Preparation method for composite polymer film with high thermal conductivity

A composite polymer and polymer thin film technology, applied in the field of thermally conductive materials, can solve the problems of low thermal conductivity of polymer nanocomposites, inability to meet ultra-high density heat dissipation requirements, high contact thermal resistance, etc., and achieve low production cost and thermal conductivity. High conductivity, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

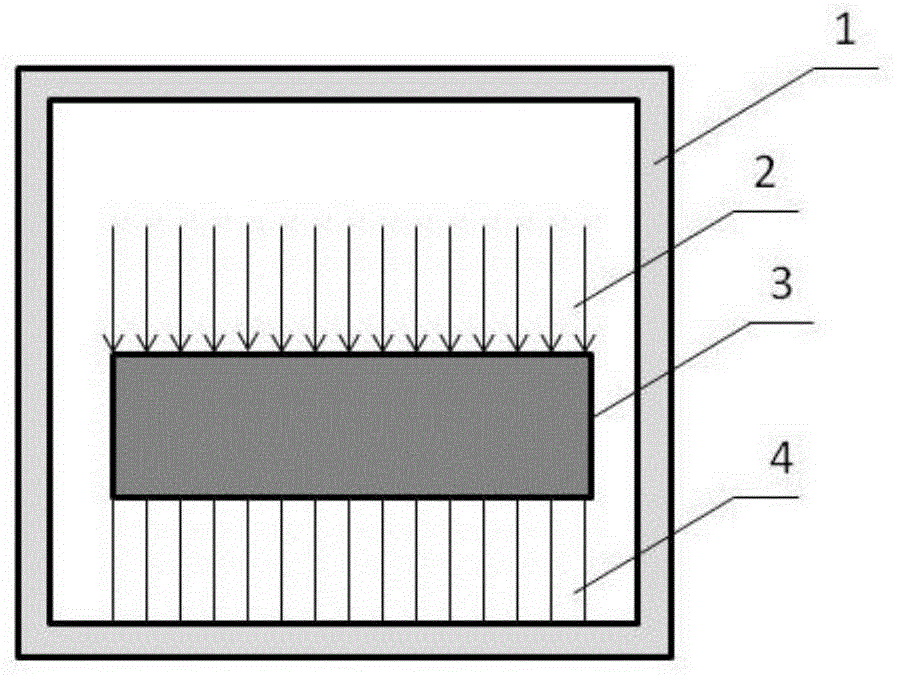

[0022] With reference to accompanying drawing, a kind of preparation method of high thermal conductivity composite polyethylene film comprises the following steps:

[0023] 1) Mix high thermal conductivity particles and polymer particles at a mass ratio of 1:10, and use an injection molding process to obtain the first polymer film 3 containing high thermal conductivity particles or fibers, the high thermal conductivity particles are Ag particles, and the polymer particles are polyethylene PE;

[0024] 2) Place the first polymer film 3 prepared in step 1) on the porous template 4, then put the porous template 4 into the vacuum heating box 1, and the vacuum heating box 1 keeps 130 0 constant temperature;

[0025] 3) After the first polymer film 3 is melted, the porous template 4 is filled under the joint action of capillary force and the external pressure provided by the pressurizing device 2 to form a second polymer film;

[0026] 4) After 30 minutes, the obtained porous templat

Embodiment 2

[0032] With reference to accompanying drawing, a kind of preparation method of high thermal conductivity composite polyethylene film comprises the following steps:

[0033] 1) Mix high thermal conductivity fibers and polymer particles in a ratio of 1:5, and use a compression molding process to obtain the first polymer film 3 containing high thermal conductivity particles or fibers, the high thermal conductivity fibers are carbon fibers, and the polymer particles are polyethylene PE;

[0034] 2) Place the first polymer film 3 prepared in step 1) on the porous template 4, then put the porous template 4 into the vacuum heating box 1, and keep the vacuum heating box 1 at a constant temperature of 150°C;

[0035] 3) After the first polymer film 3 is melted, the porous template 4 is filled under the joint action of capillary force and the external pressure provided by the pressurizing device 2 to form a second polymer film;

[0036] 4) After 60 minutes, the obtained porous template 4 c

Embodiment 3

[0042] With reference to accompanying drawing, a kind of preparation method of high thermal conductivity composite polypropylene film comprises the following steps:

[0043] 1) Mix high thermal conductivity fibers and polymer particles in a mass ratio of 1:1, and use an injection molding process to obtain the first polymer film 3 containing high thermal conductivity particles or fibers. The high thermal conductivity fibers are AIN whiskers, and the polymer particles are Polypropylene PP;

[0044] 2) Place the first polymer film 3 prepared in step 1) on the porous template 4, then put the porous template 4 into the vacuum heating box 1, and keep the vacuum heating box 1 at a constant temperature of 180°C;

[0045] 3) After the first polymer film 3 is melted, the porous template 4 is filled under the joint action of capillary force and the external pressure provided by the pressurizing device 2 to form a second polymer film;

[0046] 4) After 90 minutes, the obtained porous templa

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap