Air blowing drying machine for water cooling bracing pelletizer

A technology of granulator and dryer, which is applied in the direction of coating, etc., can solve the problems of poor drying effect of plastic strips and affect the quality of finished products, and achieve the effect of improving dehydration and drying effect, good effect and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

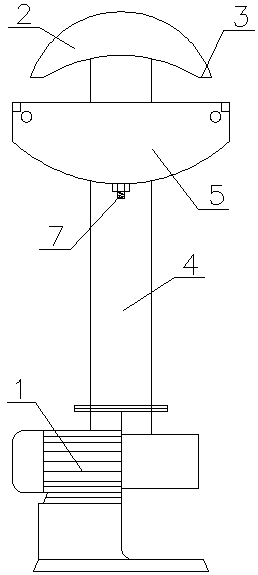

[0015] A blowing dryer for a water-cooled strand granulator, comprising a blower 1 and a bellows 2, the bellows 2 is an arc-shaped box, the arc-shaped ends of the bellows 2 are provided with air outlets 3, and the sides of the bellows 2 are The wall is connected with an air duct 4, and the air duct 4 is connected with the air outlet duct of the blower 1. A sump 5 is arranged below the bellows 2, and two load wheels 6 are arranged in the sump 5. The load wheels The outer surface of 6 is provided with a number of annular grooves, and the two bearing wheels 6 are respectively located under the air outlet 3 at both ends of the arc of the bellows 2, and the bottom of the sump 5 is provided with a drain pipe 7.

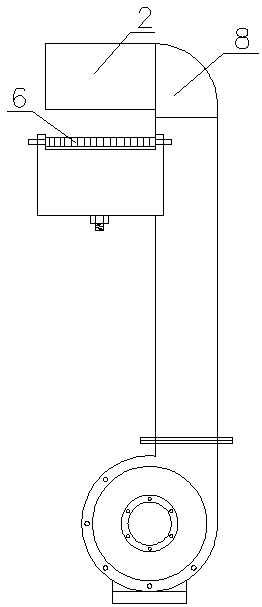

[0016] As a further improvement of the above technical solution, the blower 1 is located below the sump 5 , and the air outlet end of the air duct 4 is connected to the side wall of the air box 2 through an elbow 8 .

[0017] As a further improvement of the above technical sol

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap