Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Heat-exchange elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

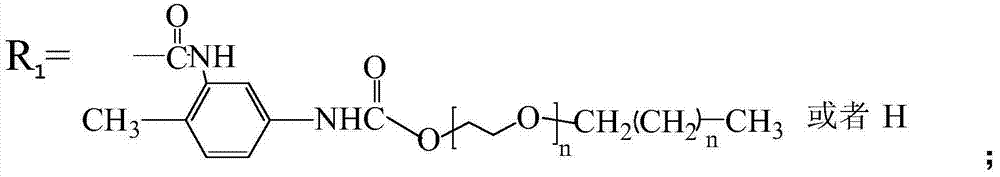

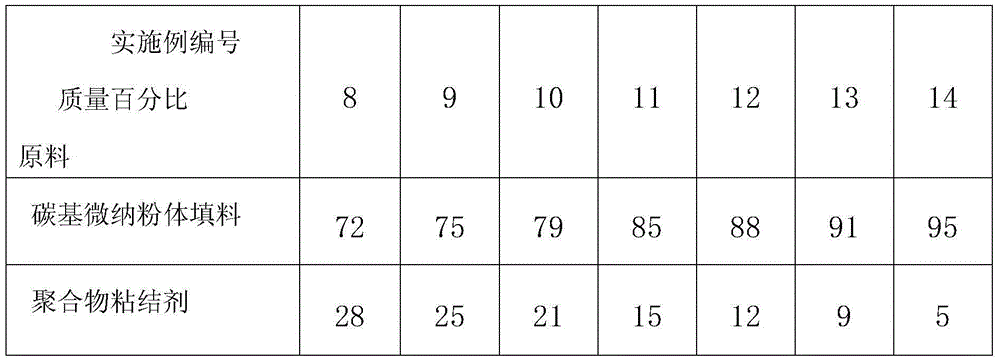

Phase change energy storage thermoplastic composite material and preparation method thereof

ActiveCN102070845AHas processing propertiesHigh elongation at breakHeat-exchange elementsPolymer scienceVulcanization

Owner:KINGFA SCI & TECH CO LTD +2

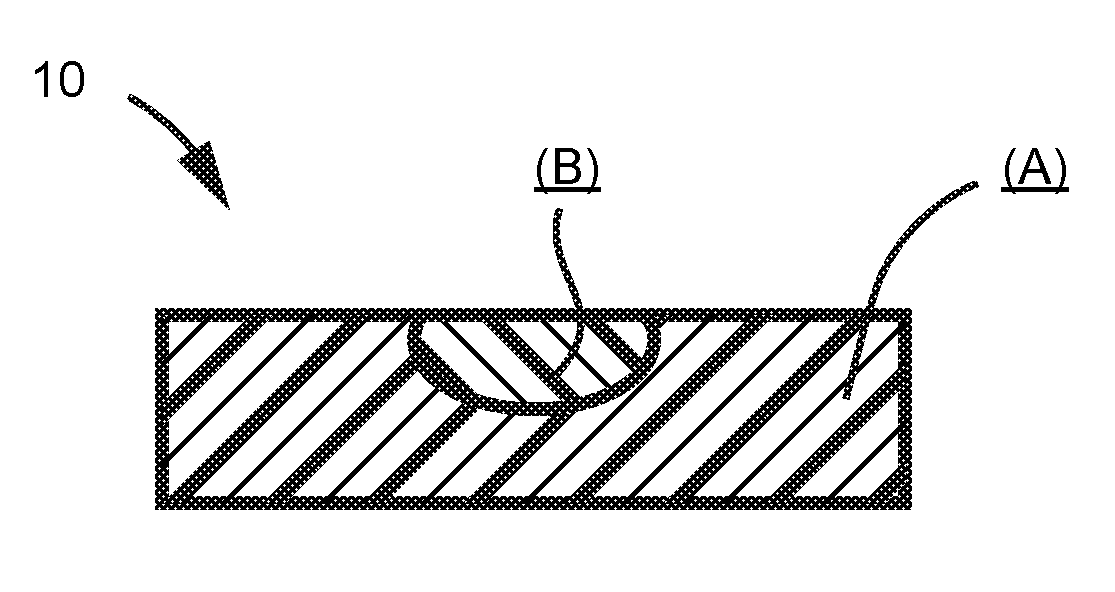

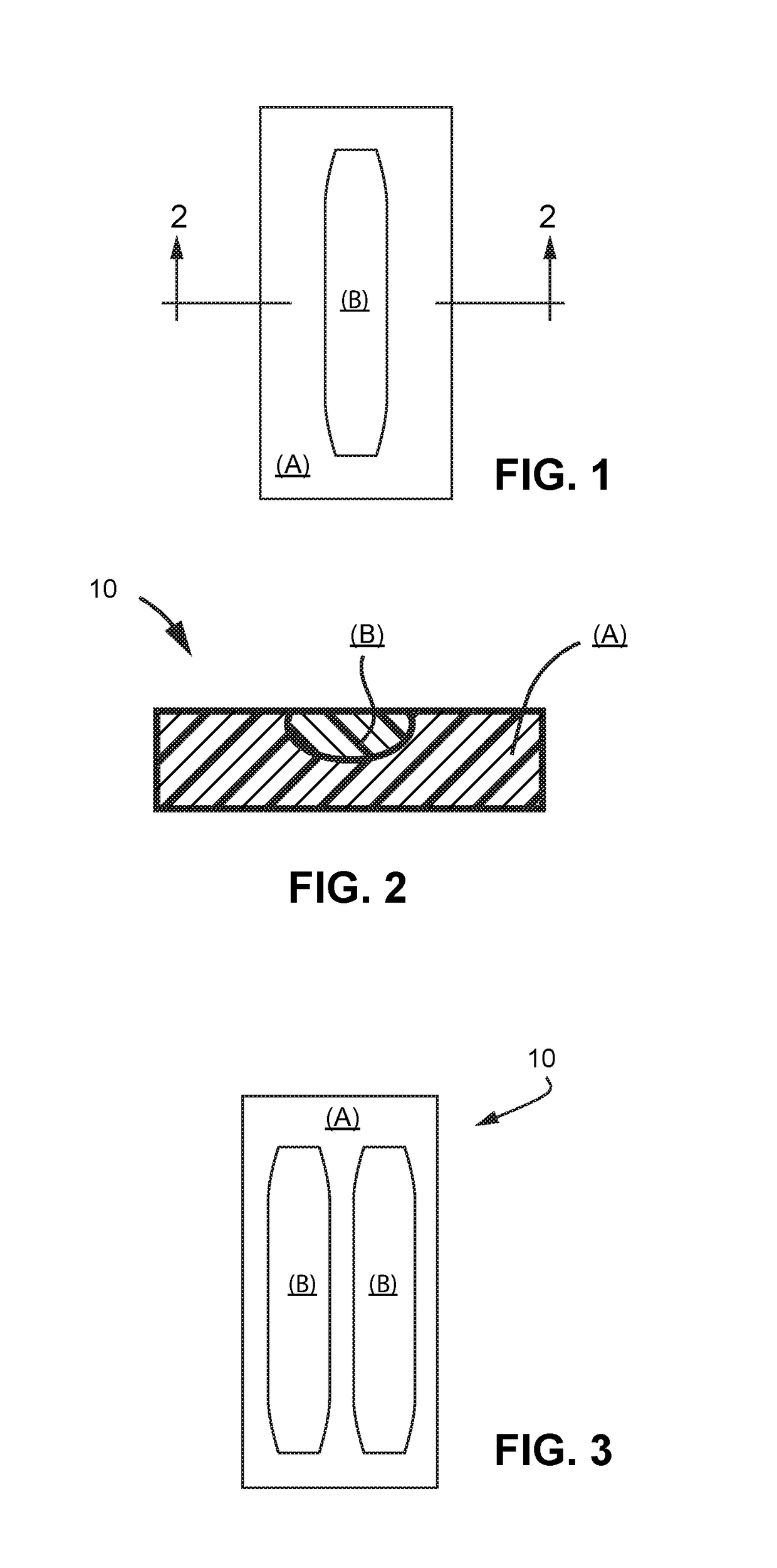

Reversibly adhesive thermal interface material

Owner:IBM CORP

Thermoplastic cellulose-based solid-solid phase transition material and preparation method thereof

Owner:TIANJIN POLYTECHNIC UNIV +1

Heat Generating Body, Heat Insulating Method Using The Same And Packaging Material For Die Molding Heat Generation

ActiveUS20080029079A1Exothermal chemical reaction heat productionOther heat production devicesMuscular fatiguePack material

Owner:S T CORP

High-thermal-conductivity high-electrical-conductivity carbon nano-grade composite material and preparation method thereof

InactiveCN104130753AImprove production efficiencyGood thermal conductivityHeat-exchange elementsDisplay deviceElectron

Owner:SOUTHWEAT UNIV OF SCI & TECH

Methods for purifying and stabilizing hydrofluoroolefins and hydrochlorofluoroolefins

Owner:ARKEMA INC

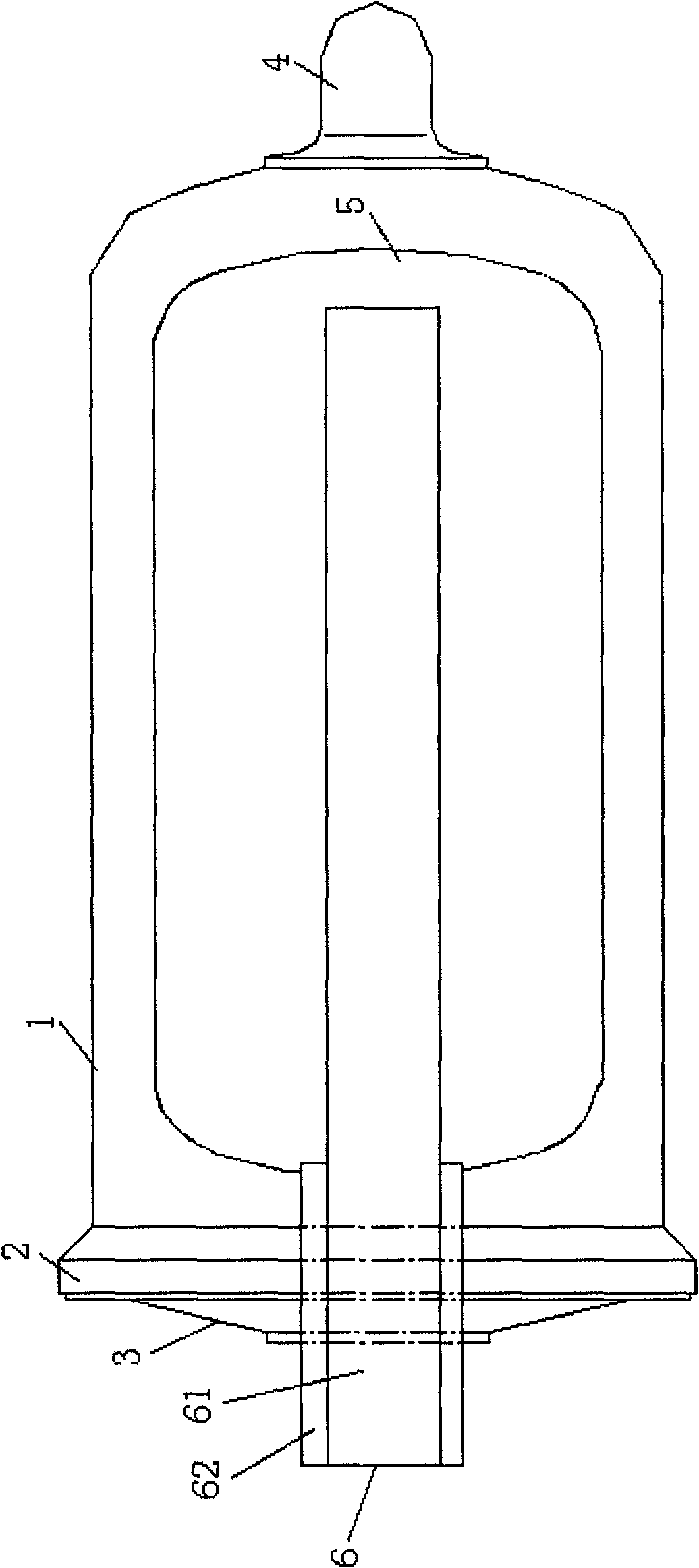

Thermal storage type vacuum tube

InactiveCN101639296AExtended service lifeIncrease the heat exchange areaHeat storage plantsSolar heat devicesSolar waterMetallic materials

Owner:北京桑达太阳能技术有限公司

Ternary fatty acid/modified expanded vermiculite composite phase-change energy storage material

Owner:FUZHOU UNIVERSITY

Multi additive multifunctional composite for use in a non-metallic fuel conveyance system

A multifunctional composite material may include a polymer matrix, at least one nano-additive, micro-additive, and / or a spherical nano-additive. The non-metallic composite material may be used to make non-metallic parts for fuel conveyance systems for use in aircraft.

Owner:EATON INTELLIGENT POWER LTD

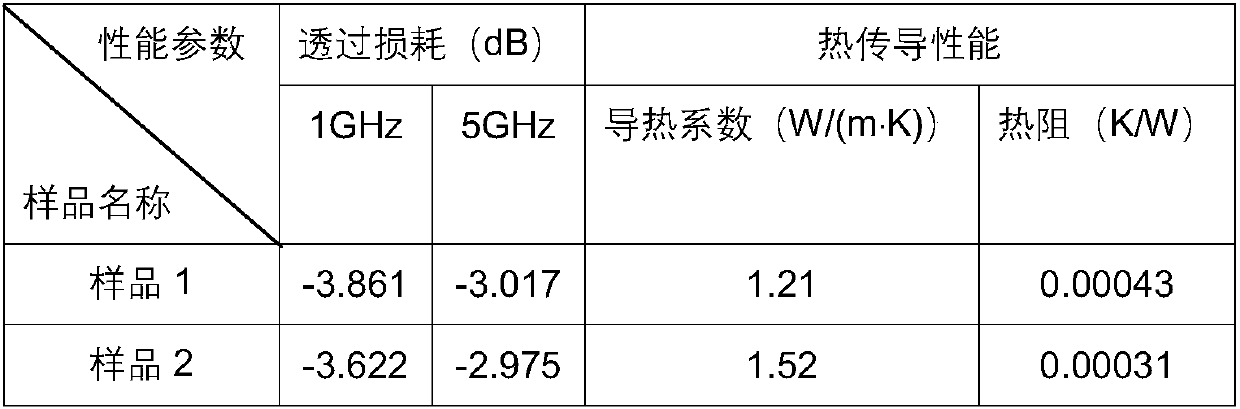

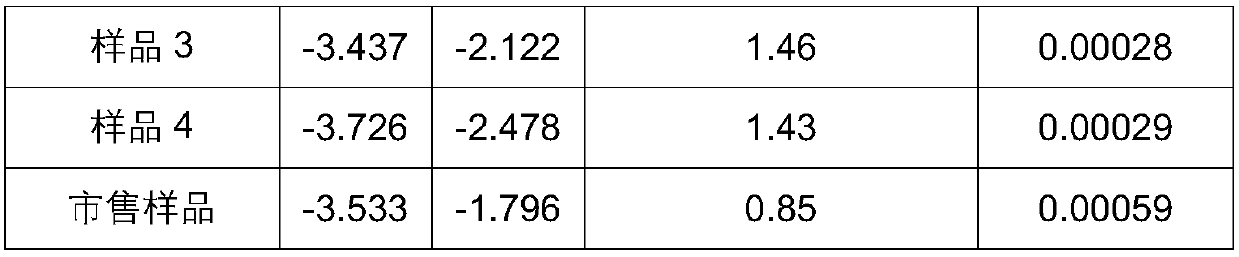

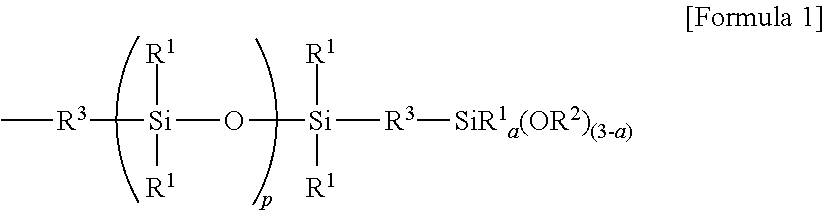

Thermally conductive silicone grease composition

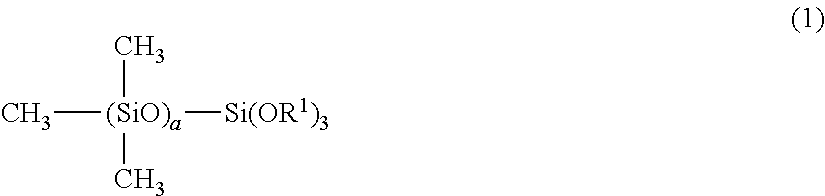

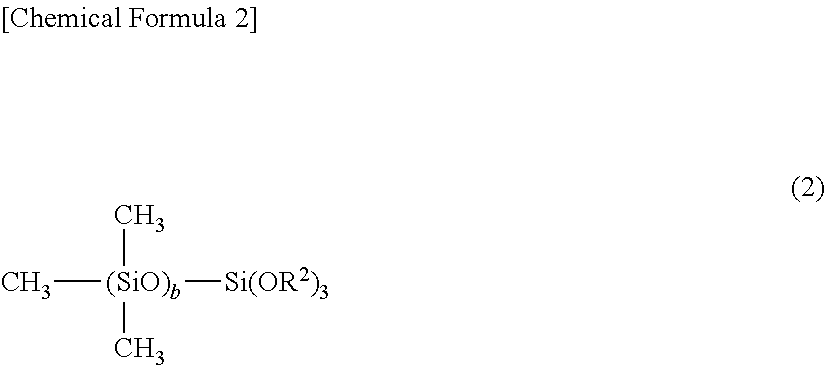

ActiveUS20150001439A1Hardness rise is smallHigh elongationHeat-exchange elementsLubricant compositionPhenyl groupMethyl group

Owner:SHIN ETSU CHEM IND CO LTD

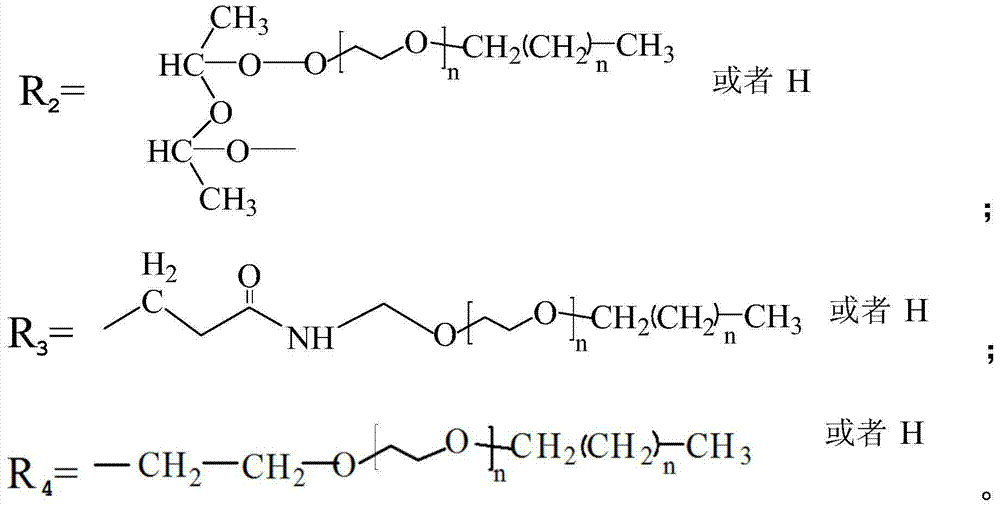

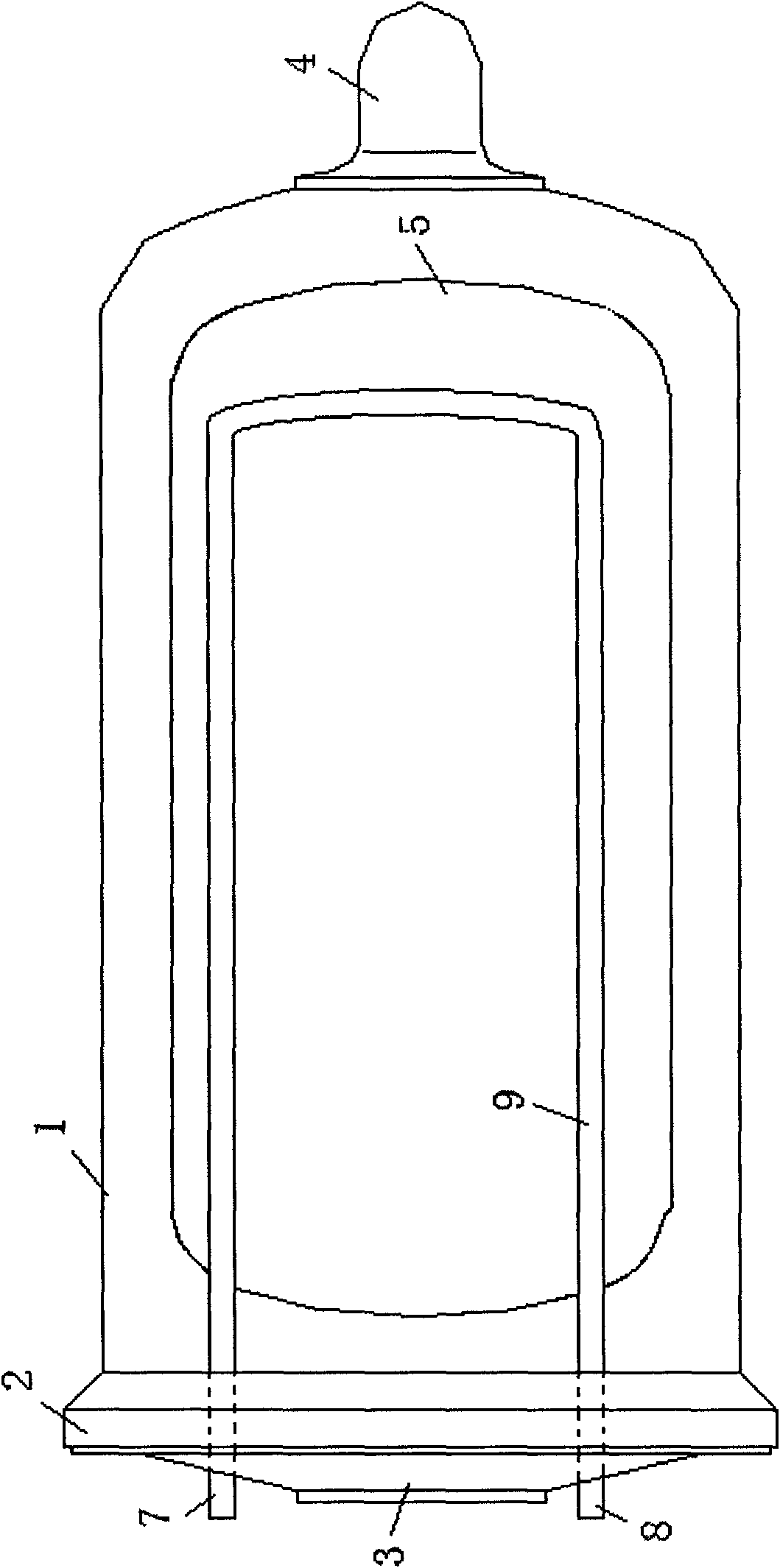

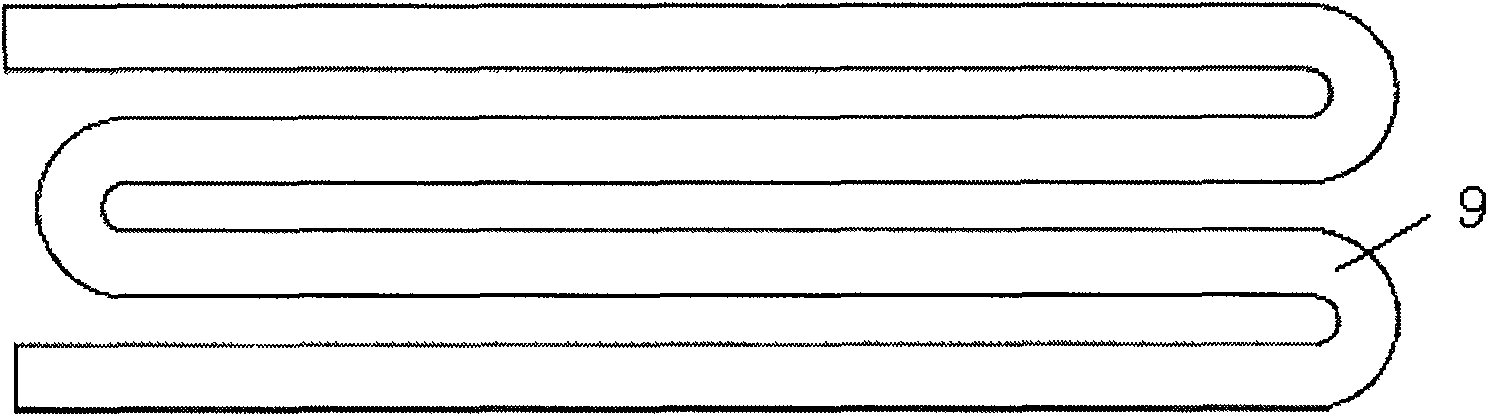

Solar-assisted heat storage device and solar-assisted water supply system comprising the same

InactiveUS20170159945A1Low costReduce productionSolar heating energyHeat storage plantsAir preheaterMolecular sieve

A solar-assisted heat storage device, including at least one molecular sieve heat storage bed and a heat storage water tank. The molecular sieve heat storage bed includes a cylindrical housing and a plurality of heat storage pipes disposed in the housing. The heat storage pipe includes metal pipes having meshes and an adsorbent layer adhered to the surface of the metal pipes. The adsorbent layer includes a molecular sieve adsorbent material adapted to match with water to form a working pair for heat exchange. Two ends of the housing are both configured with sealing valves and respectively connected to an air inlet and an air outlet of an air preheater. One end of the housing is configured with a water inlet connecting to a water outlet of the heat storage water tank, and the other end of the housing is configured with a water outlet.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

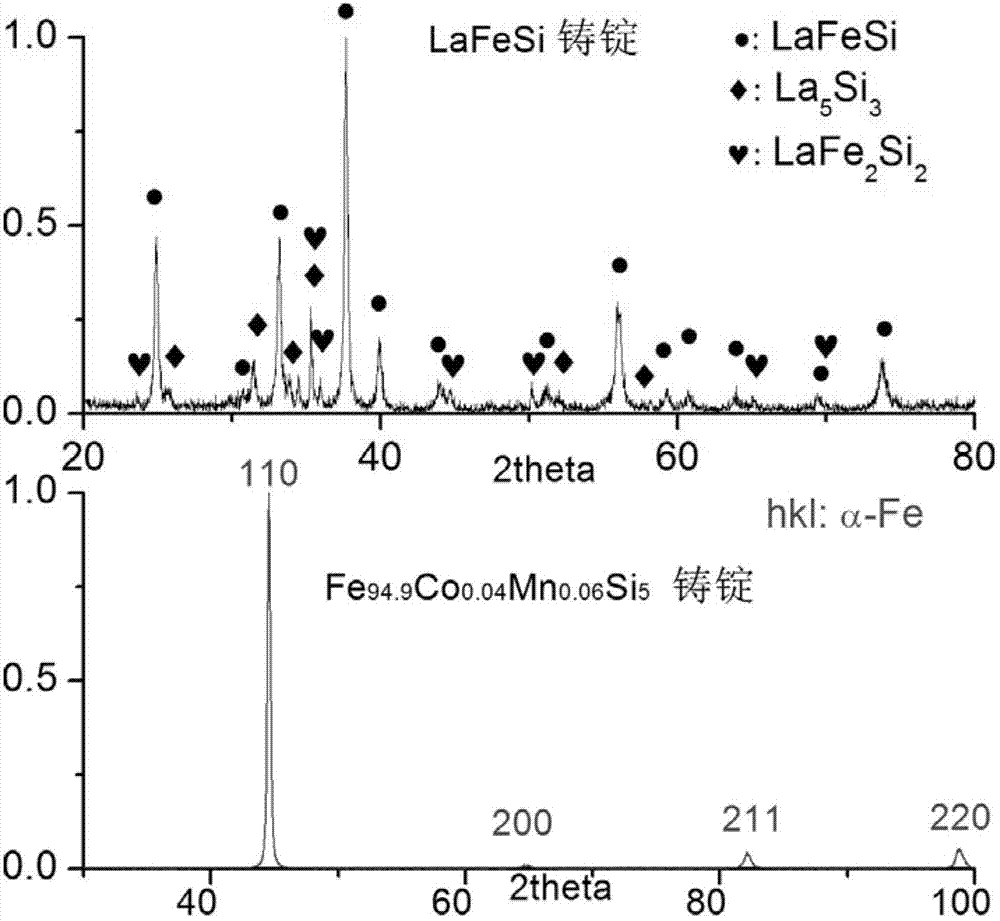

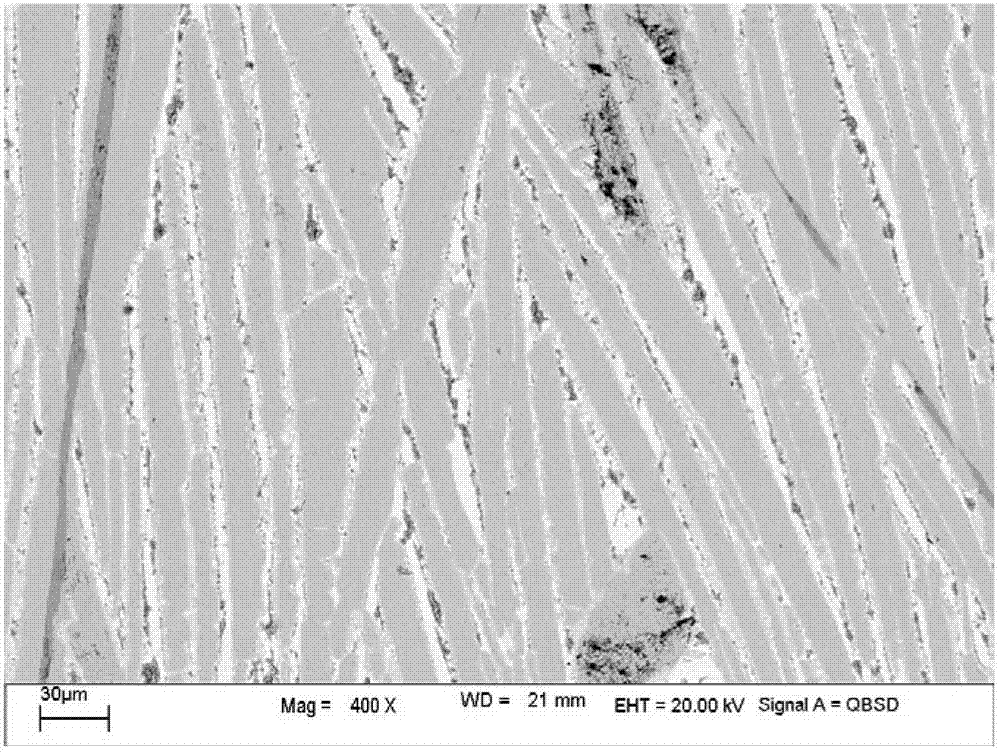

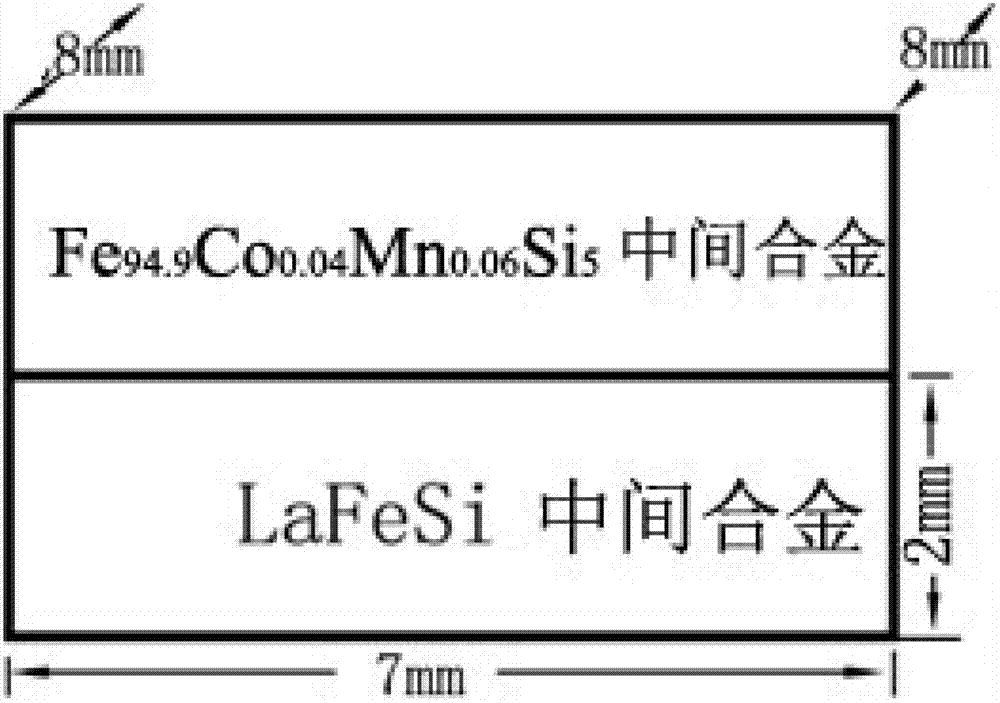

Method for preparing rare-earth compound with NaZn13 structure by solid state diffusion

Owner:UNIV OF SCI & TECH BEIJING

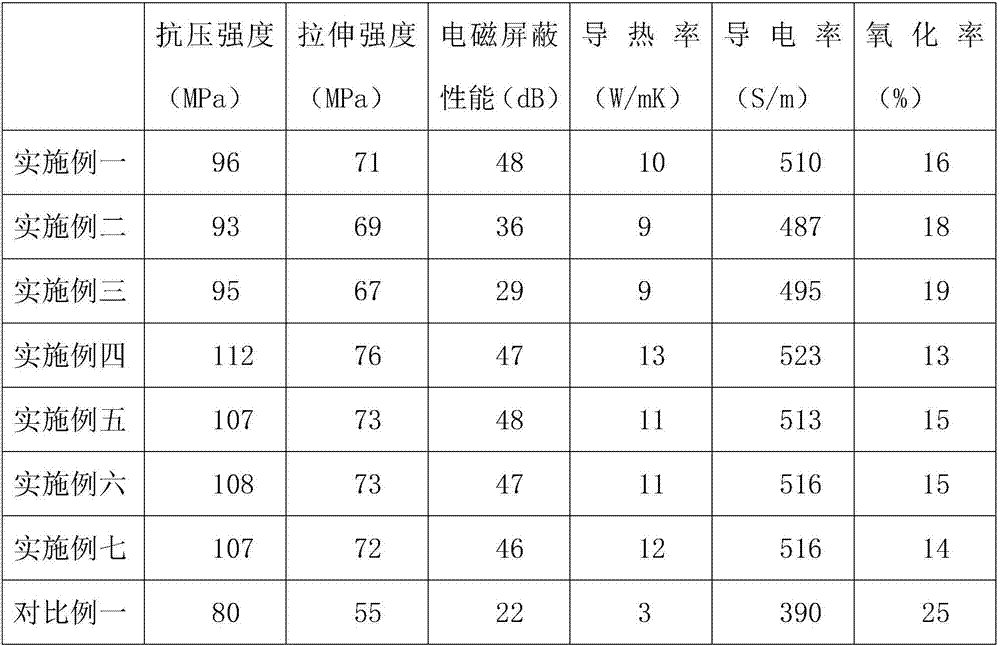

Preparation method of heat-conducting, electricity-conducting and electromagnetic-shielding multifunctional composite material

InactiveCN108003612AImprove electromagnetic shielding performanceImprove tensile propertiesHeat-exchange elementsElectricityHeat conducting

Owner:江西伟普科技有限公司

Lubricant for Low Global Warming Potential Refrigerant Systems

Owner:THE LUBRIZOL CORP

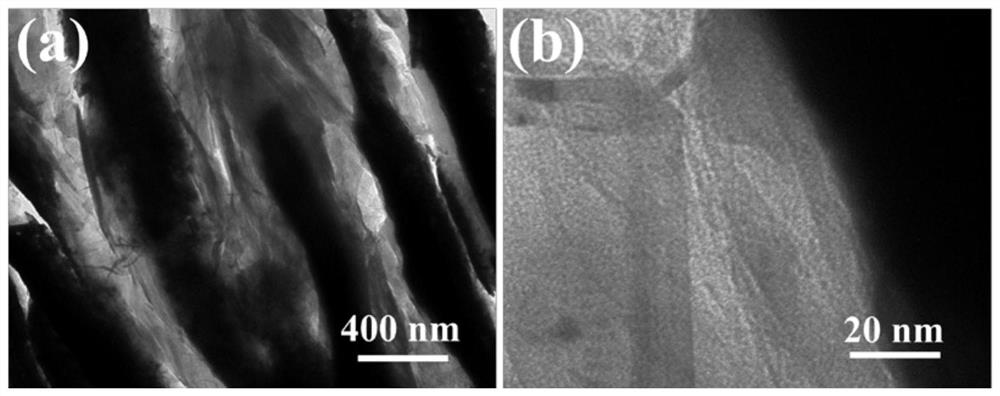

Nano-level ultra-high heat-conducting titanium-carbon composite material and preparation method thereof

InactiveCN101191050ASimple processReduce manufacturing costHeat-exchange elementsCarbon compositesTitanium

Owner:晟茂(青岛)先进材料有限公司

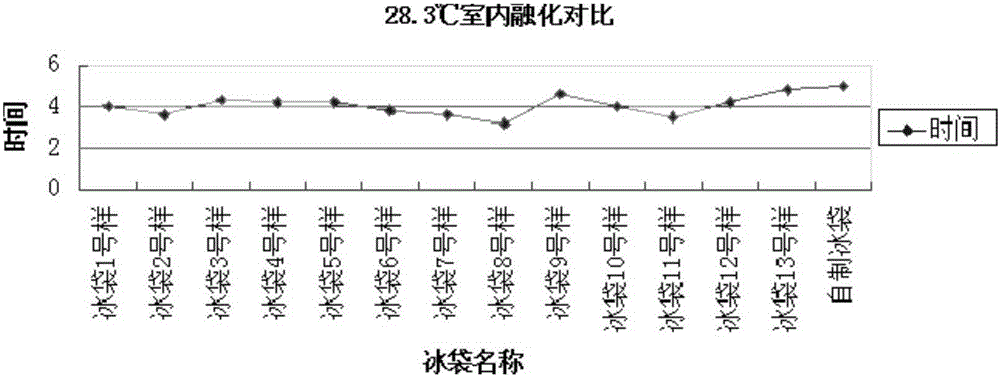

Refrigerating ice bag, refrigerant and preparation method of refrigerant

Owner:SHIYUE SHANGHAI BIOTECH CO LTD

Mixed molten salt type heat transfer and storage working medium and application thereof

InactiveCN105199678ALow cost of ingredientsSimple preparation processHeat-exchange elementsAdditive ingredientCoal

Owner:百吉瑞(天津)新能源有限公司

Composite phase change material for LED thermal interface and preparation method thereof

Owner:东莞市益飞迅光电科技有限公司

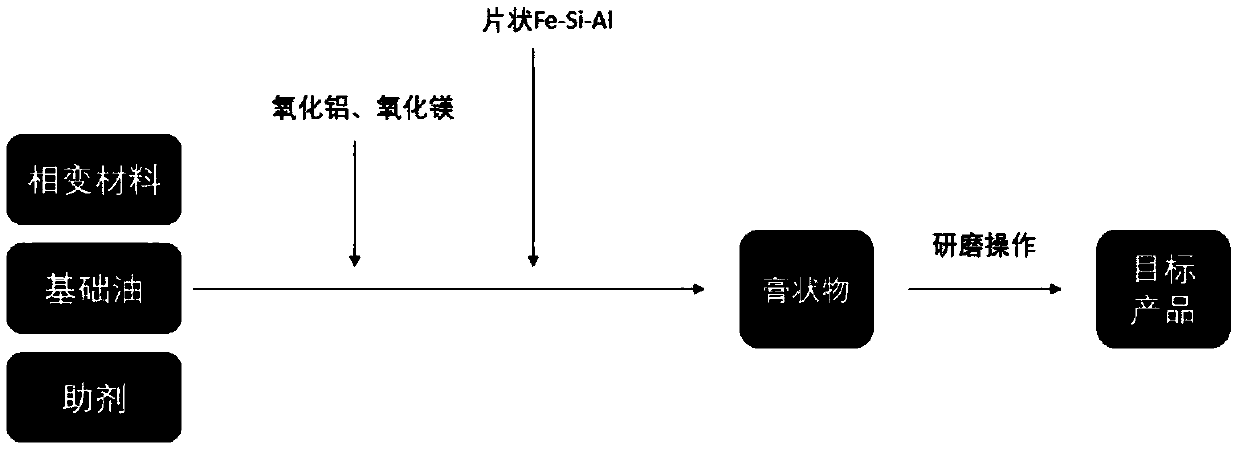

Paste-like phase-change wave-absorbing heat-conducting material and preparation method thereof

Owner:苏州铂韬新材料科技有限公司

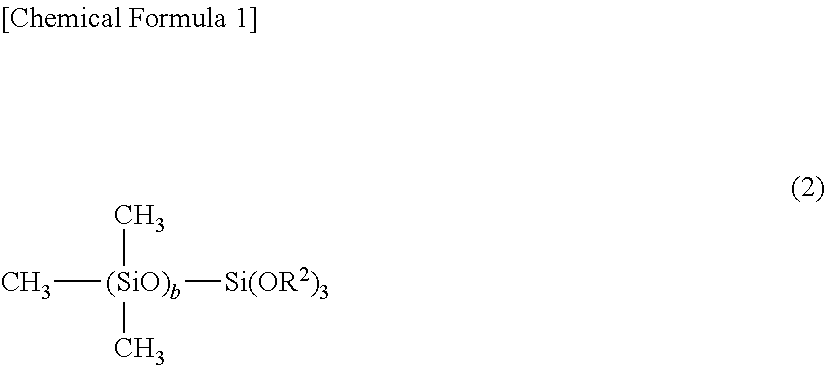

Thermally-conductive silicone gel composition, thermally-conductive member, and heat dissipation structure

ActiveUS20200239758A1Improve liquidityGood peeling effectSemiconductor/solid-state device detailsSecondary cellsPolymer sciencePtru catalyst

Owner:DOW TORAY CO LTD

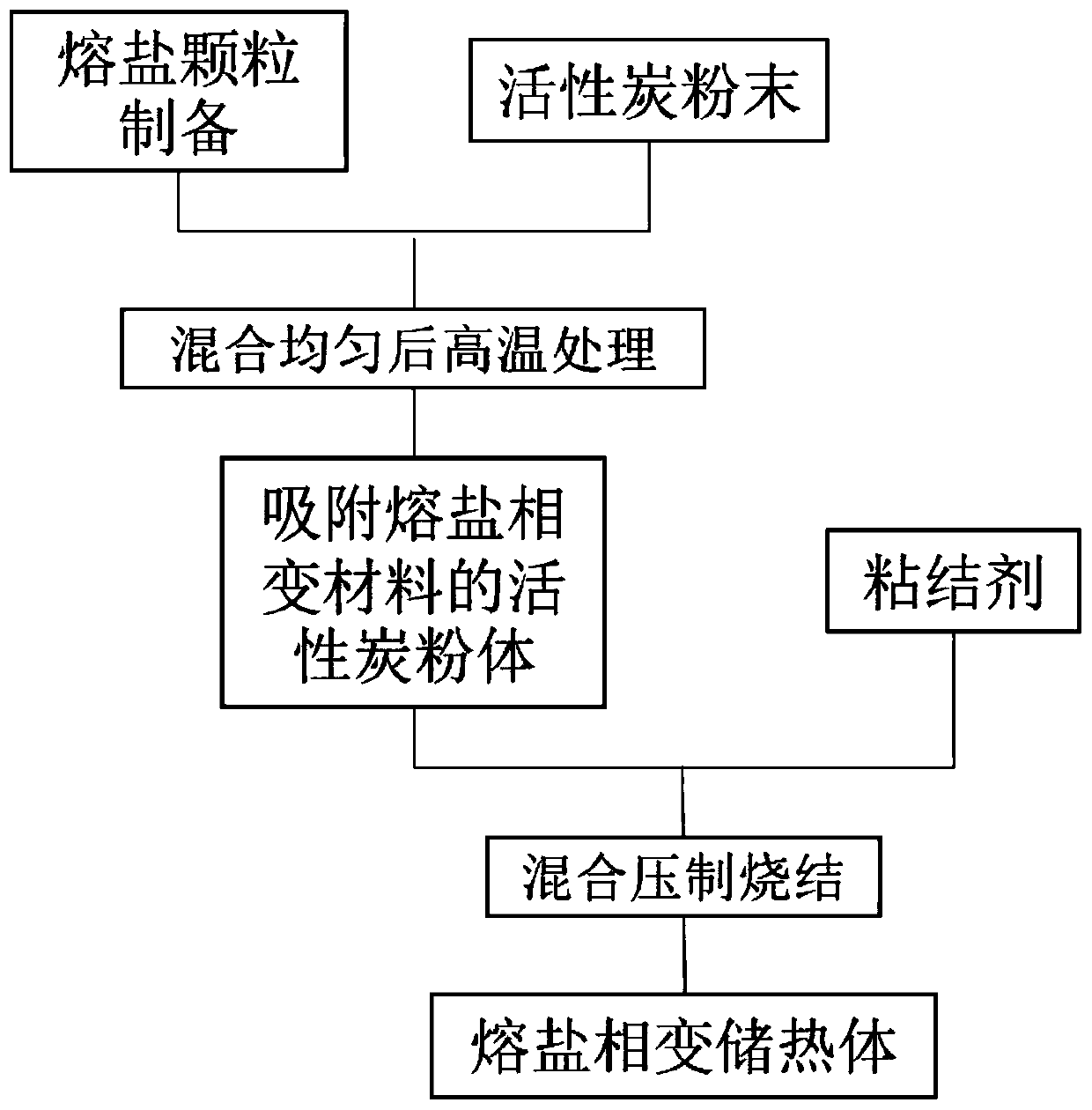

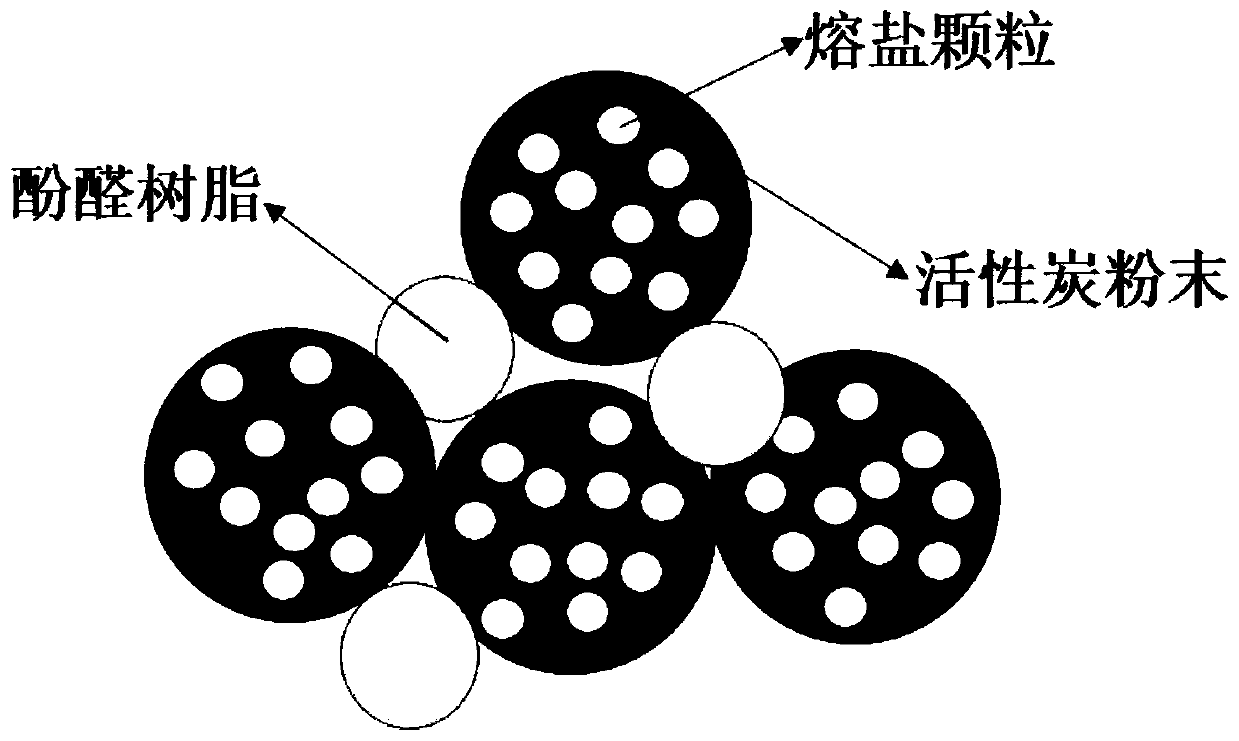

Method for preventing loss of molten salt phase-change heat storage material by utilizing activated carbon

InactiveCN111205827AHeat-exchange elementsGranular activated carbonMechanical properties of carbon nanotubes

Owner:UNIV OF SCI & TECH BEIJING

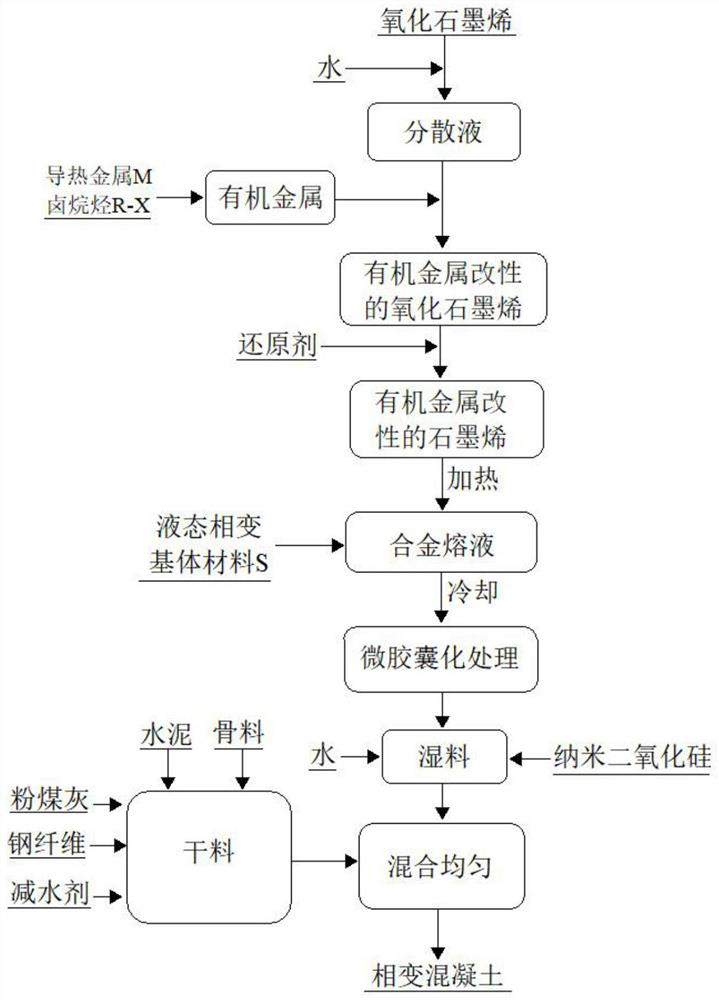

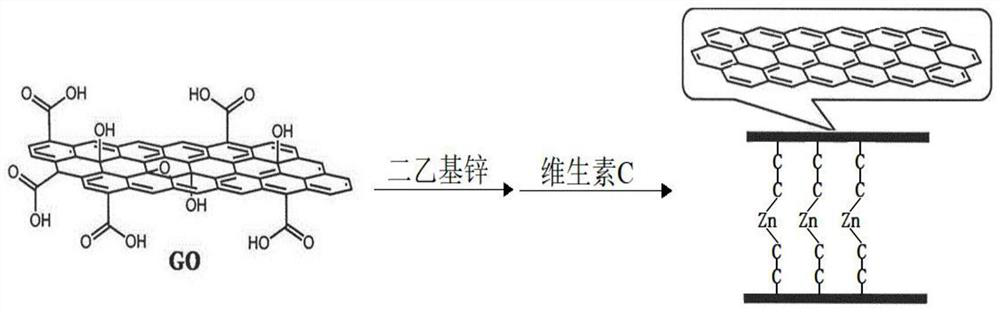

Phase change concrete and preparation method thereof

Owner:XIANGTAN UNIV

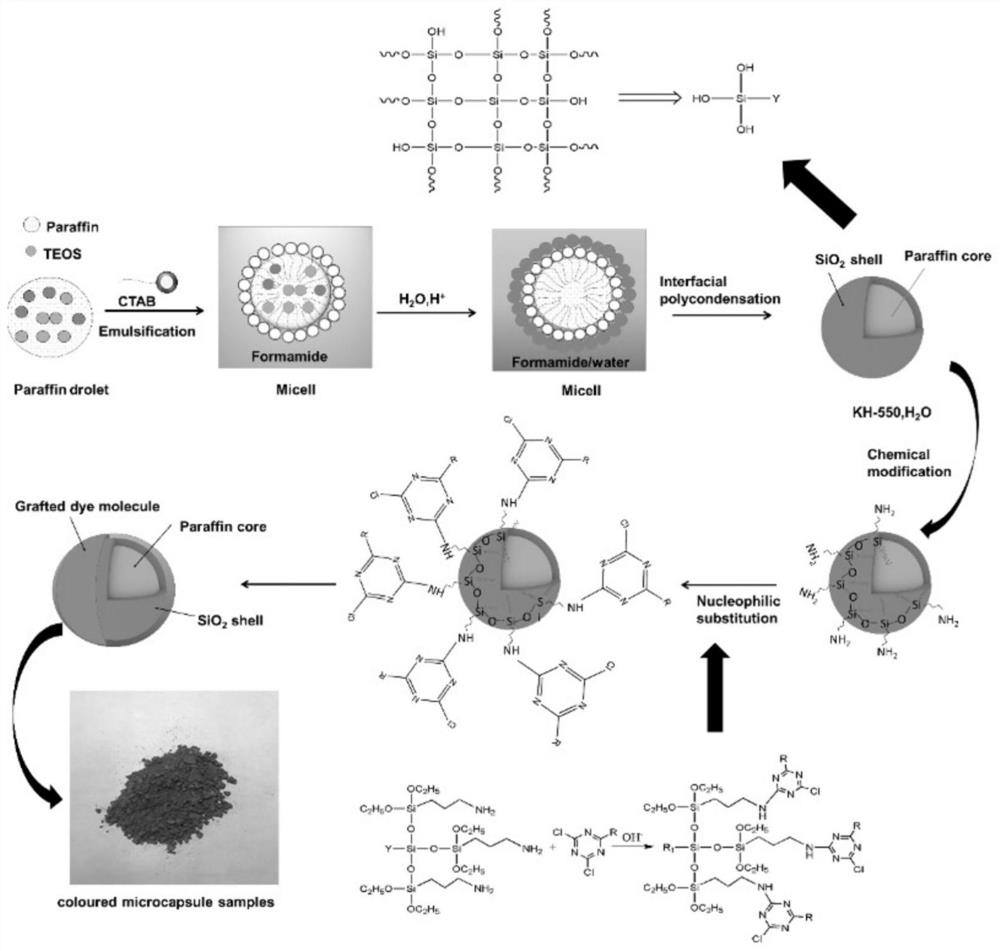

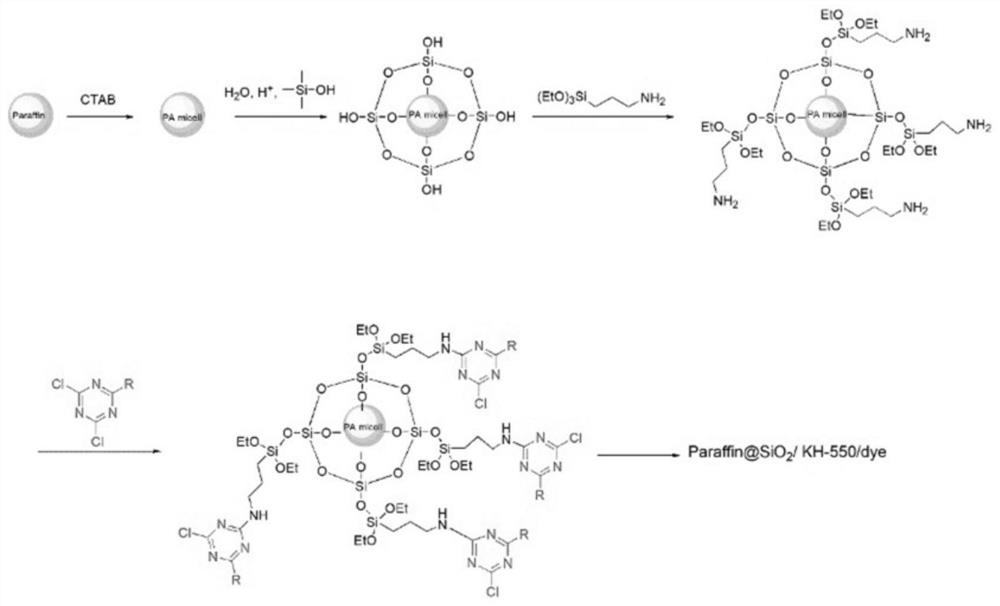

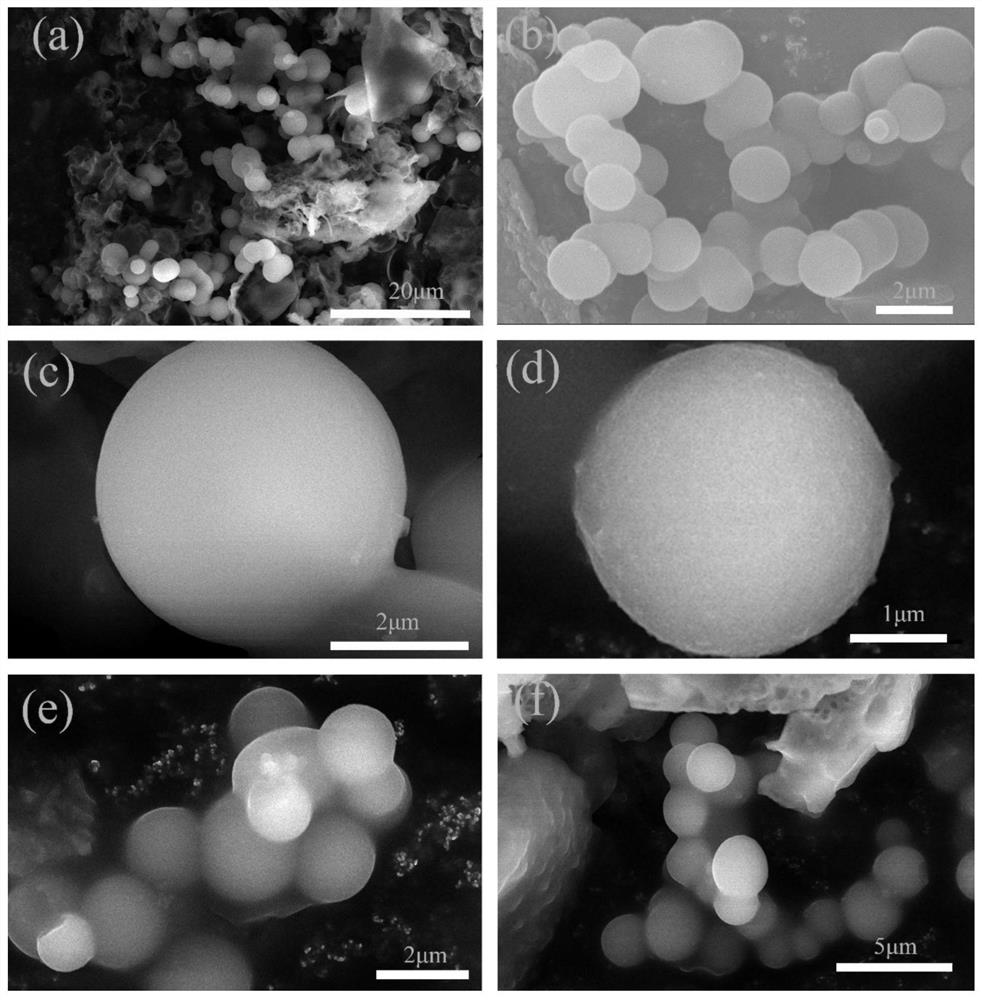

Paraffin coated SiO2 color phase change microcapsule as well as preparation method and application thereof

ActiveCN113429938AImproves UV protectionIncreased UV AbsorptionHeat-exchange elementsRadiation-absorbing paintsParaffin waxThermal insulation

Owner:XIAO HLDG

Ultrahigh-isotropy heat-conducting material of epoxy two-dimensional flaky metal nanofiller and preparation method of heat-conducting material

ActiveCN113416389AImprove thermal conductivityEfficient synergyHeat-exchange elementsLap jointResin matrix

The invention provides an ultrahigh-isotropy heat-conducting material of an epoxy two-dimensional flaky metal nanofiller and a preparation method of the heat-conducting material. The material mainly comprises the following components: epoxy resin, a two-dimensional sheet metal nanofiller, a two-dimensional sheet carbon series heat conduction filler and a diluent. The method comprises the following steps: uniformly mixing the components, removing the diluent, and preparing the heat-conducting material or a workpiece through a hot press molding process. The two kinds of two-dimensional sheet-shaped heat-conducting fillers are in lap joint in an epoxy resin matrix to form a three-dimensional heat-conducting network, efficient lap joint and efficient synergistic effect of the two-dimensional sheet-shaped metal nanofiller are achieved, the heat-conducting property of the obtained heat-conducting material or the workpiece is greatly improved, and the isotropic heat-conducting characteristic is achieved.

Owner:SICHUAN UNIV

Sized phase change material and preparation method thereof

InactiveCN105733512AMeet most of the needs of the applicationWide operating temperature rangeHeat-exchange elementsMolten statePhysical chemistry

Owner:WUHAN UNIV OF TECH

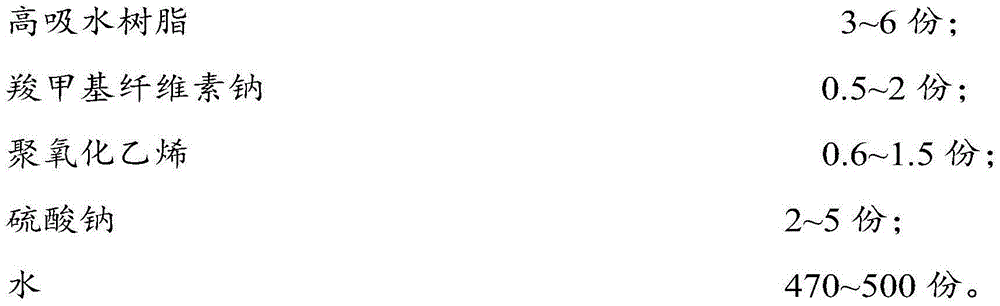

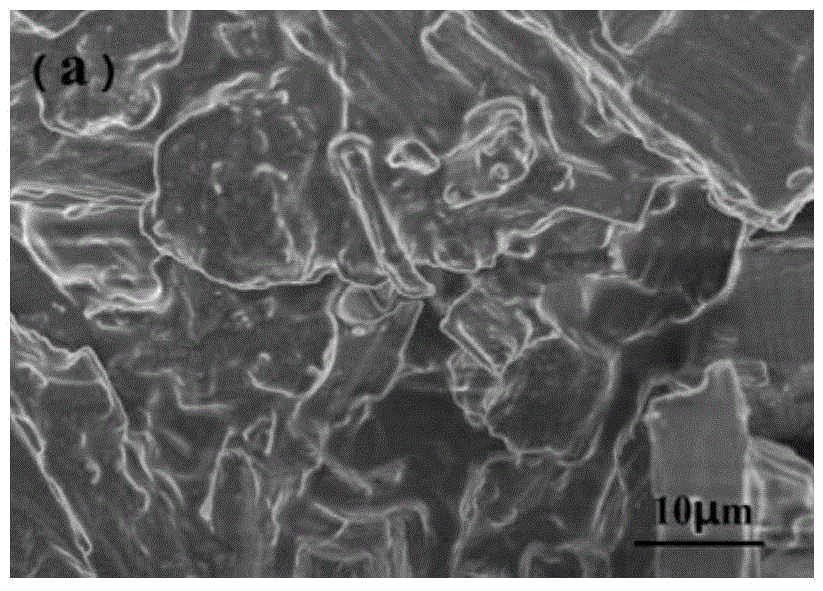

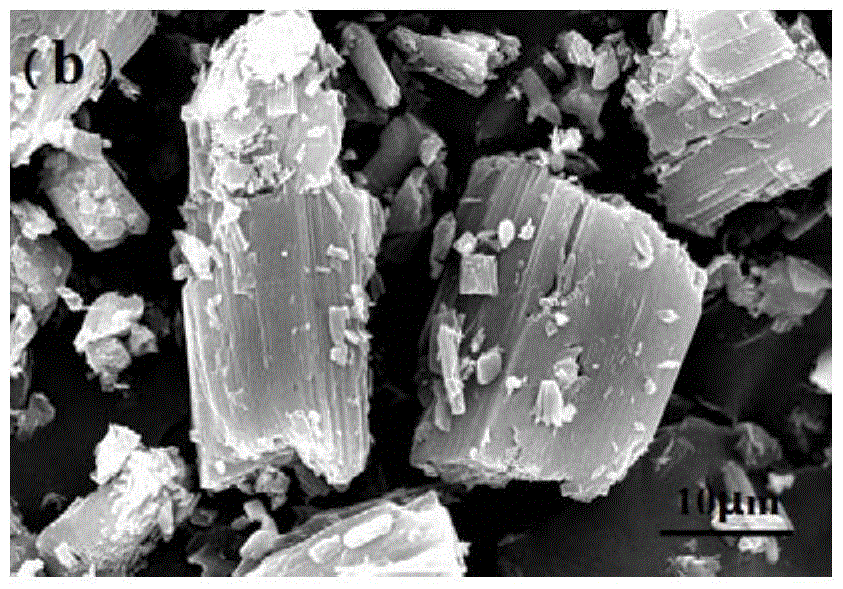

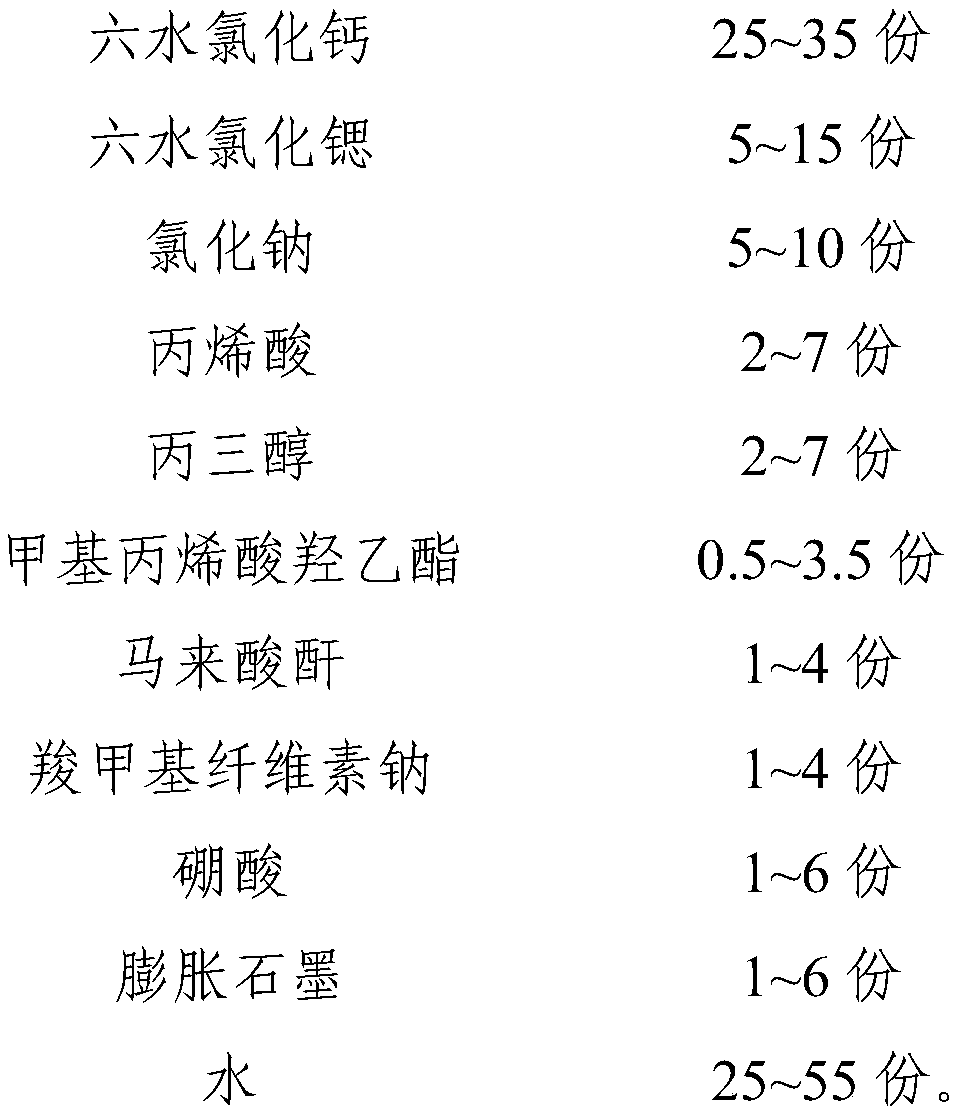

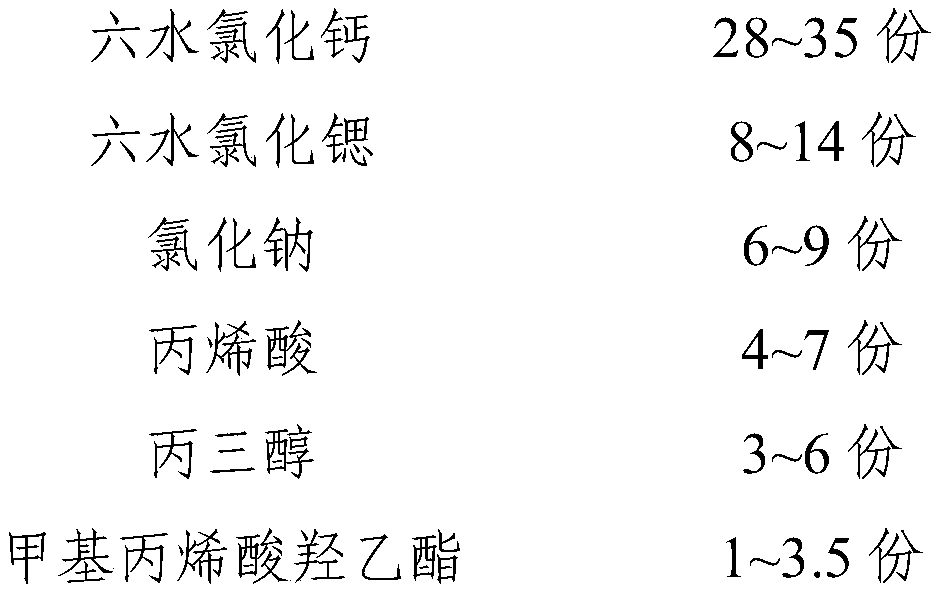

Inorganic phase-change constant-temperature material and preparation method thereof

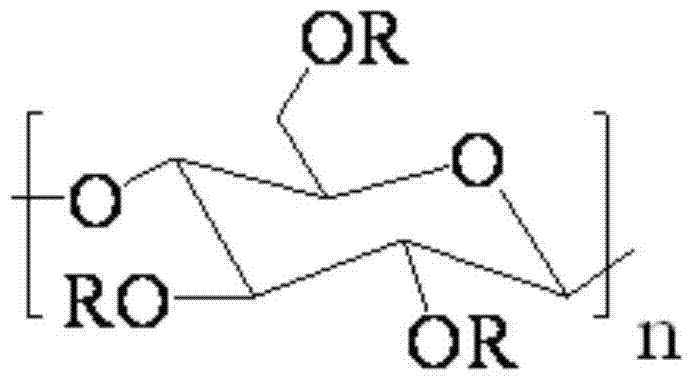

InactiveCN111117573APrevent leakageImprove performanceHeat-exchange elementsStrontium chloride hexahydrateCellulose

Owner:北京中海前沿材料技术有限公司

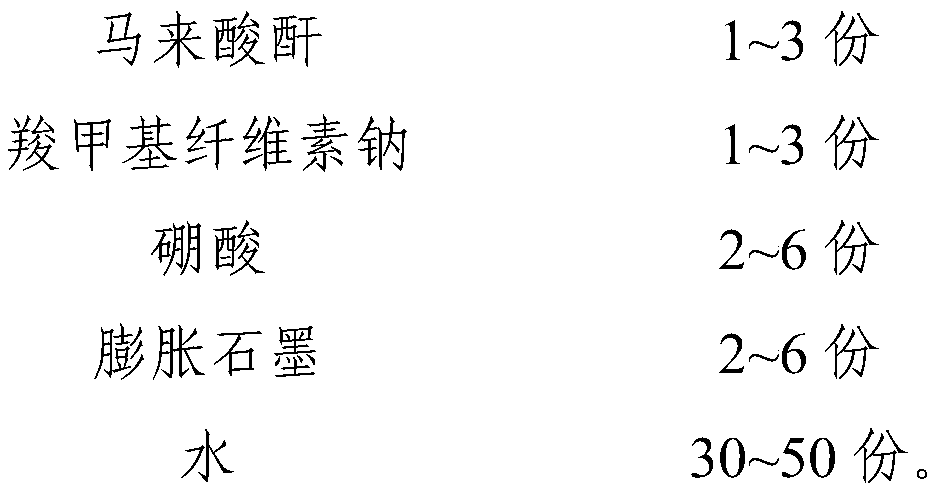

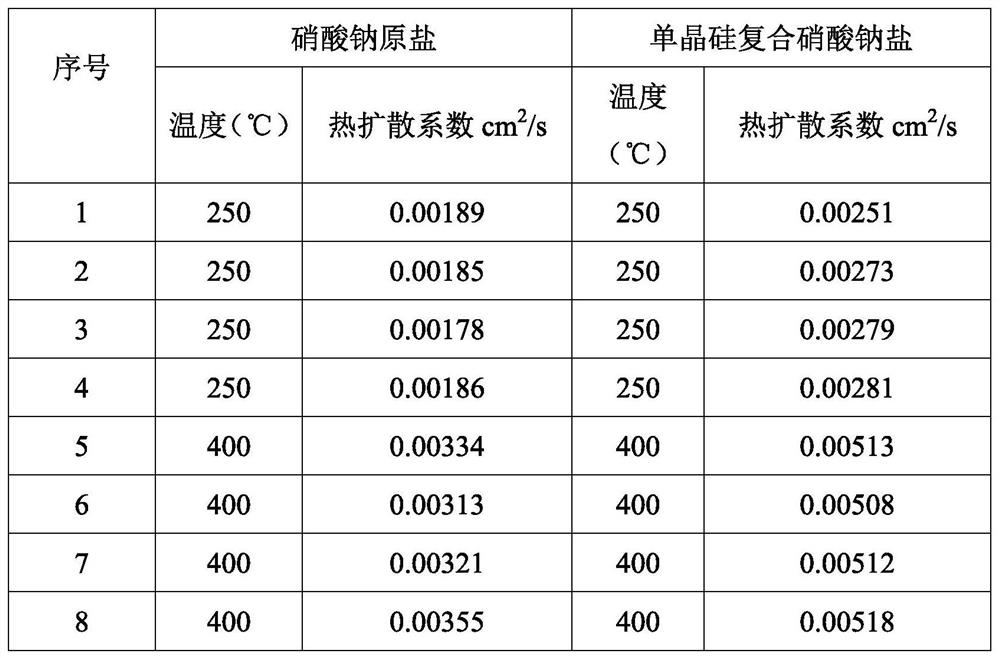

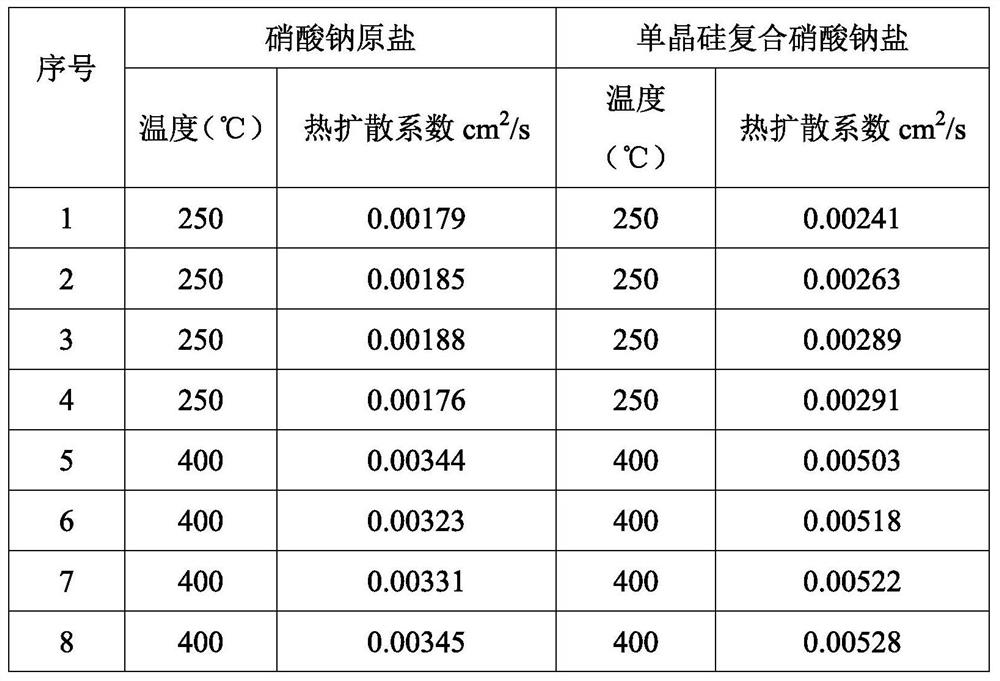

High-thermal-conductivity nitrate fused salt and preparation method thereof

Owner:宁晋县氢为新能源科技有限公司

Mixed refrigerant applicable to large-circulation temperature rise for medium-high temperature heat pump

ActiveCN102719225ALow ODPGood environmental characteristicsHeat-exchange elementsWater sourceEvaporation

The invention discloses a mixed refrigerant applicable to large-circulation temperature rise for a medium-high temperature heat pump. The mixed refrigerant comprises, by mass, 1-10% of HC1270, 2-96% of HFC134a and 3-97% of HCFC 142b. The refrigerant suitably serves as a refrigerant for a medium-high temperature heat pump system with circular temperature rise (temperature difference between evaporation and condensation) of 60-80 DEG C and the condensation temperature of 70-100 DEG C. The refrigerant is low in ozone depletion potential and greenhouse effect potential so as to meet environmental protection requirements, and is appropriate in thermal parameters and excellent in cycling performance, an HFC134a air condition compressor can be used for optimized design of a medium-high temperature heat pump unit in large-circulation temperature rise of the novel refrigerant, and the novel refrigerant can be directly applied to an original HFC134a air conditioning unit to convert the original air conditioning unit into the medium-high temperature heat pump unit in large-circulation temperature rise of the novel refrigerant. The unit can directly use normal-temperature water sources and ground sources at the temperature of about 10-40 DEG C and can provide hot water at the temperature of about 70-100 DEG C for users.

Owner:JIANGSU PROVINCE XINPUSENQICAI NEW ENERGY CO LTD

High-heat delivery device

Owner:DSM IP ASSETS BV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap