Multi-return-trip cooking and heating stove

A heating stove and multi-return technology, which is applied to household stoves/stoves, stoves/stoves with hot water devices, and household heating, etc., can solve problems such as air pollution, insufficient heat, and difficulty in cleaning, and improve the output heat. ratio, improve thermal efficiency, rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

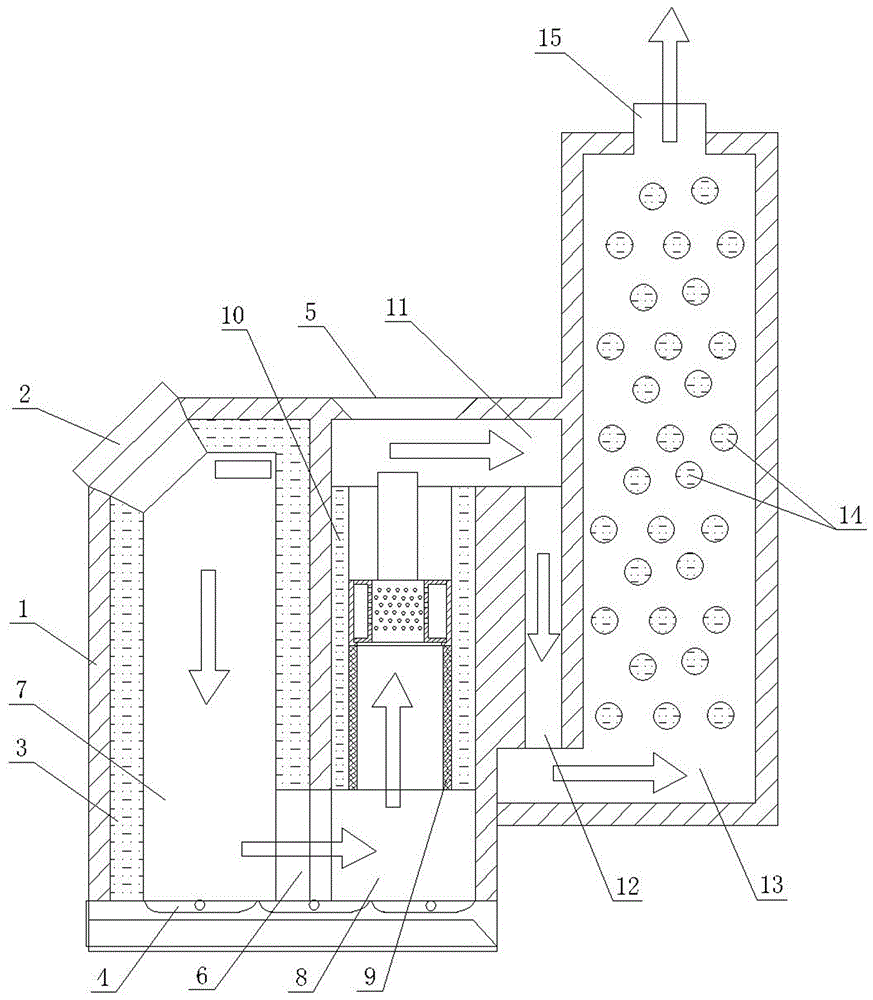

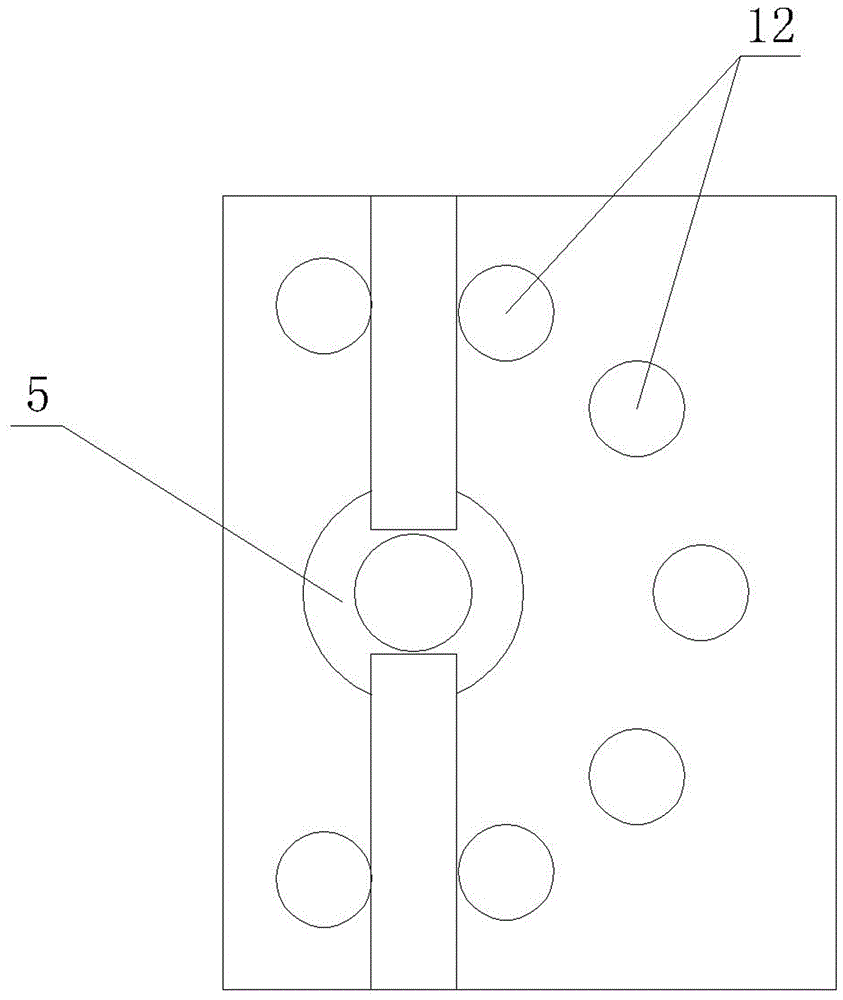

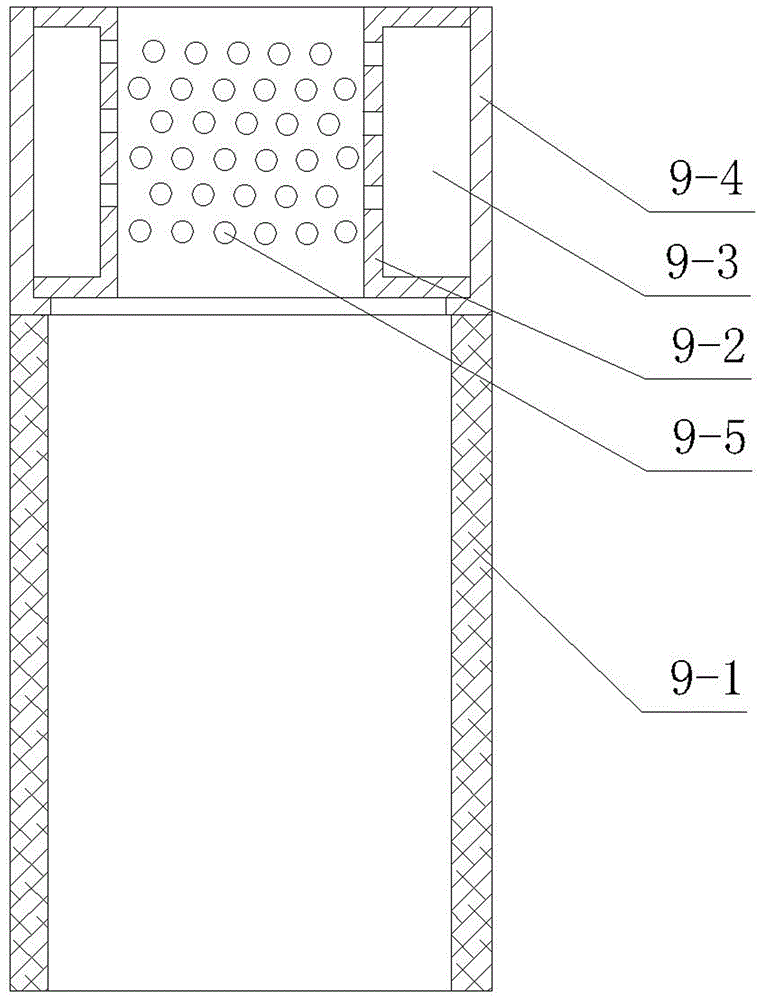

[0025] as attached Figure 1-3 As shown, a multi-return cooking and heating furnace includes a furnace body 1, a fuel bin 7 arranged in the furnace body 1, a high-temperature combustion chamber 8 communicated with the fuel bin 7 through a flame channel 6, and a high-temperature combustion chamber 8 arranged at the upper end of the high-temperature combustion chamber 8. The furnace mouth 5, the high-temperature flue gas heating chamber 11 located between the furnace mouth 5 and the high-temperature combustion chamber 8, and the flue 13 communicating with the high-temperature flue gas heating chamber 11, the flame passage 6 is arranged at the lower part of the fuel tank 7, Volatiles and flames produced by the fuel in the fuel bin 7 enter the high-temperature combustion chamber 8 through the flame passage 6 . The high-temperature combustion chamber 8 is provided w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap