Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Air blower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

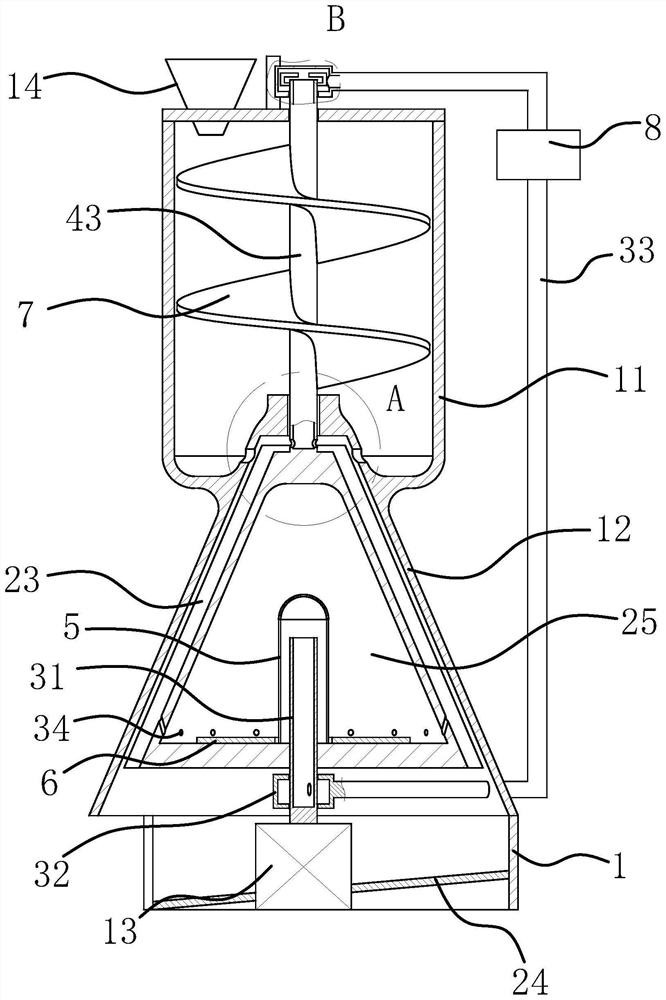

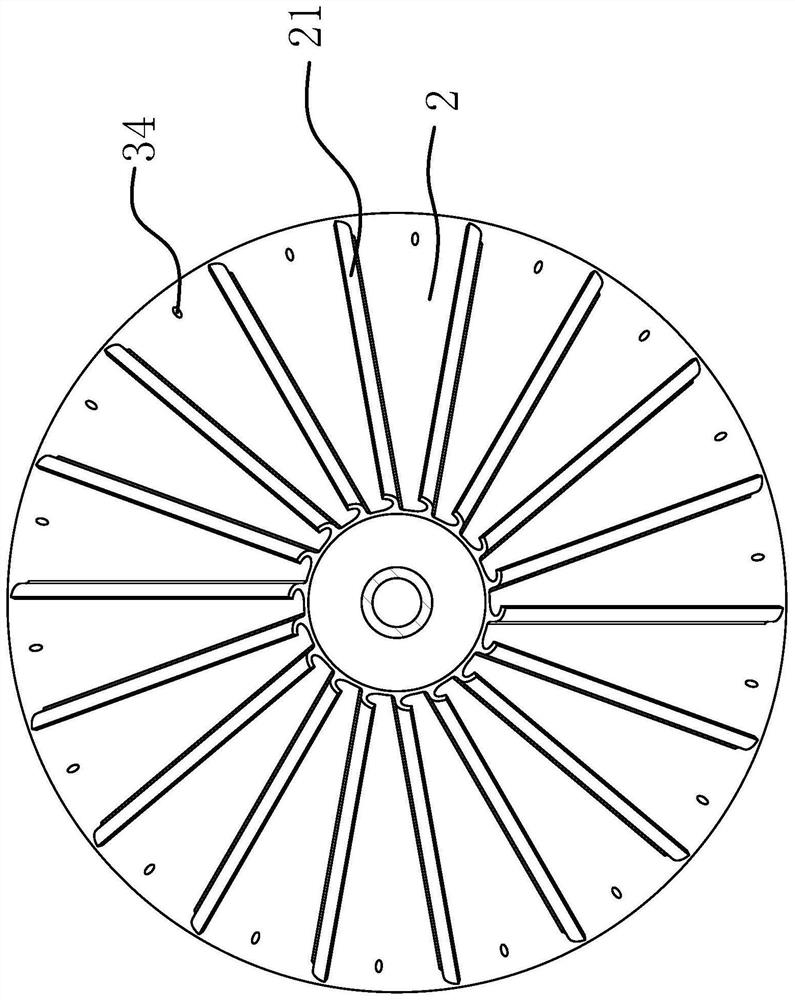

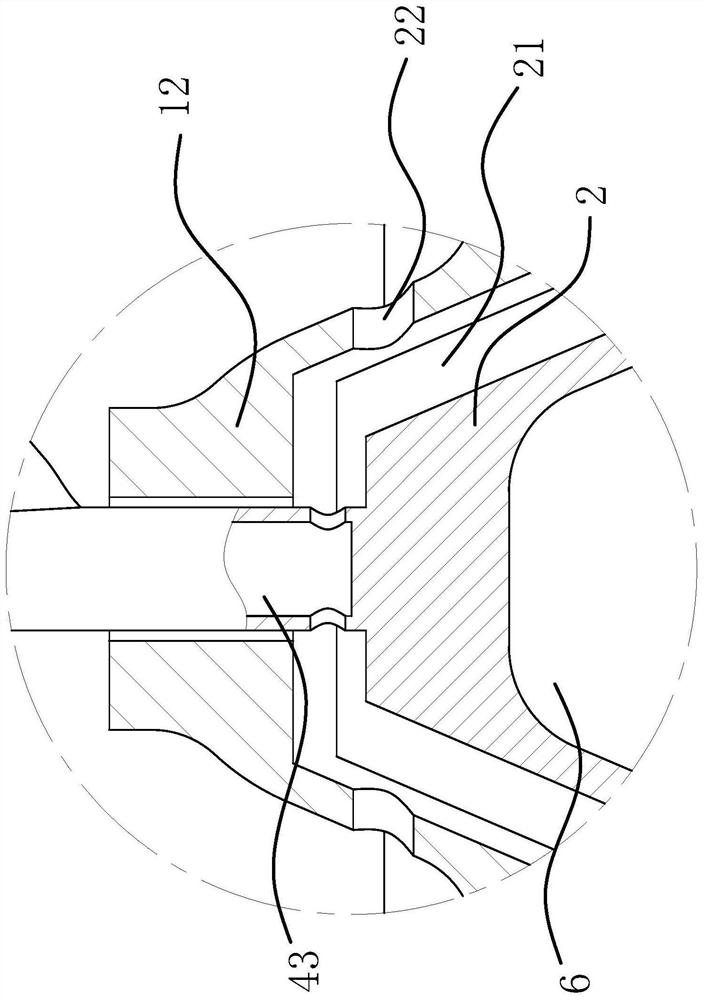

Comprehensive treating device for disassembling old shoes and recycling useful materials in old shoes

InactiveCN108453953ASolve problems that are difficult to recycle efficientlyEasy to recycleGas current separationPlastic recyclingResource utilizationEngineering

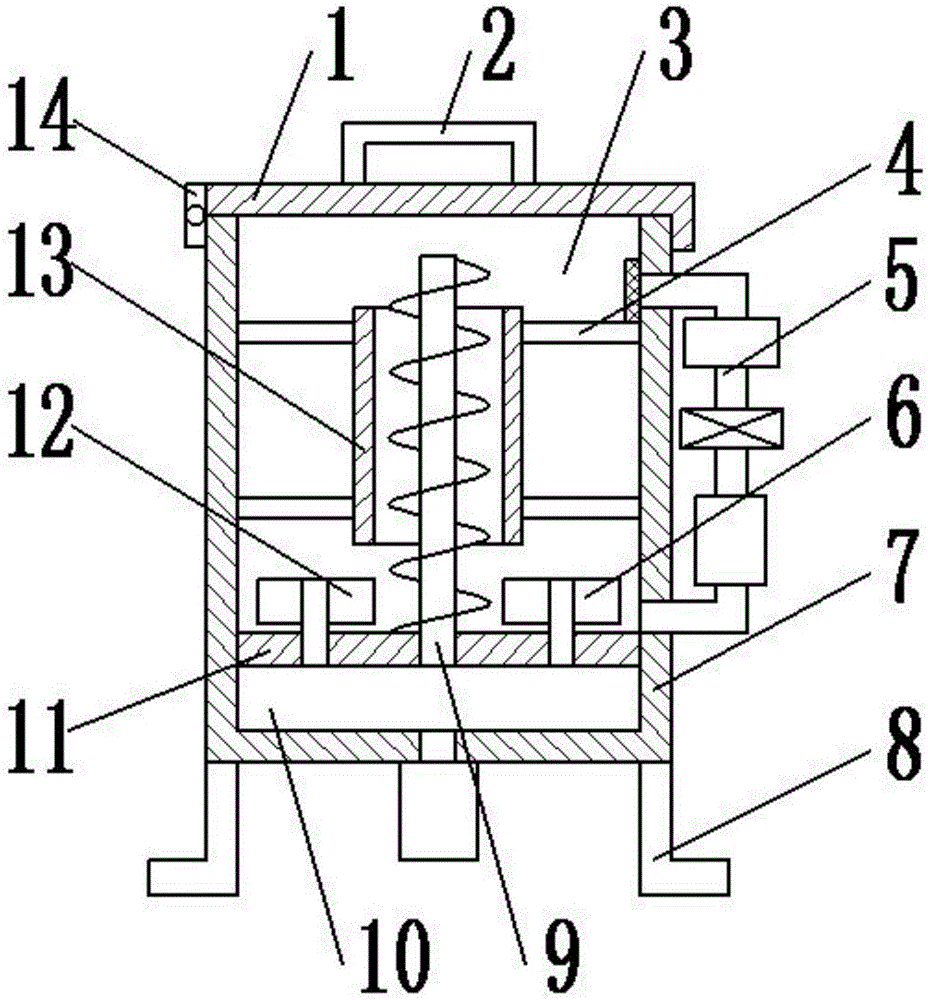

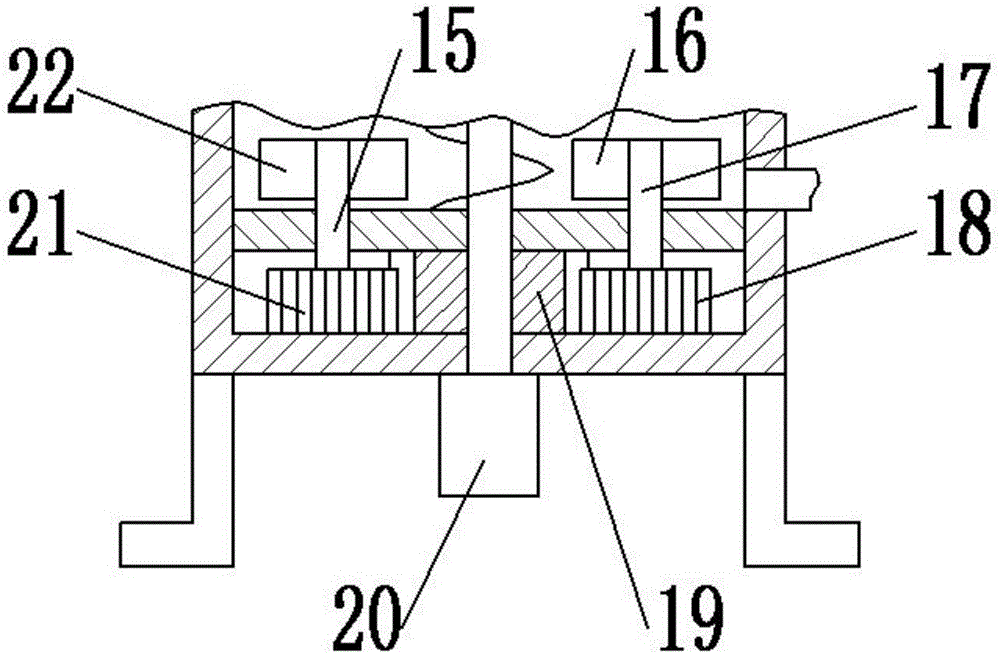

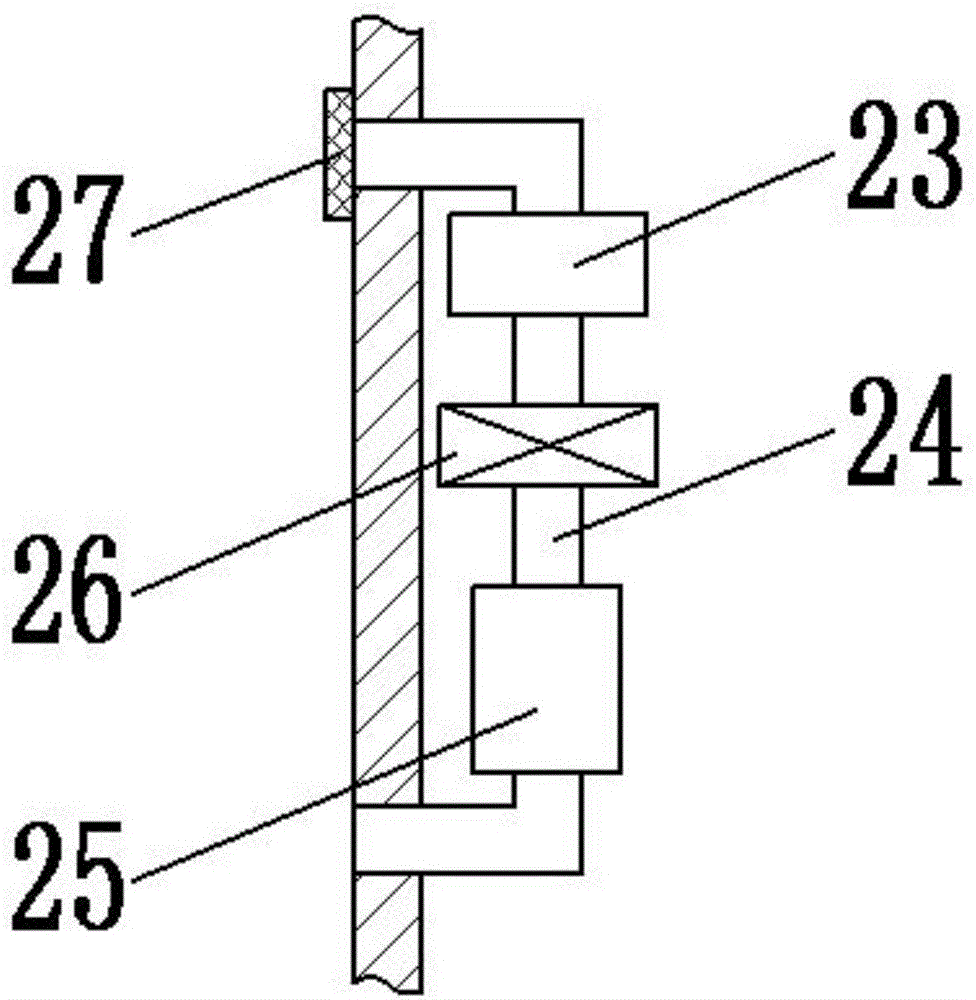

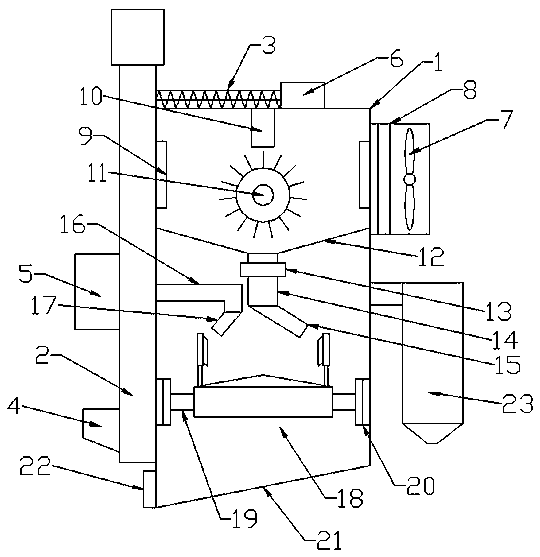

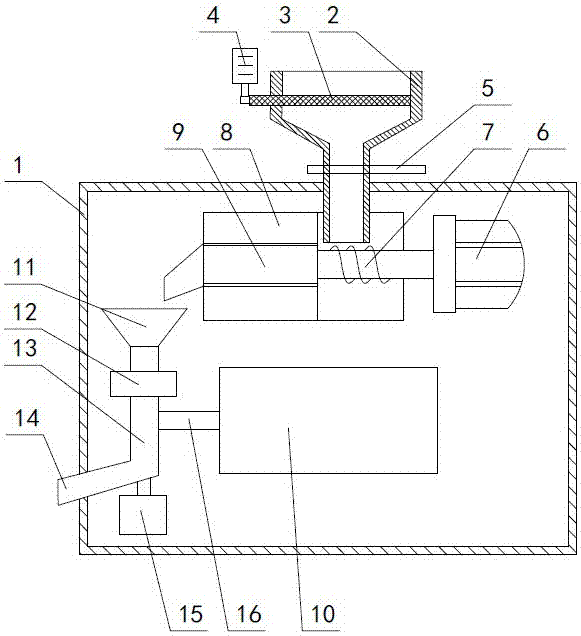

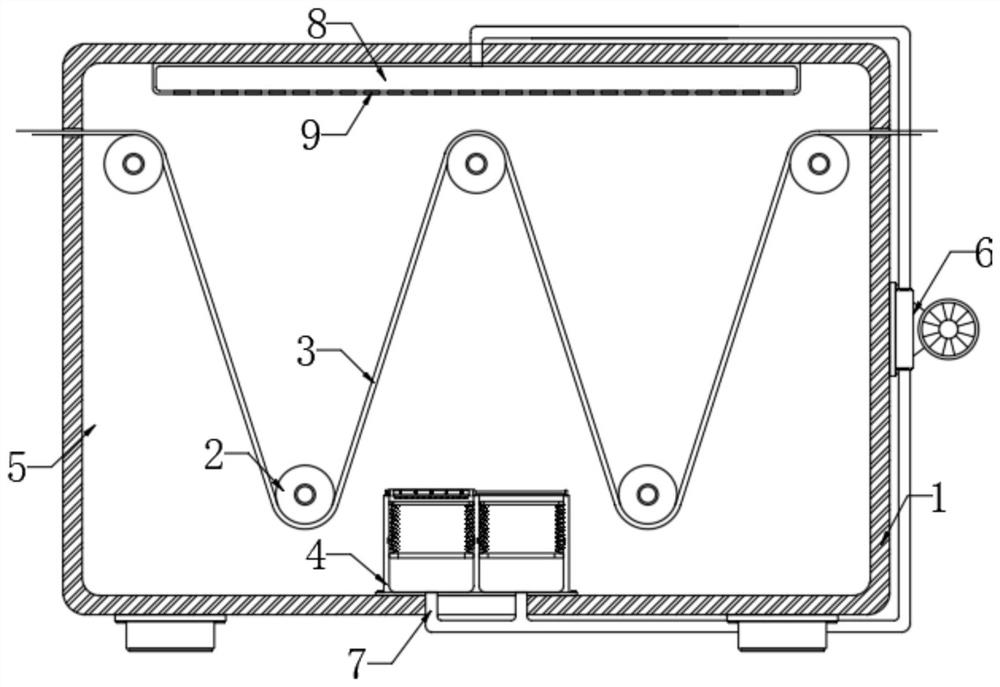

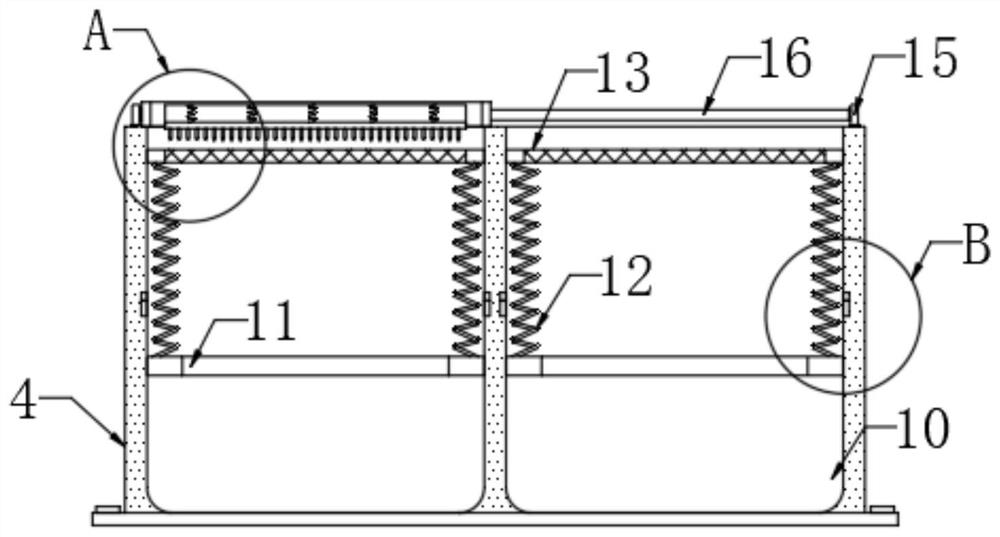

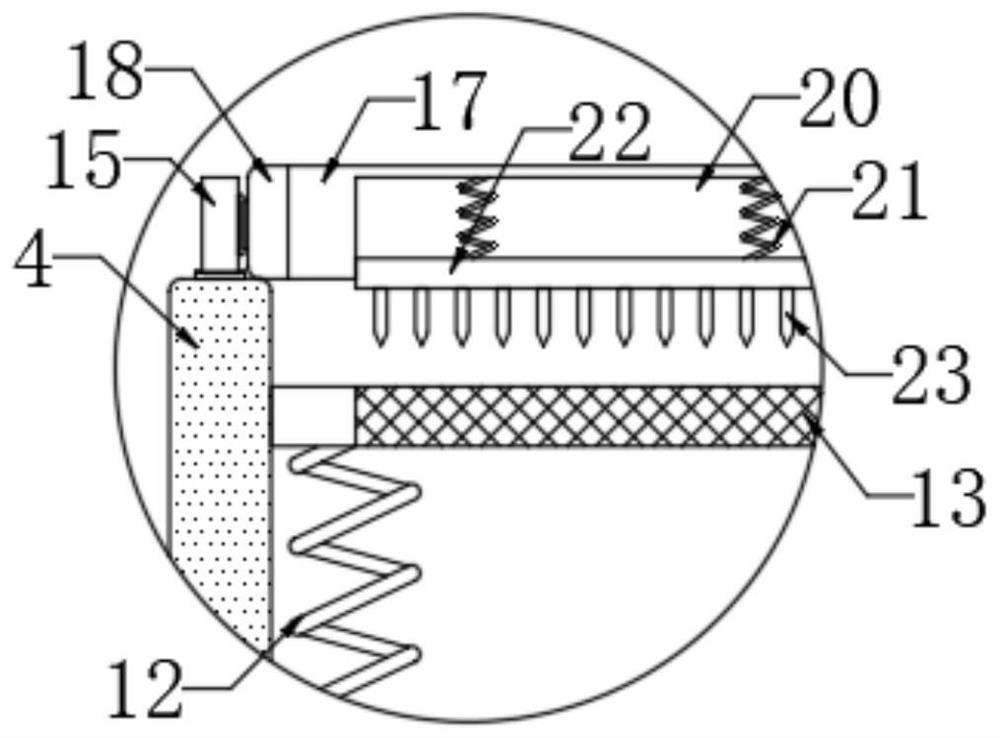

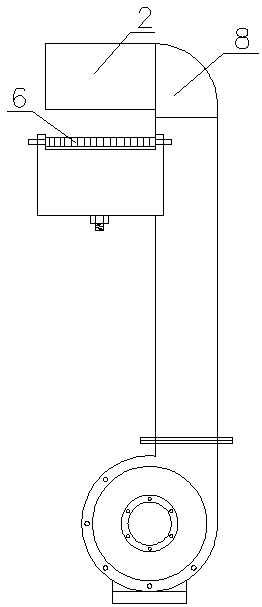

The invention relates to a comprehensive treating device for disassembling oil shoes and recycling useful materials in the old shoes. The comprehensive treating device comprises a coarse smashing module, a fine smashing module and a screening and separation module, wherein in the coarse smashing module, a plurality of saw blades are evenly arranged on two shafts and can perform opposite meshed high-speed rotation to coarsely smash the oil shoes; in the fine smashing module, four roller wheels are arranged in a cavity body regularly, two groovy rollers with the same inner diameter can achieve primary fine smashing on the old shoes through opposite meshed differential-speed rotation, two polishing rollers with the different inner diameters and two groovy rollers with the different inner diameters can achieve secondary fine smashing on the old shoes through opposite meshed equal-speed rotation, the screening and separating module can utilize an air blower to blow air to layer different masses of old shoe particles in the cavity body, and then the old shoe particles are classified and recycled. The comprehensive treating device disclosed by the invention can effectively smash waste shoes, the sizes of the smashed particles can be set as an adjustable mode according to need, the smashed materials can be screened and collected according to different masses, a resource utilization rate is improved, and environmental pollution caused by directly incinerating or burying the old shoes and resource waste are reduced.

Owner:WUHAN UNIV OF TECH

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

Heat recycling type efficient medicinal material drying device

ActiveCN106382808ADrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

Owner:深圳市惠普生科技发展有限公司

Impulse type food dryer

InactiveCN105494623AImprove drying efficiencyImprove product qualitySeed preservation by dryingAgricultural engineeringAir blower

Owner:刘操

Solar photovoltaic panel dust removal device for sand and dust land

InactiveCN112620205AAvoid damageReduce scratchesDispersed particle filtrationPhotovoltaicsDust controlEngineering

The invention discloses a solar photovoltaic panel dust removal device for sand and dust land, and relates to the technical field of power generation facilities. The solar photovoltaic panel dust removal device for the sand and dust land comprises a photovoltaic panel and a sand and dust removal device, wherein sliding frames are arranged at the front end and the rear end of the upper surface of the photovoltaic panel; sliding ways are formed in the front faces of the sliding frames; and the upper surface of the photovoltaic panel is in lap joint with the bottom of the sand and dust removal device. According to the solar photovoltaic panel dust removal device for the sand and dust land, a cleaning device is arranged on the sand and dust removal device, an air blower conveys strong wind power to the cavity of a rotary drum, the wind power is focused and blown into a dust removal box through air gathering holes, sand on the upper surface of the corresponding photovoltaic panel in the dust removal box can be blown up under the action of the strong wind power, the rotary drum is driven to rotate anticlockwise under the action of a motor, and sand and dust in the dust removal box are blown into a sand storage bag along with the wind direction, so that the sand and dust on the photovoltaic panel are cleaned and collected without coming into contact with the photovoltaic panel, and damage to the photovoltaic panel is avoided.

Owner:SUZHOU BOLI NEW ENERGY TECH CO LTD

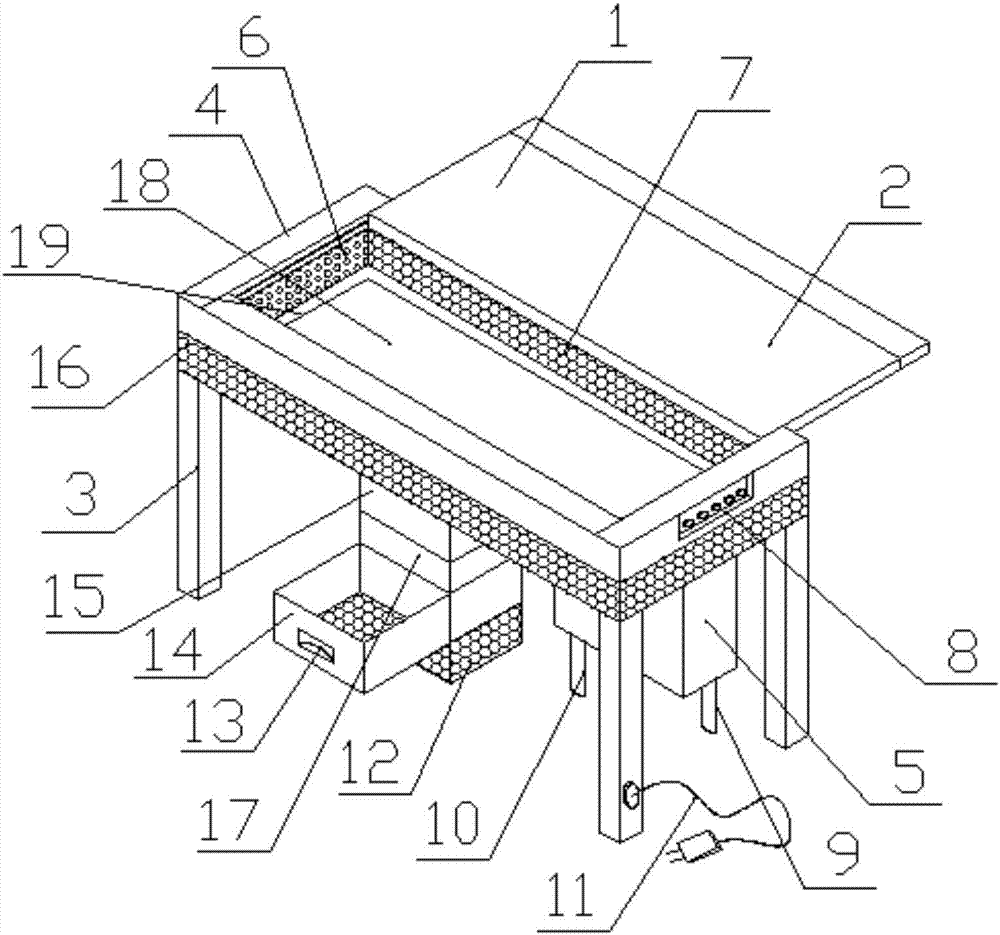

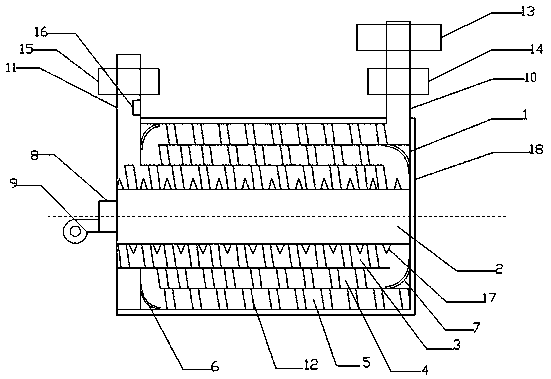

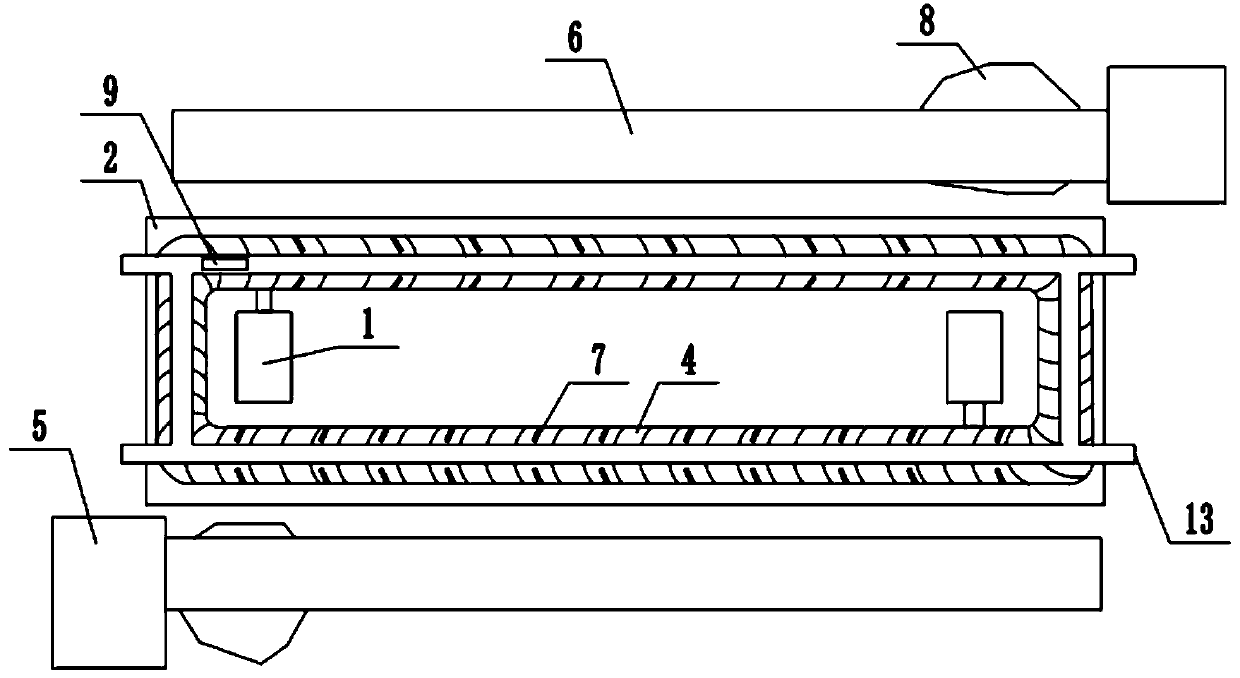

Air distribution type mobile phone shell paint baking device

InactiveCN106563625AGood paint effectImprove efficiencyPretreated surfacesCoatingsAgricultural engineeringAir blower

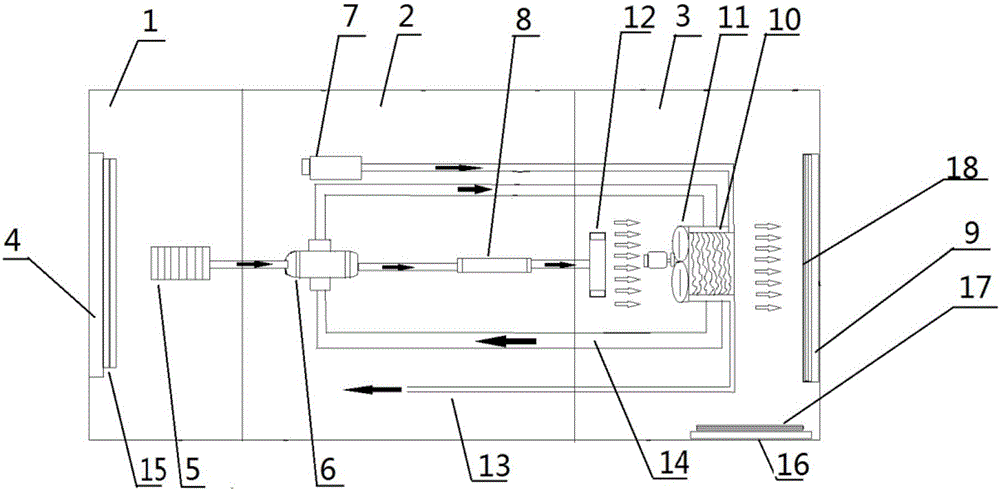

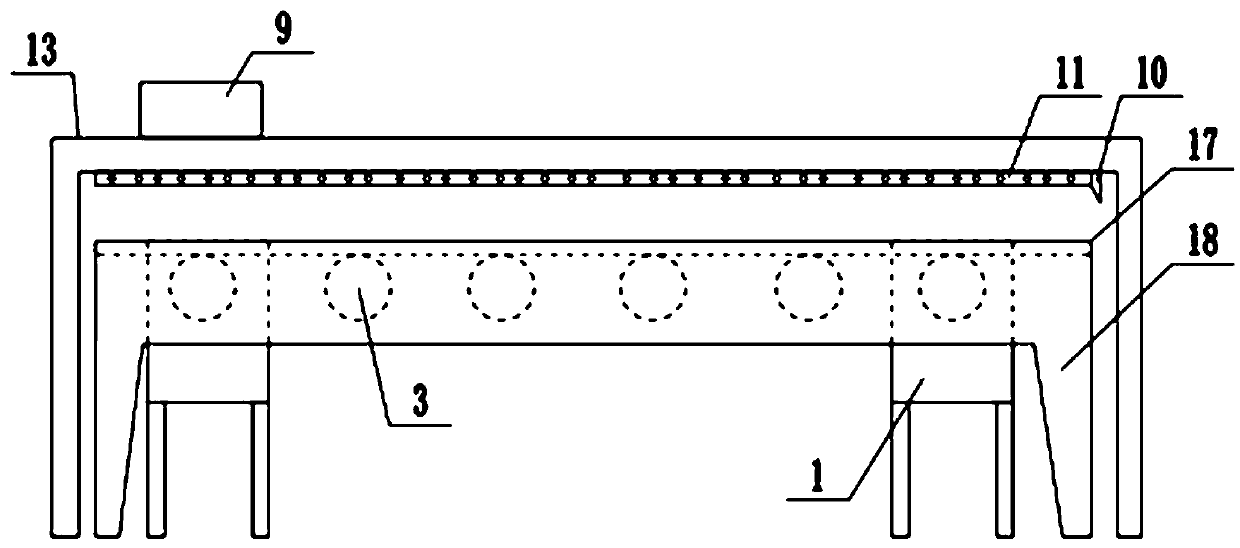

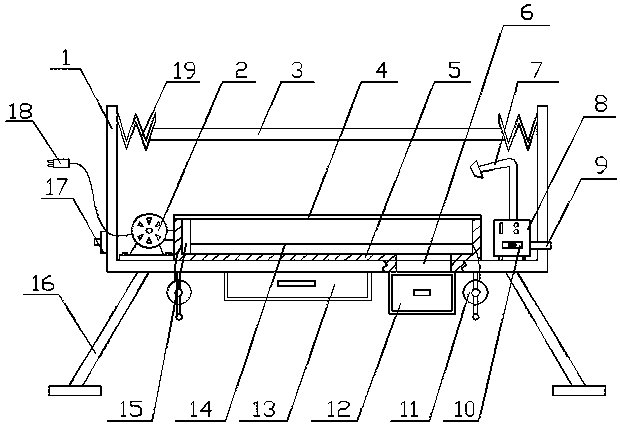

The invention discloses an air distribution type mobile phone shell paint baking device. The air distribution type mobile phone shell paint baking device comprises a plurality of mobile phone shell fixing clamps, a conveyor belt and a box. The mobile phone shell fixing clamps are uniformly arranged on the conveyor belt. The box is arranged in the middle of the conveyor belt. An electric heating meshed plate is arranged on the part, located on the upper side of the conveyor belt, of the interior of the box. An air distributor is arranged on the upper side of the electric heating meshed plate. Air blowing heads are arranged at all air outlets and located on the lower side of the air distributor. An air inlet pipe is arranged on a main air inlet and located on the upper side of the air distributor. The upper end of the air inlet pipe is connected with an air blower located on the top of the box. A motor used for driving the air blower is further arranged on the right side of the air blower. An air outlet pipe is arranged in the middle of the bottom of the box. An air purifier is arranged on the air outlet pipe. The lower end of the air outlet pipe is provided with an exhaust fan. The air distribution type mobile phone shell paint baking device has a good paint baking effect on mobile phone shells and is high in efficiency, little in pollution to the ambient environment and convenient to apply and popularize.

Owner:SHENZHEN LIANMAO PLASTIC

Rice husking machine

Owner:四川东工电机有限公司

Silent generator set

InactiveCN106499507ASmall volumnReduce noise pollutionLiquid coolingExhaust apparatusAir filterEngineering

Owner:HUBEI YINGPAI POWER TECH

Craft for processing preserved eggs by utilizing tea dust

InactiveCN104856096ACrystal clear colorThe entrance is fragrant, soft and tenderFood preparationAdditive ingredientSulfate

Owner:GUIZHOU MEITAN XIAOXIFU FOOD CO LTD

Vehicle instrument panel structure

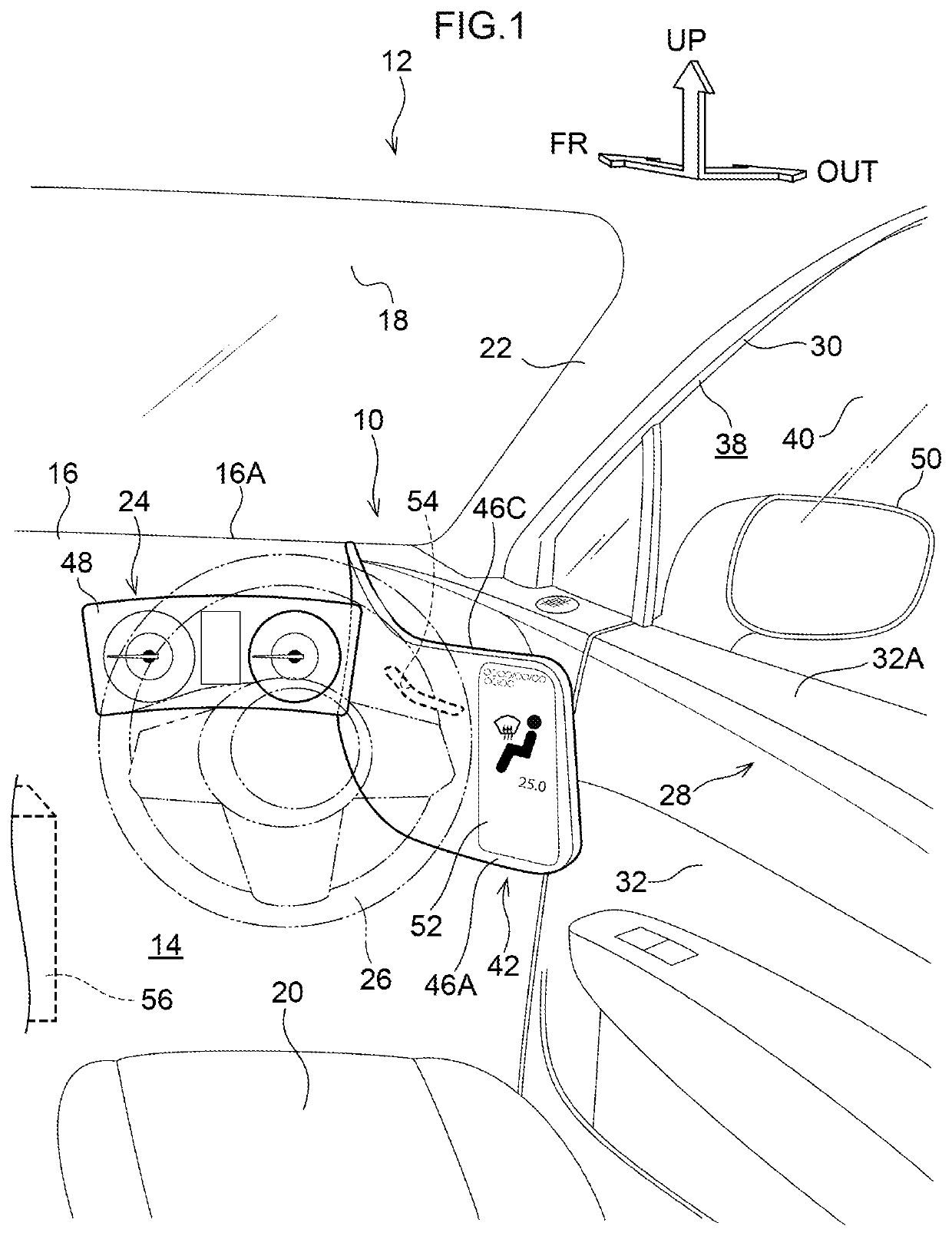

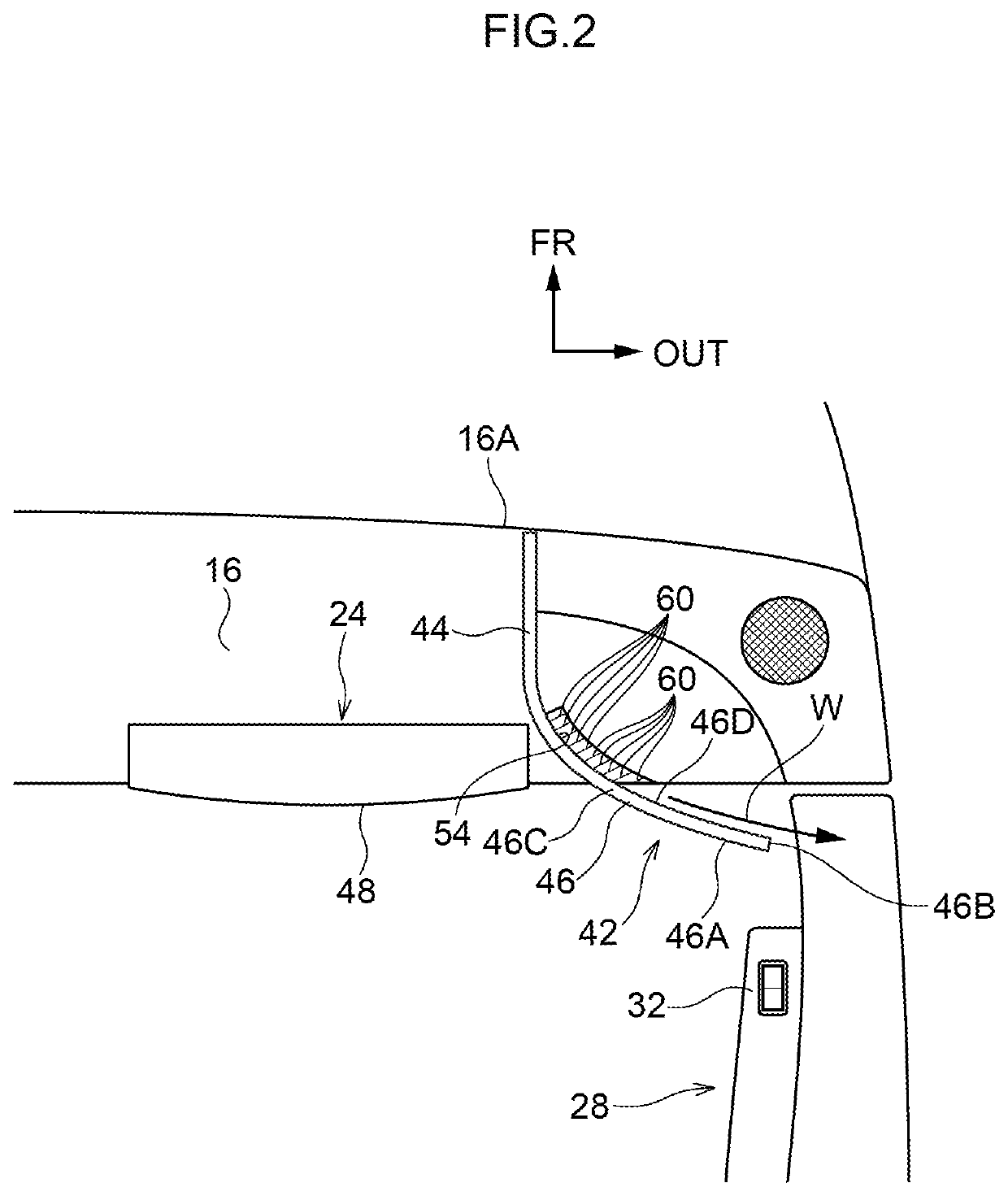

ActiveUS20200247217A1Effective contactEfficient removalAir-treating devicesVehicle heating/cooling devicesAir blowerControl theory

Owner:TOYOTA JIDOSHA KK

Continuous operation type energy-saving drying device for textile production

PendingCN113251775AWon't wasteTake advantage ofDrying gas arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringAir blower

Owner:杨干英

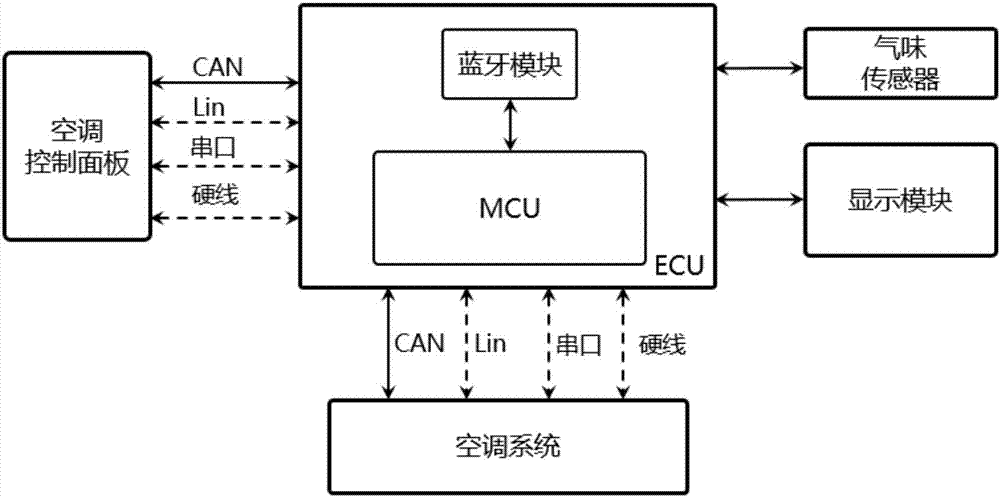

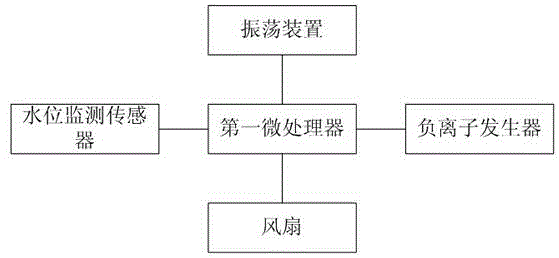

In-car air purifying system of car

PendingCN106976378AImprove operational efficiencyReduce vibrationAir-treating devicesVehicle heating/cooling devicesAir cleaningStructural engineering

Owner:美行车联网(广州)科技有限公司

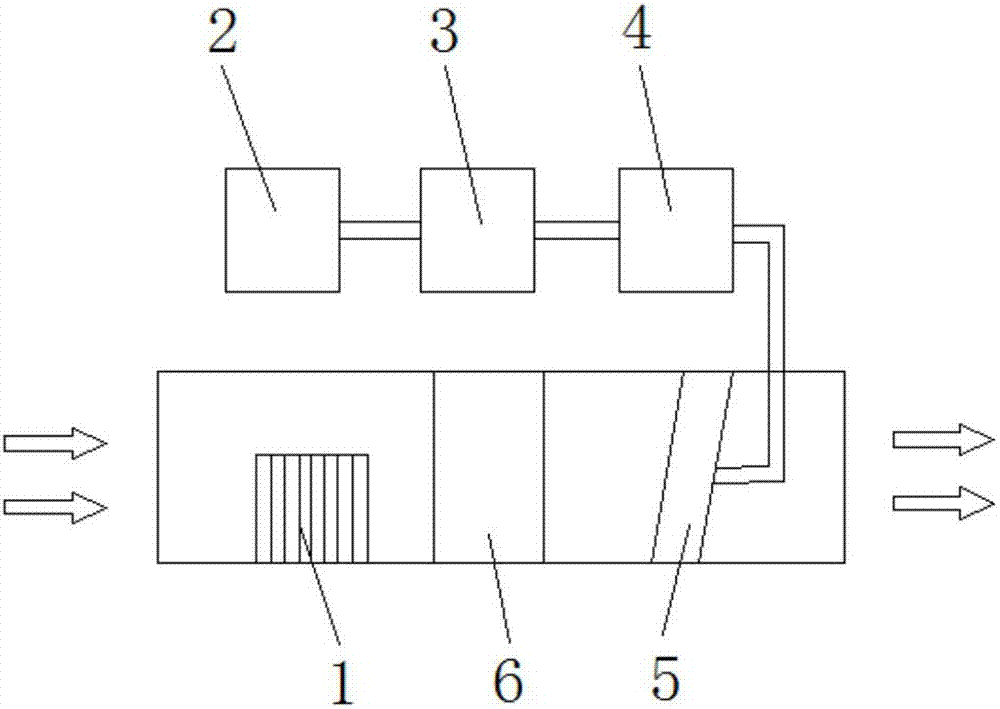

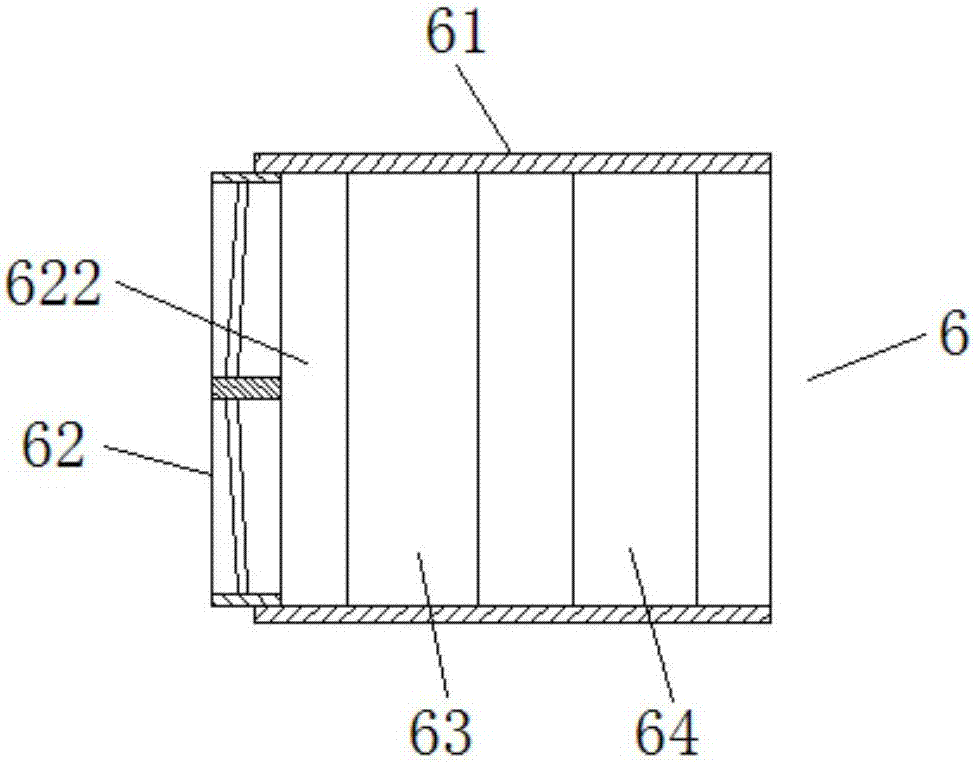

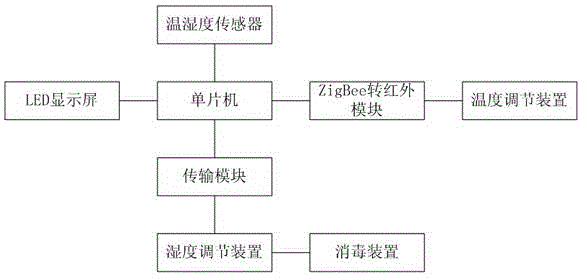

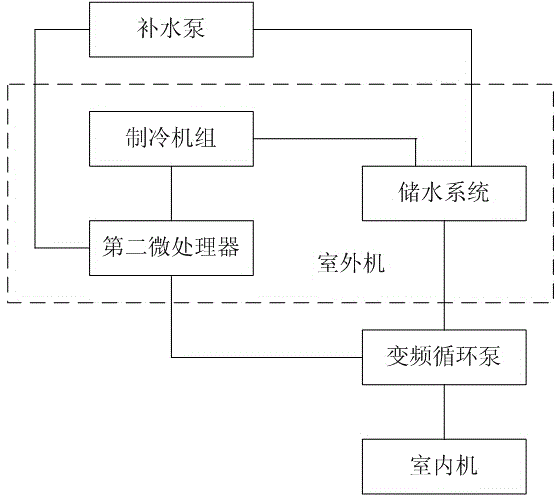

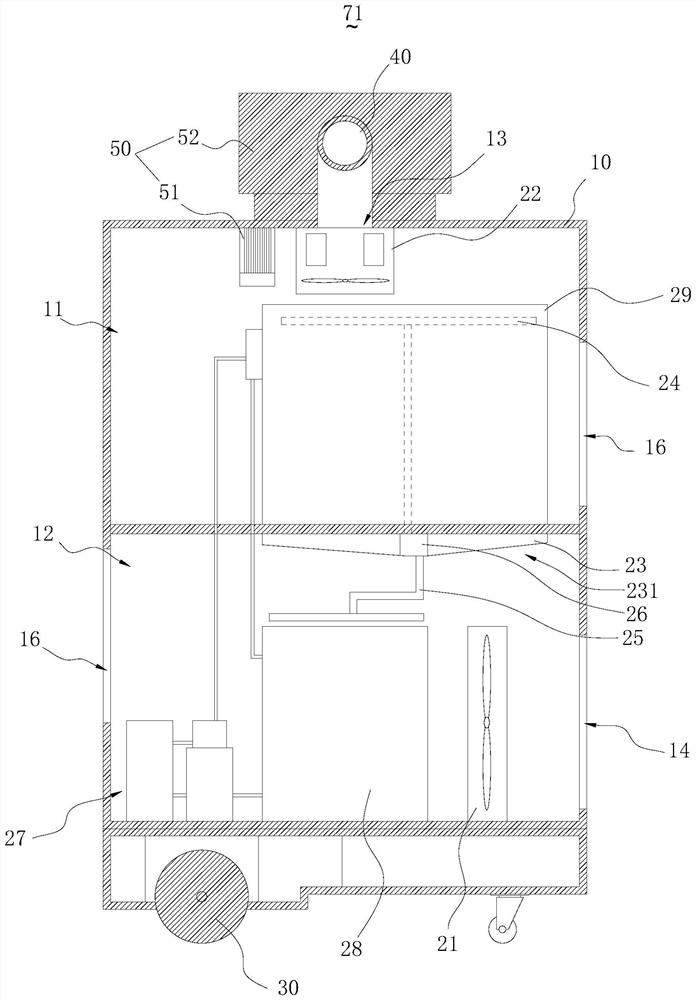

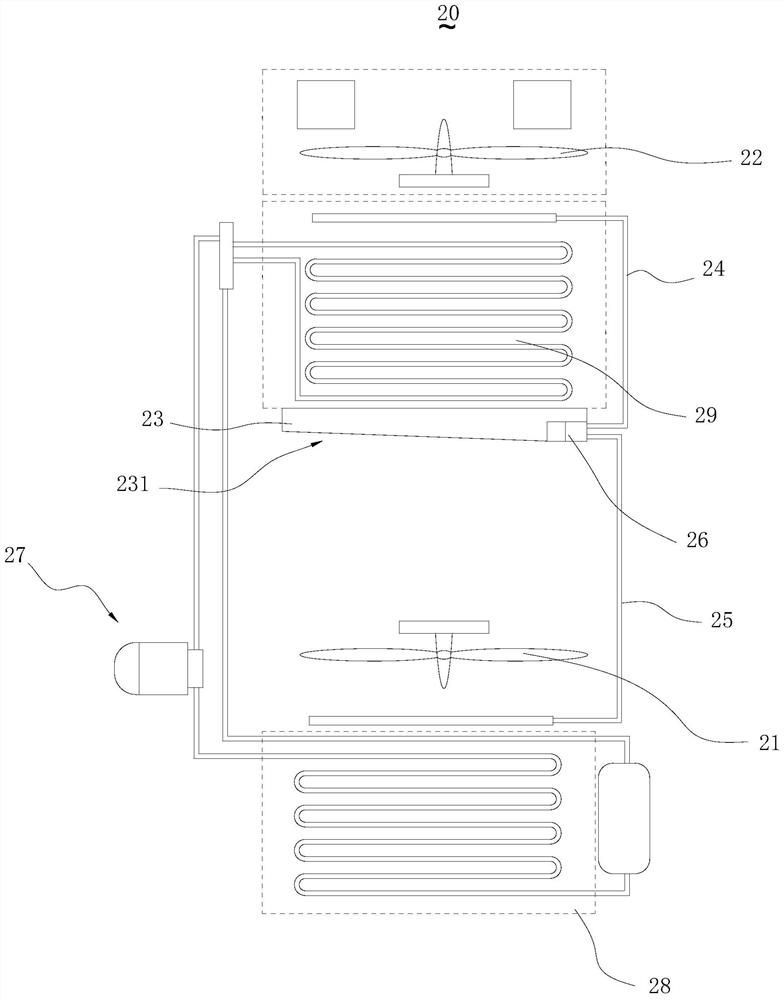

Constant temperature and humidity control system

ActiveCN104807151AEasy to moveImprove scalabilityMechanical apparatusLighting and heating apparatusMicrocomputerLED display

Owner:成都德麦科技有限公司

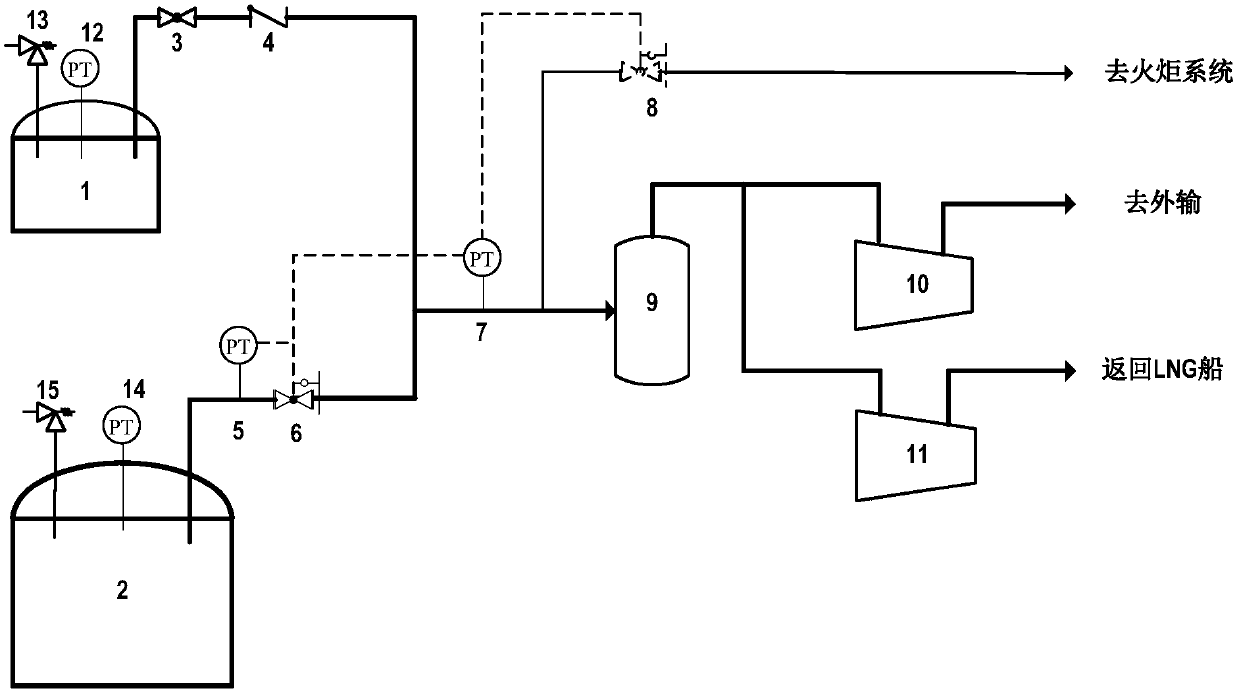

BOG treatment system and method of LNG storage tanks applicable to different design pressures

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Gas-fired boiler flue gas recirculation low-nitrogen combustion device

InactiveCN107830514AReduce nitrogen oxide contentImprove combustion efficiencyStaged combustionFluegas recirculationCombustorCombustion chamber

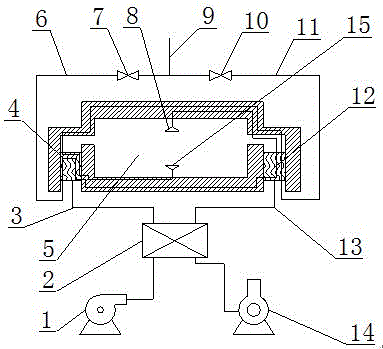

The invention discloses a gas-fired boiler flue gas recirculation low-nitrogen combustion device which comprises a boiler main body. The bottom of the boiler main body is provided with a combustor which comprises a main combustion chamber. The other side of the main combustion chamber is connected with a circulation pipeline. A flow adjusting valve is arranged inside the circulation pipeline, a recombustion chamber is connected with the main combustion chamber through the circulation pipeline, the tops of the main combustion chamber and the recombustion chamber are provided with a complete combustion chamber, one side of the complete combustion chamber is connected with a third air blower, a partition plate is arranged between the complete combustion chamber and the main combustion chamber, a partition plate is arranged between the complete combustion chamber and the recombustion chamber, circulation holes are formed in the partition plates, the top of the complete combustion chamber is provided with a flue gas purifying device, and the glue gas purifying device is connected with a flue gas exhaust device through an induced draft fan. A large amount of reducing gas is generated inthe main combustion chamber and introduced into the recombustion chamber through the circulation pipeline, nitrogen oxide is reduced to nitrogen, emission standards are met, and the purpose of low-nitrogen combustion is achieved.

Owner:GUANGDONG TUOFENG IND CO LTD

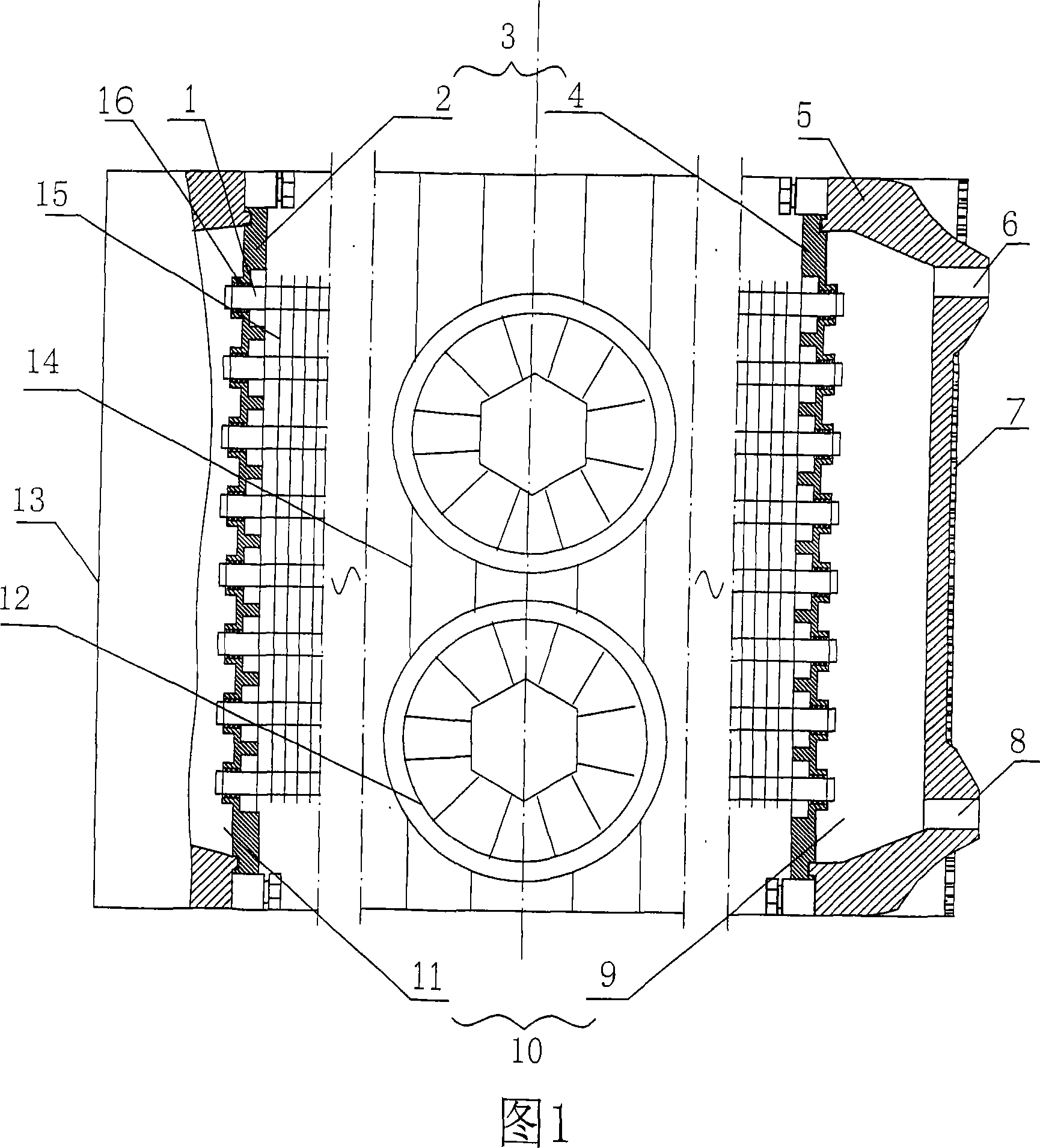

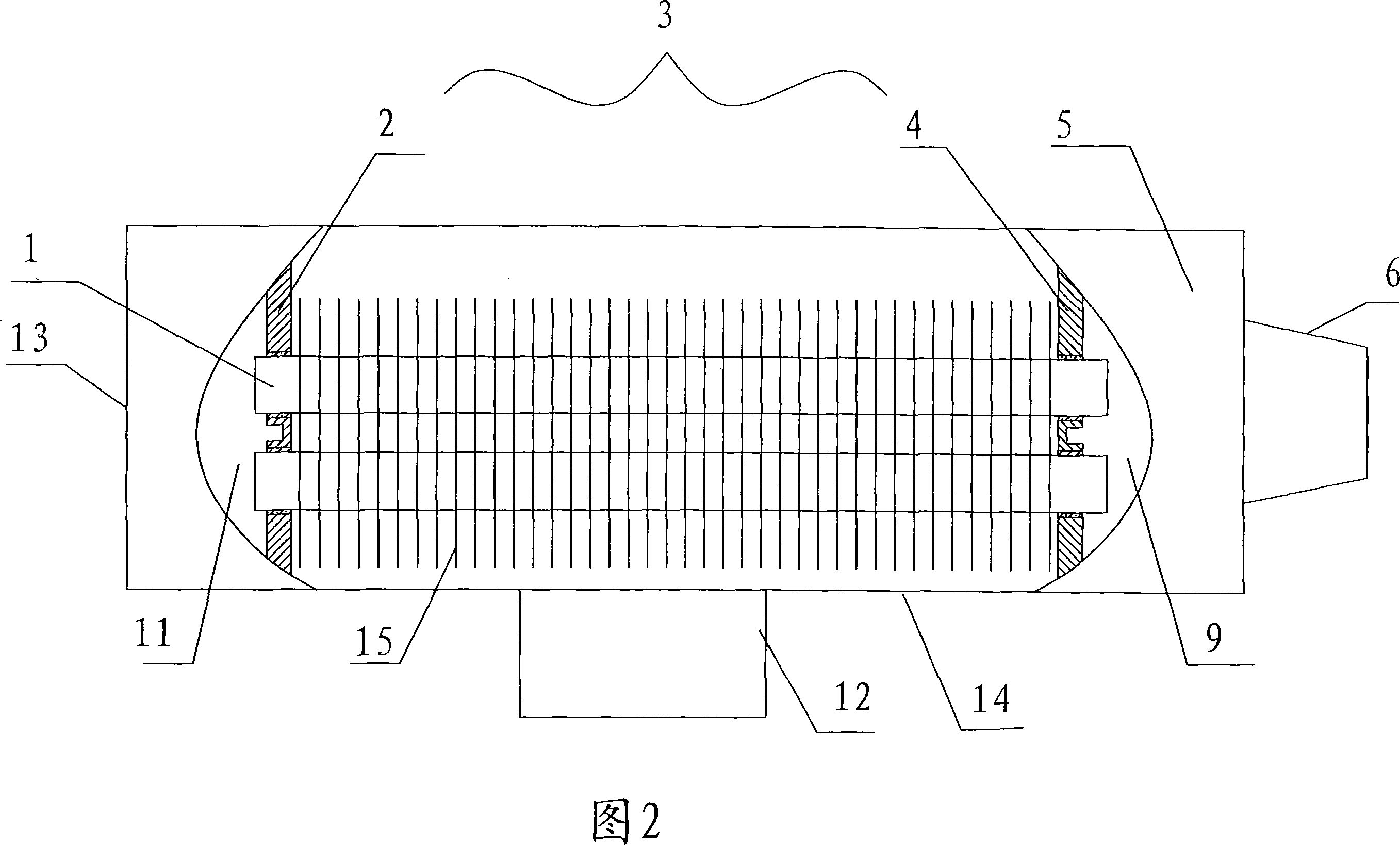

Heating heat radiator

InactiveCN101101136AReduce maintenance costsReduce weightLighting and heating apparatusSpace heating and ventilation detailsEngineering plasticEngineering

Owner:李艳妍

Drying device for processing of stone building materials

InactiveCN110849100ADischarge in timeAchieve heat preservationDrying gas arrangementsDrying chambers/containersArchitectural engineeringStructural engineering

Owner:天门市天安建材有限公司

Multifunctional dining table capable of purifying air

Owner:黄山市博森家具有限公司

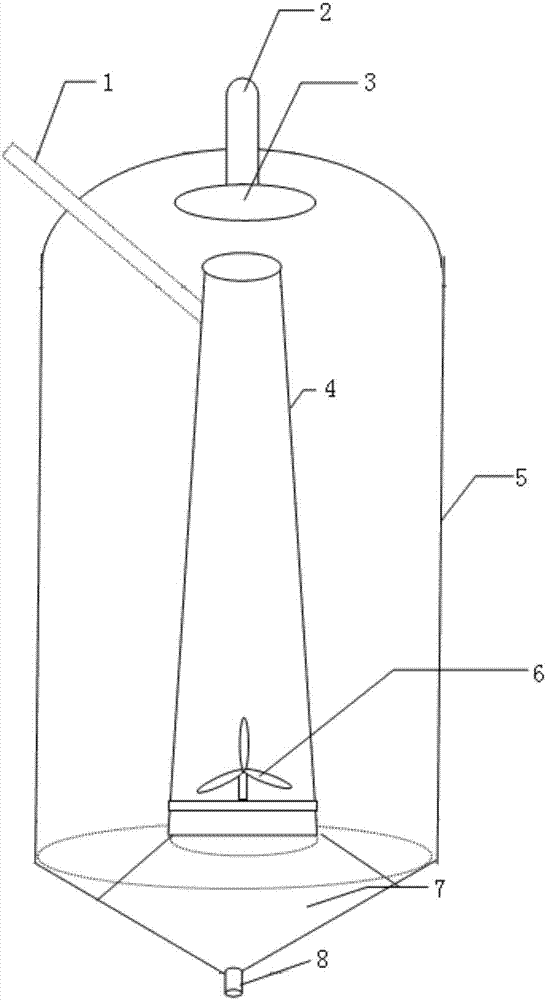

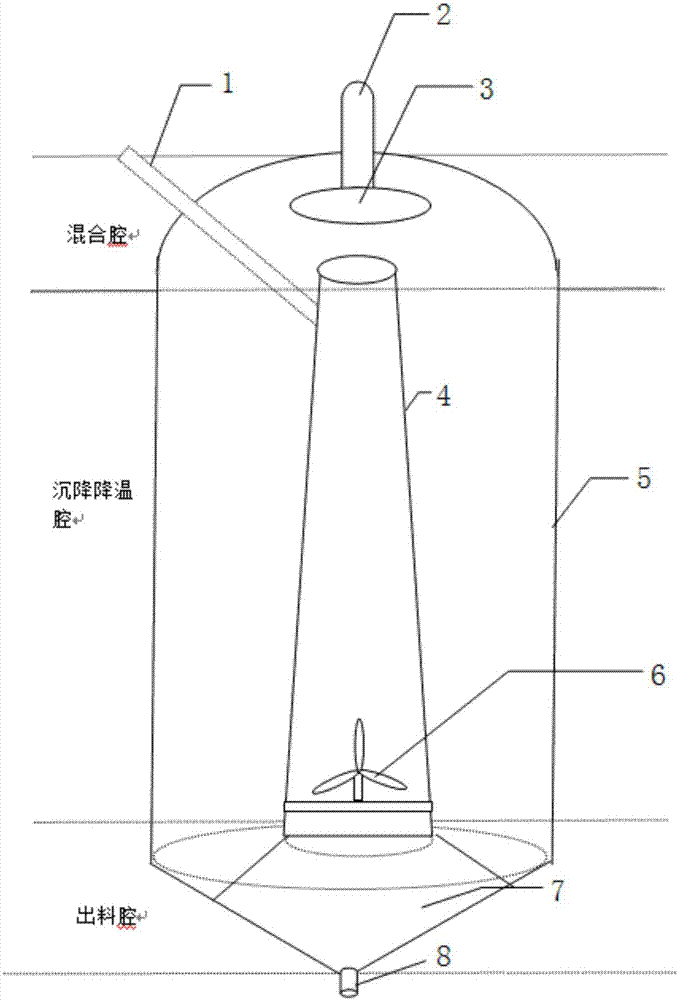

Granulated arabinose preparation method and device

PendingCN107987109AHigh hardnessHigh densitySugar derivativesSugar derivatives preparationMolten stateCooling chamber

Owner:山东绿健生物技术有限公司

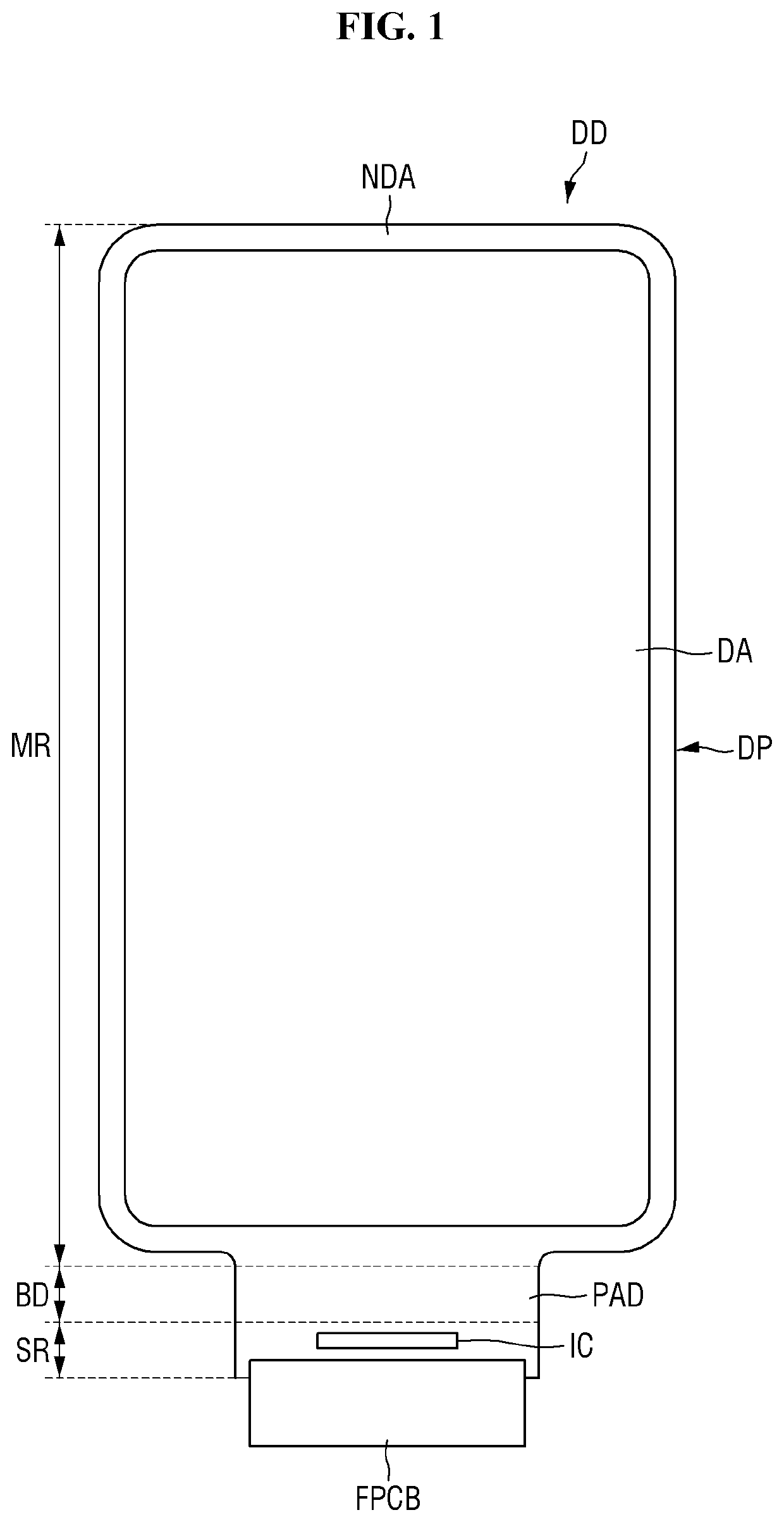

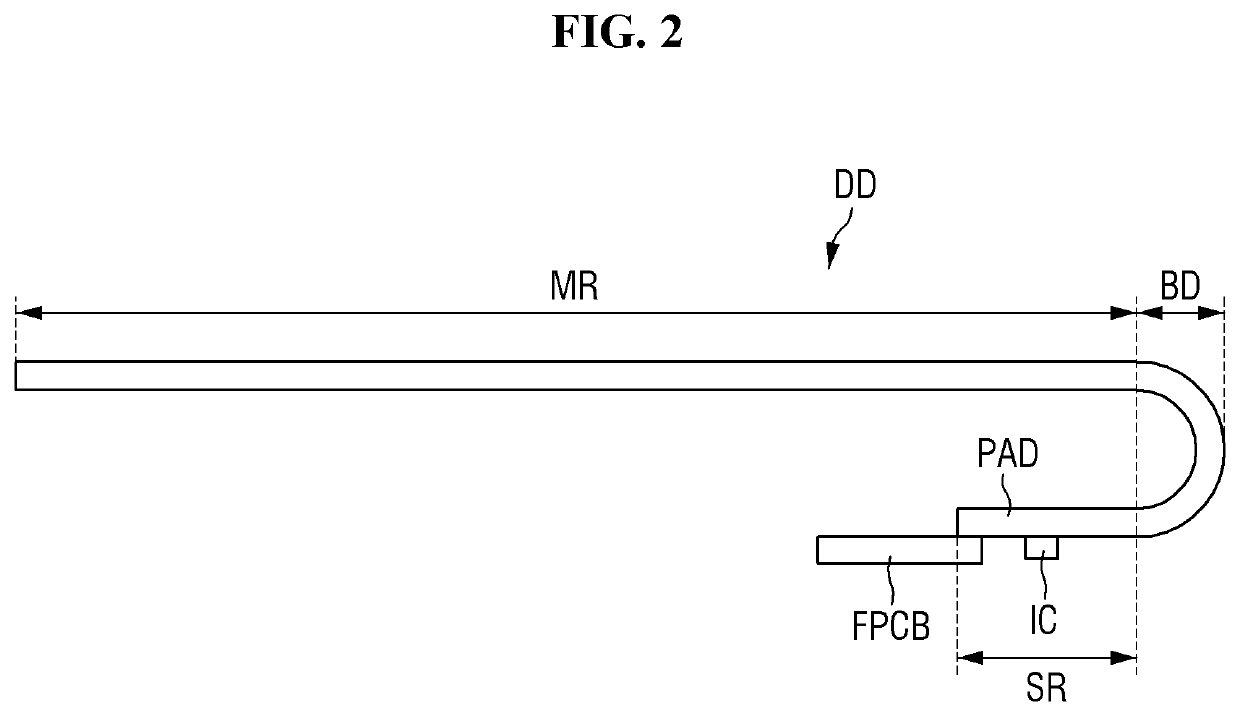

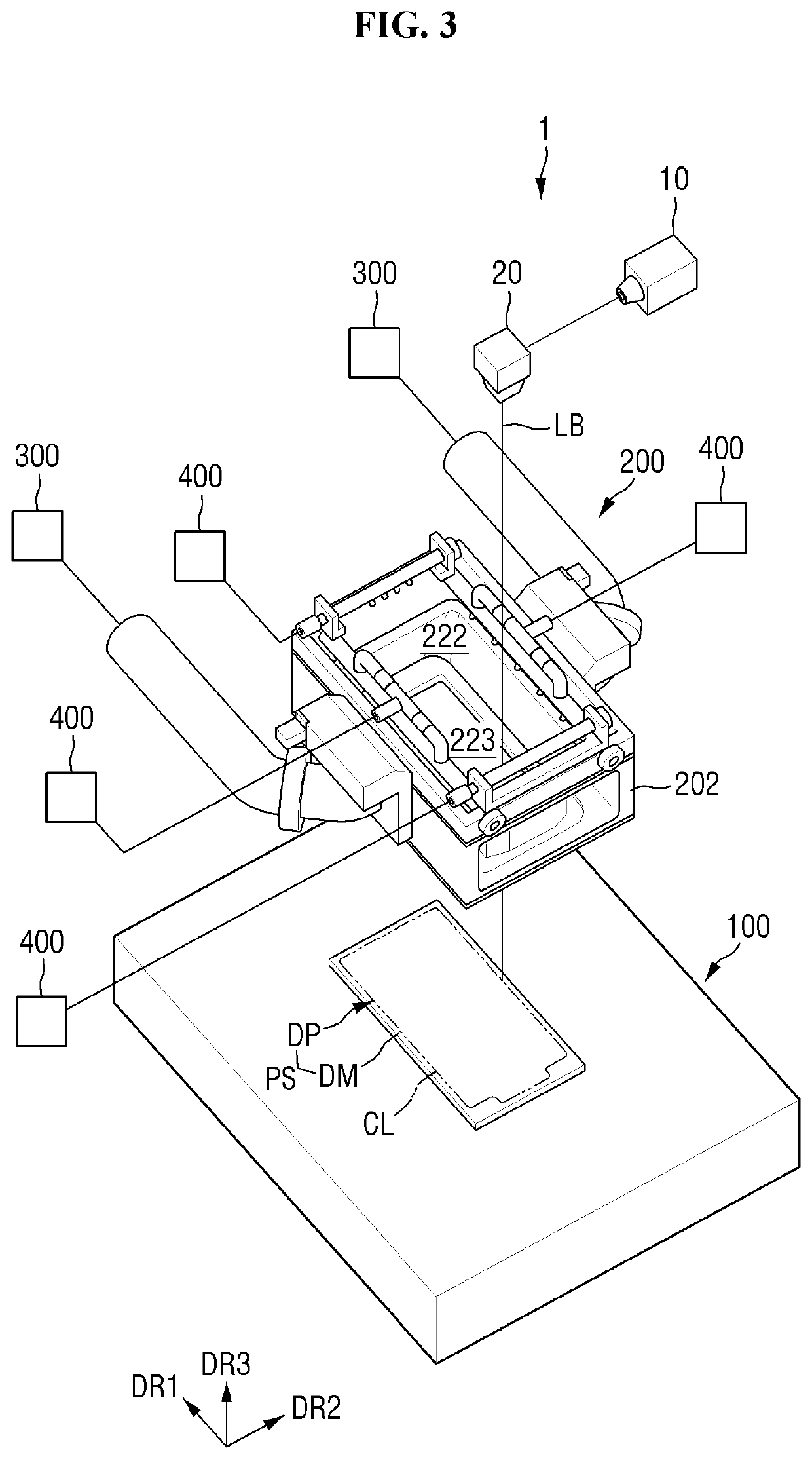

Apparatus for manufacturing display device and method for manufacturing display device

ActiveUS20210336237A1Uniformly and efficiently removeEfficient removalDigital data processing detailsSolid-state devicesDisplay deviceAir blower

Owner:SAMSUNG DISPLAY CO LTD

Gas-fired hot blast stove

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

Transmission device special for municipal waste

Owner:广西大自然再生资源有限公司

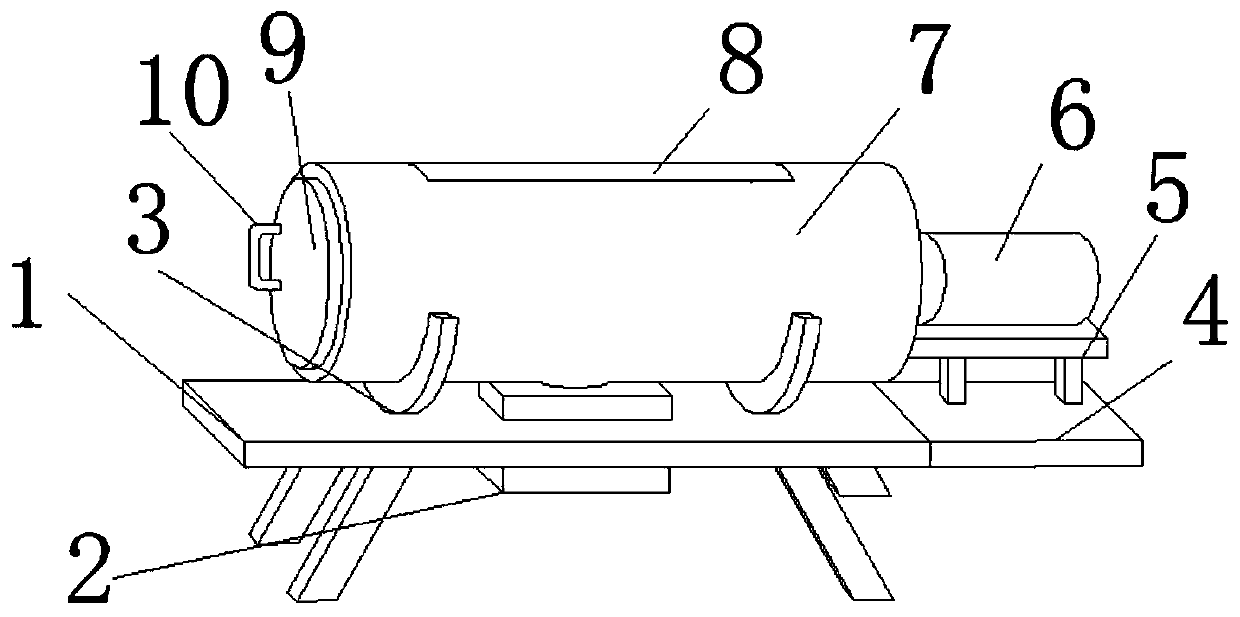

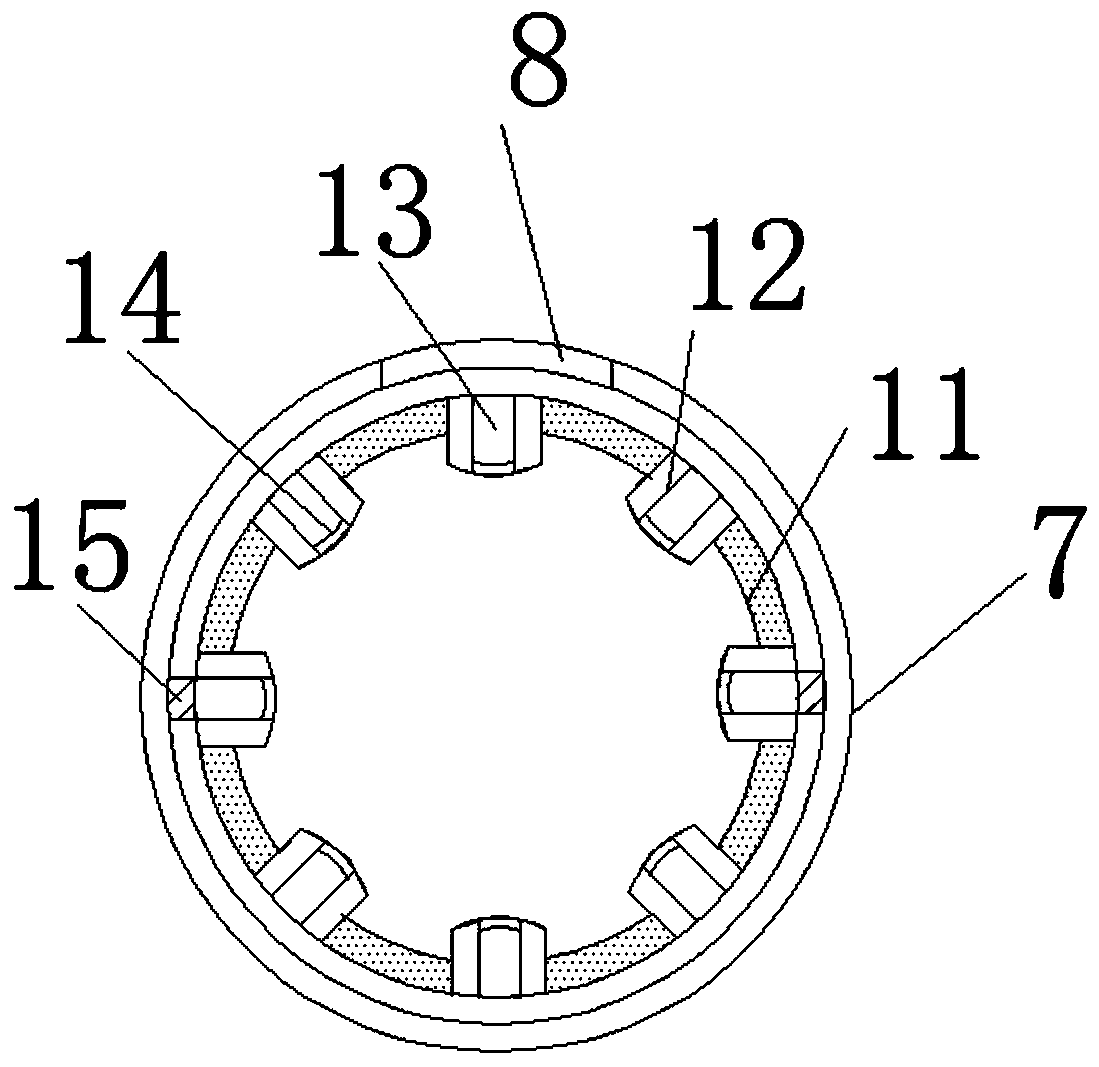

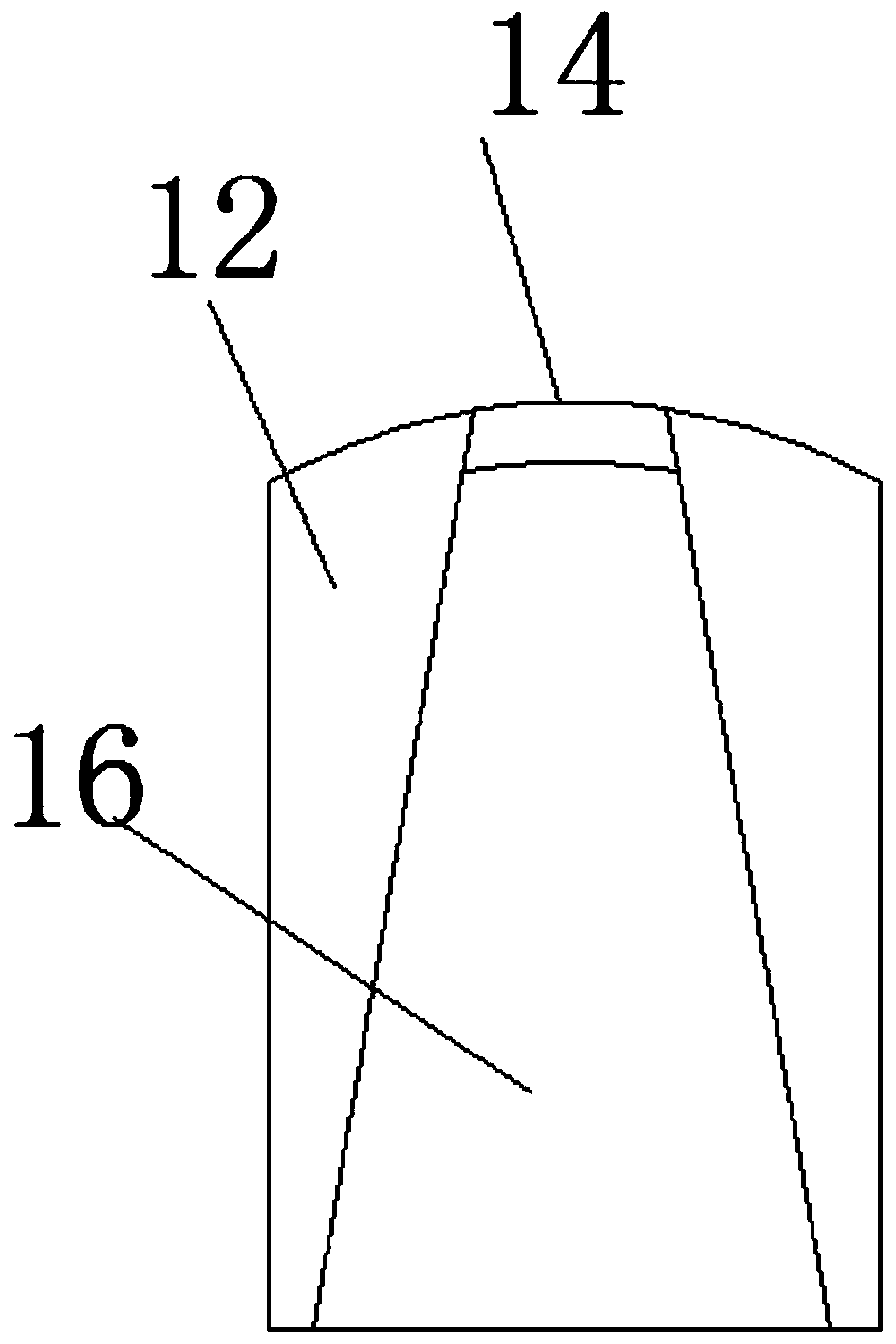

Temperature-adjusting air blower and temperature-adjustable mattress

PendingCN113647774AEasy to useAvoid safety hazards such as electric leakageStuffed mattressesDomestic cooling apparatusThermodynamicsEngineering

Owner:匡学斌

Exhaust gas recirculation system in phosphorus coal pelletizing process

ActiveCN111604005ADoes not cause emission problemsDispersed particle filtrationDrying gas arrangementsThermodynamicsExhaust fumes

Owner:JIAXING UNIV

Multifunctional wine brewing and rice steaming bed

Owner:惠州市广源机械设备有限公司

Environment-friendly barbecuing device

Owner:CHANGYI CHUANGTONG ELECTRONICS TECH CO LTD

Domestic garbage can with deodorization function

InactiveCN108773608AAvoiding problems that affect the housing environmentSatisfy the use effectRefuse receptaclesLitterEffusion

The invention discloses a domestic garbage can with a deodorization function, and relates to the technical field of environmental protection. The domestic garbage can comprises a can body, and furthercomprises a treatment box, the bottom face of the can body is fixedly connected with one surface of the first treatment box, a liquid gathering hopper is fixed to the bottom face of the can body andis located inside the treatment box, a collecting box penetrates the peripheral side face of the treatment box, a deodorization box is fixed to the inner wall of the first treatment box, and a plurality of water holes are formed in the bottom face of the can body. According to the domestic garbage can, the water holes and the liquid gathering hopper can be used for discharging garbage effusion into the collecting box, an air blower, a tee joint and an air exhaust hose are used for exhausting stinking gas inside the can body into the deodorization box for deodorization, the air blower, the teejoint and an air gathering cover can be used for exhausting the stinking gas inside the treatment box into the deodorization box for deodorization, stink contained in air inside the garbage can and stink generated by the garbage effusion can be removed, and the problem that an existing domestic garbage can does not have the deodorization function, and consequently bad smells do not influence the housing environment is solved.

Owner:WUHU XINLIN SENCHUAN ENVIRONMENTAL PROTECTION TECH CO LTD

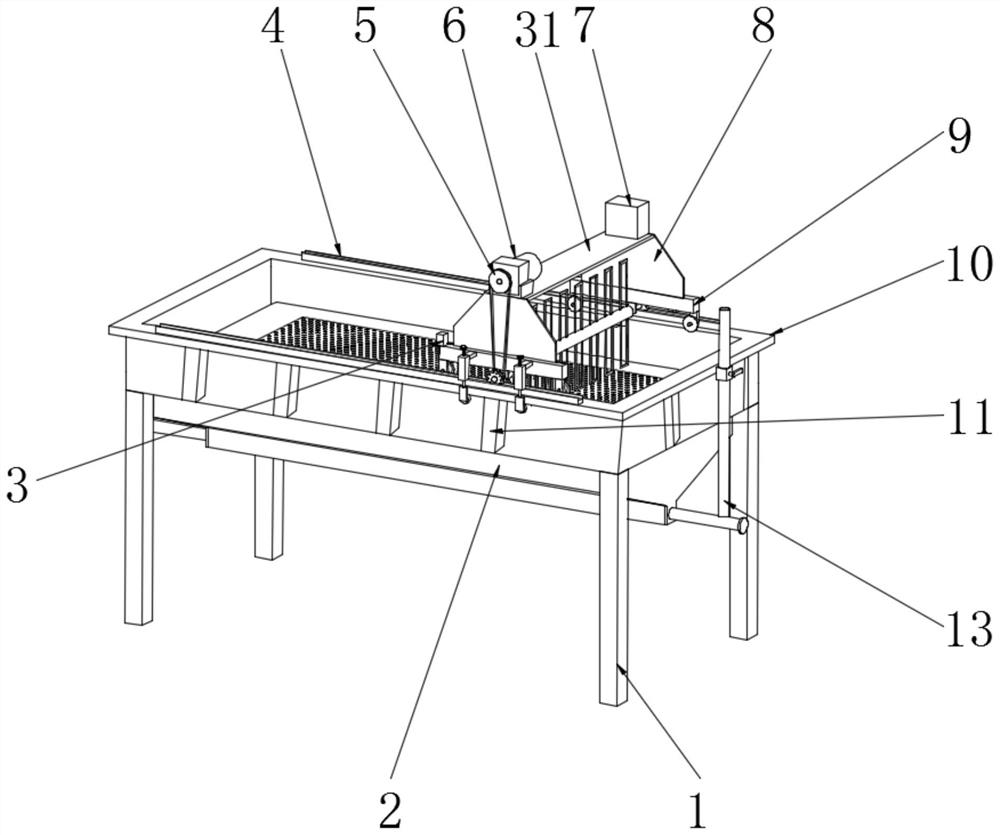

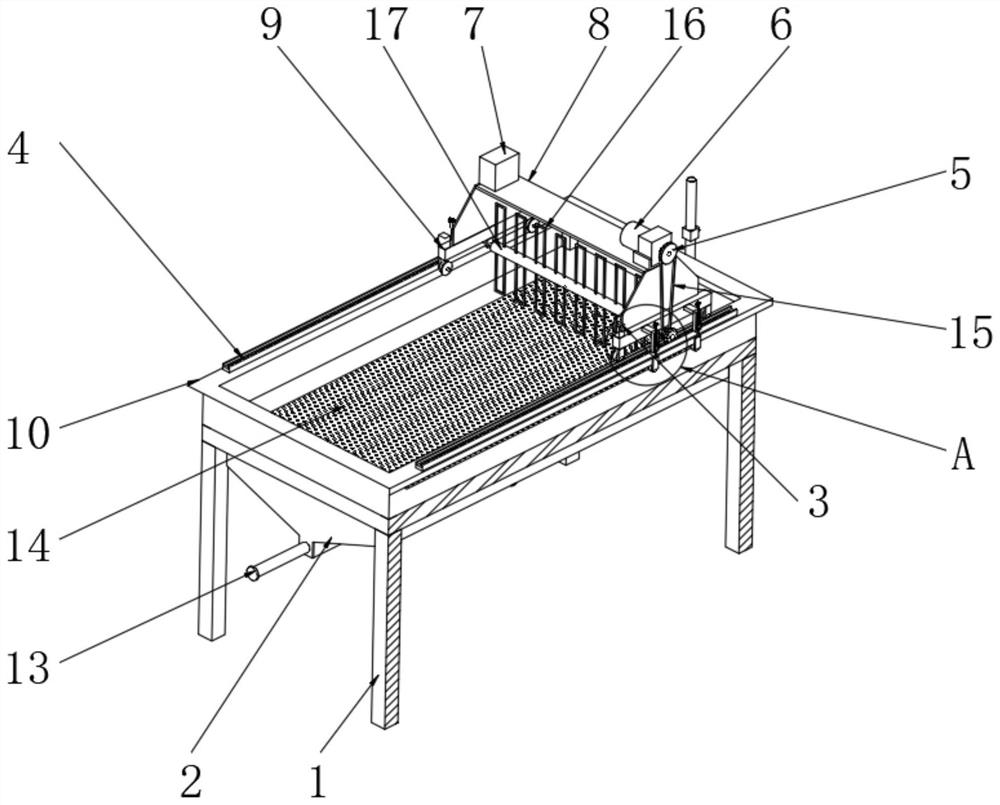

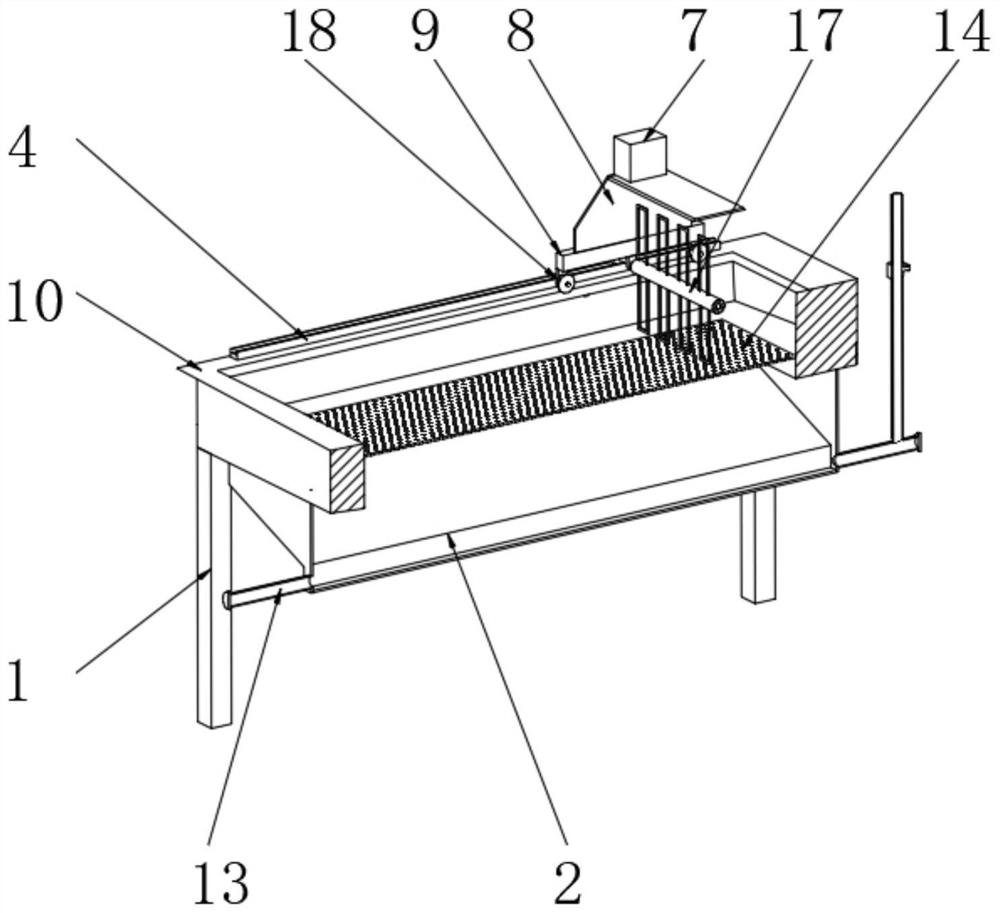

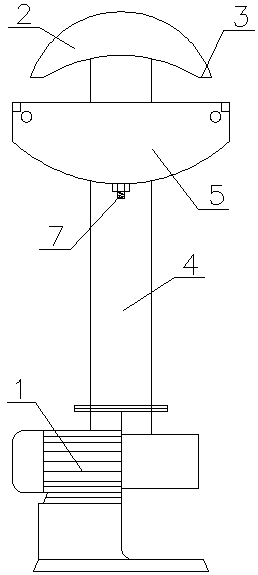

Cooling protection device for screen mesh wire production

InactiveCN111750610ACool evenlyImprove cooling efficiencyDomestic cooling apparatusLighting and heating apparatusCold airVentilation tube

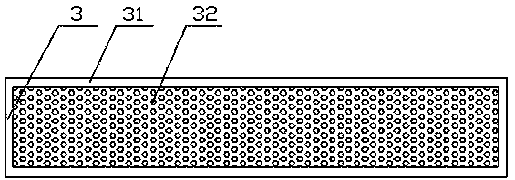

The invention provides a cooling protection device for screen mesh wire production. The cooling protection device comprises a top plate, supporting plates and a bottom plate; supporting legs are arranged on the two sides of the bottom of the bottom plate, the two sides of the top of the bottom plate are connected with the top plate through the supporting plates, a ventilation pipe is fixed to thebottom of the top plate, and a plurality of air outlets are formed in the bottom of the ventilation pipe. According to the cooling protection device, an air blower is arranged at the top to drive airto blow downwards, the air sequentially passes through a water pipe and a refrigeration plate in the downward blowing process, then passes through an air exhaust mechanism and finally reaches a rotating shaft wound with screen mesh wires, the refrigeration plate can refrigerate water in the water pipe, therefore cold air is generated, and the cold air descends; at the moment, air blown out by theair blower is changed into cold air through cold air treatment to be blown to the rotating shaft, and namely, the screen mesh wires can be cooled; and the cooled hot air rises at the moment and then is cooled through cold air again, therefore, it can be guaranteed that the screen mesh wires are rapidly cooled in the production process, and the cooling efficiency is higher.

Owner:ANHUI LANFEI CHEM FIBRE MFG CO LTD

Application method of novel heat storage heating furnace with reversing control device

InactiveCN106287703AImprove stabilityReasonable structural designFuel supply regulationDomestic stoves or rangesProcess engineeringAir blower

Owner:苏州云白环境设备股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap