Preparation method of heat-conducting, electricity-conducting and electromagnetic-shielding multifunctional composite material

A composite material and electromagnetic shielding technology, which is applied in the field of preparation of multifunctional composite materials, can solve the problems of composite materials such as poor tensile strength and compressive strength, high production cost, and general electromagnetic shielding effect, and achieve strong tensile strength Stretch and compressive capacity, improve thermal and electrical conductivity, improve the effect of electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

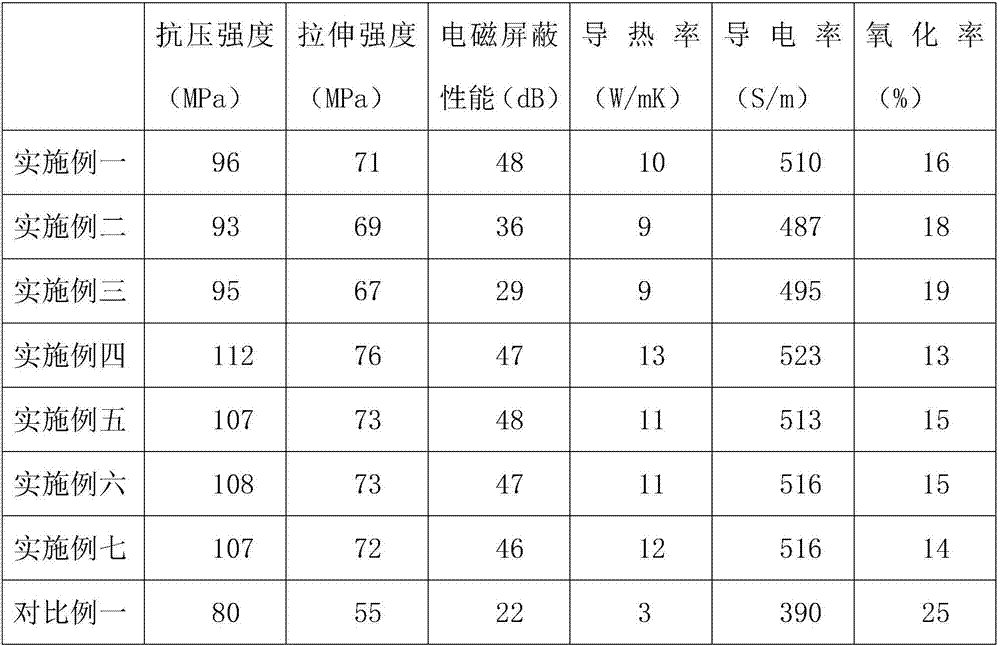

Examples

Embodiment 1

[0025] Provide a kind of preparation method of the multi-functional composite material with thermal conduction and electric conduction electromagnetic shielding among the embodiment one, adopt the following steps according to each component of parts by weight:

[0026] S1: Add 38 parts of copper powder, 22 parts of nano-silicon carbide, 17 parts of carbon black, 20 parts of nano-ferrite base and 30 parts of graphene into a high-speed mixer for high-speed stirring. Dry in an inert gas oven for 2 hours;

[0027] S2: Add the above-mentioned dried materials, 6 parts of zinc chloride whiskers, 14 parts of nano-metallic nickel and polymer materials into a high-speed mixer for high-speed stirring, and then put them into an oven filled with inert gas to dry for 1 hour;

[0028] The polymer material includes: 22 parts of nylon-66, 13 parts of poly-4-methyl-1-pentene and 7 parts of polyvinylidene chloride;

[0029] S3: Add the material obtained in S2 into a high-speed co-rotating intermes

Embodiment 2

[0031] Embodiment 2 provides a kind of preparation method of the multifunctional composite material with heat conduction and conduction electromagnetic shielding, each component adopts the following steps by weight:

[0032] S1: Add 30 parts of copper powder, 18 parts of nano-silicon carbide, 15 parts of carbon black, 16 parts of nano-ferrite base and 28 parts of graphene into a high-speed mixer for high-speed stirring, mix the materials evenly and put Dry in an oven filled with inert gas for 1 hour;

[0033] S2: Add the above-mentioned dried materials, 4 parts of zinc chloride whiskers, 10 parts of nano-metallic nickel and polymer materials into a high-speed mixer for high-speed stirring, and then put them into an oven filled with inert gas to dry for 1 hour;

[0034] The polymer material includes: 18 parts of nylon-66, 10 parts of poly-4-methyl-1-pentene and 5 parts of polyvinylidene chloride;

[0035] S3: Add the material obtained in S2 to a high-speed co-rotating intermeshin

Embodiment 3

[0037] Embodiment 3 provides a kind of preparation method of the multifunctional composite material with heat conduction and conduction electromagnetic shielding, each component adopts the following steps by weight:

[0038] S1: Add 45 parts of copper powder, 24 parts of nano-silicon carbide, 19 parts of carbon black, 23 parts of nano-ferrite base and 34 parts of graphene into a high-speed mixer for high-speed stirring. Dry in an inert gas oven for 3 hours;

[0039] S2: Add the above-mentioned dried materials, 8 parts of zinc chloride whiskers, 18 parts of nano-metallic nickel and polymer materials into a high-speed mixer for high-speed stirring, and then put them into an oven filled with inert gas to dry for 1 hour;

[0040] The polymer material includes: 26 parts of nylon-66, 16 parts of poly-4-methyl-1-pentene and 8 parts of polyvinylidene chloride;

[0041] S3: Add the material obtained in S2 to a high-speed co-rotating intermeshing twin-screw extruder for extrusion granulat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap