Thermal storage type vacuum tube

A vacuum tube, heat storage technology, applied in heat storage equipment, energy storage, heating devices, etc., can solve problems such as water temperature rise, box 5 corrosion, high temperature and high pressure, etc., to prolong service life and increase heat exchange. area, and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

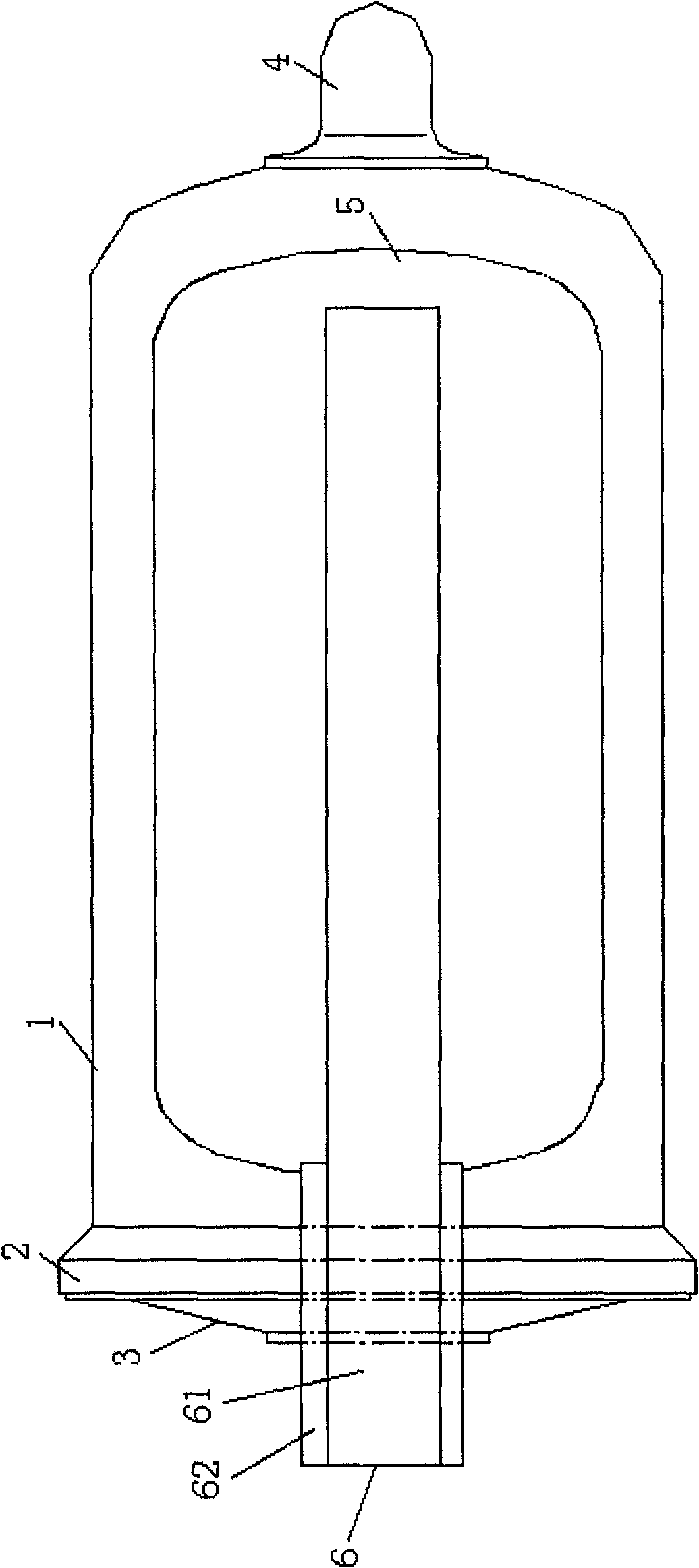

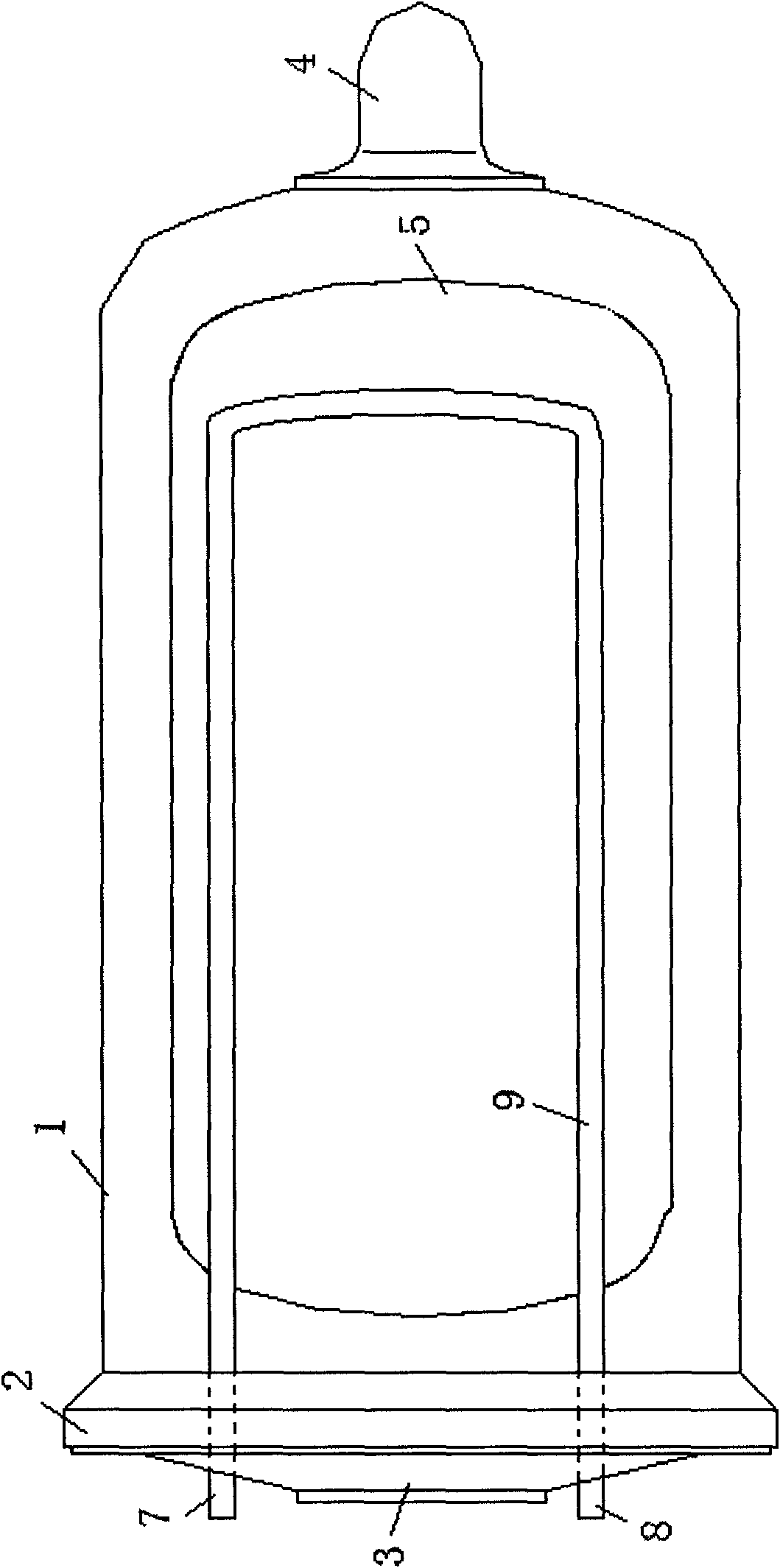

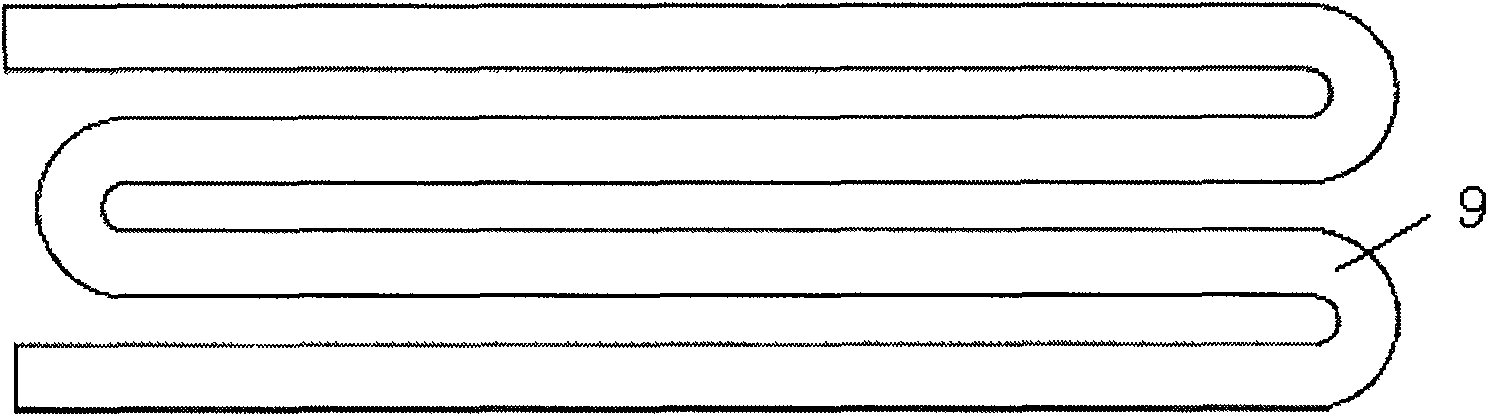

[0016] Such as figure 2 As shown, the present invention includes the same glass shell 1, glass flange 2, metal end cap 3, exhaust nozzle protective cap 4 and metal material box body 5 as the prior art, and is characterized in that the metal end cap 3 is respectively provided with a The water inlet 7 is connected to a water outlet 8 , and the water inlet 7 and the water outlet 8 are connected through a heat exchange tube 9 arranged in the box body 5 . At the same time, the working medium in the box body 5 is a solid-liquid phase change material with a phase change temperature in the range of 60°C to 80°C.

[0017] When the present invention is in use, solar energy is absorbed through the solar selective coating on the outer surface of the box body 5, and the phase change material in the box body 5 is heated. Due to the characteristics of the phase chan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap