High-thermal-conductivity nitrate fused salt and preparation method thereof

A nitrate, high thermal conductivity technology, applied in the field of molten salt, can solve the problem of using crystalline silicon powder waste in molten salt system, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

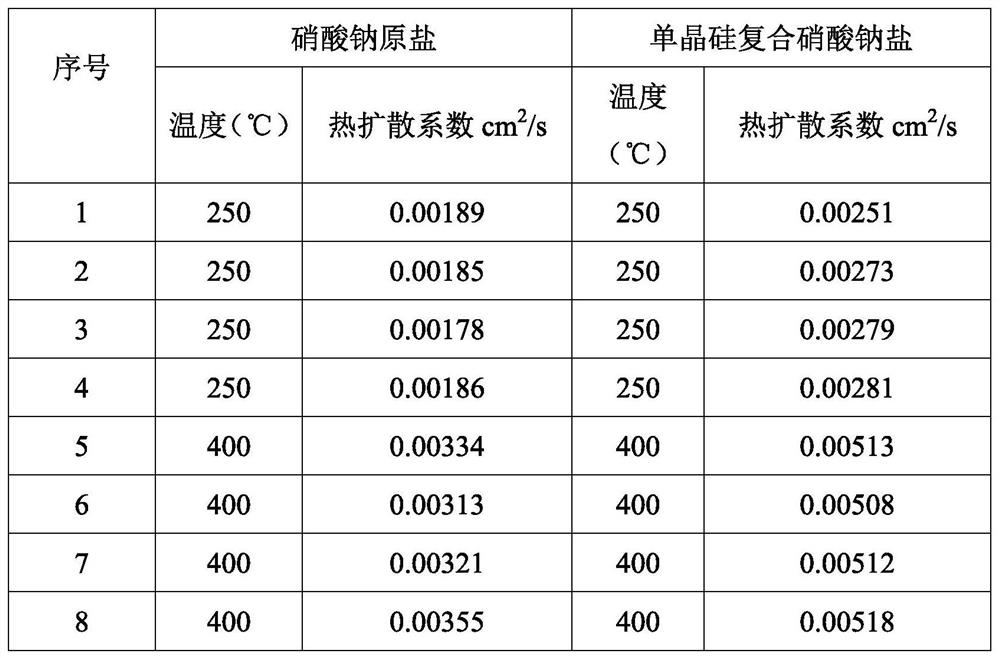

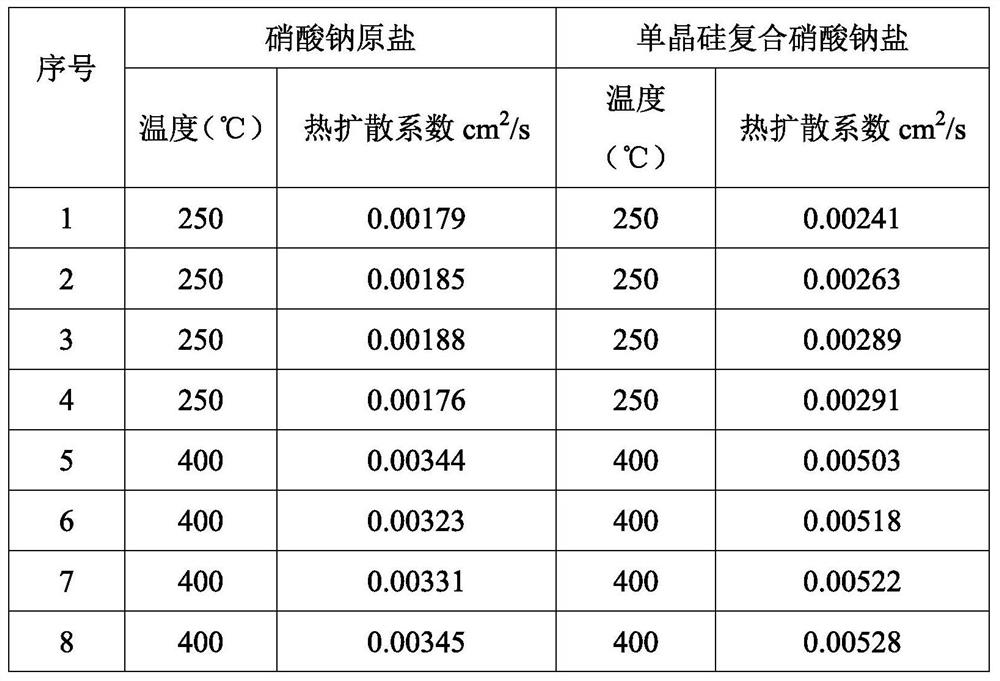

Embodiment 1

[0047] The high thermal conductivity nitrate molten salt provided in this embodiment is mainly composed of single crystal silicon and nitrate molten salt, wherein the mass percentage of single crystal silicon is 45%, and the rest is nitrate molten salt.

[0048] In this embodiment, the single crystal silicon comes from the crystalline silicon waste with a size of micrometers and above and no more than centimeters generated during the cutting process of single crystal silicon.

[0049] Monocrystalline silicon contains small amounts of conventional organic compounds and metal impurities generated during the preparation of crystalline silicon.

[0050] The nitrate molten salt is sodium nitrate.

[0051] The preparation process is as follows:

[0052] (1) Collect the single crystal silicon scraps produced by the crystalline silicon cutting process;

[0053] (2) At about 80°C, denaturation baking is performed on the contamination of organic matter (mainly the components of the wire

Embodiment 2

[0059] The high thermal conductivity nitrate molten salt provided in this embodiment is mainly composed of monocrystalline silicon and nitrate molten salt, wherein the mass percentage of monocrystalline silicon is 20%, and the rest is nitrate molten salt.

[0060] In this embodiment, the crystalline silicon powder is single-crystal silicon powder, which comes from crystalline silicon wastes of micron level and below produced during the cutting process of single-crystal silicon.

[0061] Monocrystalline silicon contains small amounts of conventional organic compounds and metal impurities generated during the preparation of crystalline silicon.

[0062] The nitrate molten salt is potassium nitrate and sodium nitrite.

[0063] Its preparation process is as follows:

[0064] (1) Collect the micron-level and below powder produced by the single crystal silicon cutting process;

[0065] (2) denaturation and baking of organic matter (main component of cutting fluid) contamination by hi

Embodiment 3

[0071] The high thermal conductivity nitrate molten salt provided in this embodiment is mainly composed of single crystal silicon and nitrate molten salt, wherein the mass percentage of single crystal silicon is 10%, and the rest is nitrate molten salt.

[0072] In this embodiment, the single crystal silicon comes from the single crystal silicon scraps of micron level and below produced in the single crystal silicon cutting process.

[0073] The monocrystalline silicon scraps contain a small amount of conventional organic matter and metal impurities generated during the preparation of monocrystalline silicon.

[0074] The nitrate molten salt is sodium nitrate.

[0075] The preparation process is as follows:

[0076] (1) Collect the scraps generated during the crystalline silicon cutting process;

[0077] (2) denaturation and baking of organic matter (main component of cutting fluid) contamination by high temperature (not lower than 80°C);

[0078] (3) use hydrochloric acid (ma

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap