Ternary fatty acid/modified expanded vermiculite composite phase-change energy storage material

A technology of expanded vermiculite and composite phase change, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low phase change latent heat, low thermal conductivity, etc., and achieve low phase change enthalpy, increase ratio Effects of surface area and adsorption rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

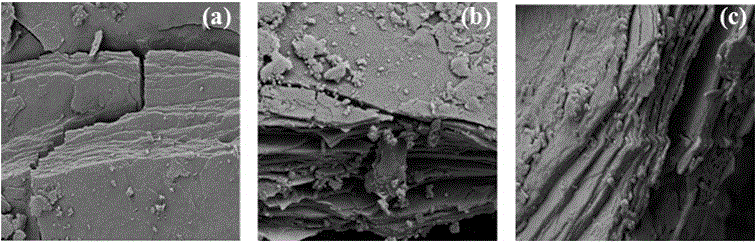

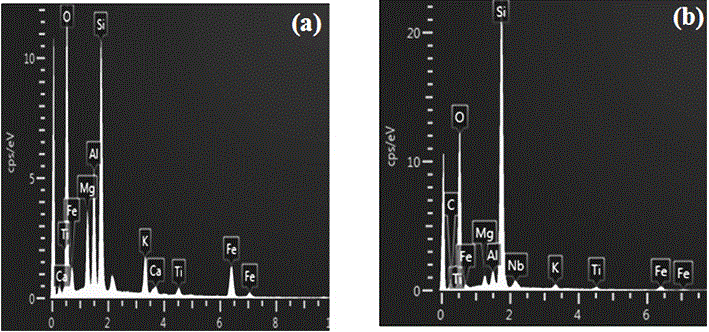

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix capric acid, lauric acid, and myristic acid evenly in a weight ratio of 55.1:30.4:14.5, put it in a constant temperature water bath at 45°C, heat and stir for 30 minutes, and take it out to cool to room temperature after ultrasonication for 5 minutes; use differential scanning The phase transition temperature of capric acid / lauric acid / myristic acid ternary eutectic mixture measured by calorimetry is 16.43℃, and the latent heat of phase transition is 153.4J / g;

[0028] (2) Weigh 30g of expanded vermiculite and add it to 600g of distilled water, place it in a 60°C constant temperature water bath and stir vigorously for 40min, then add 105g of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 1%, 70 Stir at constant temperature at ℃ for 2 hours, then keep warm in a water bath at 80℃ for 12h, stand at room temperature for 12h, then dry at 70℃ for 24h, then raise the temperature to 600℃ at a rate of 3℃ / min in a reducing atmosphere, and keep

Embodiment 2

[0031] (1) Mix capric acid, myristic acid, and stearic acid evenly in a weight ratio of 72.5:22.5:5.0, heat and stir in a constant temperature water bath at 70°C for 30 minutes, take it out and cool it to room temperature after ultrasonication for 5 minutes; The phase transition temperature of capric acid / myristic acid / stearic acid ternary eutectic mixture was determined by thermal method to be 24.02°C, and the latent heat of phase transition was 156.3J / g.

[0032](2) Weigh 30g of expanded vermiculite and add it to 600g of distilled water, place it in a constant temperature water bath at 70°C and stir vigorously for 60min, then add 105g of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 5%, 60 Stir at constant temperature at ℃ for 4 hours, keep warm in a water bath at 85°C for 10 hours, let stand at room temperature for 15 hours, then dry at 80°C for 48 hours, then raise the temperature to 700°C at a rate of 1°C / min under a reducing atmosphere, and

Embodiment 3

[0035] (1) Mix myristic acid, palmitic acid, and stearic acid evenly in a weight ratio of 51.3:33.2:15.5, put them in a constant temperature water bath at 65°C, heat and stir for 30 minutes, and take them out to cool to room temperature after ultrasonication for 5 minutes; The phase transition temperature of myristic acid / palmitic acid / stearic acid ternary eutectic mixture was determined by scanning calorimetry to be 39.62°C, and the latent heat of phase transition was 177.5J / g.

[0036] (2) Weigh 30g of expanded vermiculite and add it to 600g of distilled water, place it in a constant temperature water bath at 80°C and stir vigorously for 20min, then add 105g of cetyltrimethylammonium bromide aqueous solution with a mass fraction of 10%, 80 Stir at a constant temperature of ℃ for 2 hours, keep warm in a water bath at 90 ℃ for 8 hours, let stand at room temperature for 10 hours, then dry at 70 ℃ for 72 hours, then raise the temperature to 800 ℃ at a rate of 5 ℃ / min under a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap