Multifunctional wine brewing and rice steaming bed

A multifunctional rice steaming technology, applied in the field of brewing equipment, can solve problems such as burns and hot tiredness, and achieve the effect of avoiding burns and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

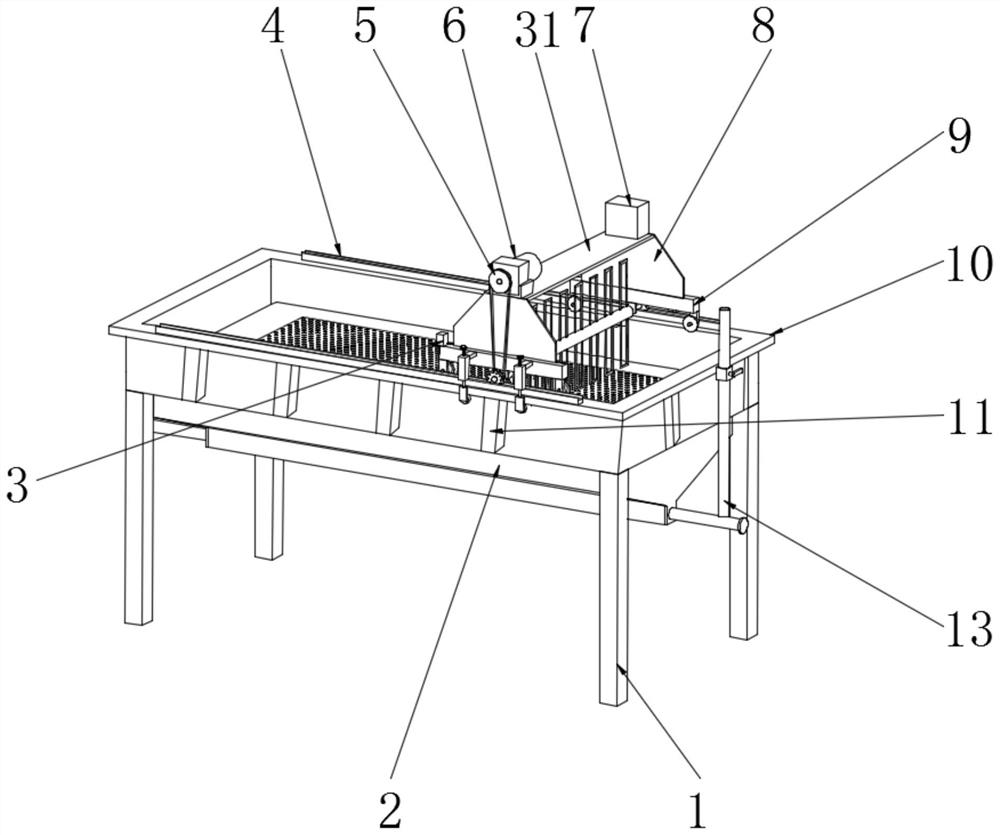

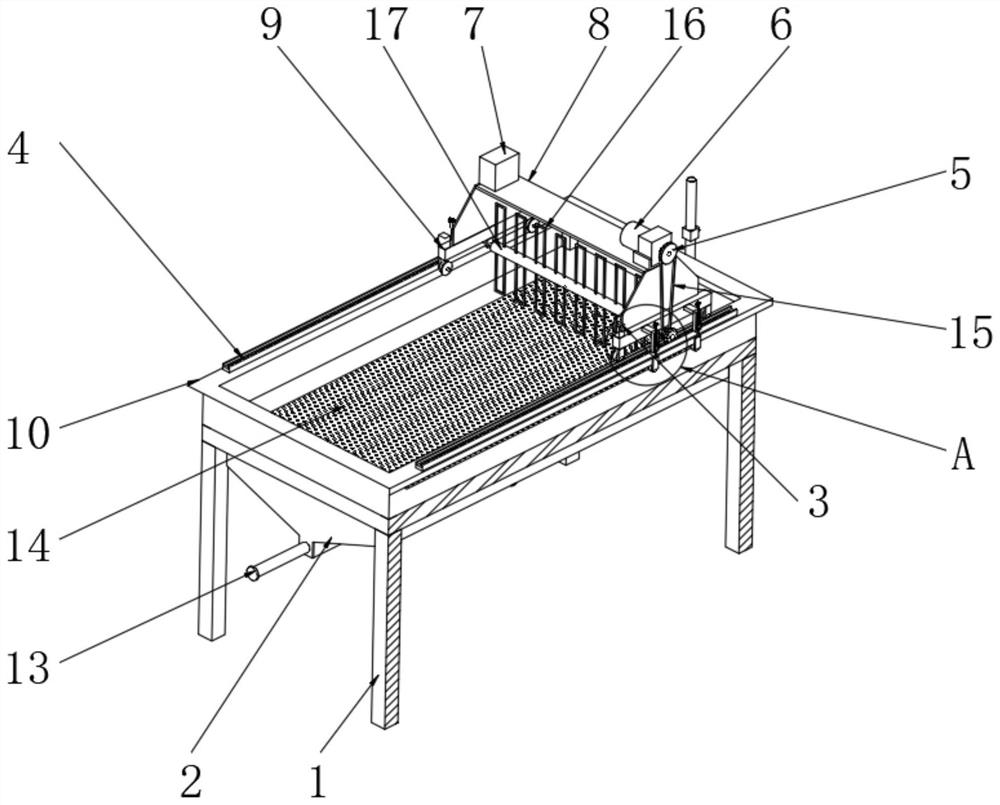

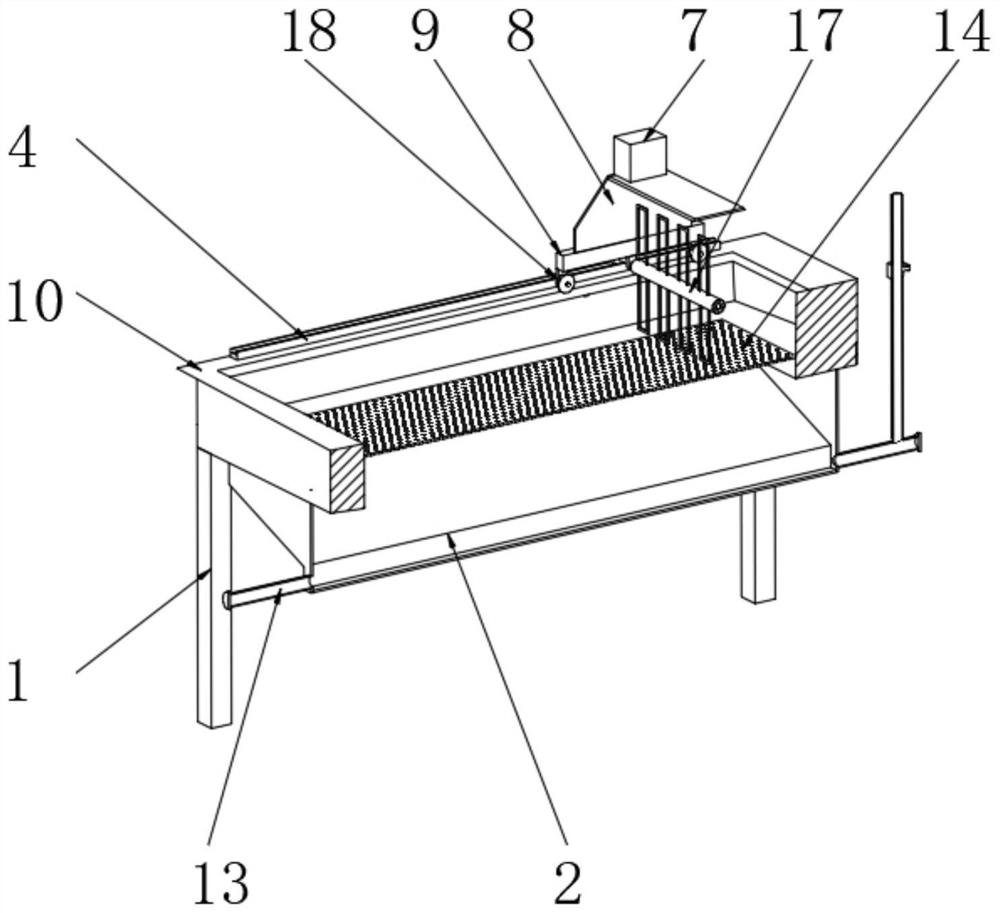

[0036] The following is attached Figure 1-5 The present invention is described in further detail.

[0037] see Figure 1-5 , the present invention provides a technical solution: a multifunctional wine making rice steaming bed, such as Figure 1-5 As shown, it includes a rice steaming bed 10 and a travel switch 3. The lower surface of the rice steaming bed 10 is provided with several support legs 1, and the lower surface of the rice steaming bed 10 is provided with a bottom steam cabin 2, and both sides of the bottom steam cabin 2 are A steam and cold air blower inlet 13 is provided, concave-convex grooves 30 and chains 4 are provided on the upper surface and the left and right sides of the rice steaming bed 10, and a loose rice assembly is arranged on the upper surface of the rice steaming bed 10 and between the two chains 4, and the travel switch 3 Set to limit the initial use of the rice steaming bed 10, the loose rice assembly includes four support bars 9 and two travel gea

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap