Small expended and vitrified ball heat accumulation and heat conduction material and preparation method thereof

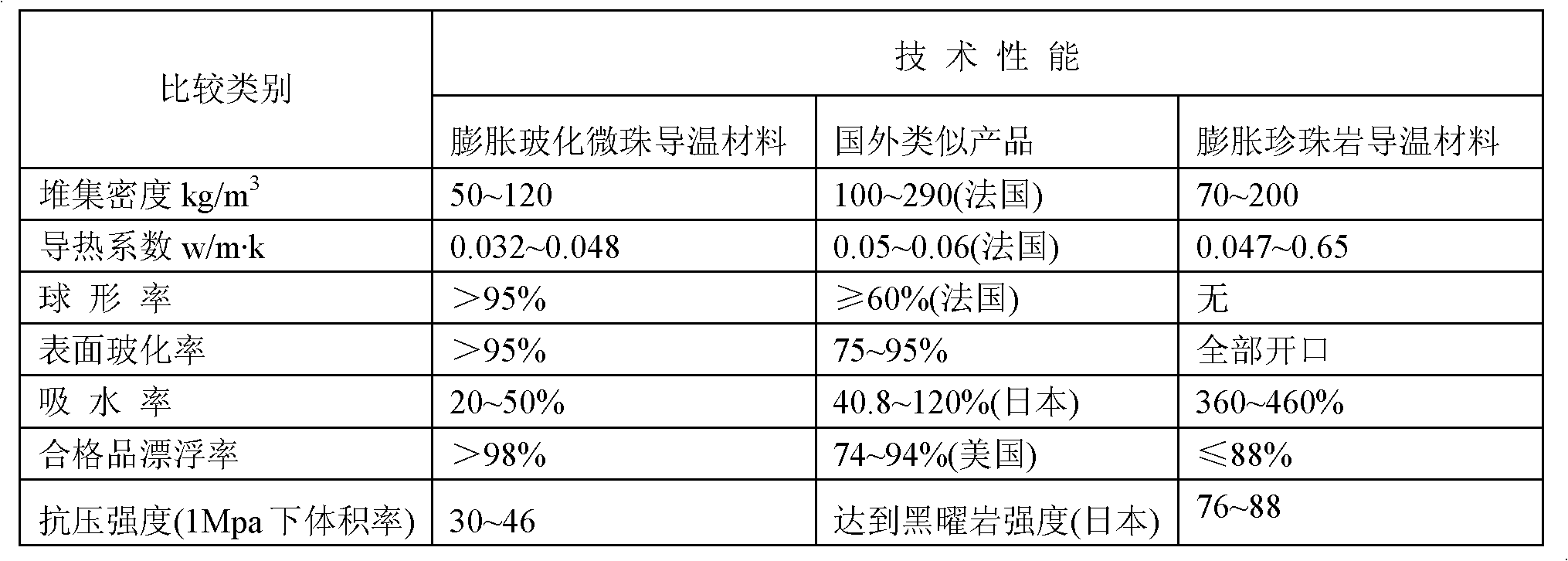

A technology of expanded vitrified microbeads and heat storage, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of complex preparation methods and processes, short-term thermal insulation effect, and small heat storage coefficient, and achieves physical and chemical properties. Stability, good workability and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: In this embodiment, the expanded vitrified microbead heat storage and heat conduction material is composed of 20% to 40% of expanded vitrified microbeads, 10% to 20% of wood fibers, and 5% to 15% of Getter, 10% to 20% antifungal agent, 5% to 15% ultraviolet fiber, 5% to 15% temperature regulator and 5% to 15% solar absorber; The bead is a kind of non-metallic mineral inorganic light heat-insulating particles with internal porous and spherical shape extracted from the mineralization of turpentine lava, with a particle density of 40-250kg / m 3 .

[0016] The expanded vitrified microbeads in this embodiment are expanded from acidic glass to lava mineralized turpentine through crushing, screening, and high-temperature instantaneous roasting after mining, and the main chemical composition is SiO 2 、Al 2 o 3 , CaO, etc.

[0017] The expanded vitrified microbeads, wood fibers, getters, fungicides, ultraviolet fibers, temperature regulators and solar

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the heat storage and heat conduction material of the expanded vitrified microbeads is composed of 24% to 36% of the expanded vitrified microspheres and 12% to 18% of the wood Fiber, 8%~12% getter, 12%~18% antifungal agent, 8%~12% ultraviolet fiber, 8%~12% temperature regulator and 8%~12% solar absorber production. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the thermal storage and heat conduction material of the expanded vitrified microbeads is composed of 28% to 32% of the expanded vitrified microbeads and 14% to 16% of the wood Fiber, 9%~11% getter, 14%~16% antifungal agent, 9%~11% ultraviolet fiber, 9%~11% temperature regulator and 9%~11% solar absorber become. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap