Application method of novel heat storage heating furnace with reversing control device

A reversing control device and regenerative technology, which are applied in combustion methods, regenerative equipment, and combustion control, etc., can solve the problems that the waste heat of flue gas cannot be used to the maximum extent and cannot be preheated, and are convenient for use and maintenance. Fast, reasonable structure design, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

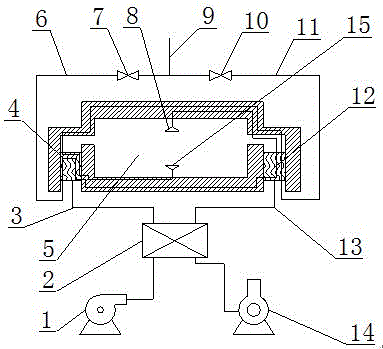

[0013] Specific embodiment one, please refer to figure 1 , a new regenerative heating furnace with a reversing control device, including an air blower 1, a reversing valve 2, a furnace 5, a gas left branch pipe 6, a gas right branch pipe 11 and a flue gas induced draft fan 14, characterized in that: the furnace One end of the 5 is provided with a regenerator 4, the other end of the furnace 5 is provided with a regenerator 12, the middle part of the furnace 5 is provided with a gas upper nozzle 8 and a gas lower nozzle 15, and the gas left branch pipe 6 It is arranged between the gas upper nozzle 8 and the gas main pipe 9, the gas left branch pipe 6 passes through the heat storage body 1 4 and the heat storage body 2 12, and the gas left branch pipe 6 is provided with a valve 1 7, the The gas right branch pipe 11 is arranged between the gas lower nozzle 15 and the gas main pipe 9, the gas right branch pipe 11 passes through the heat storage body 2 12 and the heat storage body 1 4,

specific Embodiment 2

[0017] Specific embodiment two, please refer to figure 1 , the use method of the novel regenerative heating furnace with a reversing control device, comprising an air blower 1, a reversing valve 2, a furnace 5, a gas left branch pipe 6, a gas right branch pipe 11 and a flue gas induced draft fan 14, wherein It is characterized in that its steps are:

[0018] (1) First, it enters the left circulation combustion, and the gas enters the gas left branch pipe 6 from the gas main pipe 9. At this time, the valve 1 7 is opened, and the valve 2 10 is closed at the same time, and the gas passes through the heat storage body 1 4 and the heat storage body 2 12 from the The gas upper nozzle 8 enters the furnace 5; at the same time, the air blower 1 drives the air through the reversing valve 2 to enter the furnace 5 from the pipe 3 through the regenerator 4, and the oxygen in the air and the gas are mixed and burned in the furnace 5, and the combustion The generated flue gas is driven by the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap