Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Load-engaging elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

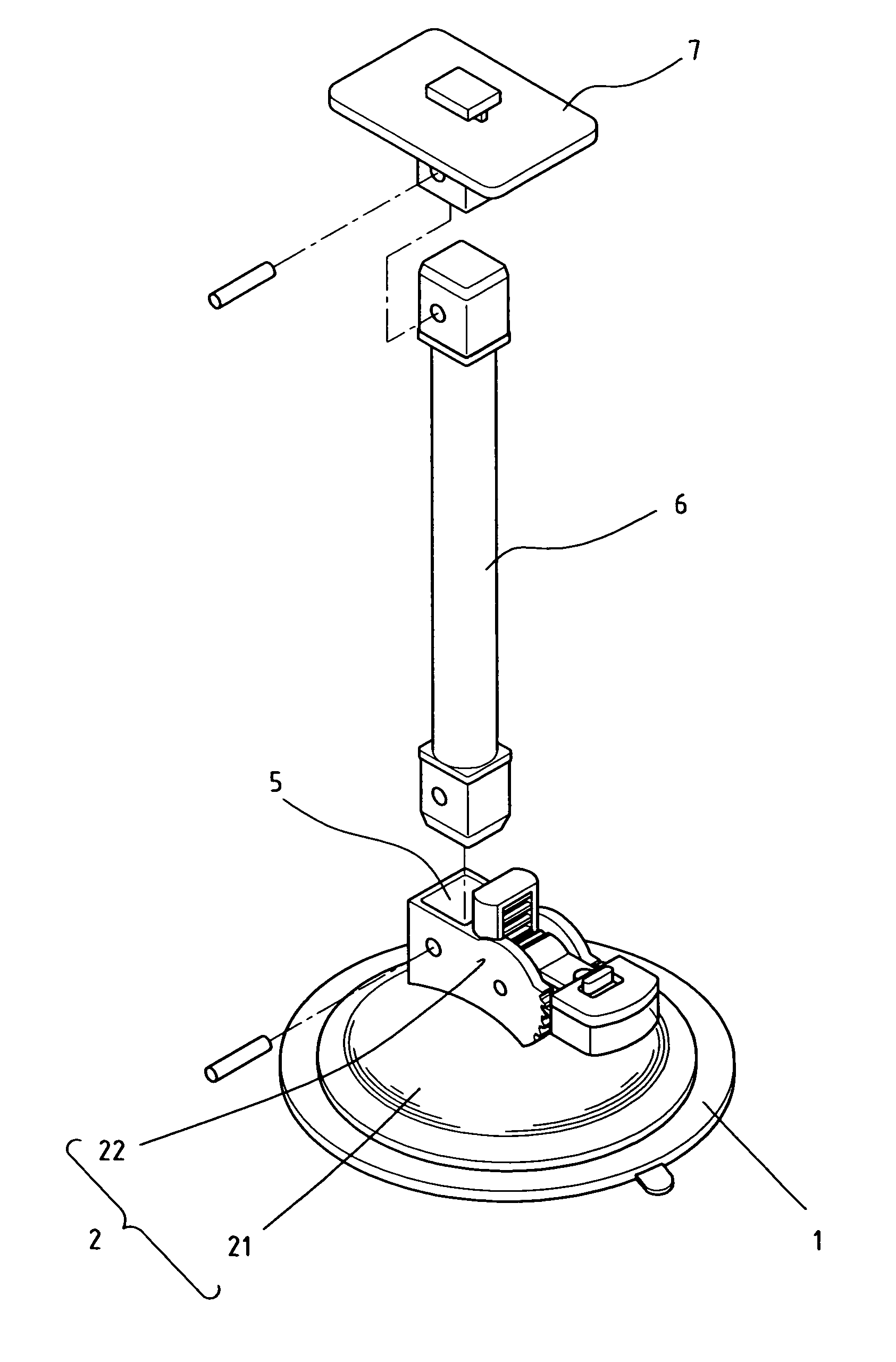

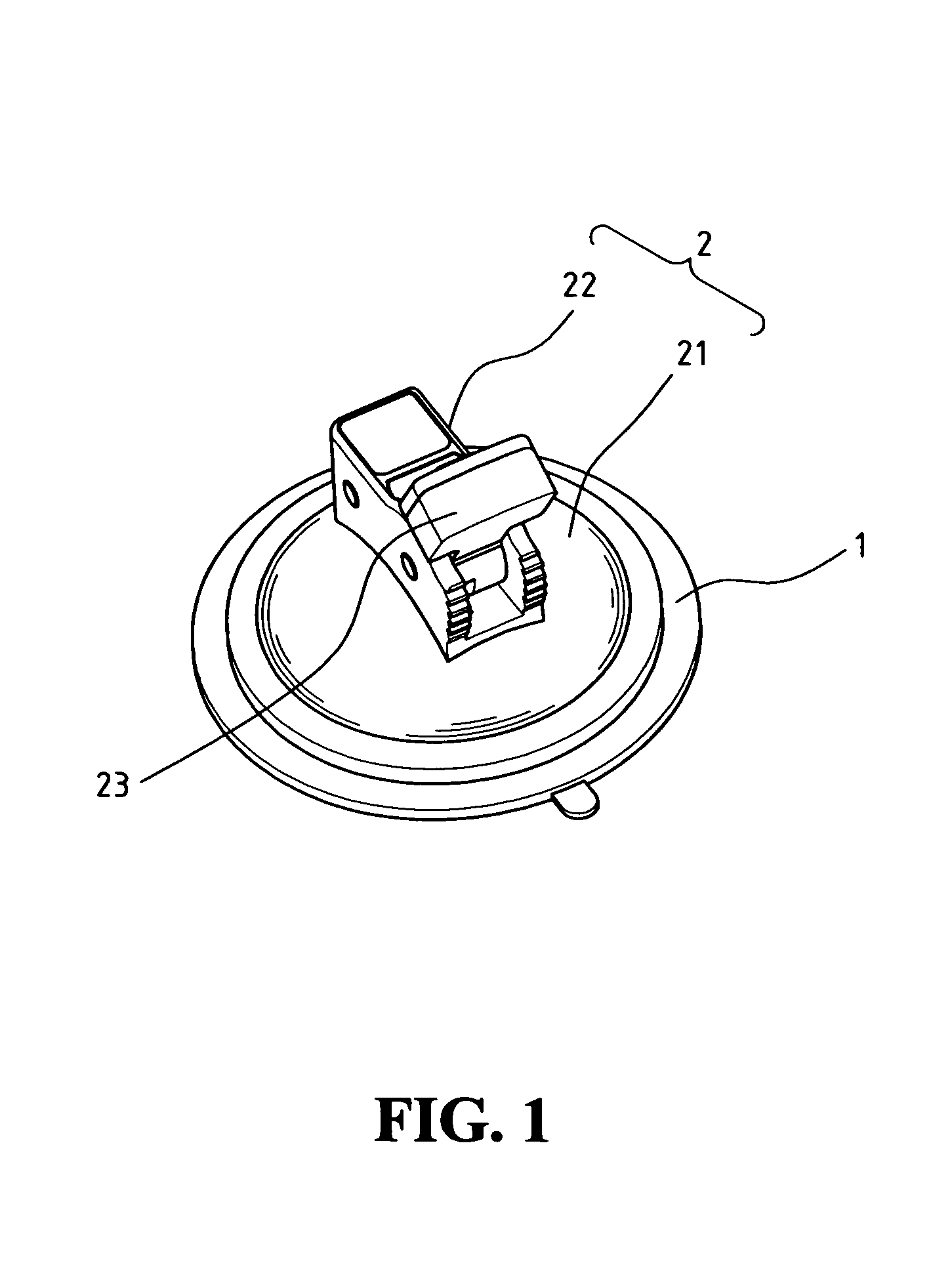

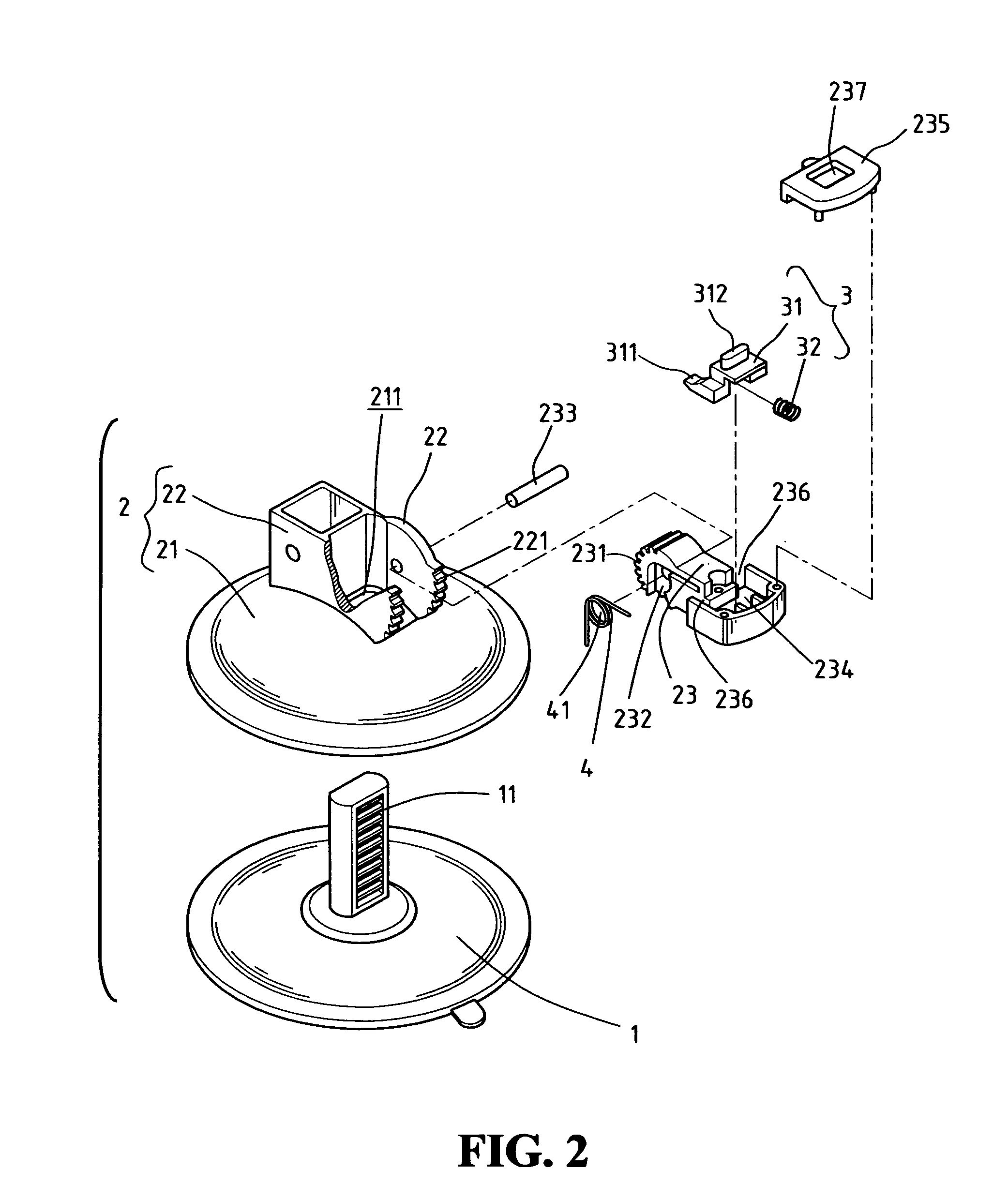

Vacuum suction apparatus

Owner:FAN EAGLE

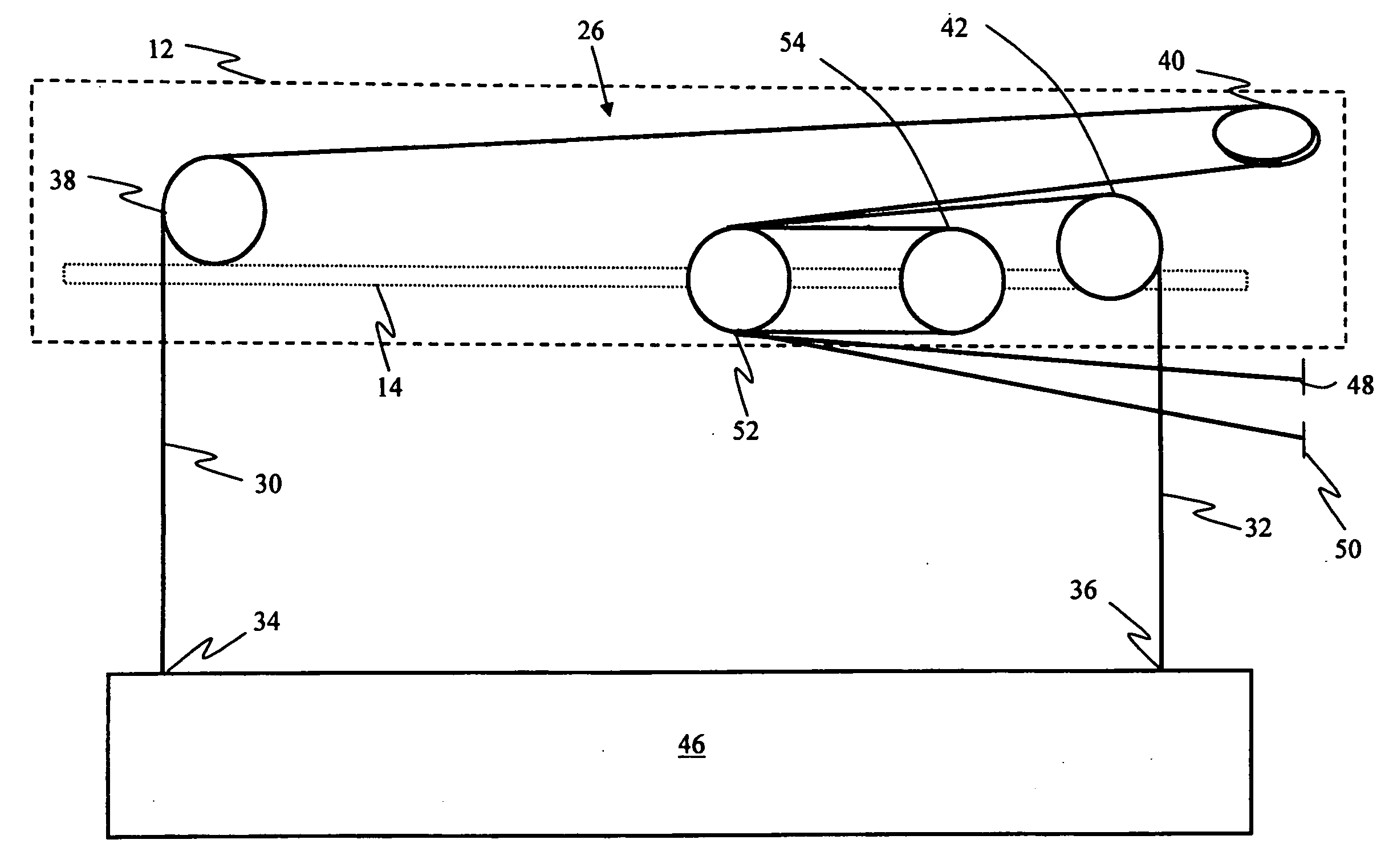

Robotic end of arm tool method and apparatus

An end of arm tool has a mounting bracket mounting the end of arm tool to the robot arm for movement therewith and has a plurality of operating mechanisms mounted to the mounting bracket, a plurality of gripping devices each operatively connected to a respective operating mechanism and movable along a path, and a plurality of individual motors each operatively connected to a respective gripping device for moving the respective gripping device along its respective path. At least one programmable controller for operating the motors is provided to adjust the positions of the gripping devices along their respective paths to one of a plurality of predetermined positions established by the controller for gripping the article and to position the end of arm tool adjacent the article so that at least one of the gripping devices grips the article.

Owner:SAS AUTOMATION

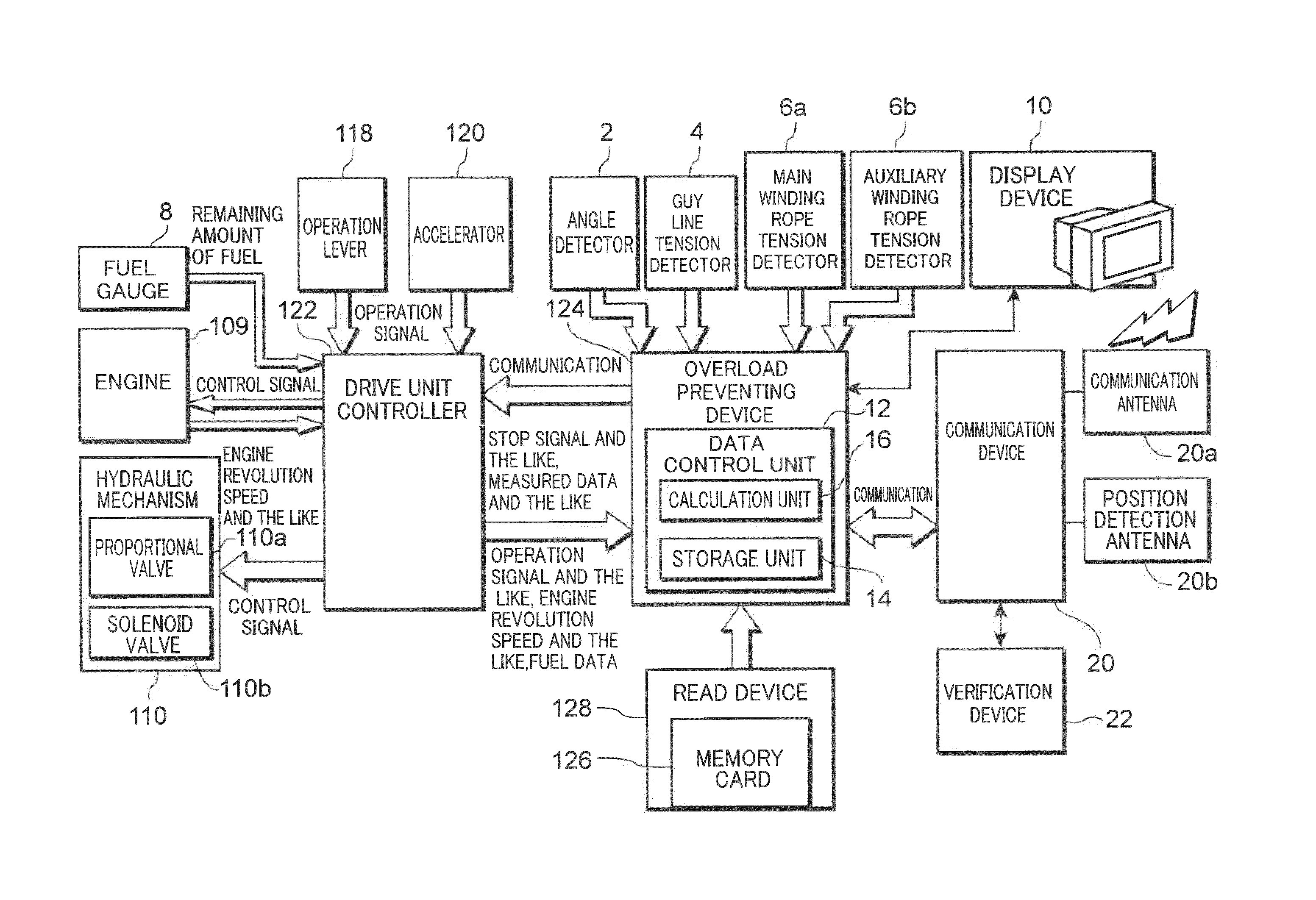

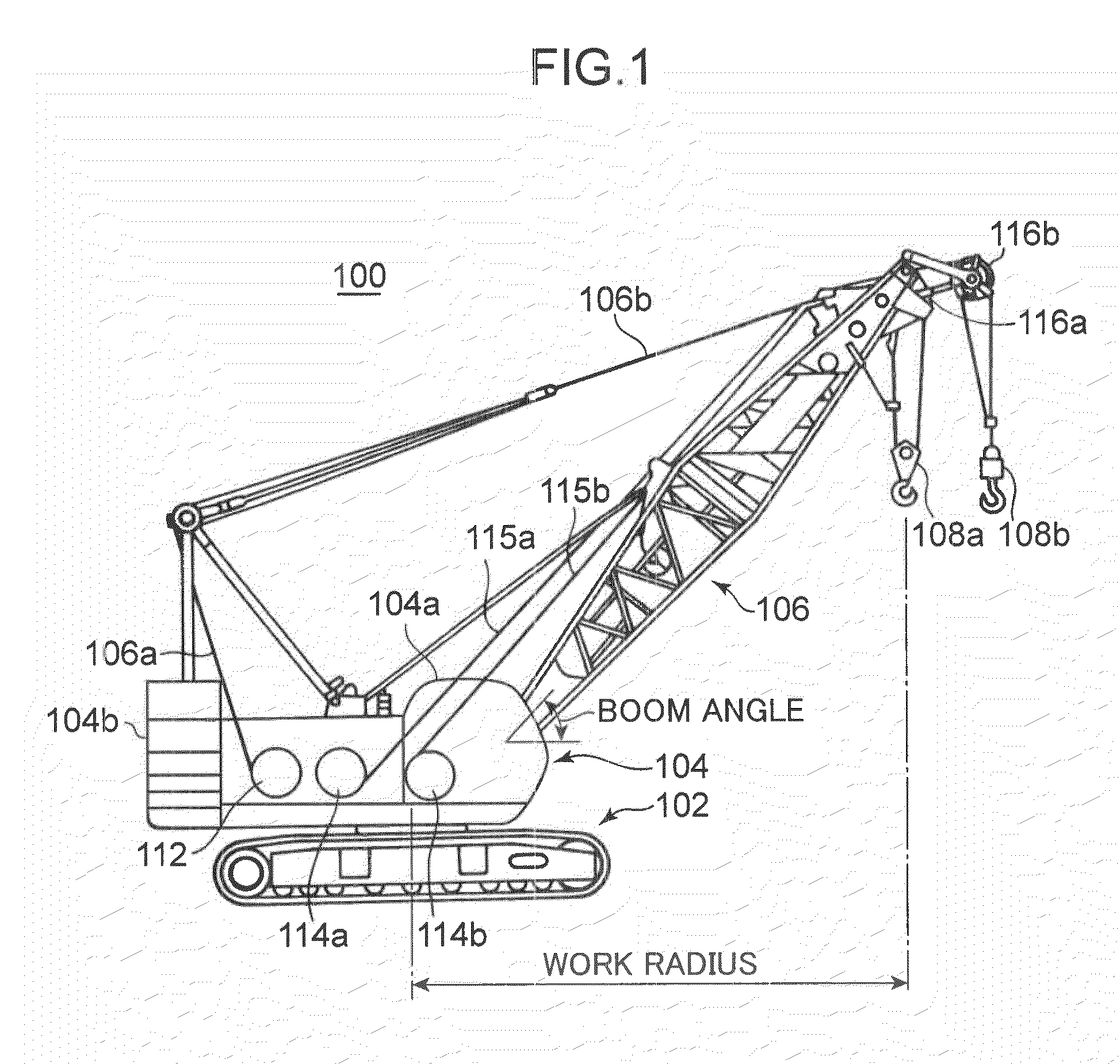

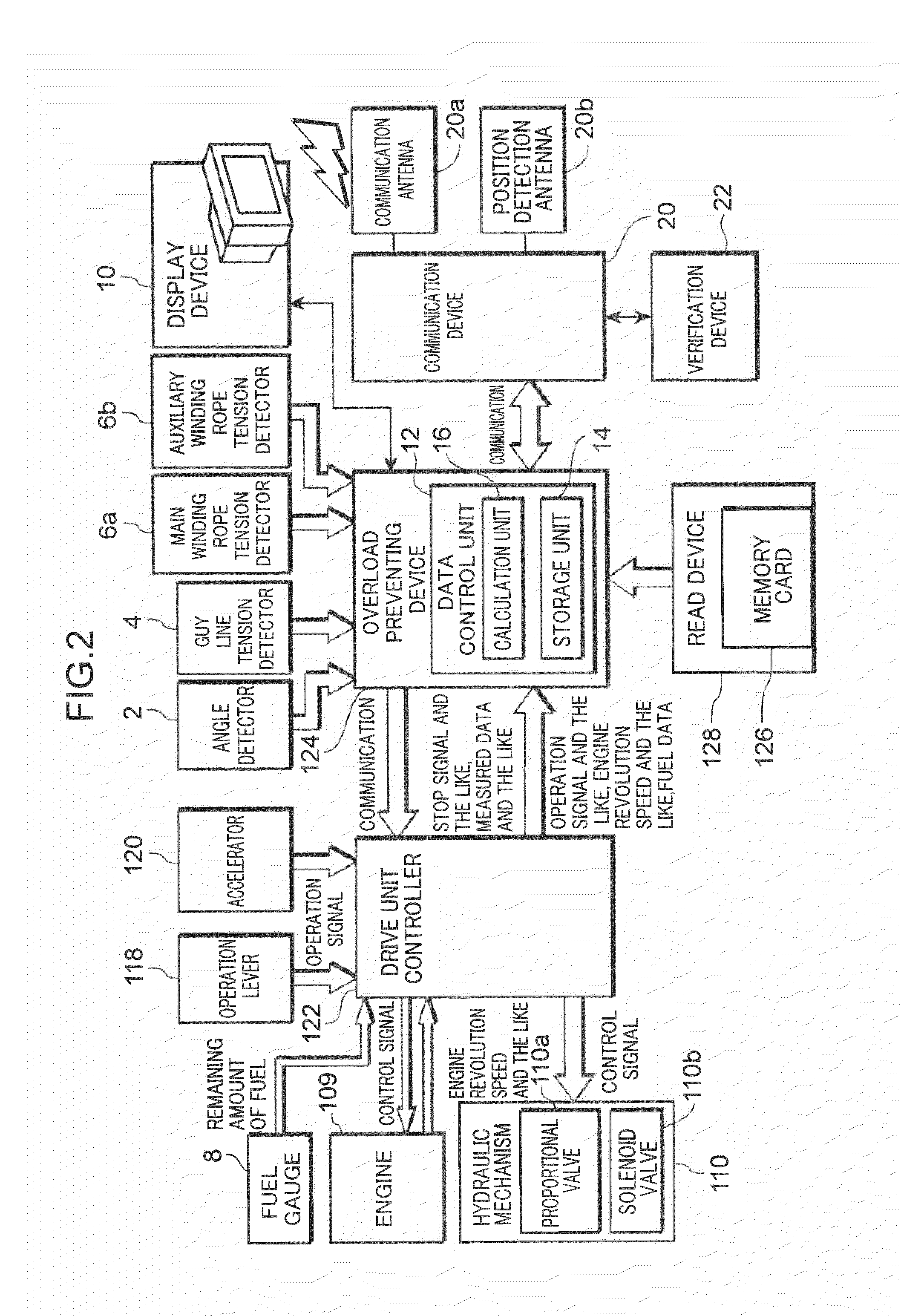

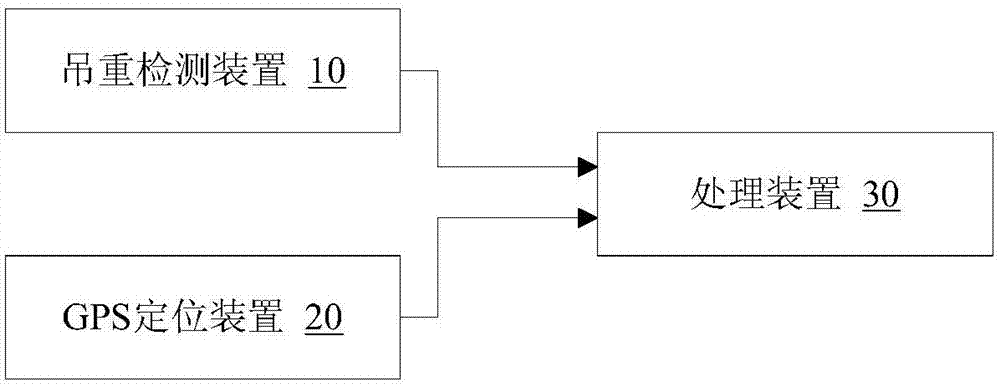

Crane operation evaluation device

ActiveUS20110276261A1Maintain accuracyLow costAnalogue computers for vehiclesAnalogue computers for trafficData controlDisplay device

Owner:KOBELCO CONSTR MASCH CO LTD

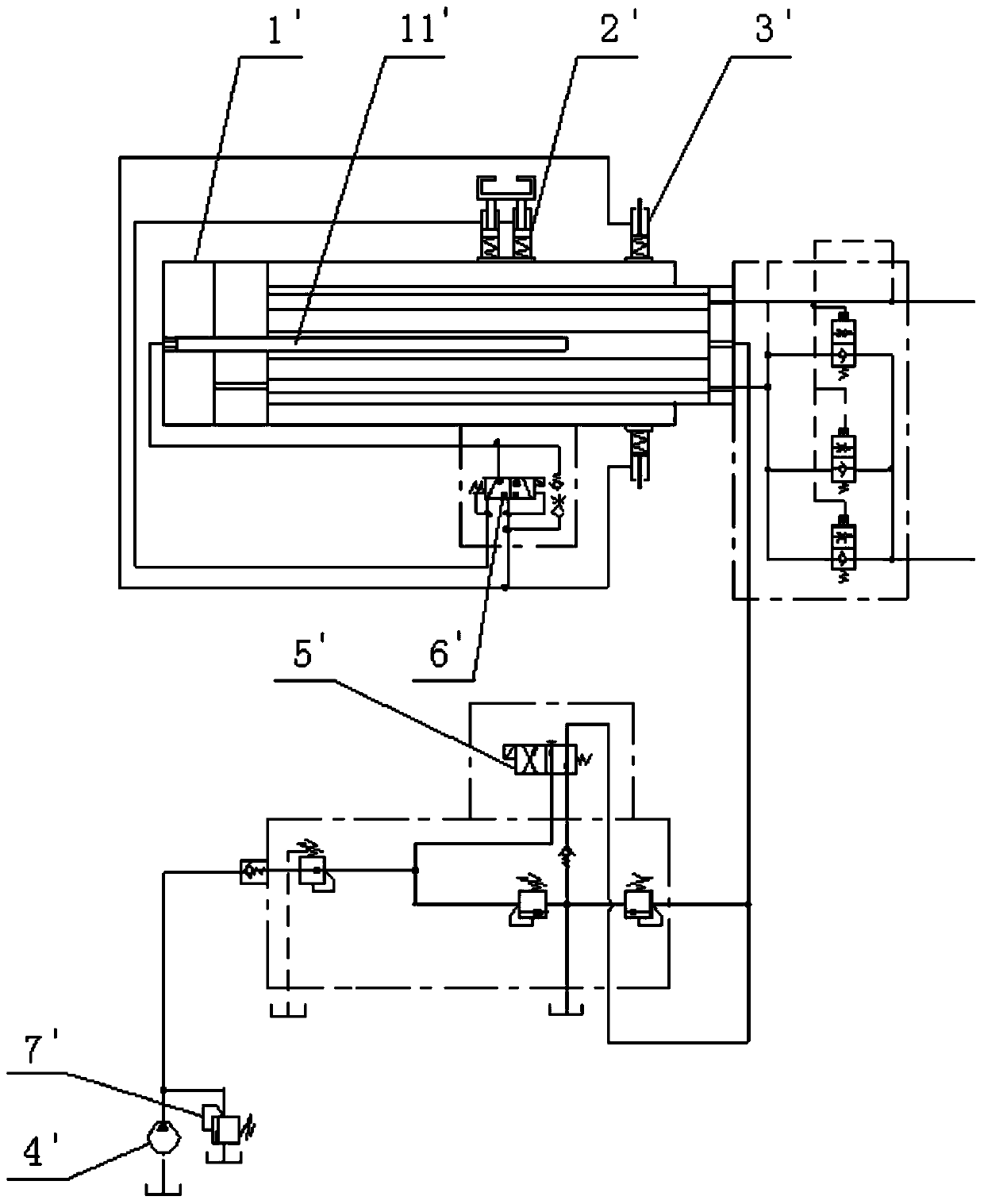

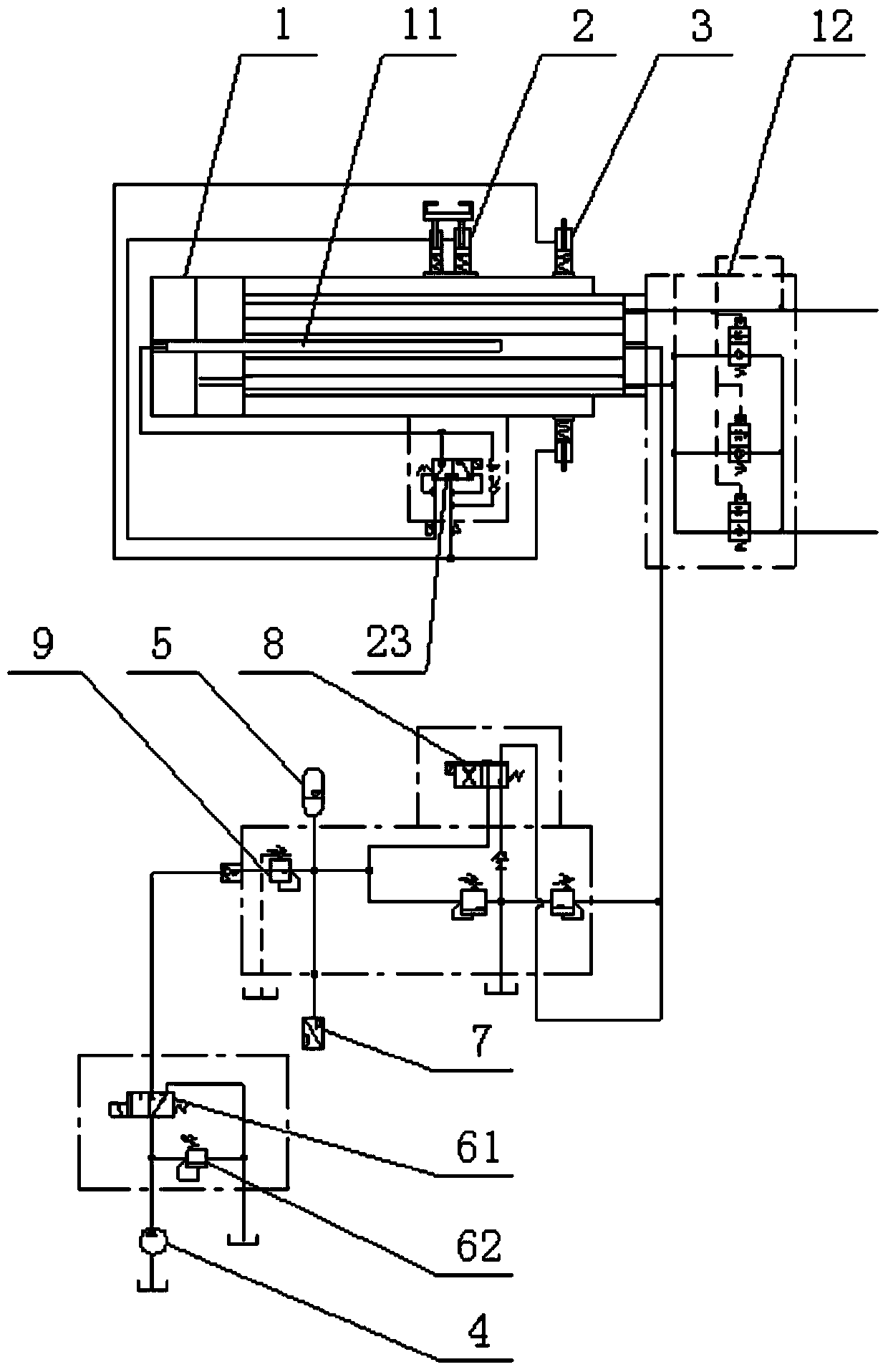

Hydraulic system and control method of single-cylinder pin type telescopic arm and crane

ActiveCN103438034AReduce temperature riseNo overflow lossServomotorsCranesSystem pressurePetroleum engineering

Owner:XUZHOU HEAVY MASCH CO LTD

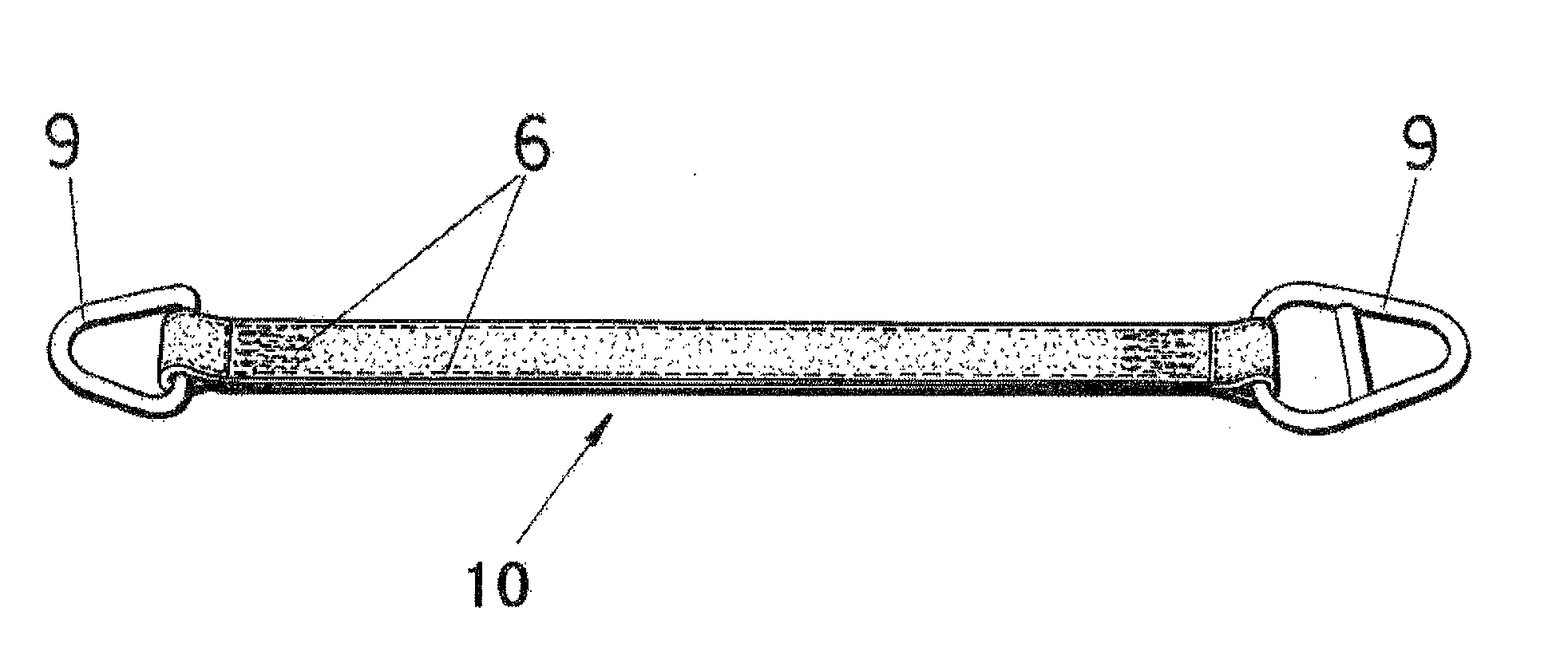

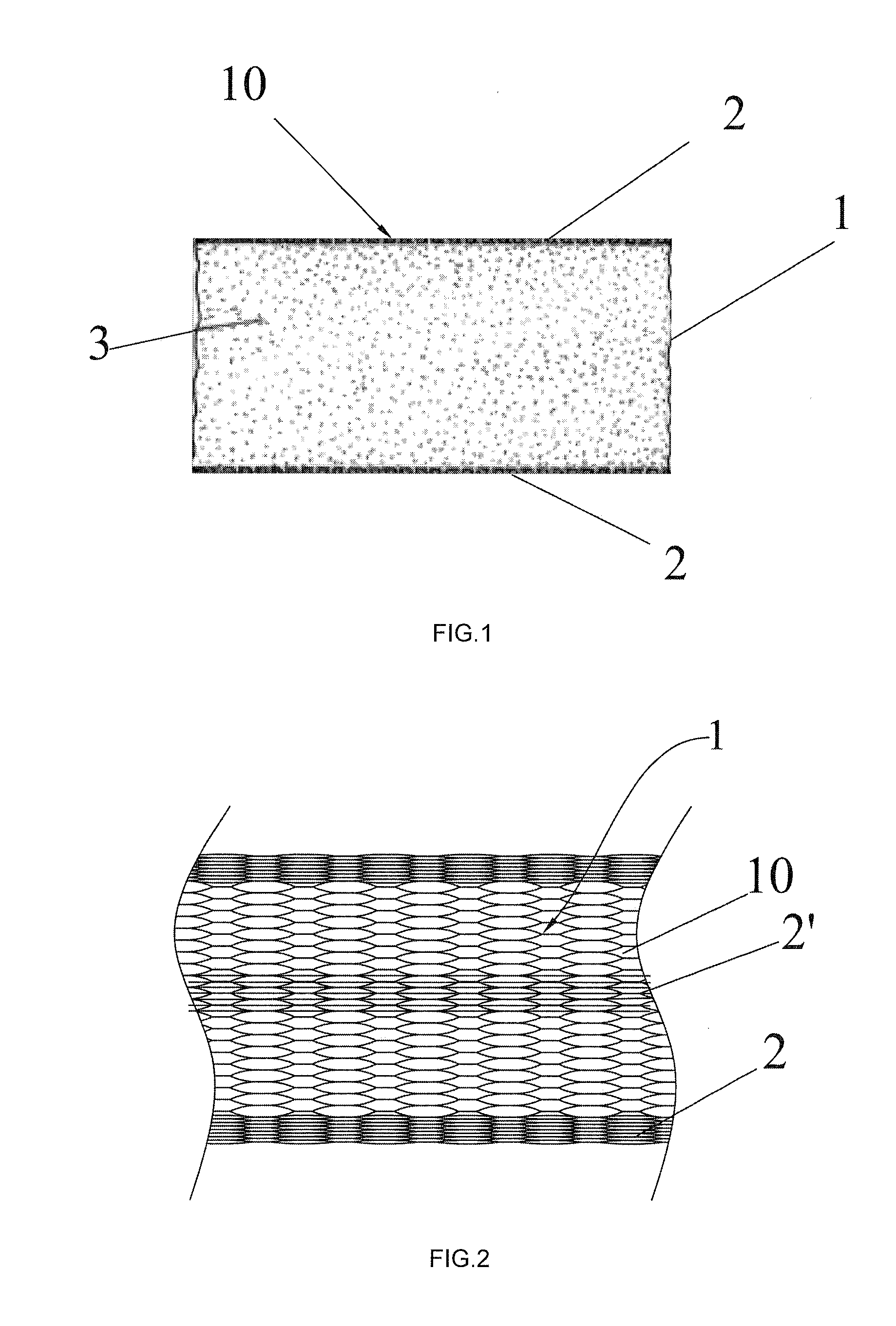

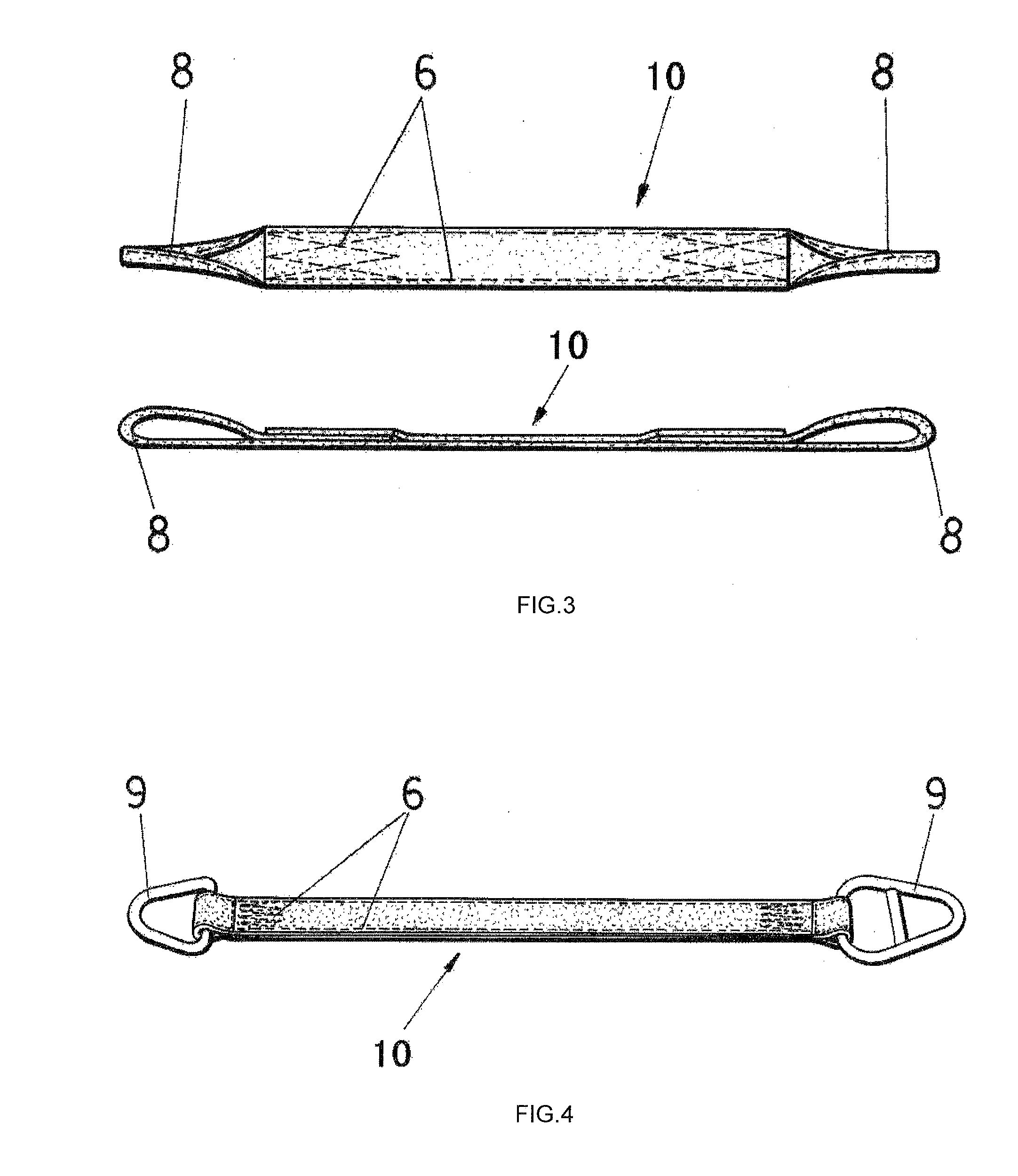

Textile sling and method of manufacturing same

InactiveUS20100327615A1Tough to abrasionTough to cutLoomsDrying machines with progressive movementsYarnPolyurethane dispersion

Owner:DONGGUAN PONSA TEXTILE

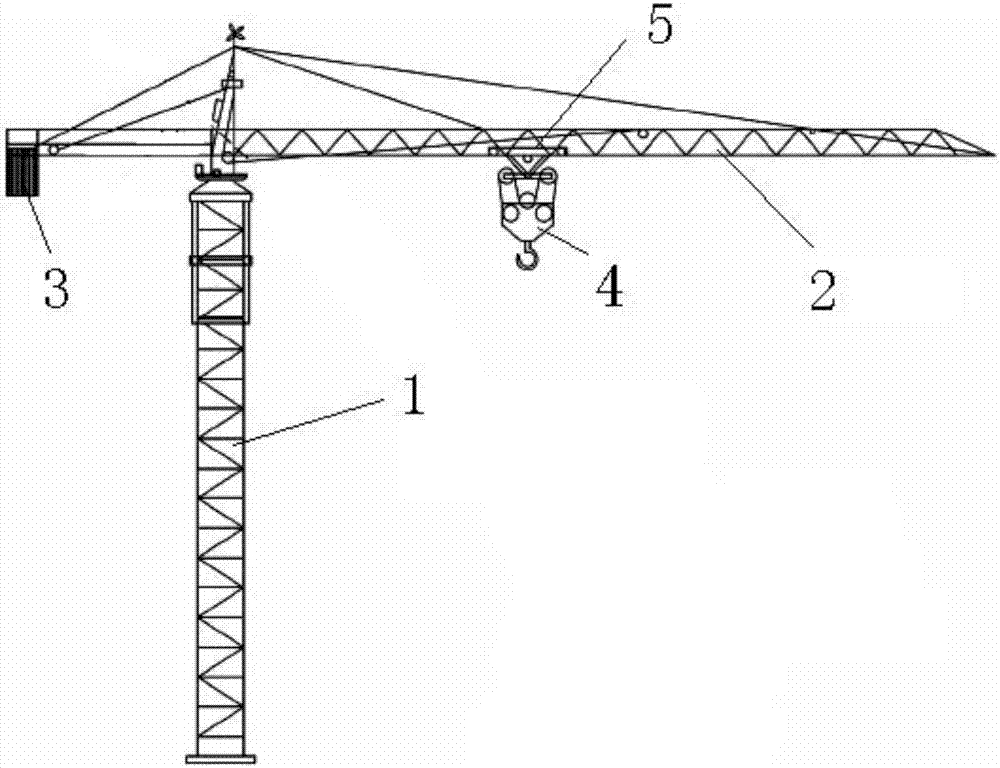

Safety monitoring system of tower crane and tower crane with same

Owner:CHANGSHA HAICHUAN AUTOMATION EQUIP

Overhead lift storage device

Owner:PRO FAB INDS

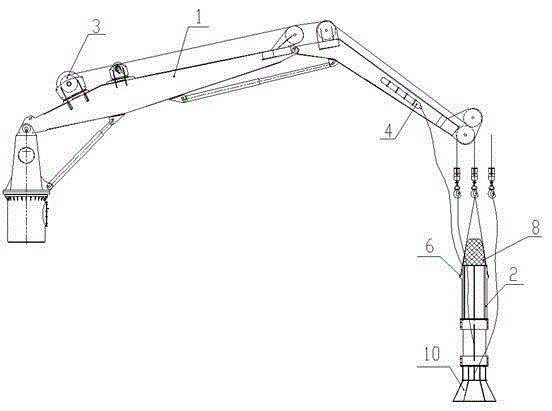

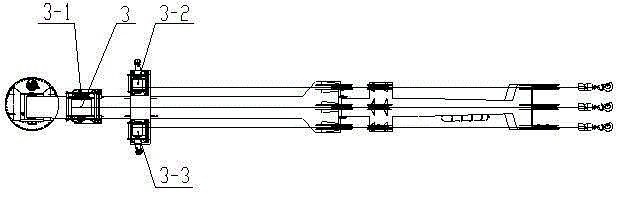

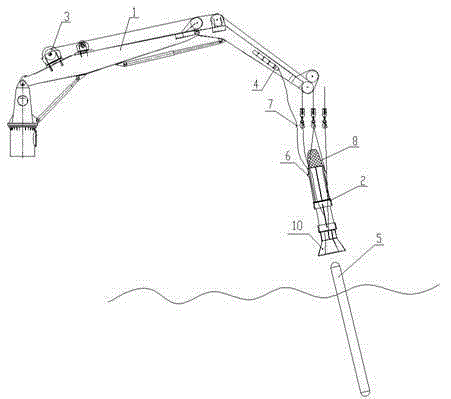

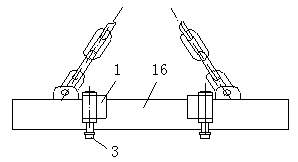

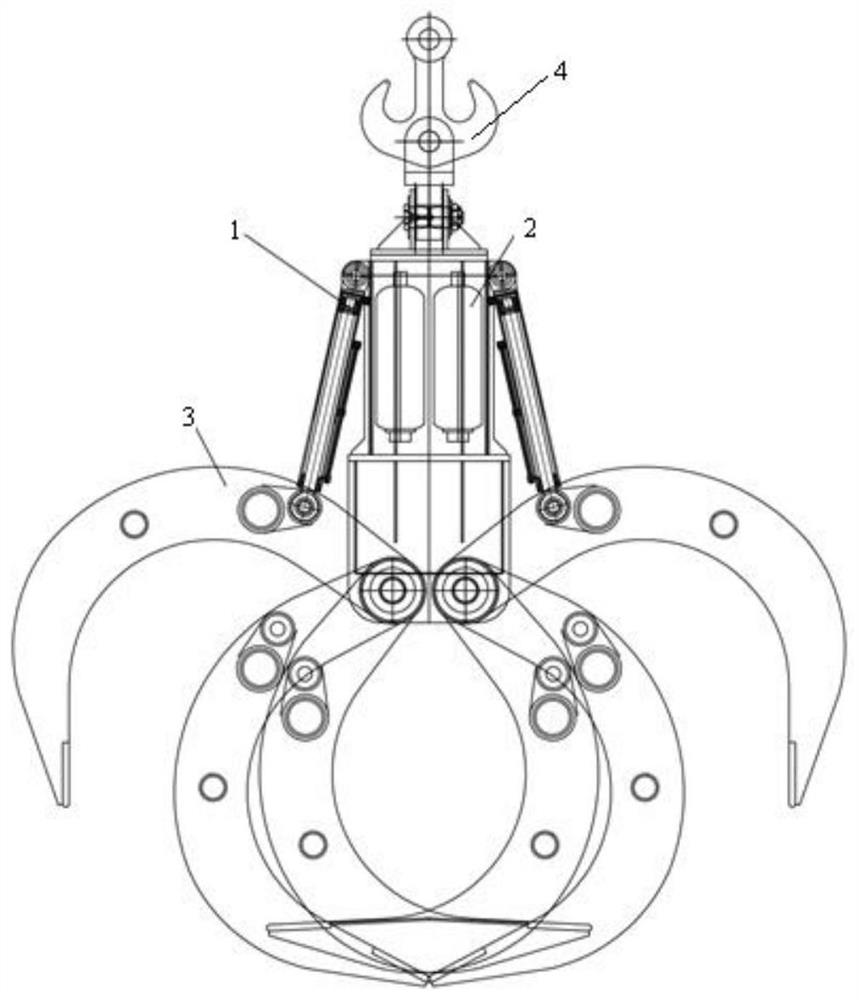

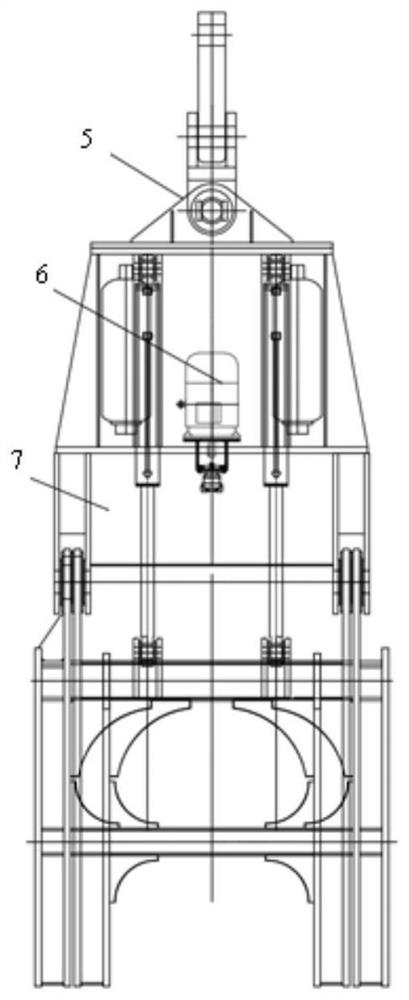

Seaborne cylindrical floating body recycling device

ActiveCN104649155ASuccessfully trapHigh recovery efficiencyCranesLoad-engaging elementsManufacturing technologyHigh pressure

Owner:SOUTH CHINA MARINE MACHINERY

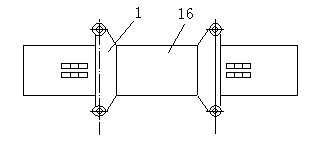

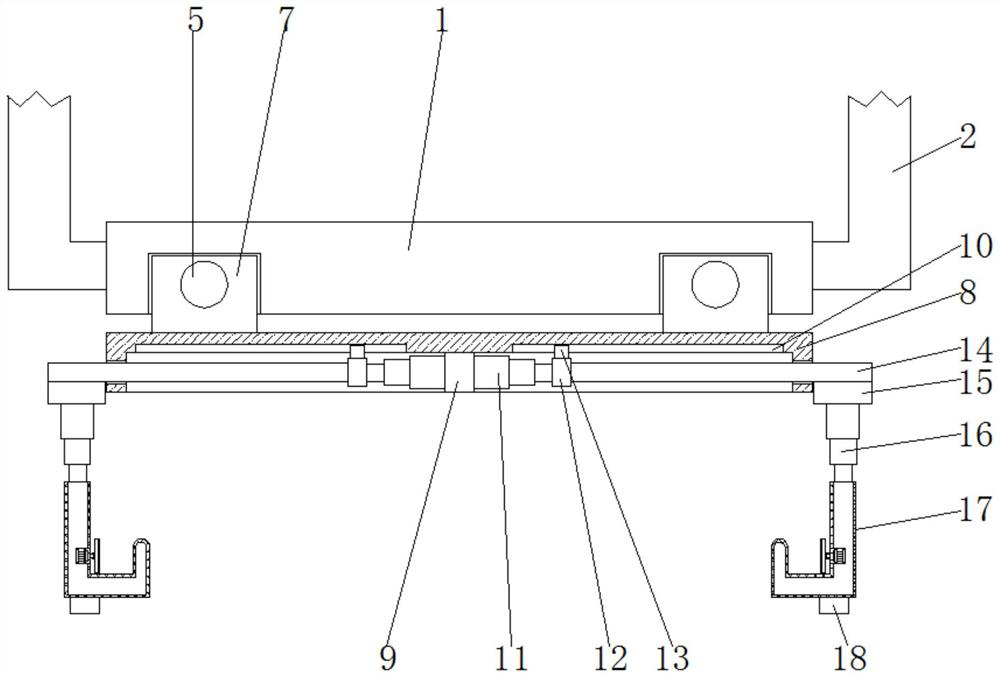

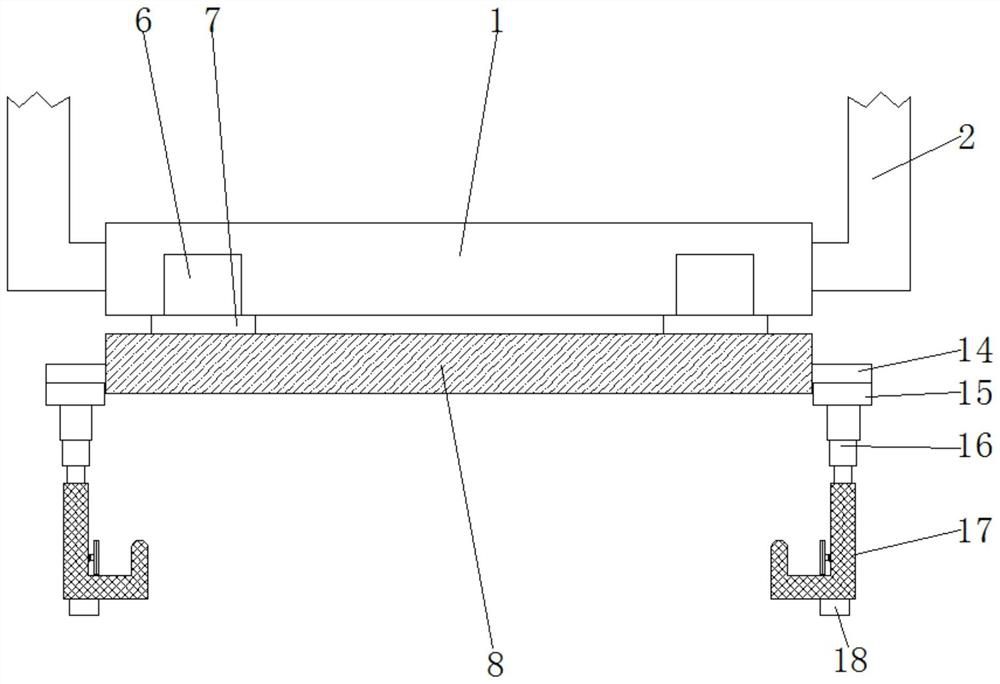

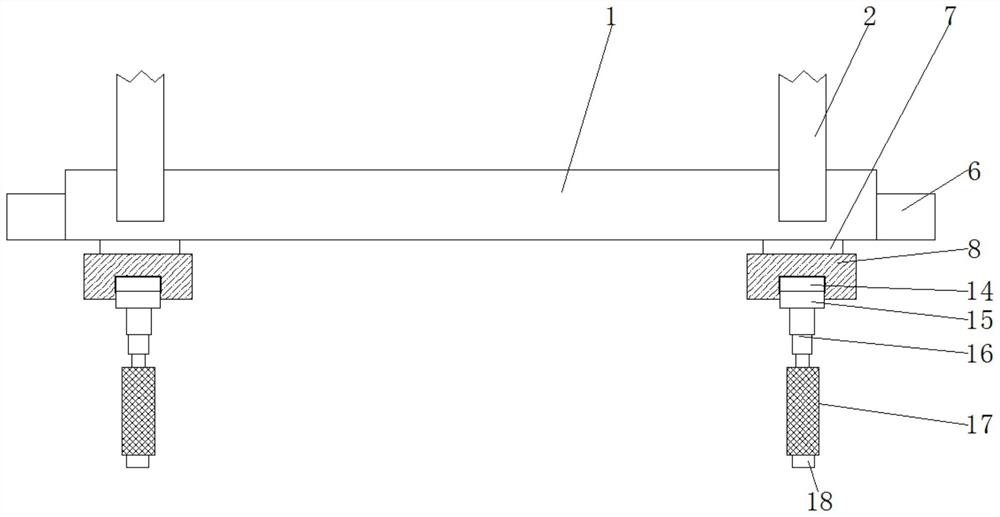

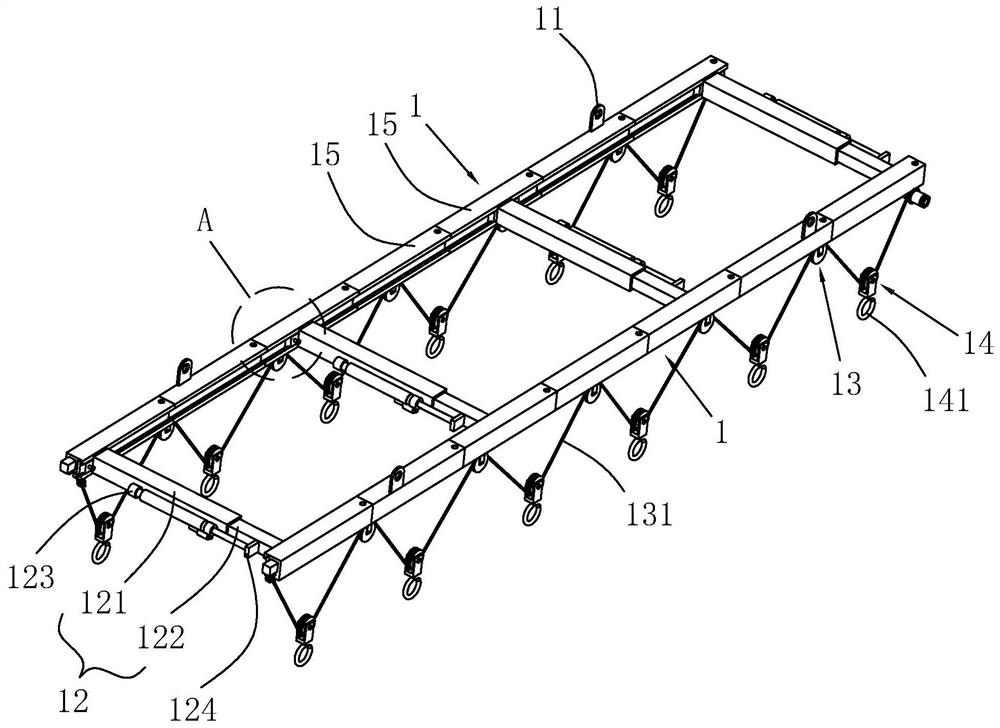

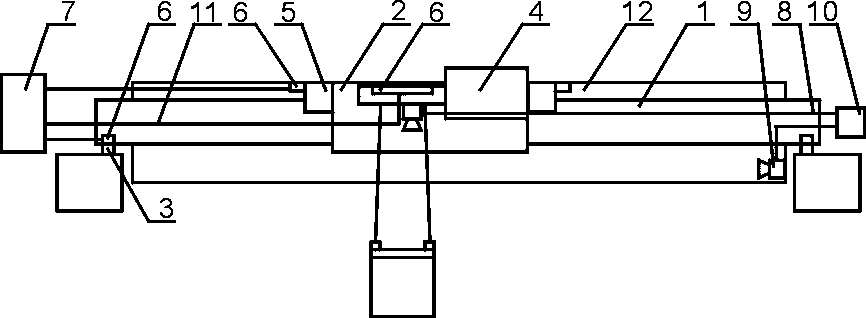

Vacuum panel sucking and hoisting crane

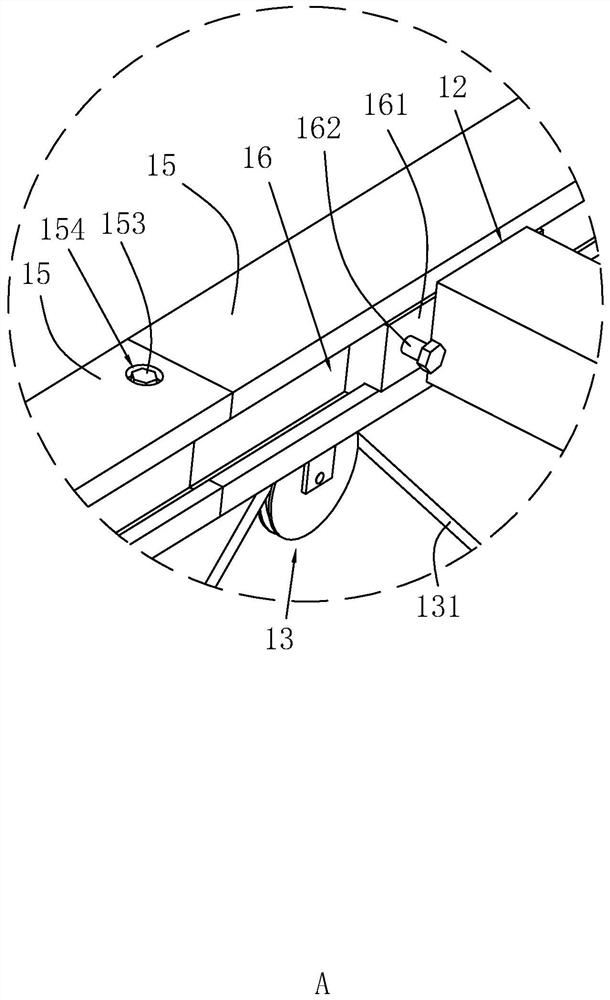

ActiveCN104016216AEnsure damage-free handlingReduce heavy laborTravelling cranesLoad-engaging elementsGear wheelEngineering

The invention relates to a vacuum panel sucking and hoisting crane. The vacuum panel sucking and hoisting crane comprises a rack, a walking mechanism, a hoisting mechanism and a vacuum chuck group, wherein the walking mechanism comprises a linear guide rail and a movable machine head, the linear guide rail is horizontally arranged on the rack, the movable machine head is capable of linearly reciprocating on the linear guide rail through a gear and a rack, the hoisting mechanism is arranged in the movable machine head and is capable of moving up and down relative to the movable machine head, a cross beam is arranged at the lower part of the hoisting mechanism, a panel detection sensing probe is connected to the cross beam through a detection rod, and a plurality of vacuum chucks are arranged on the cross beam. The vacuum panel sucking and hoisting crane provided by the invention is especially suitable for sucking and hoisting of stainless steel, and can be applied to feeding of a veneer reeling machine, thereby reducing heavy labor of manual carrying, and ensuring undamaged carrying of panels; meanwhile, through transmission of signals between upstream equipment and downstream equipment, unattended operation can be realized, and the labor is maximally saved; the vacuum sucking and hoisting crane has the characteristics of high efficiency, safety, rapidness, and labor saving.

Owner:JIANGSU CHANGCHENG ARCHIVES EQUIP

Method for hoisting and transporting steel plates by adopting electromagnet in steel plants

ActiveCN103241638AAvoid scratchesAvoid impact damageShock absorbersLoad-engaging elementsMagnetic tension forceSheet steel

Owner:CHONGQING IRON & STEEL CO LTD

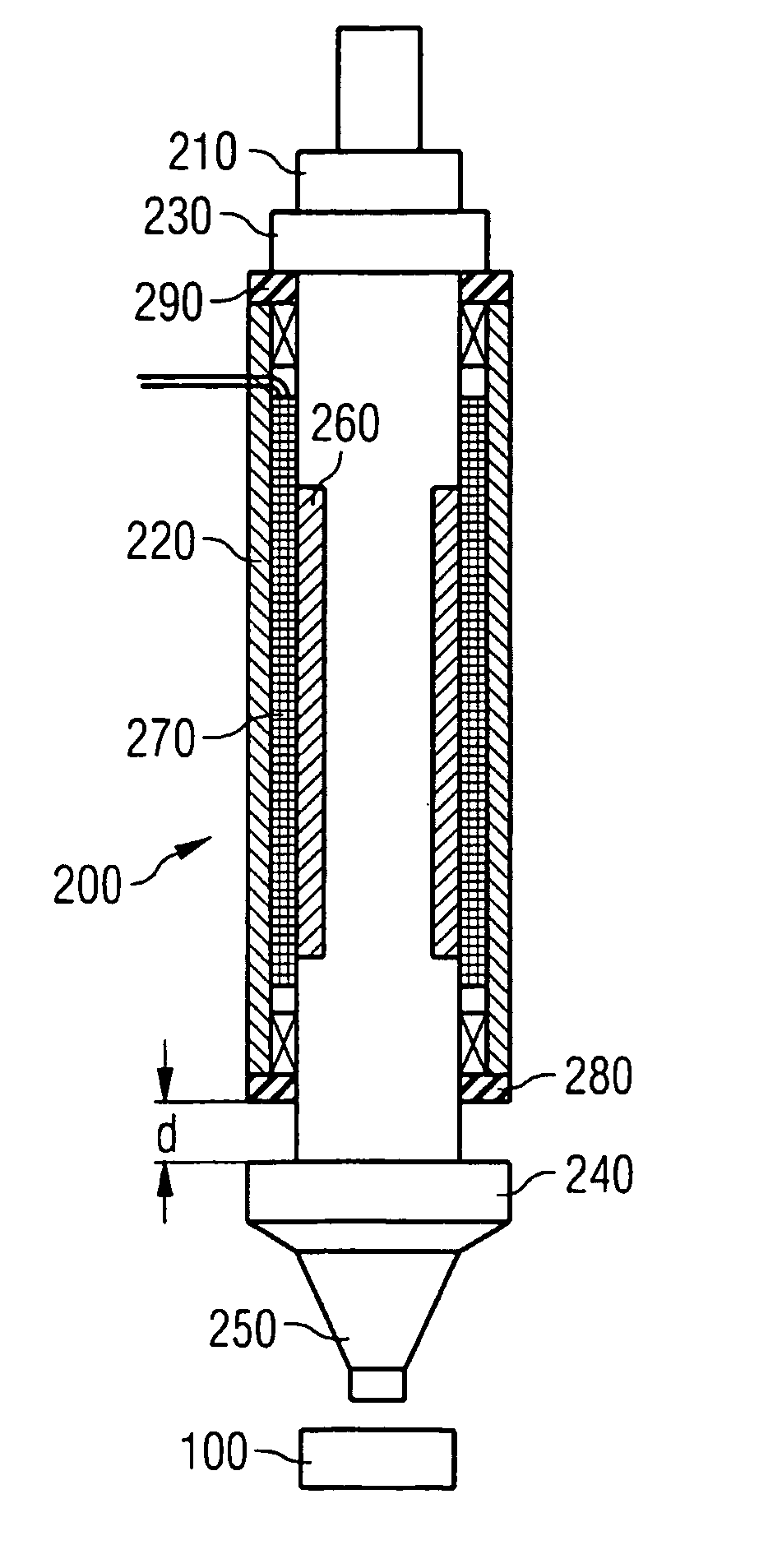

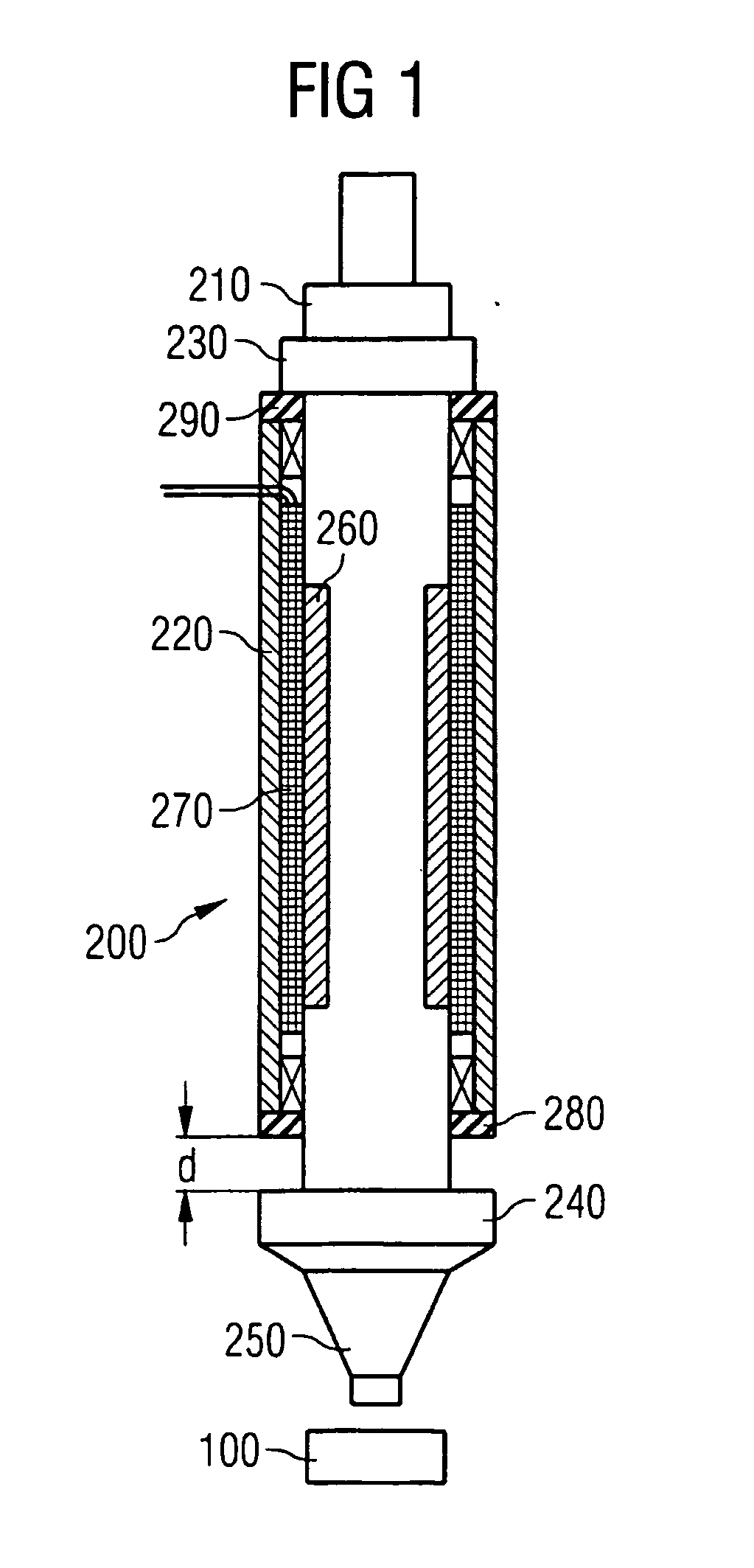

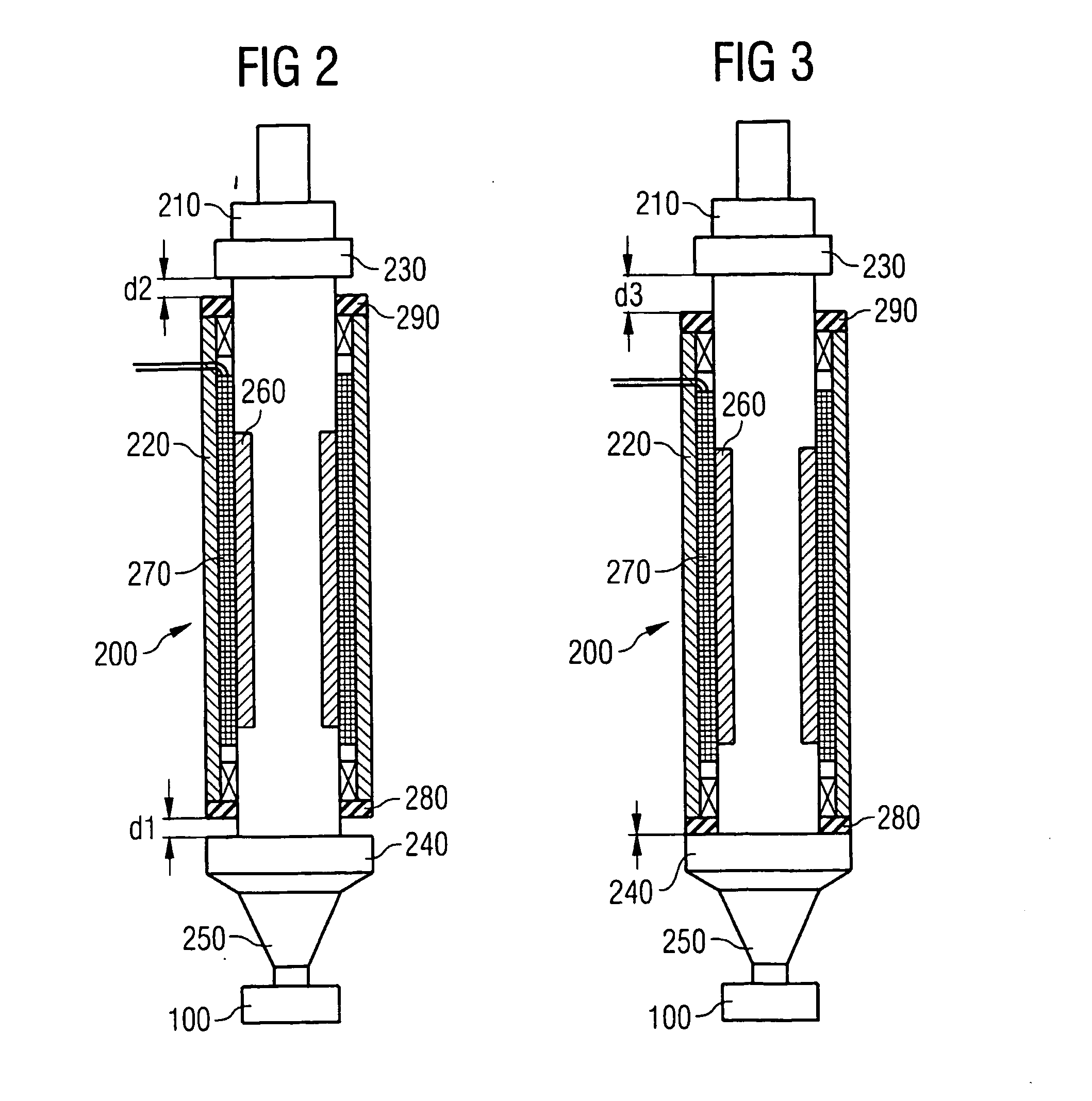

Placing device and method for placing objects onto substrates

InactiveUS20050035613A1Reduce the overall heightGripping headsSemiconductor/solid-state device manufacturingCouplingEngineering

Owner:SIEMENS AG

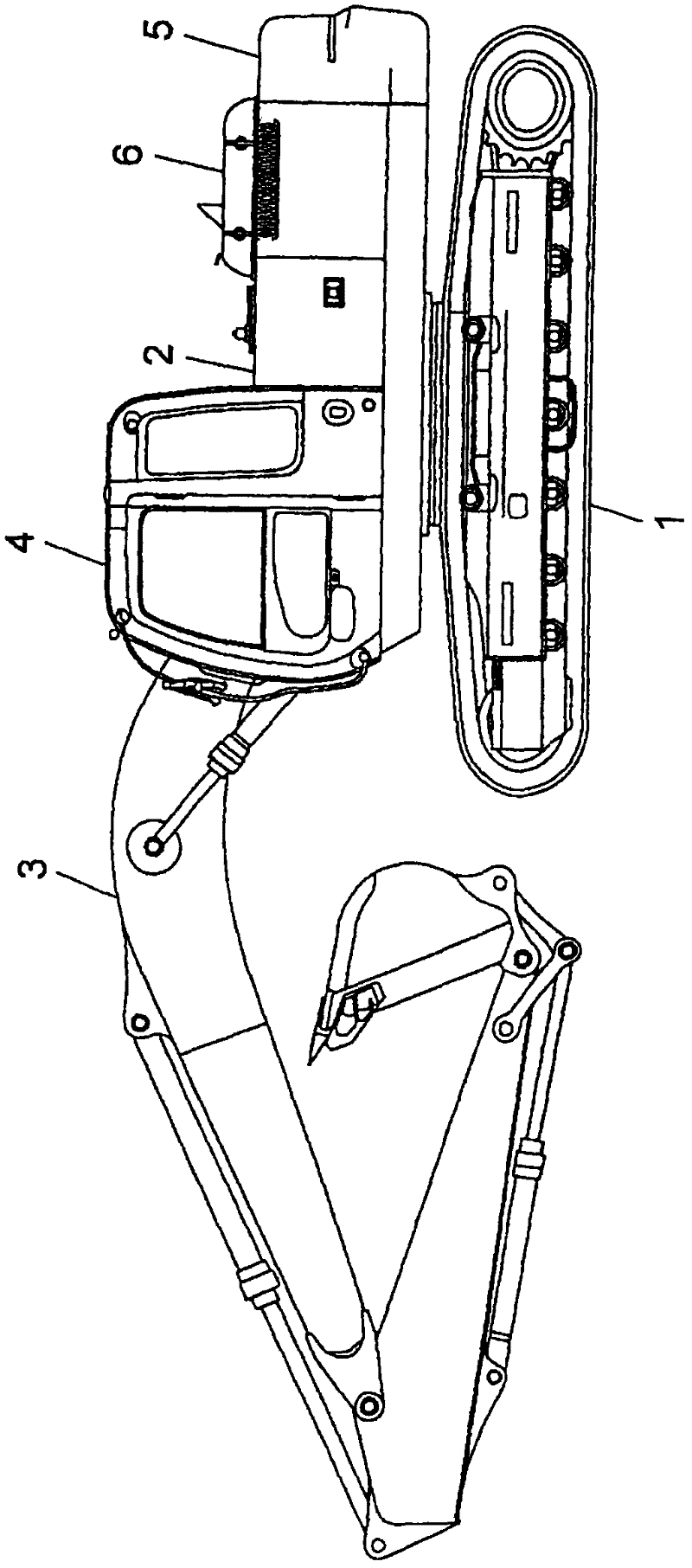

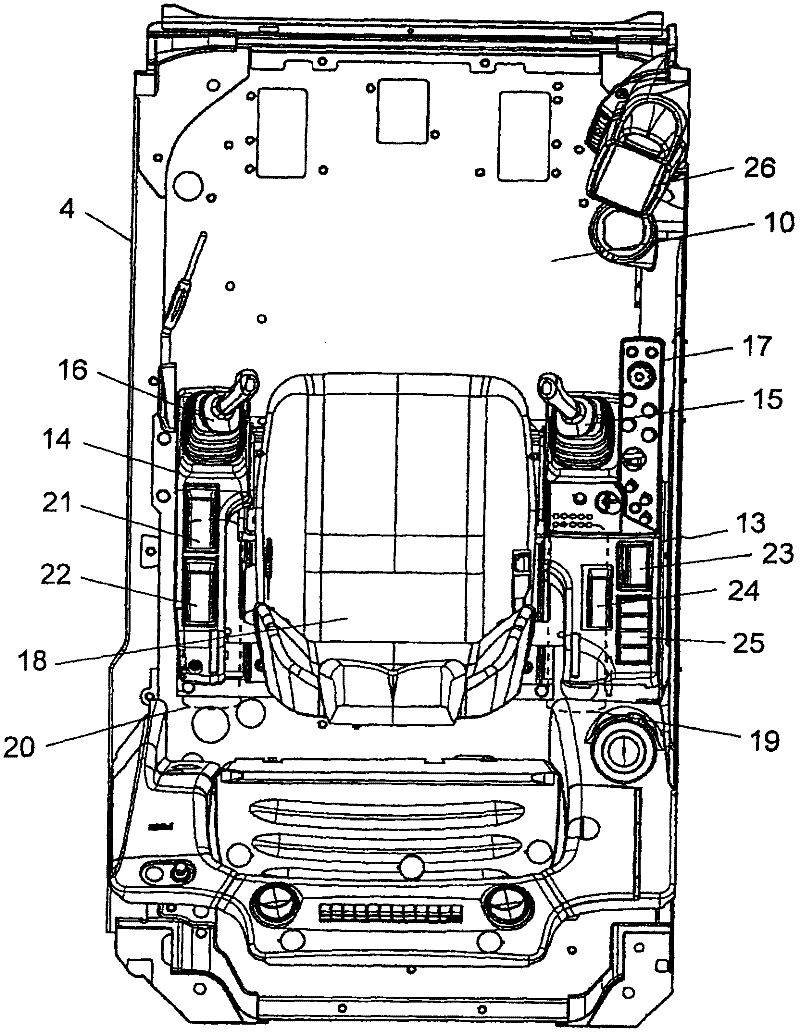

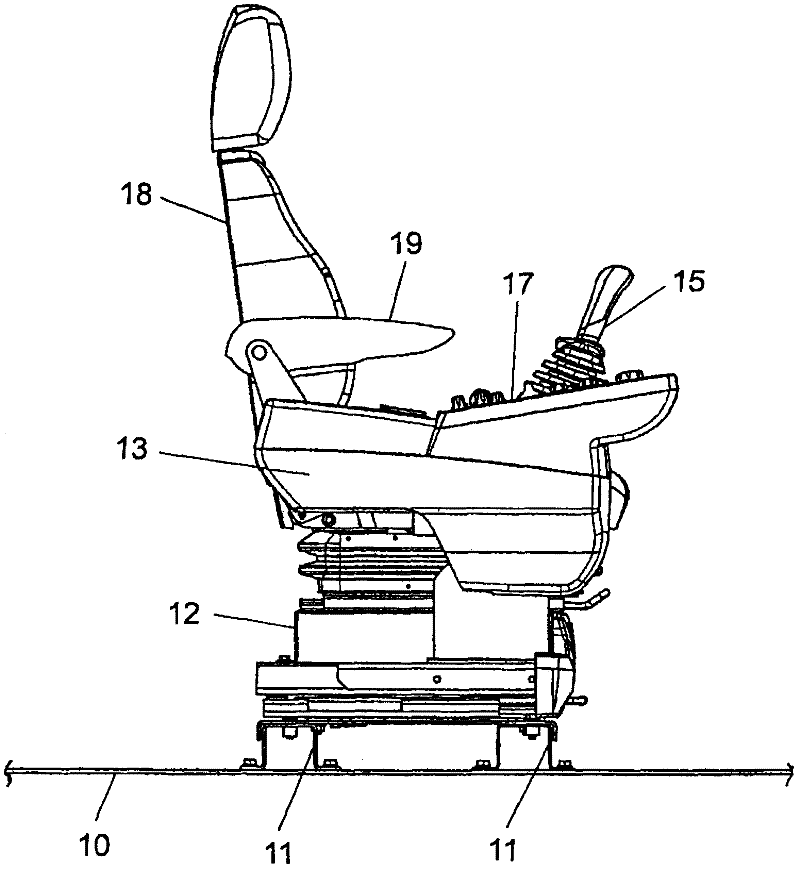

Engineering machine

Owner:NIHON KENKI CO LTD

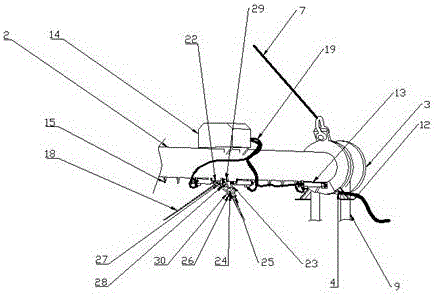

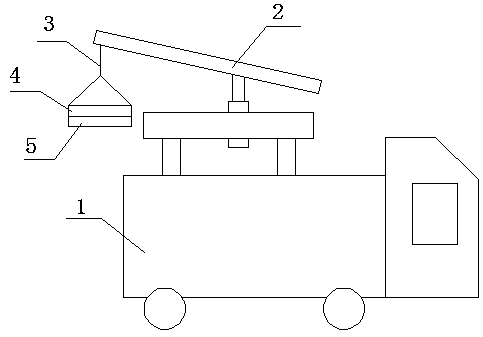

Unmanned aerial vehicle auxiliary system for tower crane construction

InactiveCN107244422AEasy to operateImprove securityAircraft componentsPosition/course control in three dimensionsGyroscopeTower crane

Owner:成都希德电子信息技术有限公司

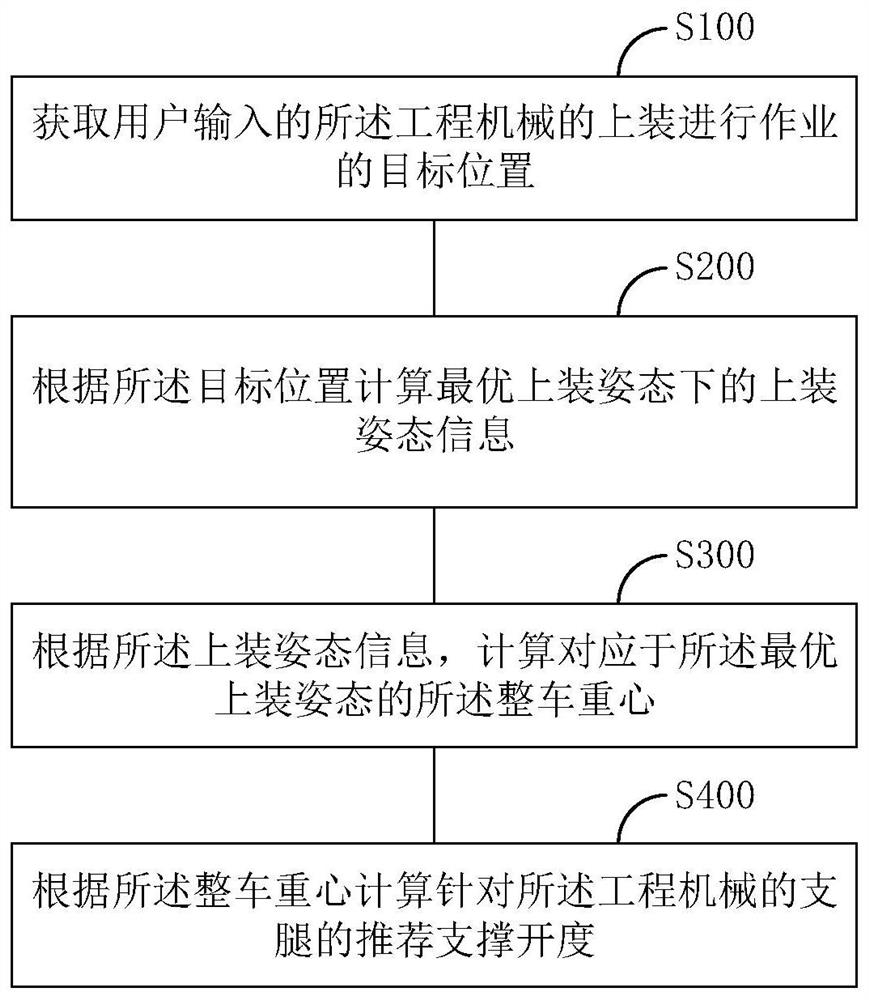

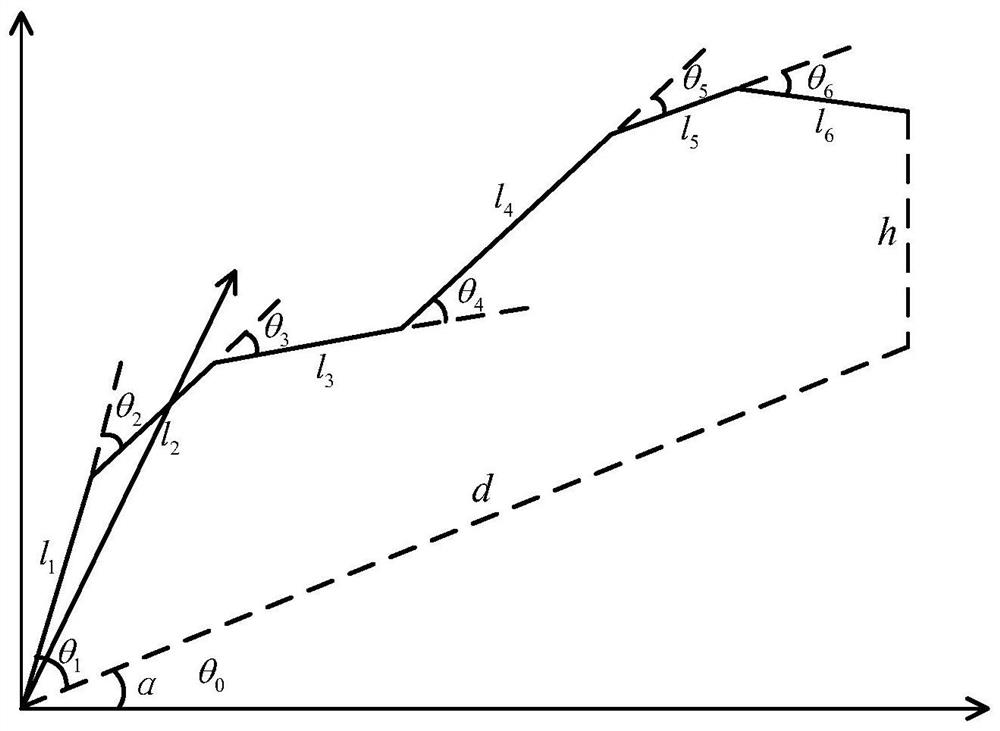

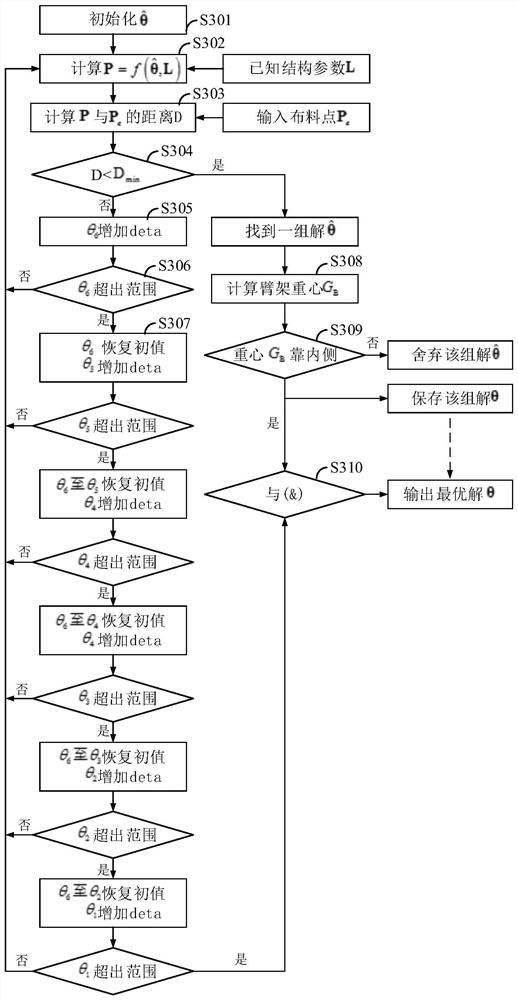

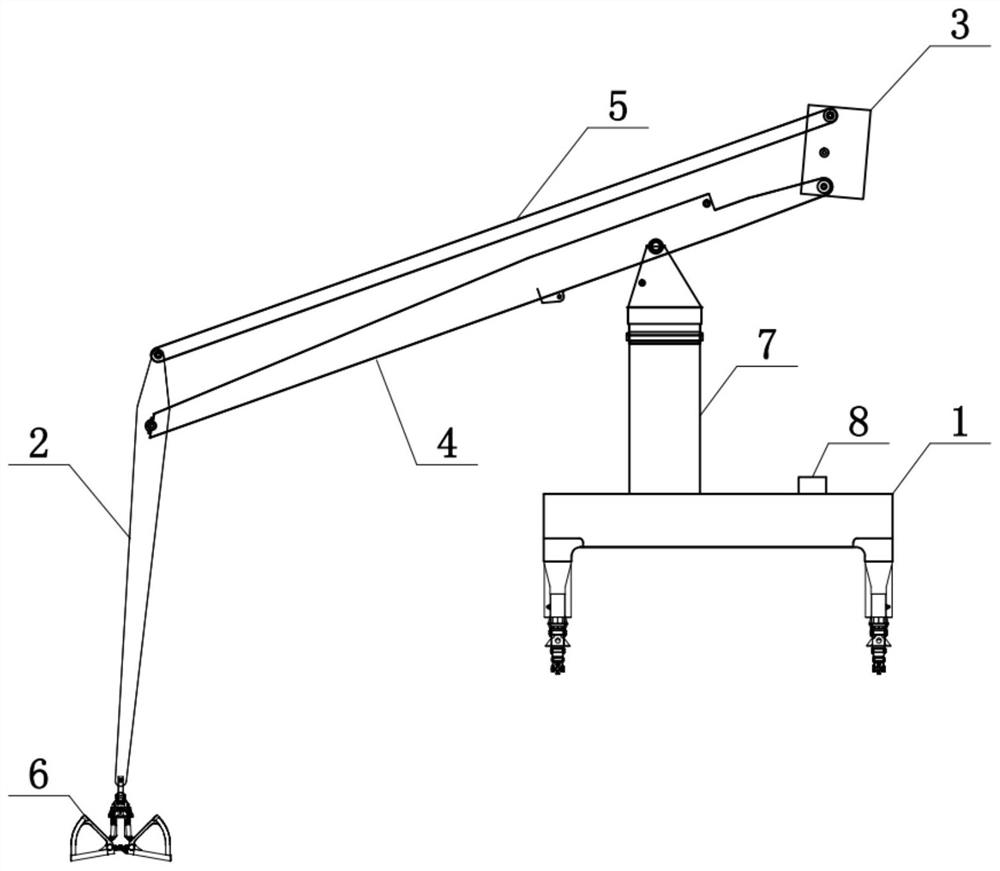

Engineering machinery, supporting control method, device and system thereof and medium

Owner:ZOOMLION HEAVY IND CO LTD

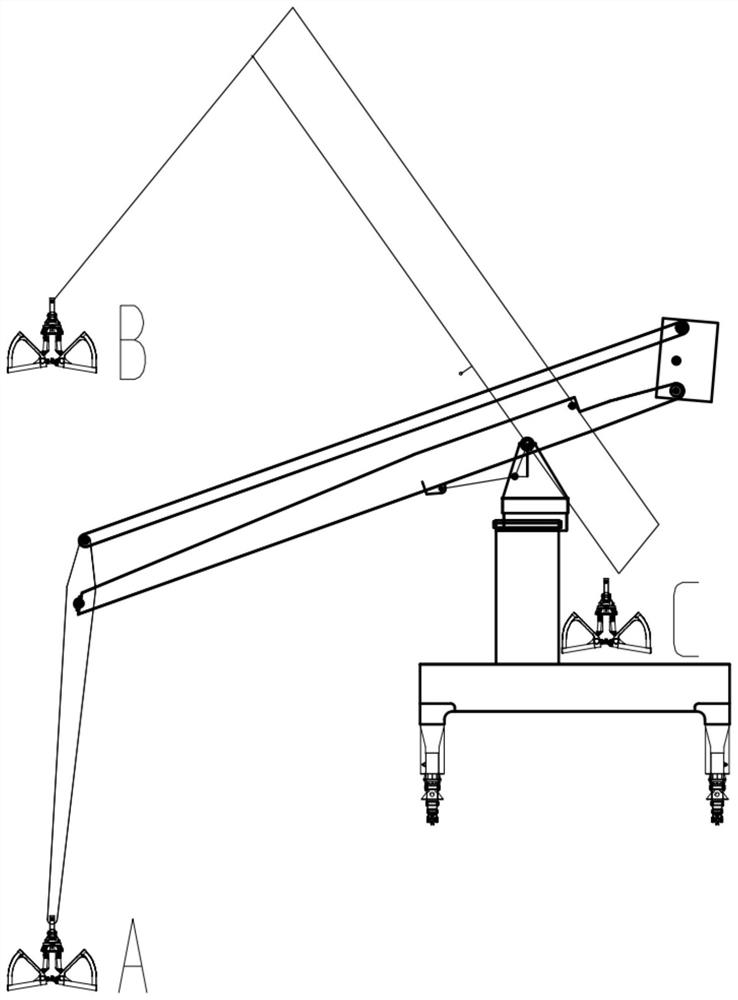

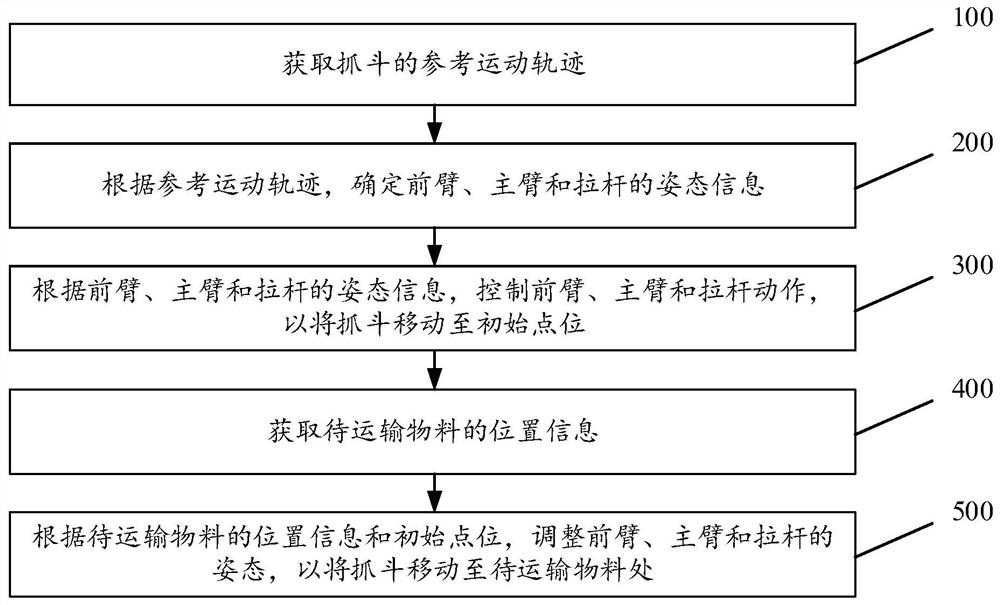

Automatic control method and device of crane and crane

Owner:SANY MARINE HEAVY IND

Remote control system for tyre gantry crane

ActiveCN105776025ASatisfy the operation mode of remote controlEasy to controlLoad-engaging elementsControl systemRemote control

Owner:NINGBO WEILONG PORT MASCH CO LTD

Cement precast slab loading and unloading device

InactiveCN104555700AEasy loadingImprove work efficiencyLoad-engaging elementsEngineeringMechanical engineering

Owner:ZHONGYUAN ENGINEERING COLLEGE

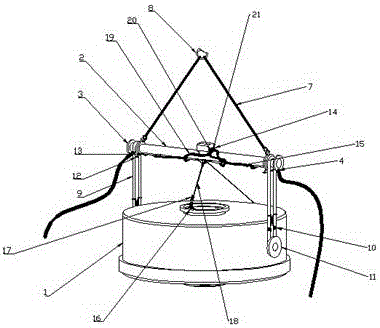

Wind power generator automatic turning lifter and mounting method

ActiveCN105936470AReasonable structureEasy to installLifting devicesLoad-engaging elementsTurn angleWind force

Owner:CHINA MCC17 GRP

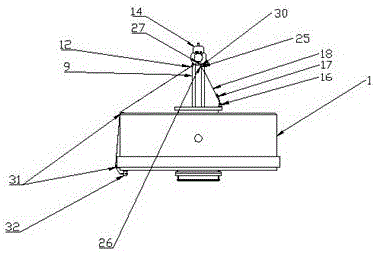

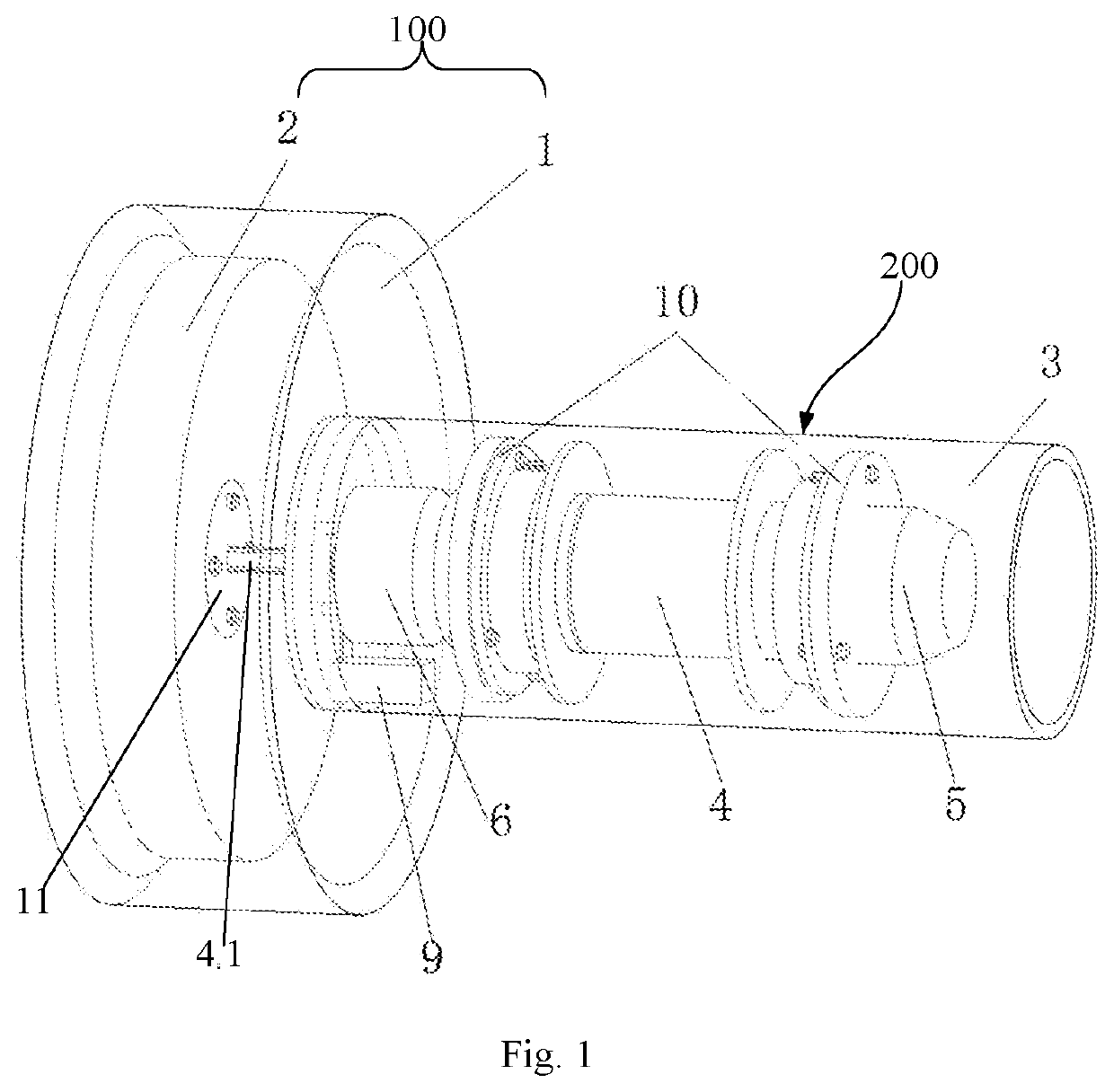

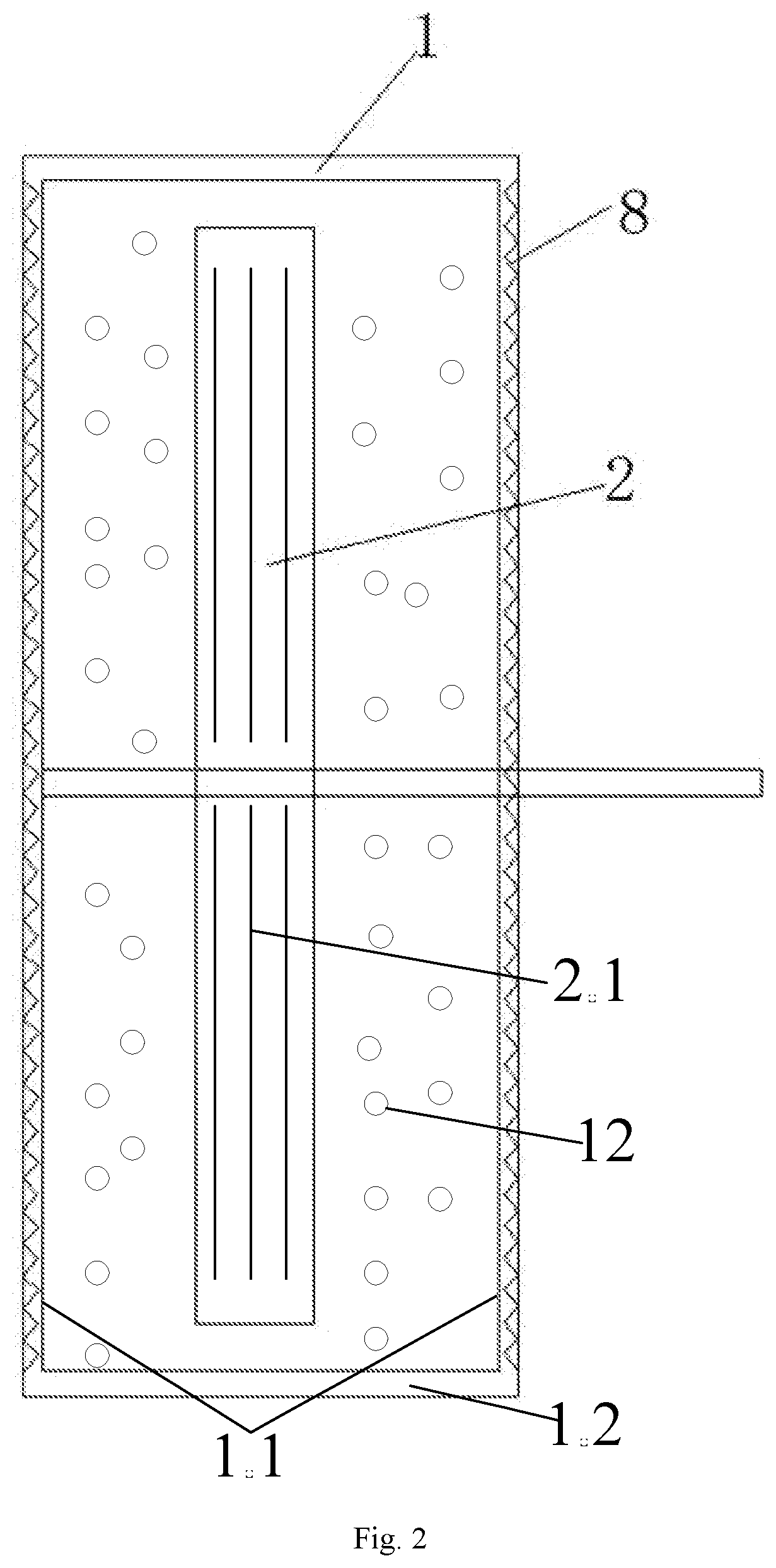

Combined pre-embedded lifting hook and construction method

ActiveCN111268559APrecise positioningBeautiful qualityBuilding constructionsLoad-engaging elementsSteel platesMechanical engineering

The invention discloses a combined pre-embedded lifting hook and a construction method, and belongs to the technical field of building construction. The combined pre-embedded lifting hook comprises apre-embedded steel plate (1) pre-embedded inside concrete through an anchoring piece, the lower surface of the pre-embedded steel plate (1) is fixedly connected with a groove box (2), the bottom of the groove box (2) is open, a positioning unit is arranged on the groove box (2), a hanging plate (3) is arranged in the groove box (2), the hanging plate (3) is integrally connected with a web (4), a lifting hole is formed in the bottom of the web (4), and the groove box (2) is fixedly connected with the hanging plate (3) through the positioning unit. The accuracy of the position of embedding of the pre-embedded lifting hook in a concrete structure is advantageously improved, quality problems such as lifting hook sagging are avoided, using functions of the lifting hook and lifting stress safetycan be effectively guaranteed, and manufacturing of the formed pre-embedded lifting hook is attractive.

Owner:CHINA MCC17 GRP

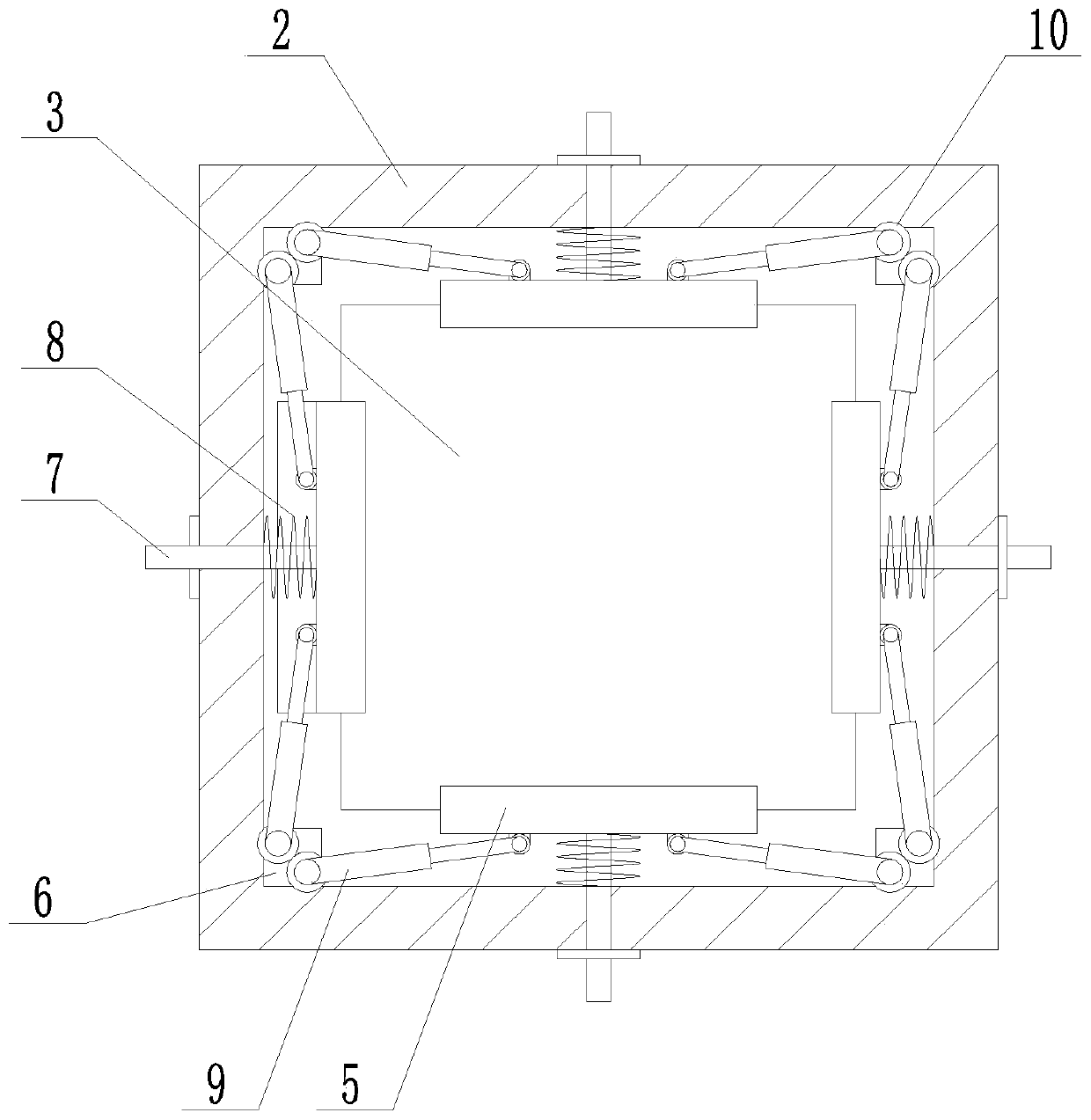

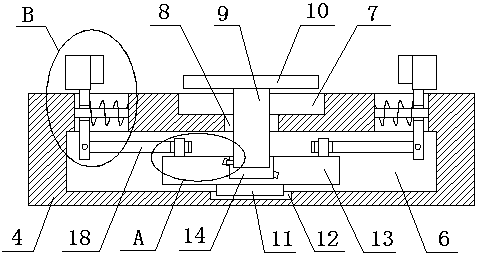

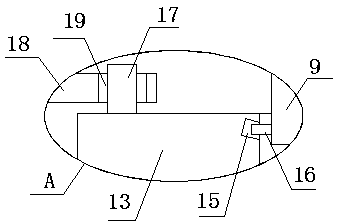

Automatic mechanical equipment lifting device

ActiveCN109879154ANon-rotating vibration suppressionLoad-engaging elementsGround vibrationsMechanical equipment

Owner:平庆义

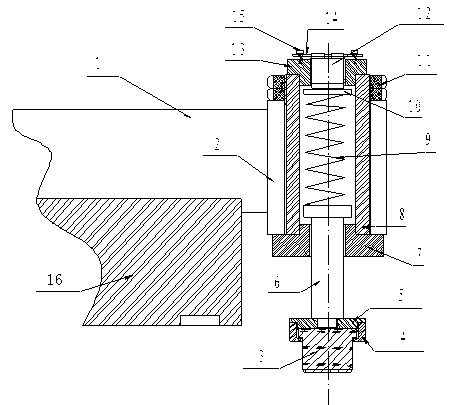

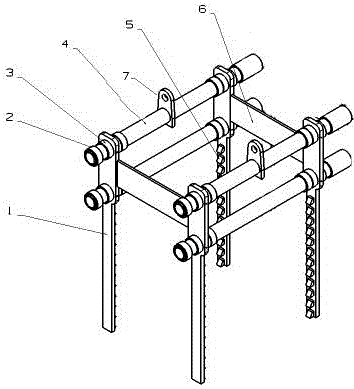

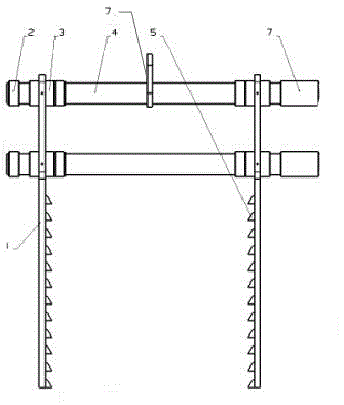

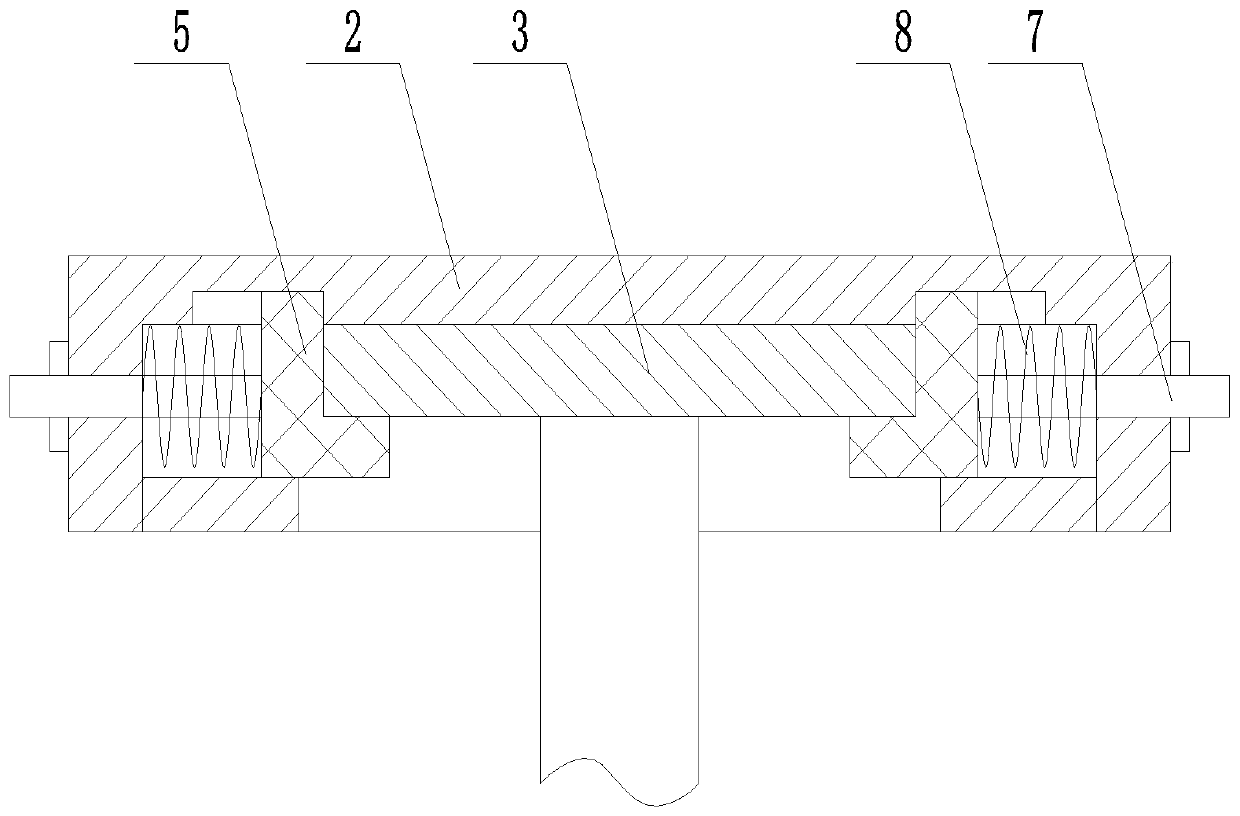

Device and method for rapid replacement of lower connecting shaft of horizontal rolling mill

ActiveCN104891323AQuick changeEfficient replacementMetal working apparatusLoad-engaging elementsEngineeringRolling mill

The invention provides a device and method for rapid replacement of a lower connecting shaft of a horizontal rolling mill. The device comprises suspension mechanisms and driving mechanisms, wherein the suspension mechanisms are used for being movably arranged on an upper connecting shaft of the horizontal rolling mill, and the driving mechanisms are arranged on the suspension mechanisms and are used for driving the suspension mechanisms to move on the upper connecting shaft of the horizontal rolling mill. The analysis result shows that the lower connecting shaft can be replaced rapidly and efficiently, and the purposes that the operation difficulty is reduced, and the labor efficiency is improved are achieved.

Owner:LAIWU IRON & STEEL GRP

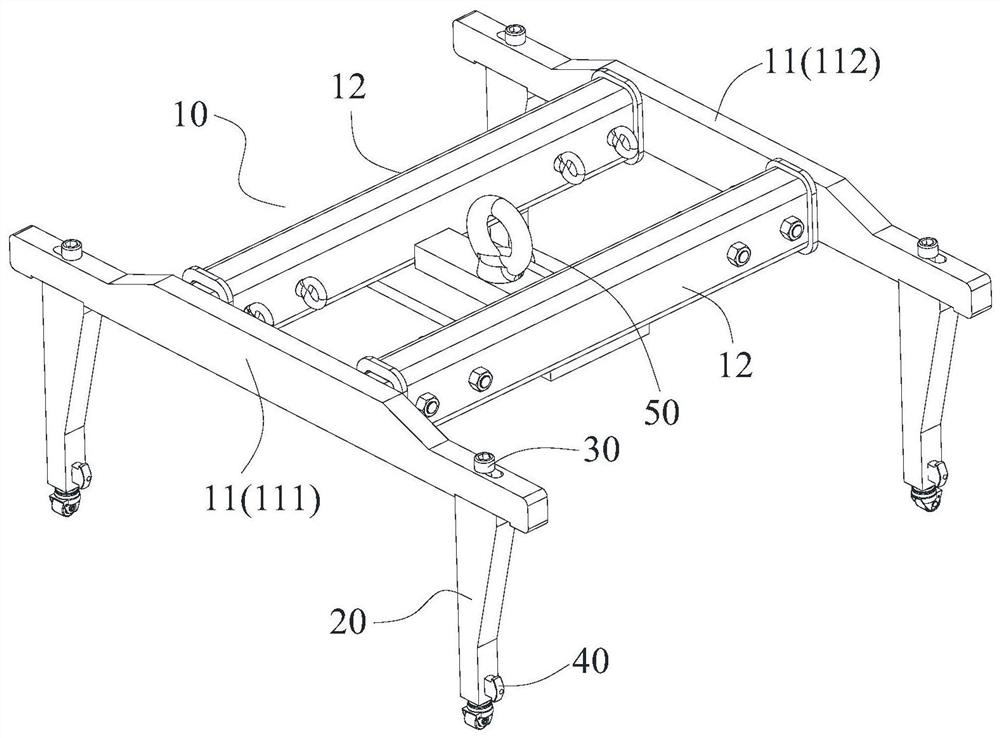

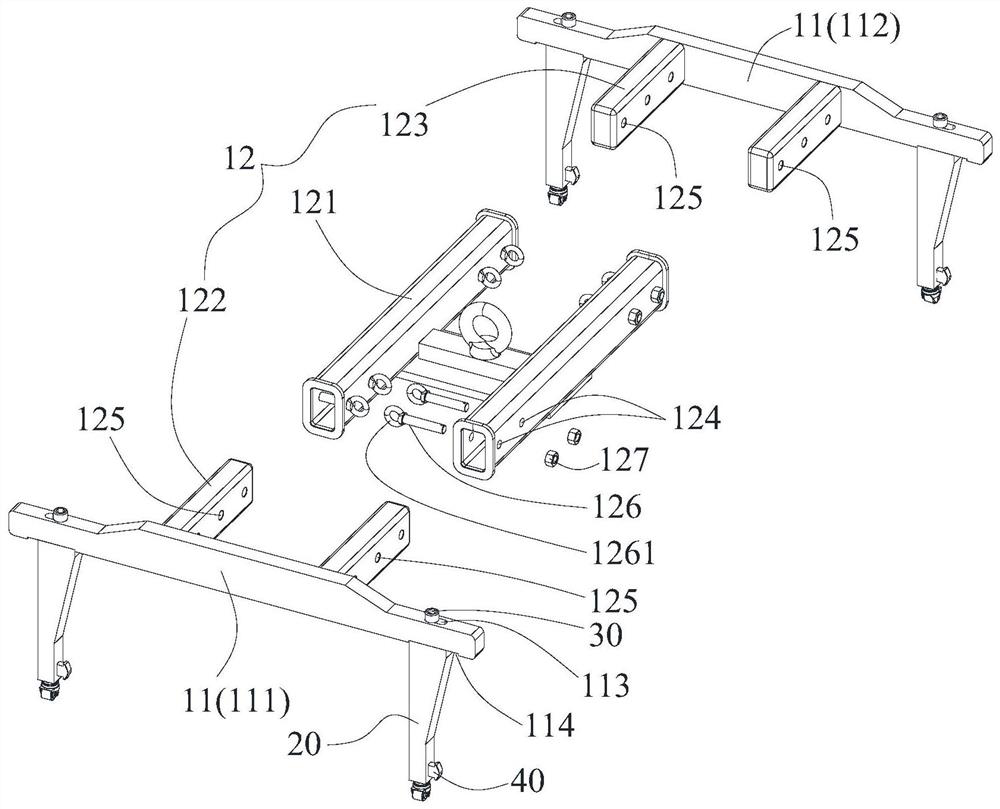

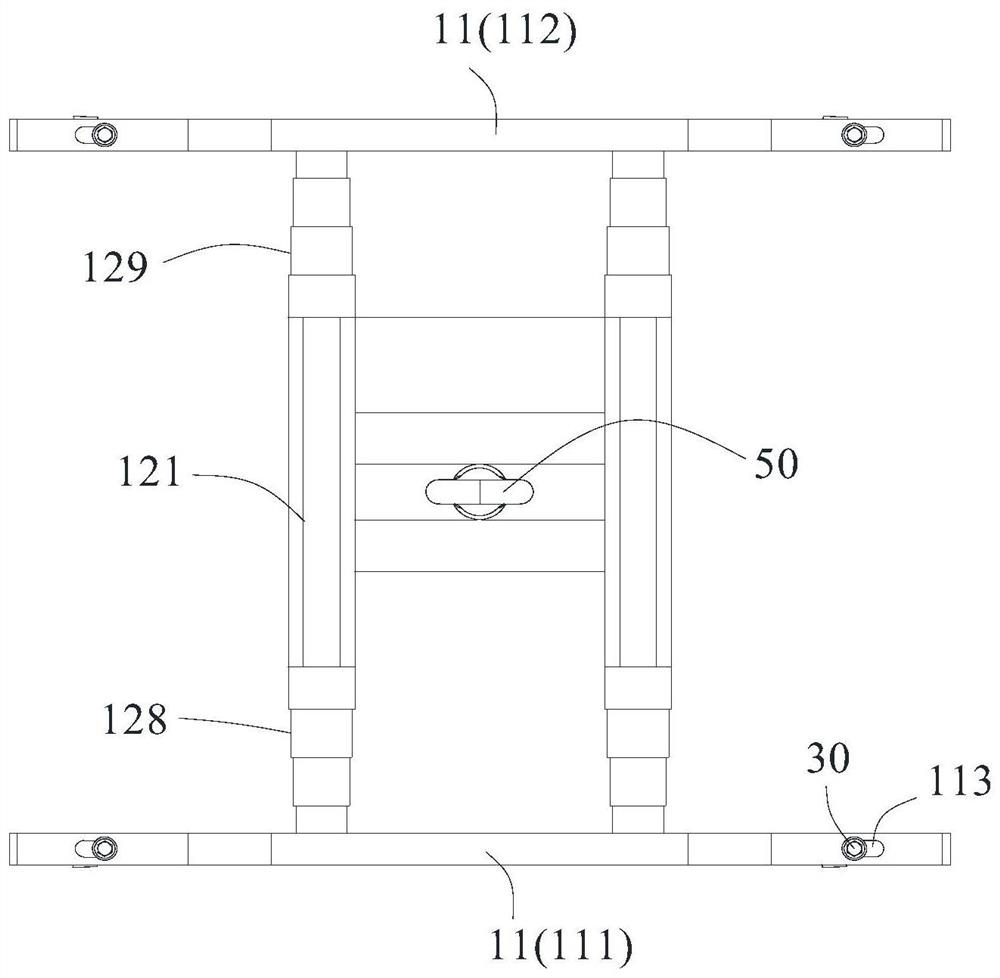

Lifting appliance suitable for automobile bodies of different sizes

InactiveCN114030983AEasy to adjust the distanceEasy to adjust the positionLoad-engaging elementsHydraulic cylinderMultiple sensor

Owner:盐城市通盈汽车车厢制造有限公司

Assembly type laminated slab installation construction auxiliary device

Owner:SICHUAN AEROSPACE CONSTR ENG

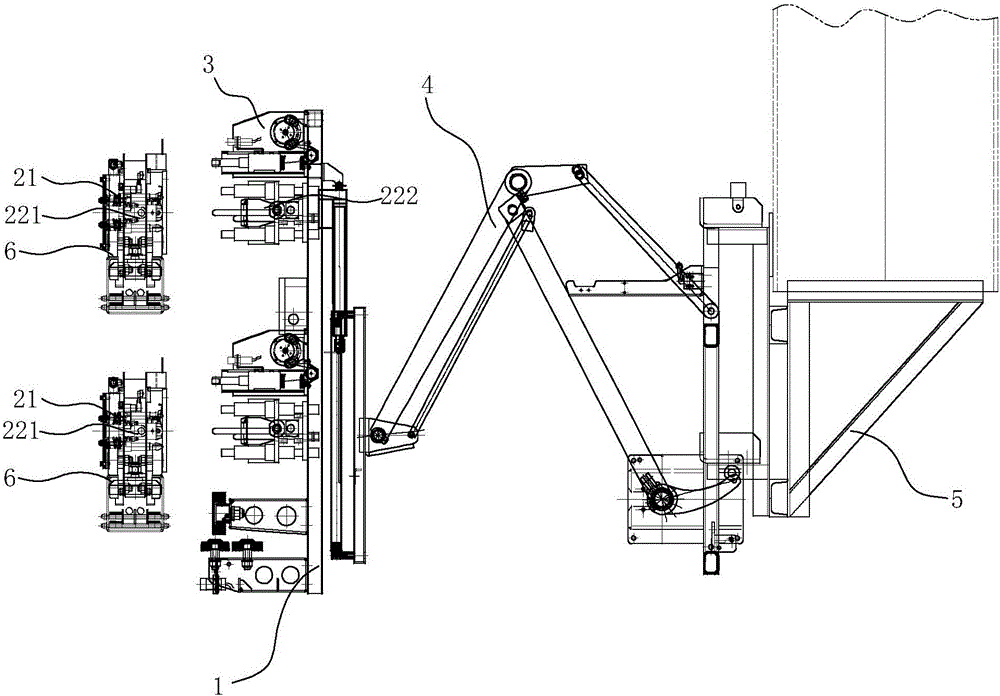

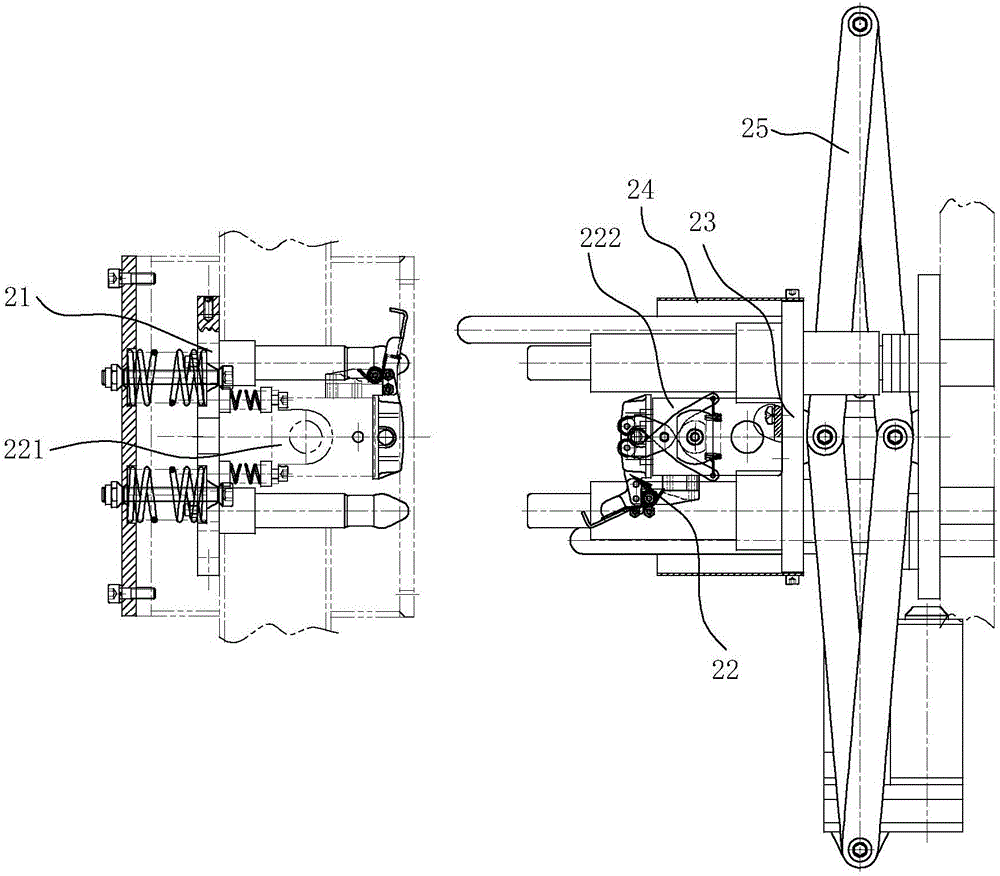

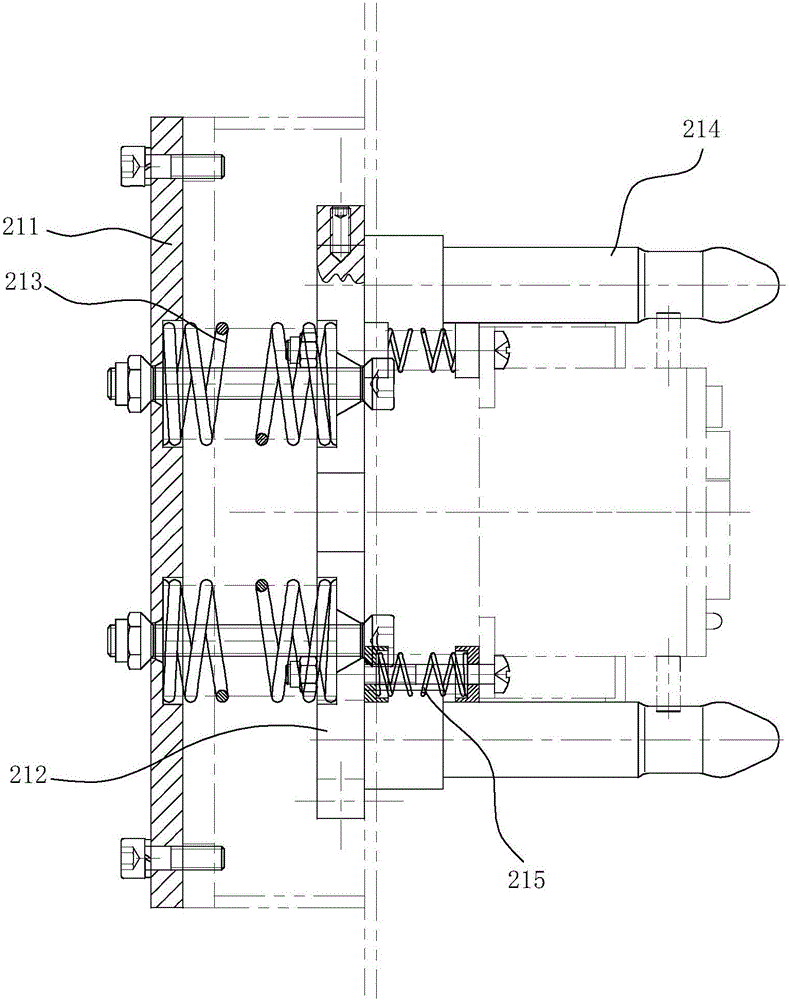

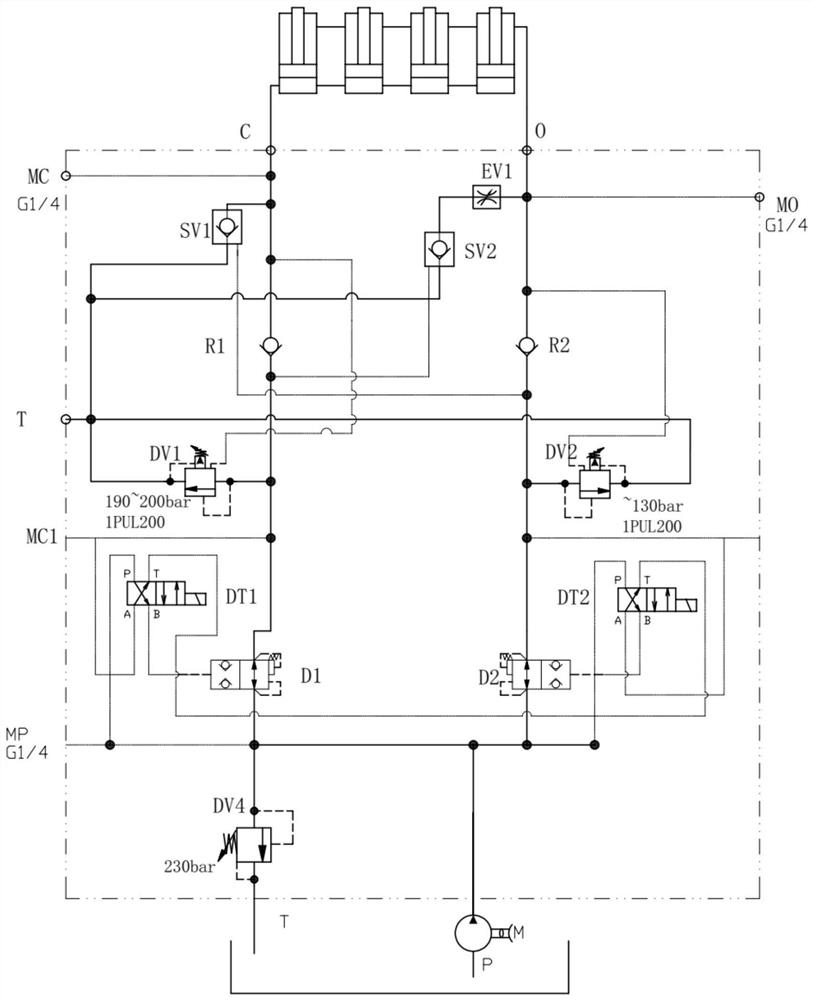

Operating system and method of electric hydraulic gripping apparatus in container loading and unloading equipment

PendingCN112897330AEasy to operateFast clamping speedServomotor componentsServomotorsPower efficientControl system

Owner:ENBEILI KUNSHAN MACHINERY

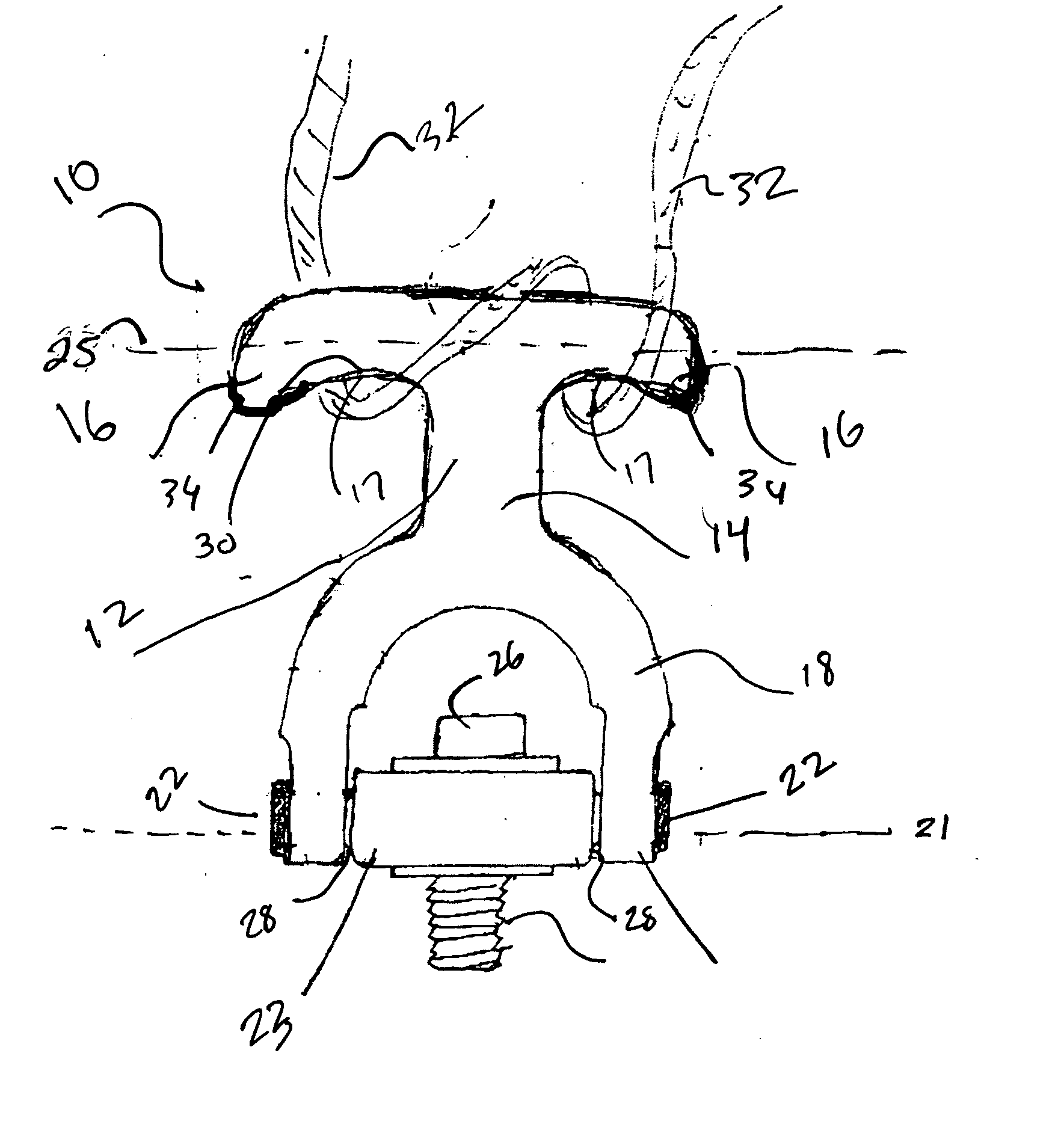

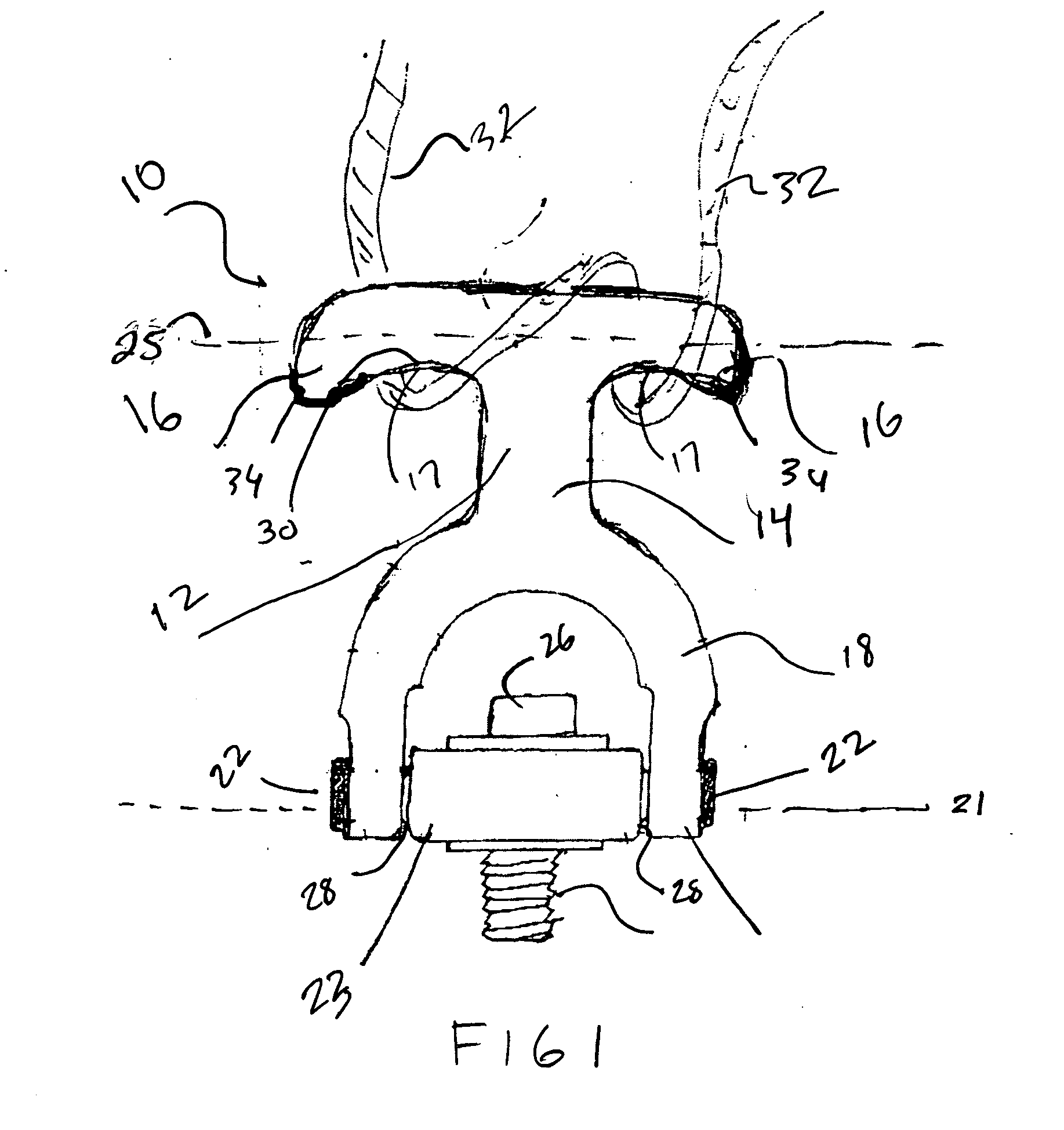

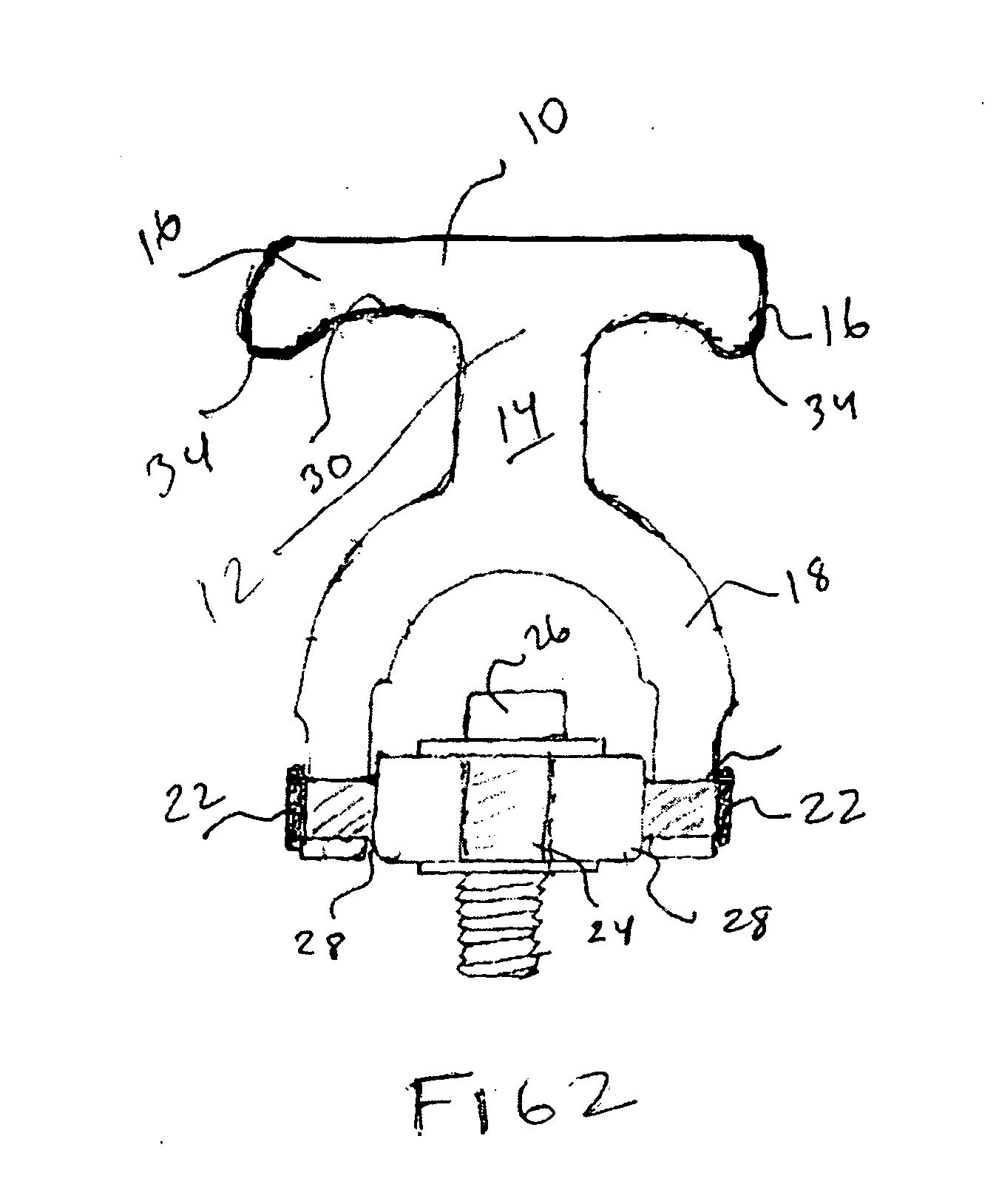

Hoist ring

Owner:MA SHU LAN

Crane for automatically positioning and aligning at position to search object in corresponding position in nuclear radiation environment

InactiveCN104176644APrecise positioning operationRealize automatic crawlingTravelling cranesLoad-engaging elementsNuclear radiationProgrammable logic controller

Owner:SICHUAN TUOJIANG CRANE EQUIP

Hoisting frame and lifting hook for hoisting frame

PendingCN112744693AEasy to operateEasy accessLoad-engaging elementsStructural engineeringControl theory

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

Active composite variable damping rotational control device

ActiveUS20200355237A1Improve robustnessRotating vibration suppressionCosmonautic vehiclesDriver/operatorDrive shaft

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Building material hoisting protection frame

InactiveCN113845029AImprove stabilityReduce load increaseLoad-engaging elementsArchitectural engineeringGravity center

The invention relates to the technical field of building materials, and discloses a building material hoisting protection frame. The building material hoisting protection frame comprises an outer shell, the outer portion of the outer shell is movably connected with a balance adjusting mechanism, the balance adjusting mechanism comprises a measuring assembly used for detecting the gravity center position of the outer shell and a counterweight assembly used for keeping the gravity center of the outer shell at the horizontal stable position, and the measuring assembly is movably connected outside the outer shell; and the swinging of a horizontal rod is sensed in time through the swinging angle of the horizontal rod outside a clamping plate and the contact between the swinging of the horizontal rod and an electrified contact and an electrified contact strip, so that the gravity center change position of building material hoisting is detected, the real-time gravity center feedback of building material hoisting is improved, the intelligent operation in the hoisting process is improved, meanwhile, a moving plate moves to enable a supporting rod to move, the supporting rod moves to enable the supporting claws to move to balance the mass difference of gravity center change, so that the masses of the two ends of the hoisted building material are always in the same state, the gravity center is dynamically balanced, and the hoisting stability is improved.

Owner:CHUZHOU WENJIAN DOOR & WINDOW ENG CO LTD

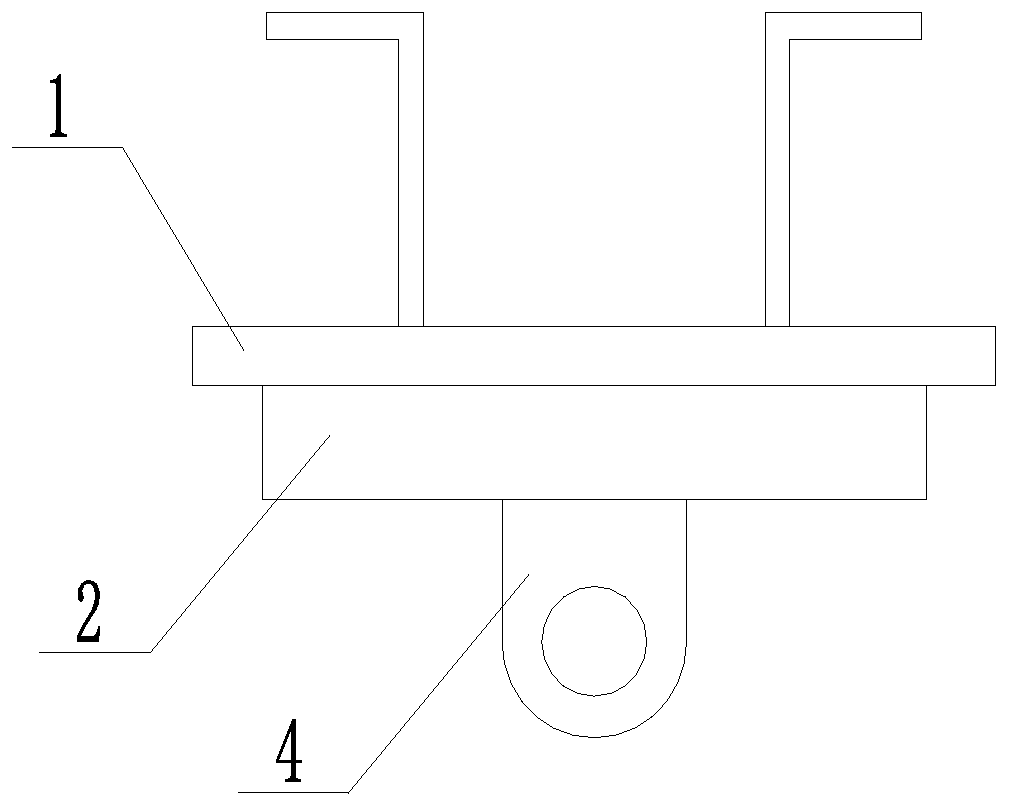

Waste steel hopper with automatic hook assembling and disassembling function

InactiveCN112279084ARealize automatic hook loadingNo need for manual hookingLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a waste steel hopper with an automatic hook assembling and disassembling function. The waste steel hopper with the automatic hook assembling and disassembling function comprises a waste steel hopper body and a lifting hook, wherein two first trunnions and two second trunnions are symmetrically arranged on the outer side wall of the waste steel hopper body; a clamping station and a mounting station are arranged on the lifting hook at an interval, and the lifting hook is connected to the waste steel hopper body through the mounting station and the first trunnions in a matched mode; during hoisting, the lifting hook slides on the waste steel hopper body through the mounting station, so that the clamping station is correspondingly clamped with the second trunnions; andduring hopper reversing, the lifting hook slides in the opposite direction of sliding during hoisting, so that the clamping station is separated from the second trunnions. According to the waste steelhopper with the automatic hook assembling and disassembling function, the lifting hook is connected to the waste steel hopper through the mounting station, when hoisting or hopper reversing is needed, after the lifting hook slides along the first trunnions, the clamping station on the lifting hook is clamped with or separated from the second trunnions, automatic hook assembling or disassembling can be realized by a crane operator during hoisting, manual hook assembling or disassembling is not needed, and potential safety hazards are eliminated.

Owner:SGIS SONGSHAN CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap