Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Lap joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

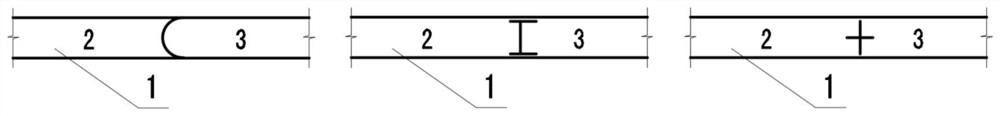

A lap joint or overlap joint is a joint in which the members overlap. Lap joints can be used to join wood, plastic, or metal. A lap joint may be a full lap or half lap. In a full lap, no material is removed from either of the members that will be joined, resulting in a joint which is the combined thickness of the two members. In a half lap joint or halving joint, material is removed from both of the members so that the resulting joint is the thickness of the thickest member. Most commonly in half lap joints, the members are of the same thickness and half the thickness of each is removed.

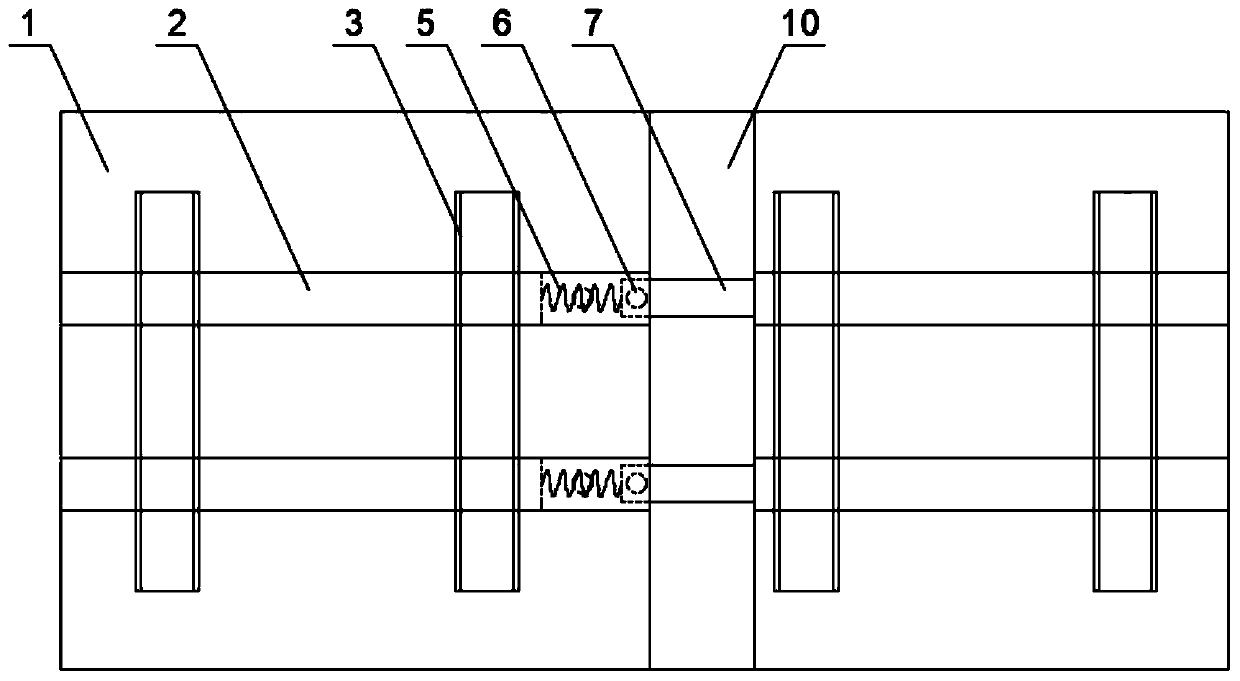

Pre-laying waterproof coiled material construction process for welding and adhesive bonding combined construction

Owner:KESHUN WATERPROOF TECH CO LTD

Safety-type maintenance power box

InactiveCN103887719APrevent intrusionFirmly connectedSubstation/switching arrangement detailsSmall animalTransformer

The invention discloses a safety-type maintenance power box which is provided with a box body and a box door. The power box is characterized in that one side of the box body is provided with a wire outlet opening and two guiderails, which extend out of the box body, are installed at the front side and the rear side of the wire outlet opening. A sliding door is installed on the guiderails in a sliding manner. The safety-type maintenance power box is simple in structure and convenient to use; the box door can be closed when a temporary power supply is lap jointed so that it can be prevented that small animals jump in and a short circuit is caused because of erosion of rain; cut-off the power supply, caused by error operations of other construction personnel can also be prevented; cable connection in the lap joint of the temporary power supply is firmer; and the safety-type maintenance power box is mainly used as a floor-type maintenance power box of a transformer substation.

Owner:POWER TRANSFORMATION OPERATION CENT HUANGSHI POWER SUPPLY

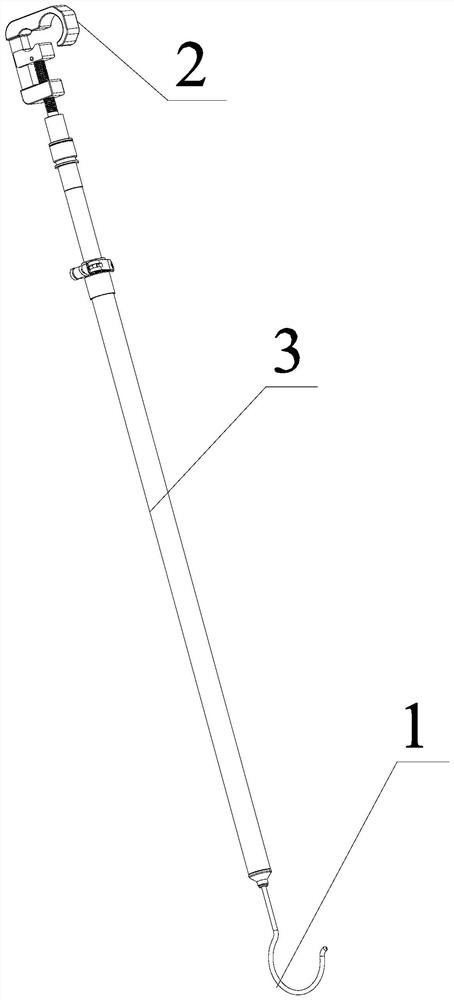

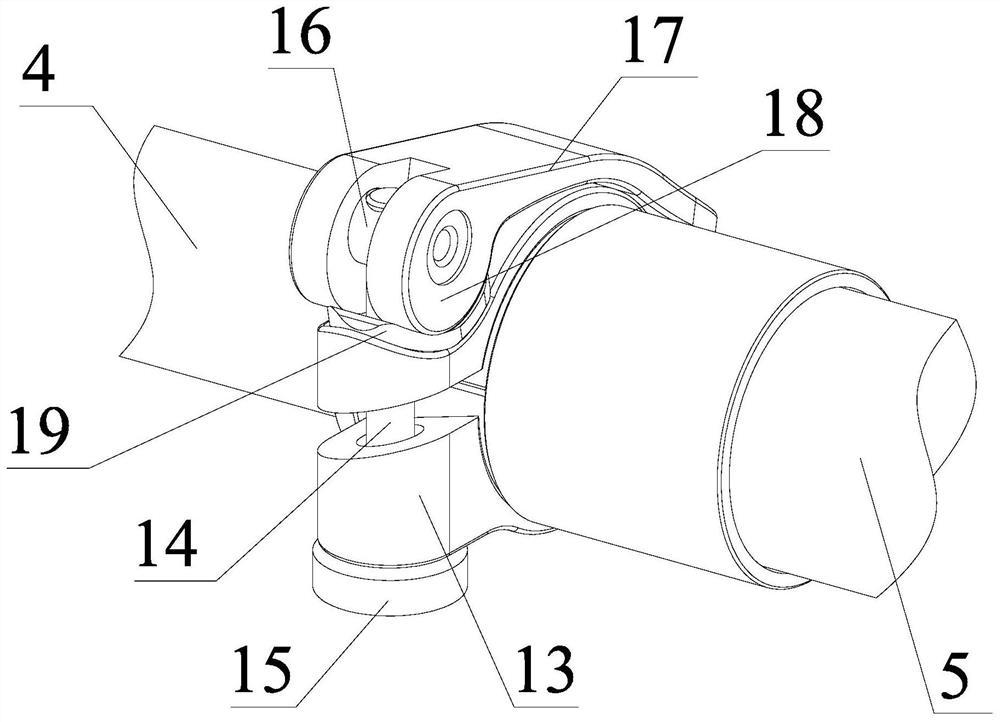

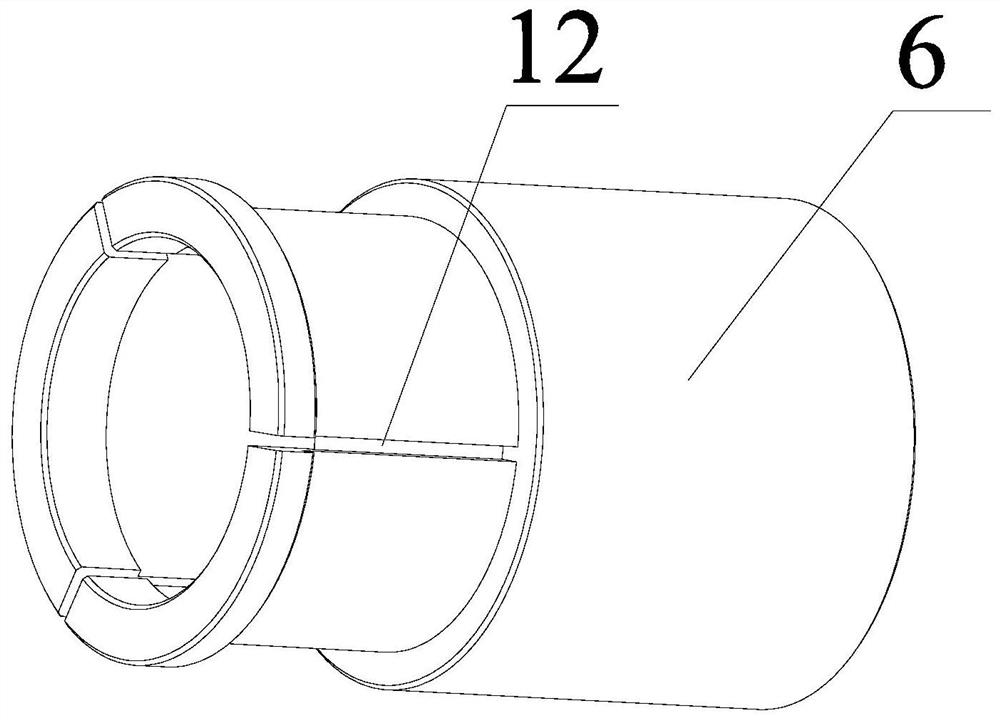

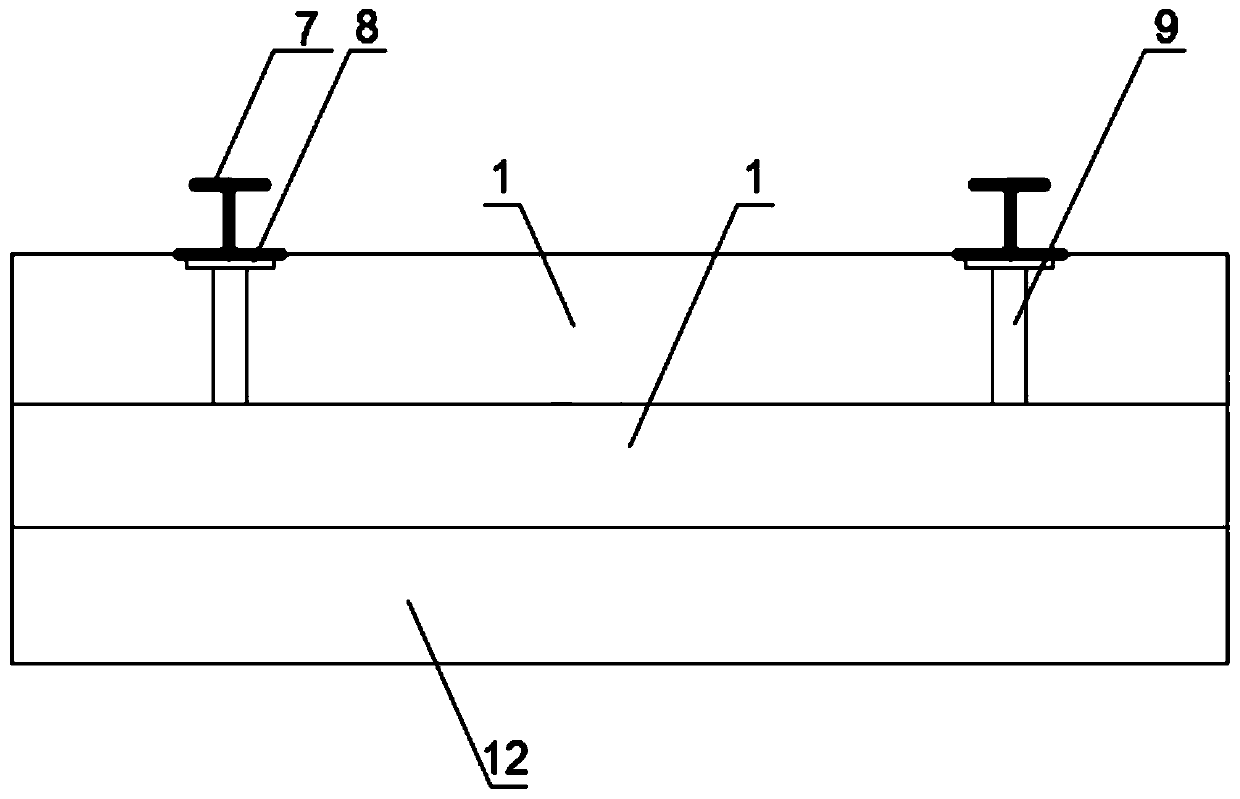

Insulating hanging rod

Owner:JIANGSU ELECTRIC POWER CO

Track-ballast bed combined system capable of moving relatively

ActiveCN111041901ABallastwayRail jointsDerailmentLap joint

Owner:SOUTHEAST UNIV

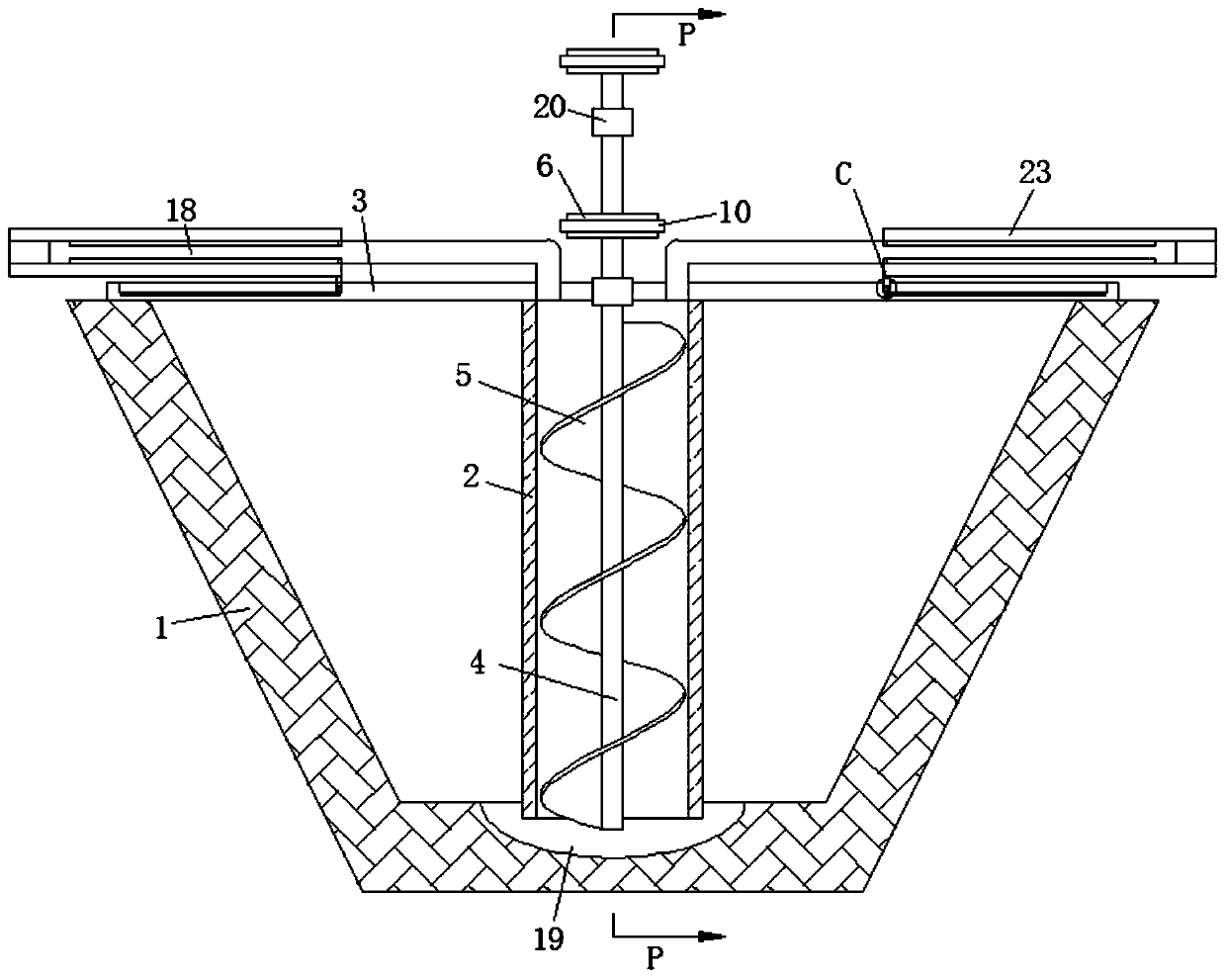

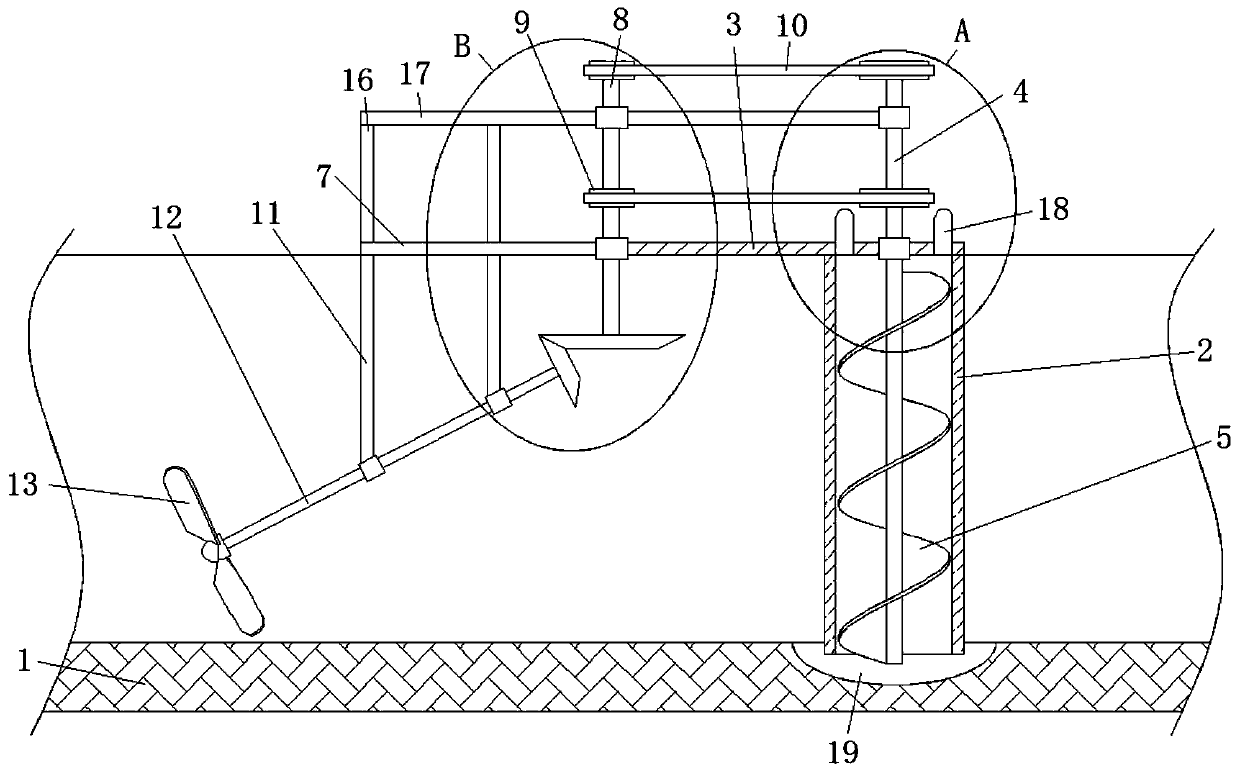

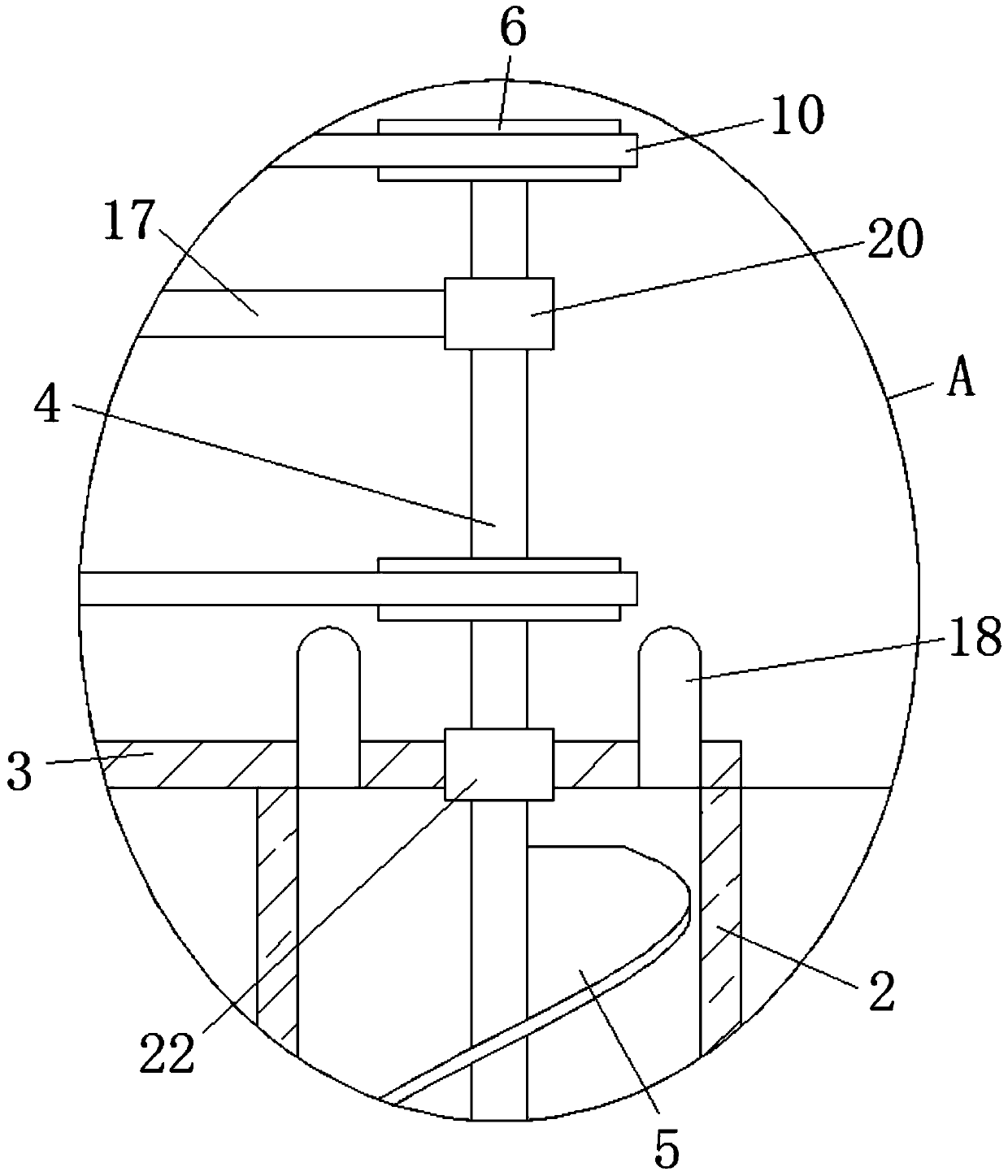

Ecological drainage channel

InactiveCN111560925AMeet the needs of useAvoid cloggingMechanical machines/dredgersSoil drainageSludgeSpiral blade

Owner:陈文娟

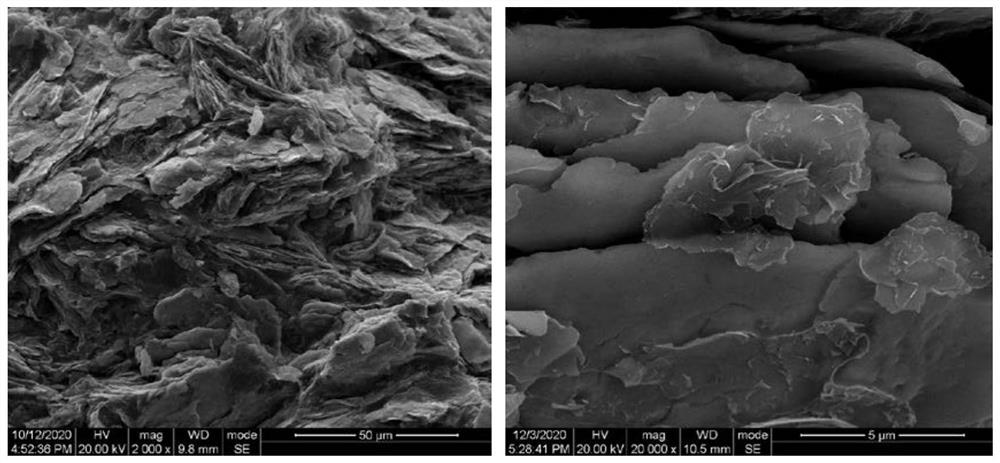

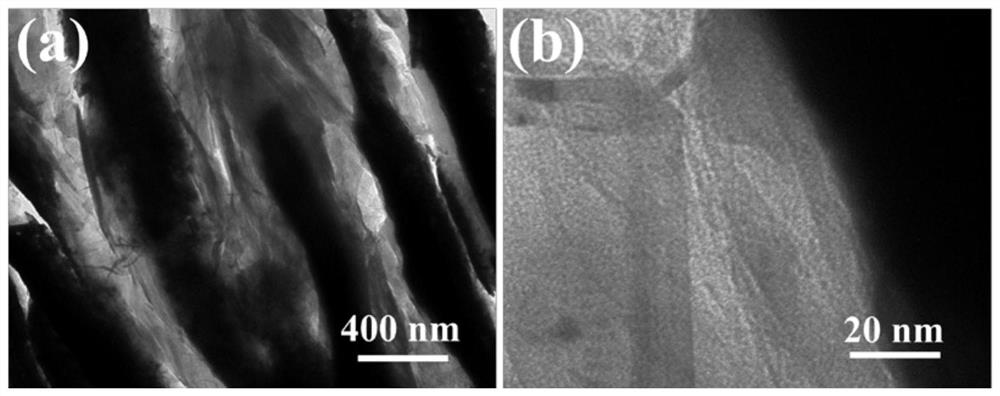

Ultrahigh-isotropy heat-conducting material of epoxy two-dimensional flaky metal nanofiller and preparation method of heat-conducting material

ActiveCN113416389AImprove thermal conductivityEfficient synergyHeat-exchange elementsLap jointResin matrix

The invention provides an ultrahigh-isotropy heat-conducting material of an epoxy two-dimensional flaky metal nanofiller and a preparation method of the heat-conducting material. The material mainly comprises the following components: epoxy resin, a two-dimensional sheet metal nanofiller, a two-dimensional sheet carbon series heat conduction filler and a diluent. The method comprises the following steps: uniformly mixing the components, removing the diluent, and preparing the heat-conducting material or a workpiece through a hot press molding process. The two kinds of two-dimensional sheet-shaped heat-conducting fillers are in lap joint in an epoxy resin matrix to form a three-dimensional heat-conducting network, efficient lap joint and efficient synergistic effect of the two-dimensional sheet-shaped metal nanofiller are achieved, the heat-conducting property of the obtained heat-conducting material or the workpiece is greatly improved, and the isotropic heat-conducting characteristic is achieved.

Owner:SICHUAN UNIV

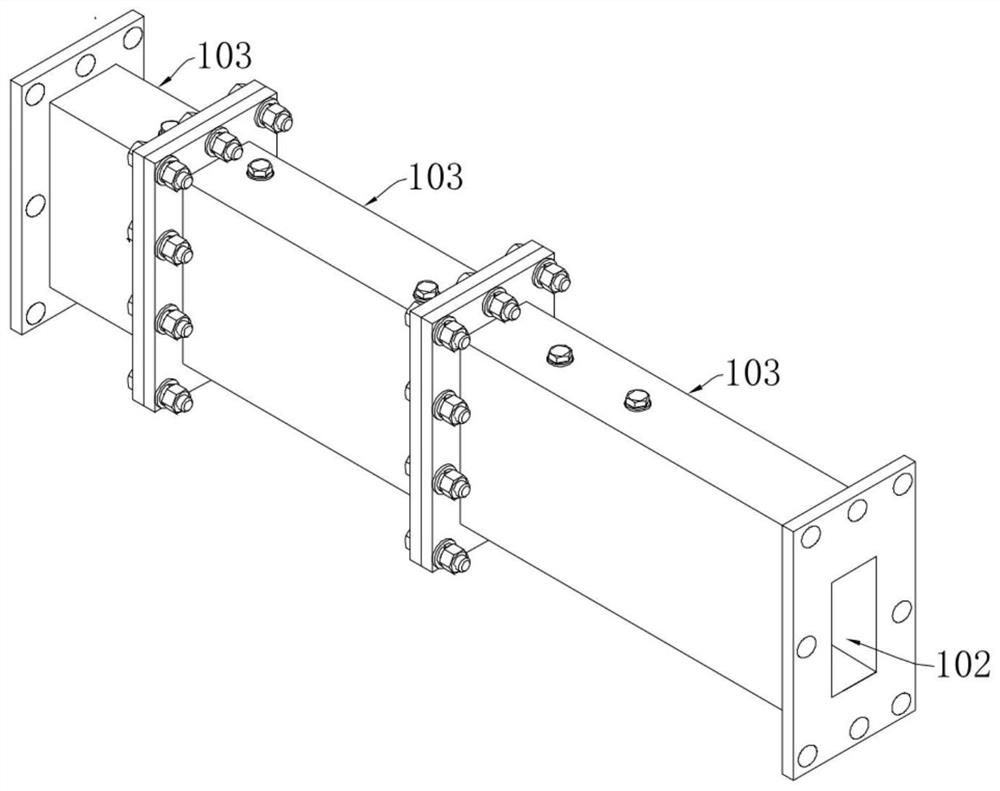

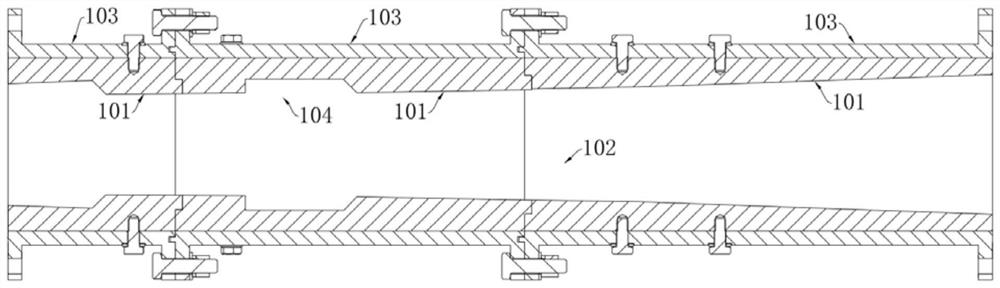

Modularized solid rocket scramjet engine test platform

PendingCN112798284AGas-turbine engine testingJet-propulsion engine testingAutomotive engineeringLap joint

Owner:NAT UNIV OF DEFENSE TECH

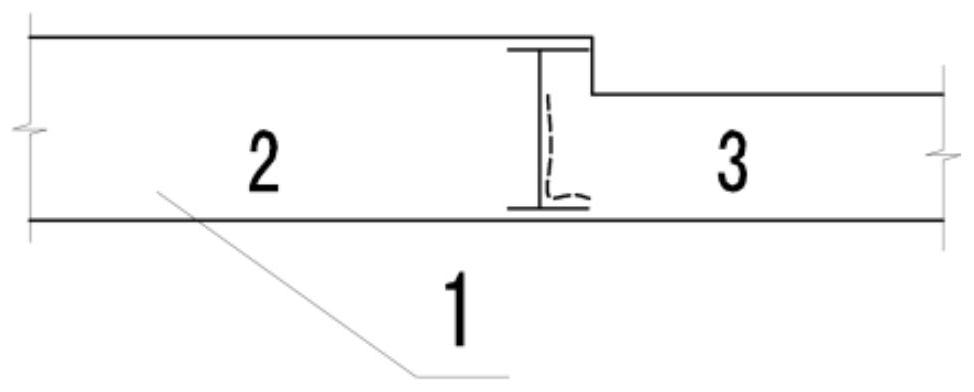

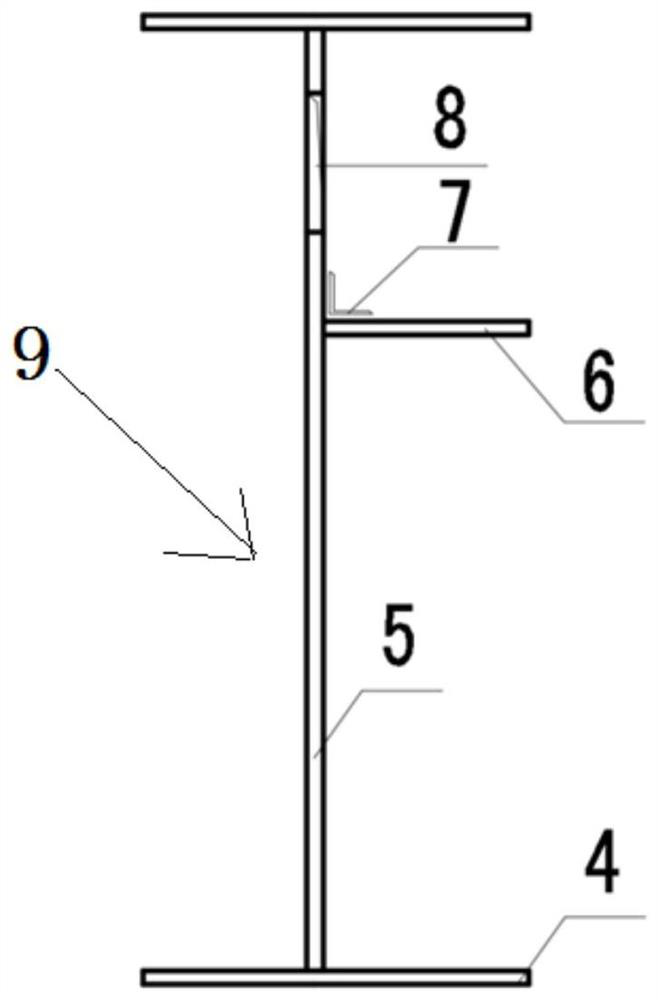

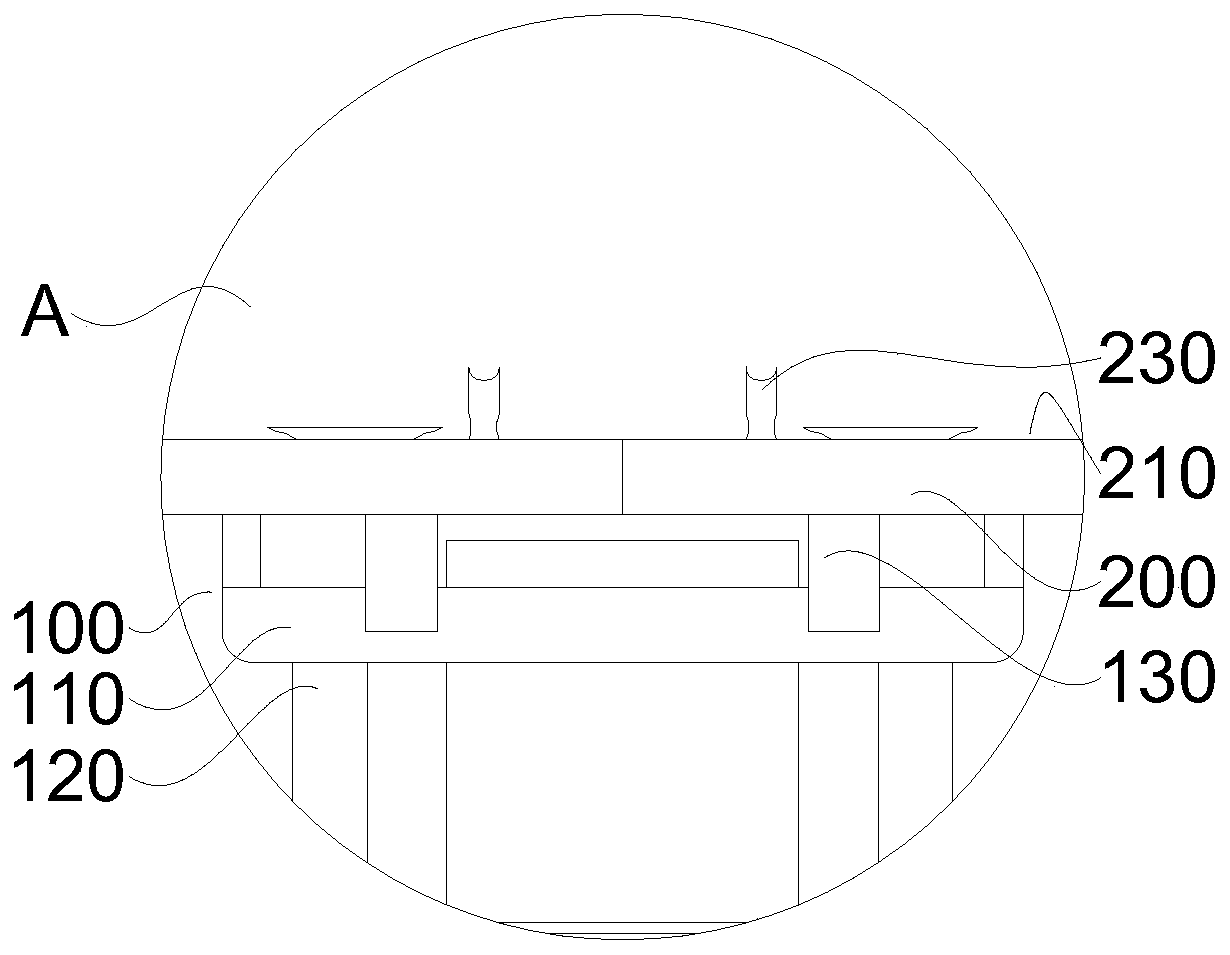

H-shaped steel structure for lap joint of underground diaphragm walls with different thicknesses

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

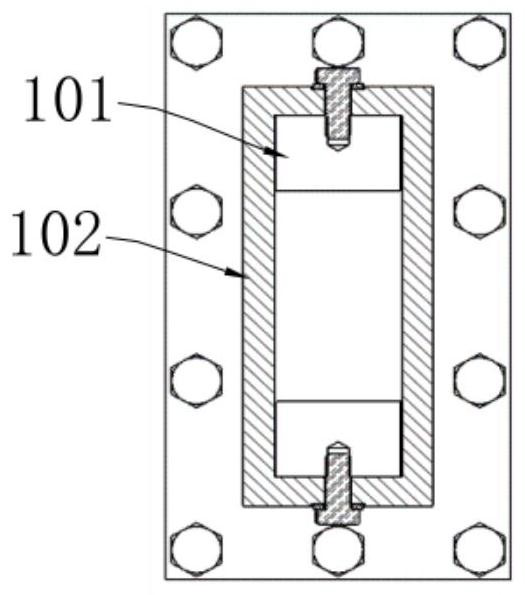

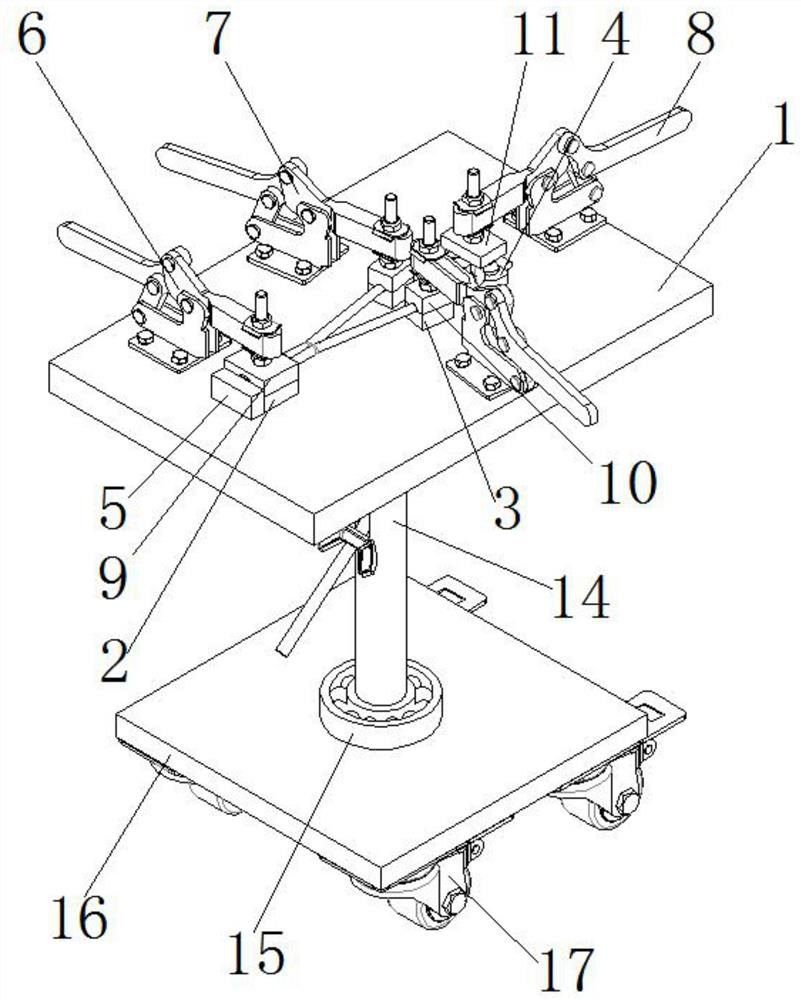

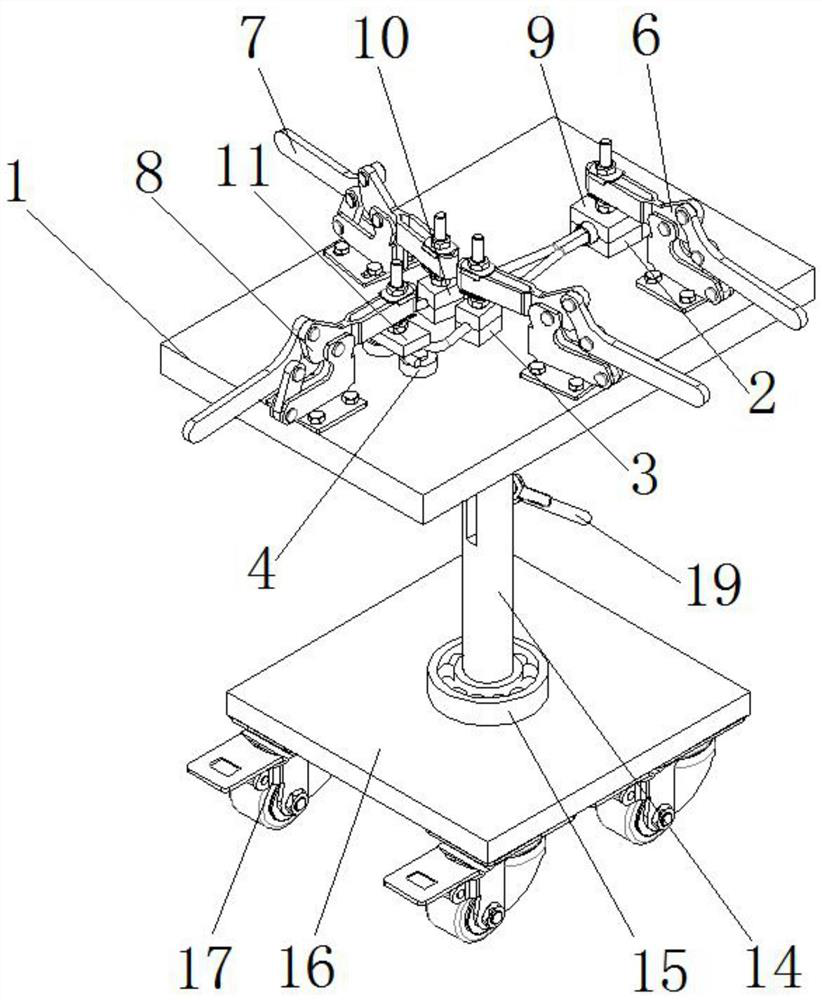

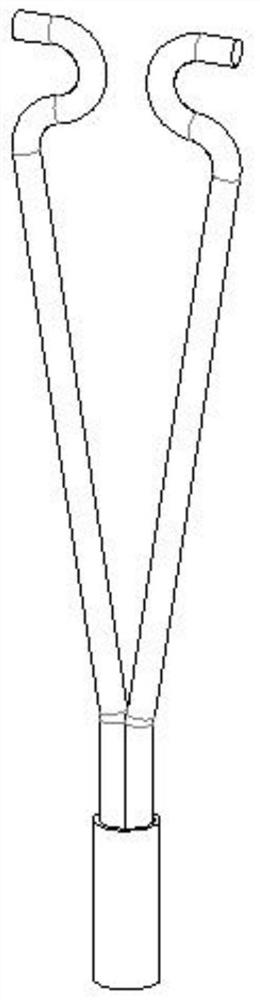

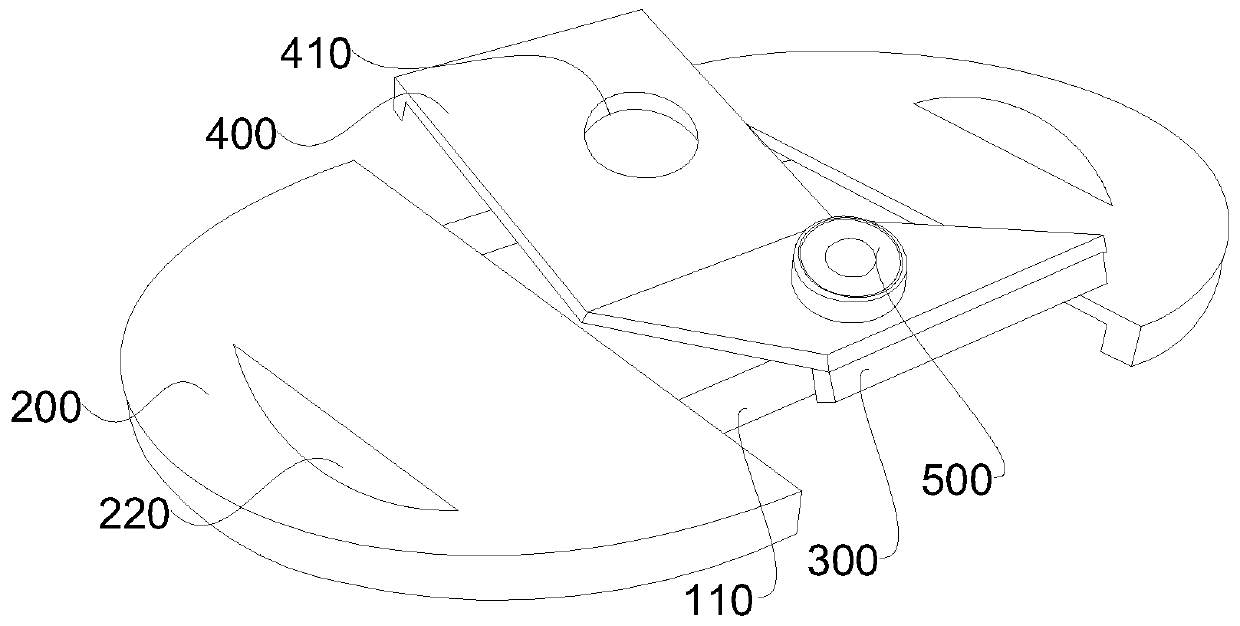

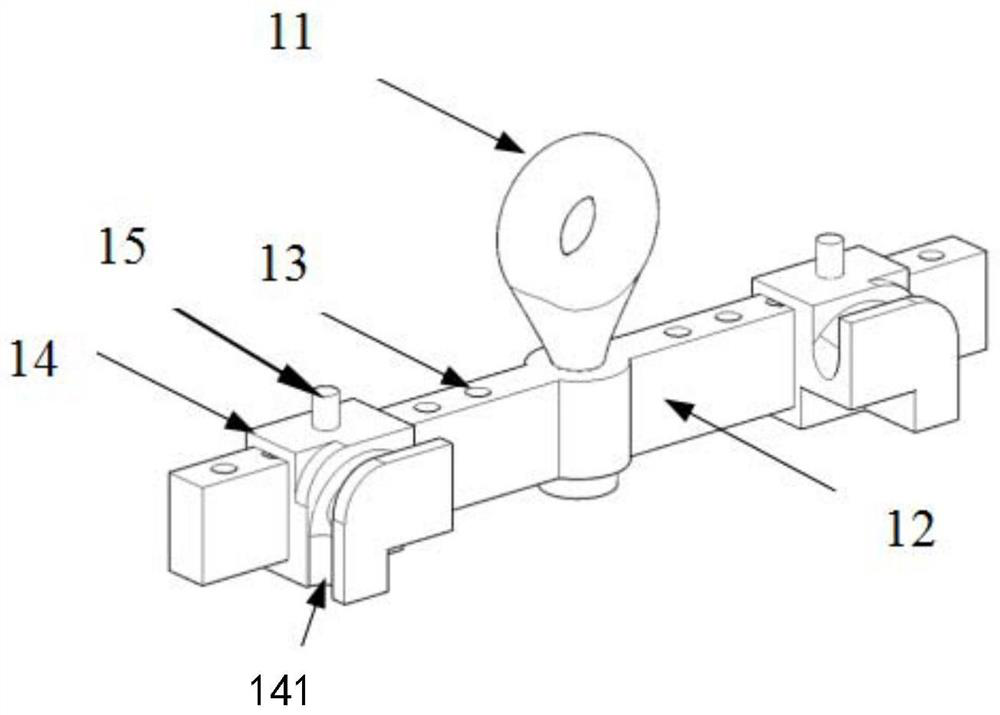

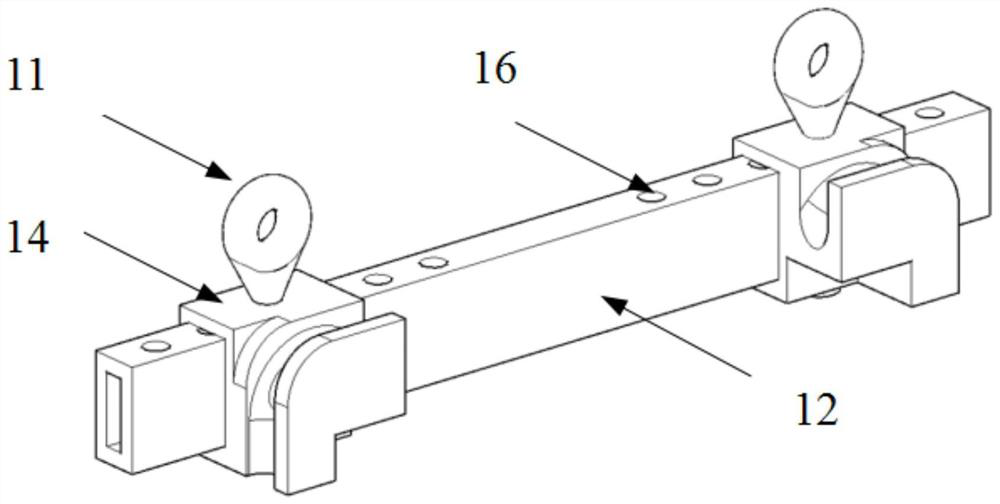

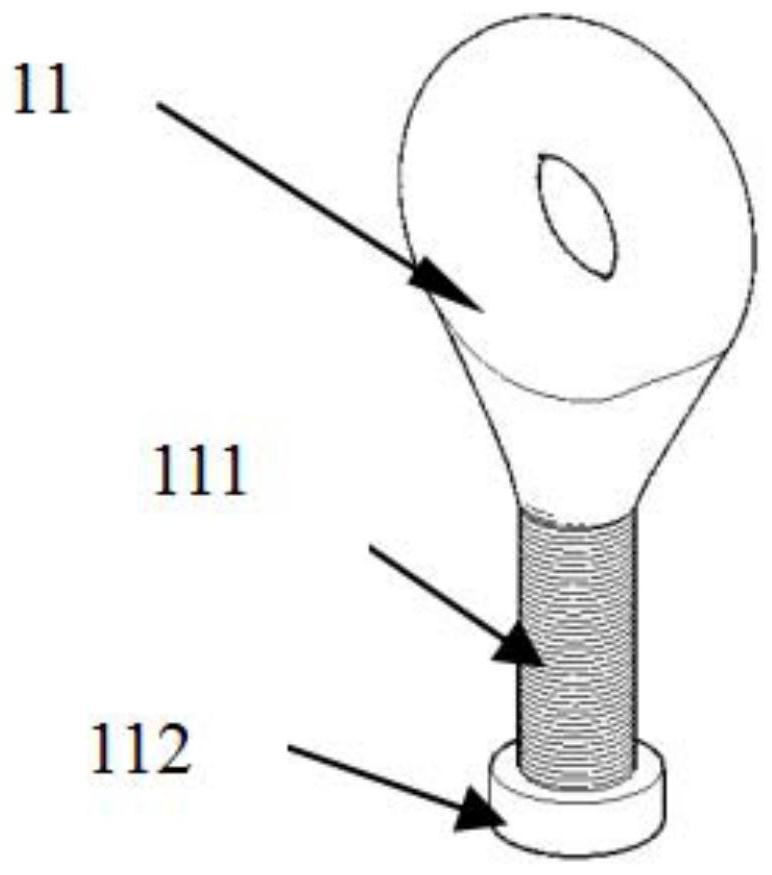

NL-3A pretreatment machine cover and rear cover jig

InactiveCN112536564ASmooth rotationMeet drawing requirementsWelding/cutting auxillary devicesAuxillary welding devicesLap jointIndustrial engineering

The invention discloses an NL-3A pretreatment machine cover and rear cover jig. The NL-3A pretreatment machine cover and rear cover jig comprises a working platform, wherein the upper surface of the working platform is fixedly connected with a first lower fixed block, second lower fixed blocks and a step column, and the upper surface of the first lower fixed block and the upper surfaces of the second lower fixed blocks are provided with clamping grooves adapted with sleeves and hook-shaped supporting rods respectively; the front face of the first lower fixed block is fixedly connected with a limiting block; and the upper surface of the working platform is fixedly connected with a first quick clamp, a second quick clamp and a third quick clamp through bolts. By arranging the limiting block,a first quick clamp, the second quick clamp and the third quick clamp, the first quick clamp, the second quick clamp and the third quick clamp can rotate conveniently to drive a first upper fixed block, second upper fixed blocks and a lap joint plate to fix the sleeves and the hook-shaped supporting rods in the NL-3A pretreatment machine cover and rear cover jig, and thus the produced and manufactured product better meets the drawing requirements.

Owner:TONGLING HUIYU IND CO LTD

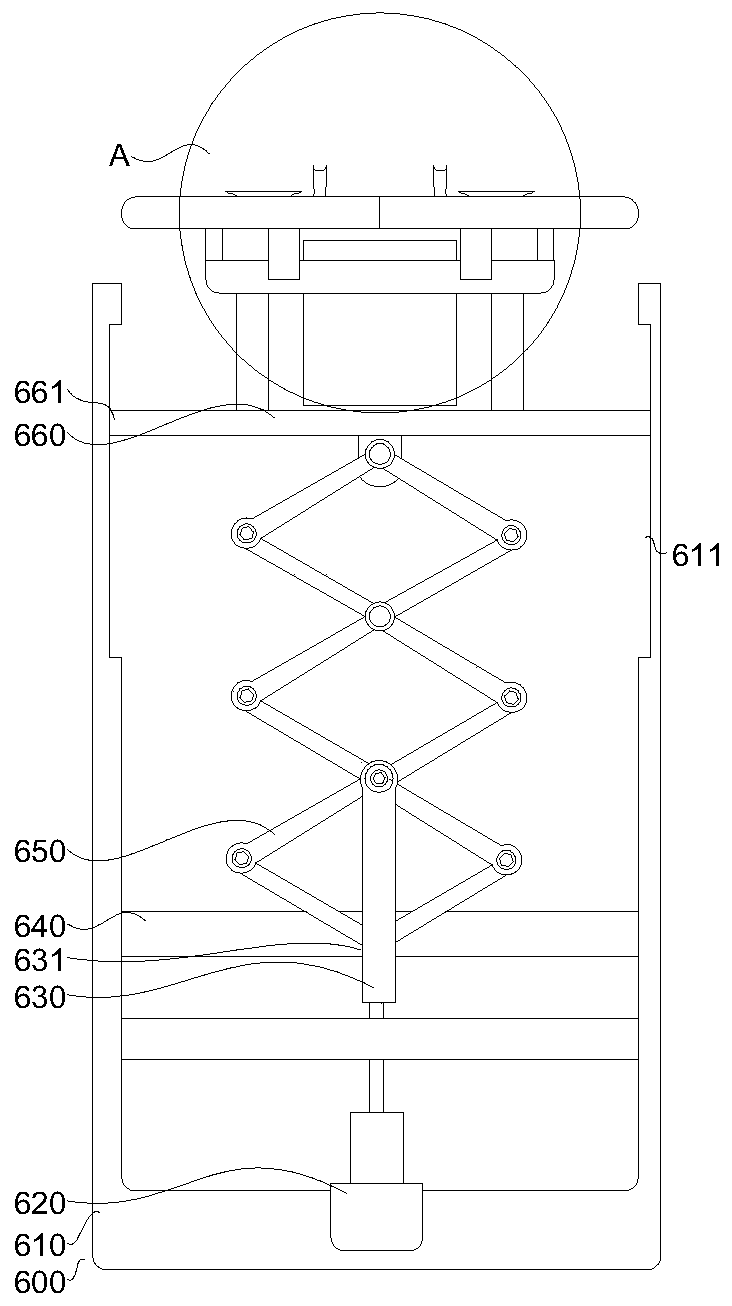

Smart home center control platform support

Owner:西安弘创信息技术有限责任公司

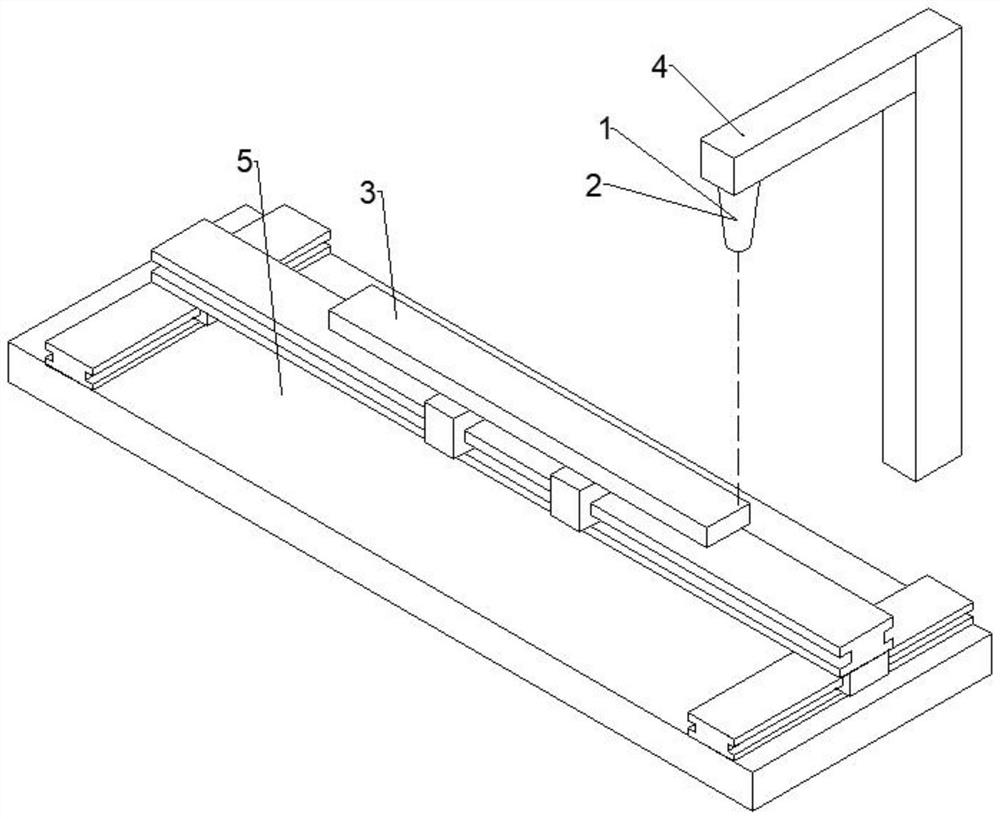

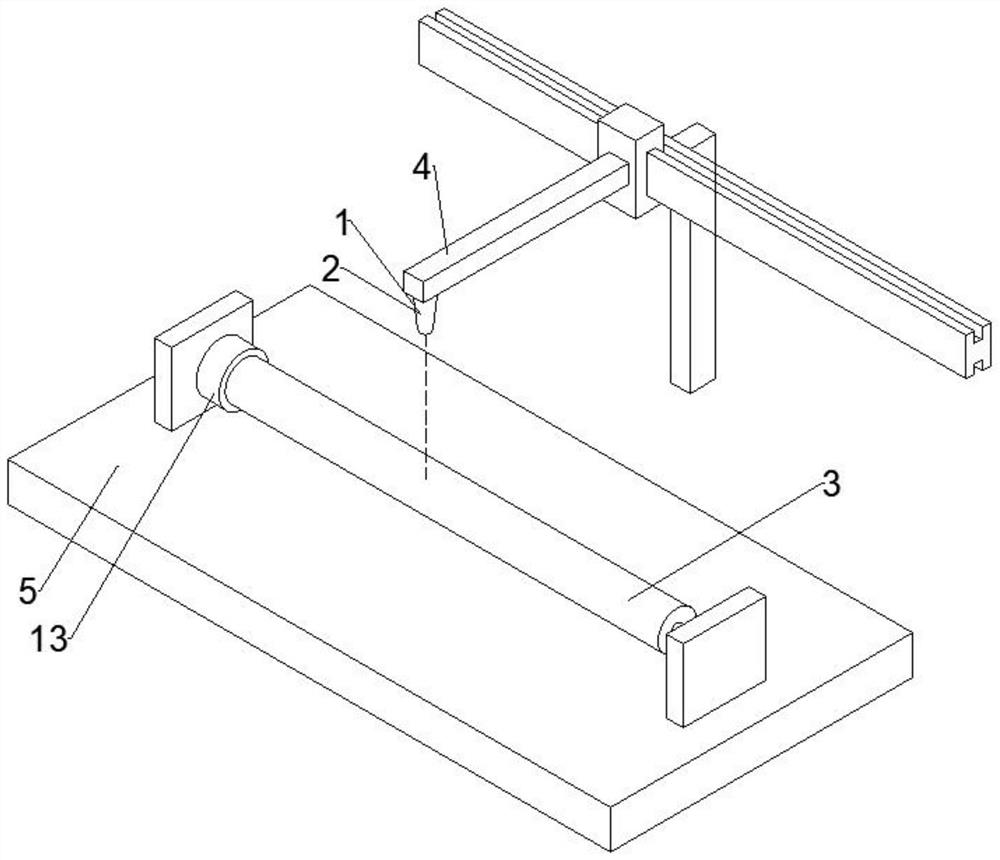

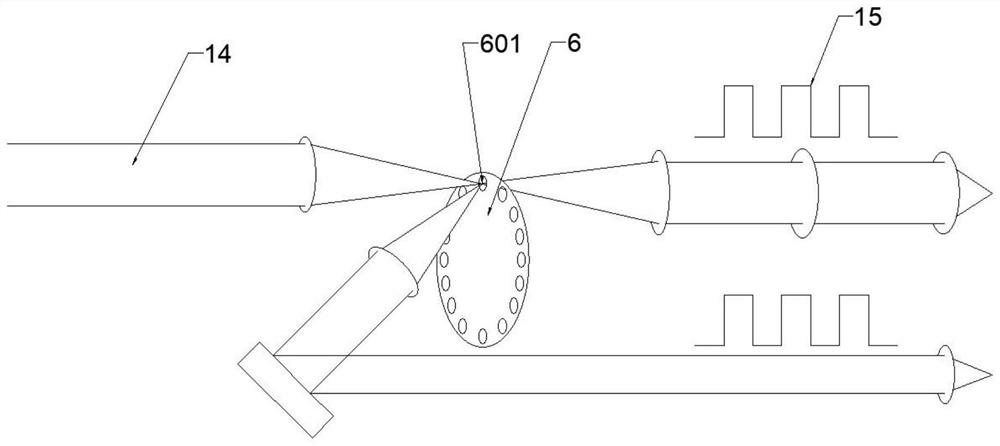

High-speed laser dot-shaped heat treatment device

Owner:安阳睿恒数控机床股份有限公司

Lap joint type solar photovoltaic module

InactiveCN111654229AEase of workReduce use costPhotovoltaic supportsRoof coveringWhole bodyLap joint

The invention relates to the technical field of solar power generation. The invention further discloses a lap joint type solar photovoltaic module comprising first wall bodies, second wall bodies anda top beam. The number of the first wall bodies and the number of the second wall bodies are both two. The second wall bodies are fixedly connected between the two first wall bodies. According to thelap joint type solar photovoltaic module, a mounting frame is pre-mounted on a roof; meanwhile, a first mounting frame and a second mounting frame are connected together; the number of the first mounting frame in asingle-row direction is one; end connecting blocks are fixedly mounted on one side of the first mounting frame and one side of the second mounting frame at the other end respectively; the end connecting block close to one end of the first mounting frame is mounted at the top of the first wall body; the end connecting block close to one end of the second mounting frame is mounted at the position close to the top beam, so that splicing of the end connecting block, the first mounting frame and the second mounting frame can be completed on the ground, then the whole body is mounted on the mounting frame. Therefore, the working difficulty is greatly reduced, and the workload on a roof is small.

Owner:DEQING HAICHAO TECH INFORMATION CONSULTING PARTNERSHIP (LLP)

Pre-embedded-free multi-functional lifting appliance for precast concrete beam

PendingCN111908318AReduce use costImprove general performanceLoad-engaging elementsConcrete beamsConstruction engineering

Owner:江苏沛丰建筑工程有限公司

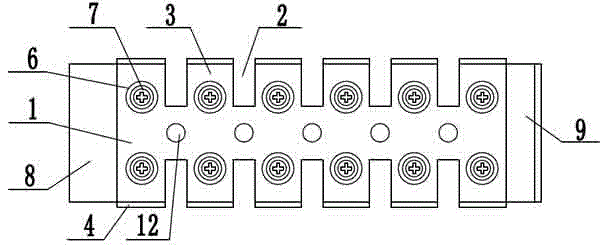

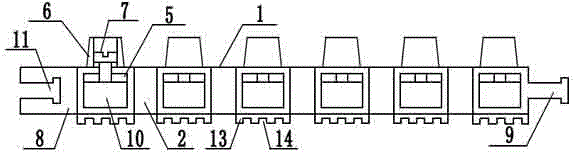

Wiring terminal with multiple segments capable of being in lap joint

InactiveCN104466451AGuarantee the number of connection holesSimple structureElectrically conductive connectionsLap jointEngineering

Owner:潘阿海

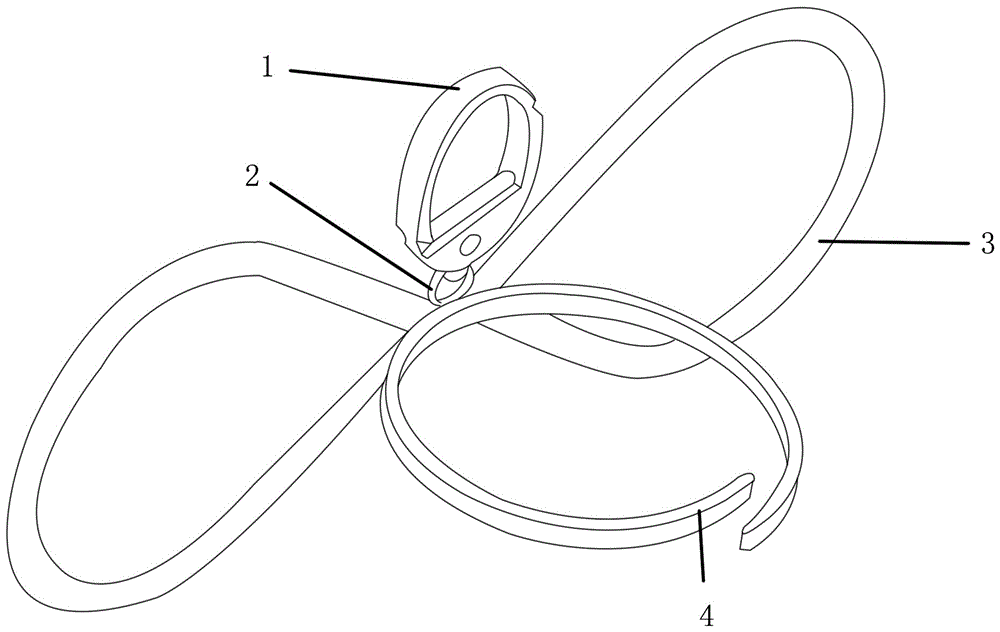

Bowtie type microphone clip

Owner:SHUNDE POLYTECHNIC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap