Inner rotor-type permanent magnet motor

a permanent magnet motor and rotor-type technology, which is applied in the direction of magnetic circuits characterised by magnetic materials, electrical apparatus, dynamo-electric machines, etc., can solve the problems of insufficient assembly precision of magnetic poles, difficult to stably reduce cogging torque, and displaced magnetic poles in the circumferential direction, so as to improve rotational performance and reduce cogging torque. , the effect of increasing the (bh)max of the magn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

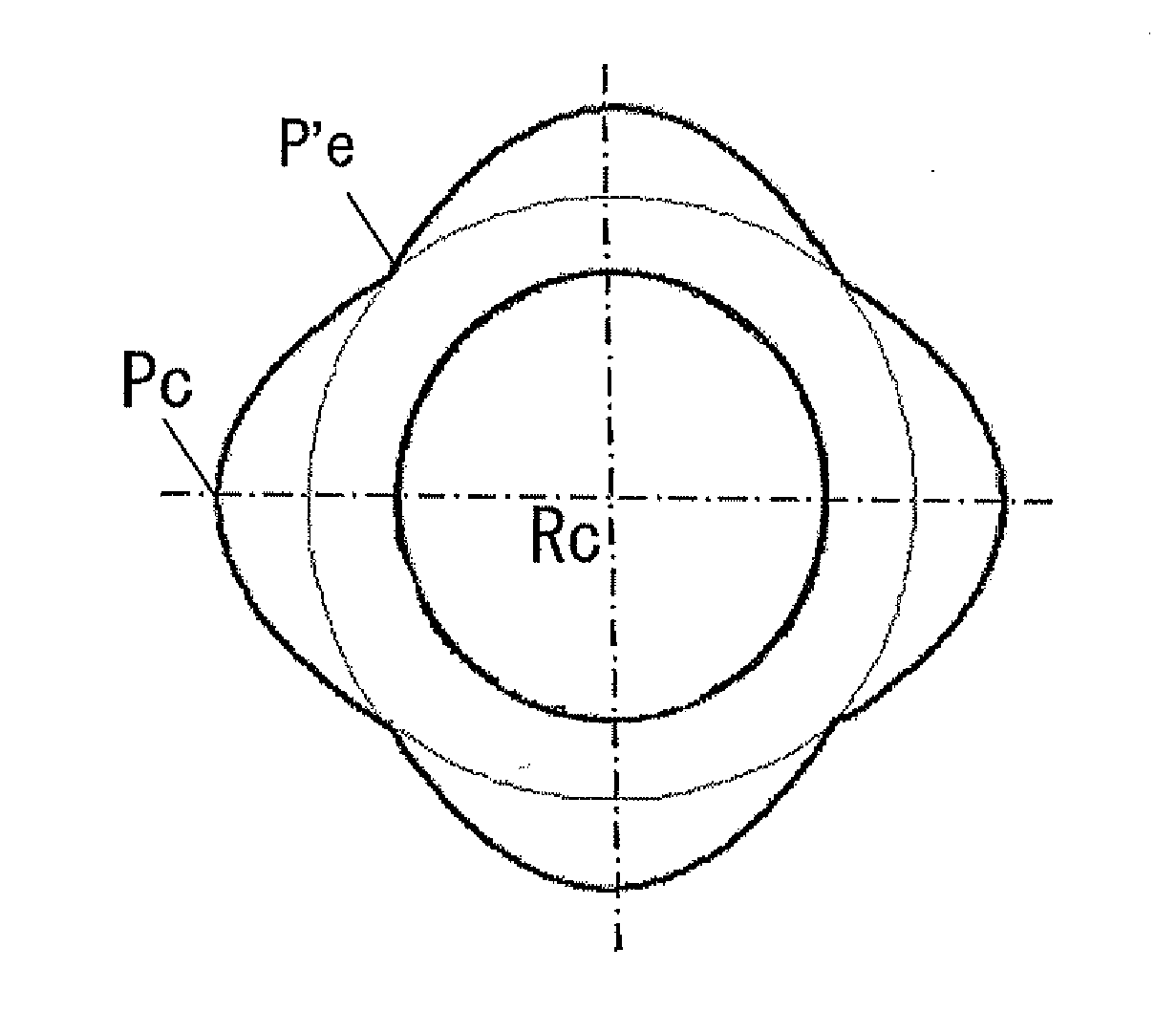

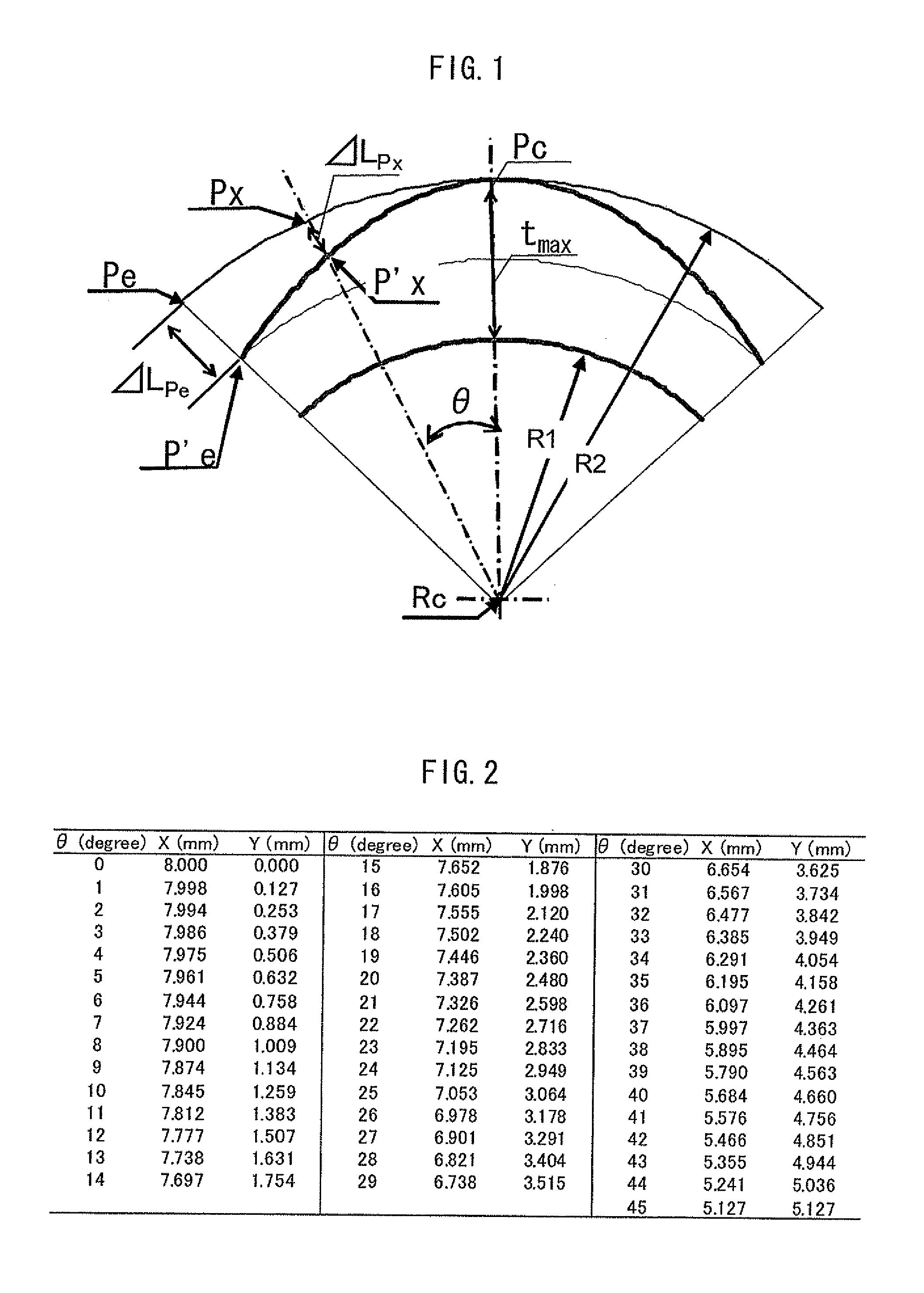

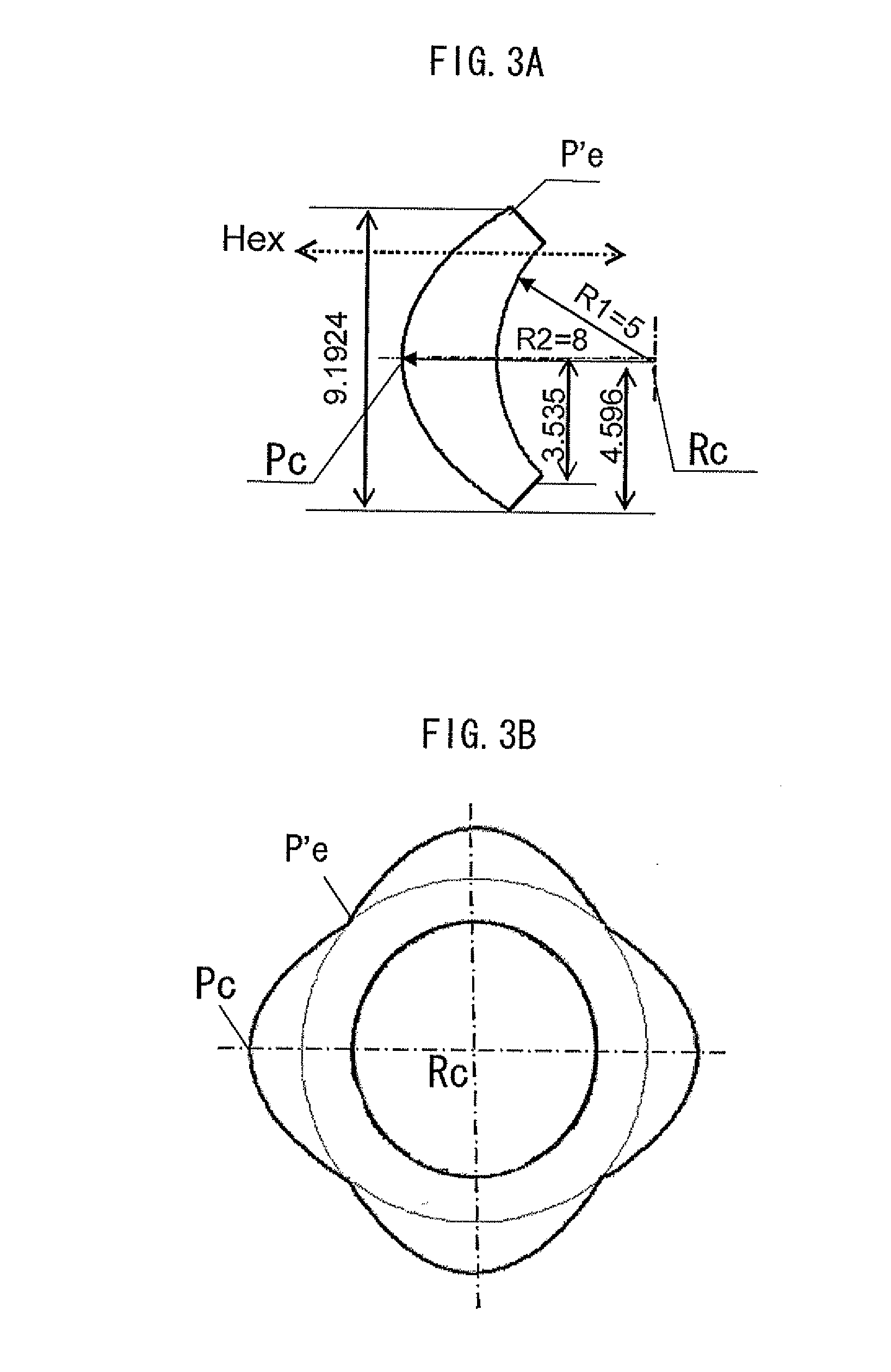

[0038]Hereinafter, embodiments regarding minimizing the cogging torque and the back-EMF in an inner rotor-type permanent magnet motor made from annular magnetic poles where the number of pole pairs Pn is 2 according to the present invention will be explained in more detail. However, the present invention is not limited to the following embodiments.

[0039]A material composition of the magnet according to the present embodiment is as follows (the units in the following are vol. %): 32.1 of an anisotropic Sm2Fe17N3-type fine powder having a grain diameter of 3 to 5 μm and a (BH)max of 290 kJ / m3, 48.9 of anisotropic Nd2Fe14B-type particles having a grain diameter of 38 to 150 μm and a (BH)max of 270 kJ / m3, 6.2 of a novolac-type epoxy oligomer, 9.1 of linear polyamide, 1.8 of 2-phenyl-4,5-dihidroxy methyl imidazole, and 1.9 of a lubricant (pentaerythritol stearic acid triester).

[0040]The magnet in the present embodiment as described above has the following characteristics: a remanence Mr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap