Secondary burning method and special energy-saving furnace for organic-fuel firepot of two-way air blower

An organic fuel and secondary combustion technology, which is applied to solid heating fuels, household cooking utensils, household stoves/stoves, etc., can solve problems such as unreasonable combustion and blasting positions, too large fuel pusher, and unsuitable combustion methods. , to achieve the effect of sufficient decomposition, stable combustion and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

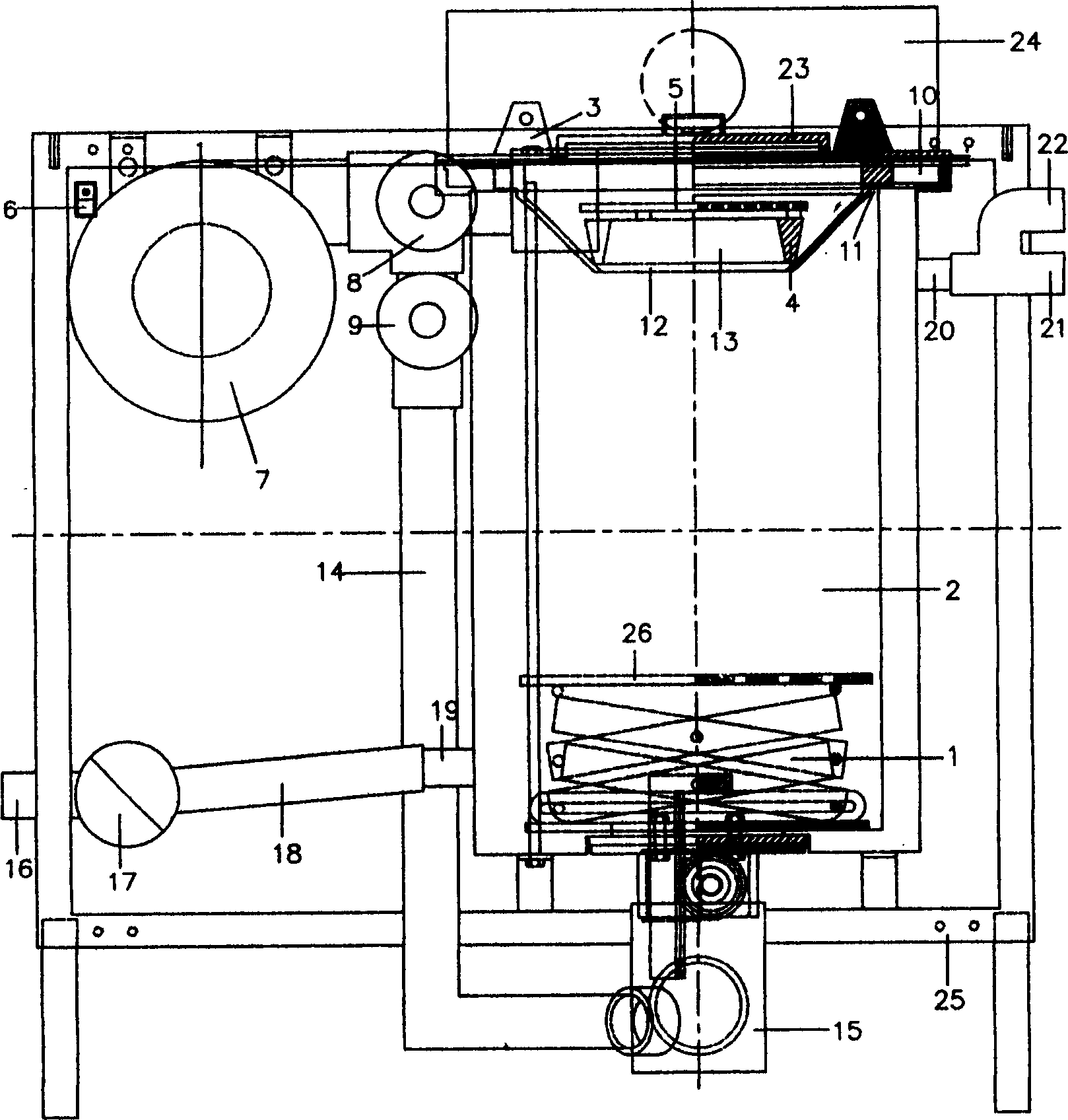

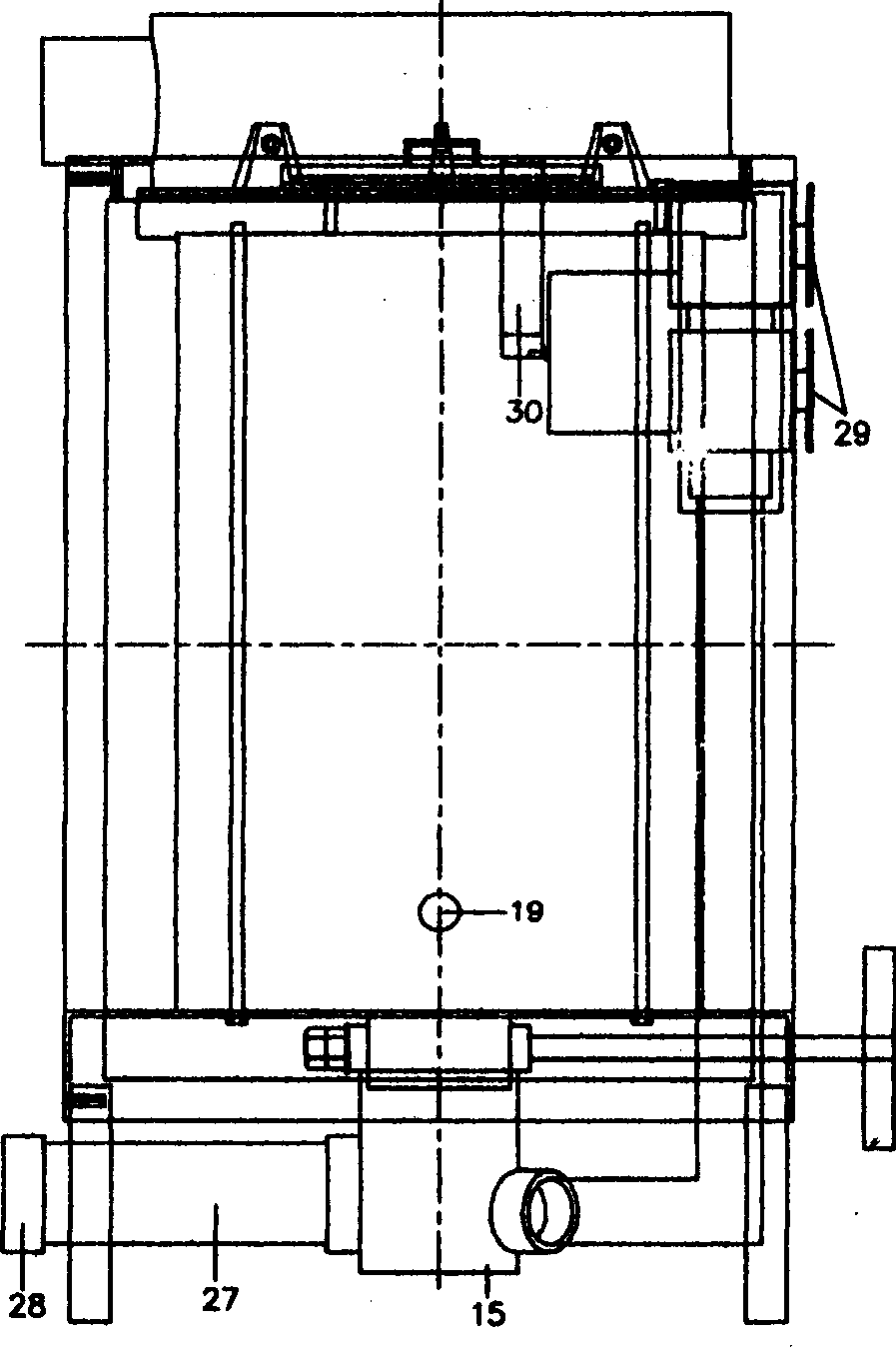

Embodiment 1

[0024] The secondary combustion method of the two-way blast organic fuel furnace is as follows: the organic fuel is chaff, and a row of firewood can also be placed on the top of the chaff in order to prevent the dust from just being ignited. The firewood is adjusted to just touch the air inlet of the burner head, and the combustion chamber is composed of the fire distribution ring and the fire distribution plate in the burner head above the air inlet of the burner head; the charcoal is filled to 1 / 2 height in the fire distribution ring, and a small piece of charcoal Light it as a fire and put it into the combustion chamber, fill the combustion chamber with charcoal, and cover the fire distribution board; turn on the blower to generate two-way blast, and the blower blows through the annular air inlet channel all the way to add oxygen to the charcoal to make it fully burnt. At the same time, the chaff in the furnace is decomposed to produce hydrocarbon gas; the blower blows air to

Embodiment 2

[0035] Embodiment 2: The furnace body 2 of the special energy-saving furnace is made of refractory material or filled with refractory material between the double-layer furnace body, and the water inlet and outlet devices are omitted. Others are similar to Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap