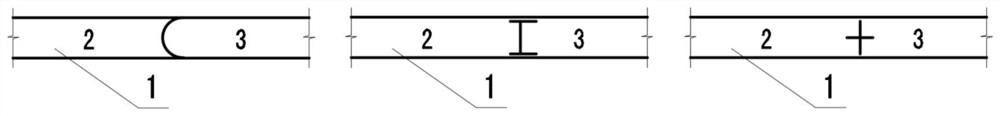

H-shaped steel structure for lap joint of underground diaphragm walls with different thicknesses

A technology of underground diaphragm wall and H-shaped steel, which is applied in the direction of foundation structure engineering, sheet pile wall, excavation, etc., can solve the problems such as the safety of foundation pits that are easily endangered and the safety of various surrounding buildings and structures, and the difficulty of pouring and compacting concrete, so as to improve the foundation pit. Construction safety, improvement of pouring quality, and effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

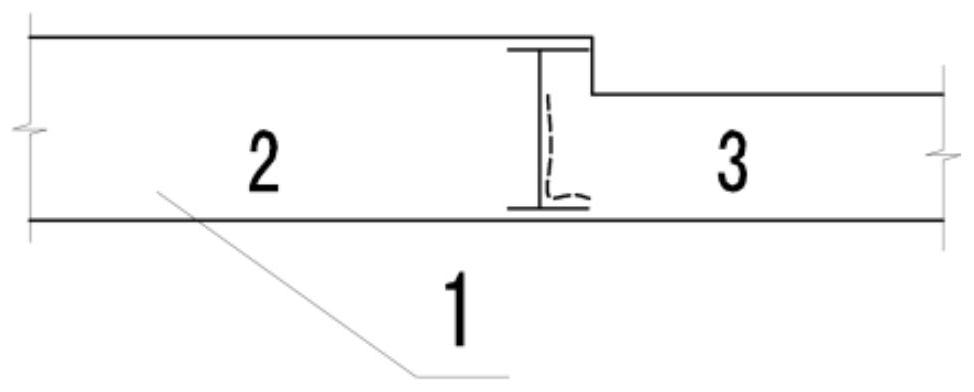

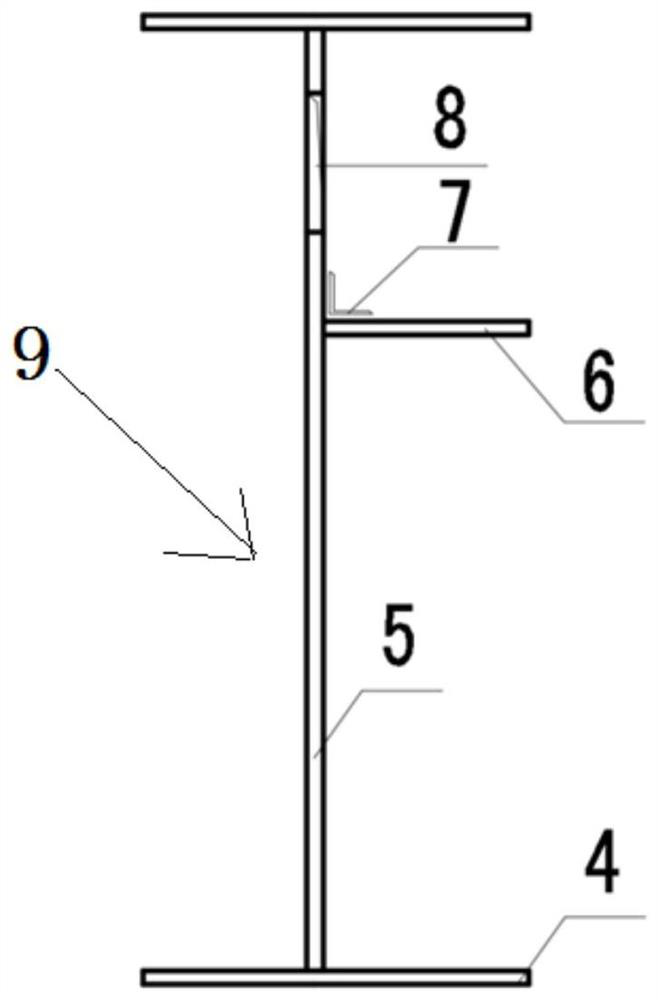

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] At present, the commonly used underground diaphragm wall 1 has a thickness of 0.6m, 0.8m, 1.0m, 1.2m, and 1.5m, and the corresponding H-shaped steel 9 has a thickness of "0.6-1.5m-2×thickness of the protective layer of steel bars+2×diameter of horizontally distributed steel bars ", taking the thickness of the inner and outer protective layer as 70mm and the diameter of the transverse reinforcement as 20mm as an example, the thicknesses of H-beam 4 are 500mm, 700mm, 900mm, 1100mm and 1400mm respectively.

[0029] The material of H-shaped steel 9 is Q235b steel, and the thickness of the weld seam is 8mm. The construction technology and precision of steel plate weld

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap