Small electric motor and method for manufacturing the same

A kind of electric motor, small technology, applied in the direction of manufacturing motor generators, electric components, electrical components, etc., can solve the problem of inflexible conception, achieve the effect of simple method, low cost, and simplified assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, like reference numerals are used to refer to like parts.

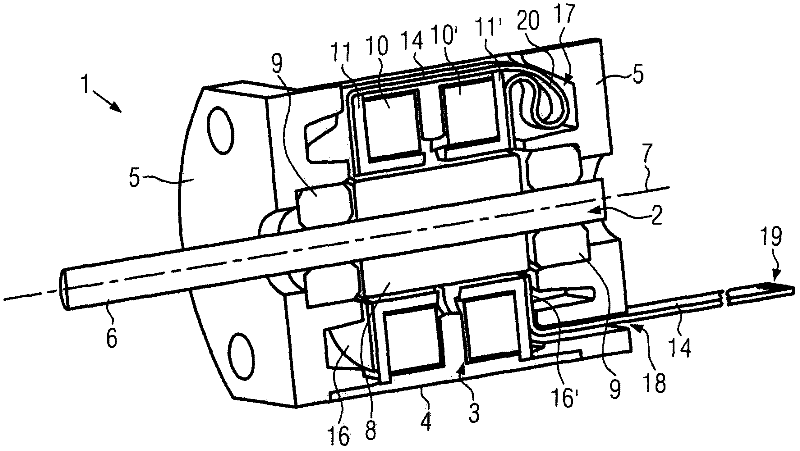

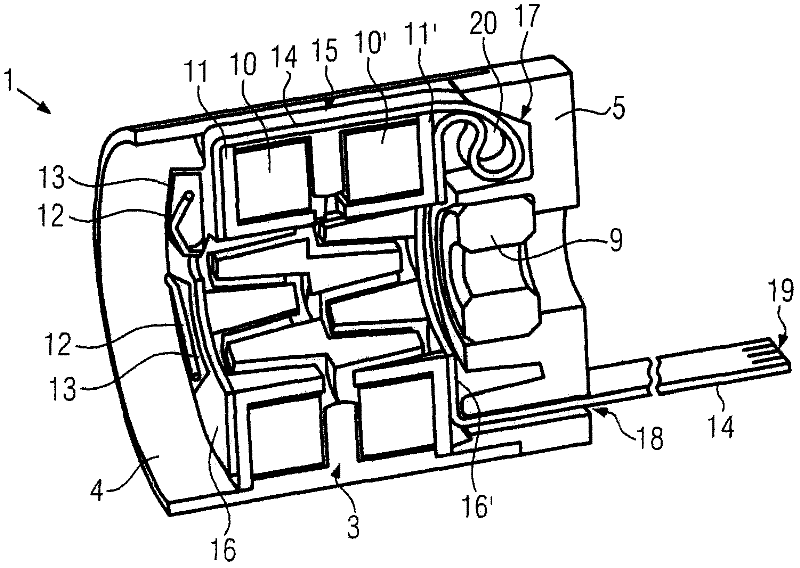

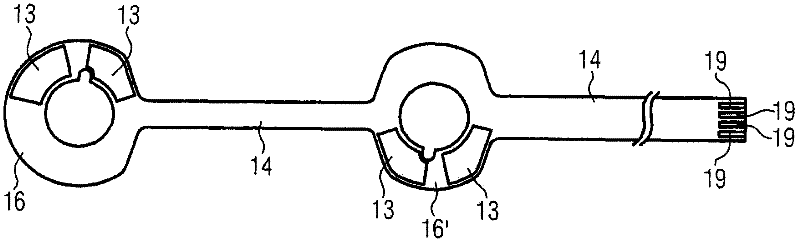

[0023] Such as figure 1 As shown, a small electric motor 1 according to the present invention is configured in the manner of a claw pole motor and includes a rotor 2, a stator 3, and a housing 4 which is firmly connected to the stator 3 and whose two ends pass through The corresponding housing cover 5 is axially closed. The stator 3 of the claw-pole motor 1 according to the invention comprises two stator coils 10 and 10 ′, which are endowed with a ring-like structure and arranged coaxially with the axis of rotation 7 of the rotor 2 . Each of the stator coils 10 and 10' is bonded to an associated pole tooth edge 11 and 11', respectively, and the stator coils 10 and 10' adjoin each other in the axial direction. Stator coils 10 and 10 ′ are surrounded on the outside by housing 4 . The rotor 2 of the claw pole motor 1 according to the invention consists essentially of a hollow cylindrical permanen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap