Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Manufacturing dynamo-electric machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

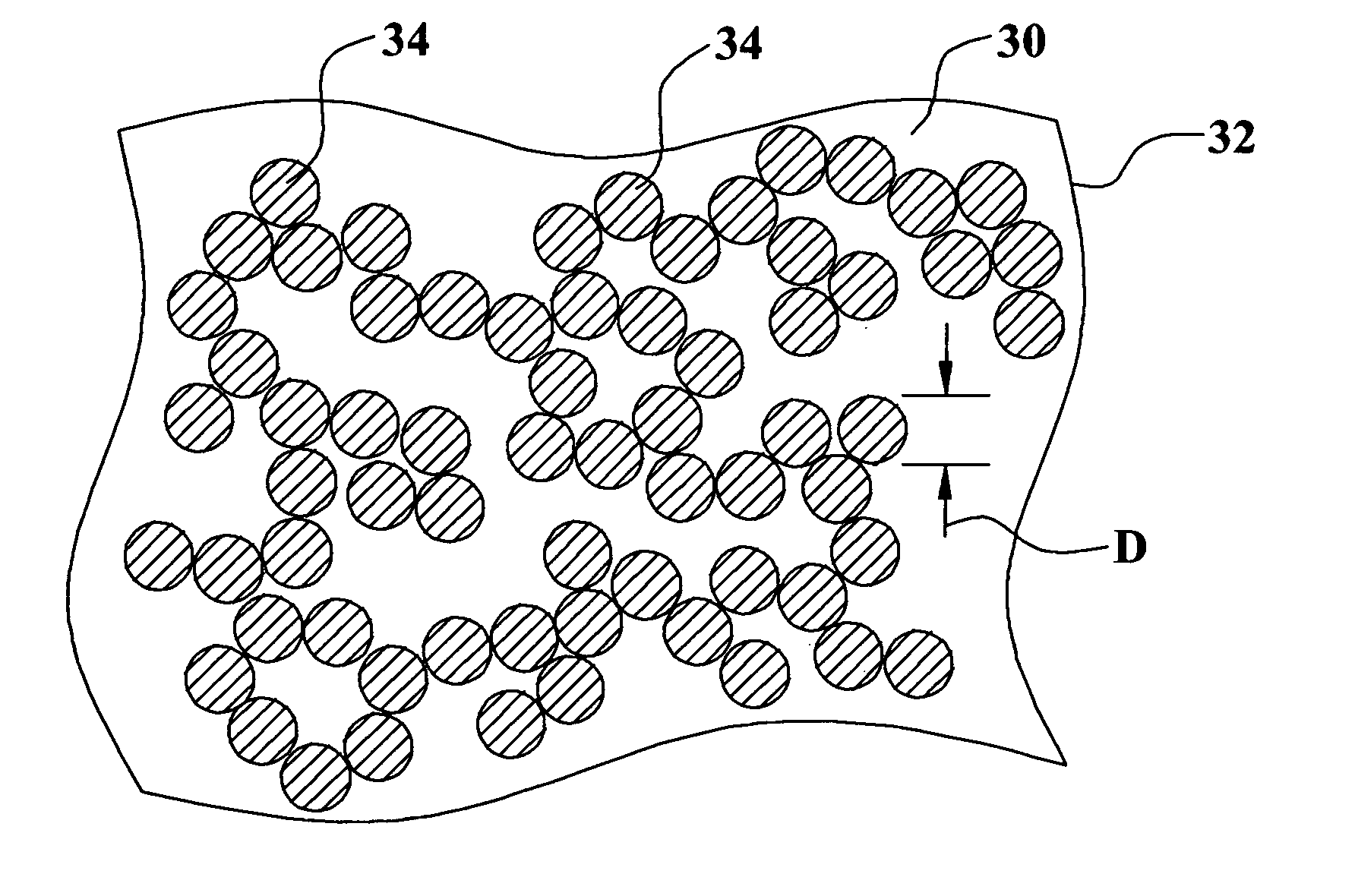

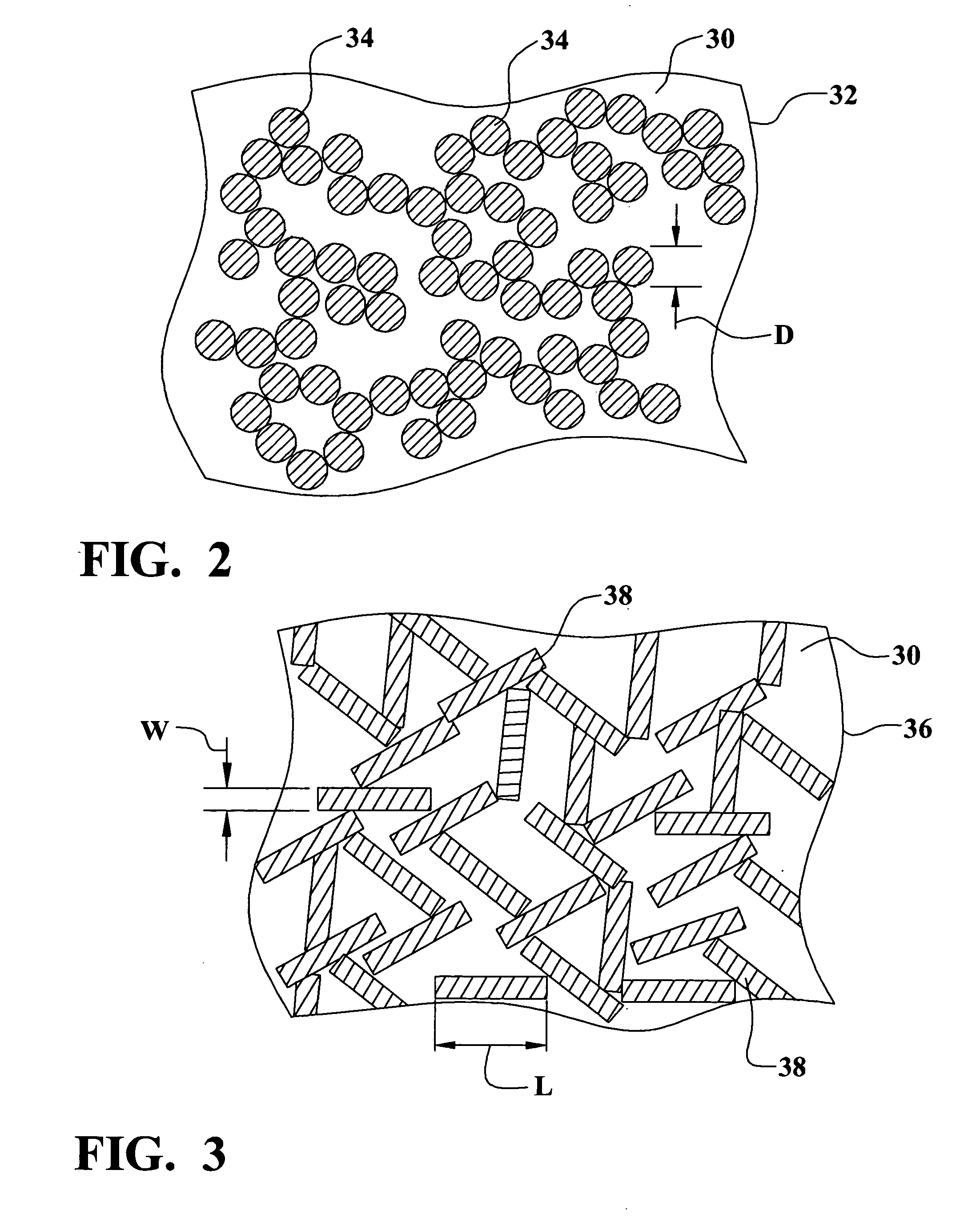

Low cost electrical motor components manufactured from conductive loaded resin-based materials

InactiveUS20050206270A1Characteristic can be alteredRotary current collectorTransformers/inductances coolingElectrical conductorMetal fibers

Owner:INTEGRAL TECHNOLOGY INC

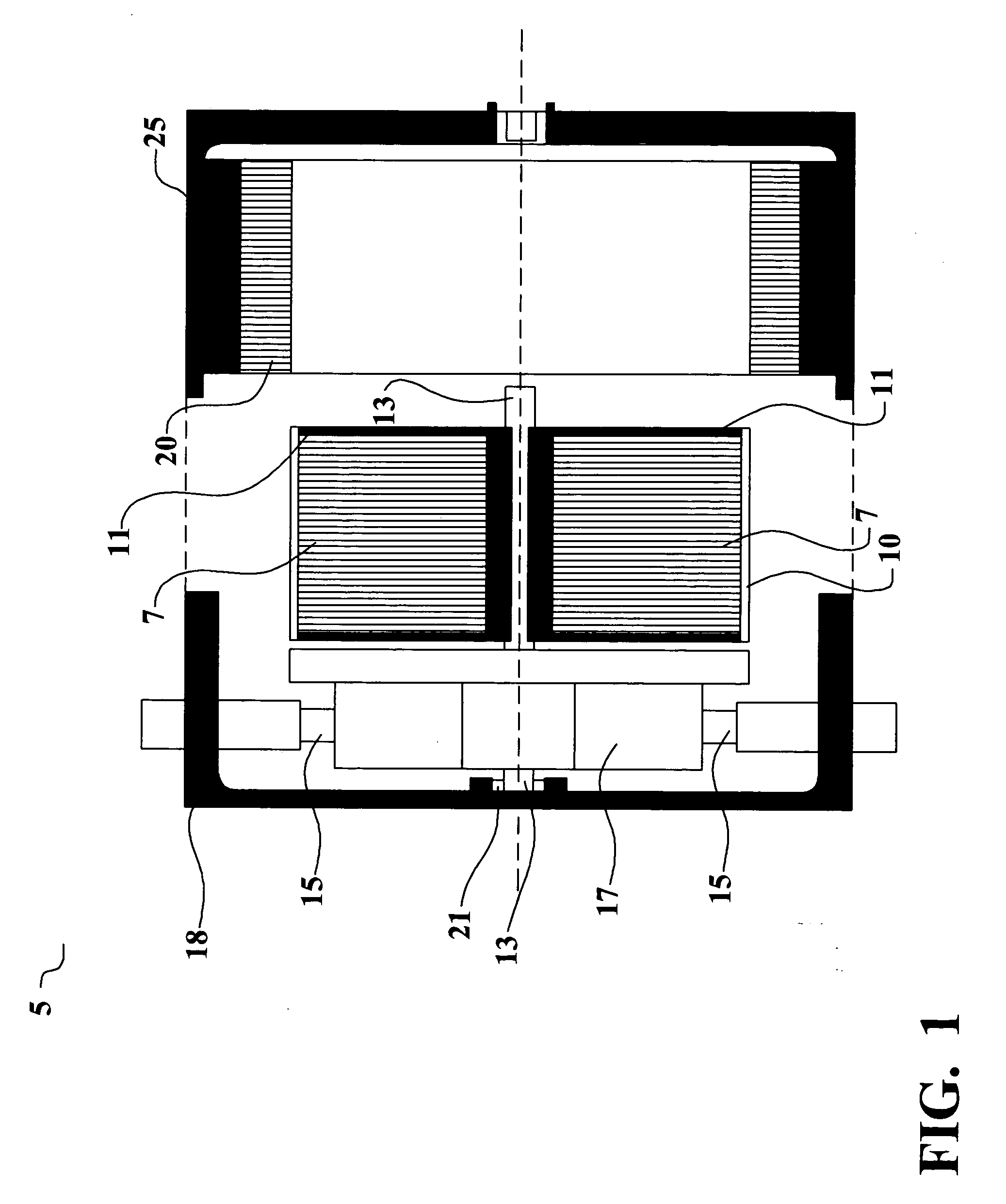

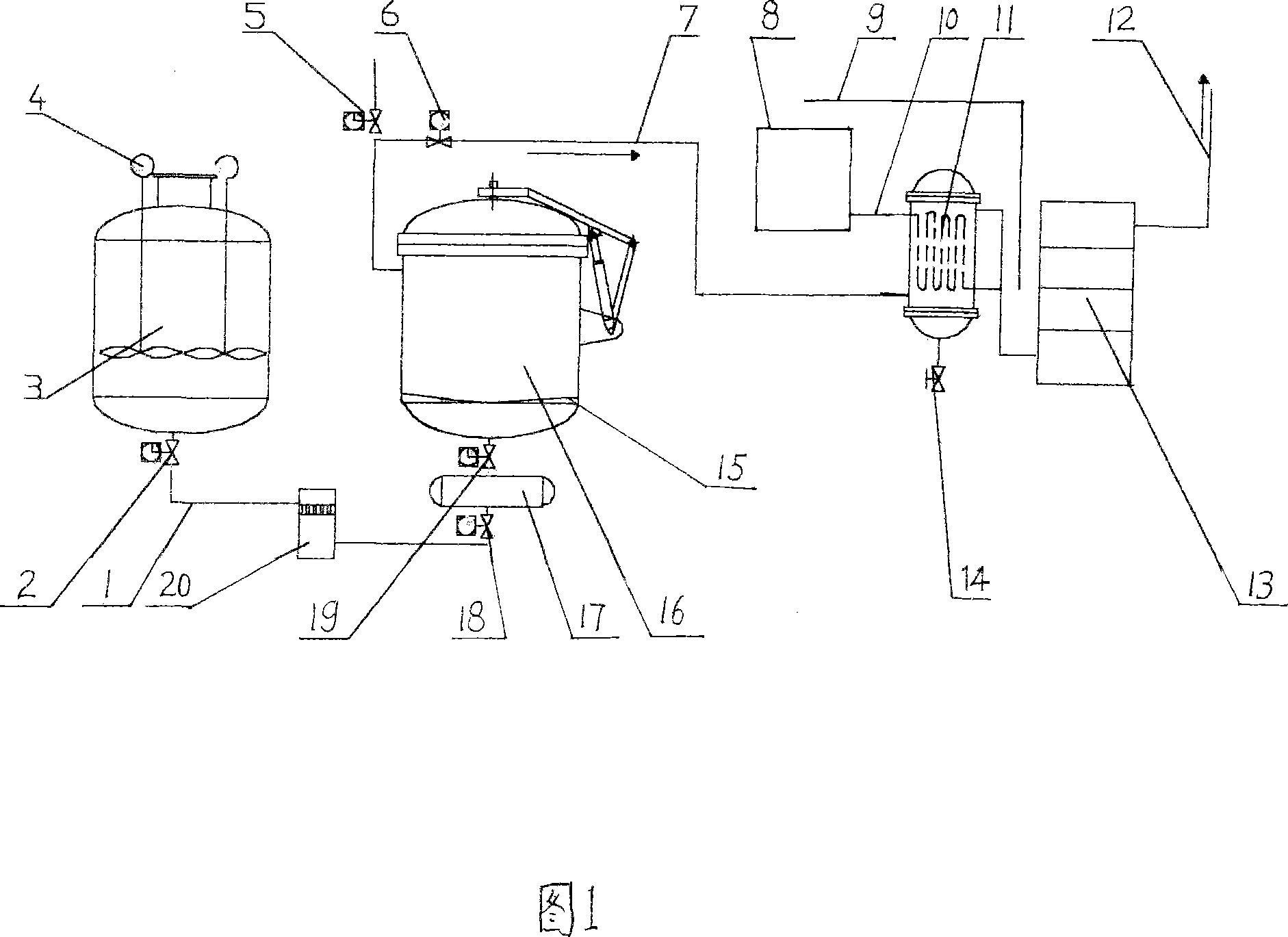

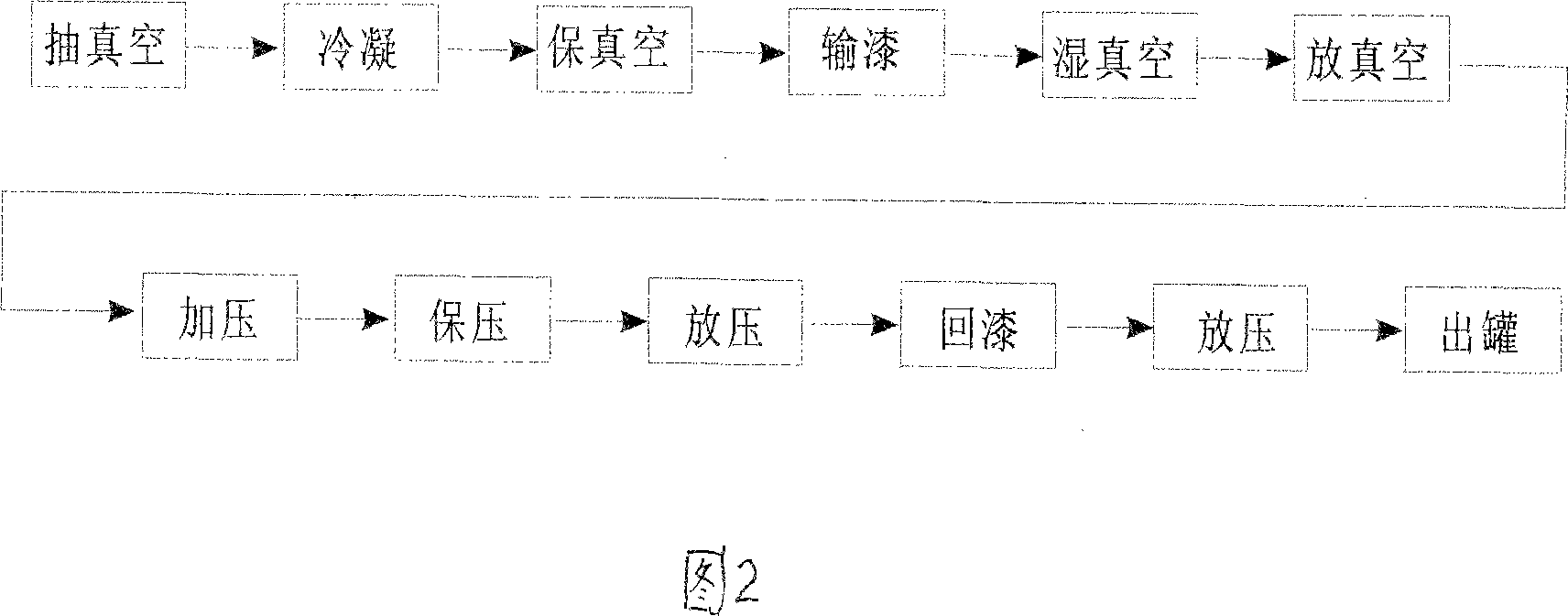

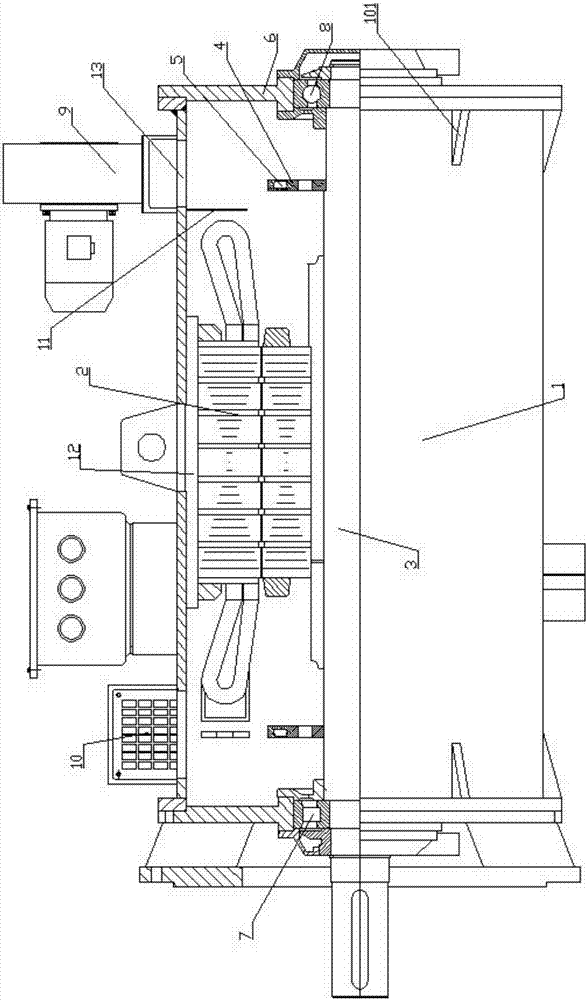

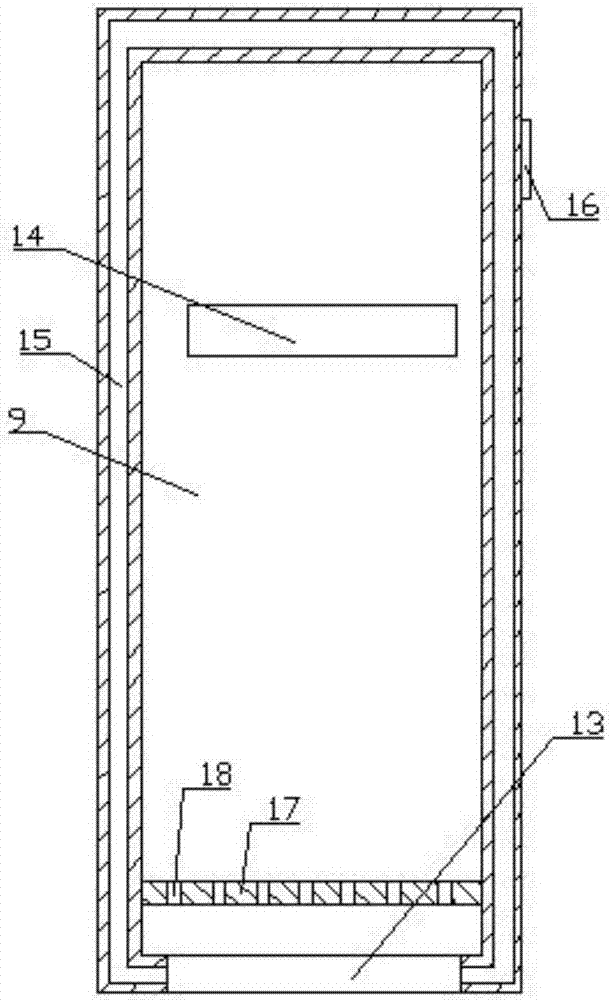

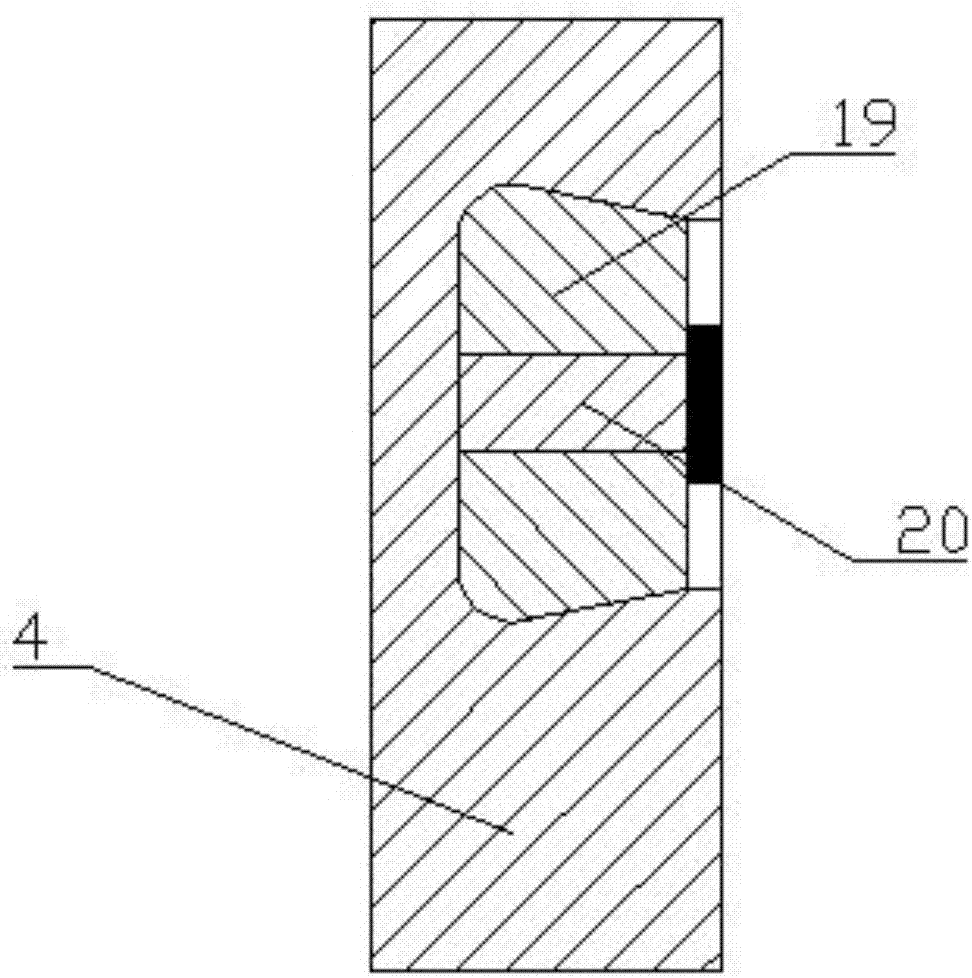

Anti-explosion vacuum pressure varnished insulation apparatus and its technical method

InactiveCN101064456ALiquid surface applicatorsManufacturing dynamo-electric machinesSolventVacuum pressure

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

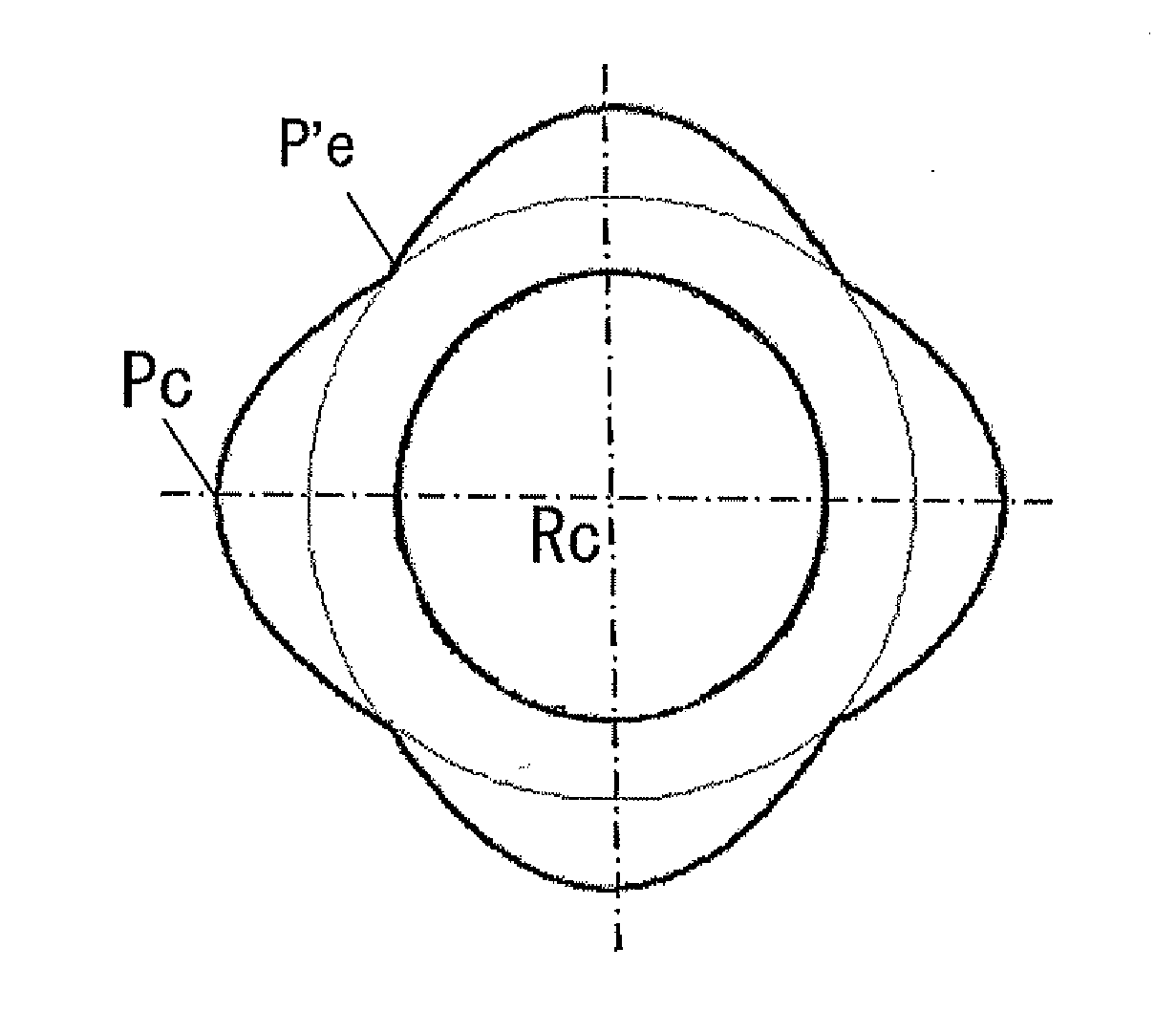

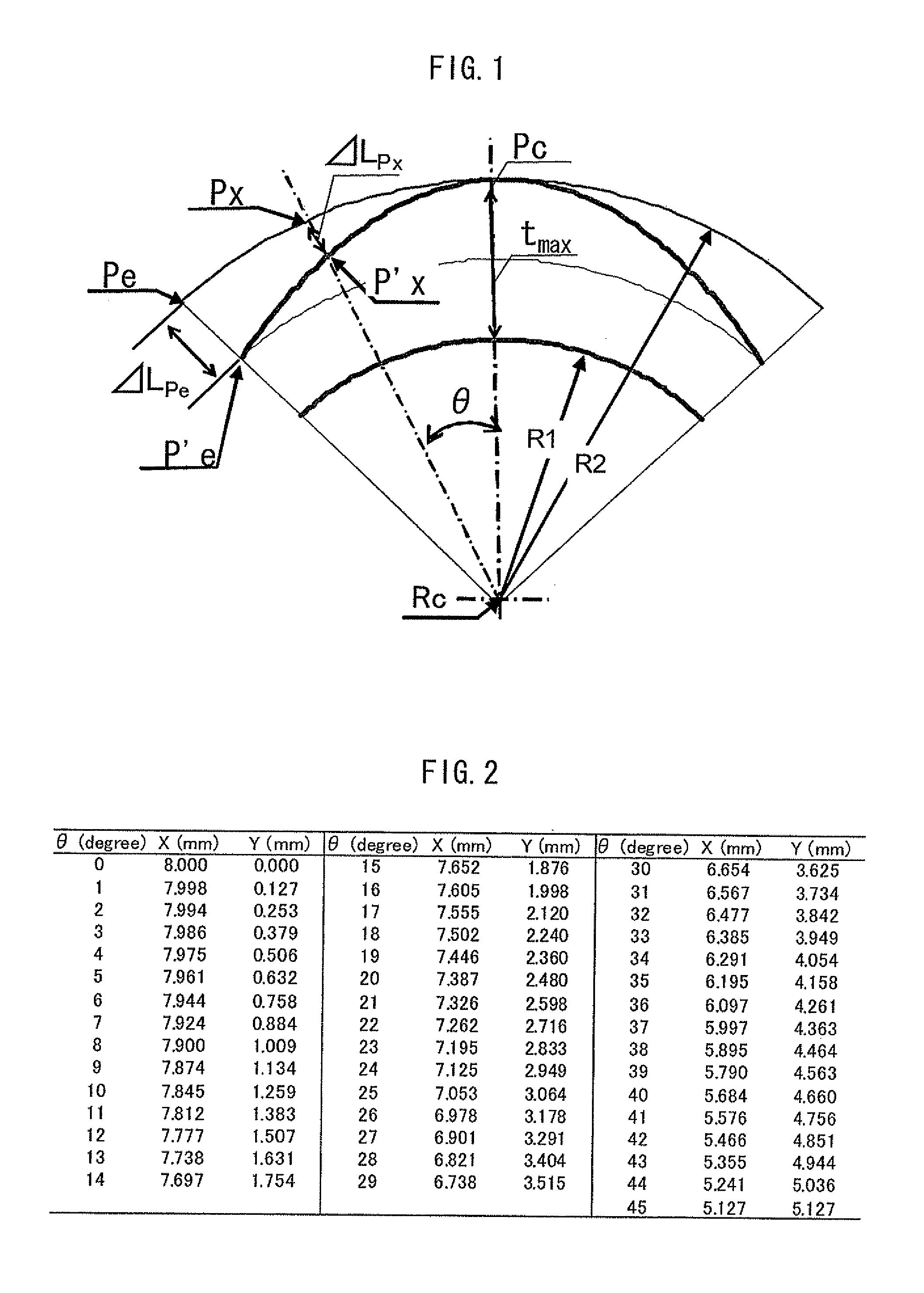

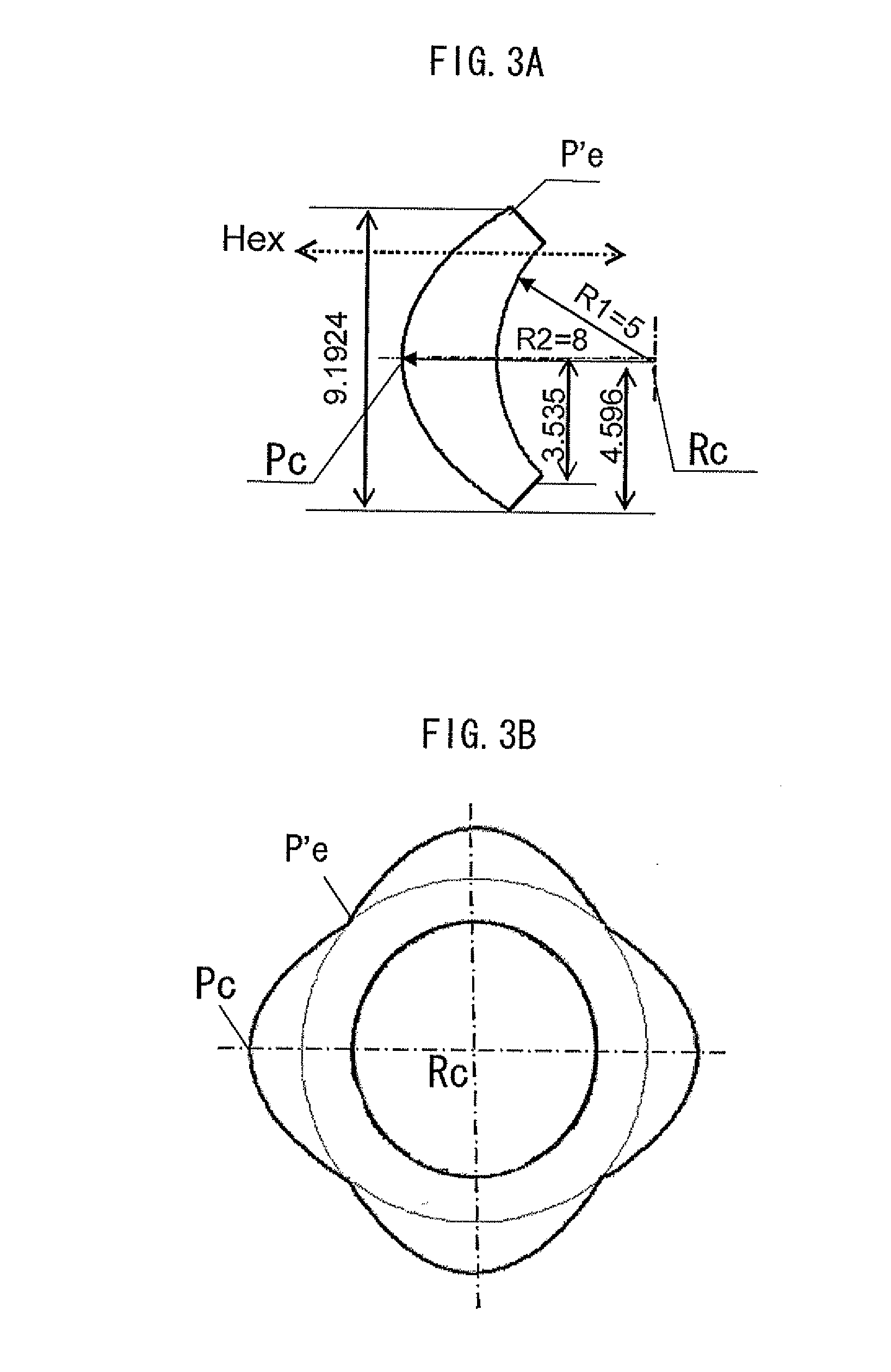

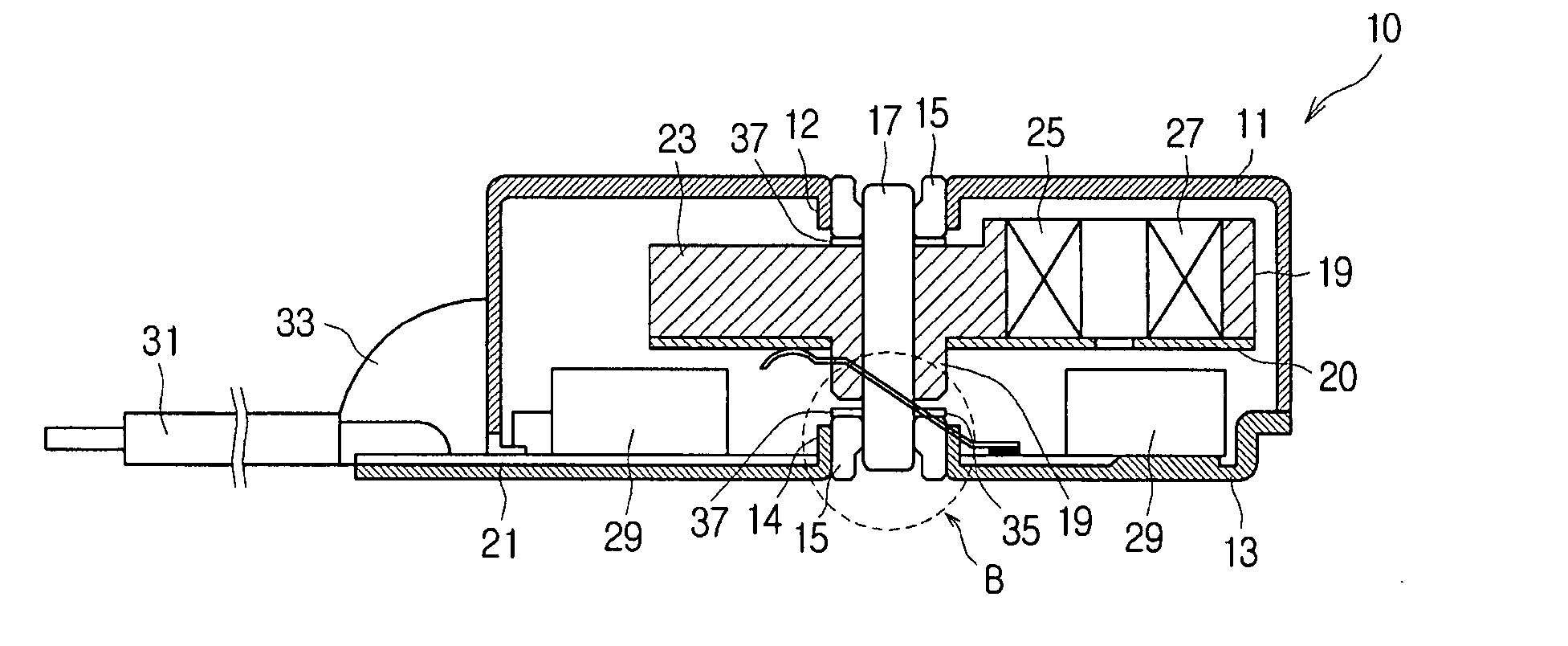

Inner rotor-type permanent magnet motor

InactiveUS20130088114A1Improve the rotation effectReduce noiseManufacturing dynamo-electric machinesMagnetic circuit characterised by magnetic materialsRemanenceRotational axis

Owner:MINEBEA CO LTD

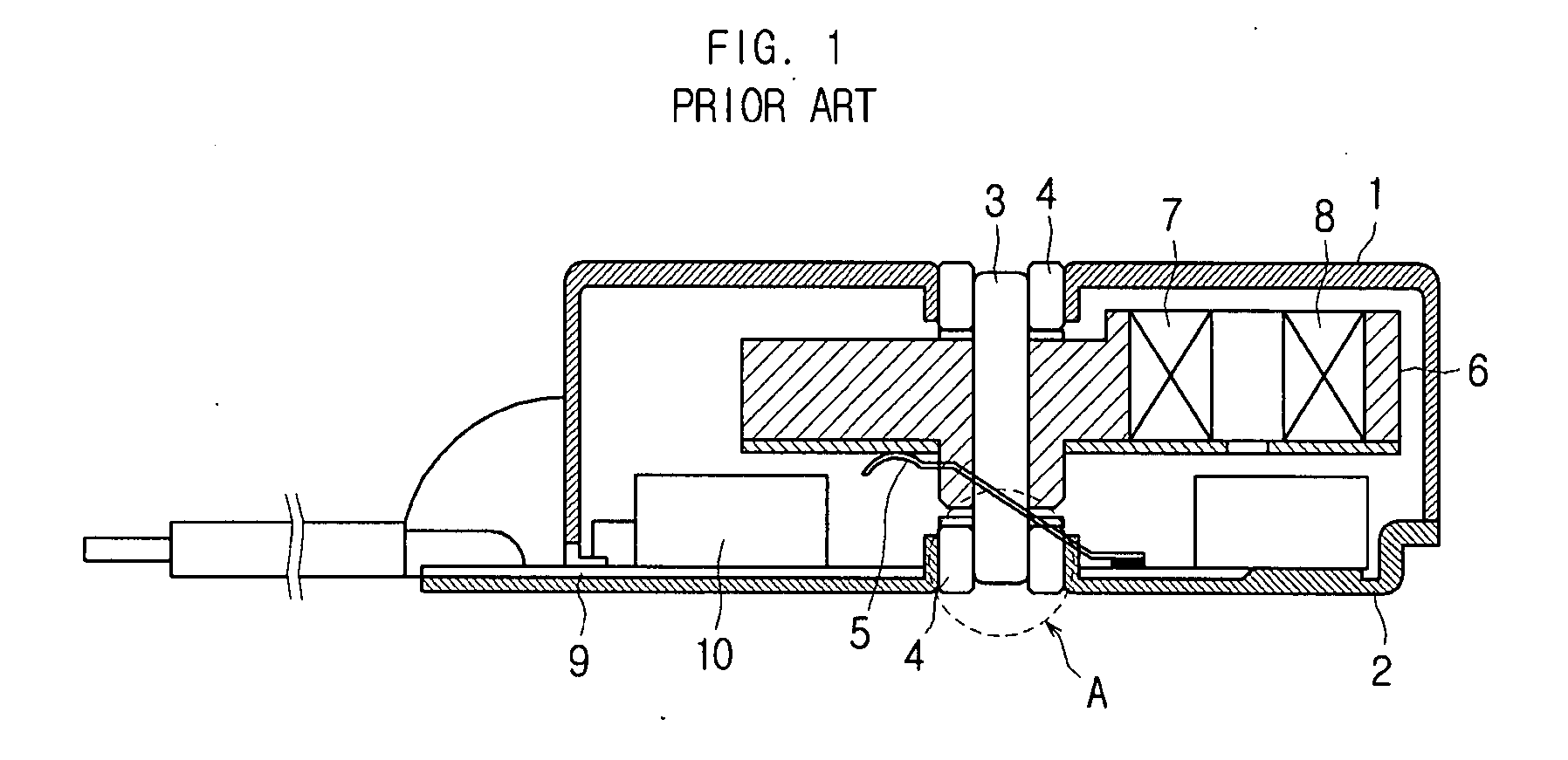

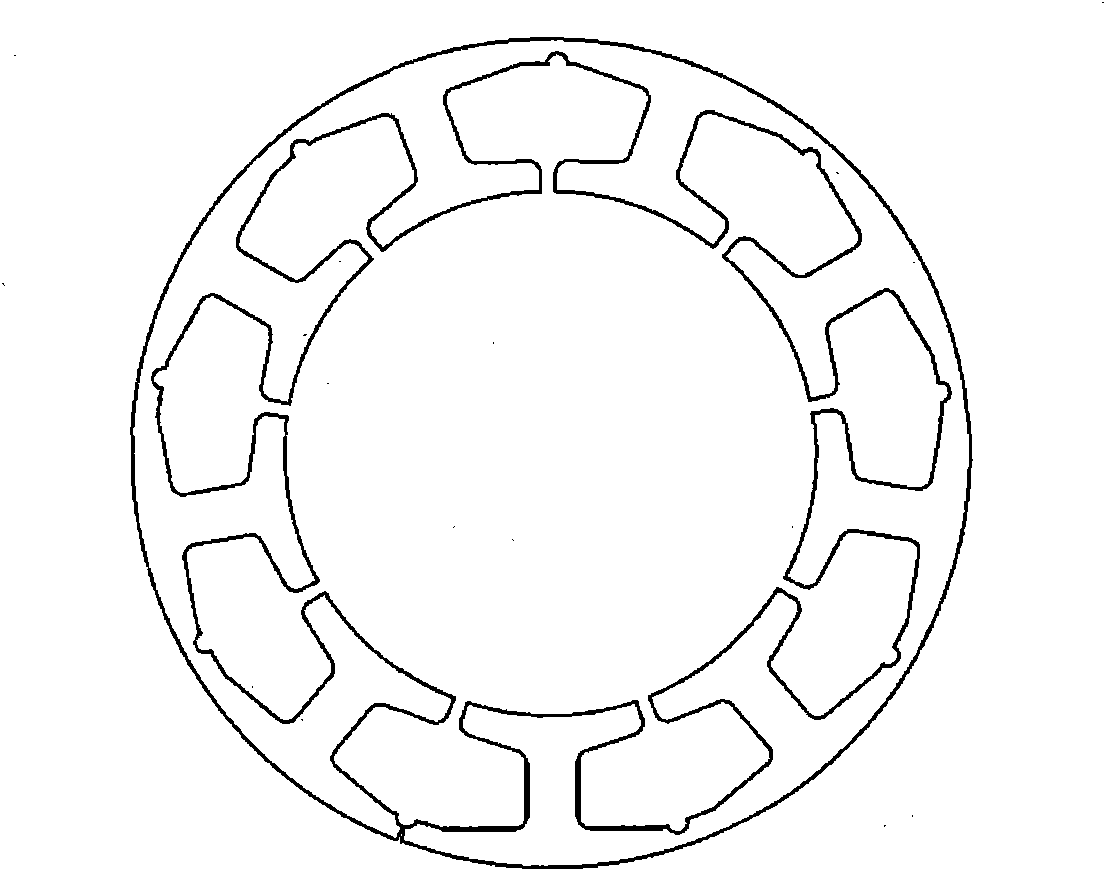

Slotless motor

ActiveUS20090315427A1Simply and accurately couplingSynchronous machinesMagnetic circuit stationary partsStator coilCircular coil

A stator coil of a slotless motor is disclosed in which the stator coil is formed in such a manner that respective both distal ends of two unit coil bodies, each unit coil body arranged to face each other, are respectively coupled to form a plurality of circular coil bodies, each circular coil body having a different inner diameter, and a circular coil body having a smaller inner diameter is sequentially inserted into an inner side of a circular coil body having a larger inner diameter, whereby a horizontal width of the plurality of unit coil bodies of U, V and W phases is equal there among to cause the strength of the magnetic field of U, V and W phases to be equal, and to allow the stator to be accurately manufactured, thereby catering to a designer's intention and markedly simplifying the assembly processes.

Owner:KOREA ELECTRONICS TECH INST

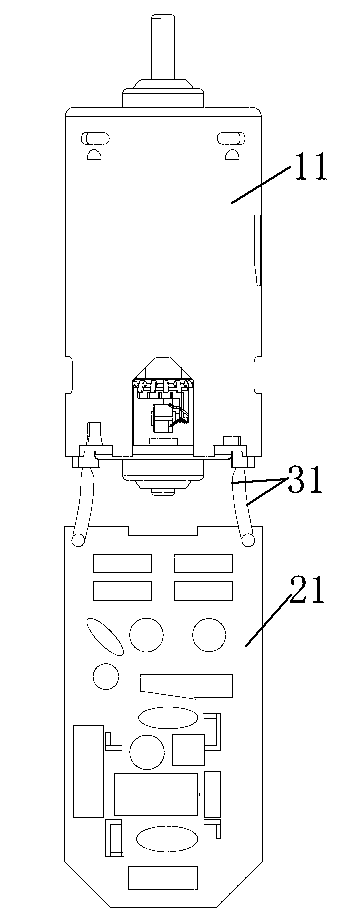

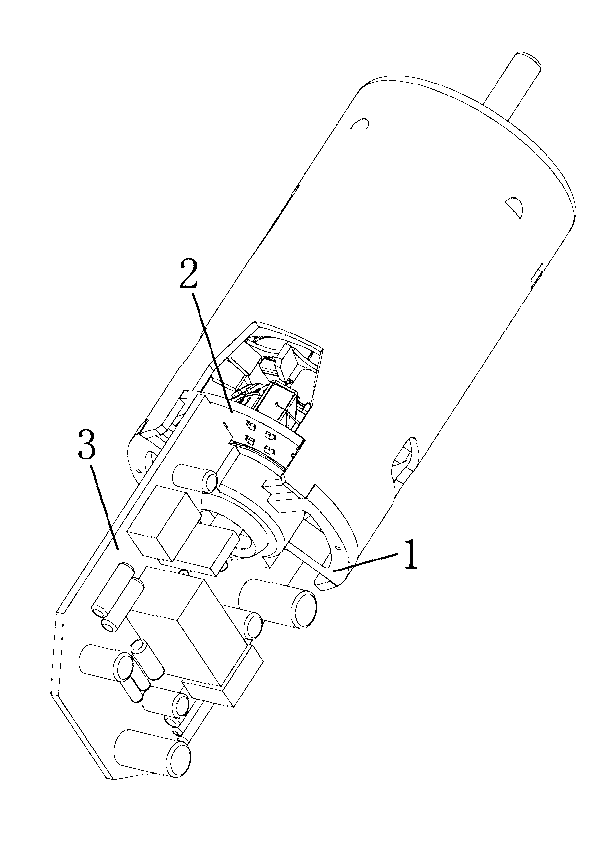

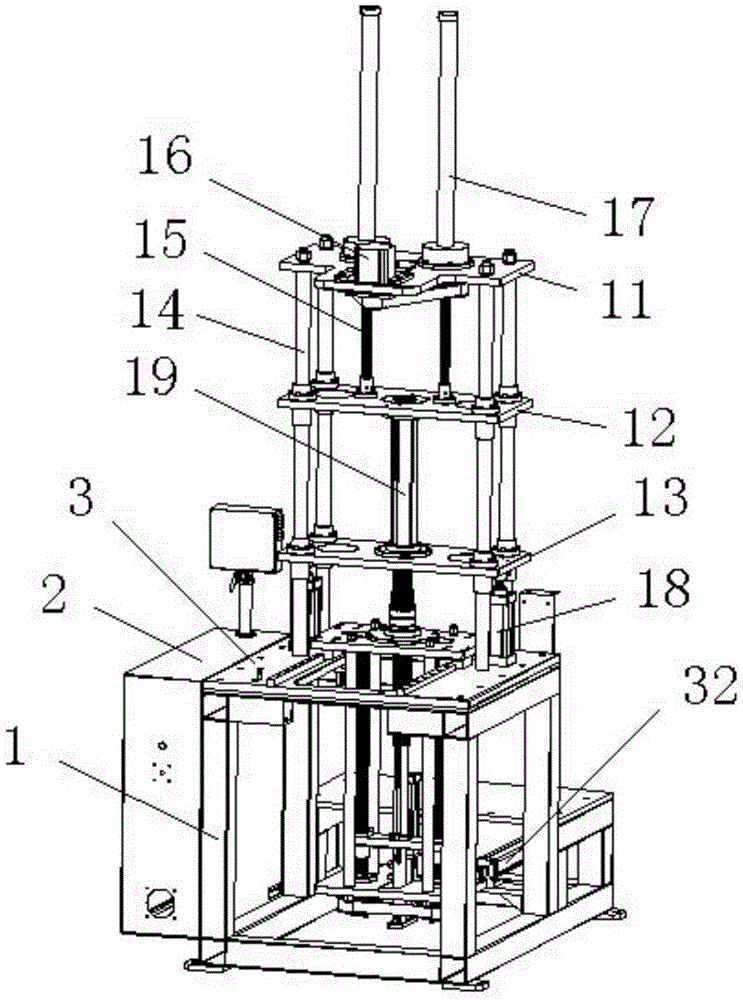

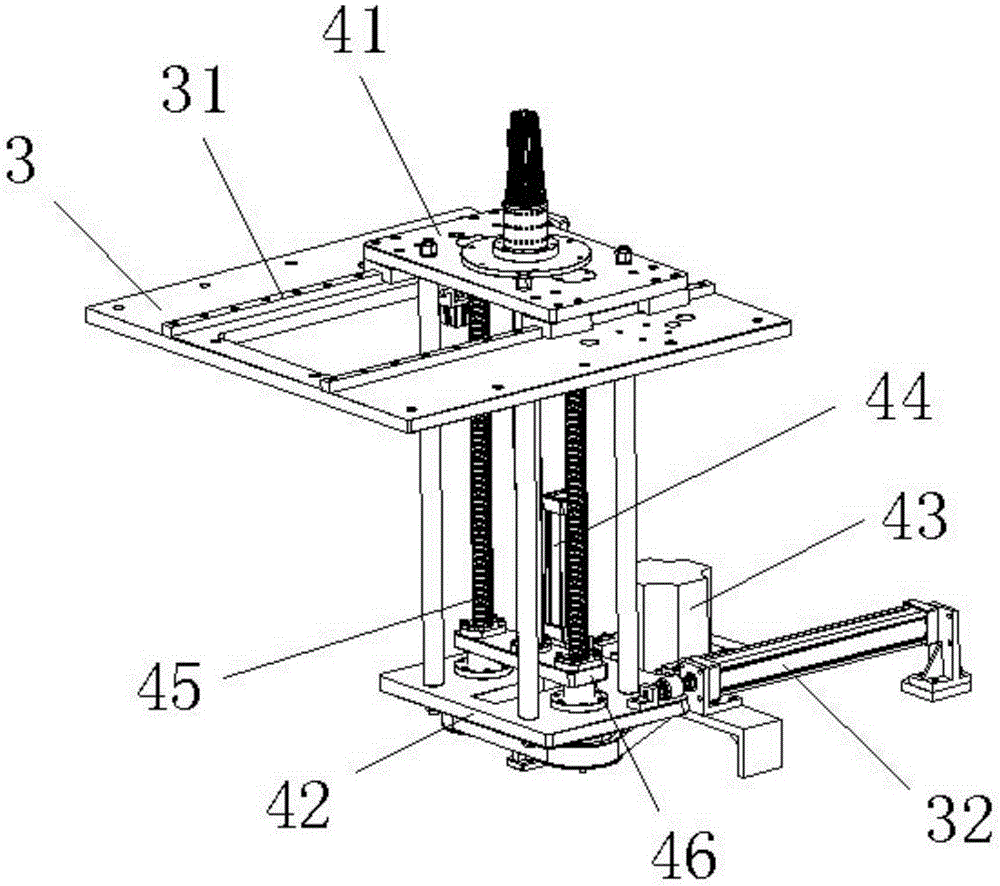

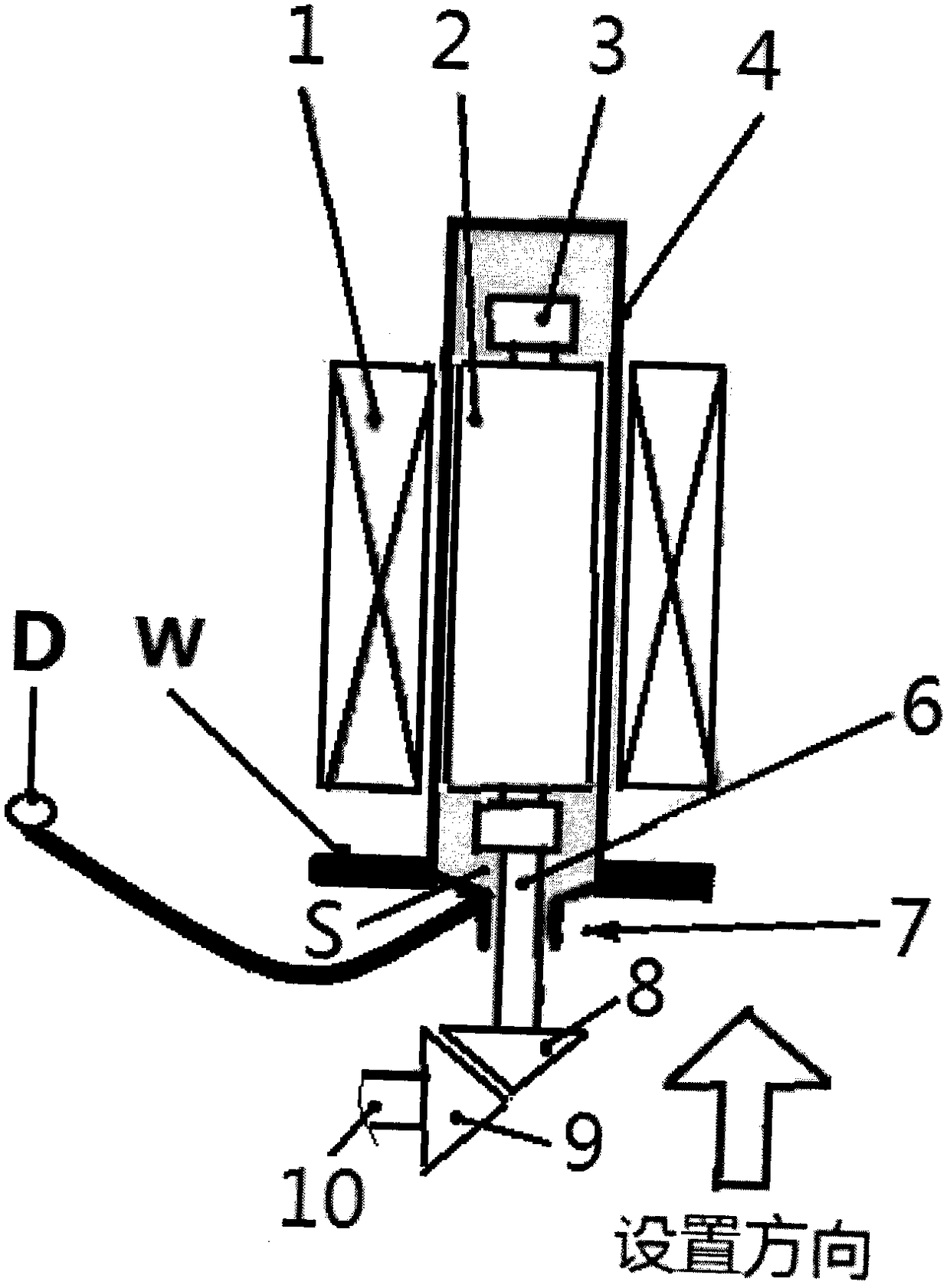

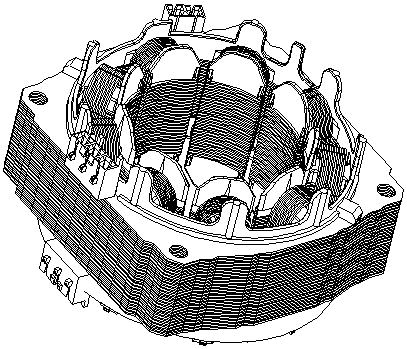

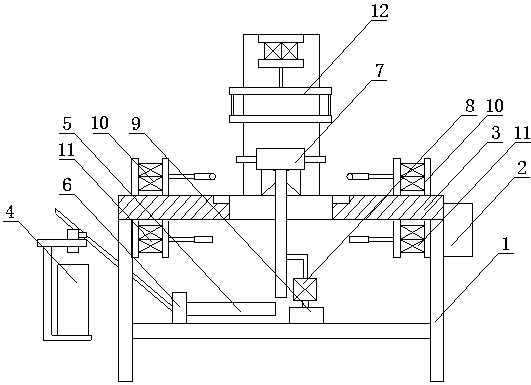

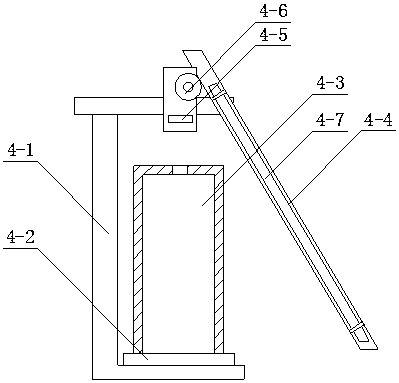

General assembly line for motor assembly

ActiveCN102820741AImprove assembly qualityImprove skill levelManufacturing dynamo-electric machinesGeneral assemblyEngineering

The invention provides a general assembly line for motor assembly. The general assembly line comprises a track, wherein a carrying flat wagon is arranged on the track; a plurality of stator outlet box mounting tables, at least one collector ring hot jacket table, at least one rotor air duct assembly table, a plurality of assembling and calibration small shaft tables, a plurality of cooler assembly tables and a plurality of motor warehousing tables are arranged on the two sides of the track in the track direction in sequence; a pneumatic suspension crane is arranged above the stator outlet box assembly tables; a rotor assembly machine is arranged beside the stator outlet box mounting tables; a collector ring heating roaster and a pneumatic suspension crane are arranged beside the collector ring hot sleeve table; and a track gantry tower crane is arranged above the cooler mounting tables. According to the general assembly line, a motor is carried through the carrying flat wagon and a turnover flat wagon, so that the potential knocking hazard is reduced, the time of waiting the crane during motor assembly is shortened, a production mode that fixed persons are allocated on fixed duties is conveniently adopted, the motor assembly quality is reliable, and the production efficiency is greatly increased.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Slotless Ac Induction Motor

InactiveUS20080054733A1Increase in sizeIncrease currentWindings insulation shape/form/constructionMagnetic circuit rotating partsElectrical conductorInduction motor

The present invention is a rotating induction motor that is capable of providing higher peak torque than a conventional design, which achieves the shortcomings of the prior art by in regard to iron saturation by a slot-less design; removing the iron slot provides more space for the conductor. The motor comprises a stator and a concentric rotor, separated from the stator by an air gap. The rotor has rotor bars and rotor windings. The stator is slot-less and comprises surface mounted conductors separated from each other by suitable insulation. An advantage of this design is that the motor does not exhibit typical behavior at high currents; there is no saturation effect.

Owner:BOREALIS TECH LTD

Brushless plastic motor and manufacturing method thereof

ActiveCN104135101AManufacturing dynamo-electric machinesSupports/enclosures/casingsMagnetEngineering

Owner:DONGGUAN YINYAN ELECTRICAL SCI & TECH CO LTD

Electric machine stator securing method

InactiveUS20140167559A1Magnetic circuit stationary partsManufacturing dynamo-electric machinesEngineeringElectric machine

Owner:DEERE & CO

Vibration motor and oilless bearing

InactiveUS20070273224A1Improve propertiesReduce mechanical noiseManufacturing dynamo-electric machinesMechanical vibrations separationMotor vibrationElectric machinery

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Centrifugal casting material returning method for squirrel cage rotor and centrifugal casting die for implementing method

ActiveCN103084556AOut of order controllableNo deformationAsynchronous induction motorsManufacturing dynamo-electric machinesEngineeringMechanical engineering

Owner:HANGZHOU FUSHENG ELECTRICAL APPLIANCE

Permanent magnet rotor and method for mounting permanent magnet rotor

InactiveCN102163899AMagnetic circuit rotating partsManufacturing dynamo-electric machinesMagnetic fluxMagnet

Owner:THE GATES CORP

Stator coil winding process

InactiveCN102097899ACompact structureAvoid Stator Performance ImpactManufacturing dynamo-electric machinesBrushless motorsWinding machine

Owner:惠州龙德科技股份有限公司

Slot-type circuit board applied to motor and assembly process thereof

InactiveCN103259371AAvoid breakingAvoid problems such as exposed leakageAssociation with control/drive circuitsManufacturing dynamo-electric machinesMaterial consumptionElectronic component

Owner:DONGGUAN GAOCHUANG MOTOR TECH

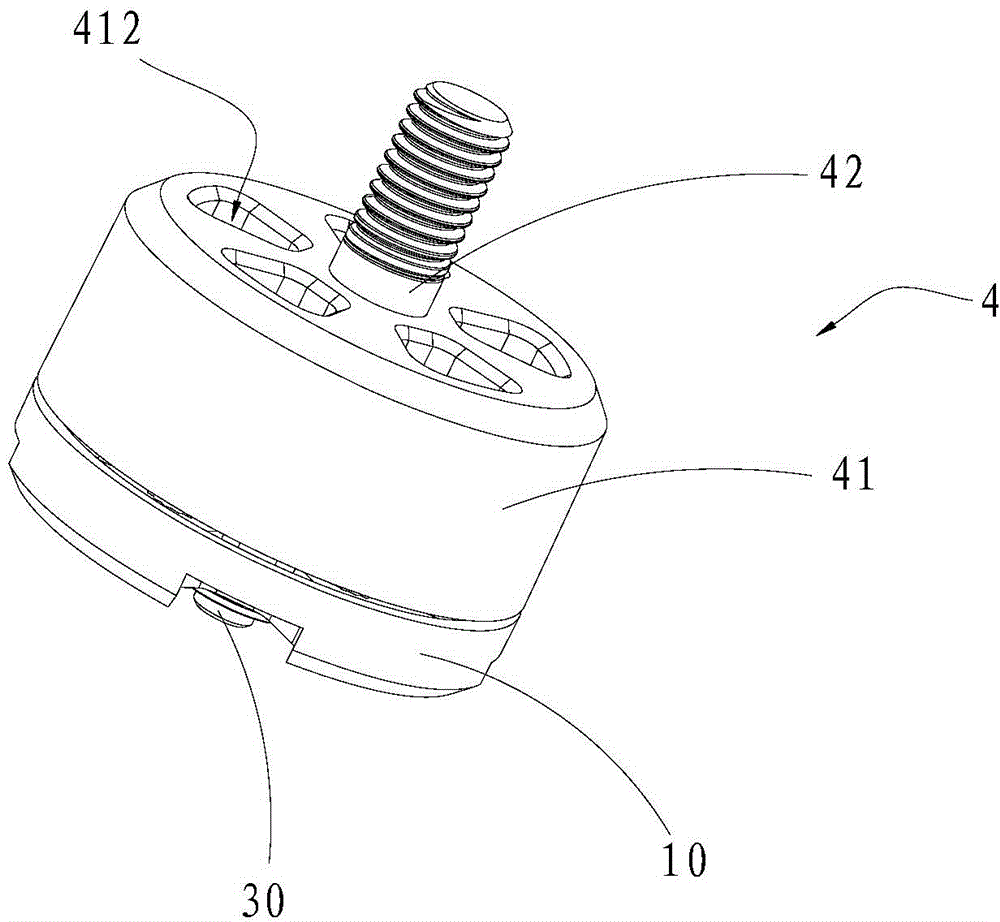

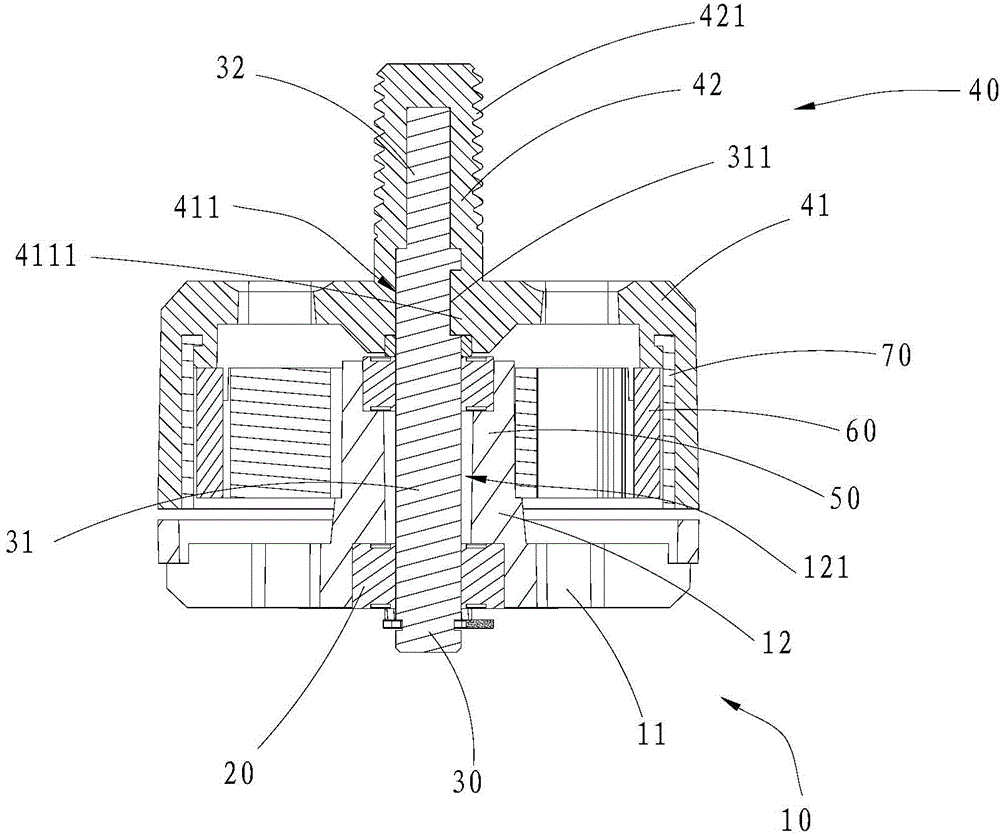

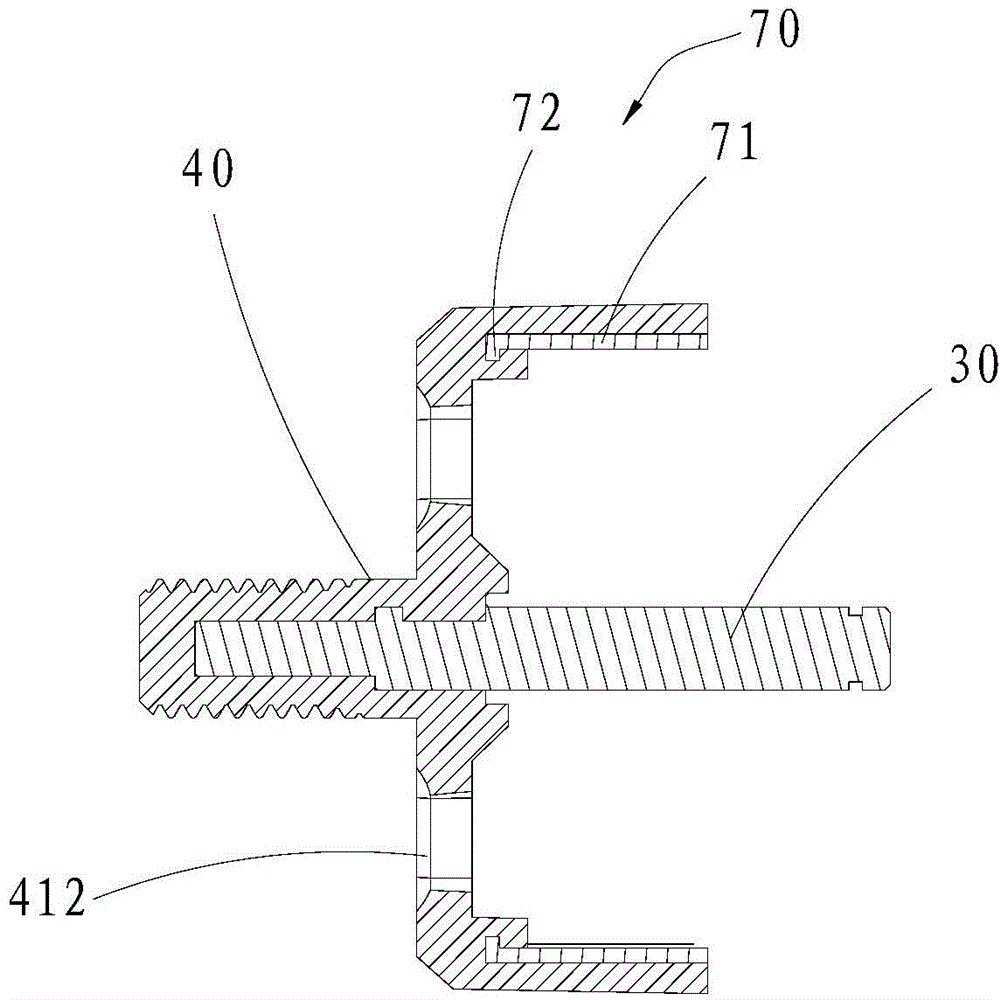

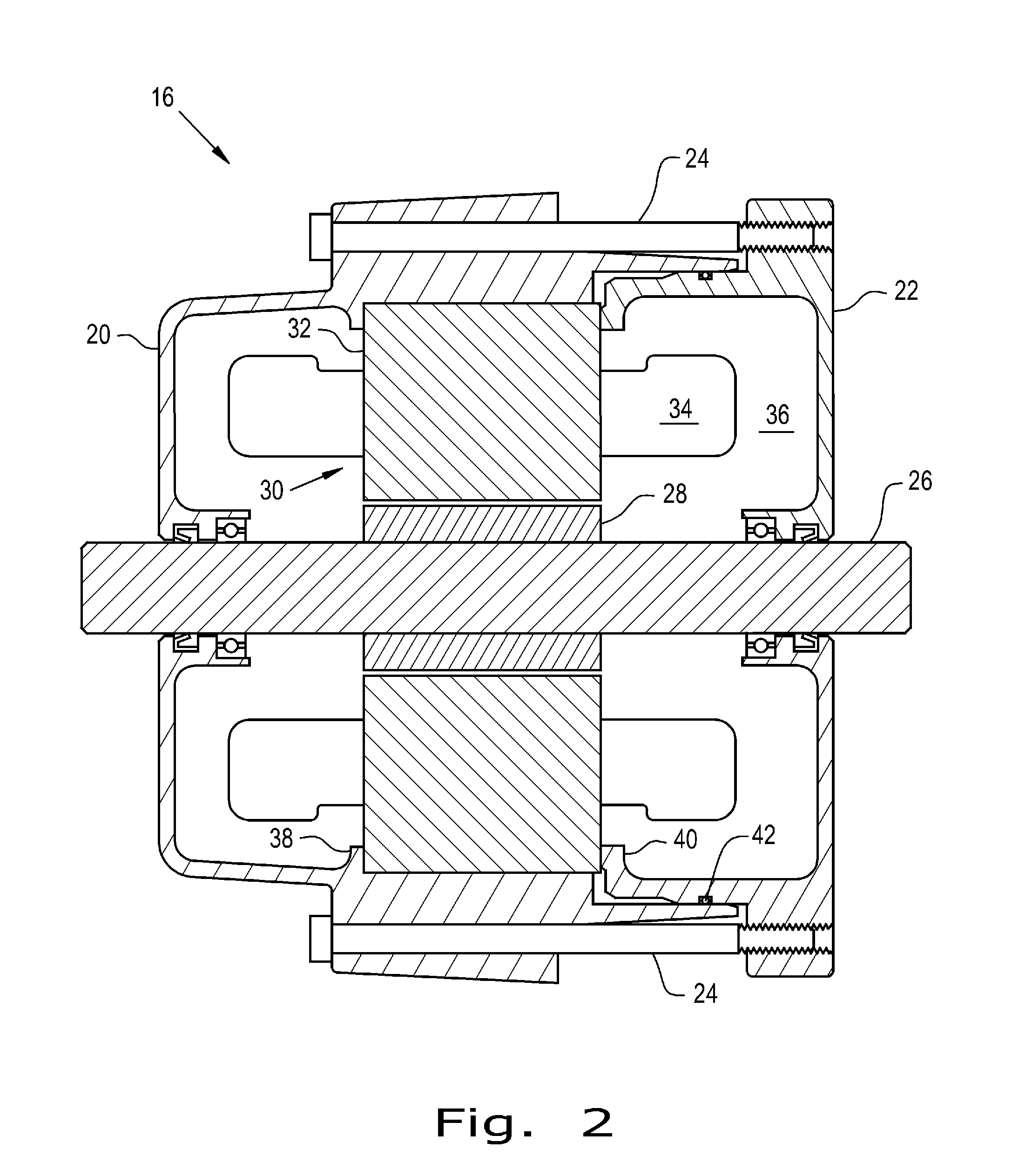

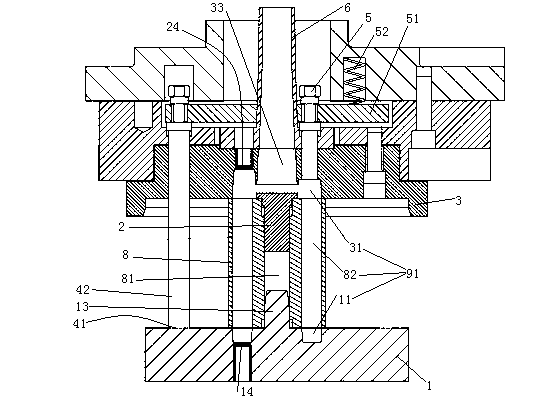

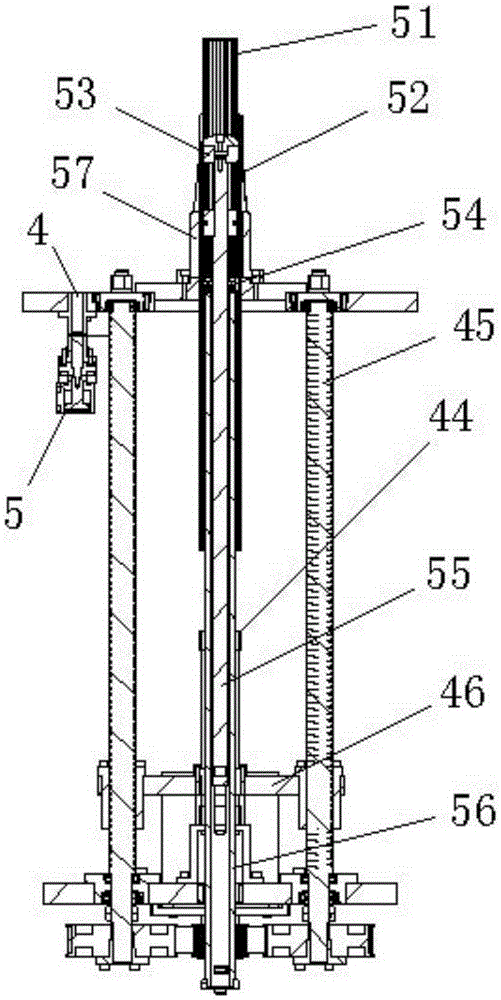

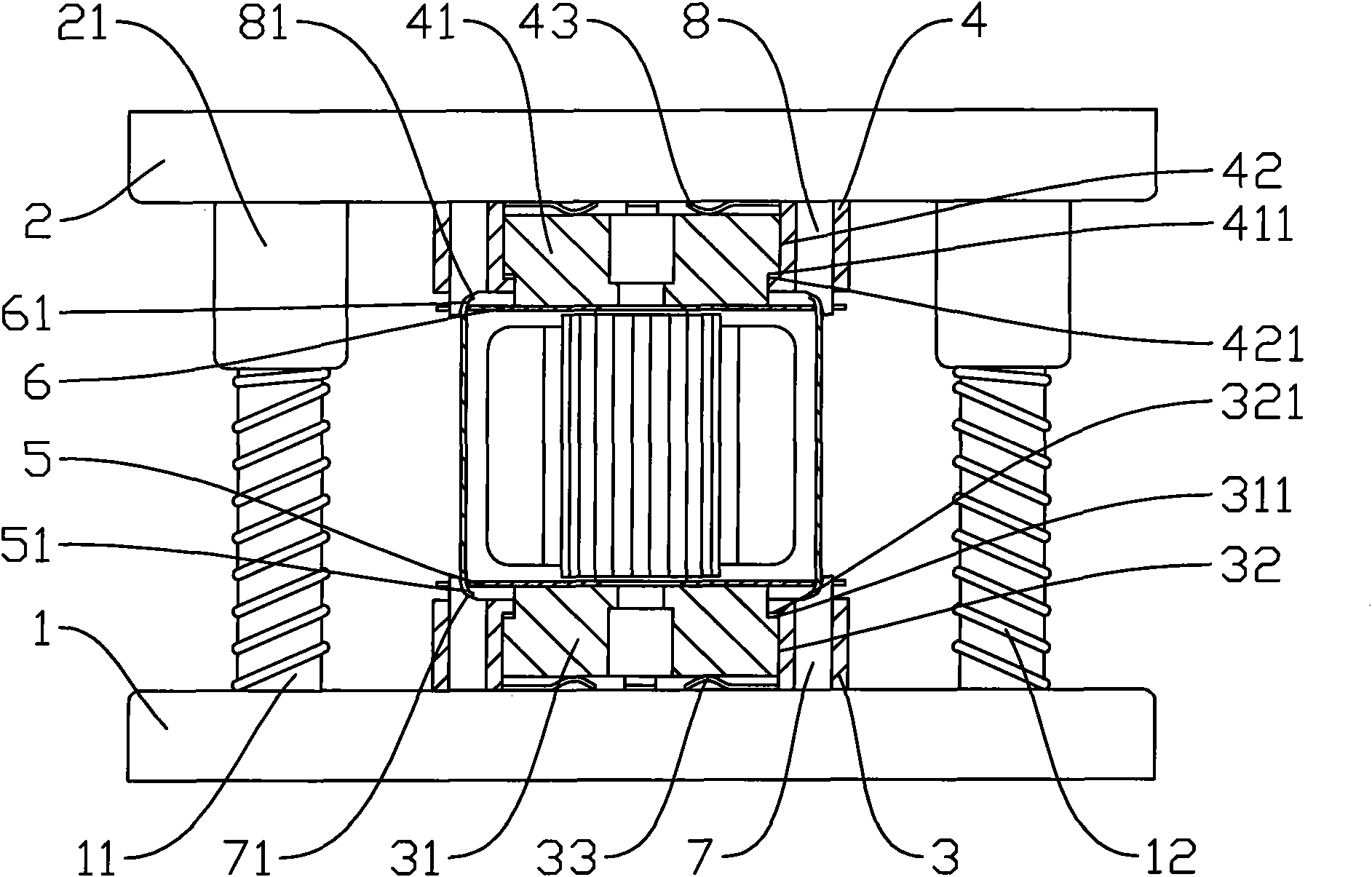

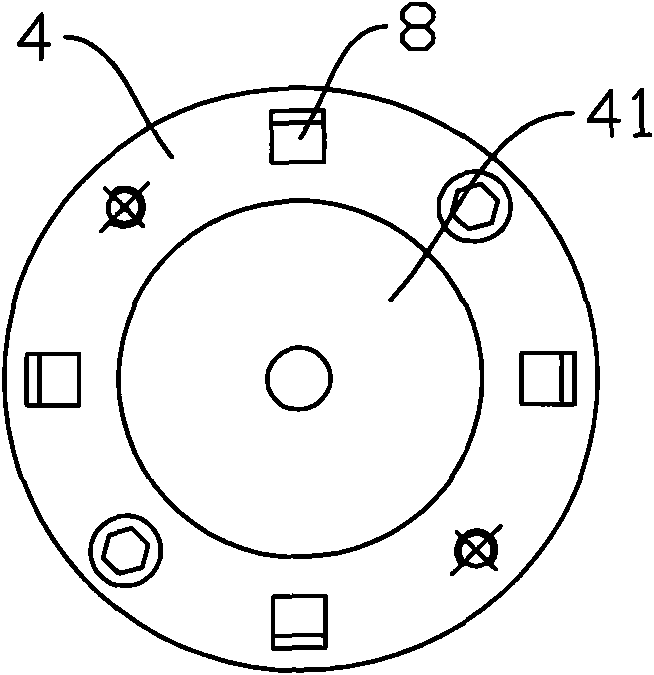

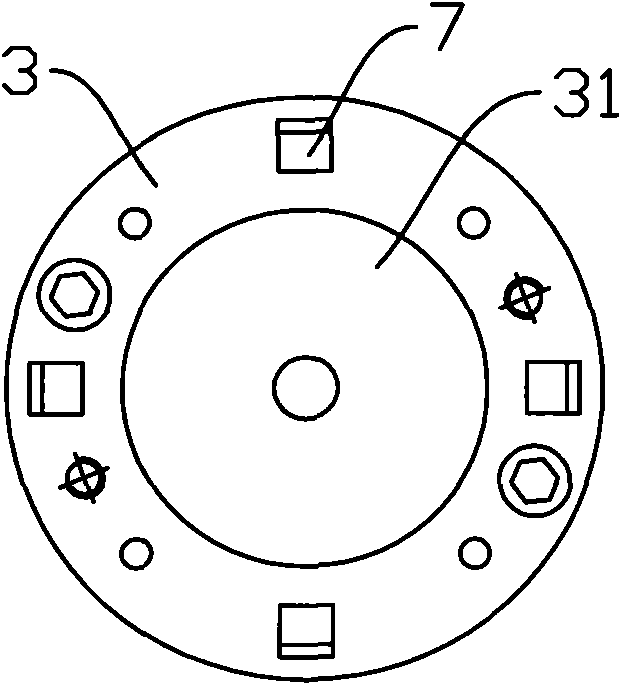

Bearing preload adjusting and locking structure for a small and special electrical machine and implementation method

ActiveCN110867984ARealize imposingRealize mass productionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMachine

Owner:TIANJIN NAVIGATION INSTR RES INST

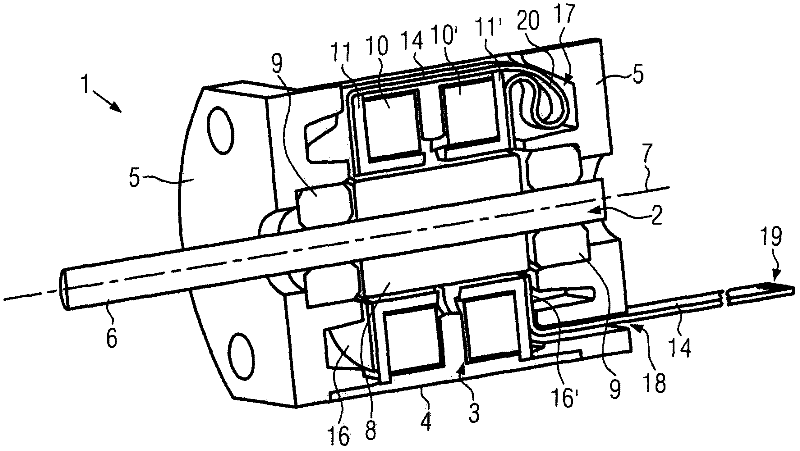

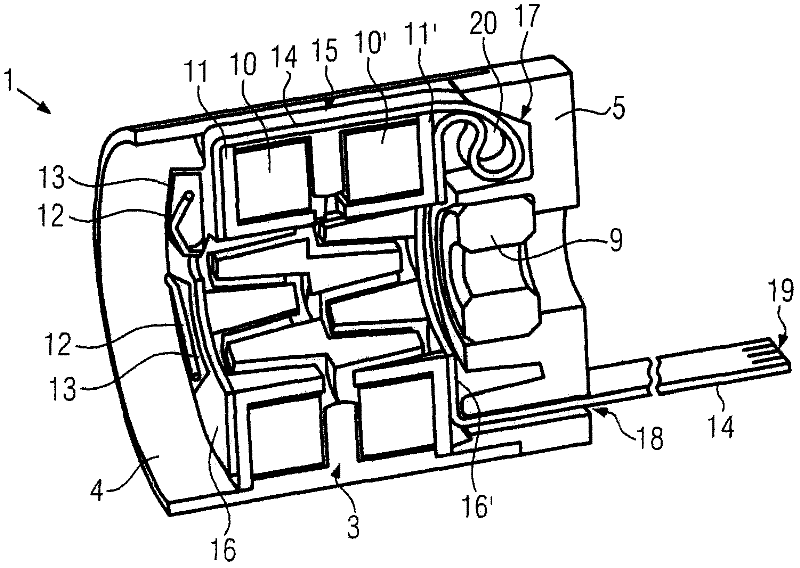

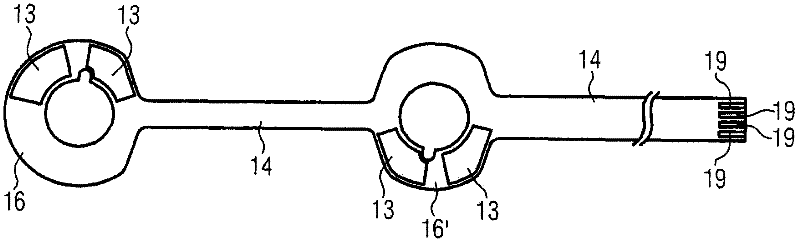

Small electric motor and method for manufacturing the same

ActiveCN102340202AReliable jointEasy to assembleWindingsManufacturing dynamo-electric machinesRotational axisElectrical conductor

Owner:MAXON MOTOR AG

Coil inserting machine

InactiveCN105429394AGuaranteed stabilityEasy to assembleManufacturing dynamo-electric machinesMechanical engineeringStator

Owner:JIANGSU NIDE AUTOMATION TECH

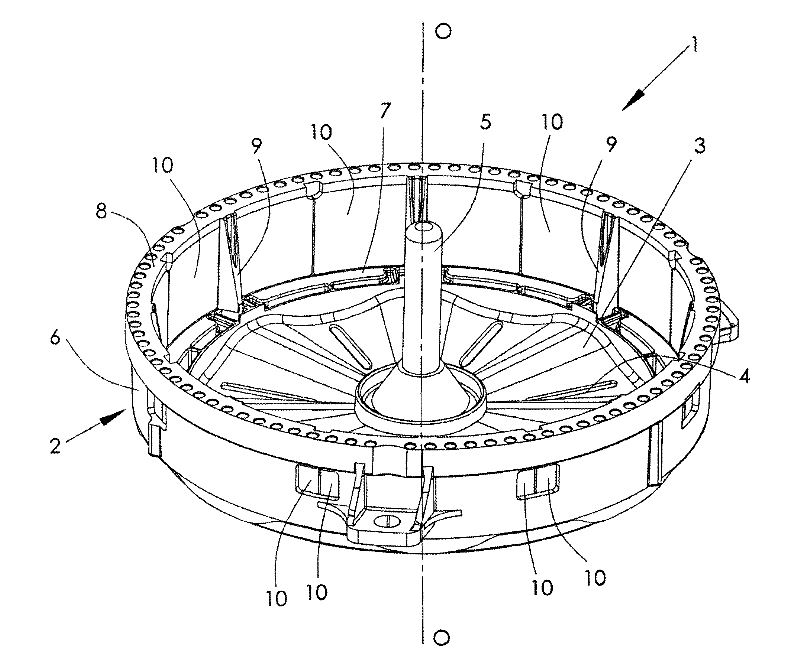

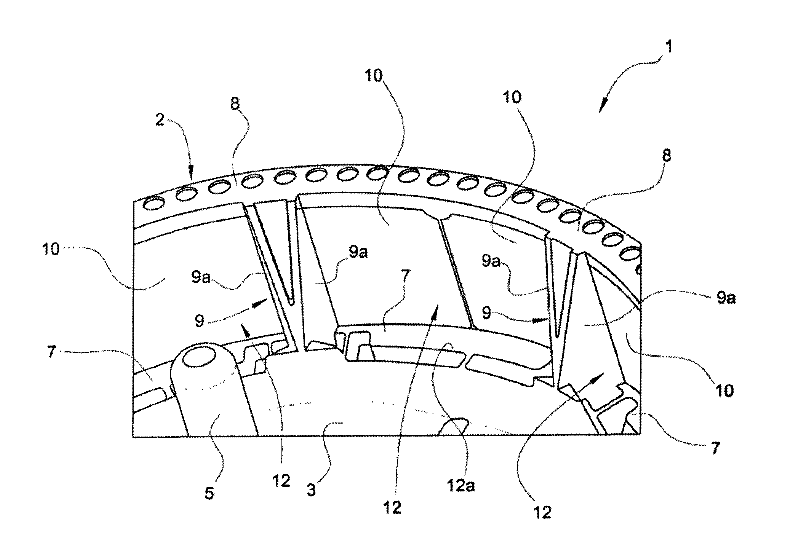

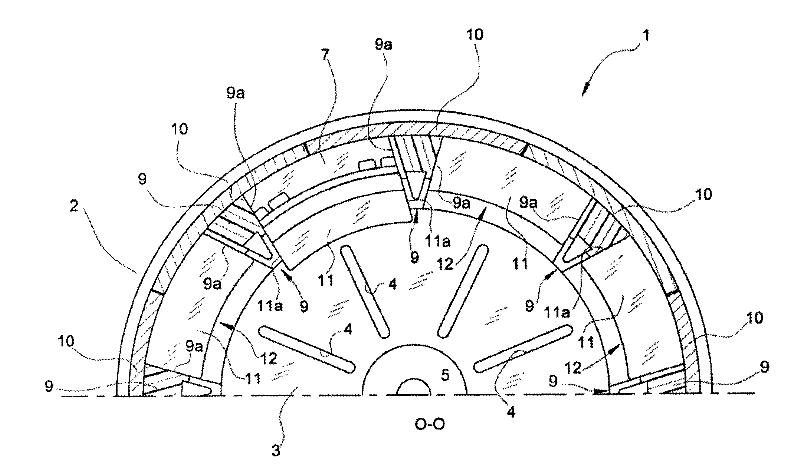

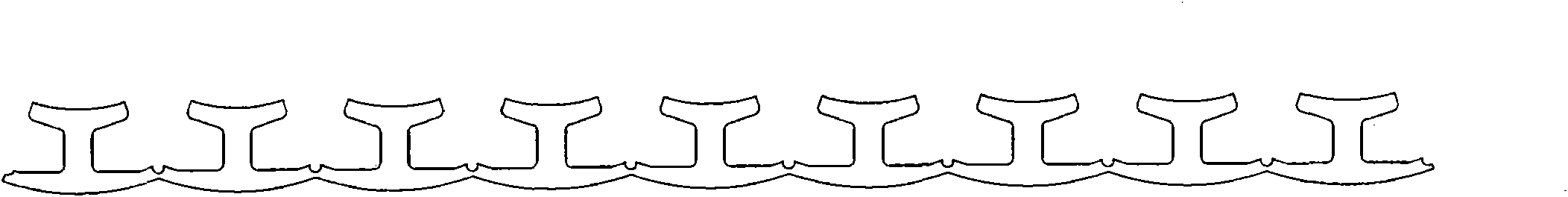

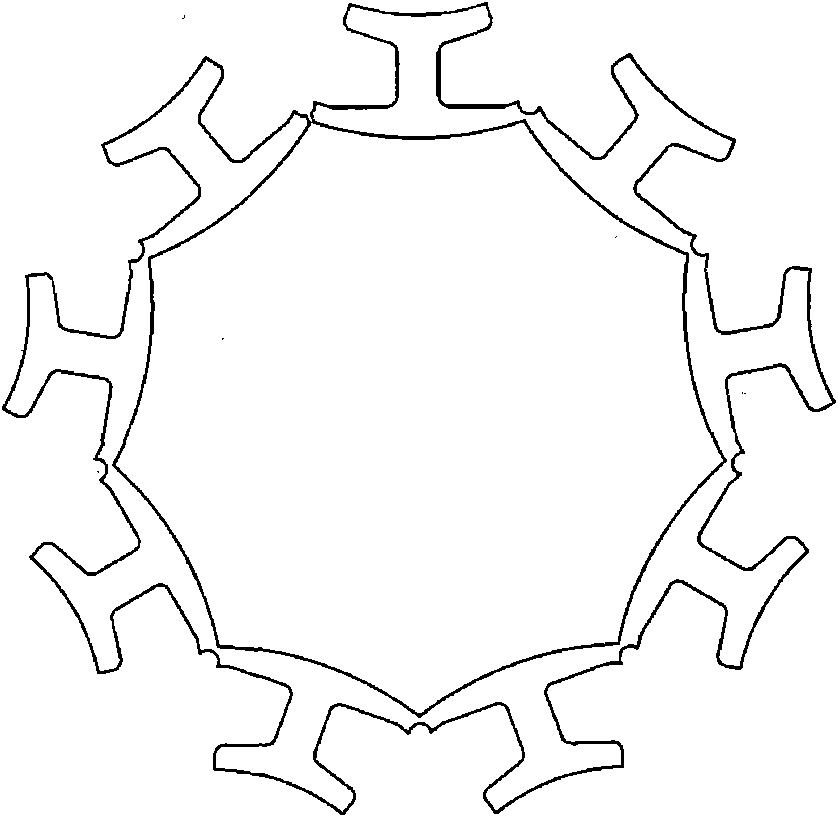

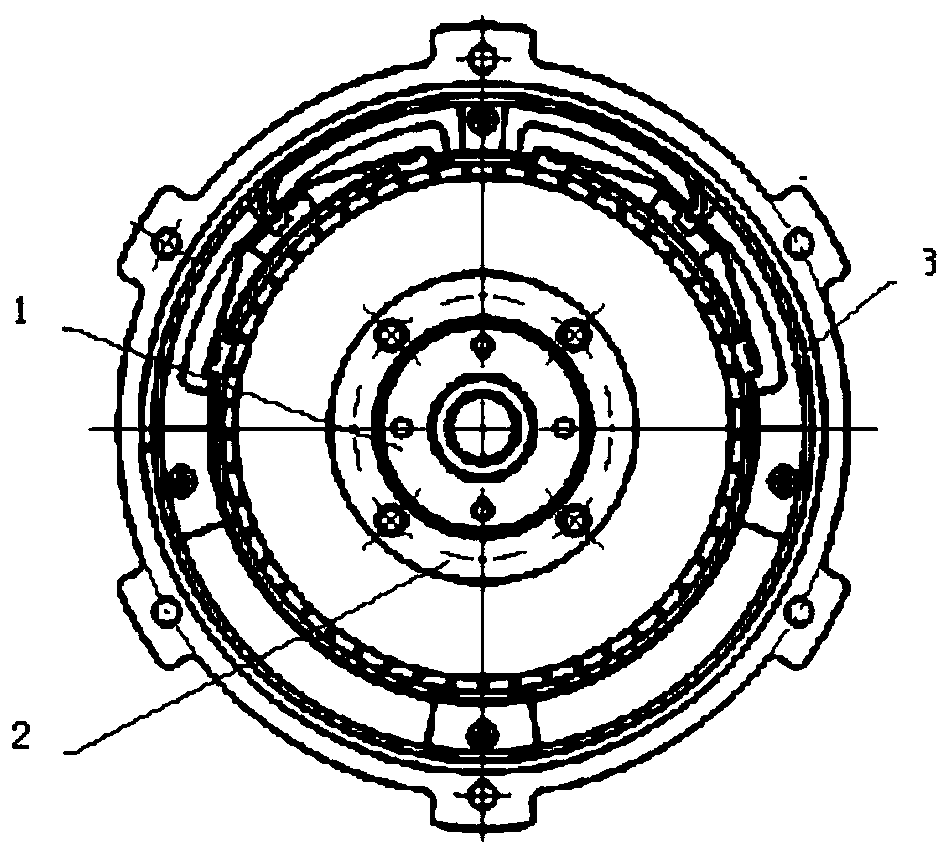

Stator core for an electronically commutated direct-current motor and method for producing a stator

InactiveCN105393434ASignificant mechanical damageReduce bending forceMagnetic circuit stationary partsManufacturing dynamo-electric machinesCurrent meterEngineering

The invention relates to a stator core (1) for an electronically commutated DC motor comprising an internal rotor, having several radially inwardly directed pole cores (2), which at their periphery are integral with back iron segments (3), and the back iron segments (3) are integral with adjacent back iron segments (3) via webs (4), wherein the back iron segments (3) alternate with the webs (4), and jointly form a seamlessly closed one-piece ring. The problem addressed by the invention is that of ensuring that in case of a stator core of this class, upon a reduction of the stator diameter and reduction of the pole distances after a winding, a clearly defined end position of the adjoining regions can be assumed, and that for this process step, only minimal forces are necessary, in which damage to the stator core is not to be expected, and that at the end of the process only a very small and uniform air gap remains at a lowest possible spring-back. This problem is solved by means of the characteristic of claim 1 and the method steps of claim 7.

Owner:BUHLER MOTOR GMBH

Auxiliary device for riveting end covers with shell of motor

InactiveCN101860147AWrong damagePracticalManufacturing dynamo-electric machinesEngineeringMechanical engineering

Owner:ZHEJIANG LINIX MOTOR

Method for binding end coil of motor stator

InactiveCN101582609AIncreased capacity for heavy load operationExtended service lifeManufacturing dynamo-electric machinesSpiral bindingWhole body

The invention discloses a method for binding an end coil of a motor stator, which relates to a motor end coil binding method, in particular to the fixing and binding of the end coil of a high-power alternating current motor. The method involves an outer coil, an inner coil, end hoops and a binding point. A certain number of end hoops are installed between the outer and the inner coils, and the outer coil, the inner coil and the end hoops are bound into a whole body in the position of the binding point. The method enhances the capability of a stator coil end in resisting insulation damage caused by electromagnetic vibration, remarkably improves the heavy load operation capability of the motor and prolongs the service life.

Owner:杨存高

Motor end cover dismounting device for preventing motor end cover from falling off

PendingCN111756192APrevent movementAdjustable horizontal positionManufacturing dynamo-electric machinesElectric machineEngineering

The invention is applicable to the technical field of dismounting devices, and provides a motor end cover dismounting device capable of preventing a motor end cover from falling off. The motor end cover dismounting device comprises a dismounting device used for dismounting the motor end cover, and a clamping device used for clamping a motor, wherein the dismounting device comprises a cross beam and a screw rod, a first supporting column is installed at one end of the cross beam, and a hexagonal wrench head is arranged at the bottom end of the screw rod; and the clamping device comprises a first sliding rod and a second sliding rod, and the first sliding rod penetrates through the first supporting column. According to the motor end cover dismounting device, a worker places a base on a workbench, places the motor between the first supporting column and the second supporting column, then pushes the first sliding rod and the second sliding rod until a silica gel pad makes contact with theouter side wall of the motor, and then screws locking bolts into threaded holes, so that the two sets of sliding rods can be limited, and the motor is prevented from moving when the motor end cover isdisassembled.

Owner:JIANGSU LIANFENG IND EQUIP TECH CO LTD

Method for producing high-voltage generator and stator with stator winding in circular cross section

InactiveCN101212155AReduce lossImprove availabilityWindings insulation materialWindings insulation shape/form/constructionElectrical conductorInsulation layer

The invention discloses a high-voltage generator with a circular section stator winding and a stator manufacture method, which relates to a filed of a motor. The invention solves the problems of small rating output voltage, large eddy current loss and complex devices which exist in the current generators. The stator winding section of the generator is circular; the generator comprises a conductor, an internal semiconductor layer, an insulation layer and an external semiconductor layer from the internal to the external in sequence; the conductors is one or a plurality of hinged wires; a wave winding groove is opened along a radial direction of an iron core; the stator winding is arranged in the wave winding groove of the iron core to cooperate at the interval; at least four circular dissipation grooves are evenly opened in a circumferential direction of an iron core yoke, in which dissipation water pipes are arranged. The stator manufacture method includes the processes as follows: firstly, the iron core is arranged on a generator base; secondly, one end of the stator winding is penetrated from one end of the wave winding groove of the iron core to the other end of the wave winding groove of the iron core; according to the requirements of a pitch, the end of the stator winding is penetrated back and the penetration is carried out repeatedly; thirdly, the dissipation water pipes are introduced into the circular dissipation groove; lastly, the pipes are enlaced in order. The invention has the advantages of simple structure, high stability and simple cooling system.

Owner:HARBIN UNIV OF SCI & TECH

Preparation method for motor slot wedge

InactiveCN102594040AReduce iron consumptionReduce temperature riseManufacturing dynamo-electric machinesGlass fiberAlkali free

The invention discloses a preparation method for a motor slot wedge. The slot wedge comprises the following components in percentage by weight: 14 to 16 percent of unsaturated polyester resin, 0.1 to 0.3 percent of internal release agent, 0.8 to 1.2 percent of tert-butyl perbenzoate, 0.6 to 1.0 percent of dibenzoyl peroxide, 5 to 8 percent of talcum powder, 28 to 30 percent of alkali-free glass fiber, and the balance of iron-nickel alloy powder. The preparation method comprises the following steps of: (1) preparing an adhesive with the iron-nickel alloy powder; (2) impregnating the glass fiber with the adhesive; (3) performing pultrusion; (4) cooling and cutting; (5) grinding the head of the cut slot wedge; (6) painting the surface of the slot wedge to make the surface of the slot wedge smooth and burr-free; and (7) drying, detecting and packing.

Owner:WUXI WANBANG MASCH MFG FACTORY

Open-type suspension variable frequency motor and method for assembling the same

InactiveCN106992631AImprove the safety of useAchieve axial ventilation coolingManufacturing dynamo-electric machinesMechanical energy handlingEngineeringStator

Owner:PUYANG HUANAN HEAVY IND SCI & TECH CO LTD

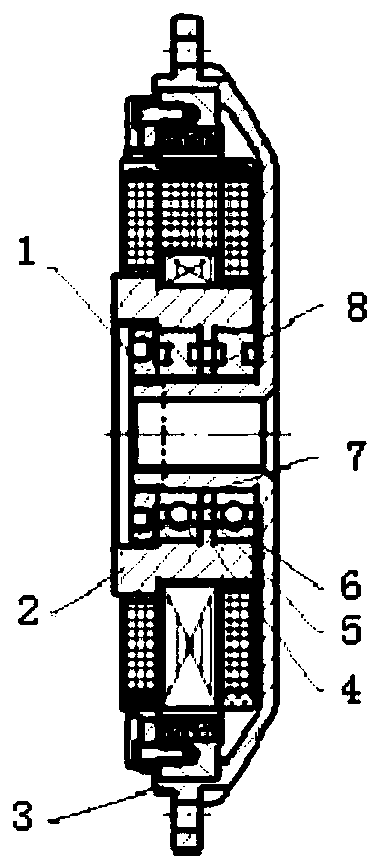

Ideal dragging motor of waterproof sealing using oil liquid jacking and capable of deep diving and free of maintenance and applied to underwater device

InactiveCN108155750AManufacturing dynamo-electric machinesSupports/enclosures/casingsMotor shaftMarine engineering

Owner:CHINA JILIANG UNIV

Circulating water pump motor maintenance device for nuclear power station

InactiveCN107872128AEasy to disassembleEasy to transportManufacturing dynamo-electric machinesSolid structureNuclear power

The invention relates to a maintenance device for a circulating water pump motor used in a nuclear power plant, which includes a body, the body is composed of an upper base, a lower bottom plate and a vertical plate, and the upper and lower ends of the vertical plate are respectively connected to the upper base, the lower The bottom plate is fixedly connected; the center of the upper base is provided with a through hole for placing the motor. Compared with the prior art, the invention maintains the vertical heavy-duty motor, and has the advantages of firm structure, stable center of gravity, safe maintenance, and convenient disassembly and transportation of the motor coupling and the lower guide bearing chamber of the motor.

Owner:CLP CHINA NUCLEAR POWER ENG TECH

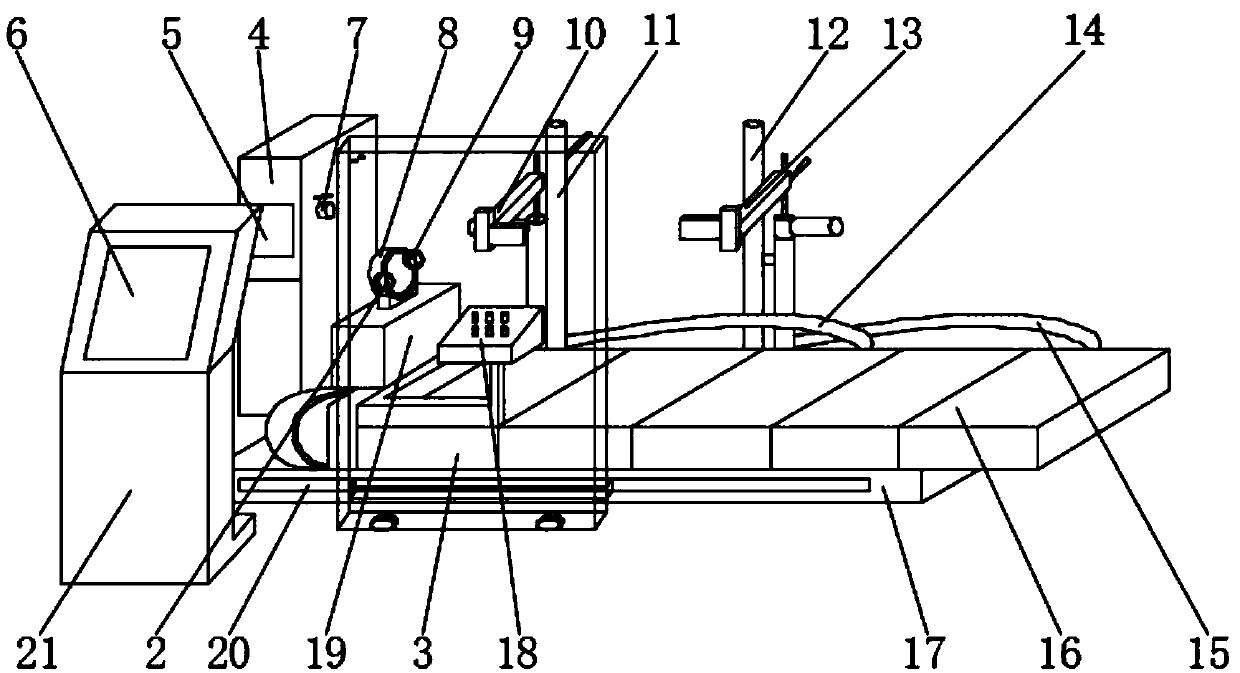

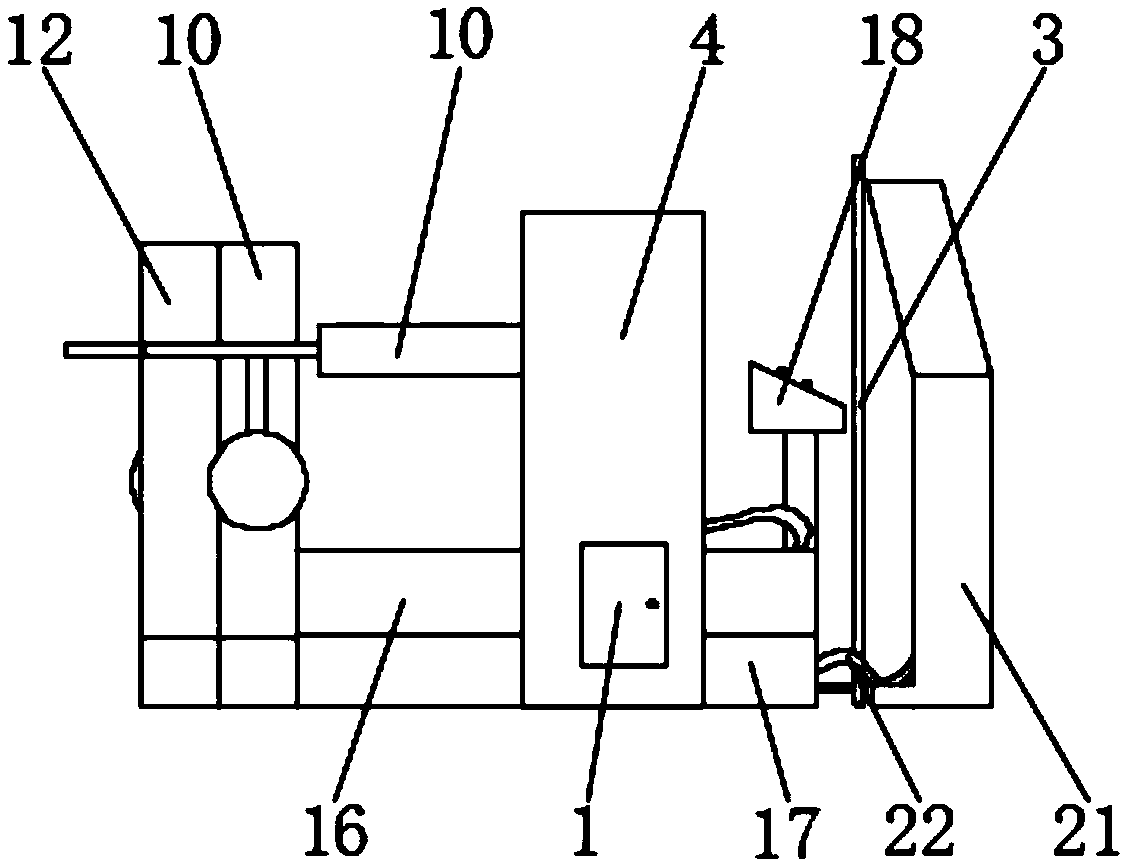

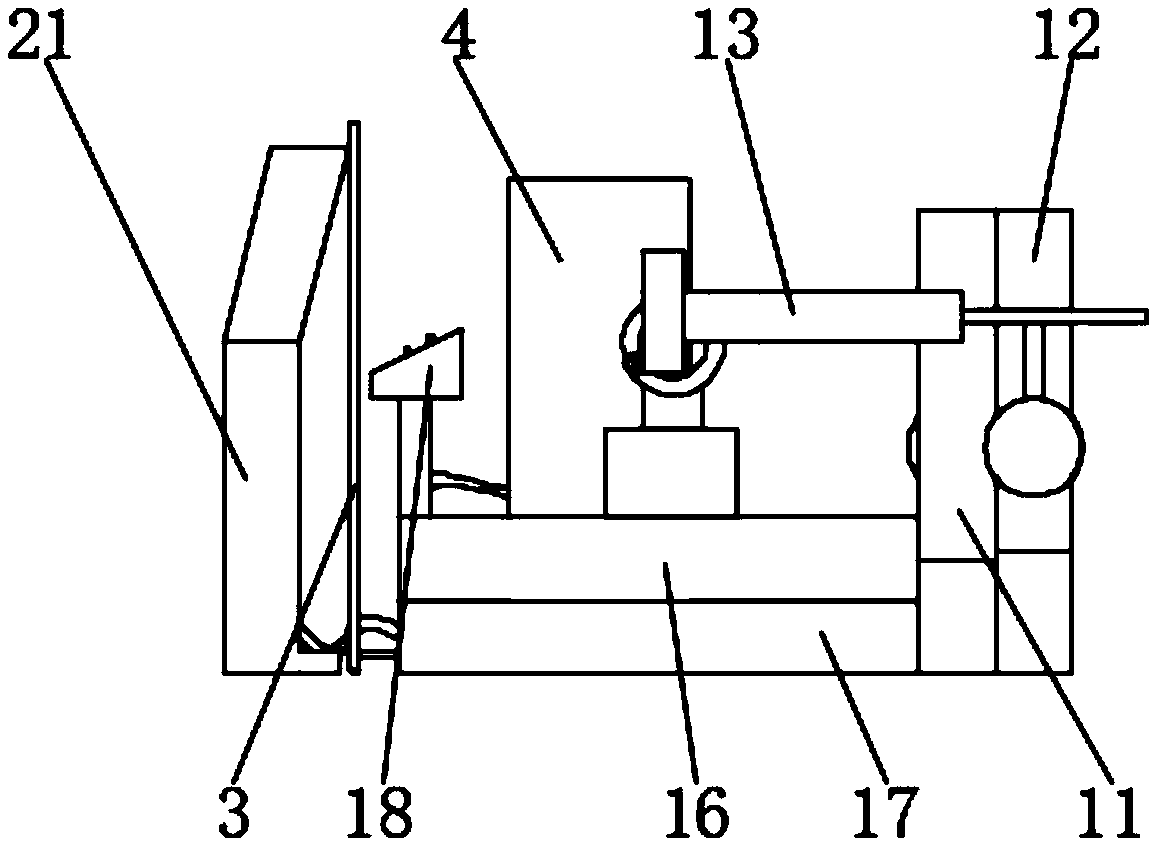

Efficient motor lead winding equipment

PendingCN108347139AGuaranteed stabilityQuality assuranceManufacturing dynamo-electric machinesConductor CoilIndustrial engineering

The invention relates to the technical field of motor processing, particularly efficient motor lead winding equipment, and aims to provide the efficient motor lead winding equipment capable of improving working efficiency, realizing high winding positioning accuracy and ensuring the winding quality; the efficient motor lead winding equipment comprises a rack, a controller, a working table, a material placement mechanism, a conveying pipe, a lead tension adjustor, a rotary revolution assembly, a motor, a lifting assembly, a positioning hook line mechanism, a shearing mechanism and a tighteningmechanism; the working table is fixed on the rack; a though hole is formed in the upper surface of the working table, and a positioning groove is formed in the periphery of the through hole in a downward extension manner; the downward side, aligned to the through hole of the working table, is connected with the rotary revolution assembly through the motor, and the motor is connected with the lifting assembly; and the rotary revolution assembly consists of a hollow structured feeding pipe, a rotary head, a discharging pipe and the like; and the efficient motor lead winding equipment has the characteristics of simple structure, reasonable design and convenience in use.

Owner:格兰德电气有限公司

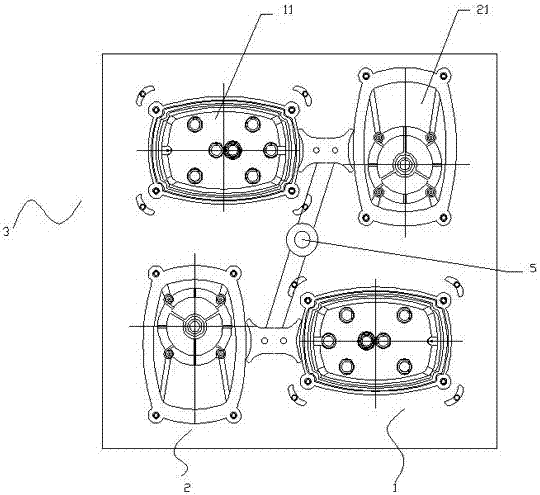

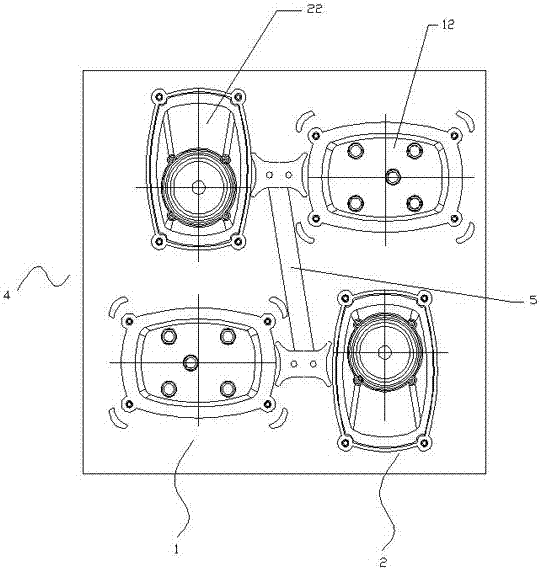

Die-casting forming die for motor conjunction box

ActiveCN107171518AIncrease profitEvenly distributedManufacturing dynamo-electric machinesSupports/enclosures/casingsDie castingEngineering

Owner:JIANGSU HUACAN TELECOMM

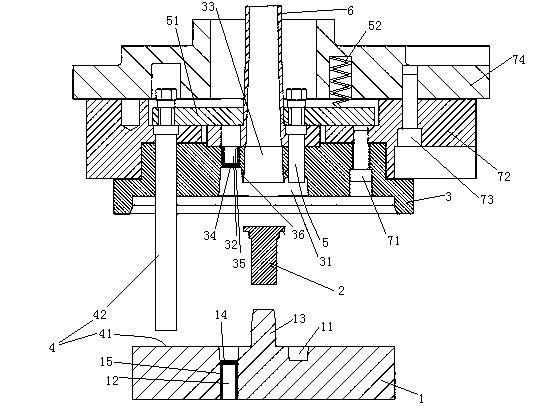

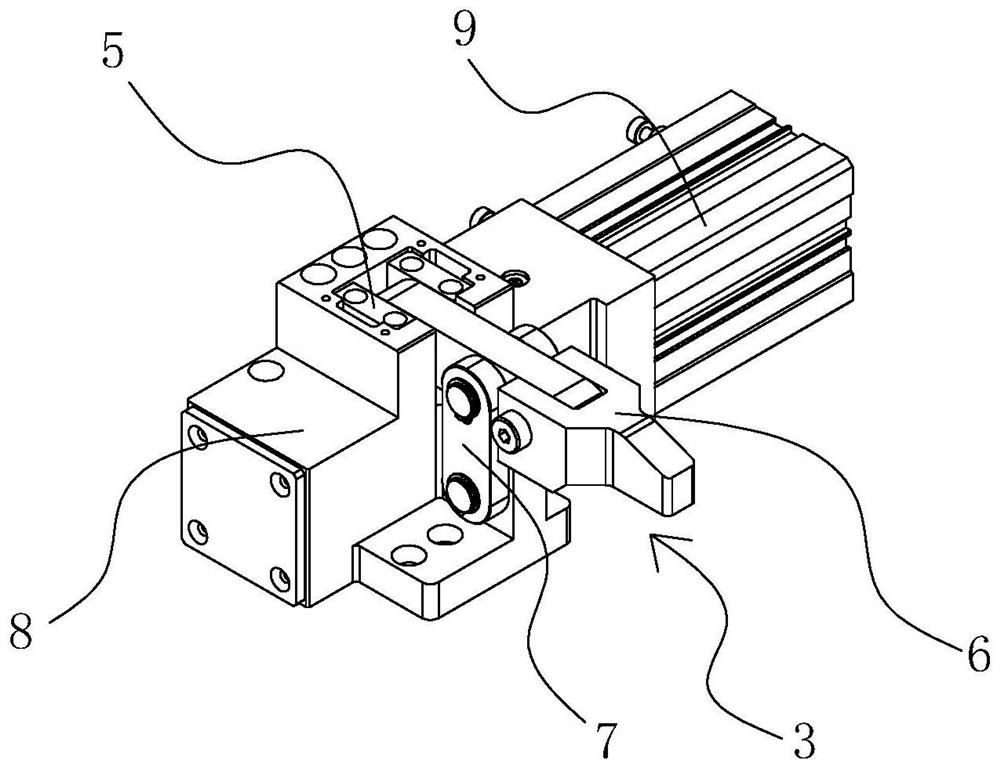

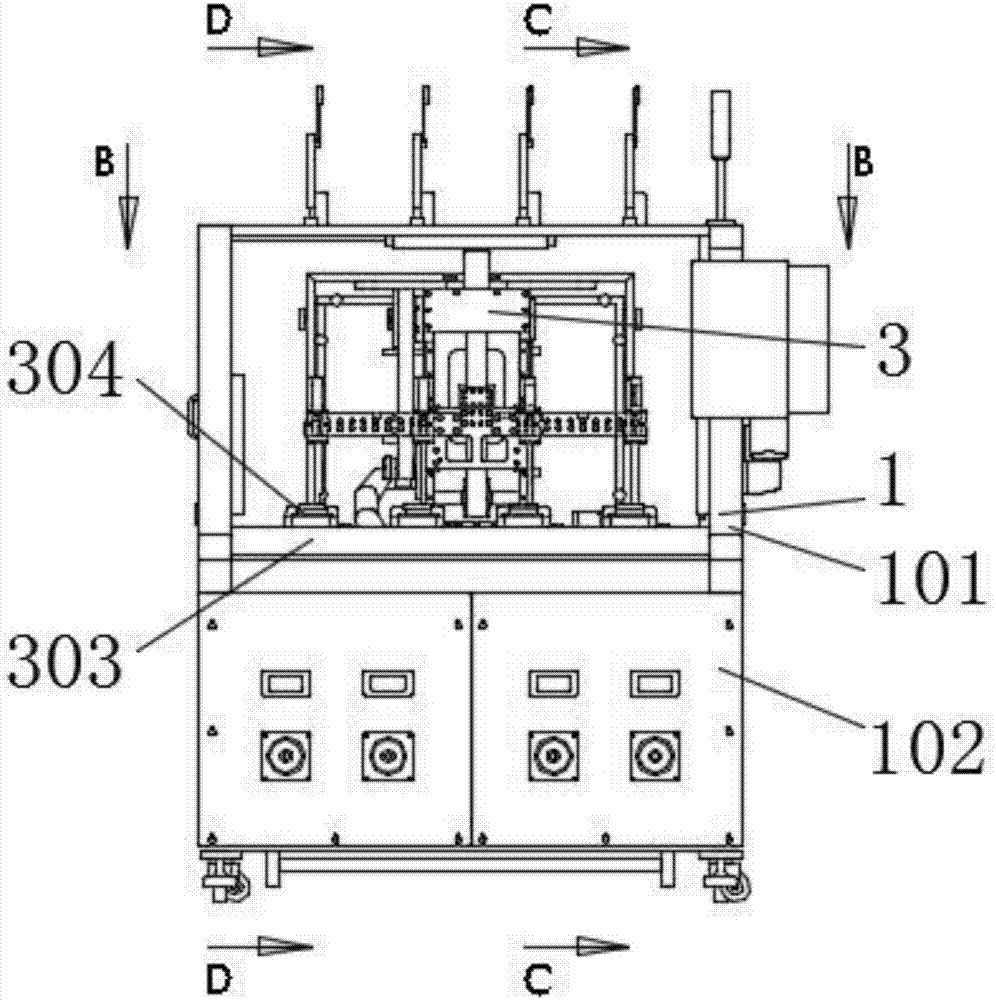

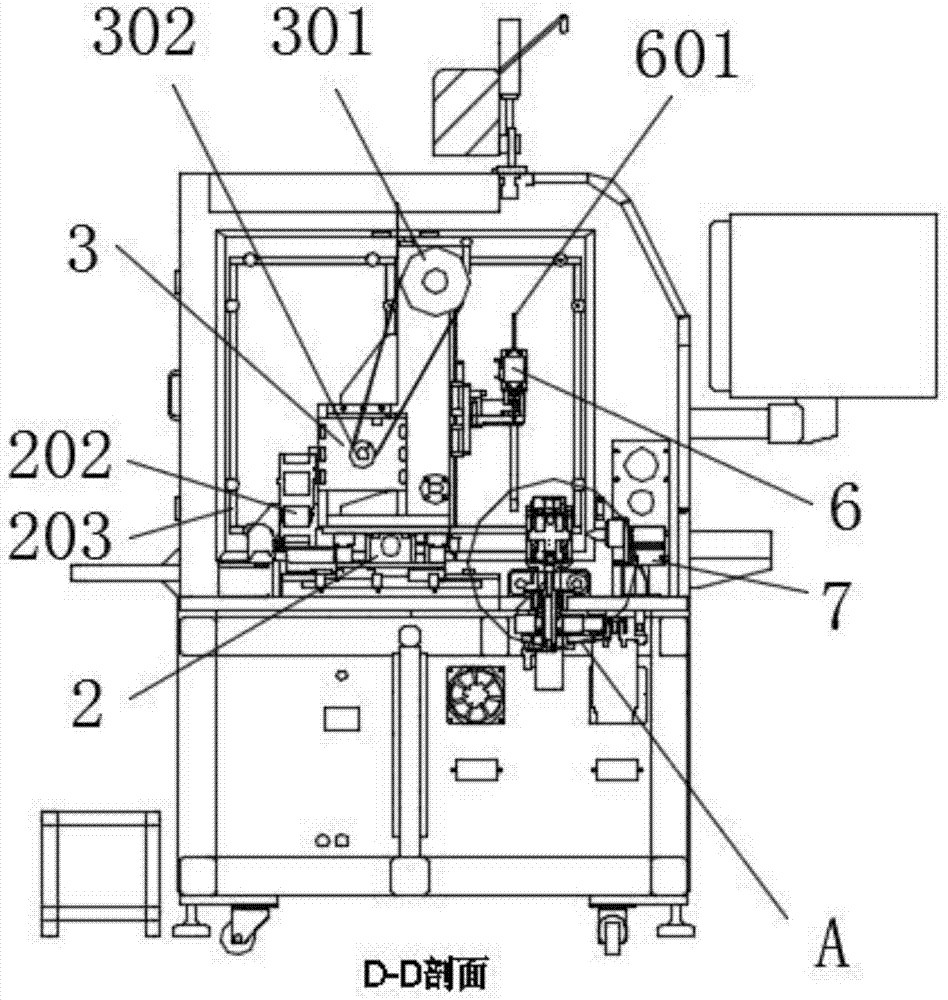

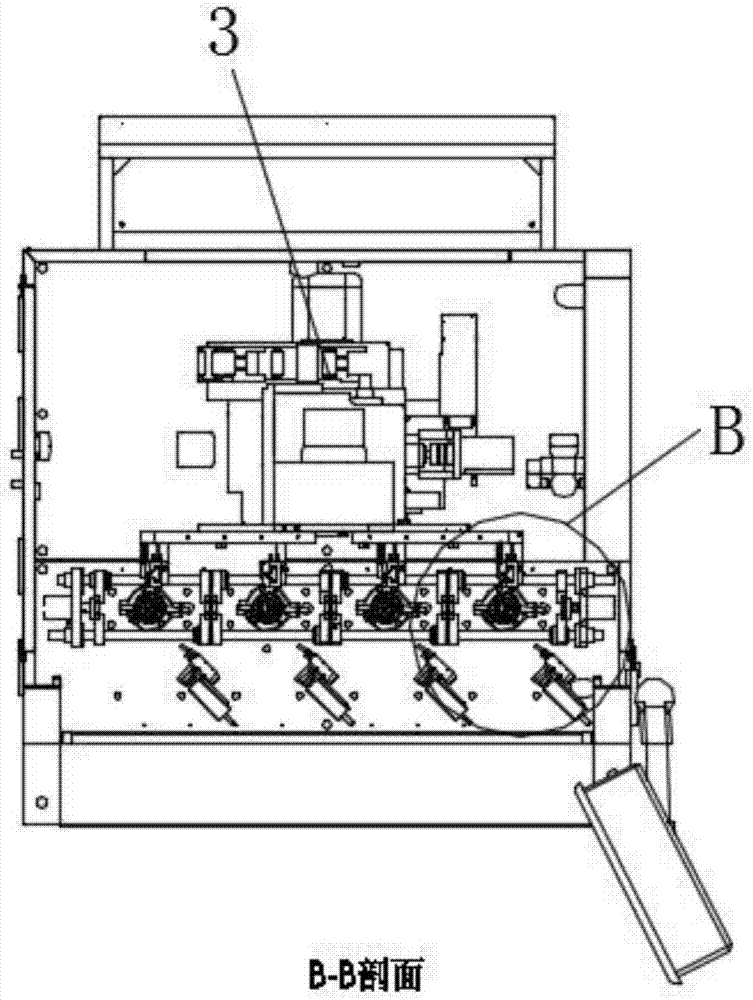

Clamping mechanism and disc type motor stator clamp

PendingCN113119003AImprove clamping effectCompact structureWork holdersManufacturing dynamo-electric machinesElectric machineClassical mechanics

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

Seven-axis brushless motor stator winding machine

PendingCN107294319AImprove structural stabilityCompact structureManufacturing dynamo-electric machinesBrushless motorsWinding machine

Owner:广东顺德威技自动化科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap