Vacuum suction apparatus

a vacuum suction and suction tube technology, applied in the direction of machine supports, building scaffolds, other domestic objects, etc., can solve the problems of gradual loss of elasticity and suction strength, clippers not fitting on all automobiles, etc., and achieve the effect of reliable mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

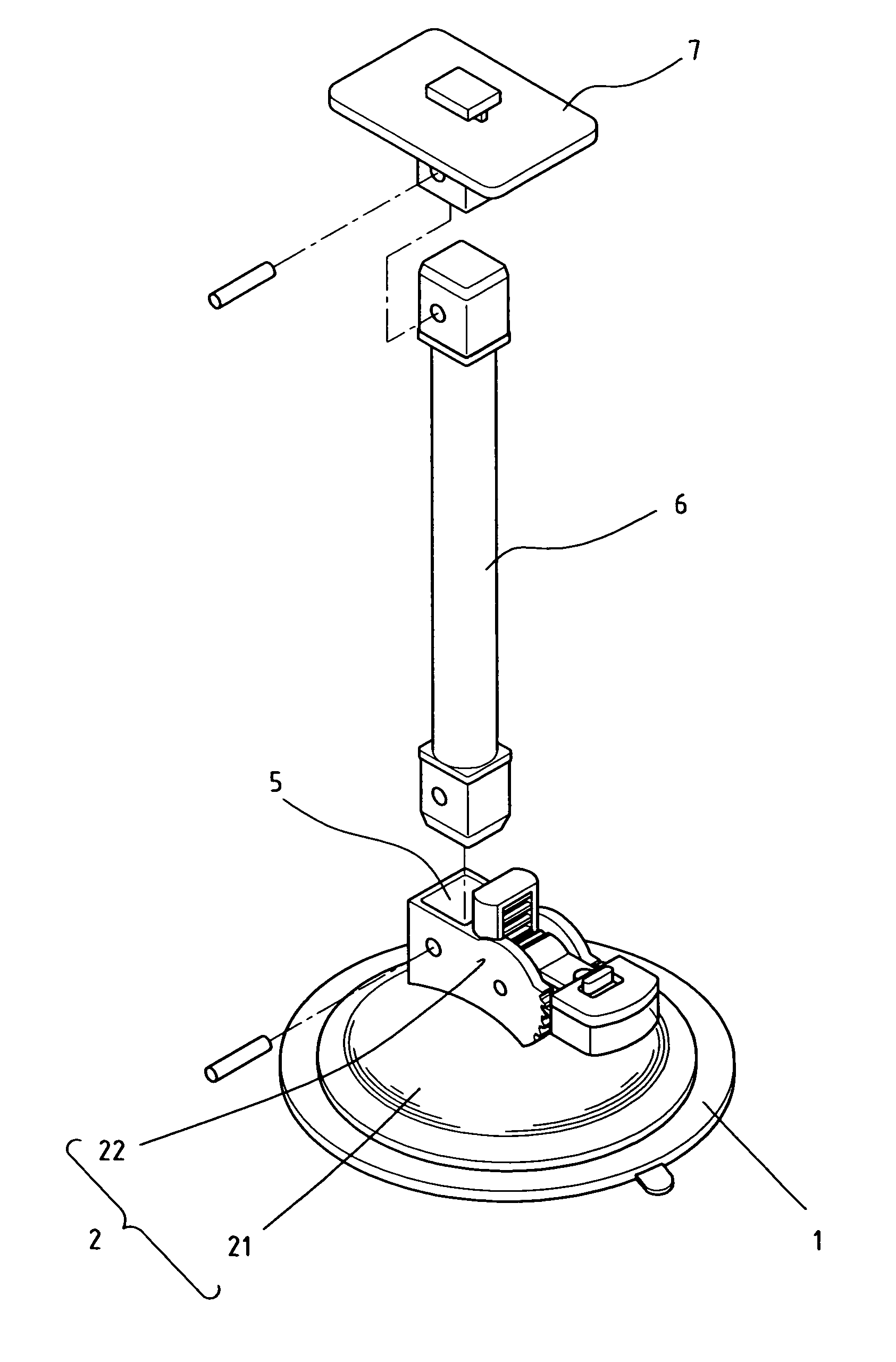

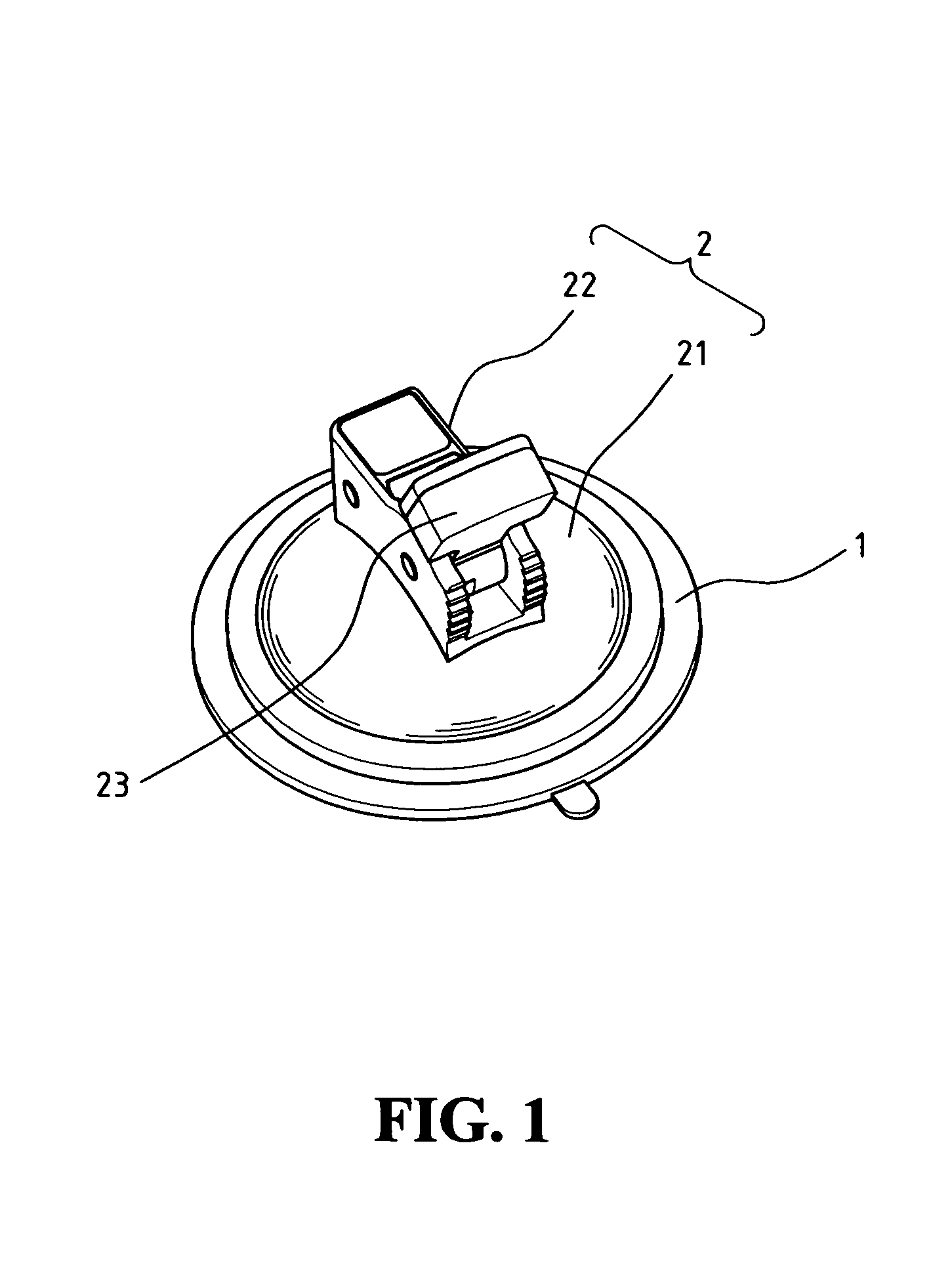

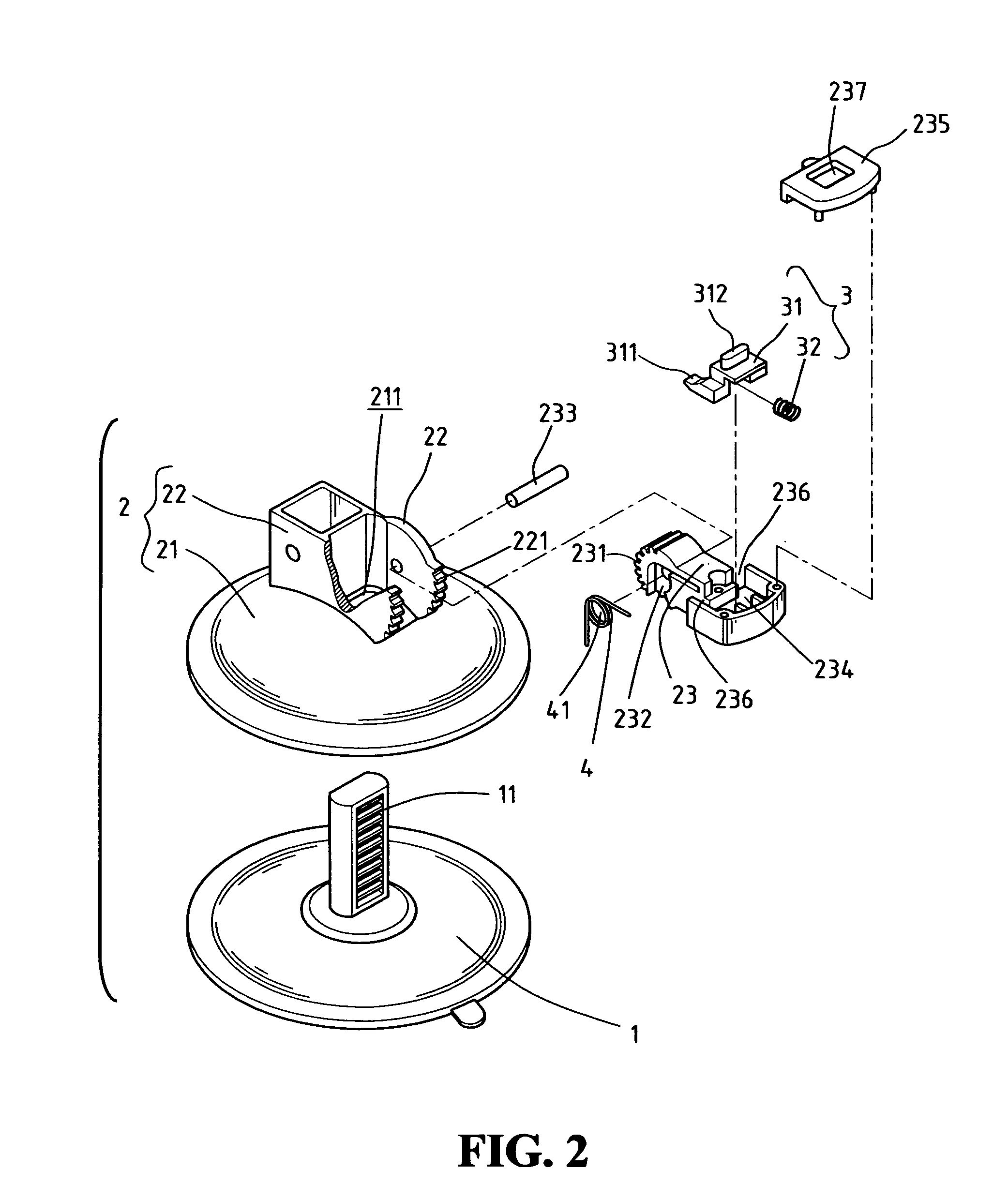

[0019]Referring to FIGS. 1 and 2, a vacuum suction apparatus in accordance with the present invention includes a suction cup 1, and a wheel base 2 that is installed over the suction cup 1. A rack 11 is vertically erected from the center of the suction cup 1 passing through the wheel base 2. The suction cup is formed by rubber or polyvinyl chloride (PVC) material, and the rack 11 is made out of material harder than the suction cup 1.

[0020]Referring to FIG. 3A, the wheel base 2 has a receptacle 21 attached by the suction cup 1 from underneath, a cogwheel 22 being fixed over the receptacle 21, and an adjustment lever 23 pivotally connected through a slot opening. The receptacle 21 is a circular body with a hunched back toward the center, with a slot opening 211 at the center that allows the rack 11 to pass through to the outside, also passing through the inner space of the cogwheel 22, where an adjustment lever 23 is pivotally connected having a pinion 231 on one end. Once assembled onto

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap