Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Water jacket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water jacket is a water-filled casing surrounding a device, typically a metal sheath having intake and outlet vents to allow water to be pumped through and circulated. The flow of water to an external heating or cooling device allows precise temperature control of the device.

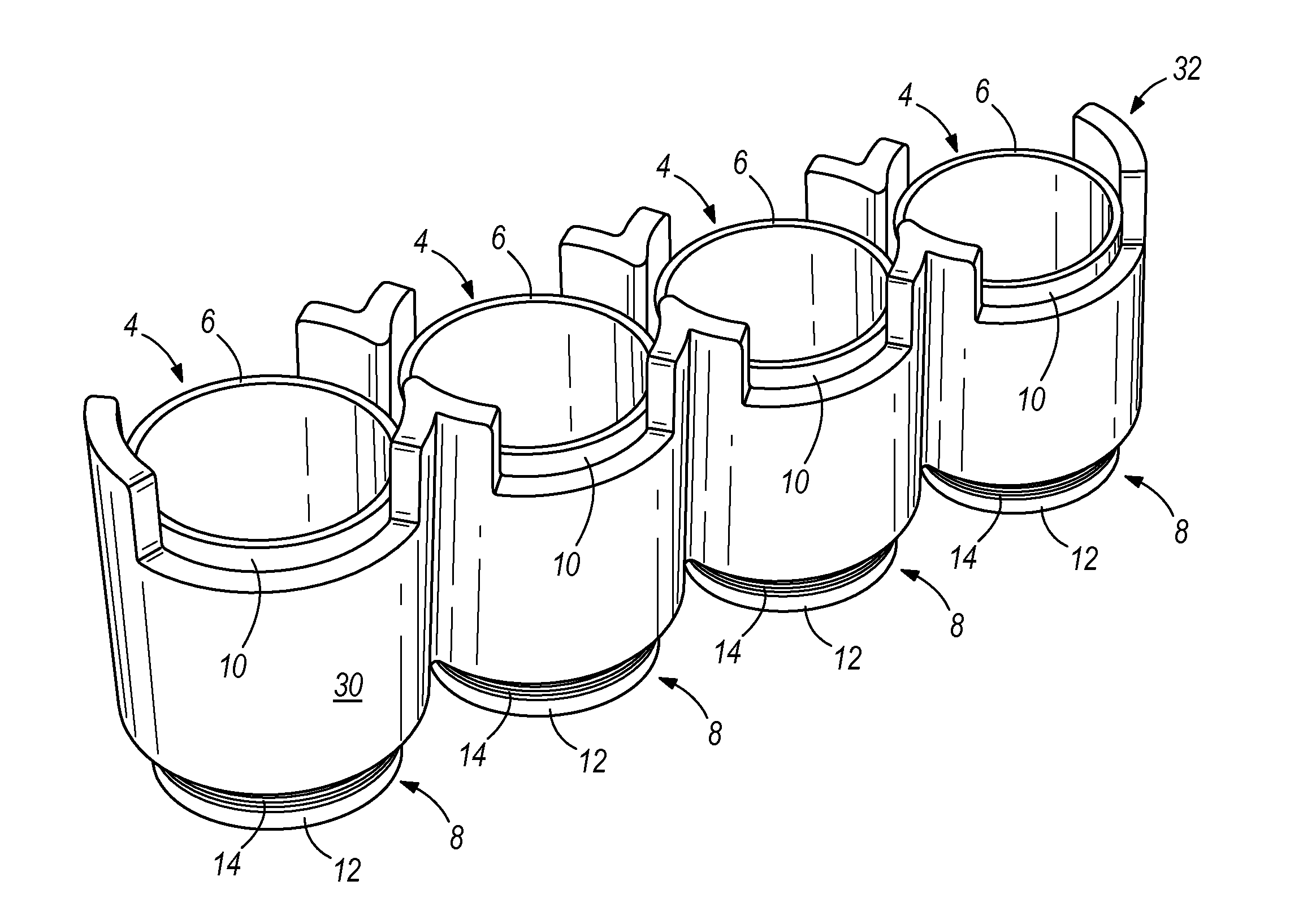

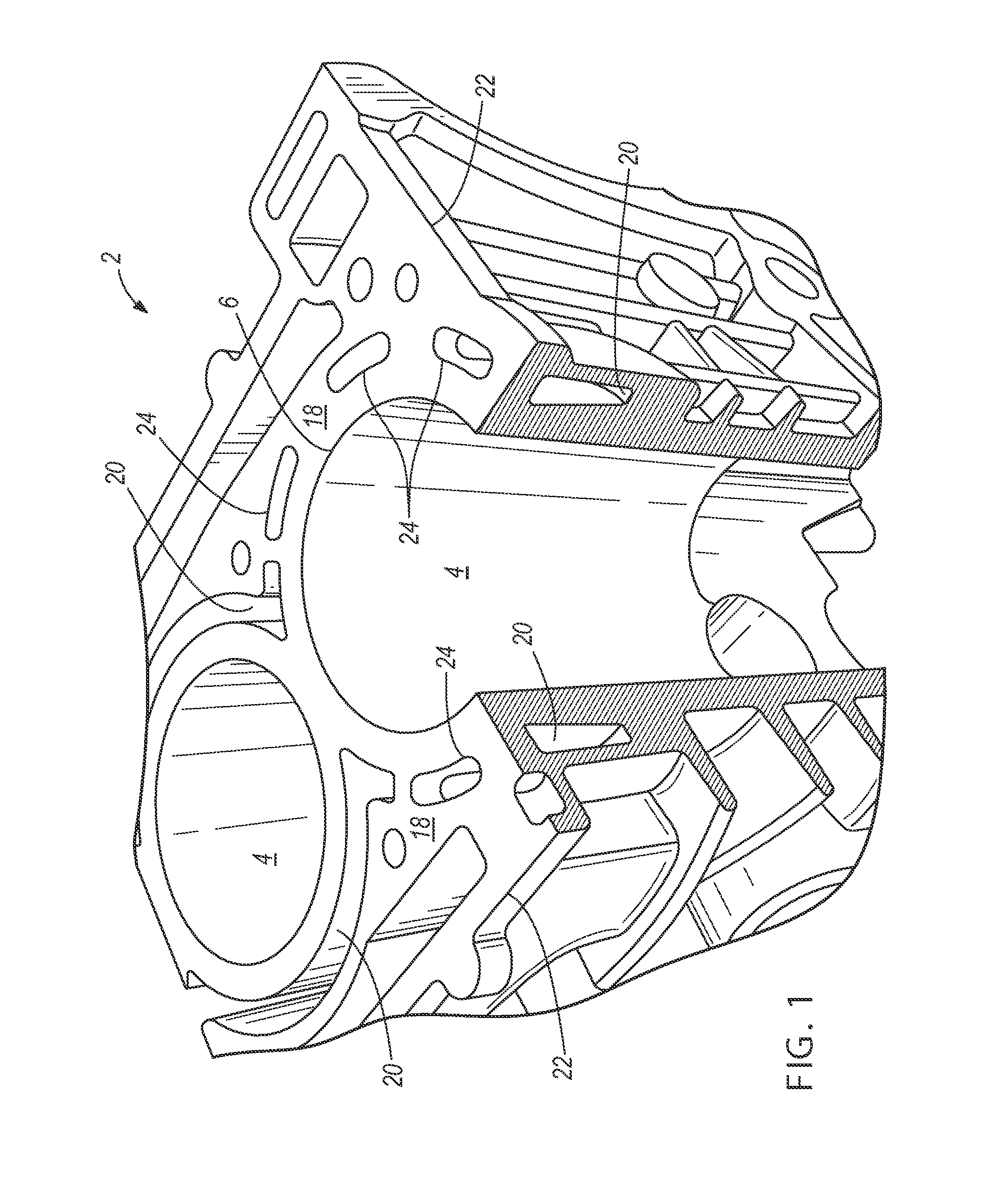

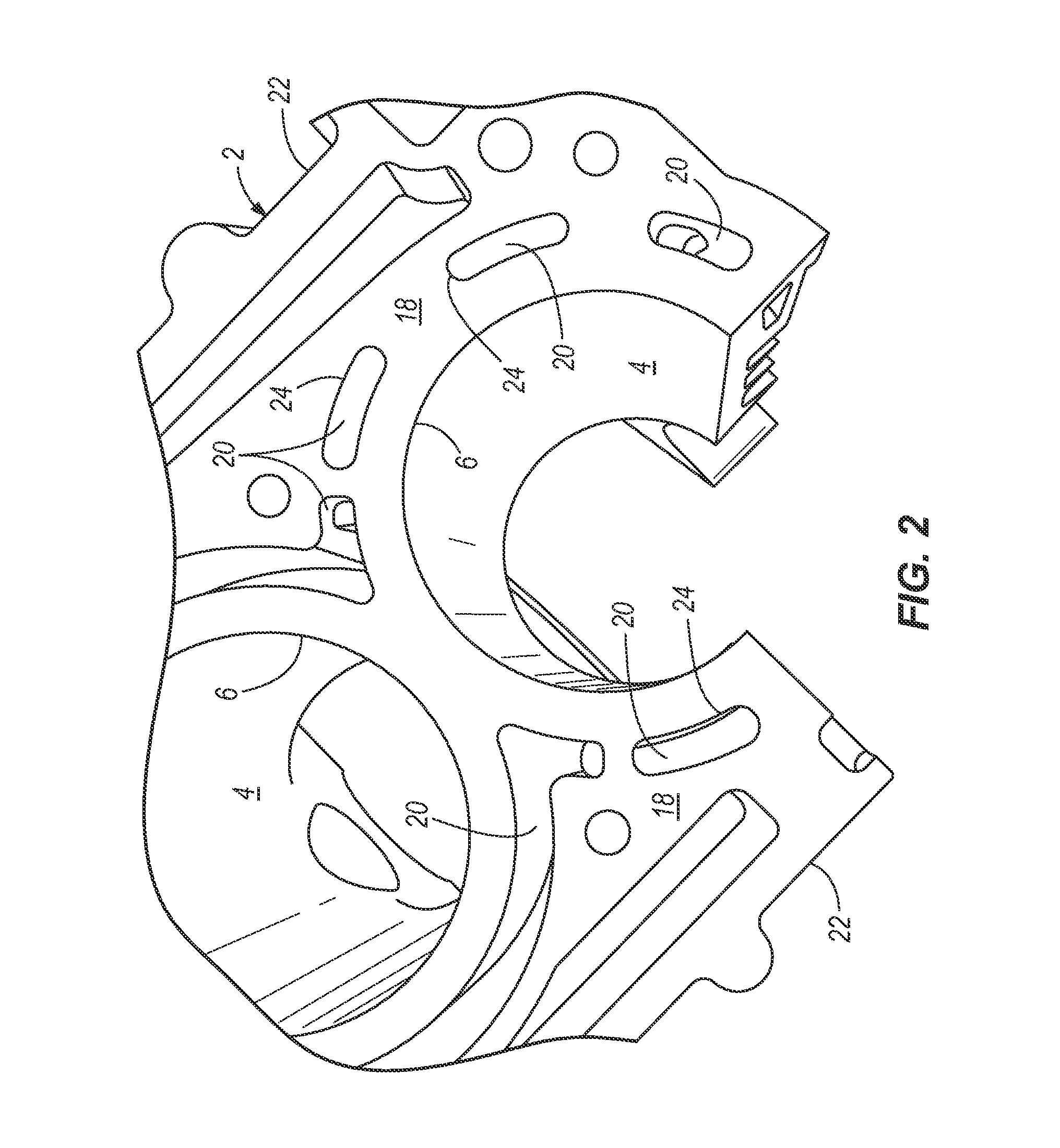

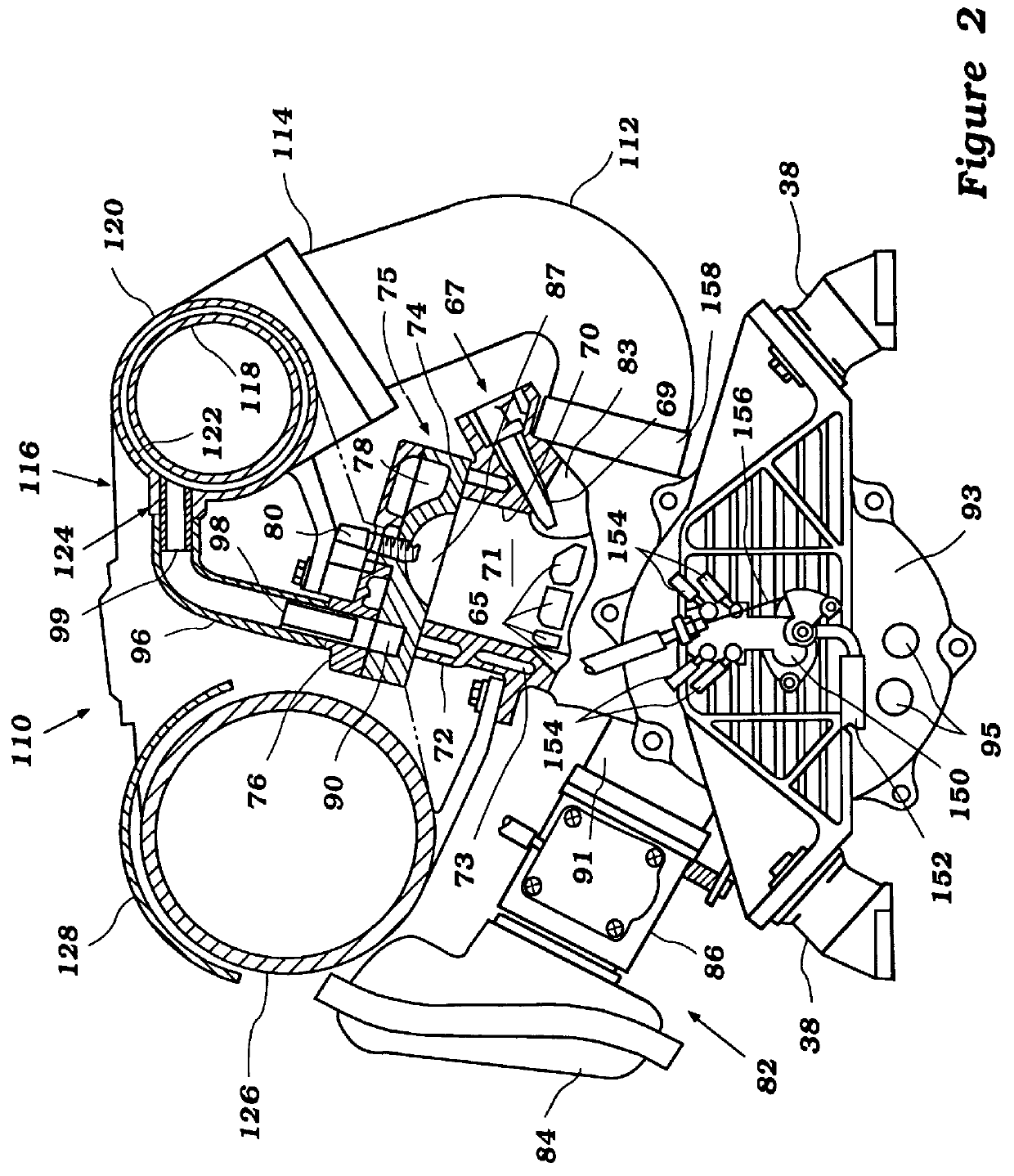

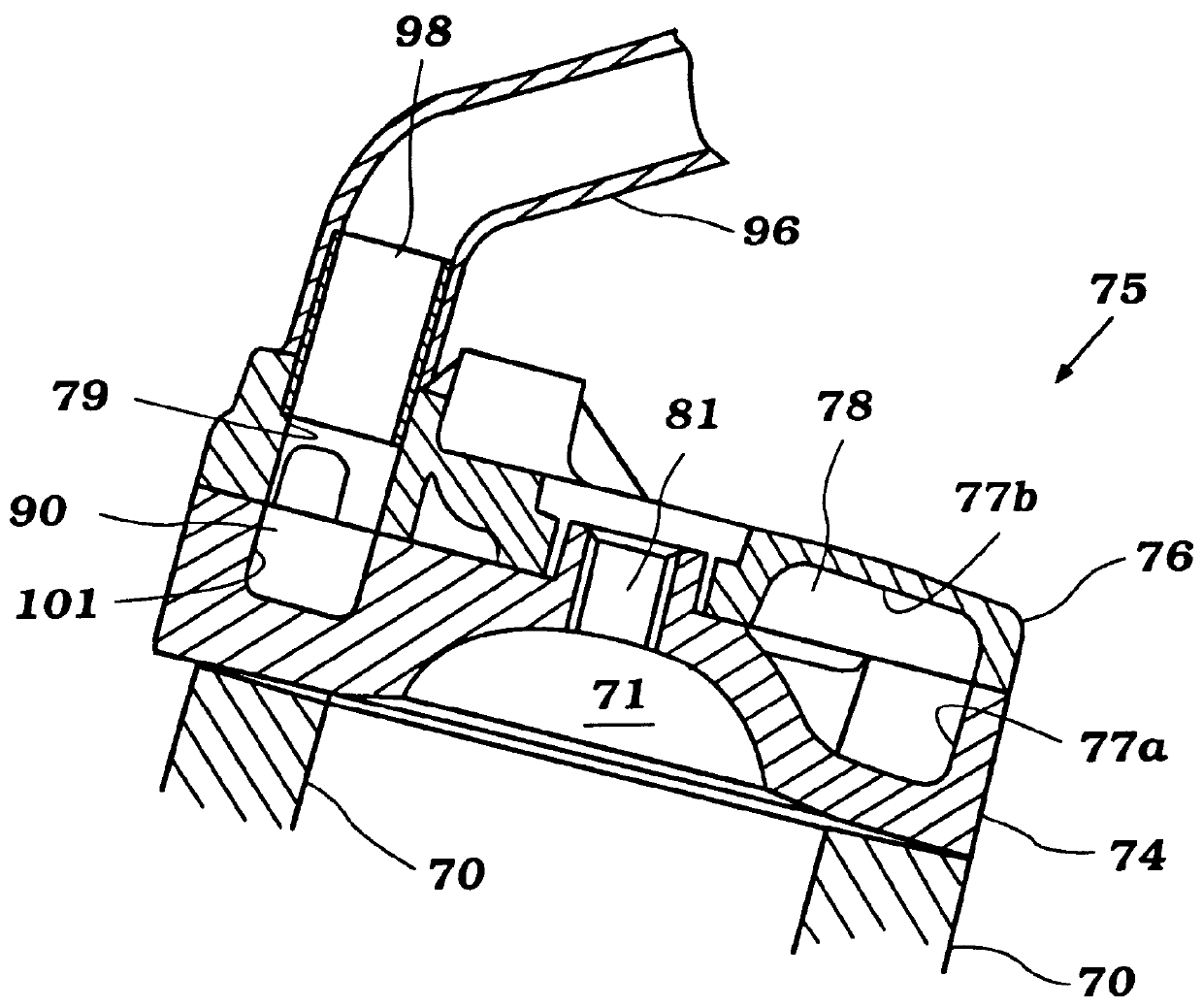

Composite core for the casting of engine head decks

InactiveUS8820389B1Uniform cylinder wall coolingReducing thermal hot spottingFoundry mouldsCylindersDie castingEngineering

Owner:BRUNSWICK CORPORATION

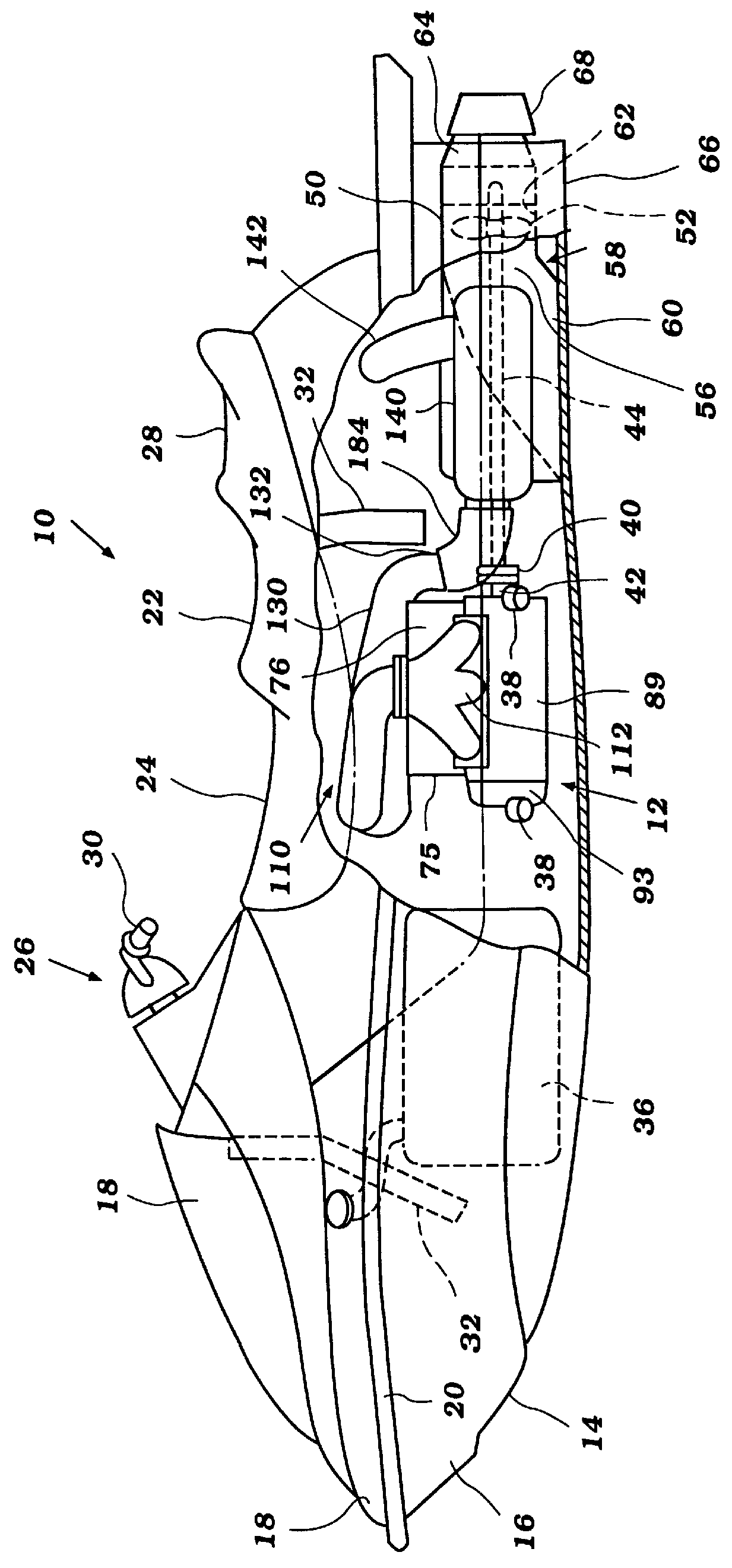

Engine cylinder head coolant jacket

Owner:YAMAHA MOTOR CO LTD

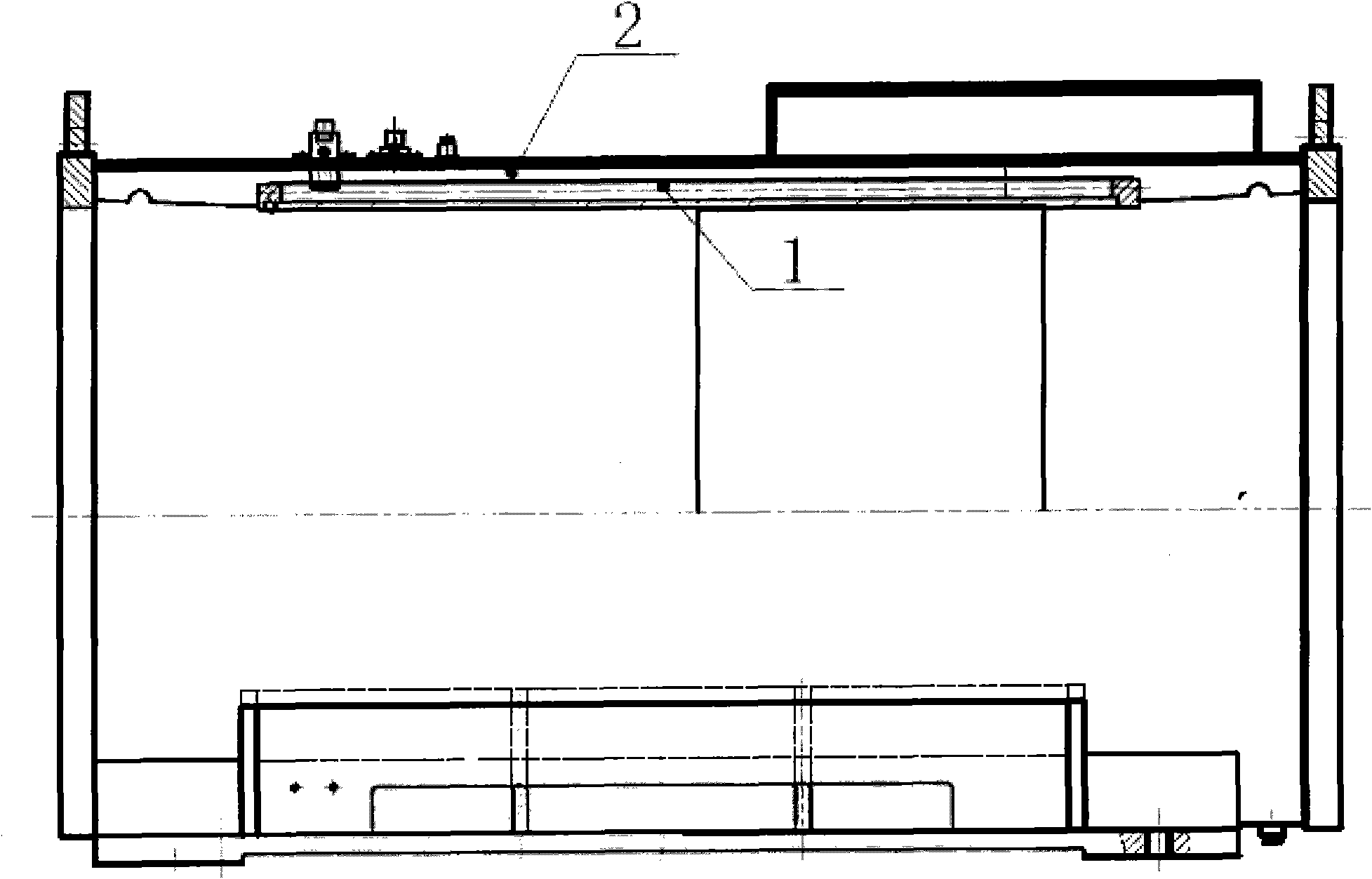

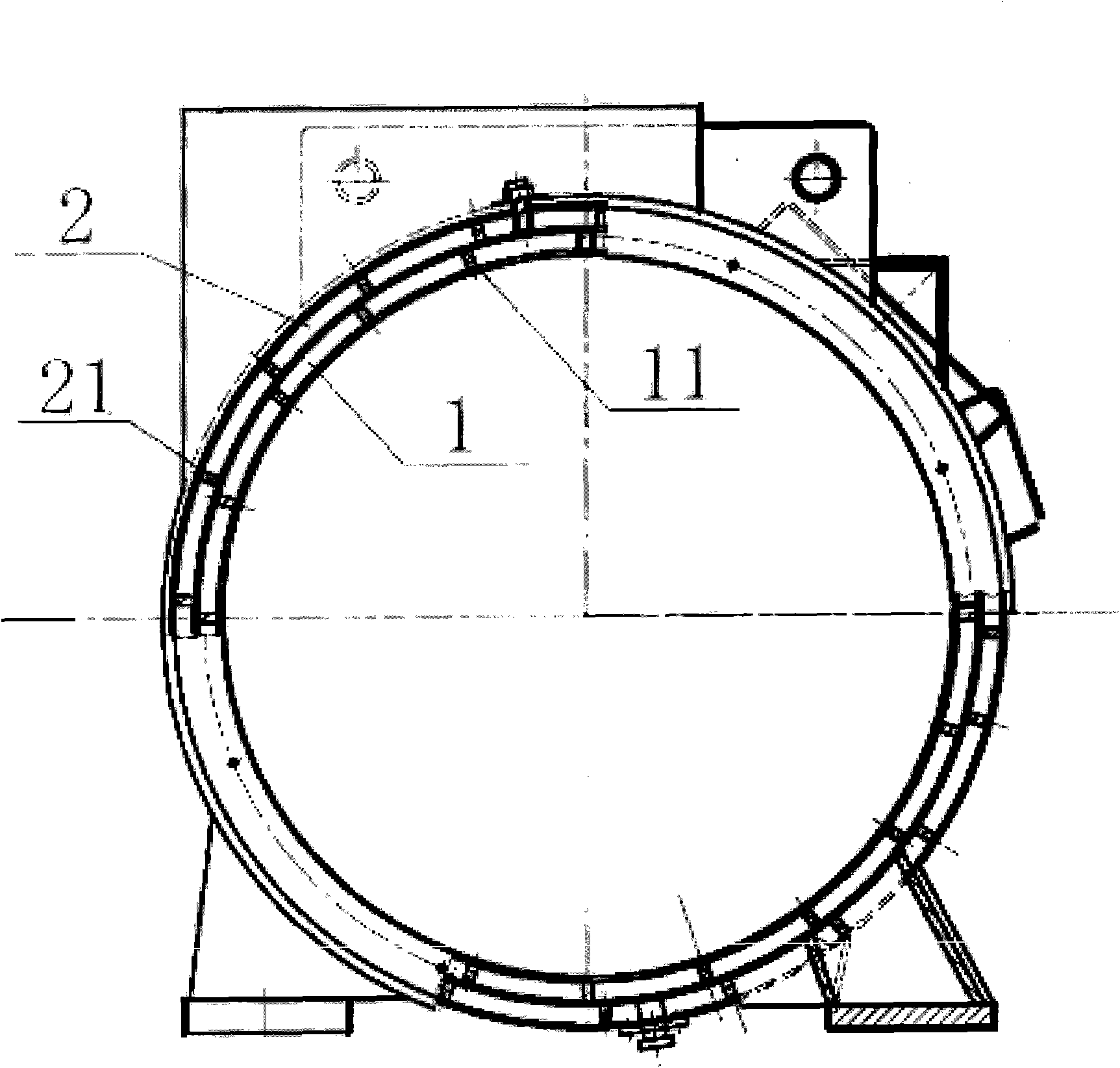

Aerogenerator machine base

InactiveCN101527478ALow costImprove cooling effectSupports/enclosures/casingsCooling effectEngineering

Owner:上海电气集团上海电机厂有限公司

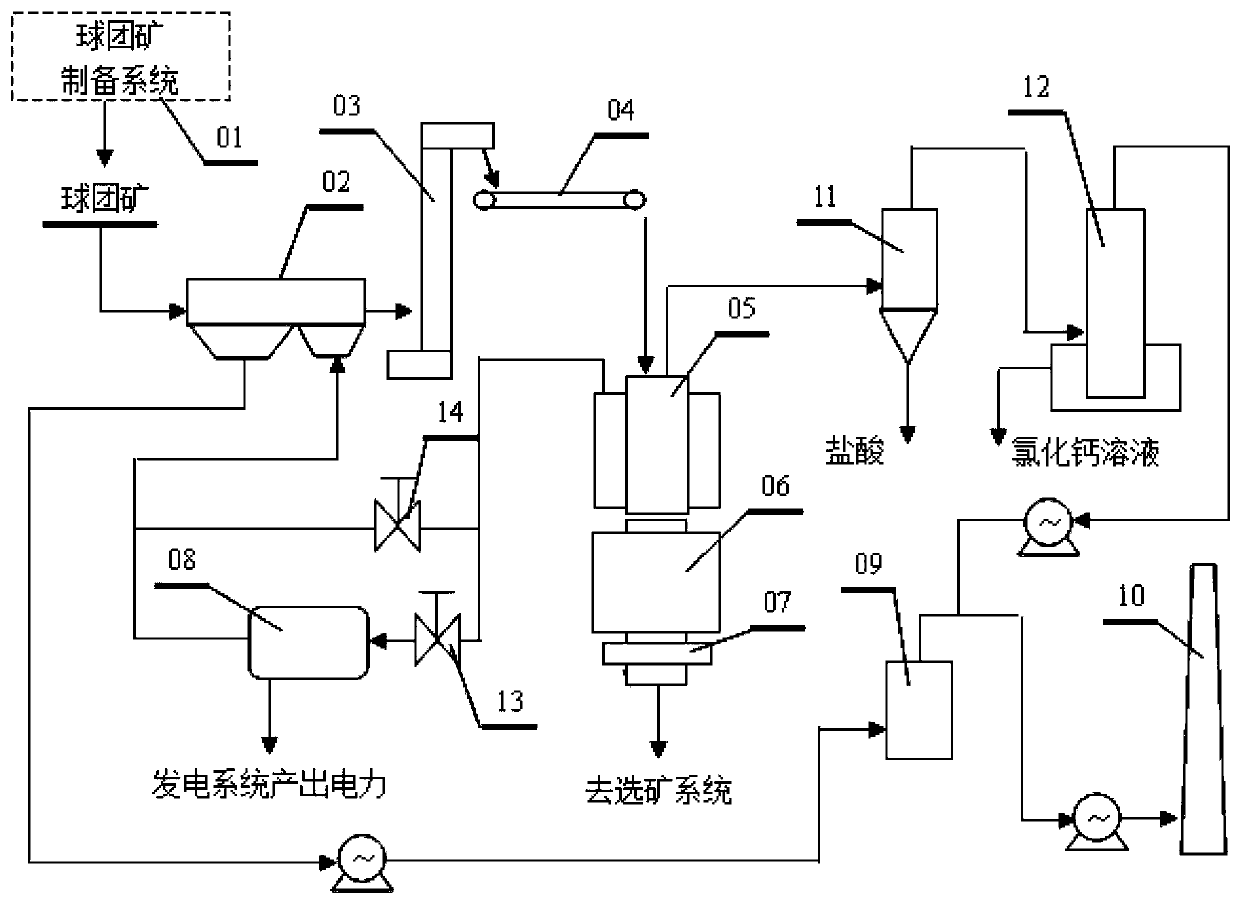

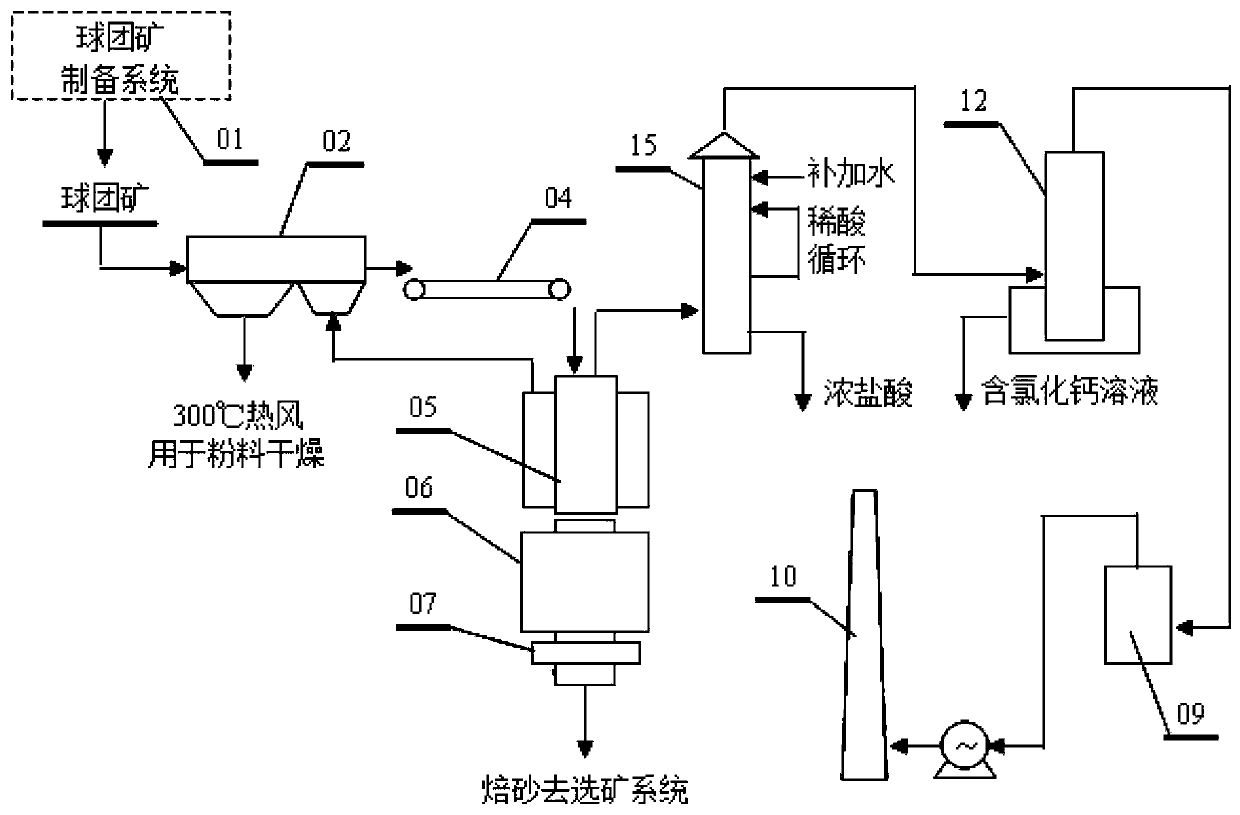

Roasting method for laterite-nickel ore pellets

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing feeding nozzle for continuous high-purity alumina melting furnace and continuous melting furnace

Owner:SHANDONG UNIV OF TECH

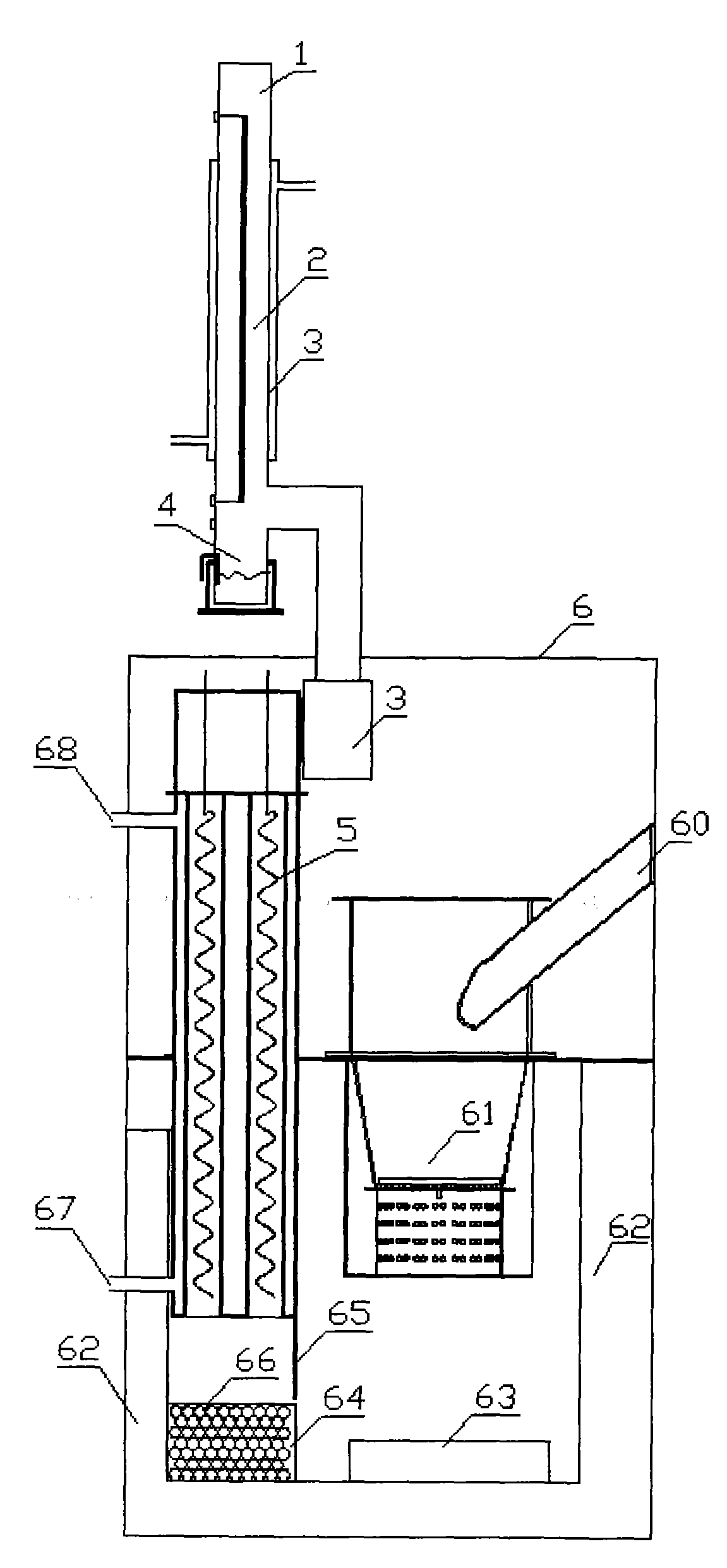

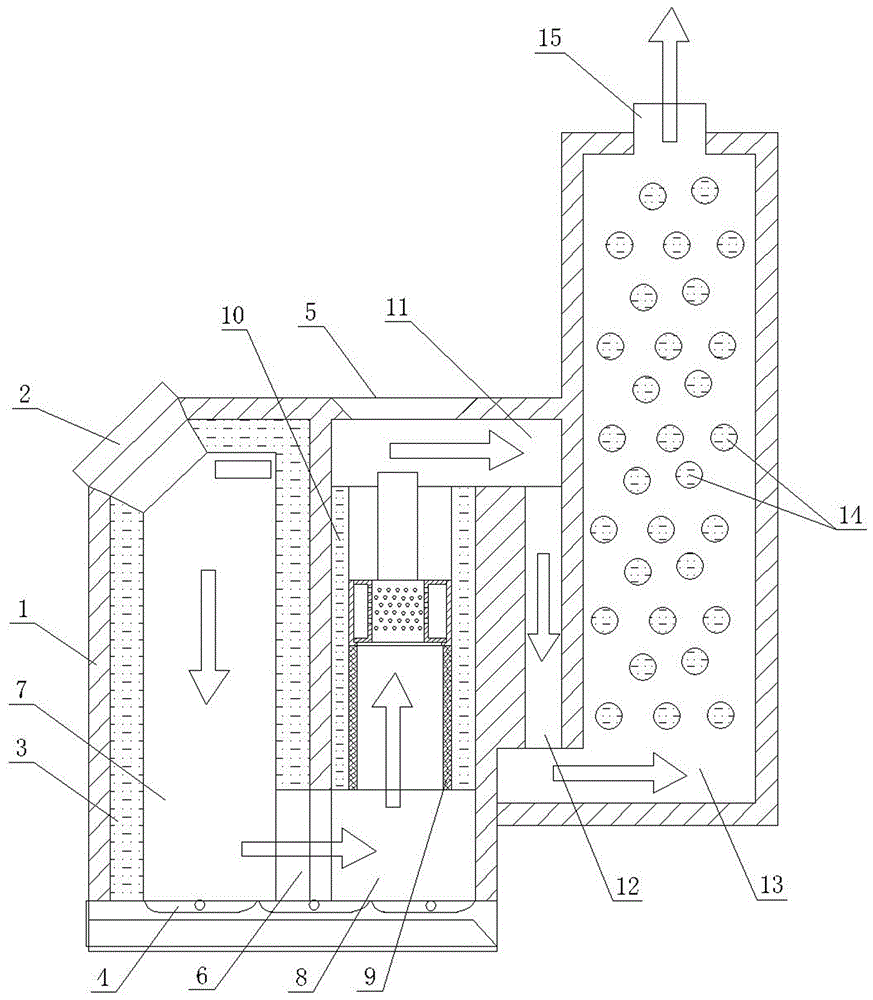

Removing device and removing method for particulate pollutants generated by combustion of biomass fuel

ActiveCN103912889ALighting and heating apparatusDispersed particle separationParticulatesCombustion chamber

Owner:SHANDONG JIANZHU UNIV

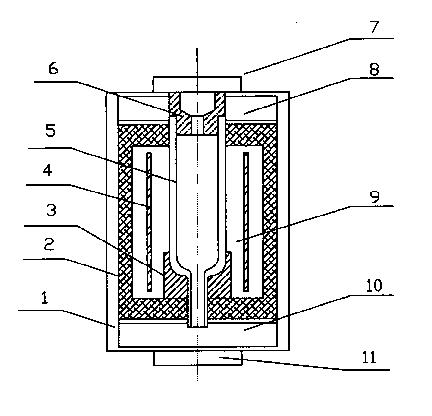

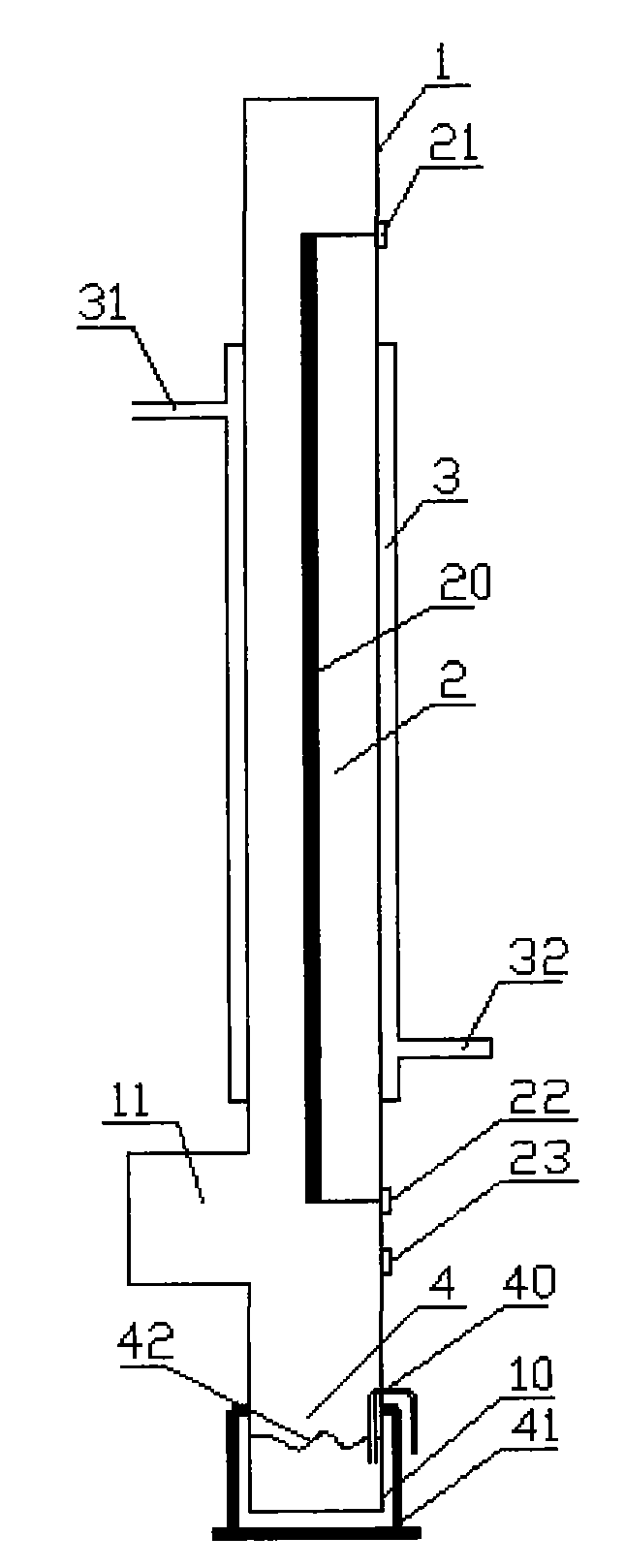

Electric arc discharge cutting head

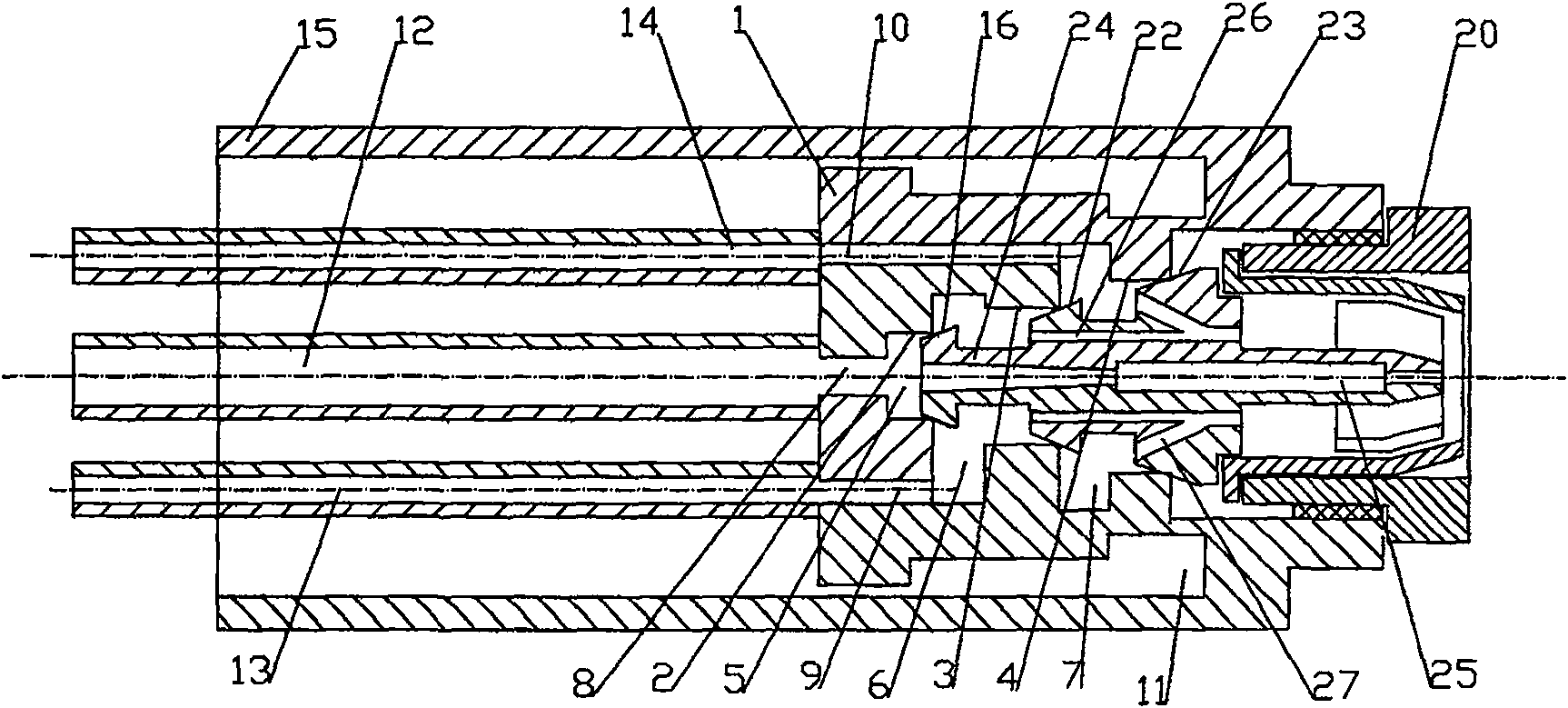

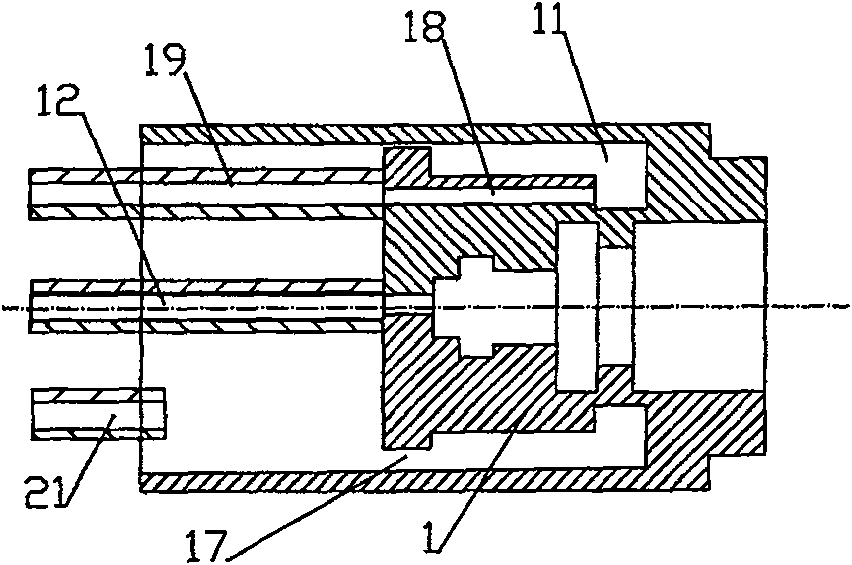

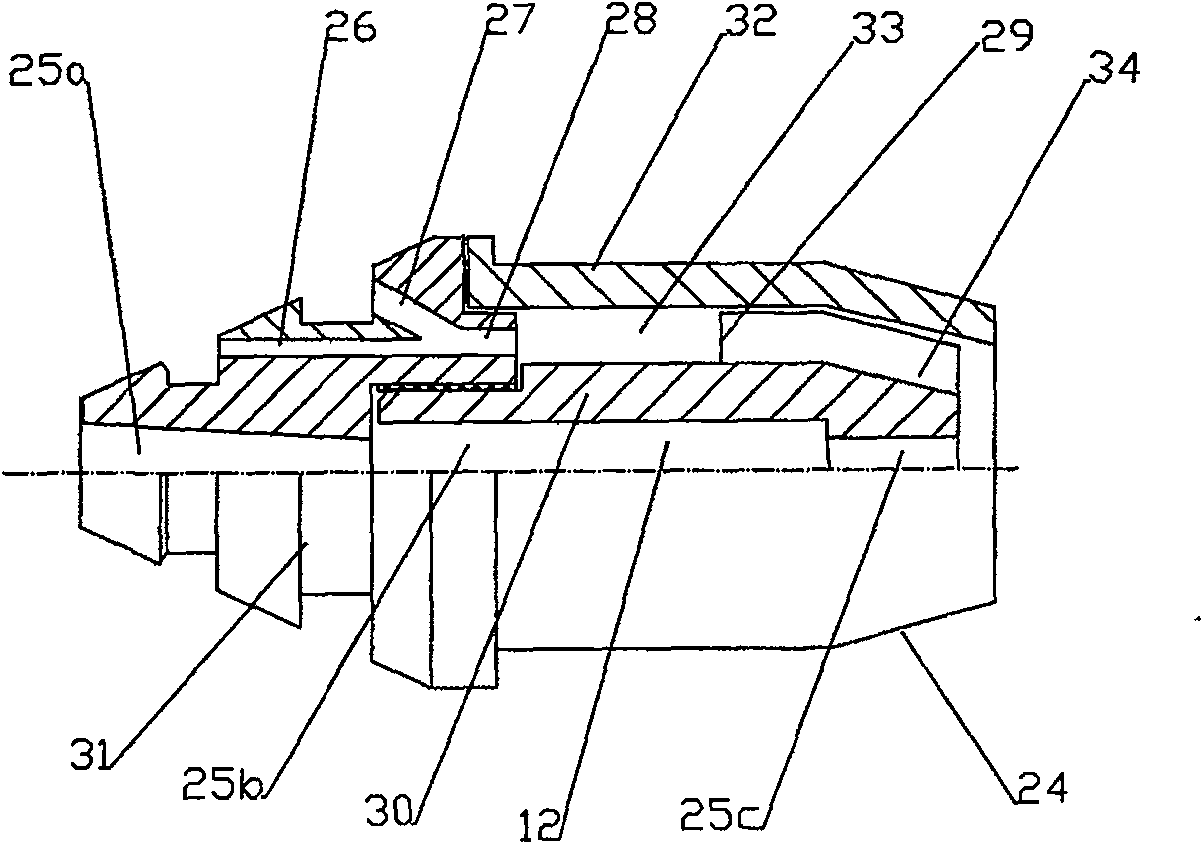

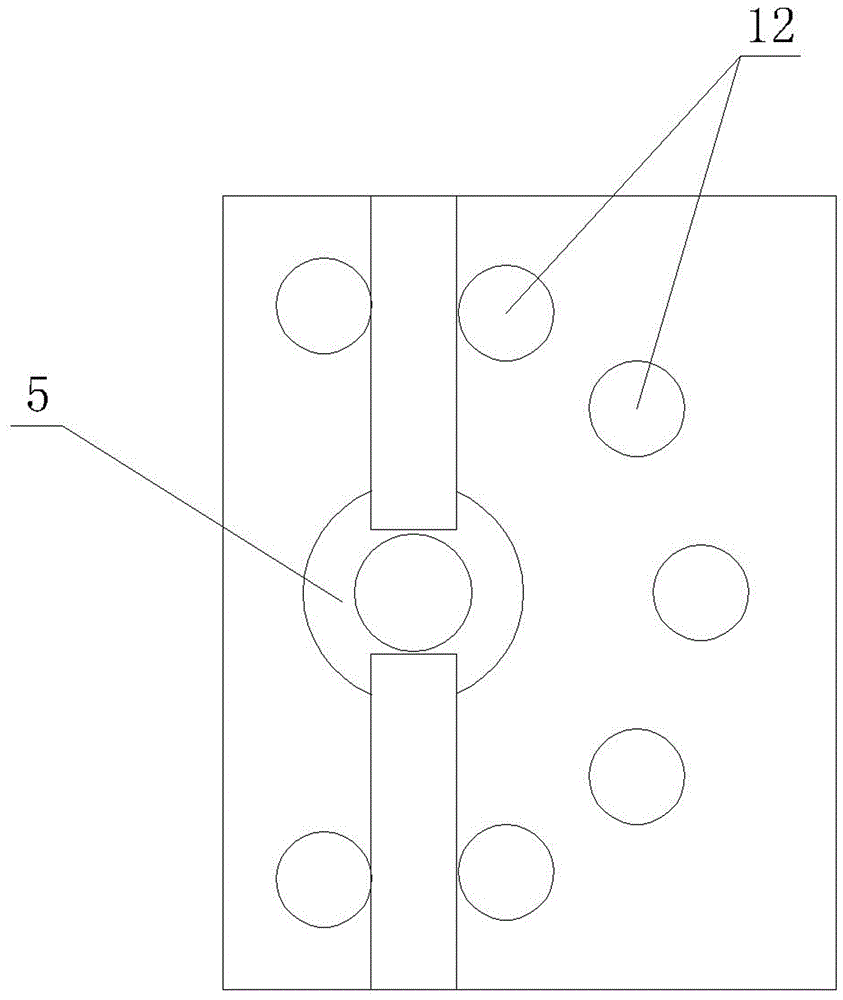

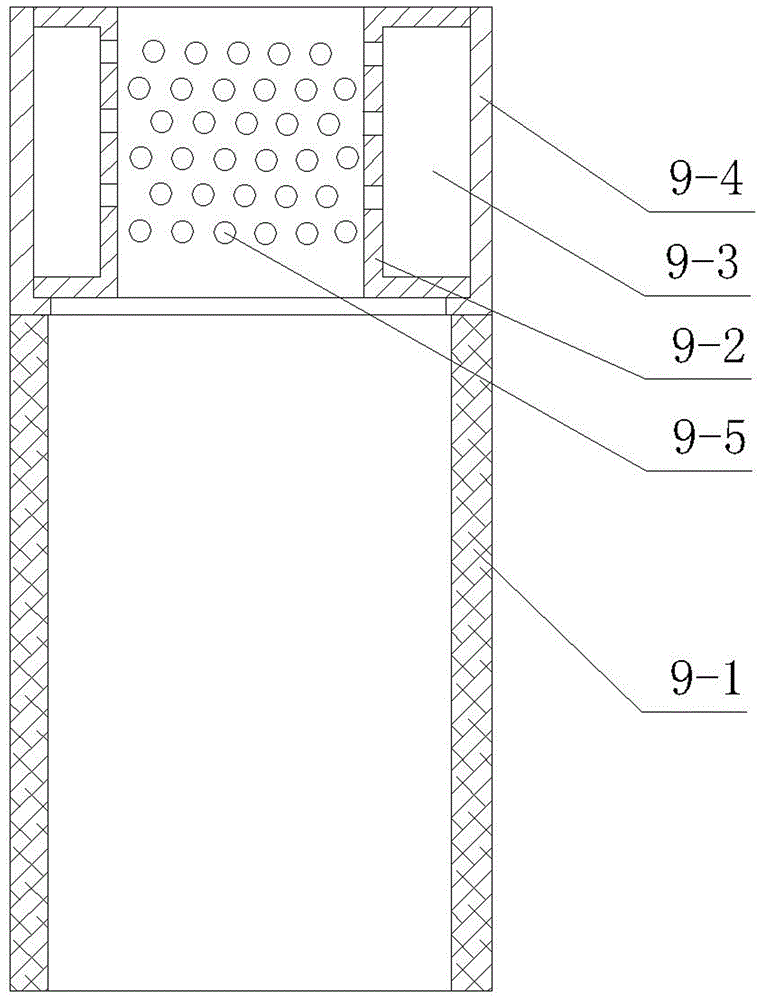

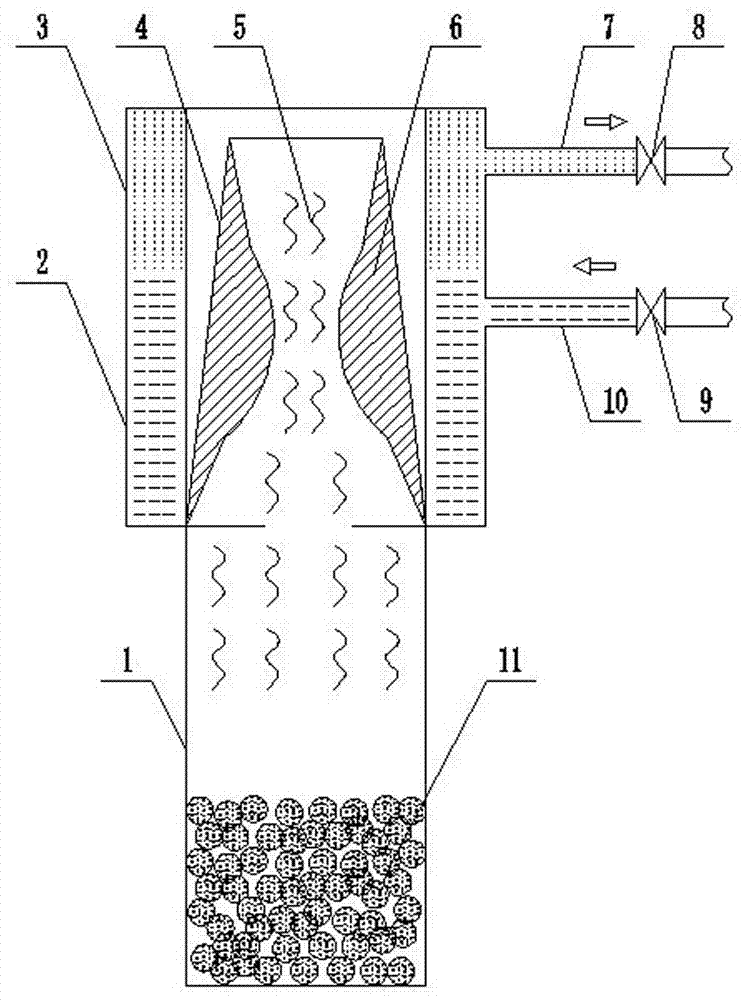

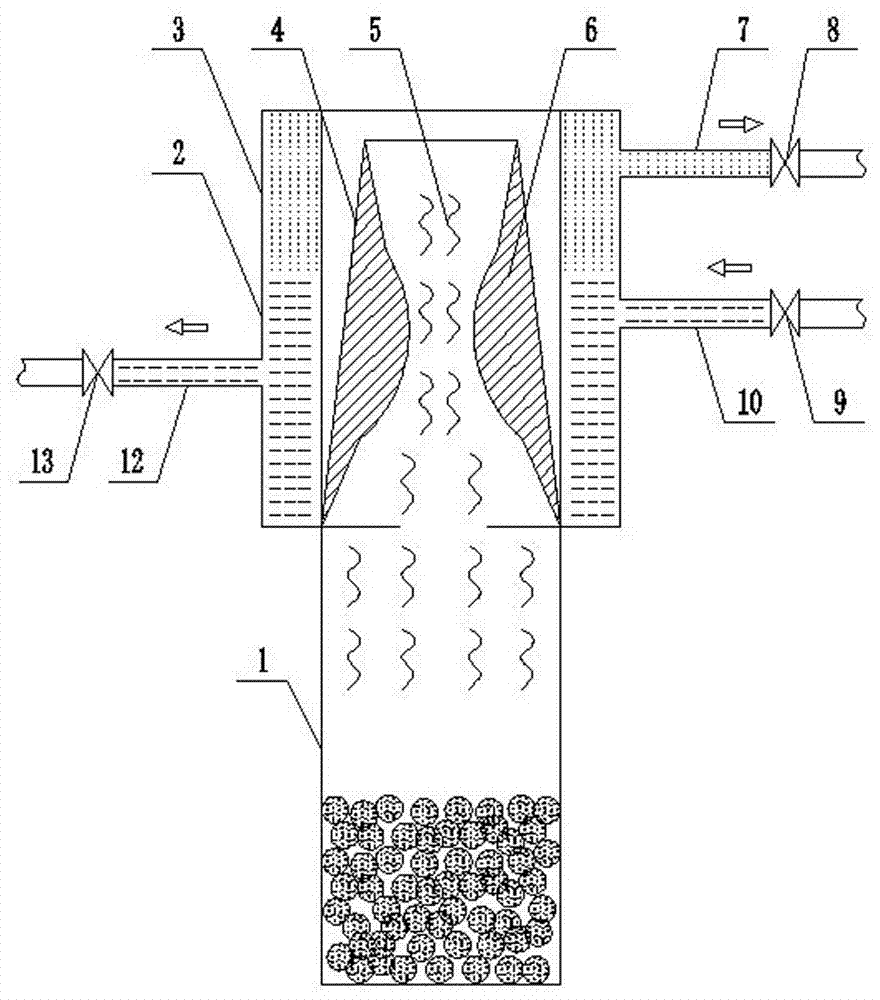

The invention discloses an electric arc discharge cutting head which comprises a positive electrode and a negative electrode. The electric arc discharge cutting head is characterized in that the positive electrode is made of cone high temperature resisting conductive materials including an inner cone hole, the negative electrode is made of a cone bar high temperature resisting conductive materials including a circular cone head, a through hole is formed in the bottom of the cone hole of the positive electrode, high-temperature hot airflow is sprayed to a steel part through the through hole, the cone head of the negative electrode is inserted into the cone hole of the positive electrode, a metal sleeve is arranged on the outer column face of the positive electrode to prevent the positive electrode from bursting at high temperature and hurting people, a water jacket is arranged on the outer layer of the metal sleeve, a water inlet and a water outlet are formed, a high-temperature ceramic cover plate is fixedly connected to the upper end face of the positive electrode through screws, mirror face treatment is carried out on a combination face, the combination face is effectively sealed, a compressed gas inlet and a conductive column through hole of the negative electrode are formed in the high-temperature ceramic cover plate, mirror face treatment is carried out on the combination face of the upper end plane of the negative electrode and the high-temperature ceramic cover plate, a conductive column is fixed to the upper end plane of the negative electrode, and the combination face of the negative electrode and the high-temperature ceramic cover plate is effectively sealed under the traction of the conductive column.

Owner:ZHENJIANG NEW DISTRICT HUIDA ELECTROMECHANICAL TECH CO LTD

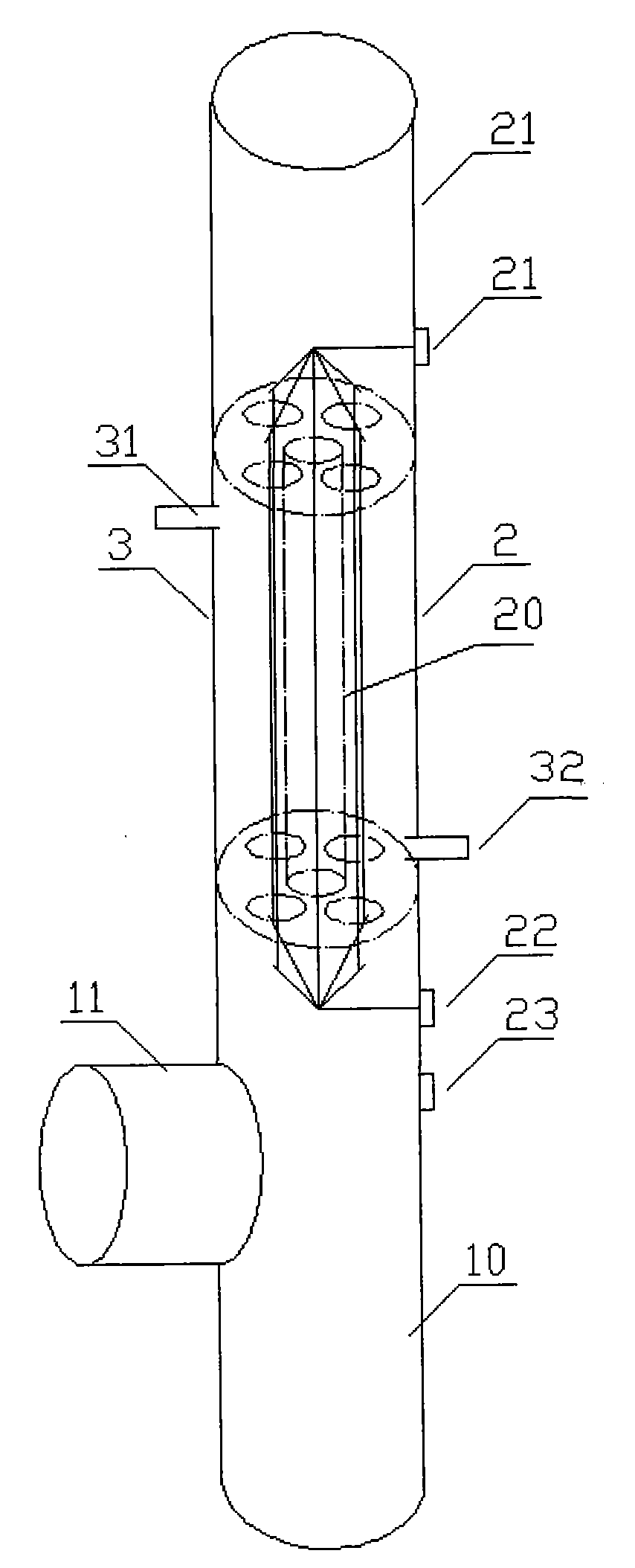

Steel-smelting continuous casting cutting torch

InactiveCN100561048CImprove cooling effectAvoid deformationGaseous fuel burnerSteelmakingCooling effect

Owner:陈寅明

Multi-return-trip cooking and heating stove

InactiveCN105953269AIncrease heat output ratioFully gasified combustionLighting and heating apparatusStove/ranges for heating waterCombustion chamberCombustor

Owner:SHIJIAZHUANG ZHONGJIA HEATING EQUIP

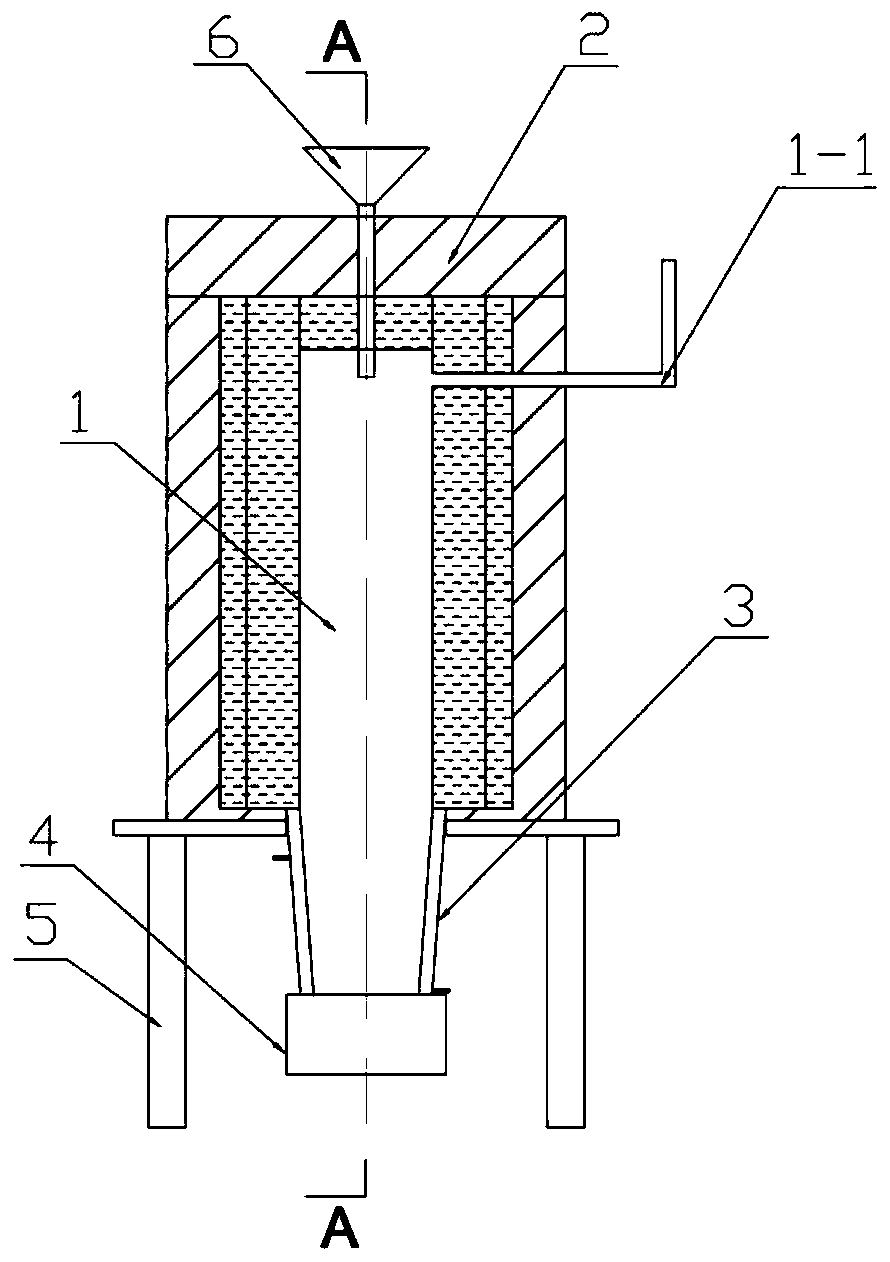

Magnesium steam crystallization waste heat utilization device for recycled magnesium smelting

PendingCN107058763AEfficient use ofImprove utilization efficiencyIncreasing energy efficiencyWaste heat treatmentCooling towerWater vapor

Owner:ZHENGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap