Steady-state-temperature-field-included simulation test bench of aero-engine combustor

A technology of aero-engine and simulation test bench, which is applied in jet engine test, gas turbine engine test, etc., can solve the problems of lack of test equipment and achieve the effect of low risk, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically described below with reference to the accompanying drawings. It should be understood that the drawings and the following description are only used as descriptions of preferred embodiments of the present invention, and should not be construed as limiting the protection scope of the present invention, which is only limited by the claims.

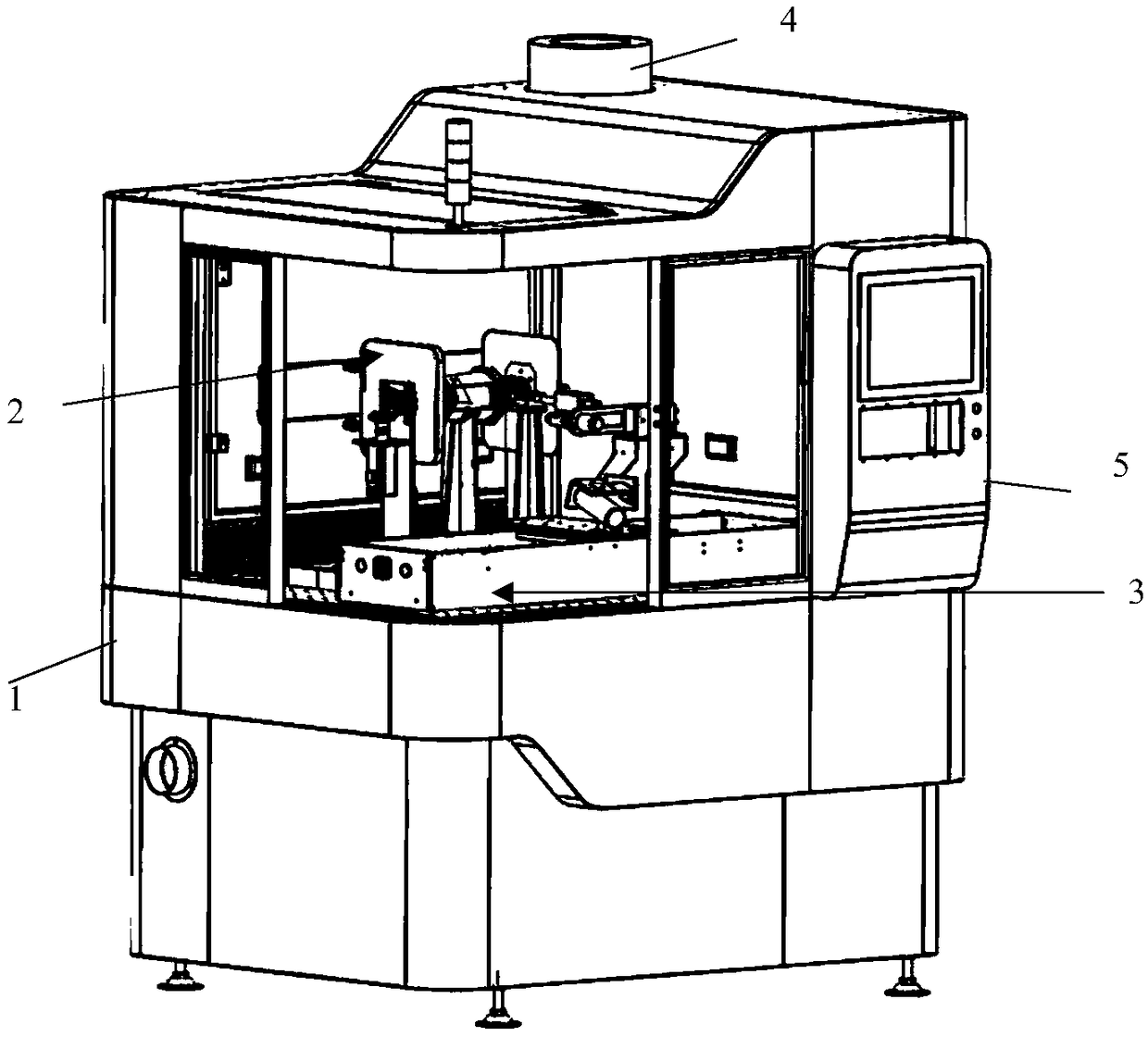

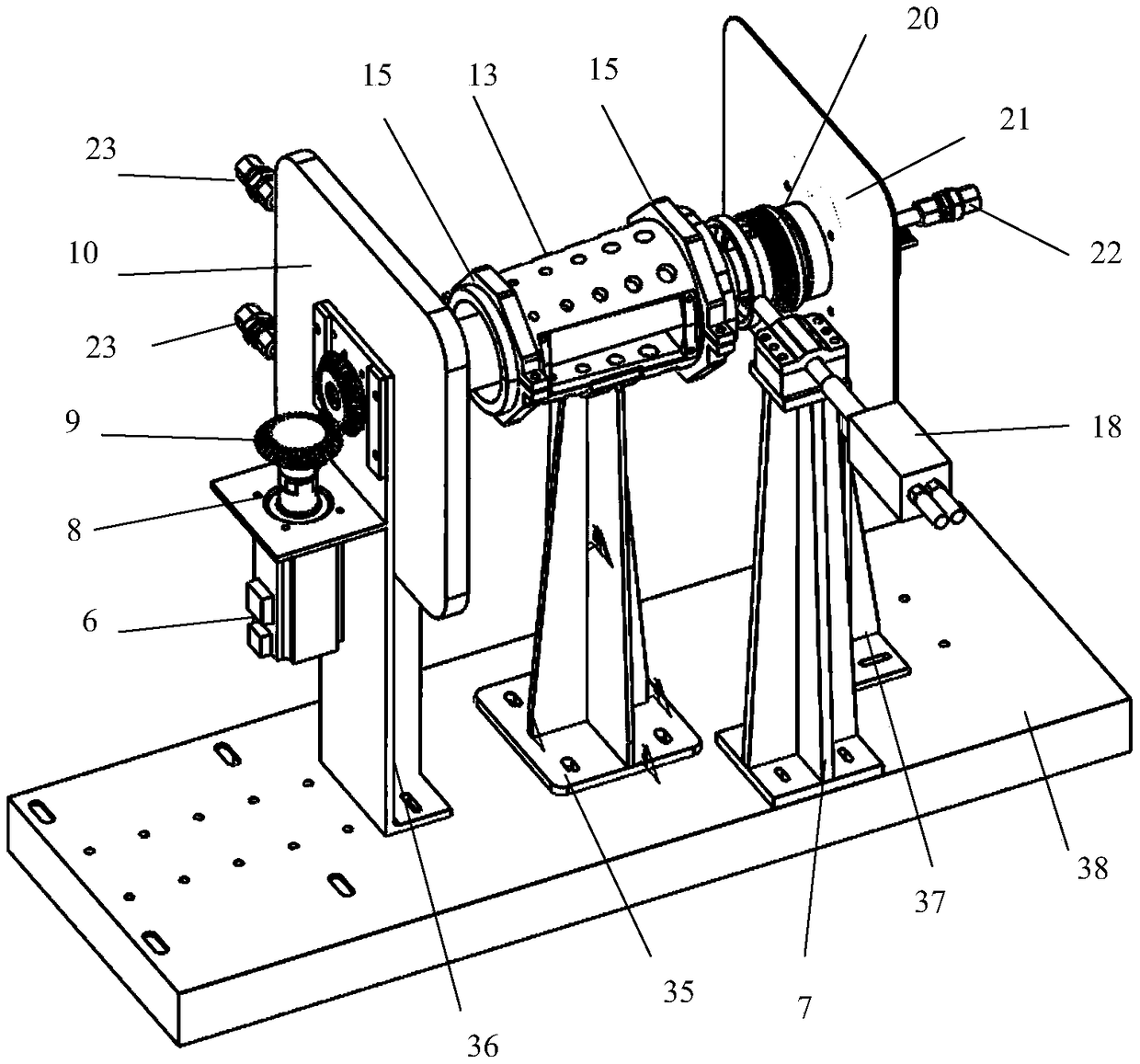

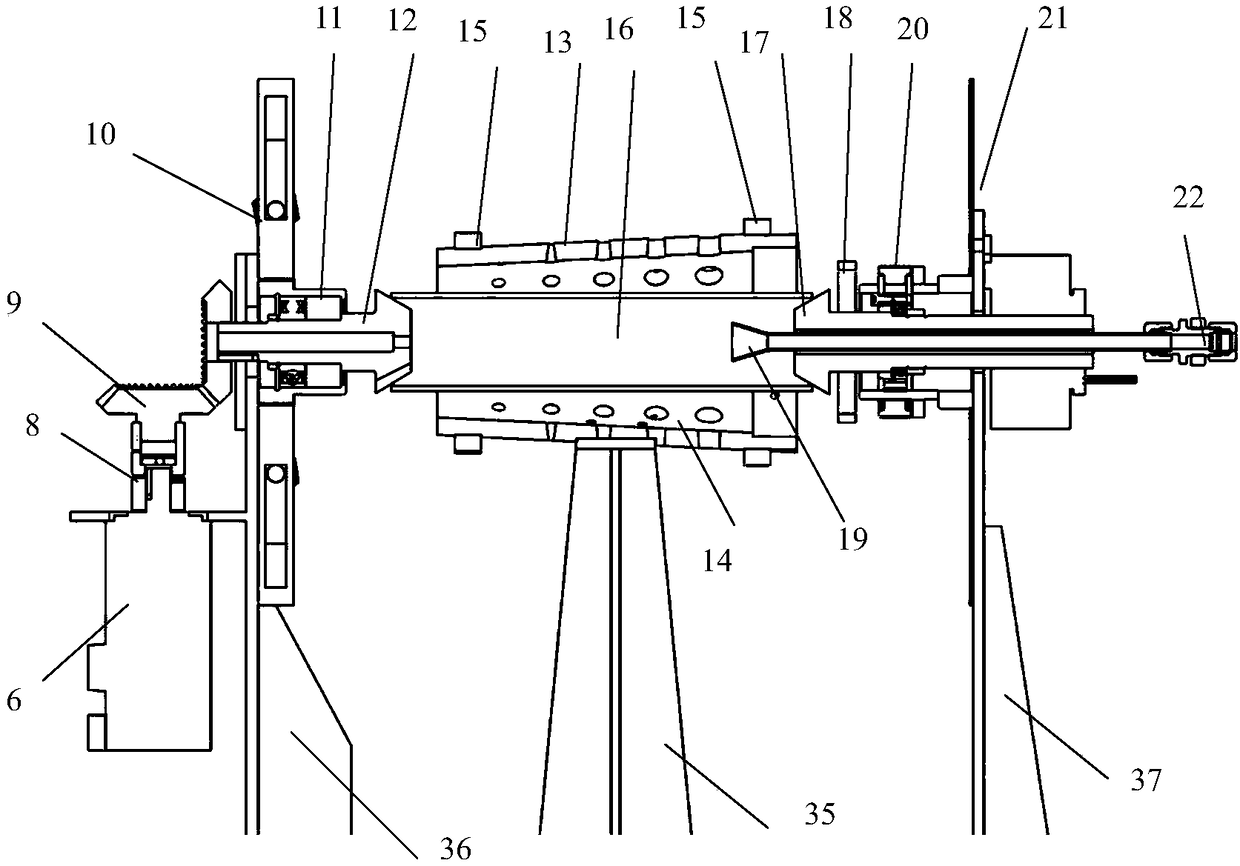

[0019] Such as figure 1 As shown, the aero-engine combustion chamber simulation test bench provided by the present invention has a steady-state temperature field comprising: casing 1, combustion chamber simulation device 2, test device 3, air supply system, ventilation system, cooling system and control system; wherein , the middle part of the box body 1 is provided with a partition, thereby dividing its internal space into an upper box body and a lower box body. There are ventilation holes on the partition board, and the front end and one side of the upper box body are open, and the opening is pr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap