Auxiliary electrode structure for large-scale grounding grid ground resistance measurement

A technology of grounding resistance and auxiliary electrode, applied in the field of auxiliary electrode structure, can solve problems such as poor grounding of auxiliary electrodes, and achieve the effects of overcoming poor grounding effect, being convenient to carry, and improving measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

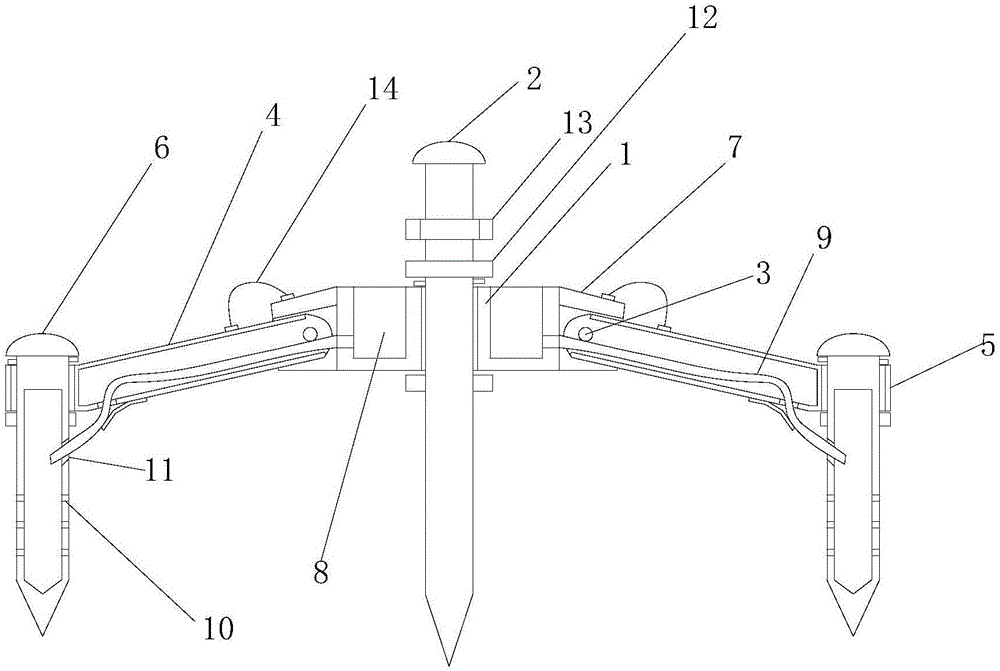

[0016] Examples. Auxiliary electrode structure for ground resistance measurement of large grounding grid, such as figure 1 As shown in Figure 2: It includes a center bracket 1 made of metal. The center bracket 1 is provided with a positioning hole in the center, and a center metal pile 2 is arranged in the positioning hole. The outer side of the center bracket 1 is connected with 6 evenly distributed pins 3 through 6 rotating pins. The support arms 4 made of metal are connected; the end of each support arm 4 is provided with a positioning sleeve 5, and a side metal pile 6 is provided in the positioning sleeve 5. The connection between the central support 1 and the support arm 4 is provided with a limit frame 7 that limits the maximum opening angle of the support arm 4 to less than 90° (in use, the support arm 4 is

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap