High-speed laser dot-shaped heat treatment device

A heat treatment device and laser spot technology, applied in metal material coating process, coating and other directions, can solve the problems of tempering softening and easy occurrence of micro-cracks in the overlapping area, and achieve high cooling speed, fast heating speed, and application fields. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

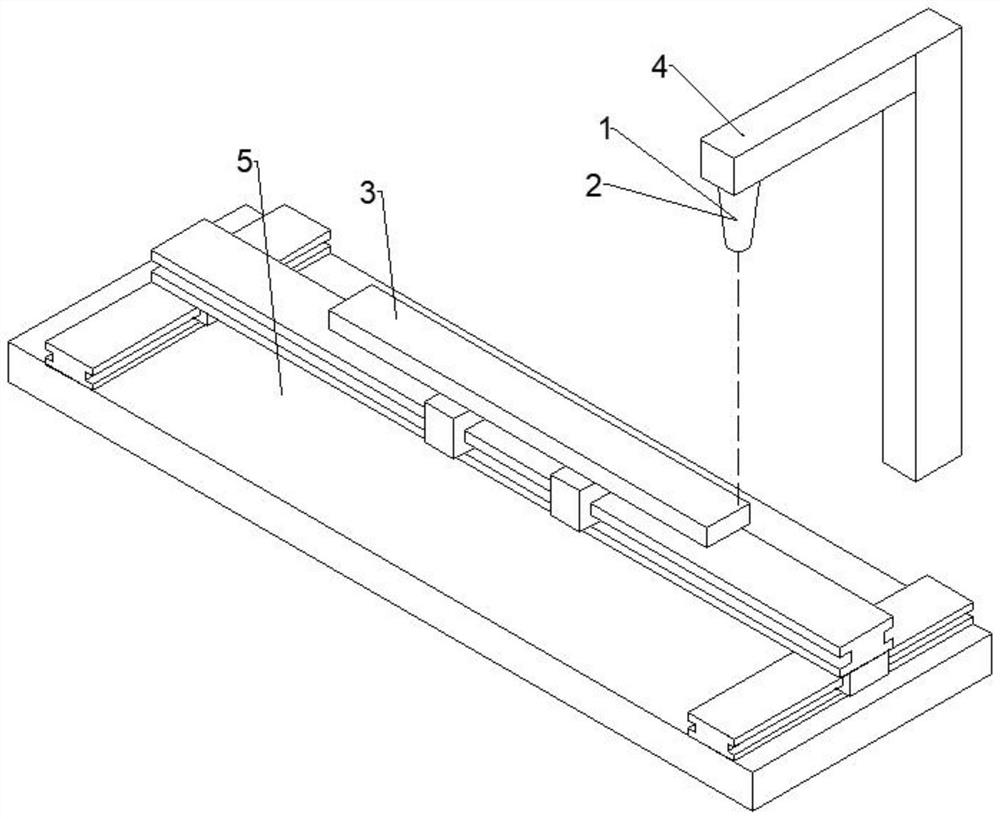

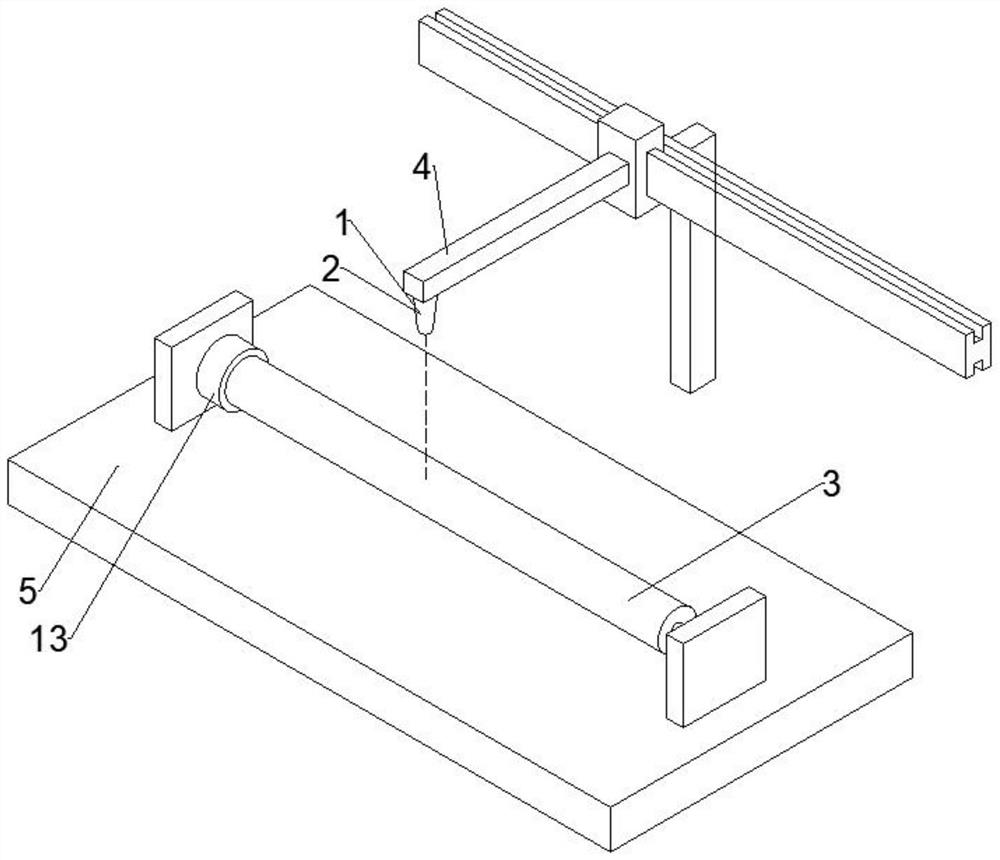

[0034] Such as Figure 1-Figure 2 , Figure 6-Figure 10 Shown:

[0035]The invention provides a high-speed laser spot heat treatment device, including a pulse laser, the pulse laser is used for surface heat treatment of workpieces, the output laser pulse width is less than 0.1 second, and the pulse duty ratio of the pulse laser is 10%- 80% variable; focusing system, located on the exit side of the pulse laser, for focusing the laser light emitted by the pulse laser; mounting base, for installing the pulse laser and the focusing system; workbench, for The workpiece is fixed, and the movement of the workpiece is controlled. Since the laser pulse width used is less than 0.1 second, the laser pulse width is very narrow, so the laser heating process on the material surface is very fast, and the heat-affected zone generated during the heat treatment process is also very small. After the pulse passes, the heated area of the material is passed through the cooling process. The coolin

Embodiment 2

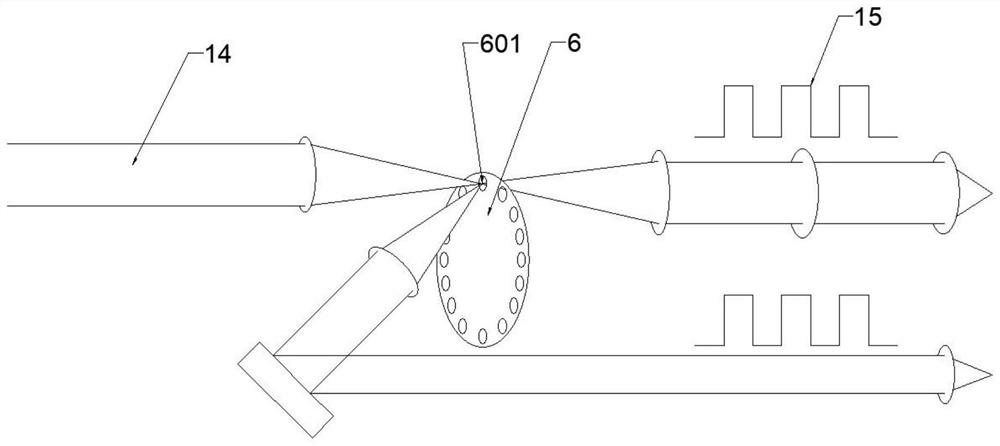

[0047] Such as Figure 3-Figure 5 Shown:

[0048] The difference between this embodiment and Embodiment 1 is that instead of directly using a pulsed laser, a continuous laser modulated by an external mechanical switch is used to cooperate with a focusing head to convert the continuous laser 14 into a pulsed laser 15, and the other parts are the same as in Embodiment 1. , which will not be repeated here;

[0049] The present invention provides a high-speed laser spot heat treatment device, including a continuous laser modulated by an external mechanical switch for surface heat treatment of the workpiece 3, and the continuous laser modulated by an external mechanical switch outputs a high-speed laser with a laser pulse width less than 0.1 second, And irradiated on the workpiece 3, and the pulse duty ratio is variable from 10% to 50%; the focusing head is located at the exit side of the continuous laser modulated by an external mechanical switch, and is used to focus the emitted la

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap