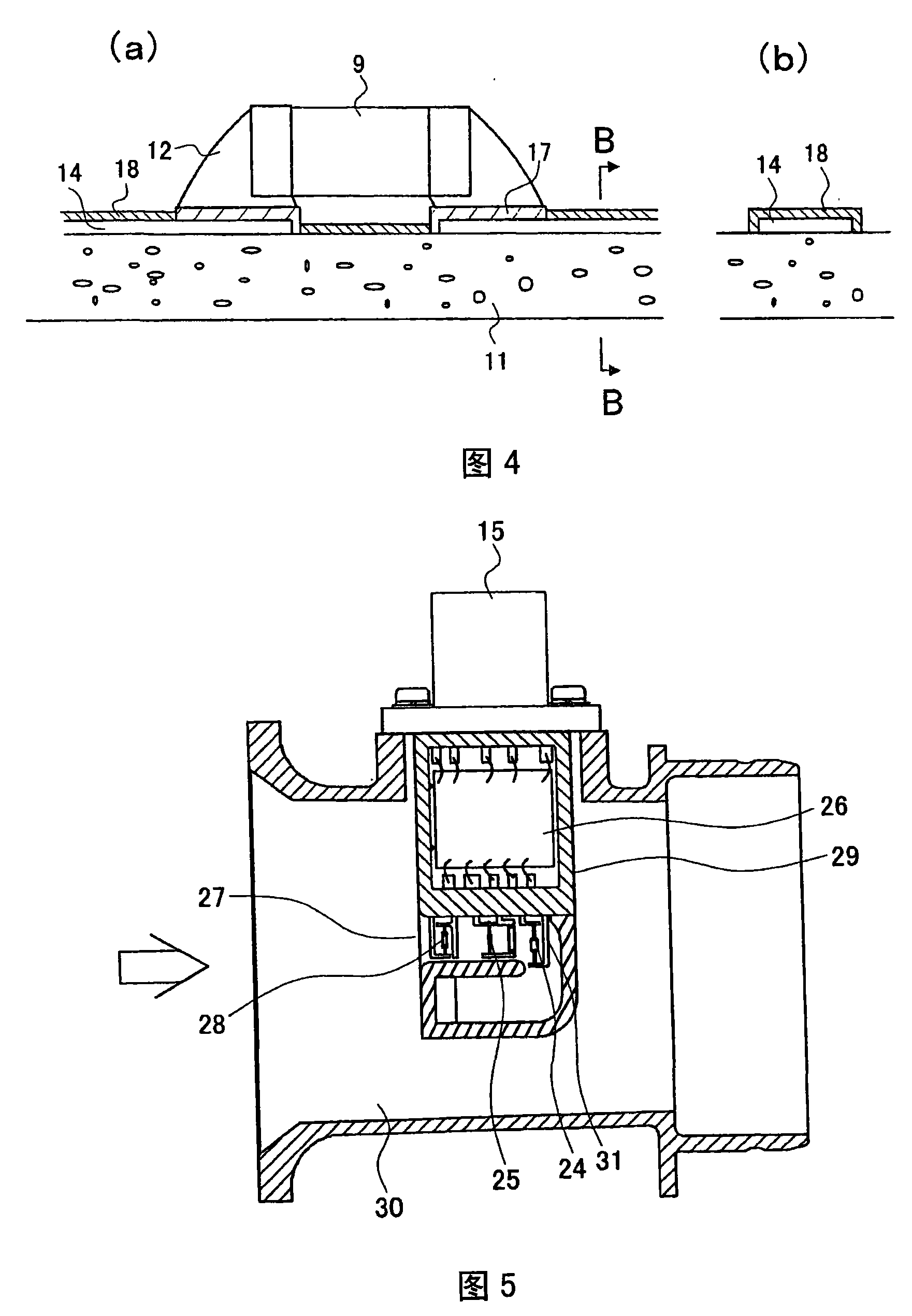

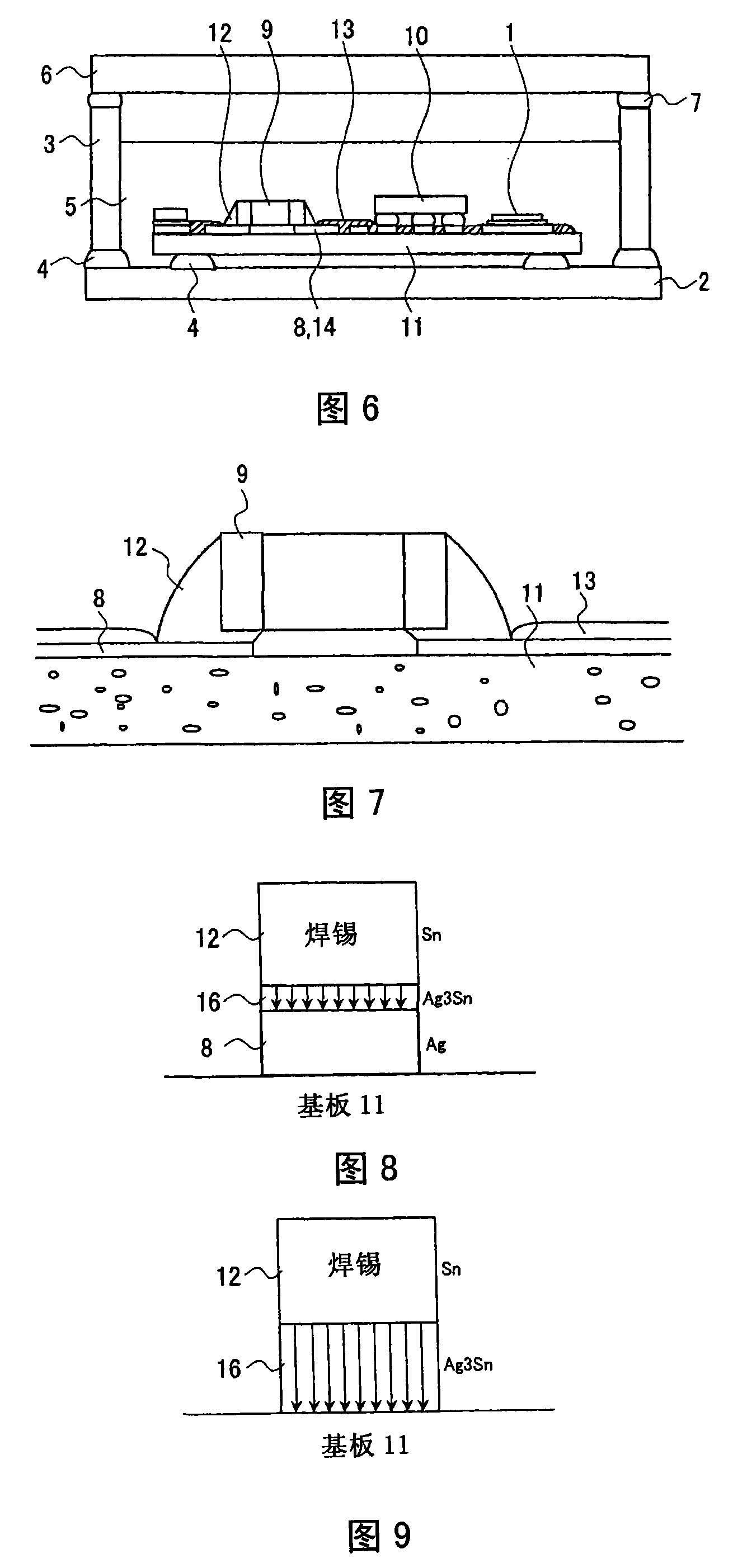

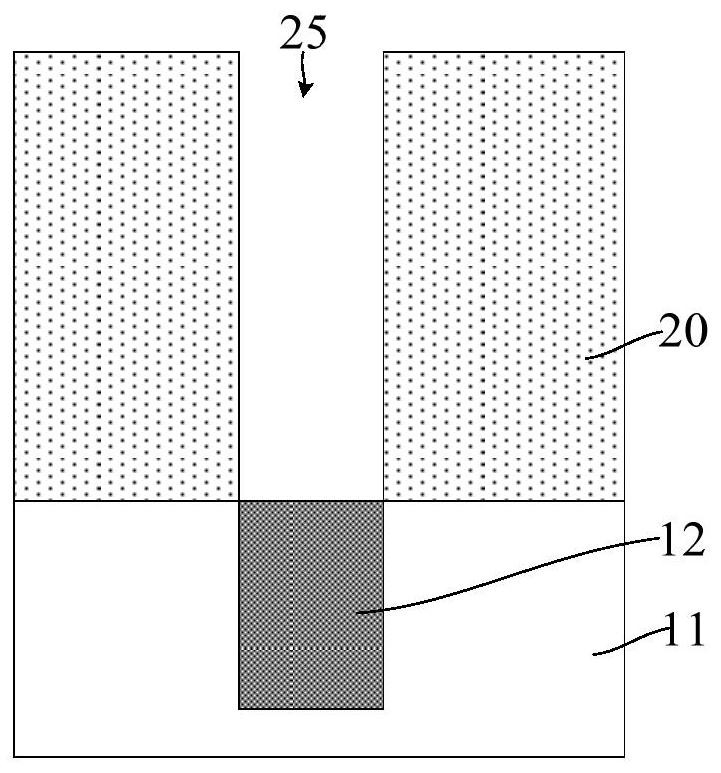

Electronic device installed in an engine room

InactiveCN101246027AWill not disconnectImprove connection lifeVolume/mass flow measurementSolid-state devicesElectricityDiffusion

Owner:HITACHI LTD

Semiconductor structure and forming method thereof

PendingCN112825308AImprove formation qualityReduce the impactSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap