Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Motor shaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nippon Pulse’s Linear Shaft Motor is a brushless, high-precision direct drive linear servo motor with a tubular design. The linear actuator consists of a magnetic shaft and coil assembly (forcer), and is driven and controlled by the flow of current.

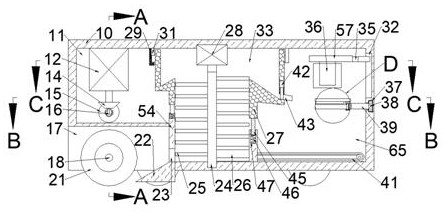

Crushing quantitative mixing pharmaceutical device for traditional Chinese medicinal material

Owner:邹铁梅

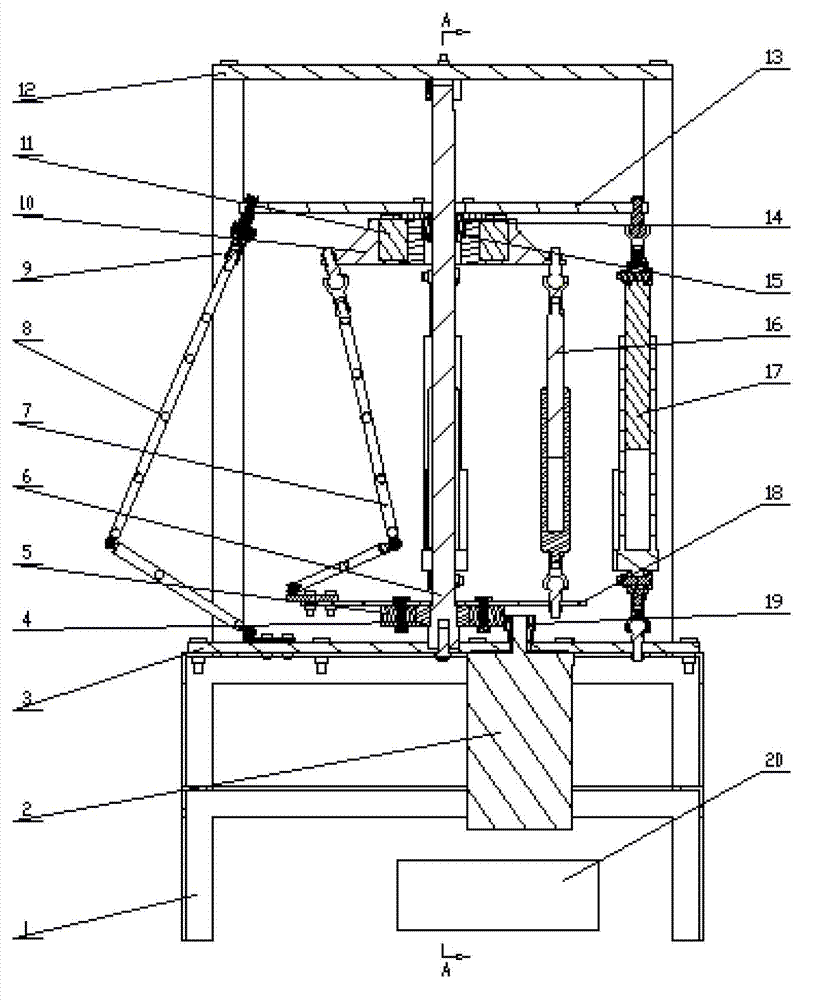

Helicopter automatic inclinator spherical hinge bearing comprehensive fatigue testing machine

InactiveCN103162963AReduce energy consumptionHigh precisionMachine bearings testingFatigue testingMotor shaft

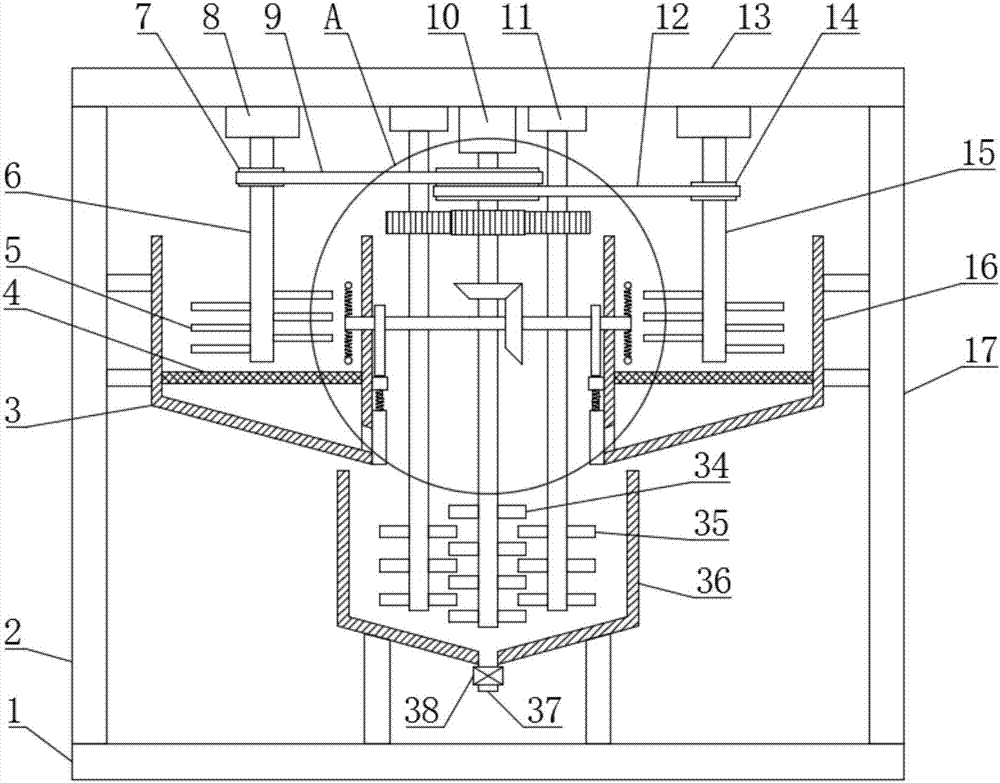

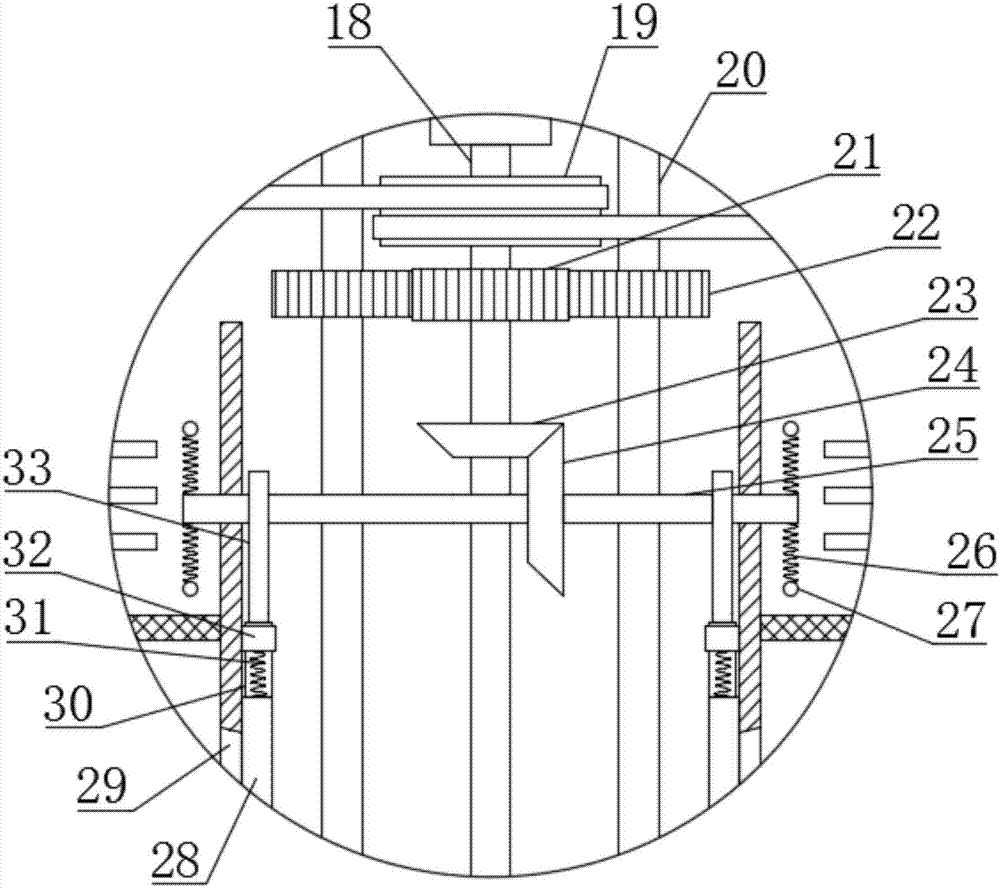

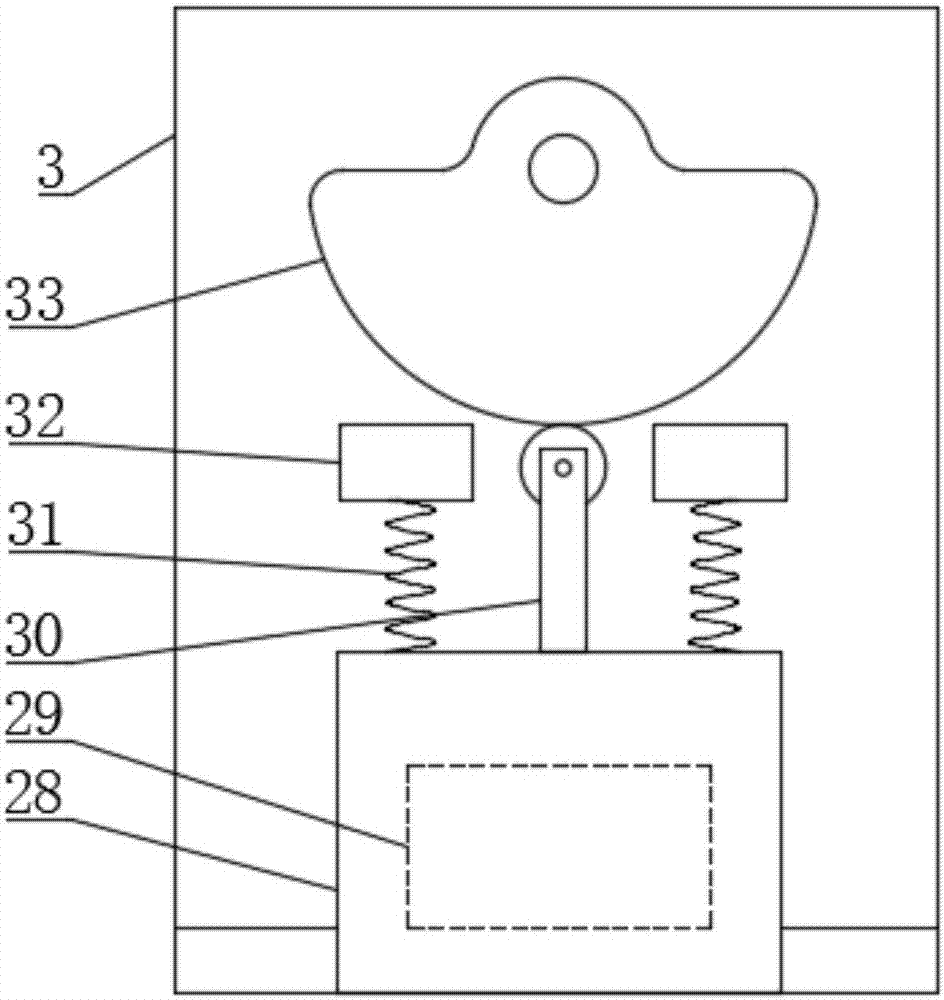

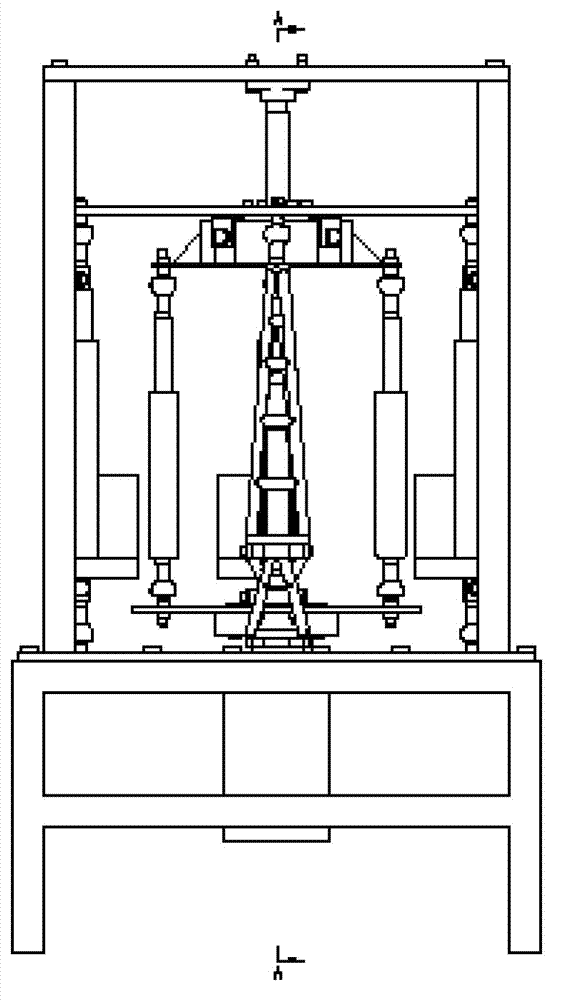

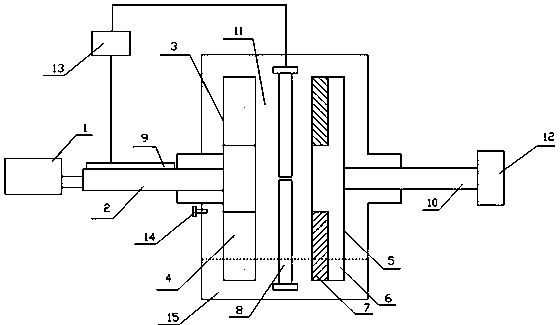

The invention relates to a helicopter automatic inclinator spherical hinge bearing comprehensive fatigue testing machine which comprises a support, a base, an inner ring parallel mechanism, an outer ring parallel mechanism, a power transmission mechanism and a control system. The helicopter automatic inclinator spherical hinge bearing comprehensive fatigue testing machine is characterized in that the base is fixed on the support, stand columns are arranged on the same circumference of the base at intervals, an upper cover is arranged on top ends of the stand columns, a main shaft is arranged between the base and the upper cover, the inner ring parallel mechanism is composed of an inner ring upper platform, a joint bearing, a first twist preventing arm, and an electric power booster, the outer ring parallel mechanism is composed of an outer ring lower platform, a first bearing, a first gear, an outer ring upper platform, an adjustable pressure controller, and a second twist preventing arm, the power transmission mechanism comprises a motor and a second gear fixed on a motor shaft, the motor is fixed on the base, and the second gear is meshed with the first gear. The helicopter automatic inclinator spherical hinge bearing comprehensive fatigue testing machine has the advantages of being capable of realizing fatigue experimental tests on a ball hinge bearing, a joint bearing, a double-row contact bearing, and the like in a helicopter rotor system.

Owner:YANSHAN UNIV

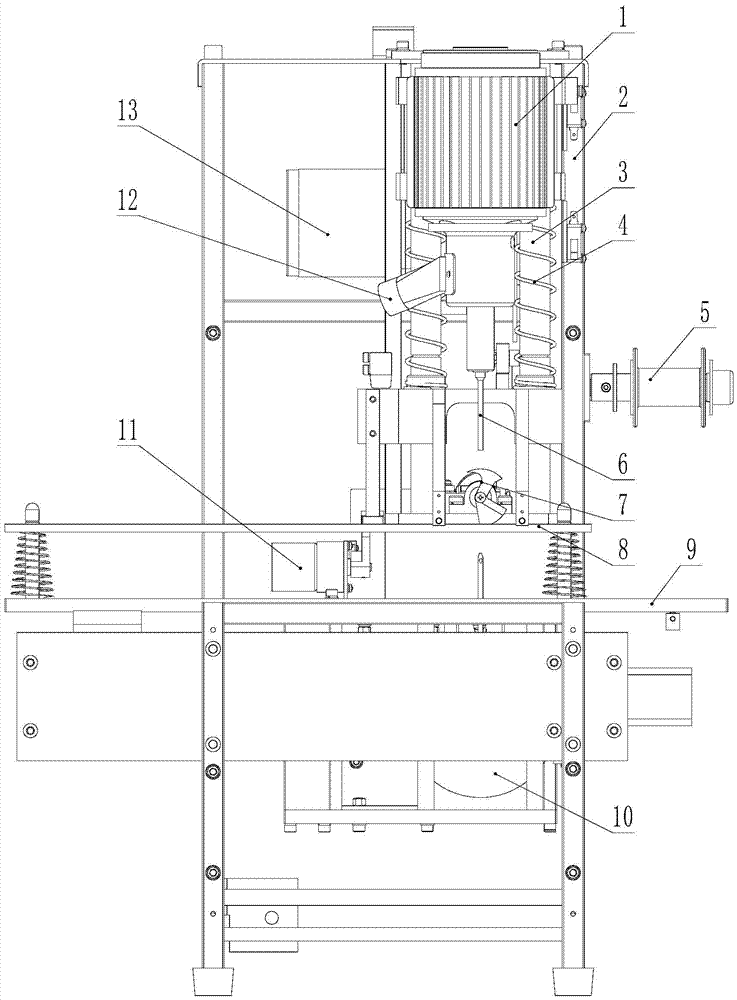

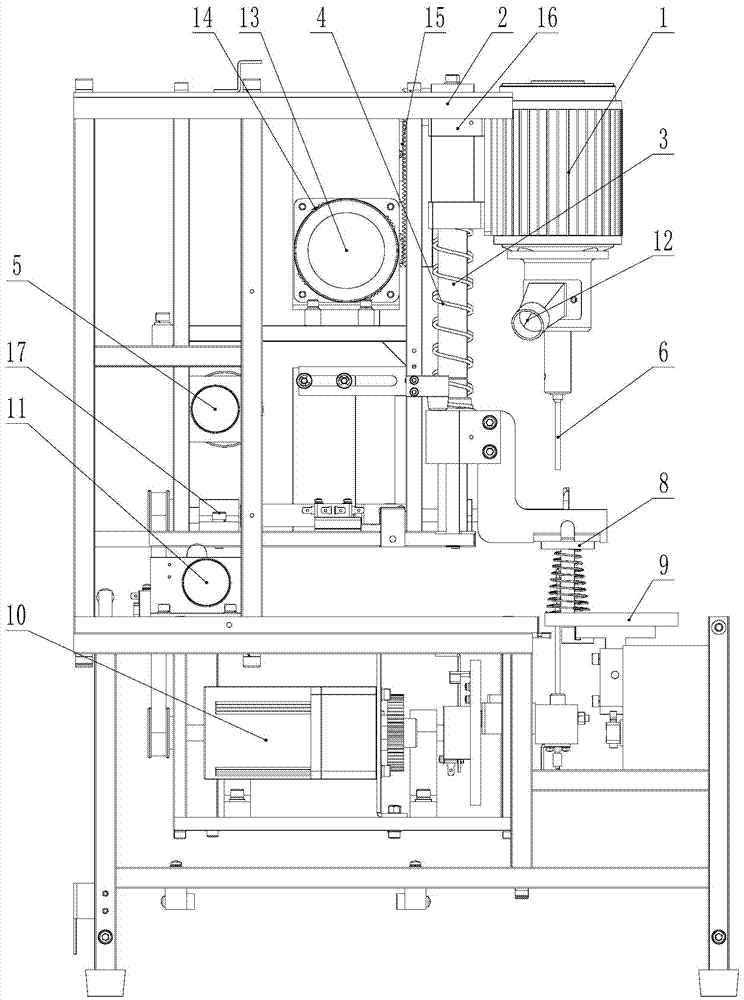

Wire type completely intelligent bookbinding machine

Owner:ZHONGCHAUNGEN TIANJIN TECH CO LTD

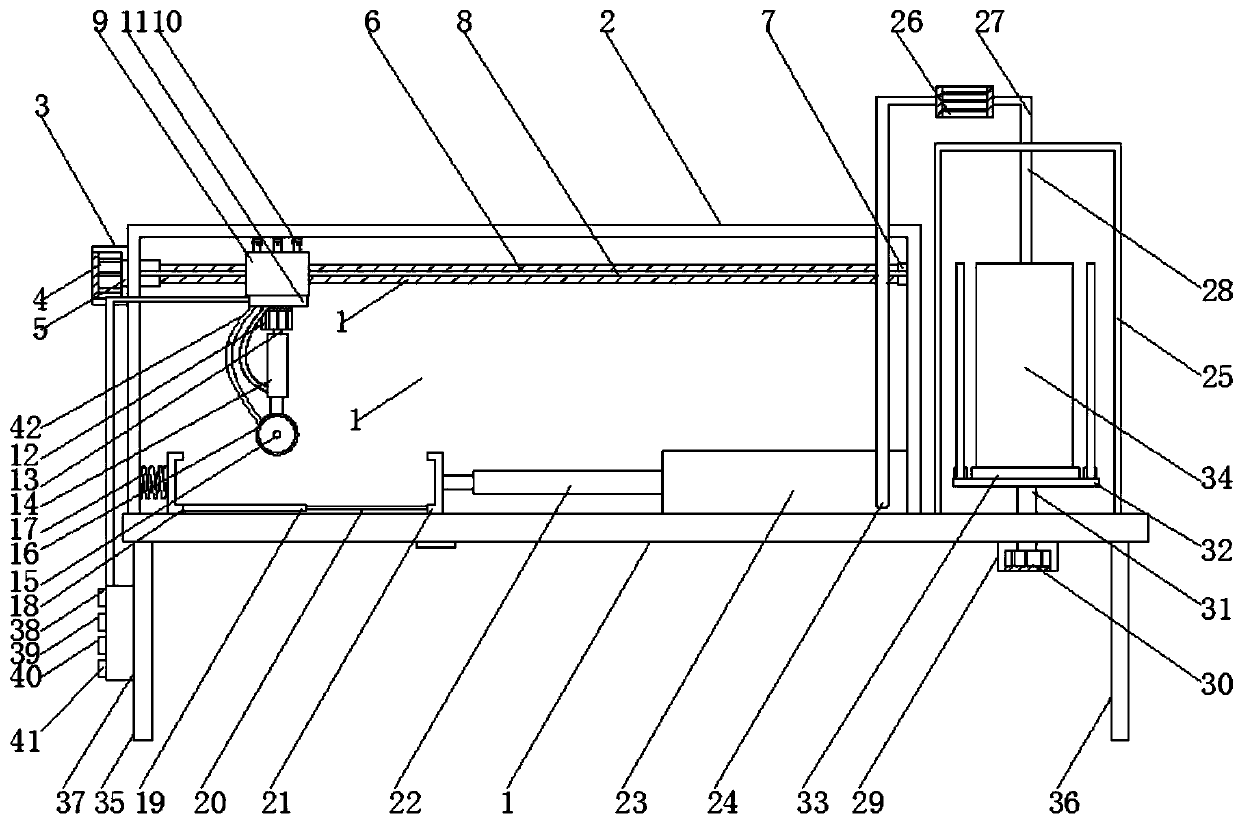

Steel seal stamping machine with automatic feeding and discharging functions

InactiveCN105035638AProcess stabilitySimple structureConveyorsConveyor partsDrive wheelElectric machine

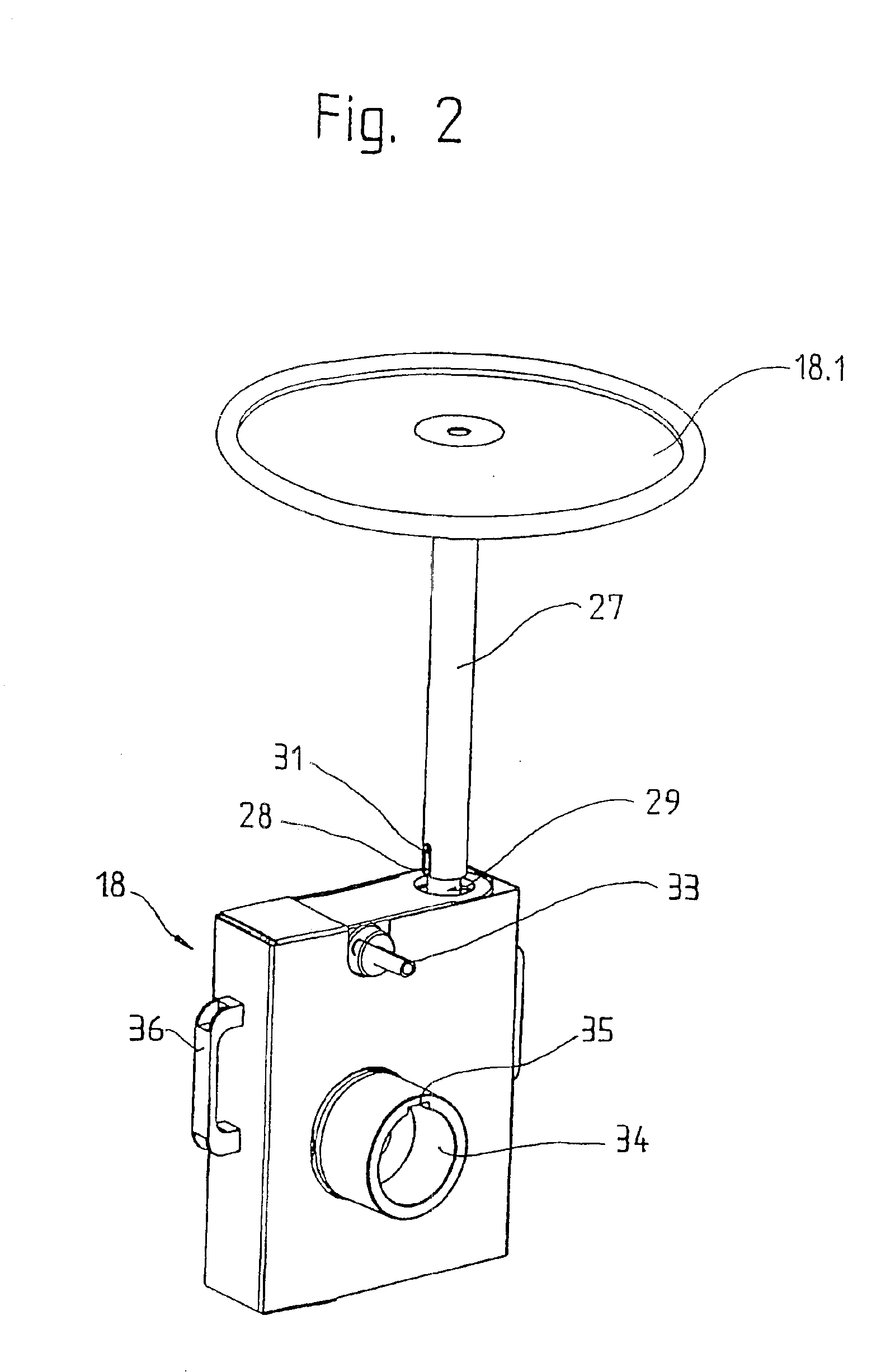

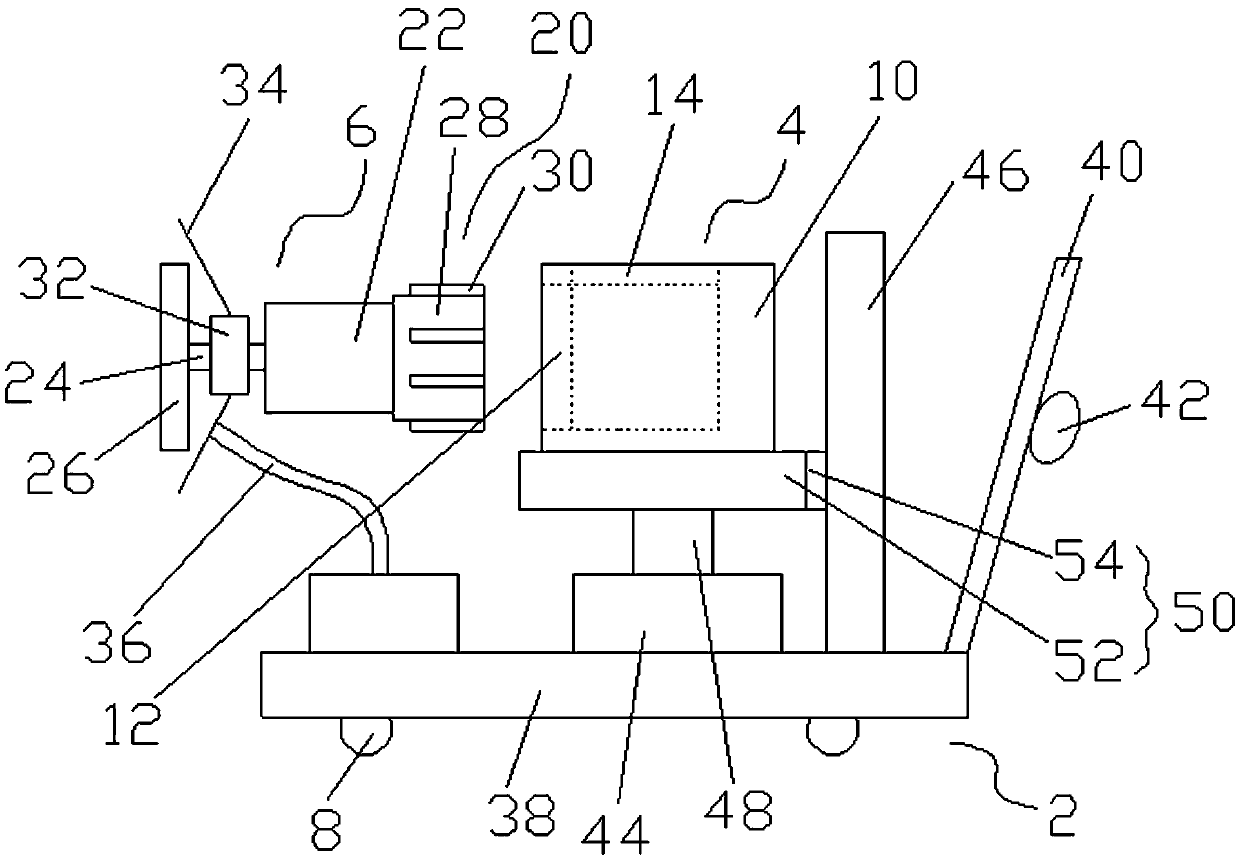

The invention provides a steel seal stamping machine with automatic feeding and discharging functions. The steel seal stamping machine comprises a working table, a supporting plate, a motor, a controller, a driving wheel, a driven wheel, a plurality of conveying plates, a chain and a steel seal stamping device. The working table further comprises a table top, table legs, a rocking handle, a rotating disc, a slide rod and track grooves, the rocking handle is fixedly connected with the rotating disc, the rotating disc and the slide rod are fixedly connected, the driving wheel is arranged above the table top, a motor shaft penetrates through the table top and is connected with the driving wheel, and the driven wheel is located above the table top. The steel seal stamping machine is simple in structure; as the chain is used for transmission, it is ensured that the transmission ratio is accurate, the transfer power is large, force exerted on the shaft is small, and the transmission efficiency is high; the steel seal stamping machine can work in an atrocious environment, the rotating speed can be controlled by the controller, the automation degree is high, the rotating speed is appropriate, steel seals can be replaced, and the steel seal stamping machine is wide in application range, high in the steel seal stamping quality, capable of automatically feeding and discharging materials and high in working efficiency.

Owner:ZHEJIANG YATAI FORGING MFG CO LTD

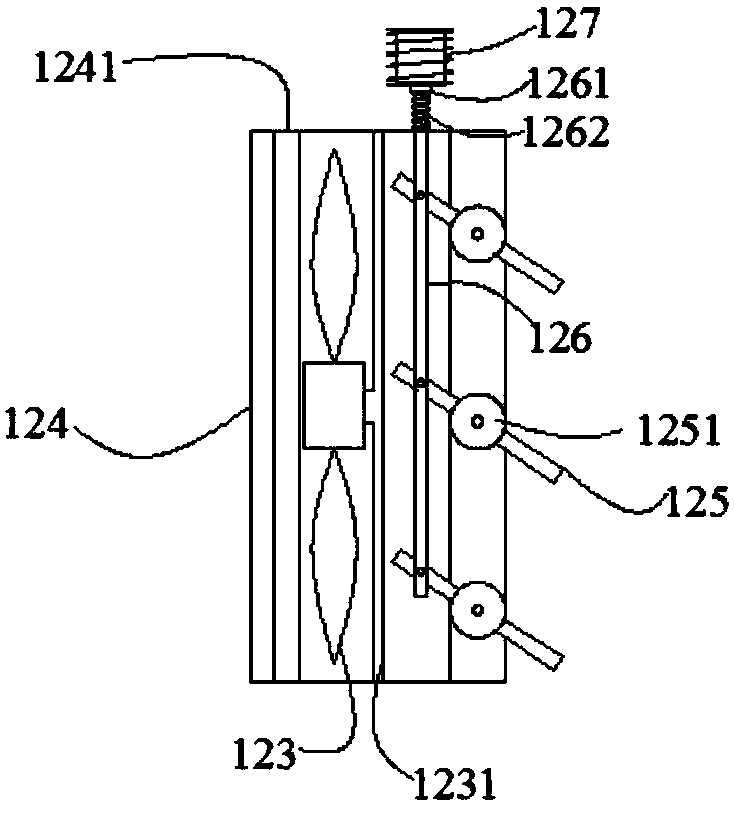

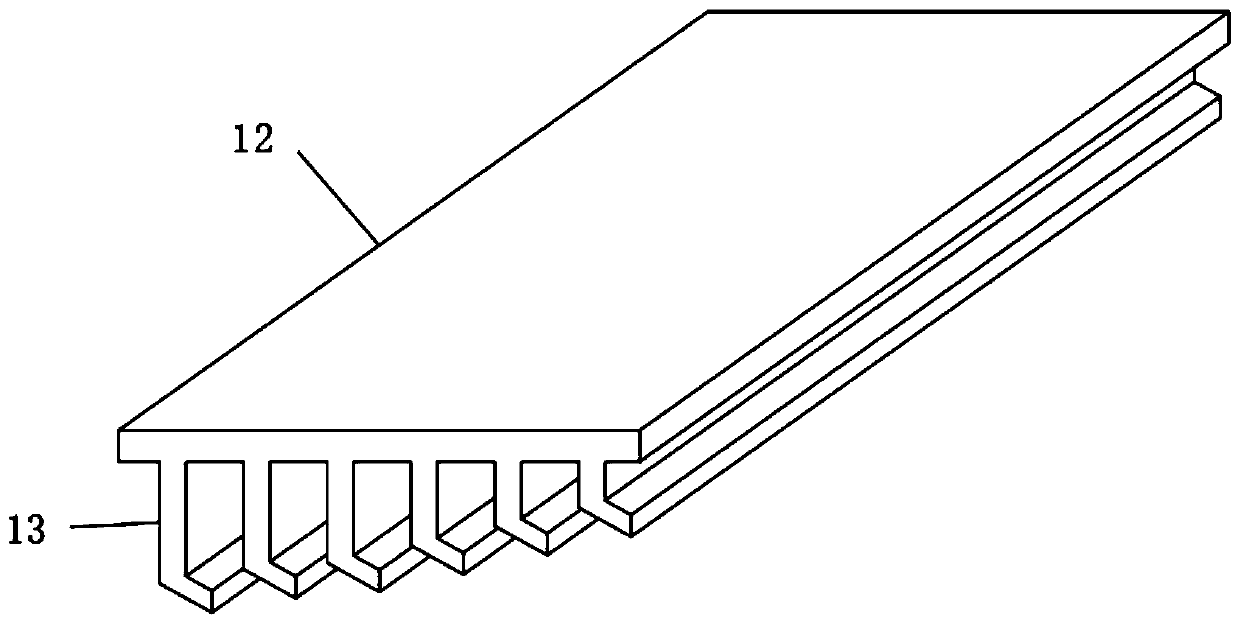

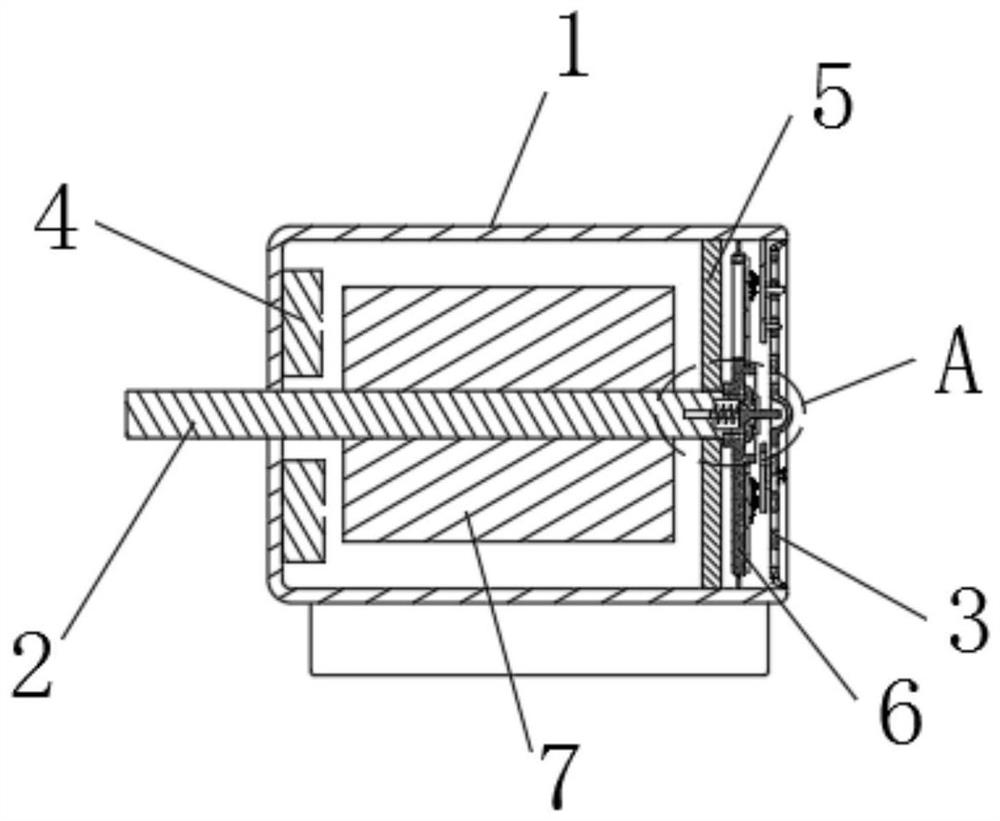

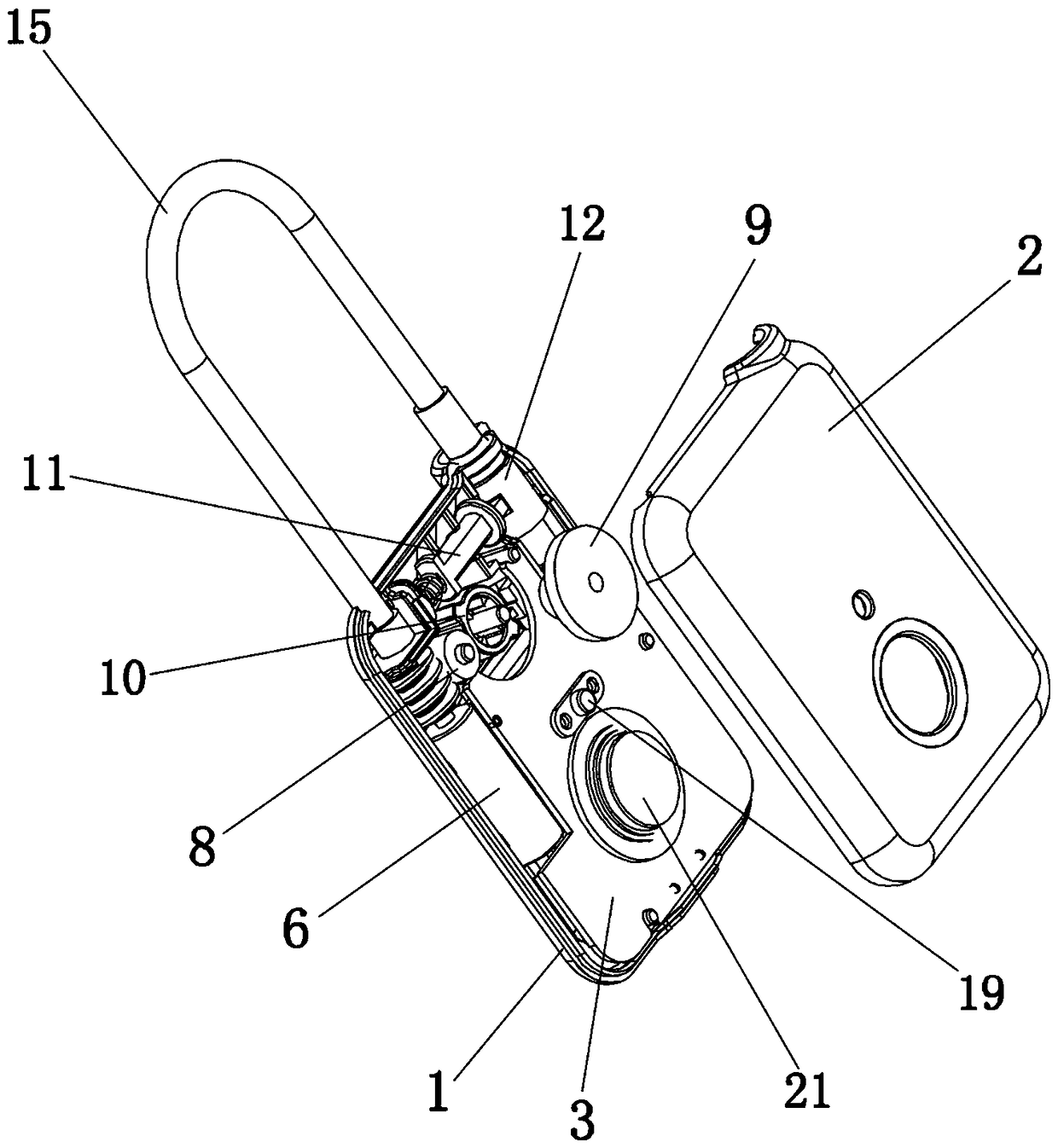

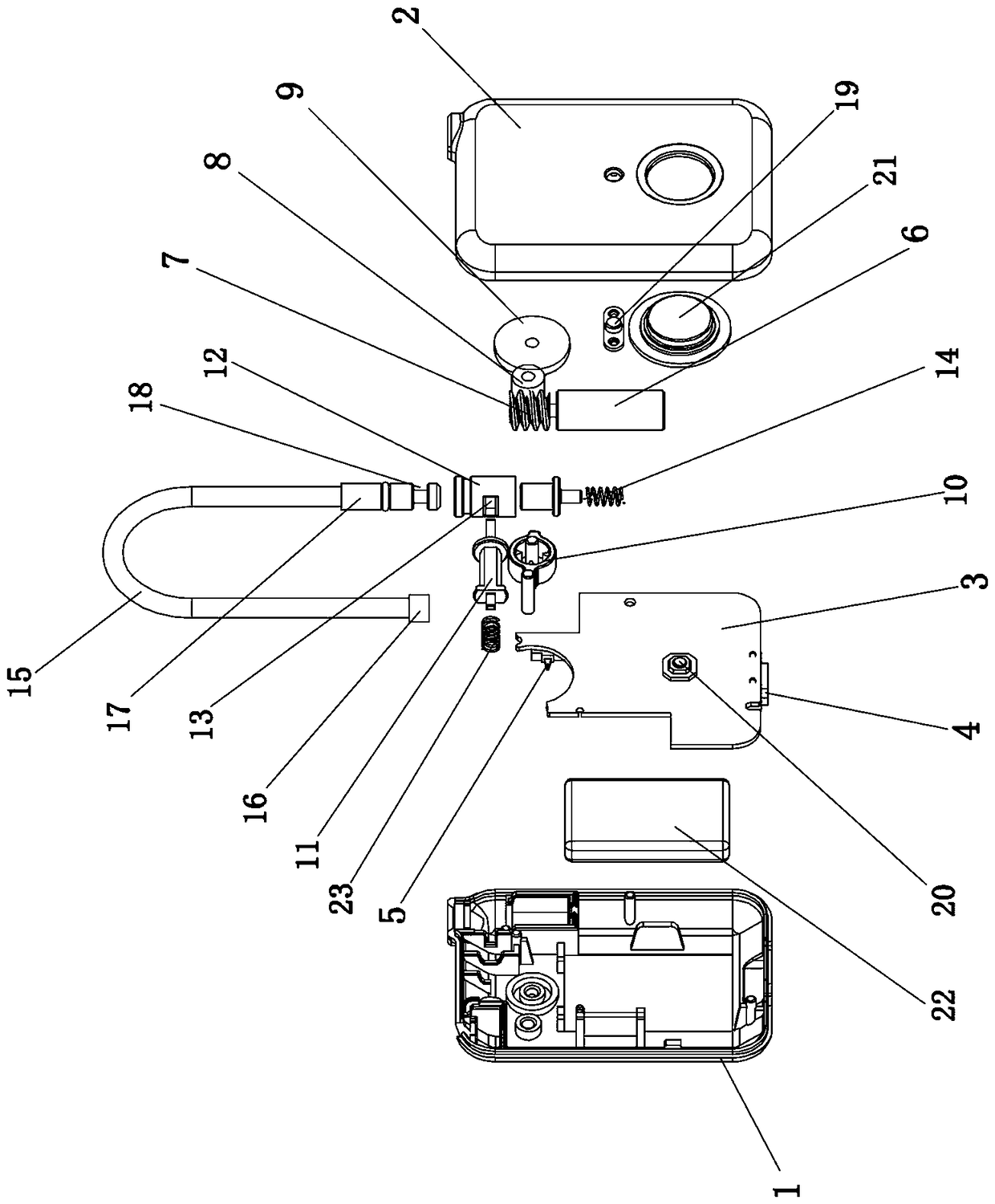

Pan-tilt motor and pan-tilt

ActiveCN104756373AShooting stabilityEnsure consistencyAircraft componentsMechanical energy handlingEngineeringMotor shaft

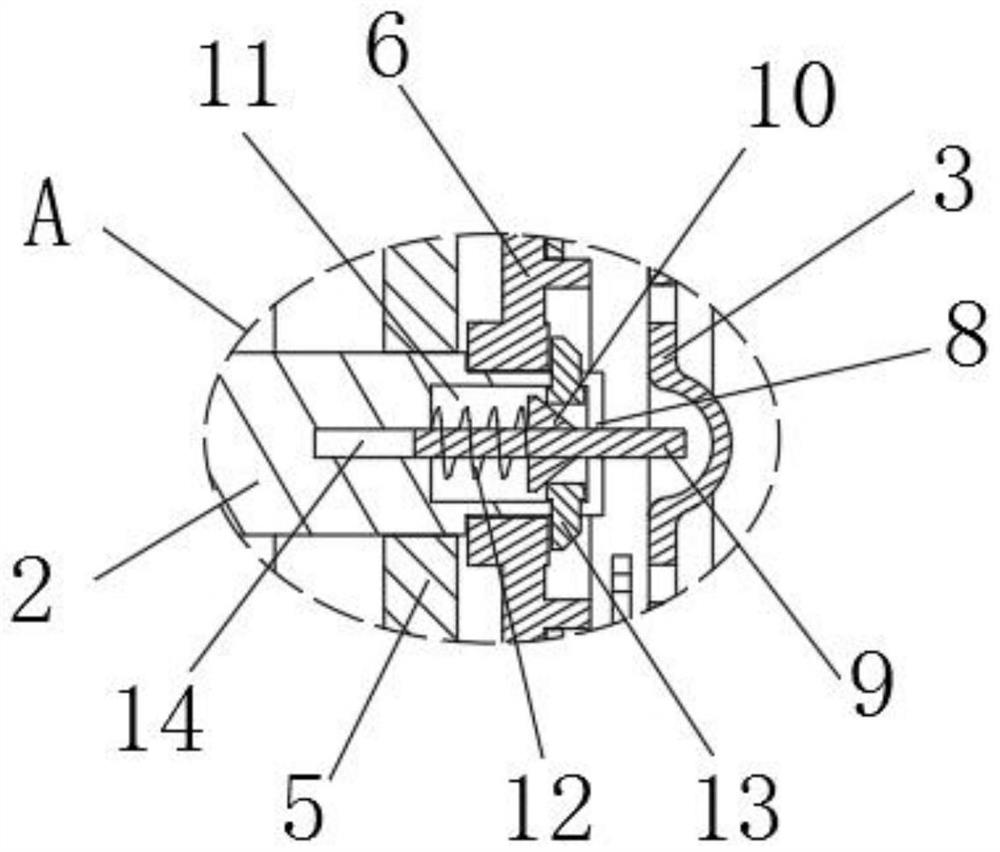

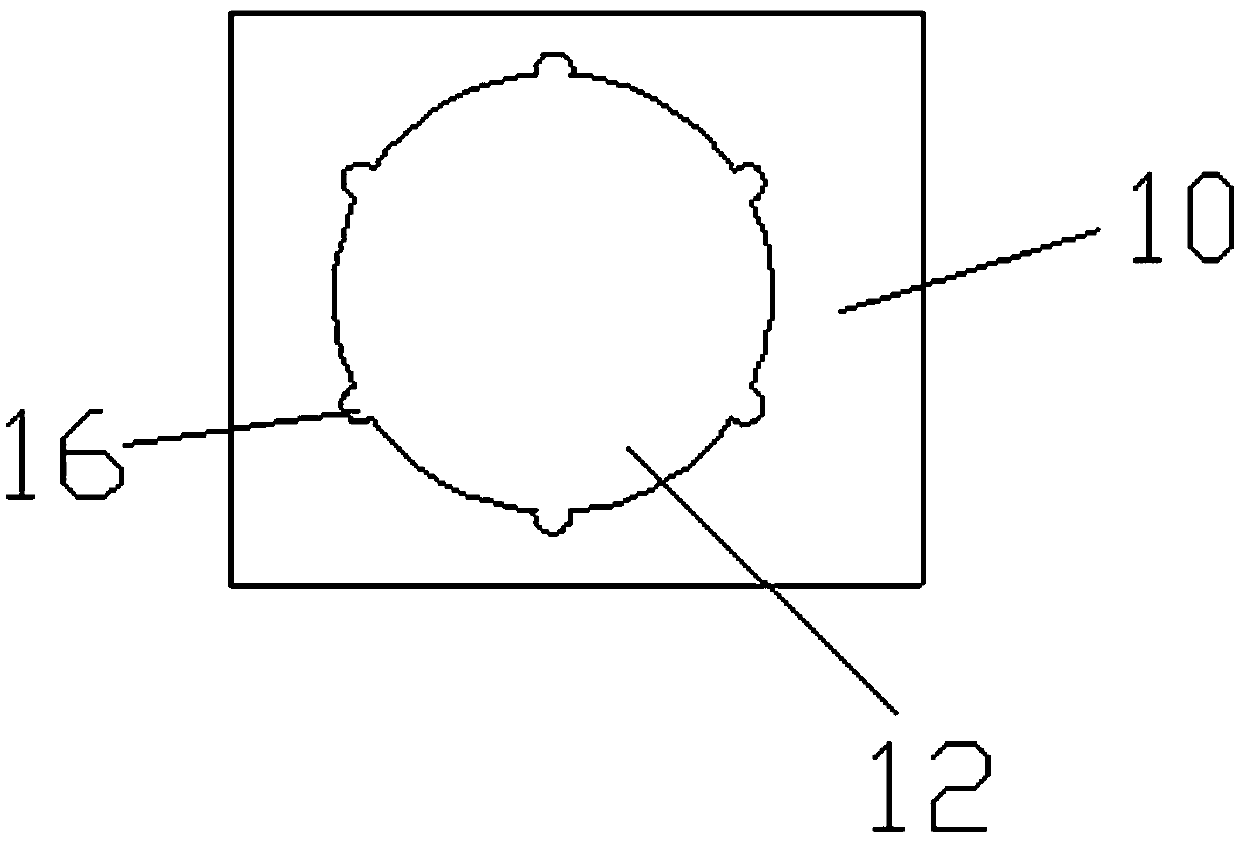

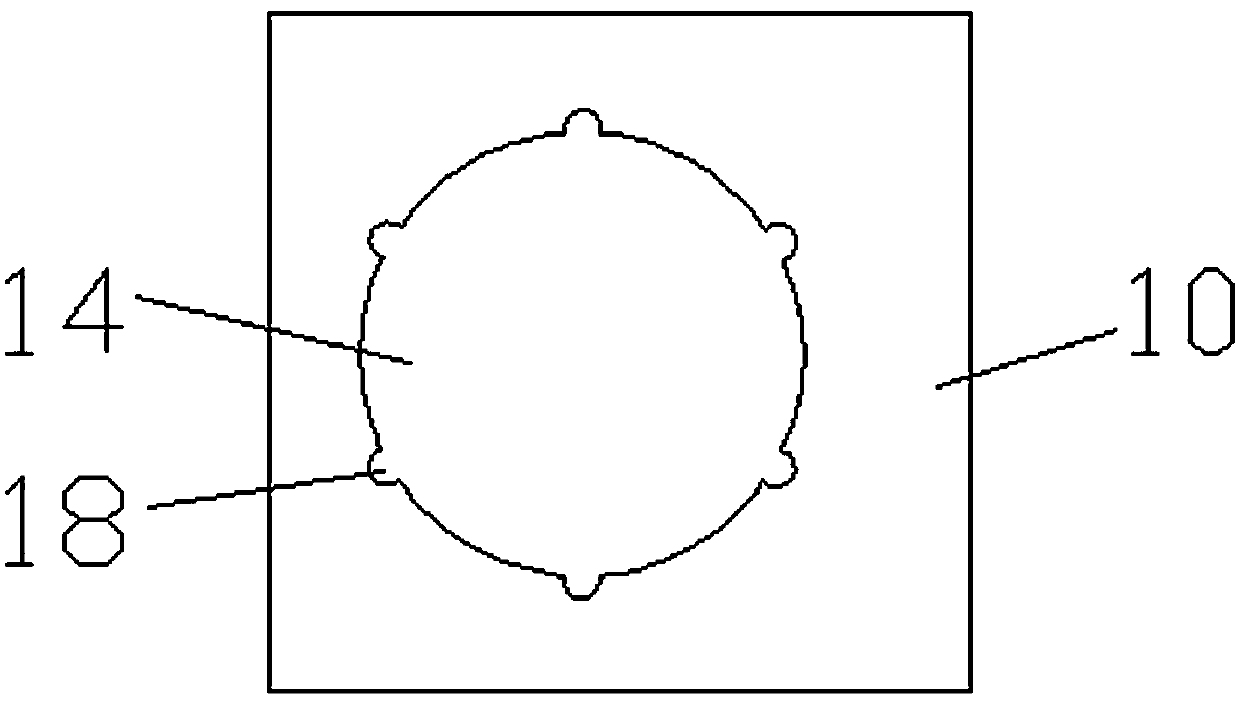

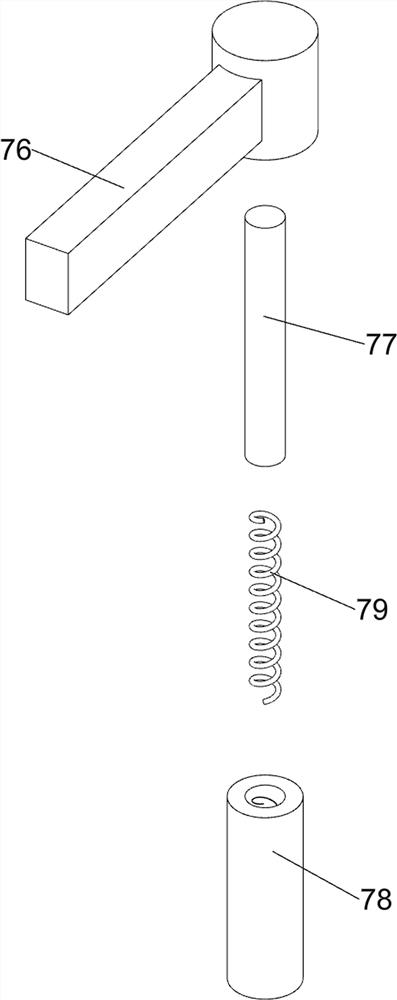

The invention discloses a pan-tilt motor (10), comprising a rotor component (11), a motor shaft (12) and a stator component (13). The motor shaft (12) comprises a shaft body (122), a first end (124) and a second end (126). The first end (124) if fixedly connected to the rotor component (11). The stator component (13) sleeves the periphery of the shaft body (122) and is connected to the motor shaft (12) in a rotating manner through a pair of bearings (15). The pair of bearings (15) are disposed near the first end (124) and the second end (126). The pan-tilt motor (10) also comprises a compressing piece (16) and an elastic body (18). The compressing piece (16) matches with the second end (126), and thereby the stator component (13) is positioned at the motor shaft (12) in an axial direction. The elastic piece (18) and a bearing pad (152) are both disposed between the compressing piece (16) and the bearing (15) adjacent to the second end (126). The bearing pad (152) clings to the bearing (15). The elastic piece (18) is disposed between the bearing pad (152) and the compressing piece (16). The elastic body (18) is elastically deformed through the compressing piece (16), and thereby the axial pretightening force of the pan-tilt motor (10) can be ensured.

Owner:SZ DJI OSMO TECH CO LTD

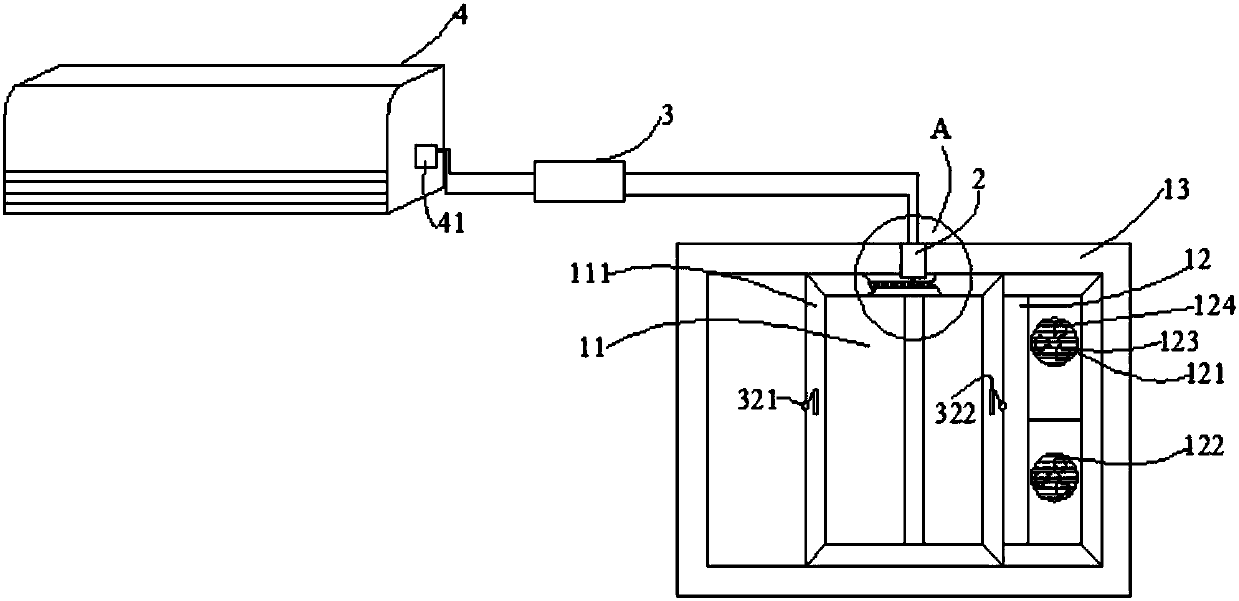

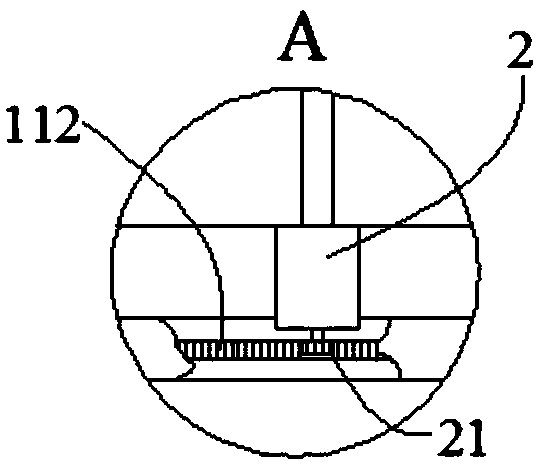

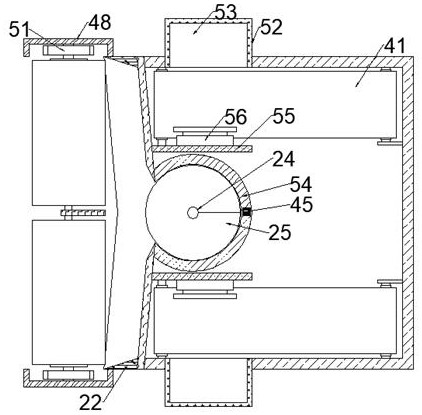

Air conditioner with top cover lifting device

ActiveCN103776147ASmooth liftSimple structureHeating and ventilation casings/coversDrive motorEngineering

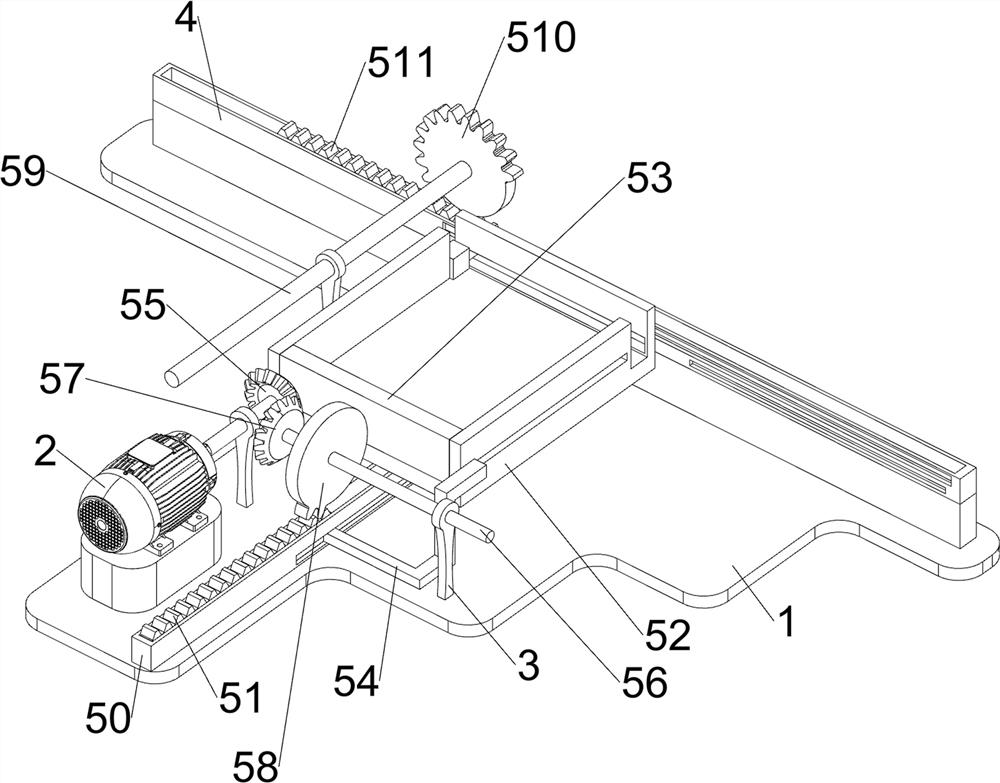

The invention discloses an air conditioner with a top cover lifting device. The air conditioner with the top cover lifting device comprises a machine casing, a top cover, a first rack, a second rack, a first driving motor and a second driving motor, an air duct is formed in the machine casing, the top of the machine casing is open, and an air inlet commutated with the air duct is formed in the machine casing. The top cover can vertically and movably arranged at the top of the machine casing, and an air outlet communicated with the air duct is formed in the top cover. The first rack and the second rack are connected with the top cover so as to drive the top cover to vertically move. The first driving motor and the second driving motor are installed on the machine casing, a first motor shaft of the first driving motor is provided with a first gear meshed with the first rack to drive the first rack to vertically move, and a second motor shaft of the second driving motor is provided with a second gear meshed with the second rack to drive the second rack to vertically move. In the air conditioner, vertical movement of the top cover is controlled through meshing of the gears and the racks, and accordingly the top cover is stable in lifting. In addition, the air conditioner is simple in structure.

Owner:MIDEA GRP CO LTD

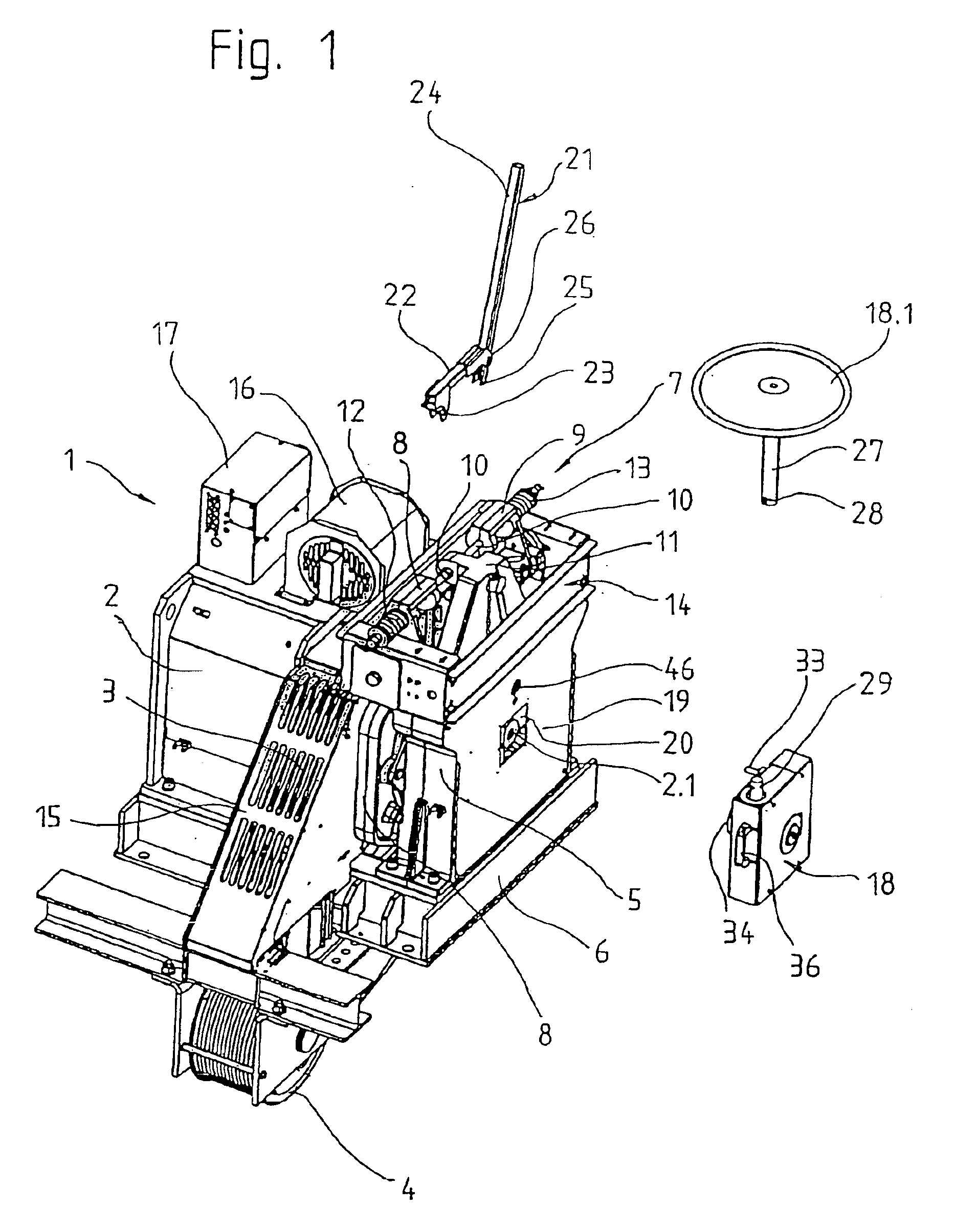

Actuating device for emergency operation of a gearless drive machine of an elevator

Owner:INVENTIO AG

Micro-wave oven air discharging electric motor units possessing oil smoke suction function

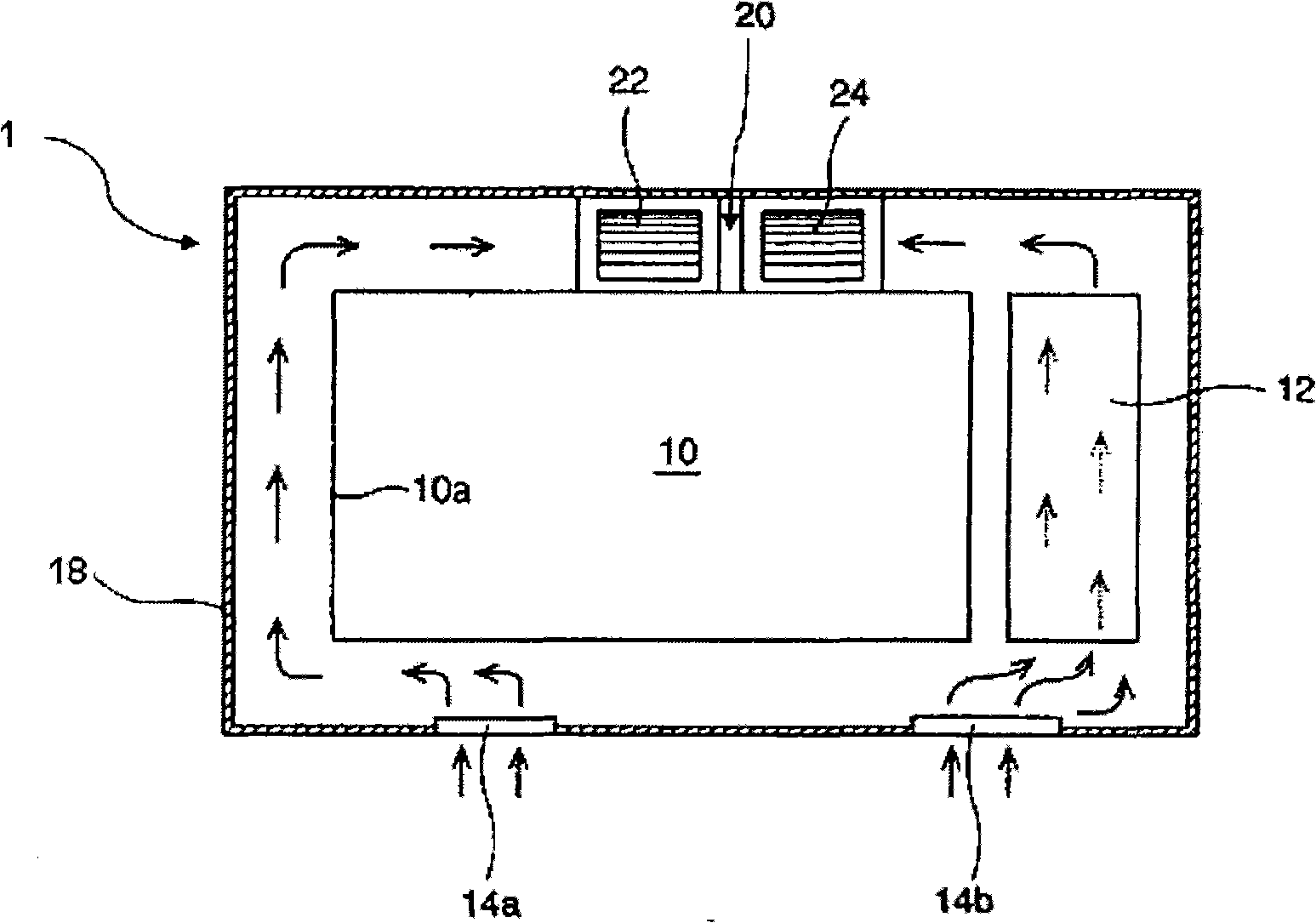

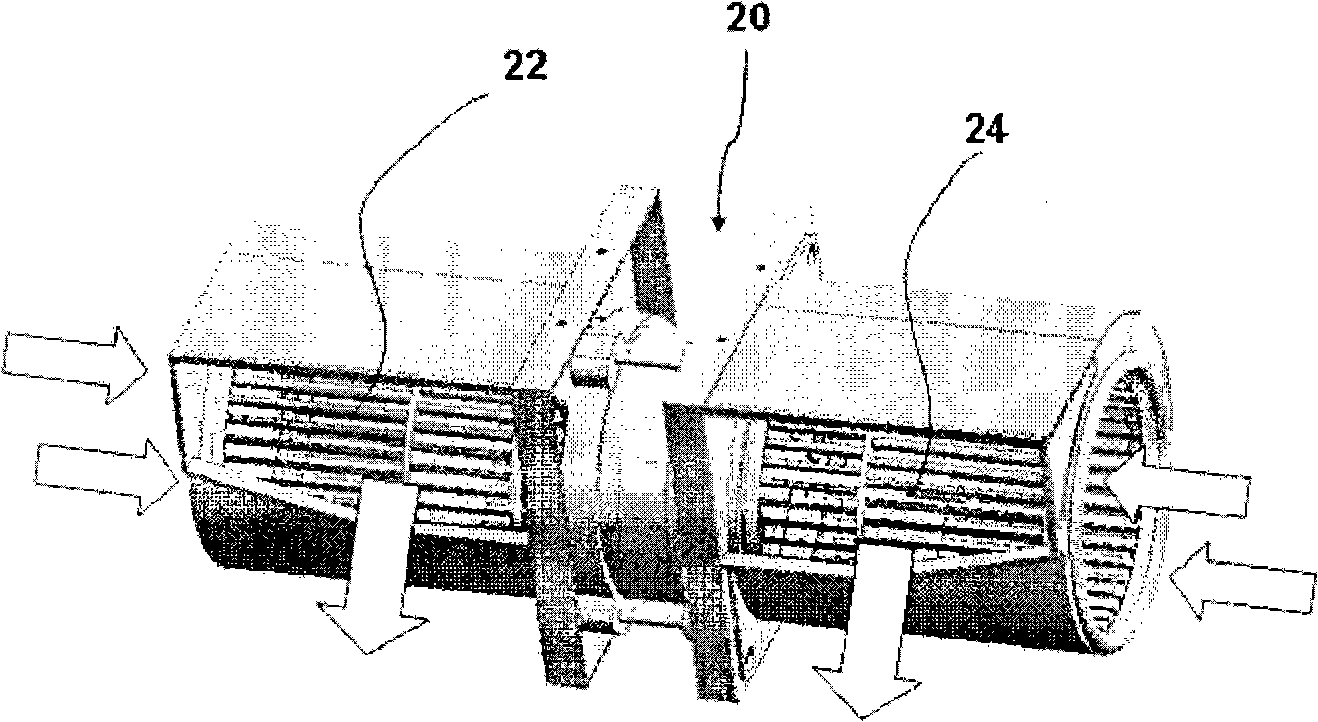

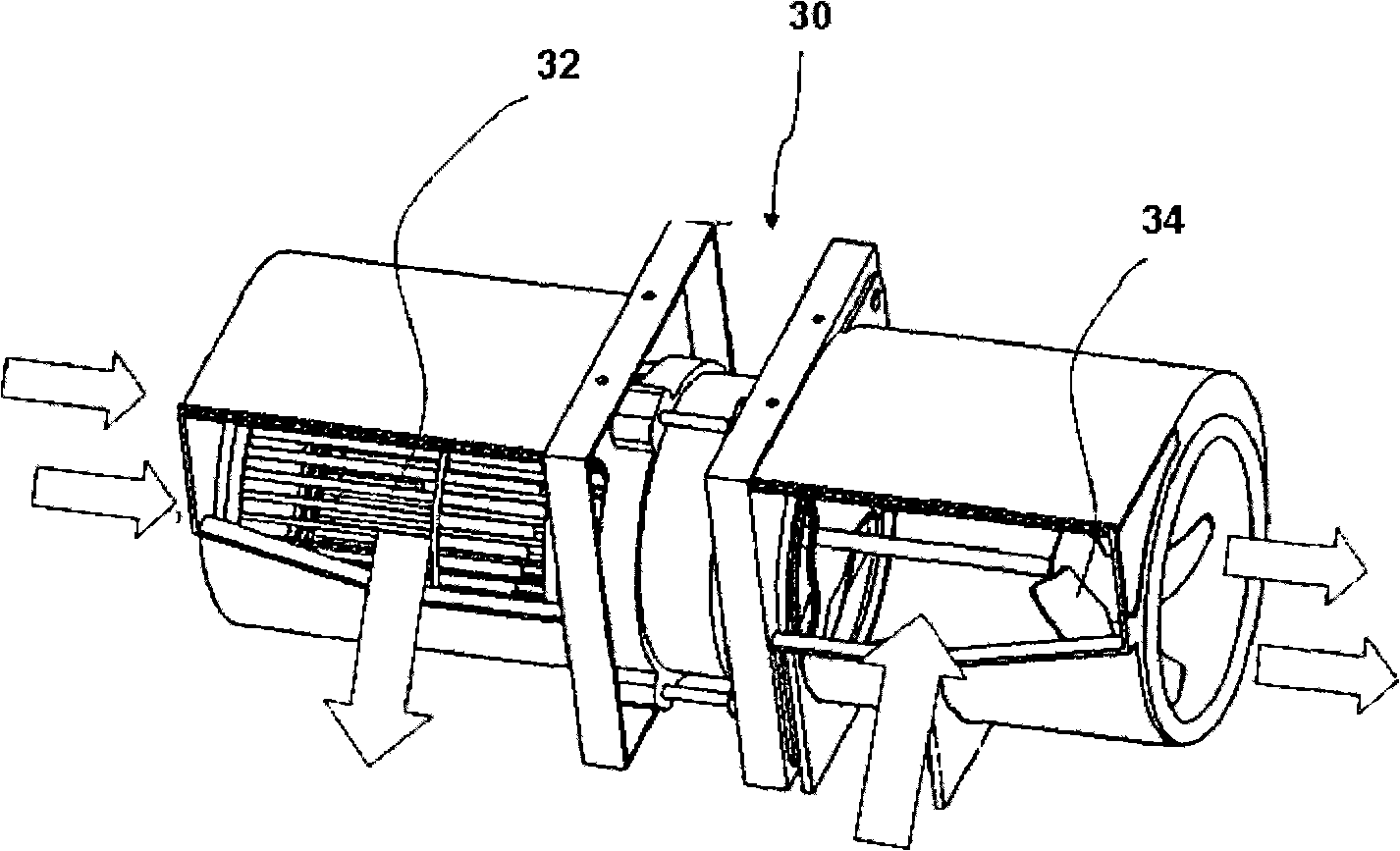

InactiveCN101307918AImprove cooling effectAvoid corrosionDomestic stoves or rangesLighting and heating apparatusMotor shaftCorrosion

The invention discloses a microwave furnace exhaust motor set with function of absorbing oil smoke, comprising a motor, motor shafts, exhaust fans, and wind scoopers. The motor generates drive force when a power source is connected; the motor shafts are respectively connected with two sides of the motor and are rotated by the drive of the motor; the exhaust fans are respectively connected with the two sides of the motor and are rotated by the rotation of the motor shaft; and the wind scoopers are respectively connected with the two sides of the motor, and the wind scoopers of the exhaust fans are used for guiding air current when the exhaust fans are rotated, and at least one axial fan is arranged in the exhaust fans. The microwave furnace exhaust motor set can obviously improve cooling effect of electric appliance parts of a magnetron and so on which are arranged inside an electric appliance room of a microwave furnace, and effectively prevent corrosion of the electric appliance parts, thereby prolonging service life of the electric appliance parts, lightening weight of the integral exhaust motor set, and reducing manufacturing cost at the same time.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

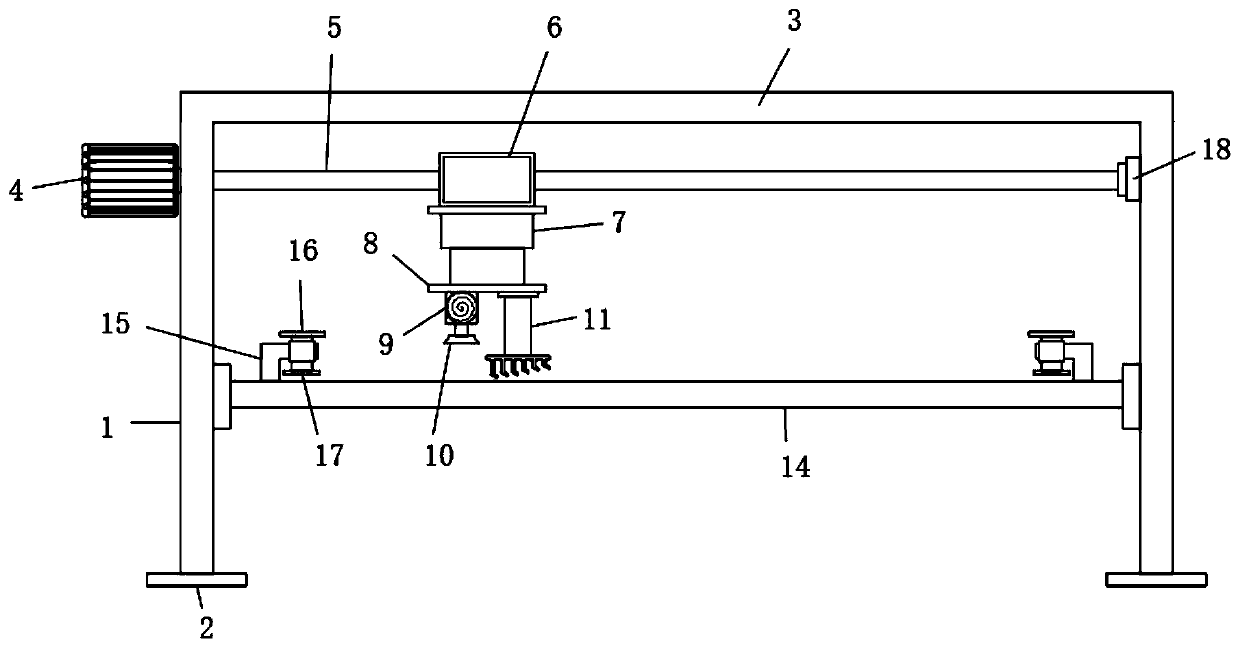

Window matched with air conditioner in use

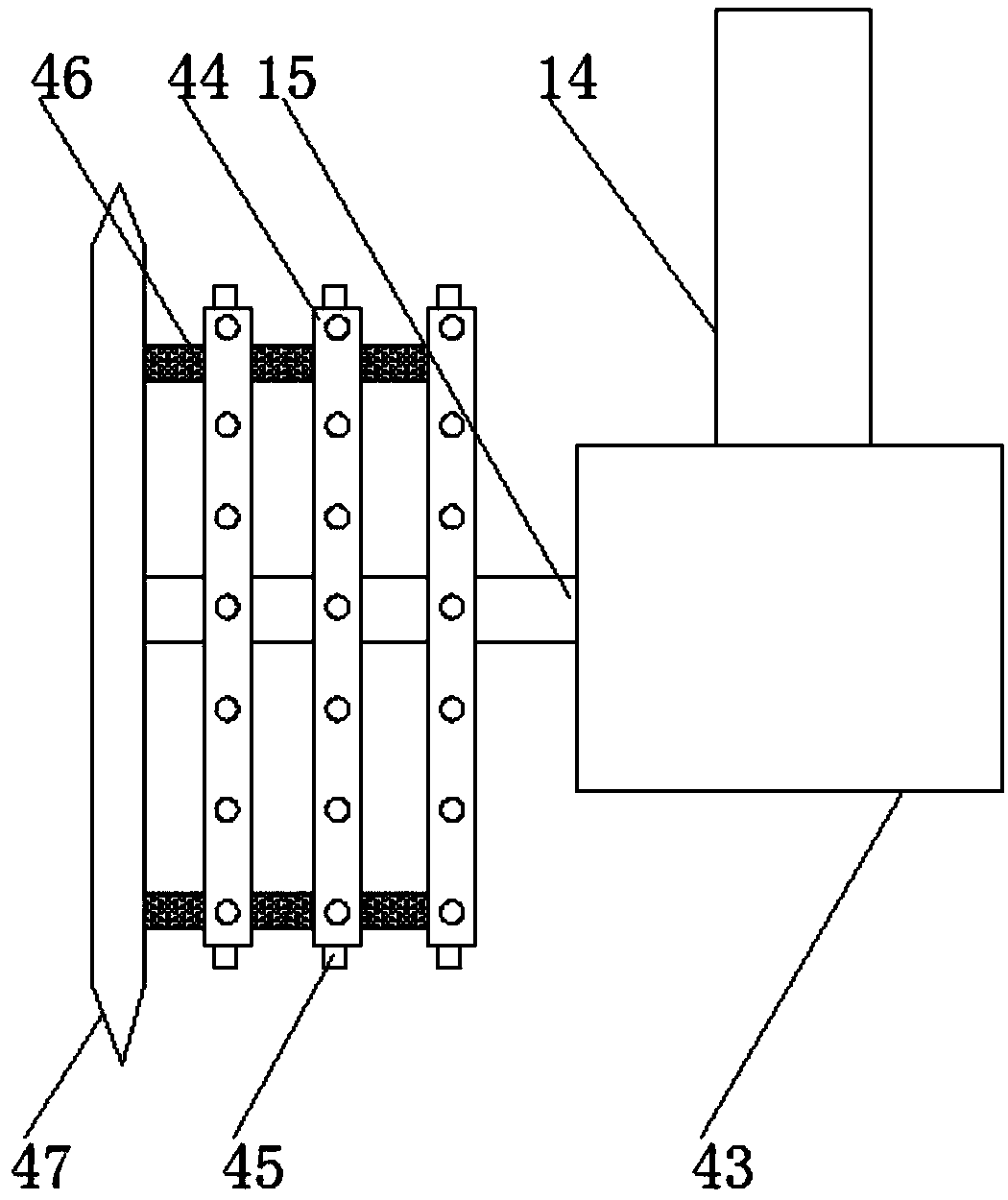

InactiveCN107630623ASpeed up circulationPower-operated mechanismSpecial door/window arrangementsElectric machineryEngineering

Owner:广西驰胜农业科技有限公司

Color steel deburring device

InactiveCN110116241APlay a role in cleaningImprove practicalityFeeding apparatusPositioning apparatusFixed frameArchitectural engineering

Owner:ZHONGXIANG DINGMAO TECH

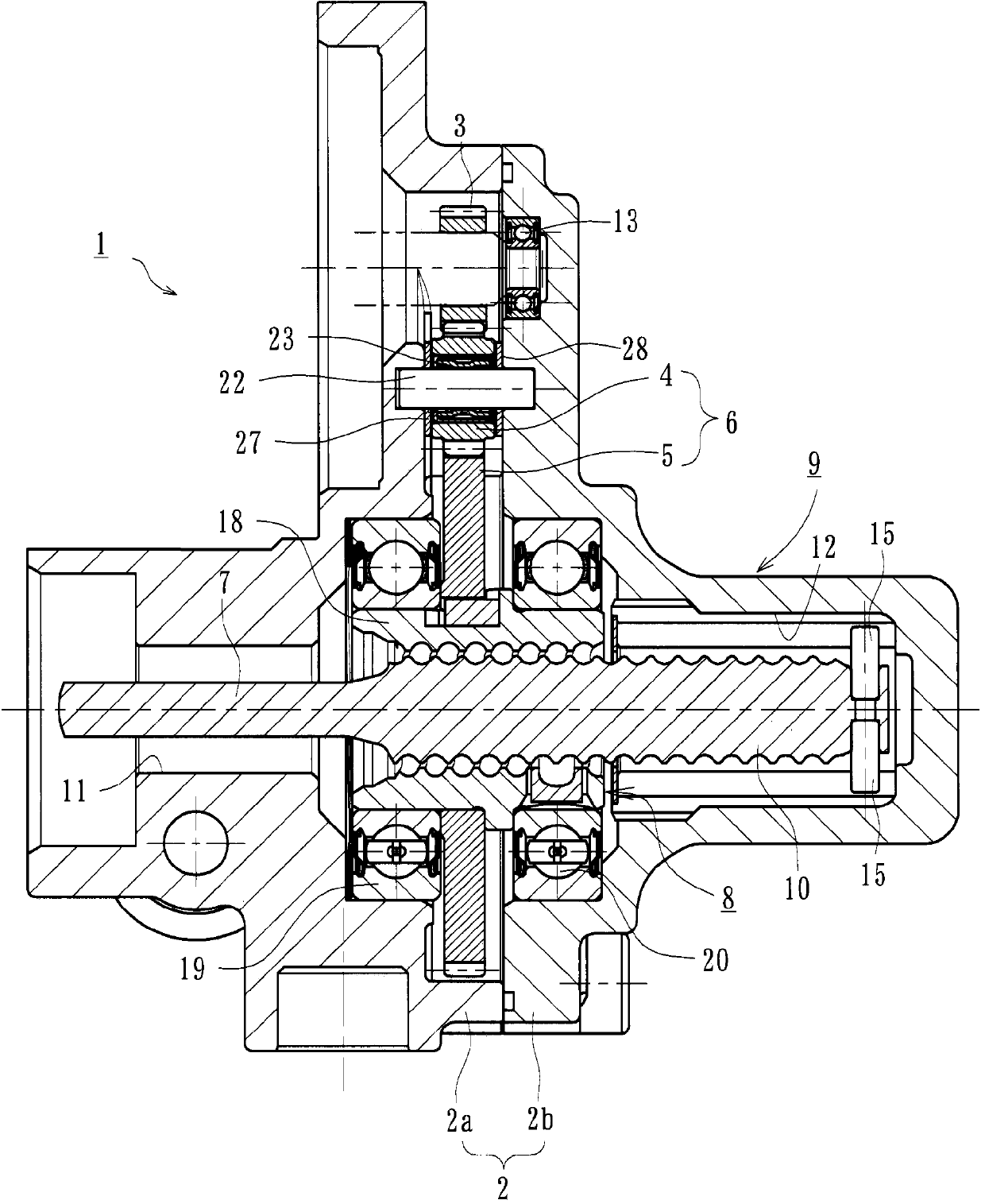

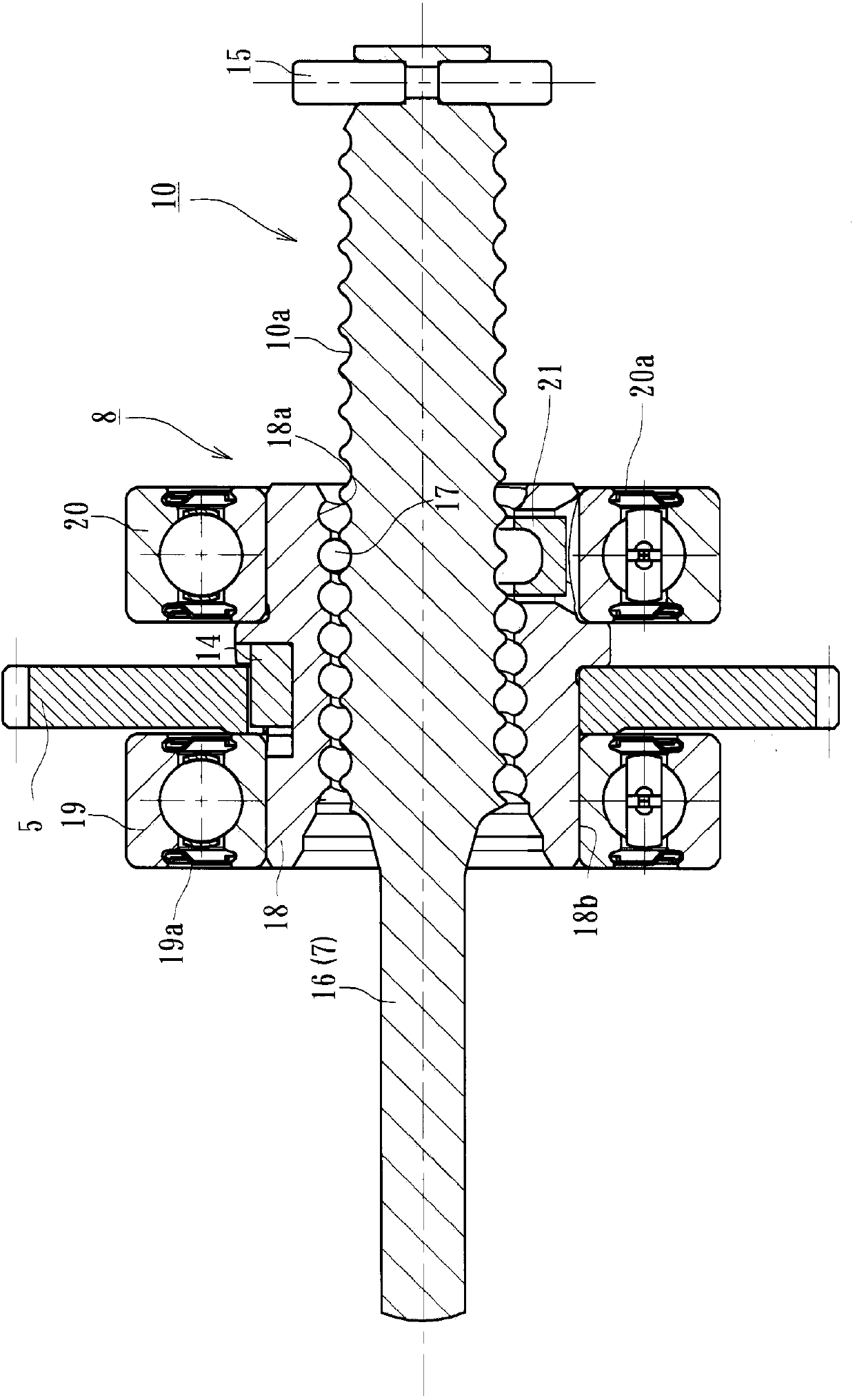

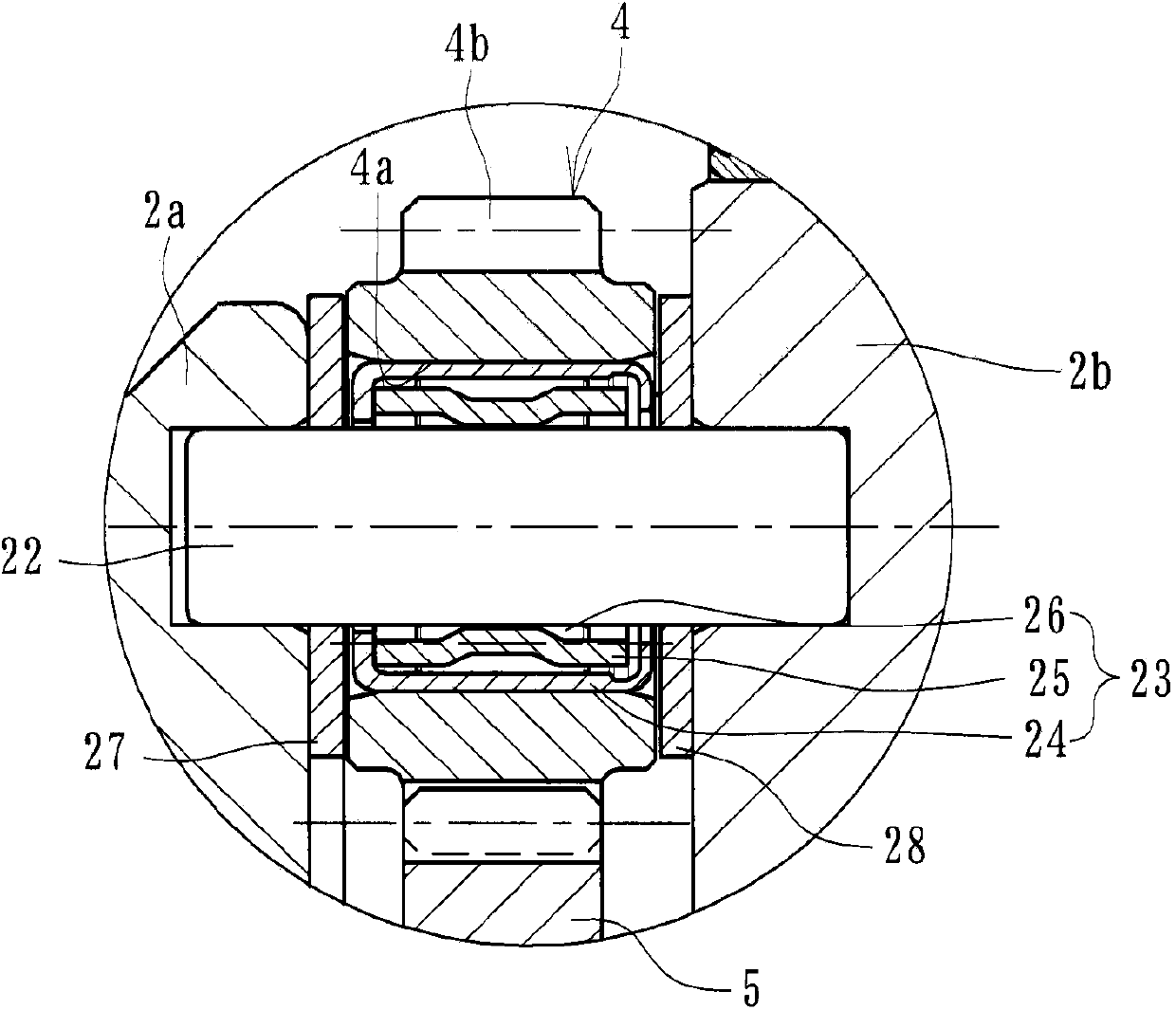

Electric linear actuator

Owner:NTN CORP

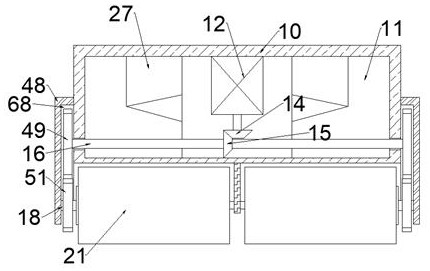

Multifunctional washing machine with super-strong detergency

PendingCN111270476ARealize the function of tapping deep cleaningOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

The invention discloses a multifunctional washing machine with super-strong detergency and belongs to the field of household appliances. A motor shaft assembly transmits driving force to a middle gear-shifting transmission assembly through belt transmission; the middle gear-shifting transmission assembly can realize two-gear power transmission, a main transmission mechanism assembly can realize two-gear power transmission of synchronous rotation and asynchronous rotation of a central pinion and a main transmission shaft, the main transmission mechanism assembly is in flat key connection and synchronous rotation with an inner impeller assembly, a sun wheel is fixedly connected and synchronously rotates with an outer impeller, and an inner impeller single-rotation washing mode, an outer impeller single-rotation washing mode and an inner and outer impeller synchronous rotation washing mode can be realized based on gear cooperation of the middle gear-shifting transmission assembly, the main transmission mechanism assembly and a planet wheel assembly; a waterway may cooperate with various washing modes to realize inner barrel independent inflow, outer barrel independent inflow and innerand outer barrel synchronous inflow; and a deep cleaning mechanism assembly is designed between the inner barrel and the outer barrel and is only started when the outer impeller works, so that the flapping type deep cleaning function can be realized.

Owner:CHANGCHUN INST OF TECH

Walking device

Owner:周新才

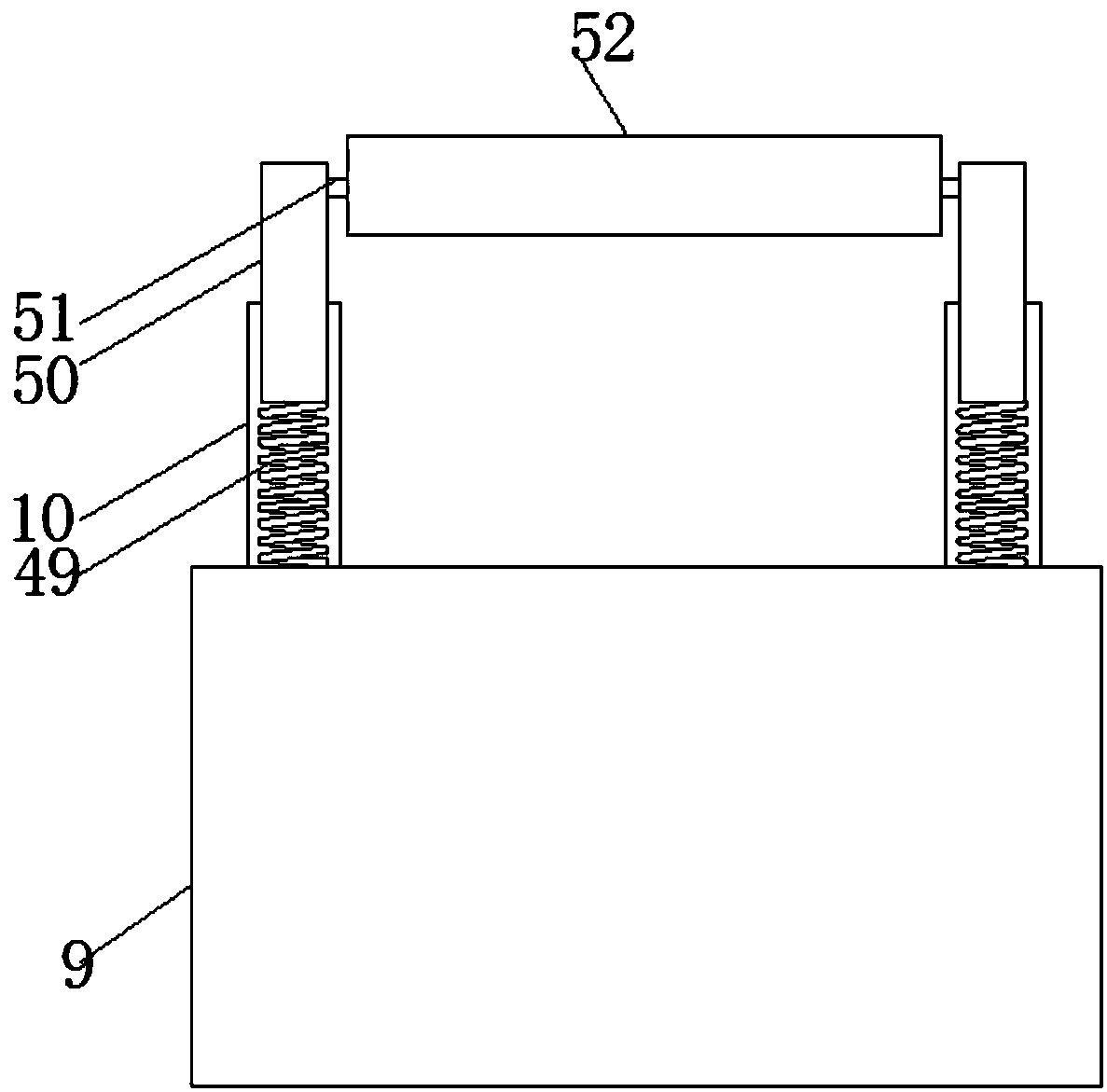

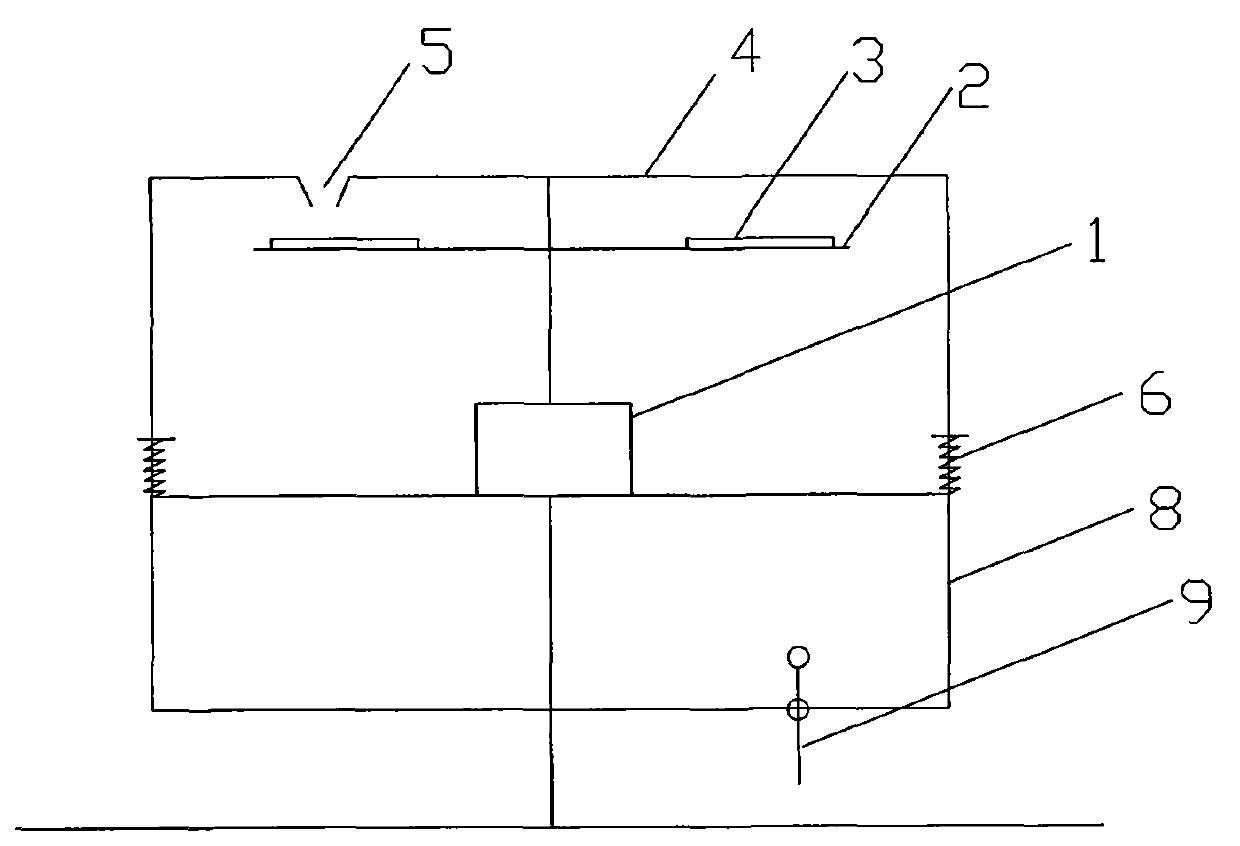

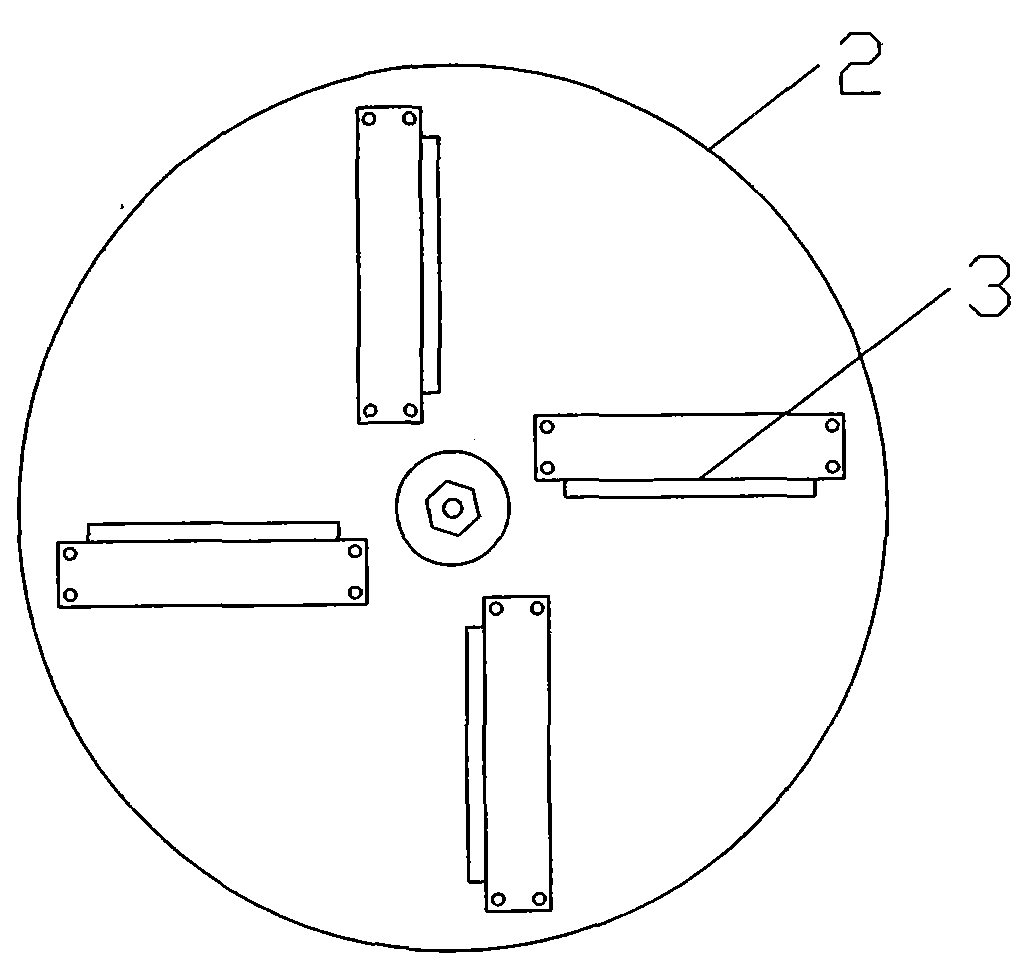

Novel electromechanical equipment having function of shock absorption

Owner:JIAXING UNIV

Yellow sand removing and road profile marking placing equipment for highway pavements in unmanned areas

Owner:杭州南之心科技有限公司

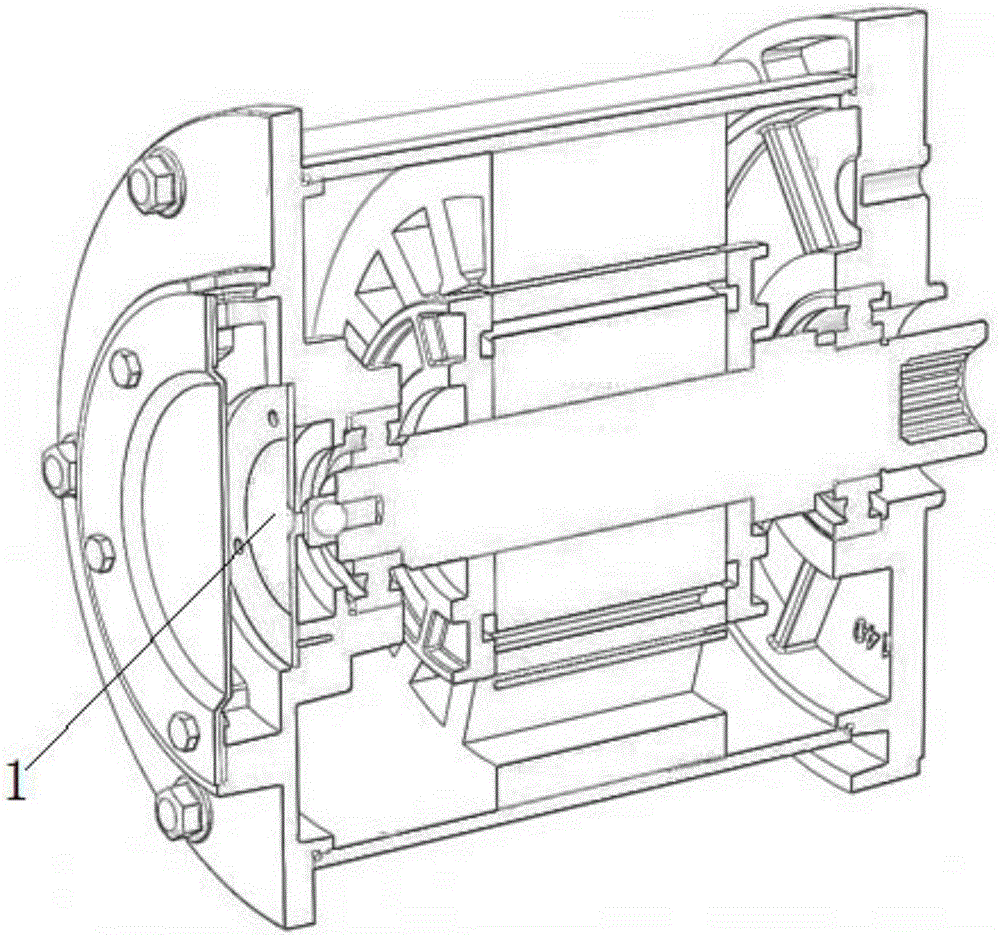

Two-shaft acoustic motor

PendingCN110798014ASimple structureSolve common production problemsShaftsMechanical energy handlingElectric machineMotor shaft

The invention relates to the technical field of acoustic motor, and discloses a two-shaft acoustic motor. The two-shaft acoustic motor includes a motor, a motor shaft and a toothbrush matching shaft.The toothbrush matching shaft includes a shaft head, a shaft journal and a shaft body which are successively connected end to end. A first end face of the toothbrush matching shaft is located at the shaft head, and the second end face of the toothbrush matching shaft is located at the shaft body; the shaft head has a first cross section, a second cross section, a third cross section and a fourth cross section in the axial direction; the side wall of the shaft journal is provided with a first groove, a second groove and a third groove; and the shaft body is provided with blind holes. The structure of the whole motor is simple. For different customers, through setting and cooperative use of the toothbrush matching shaft, the acoustic motor and the motor shaft, different shafts are used for the junction part between the motor shaft and the toothbrush head, thus bringing great convenience for the processing of the central shaft of an electric toothbrush and the general production of the motor, reducing the production cost of the electric toothbrush and solving the general production problem of motors in the prior art.

Owner:ANHUI MIBEI ELECTRONIC TECH CO LTD

Magnetic coding permanent magnet synchronization method used for driving of electric vehicle

Owner:江苏大电机电有限公司

Dustproof motor

PendingCN114301211AAvoid enteringNormal coolingDispersed particle filtrationMechanical energy handlingElectric machineMotor shaft

Owner:陈明芮

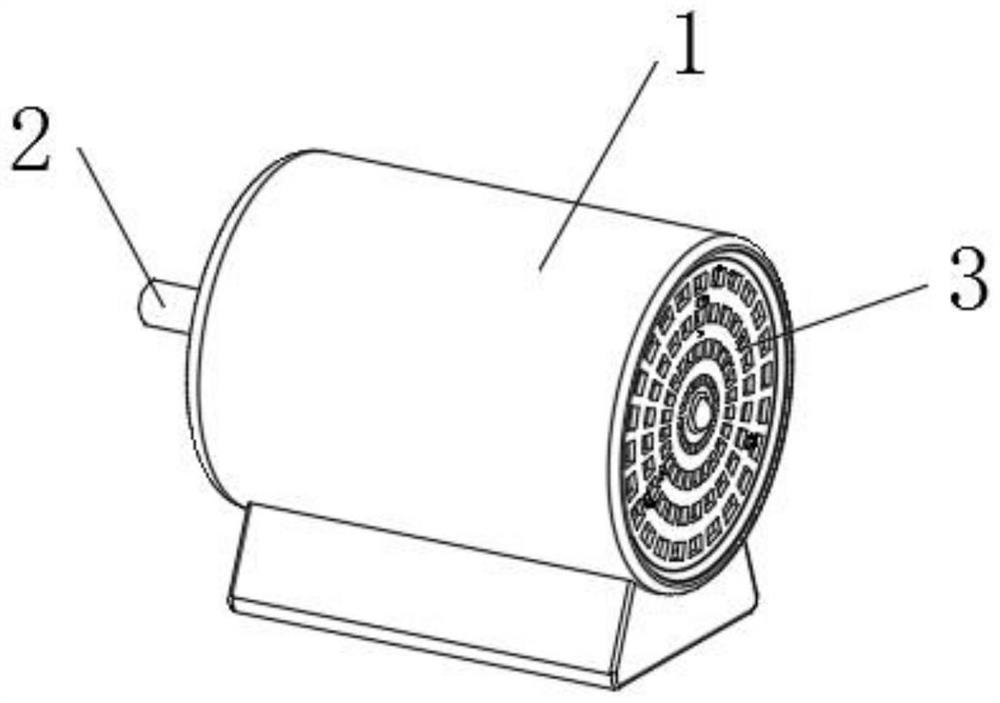

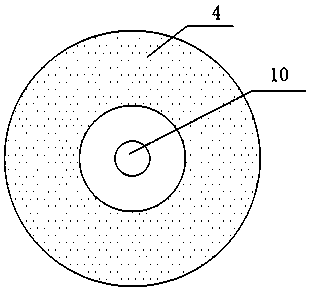

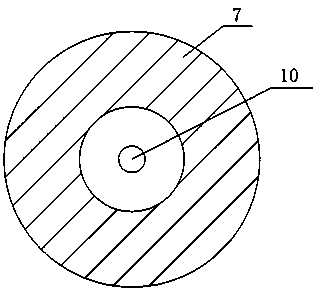

Special three-phase asynchronous motor for compressor

InactiveCN101867271ASimple structureCompact structureMagnetic circuit stationary partsAsynchronous induction motorsManufacturing cost reductionThree phase asynchronous motor

The invention relates to a special three-phase asynchronous motor for ZYS series compressors, which mainly adopts the technical scheme that a front end cover, a back end cover and a motor case are connected and fixed into a motor case, a motor shaft is supported and arranged in the motor case through a bearing assembly, a rotor is arranged on the motor shaft, a stator is arranged on the motor case, a fan is fixed on the motor shaft, and a wind cover is fixed on the back end cover. The invention is characterized in that the shaft end of the motor shaft extends out of the front end cover, and keys are arranged in key slots in front of the motor shaft. A circlip for hole is arranged between the bearing assembly and the front end cover, a wave form leaf spring is arranged between the bearing assembly and the back end cover, and a wiring box is connected on the stator through a screw bolt. The invention can reduce the manufacture cost and raw materials, can reduce the energy consumption, and has small size. The bearing installation and bearing locking mode can be changed according to different connection modes of the compressor and the motor for meeting the requirements of specific conditions of different compressors.

Owner:WUXI ZHONGDA MOTORS

Polishing mechanism

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

Permanent magnet energy-saving electronic automatic gearbox

InactiveCN110994941AReduce vibrationReduce noiseAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorCopper conductor

Owner:郝心怡

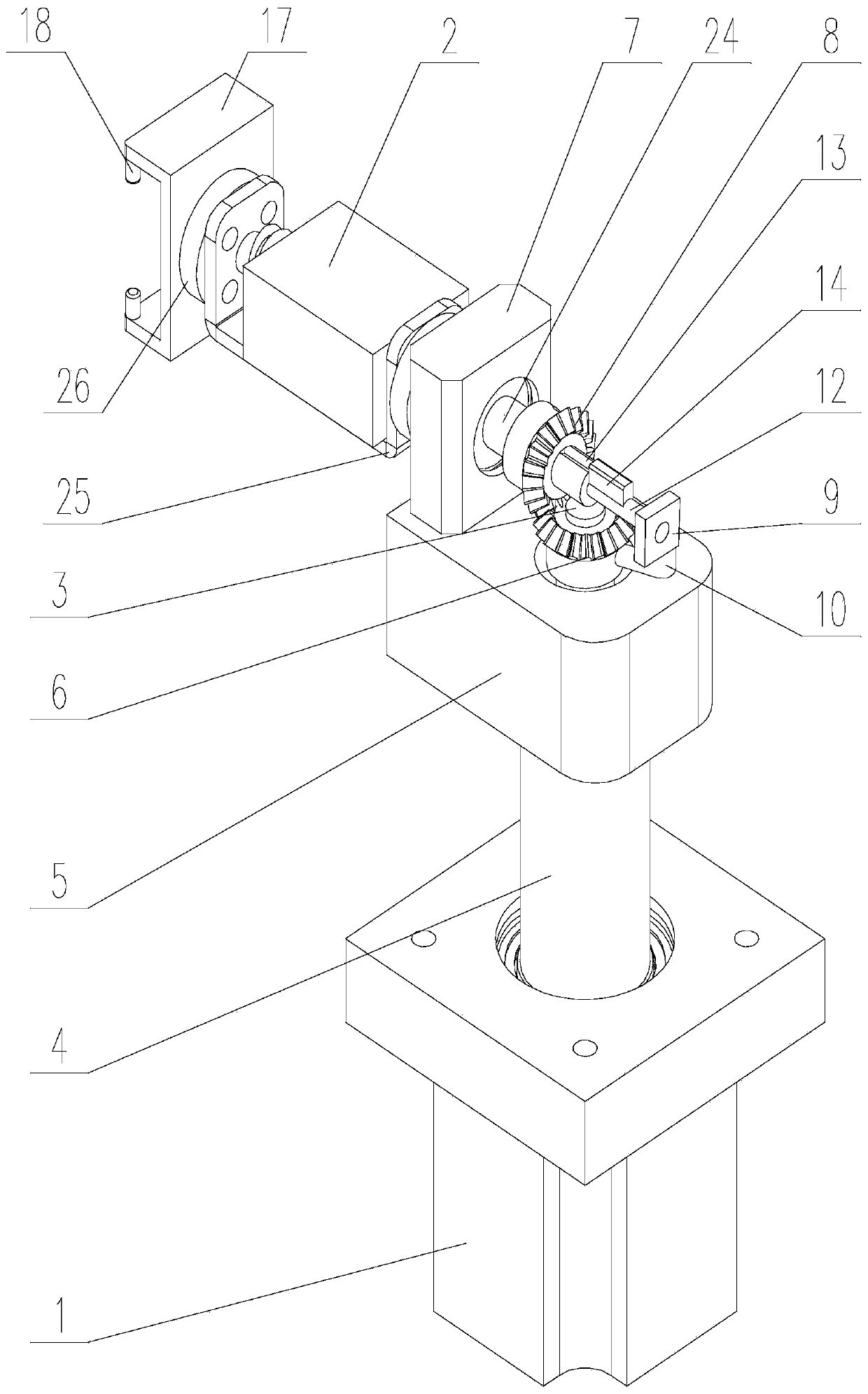

Power distribution network overhead line lifting tool with supporting frame

InactiveCN111747337AImprove efficiencyPrevent the phenomenon of falling offOverhead installationLifting framesGear wheelElectric machine

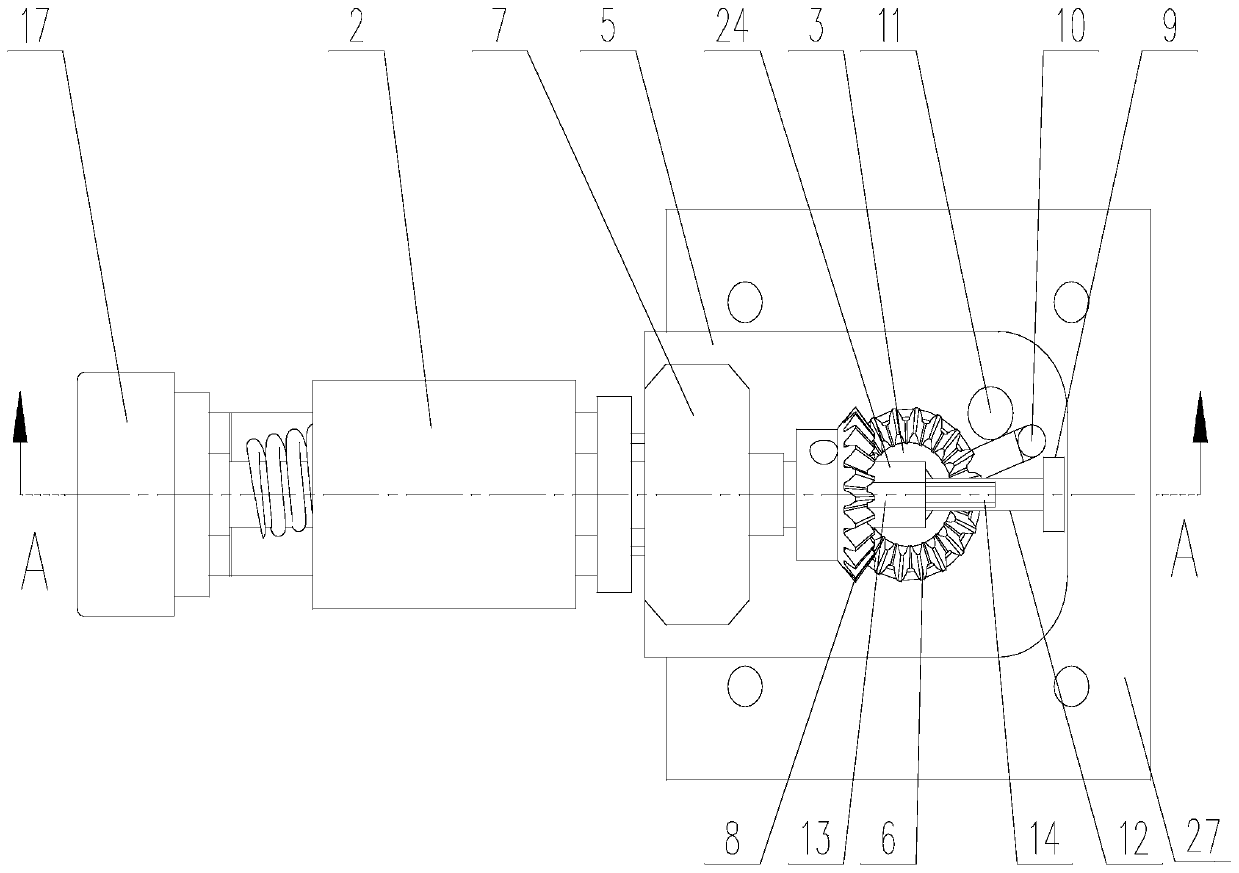

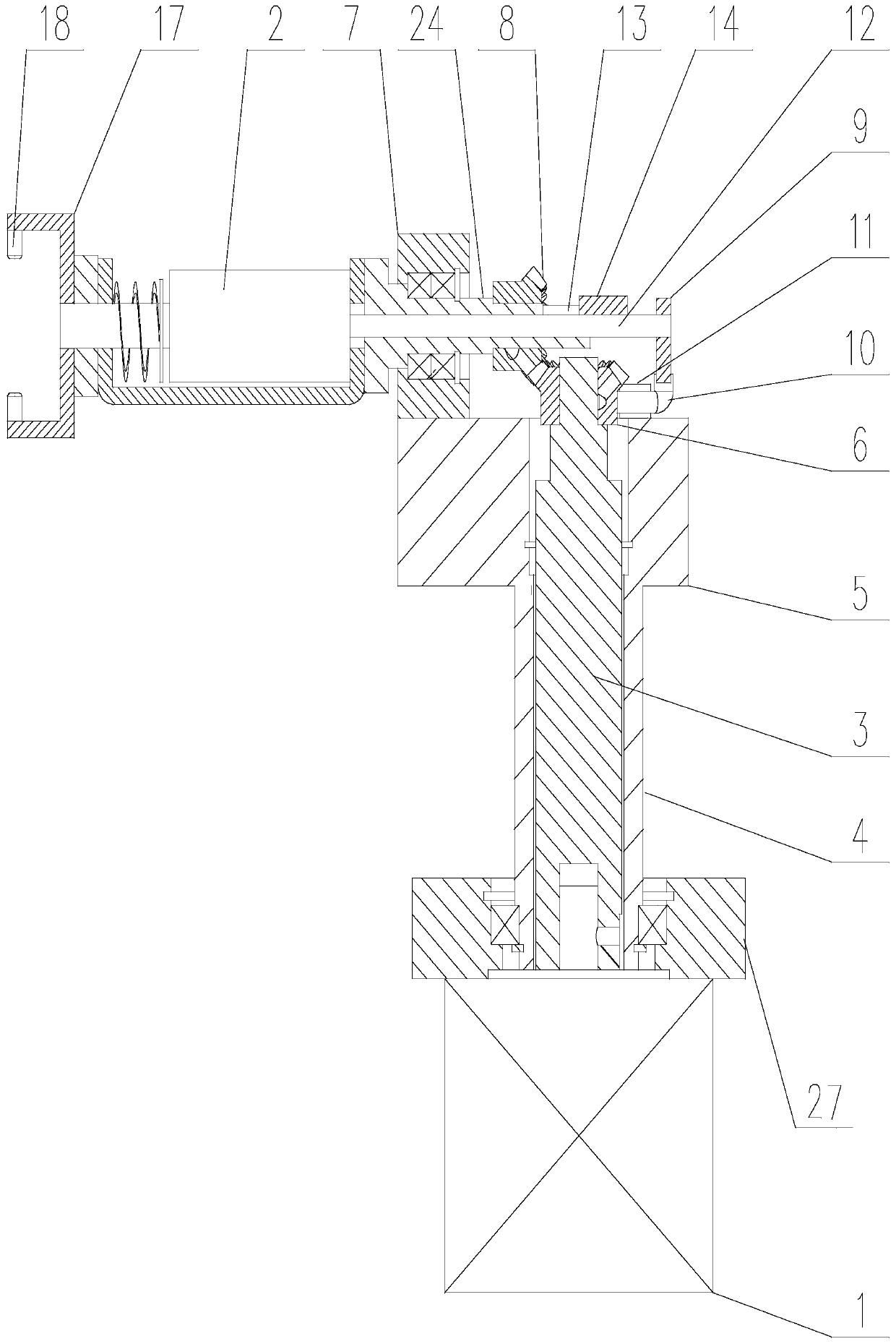

The invention discloses a power distribution network overhead line lifting tool with a supporting frame in the technical field of grid equipment. The power distribution network overhead line lifting tool with the supporting frame comprises two groups of vertical plates; the two groups of vertical plates are arranged in a bilaterally symmetric manner; the tops of the two groups of vertical plates are connected with top plates, wherein a motor base is arranged at the top of the left end surface of the group of the vertical plates on the right side; a motor is transversely arranged in a cavity ofthe motor base; a motor shaft is arranged on the right side of the motor; a conical gear I is arranged on the motor shaft; a conical gear II matched with the conical gear I is arranged at the top ofthe conical gear I; a screw rod is fixedly arranged and connected to a cavity of the conical gear II in a sleeving manner; and a fixing plate is arranged at the bottom of the right end surface of thegroup of vertical plates on the right side. According to the power distribution network overhead line lifting tool with the supporting frame, an insulated tower top is stably hoisted; during hoisting,the insulated tower top is firmly hooped to be prevented from falling off to be damaged; and moreover, as a reinforcing device is arranged at the bottom of the supporting frame, the supporting frameis prevented from shaking to cause collapsing of the supporting frame to damage the tower top.

Owner:GUANGXI NANNING HONGXIANG ELECTROMECHANICAL EQUIP CO LTD

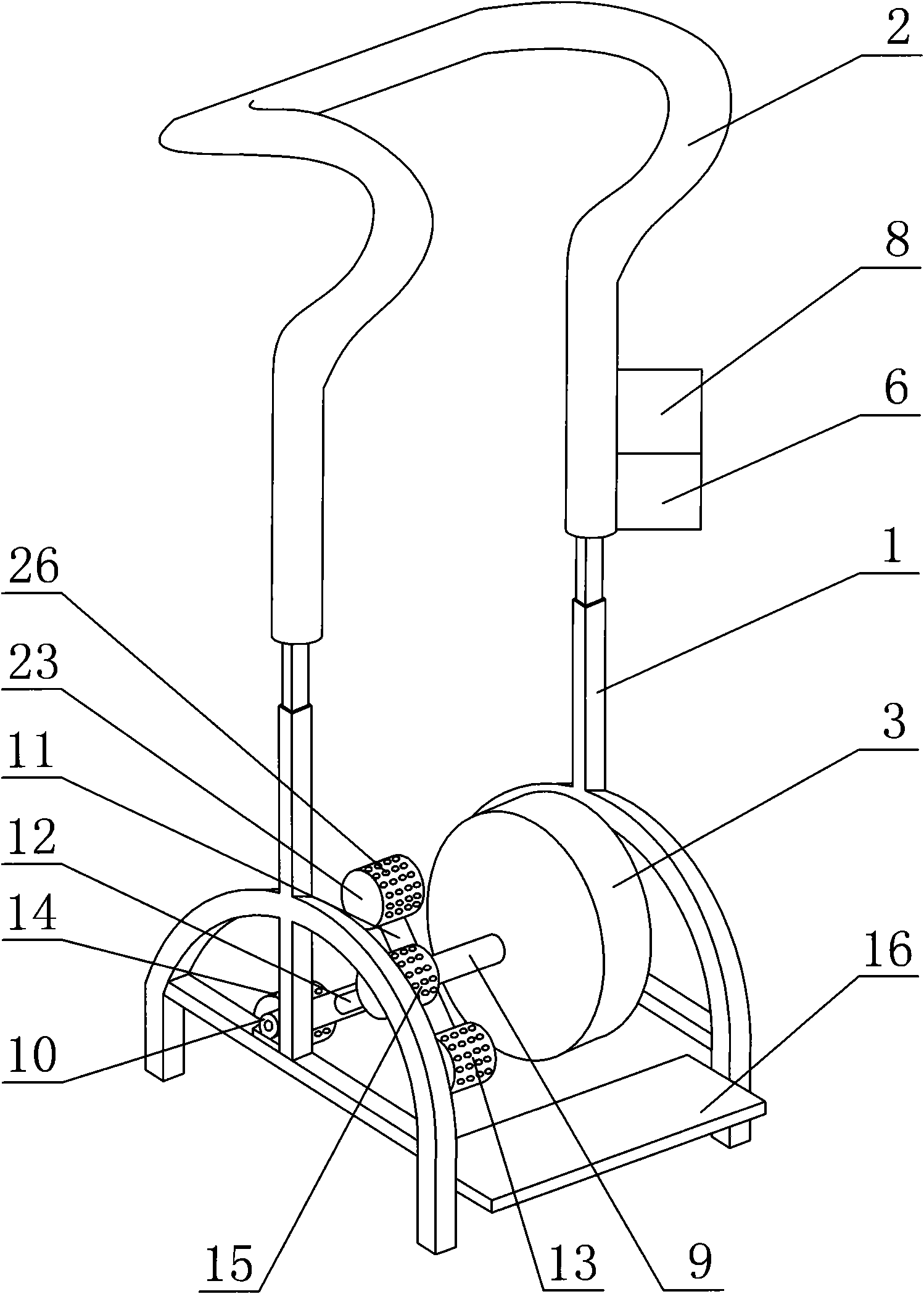

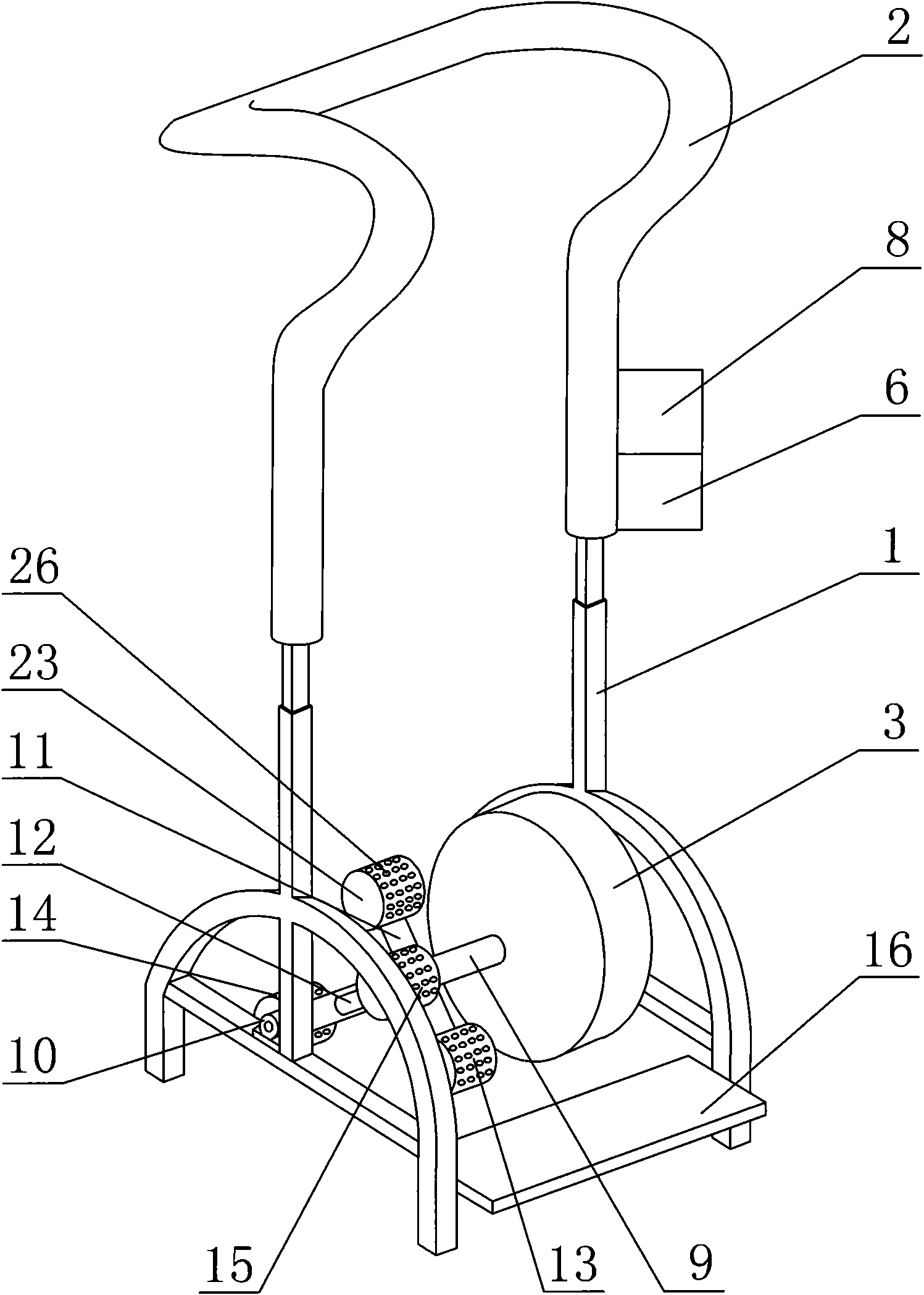

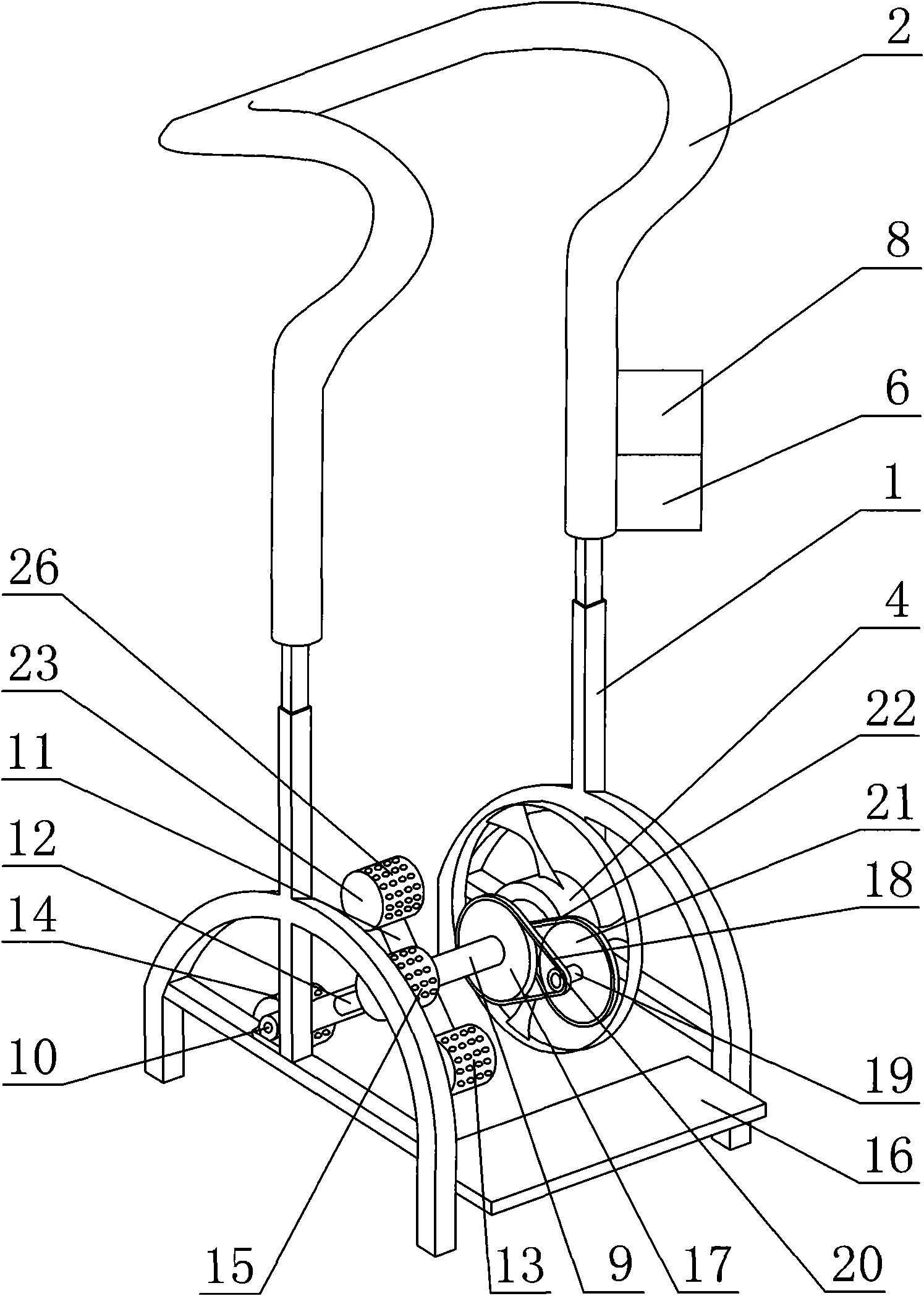

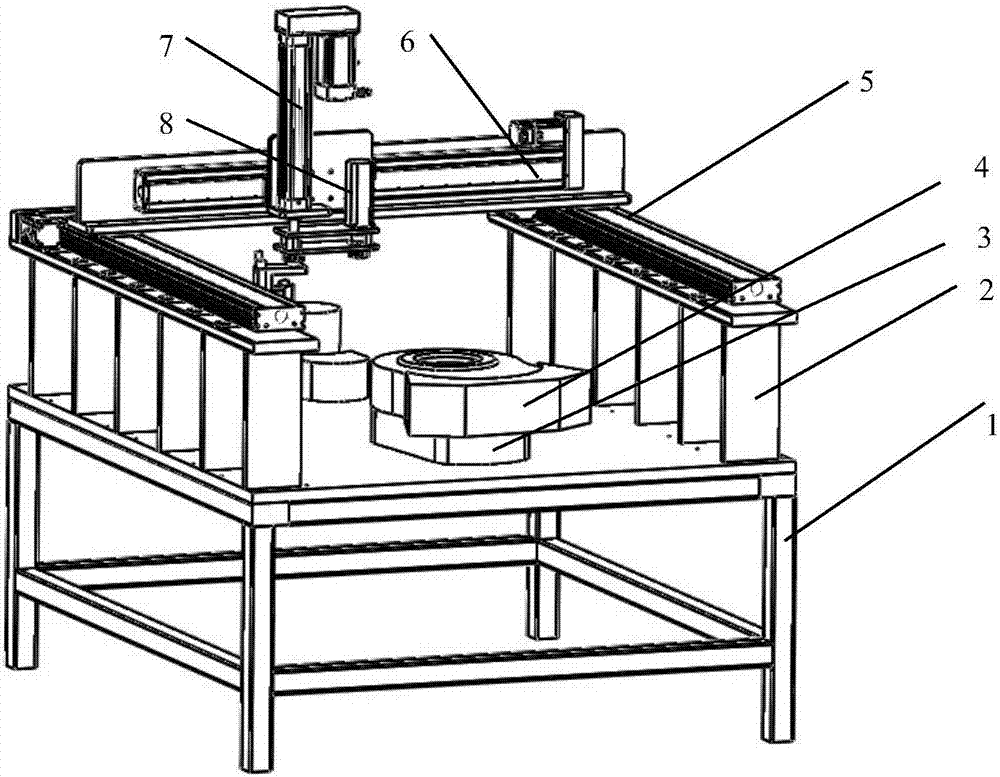

Multi-functional animal craniocerebral injury instrument

InactiveCN109820614AReduce deathEasy height adjustmentAnimal fetteringSurgical veterinaryEngineeringDrive motor

The invention discloses a multi-functional animal craniocerebral injury instrument. The instrument comprises a base, brackets are arranged on the two sides of the middle of the base, and columns are symmetrically arranged on the two sides of the front end of the base; sliding grooves are formed in the inner sides of the columns, the upper and lower ends of the bottom of each sliding groove of thecolumns are movably connected with two driving gears through connecting shafts, and chains are arranged on the outer sides of the two driving gears; driving motors are fixedly connected with the outersides of the columns, and motor shafts of the driving motors are in power connection with the driving gears at the upper ends; rotary frames capable of rotating are arranged in the centers of the tops of the brackets. The multi-functional animal craniocerebral injury instrument can accurately and continuously control the impact speed and acquire parameters of actual impact depth, remaining time and the like and cannot conduct impacting of the large weight difference. A contusion injury model can be accurately and repeatedly made, animal death is reduced, and the experiment process is more visible and more controllable; an animal head height measuring device is arranged to conveniently adjust the height of the craniocerebral injury instrument, and the experiment accuracy is improved.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV +1

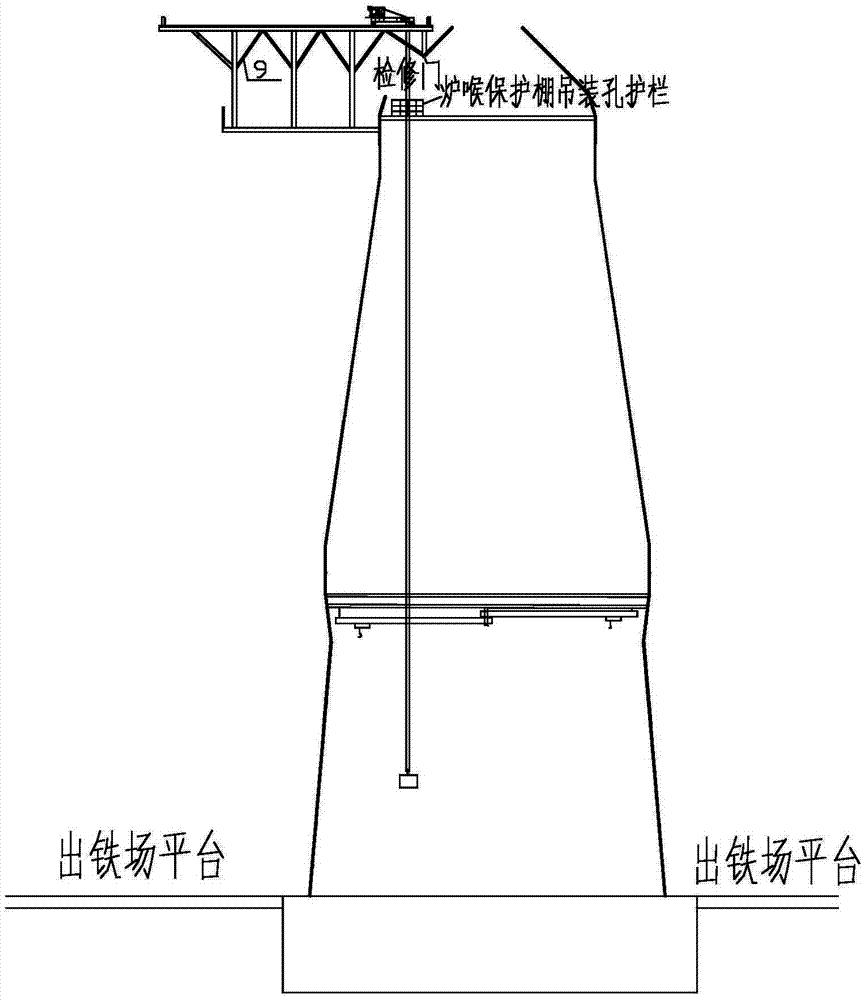

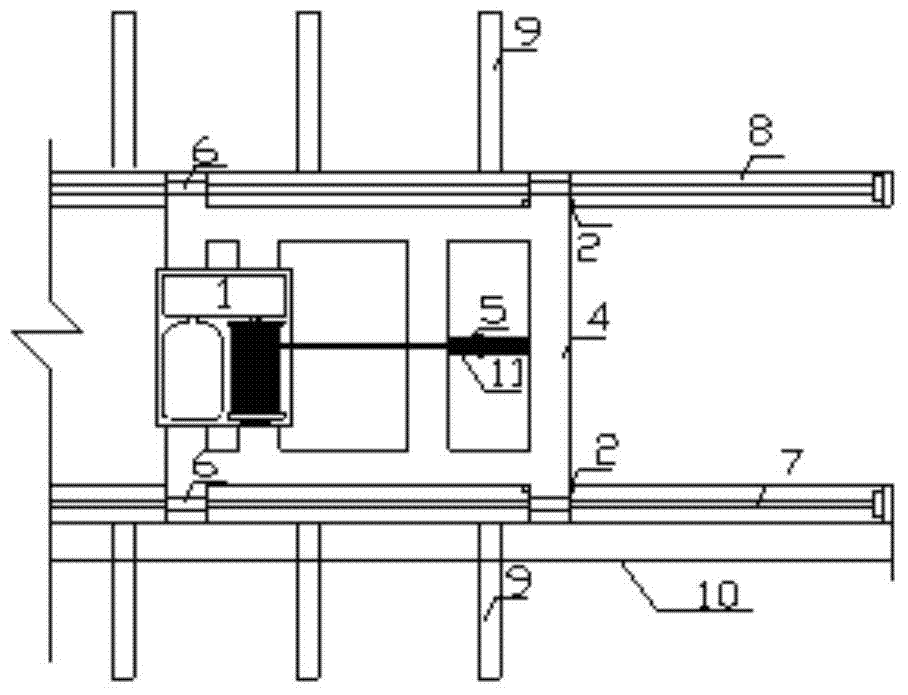

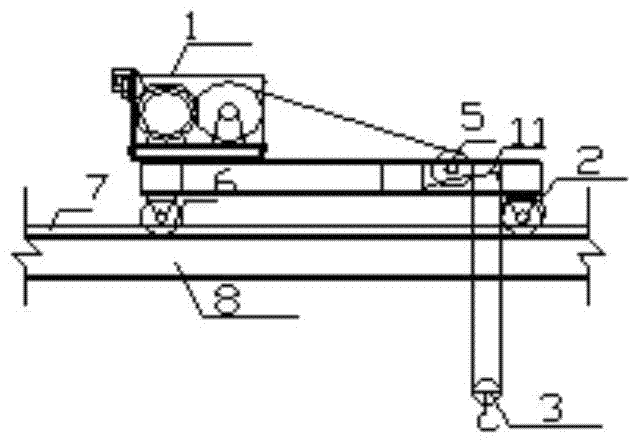

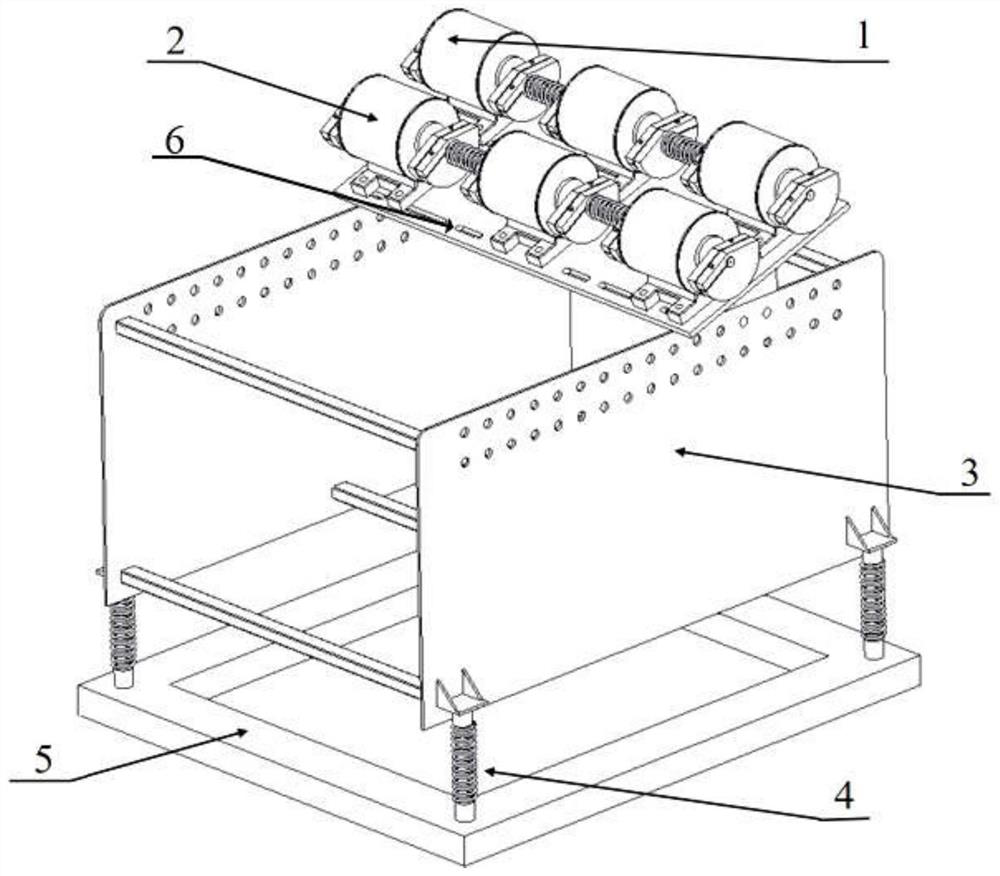

Blast furnace large pre-building block furnace feeding device and method

Owner:TIANJIN 20 CONSTR

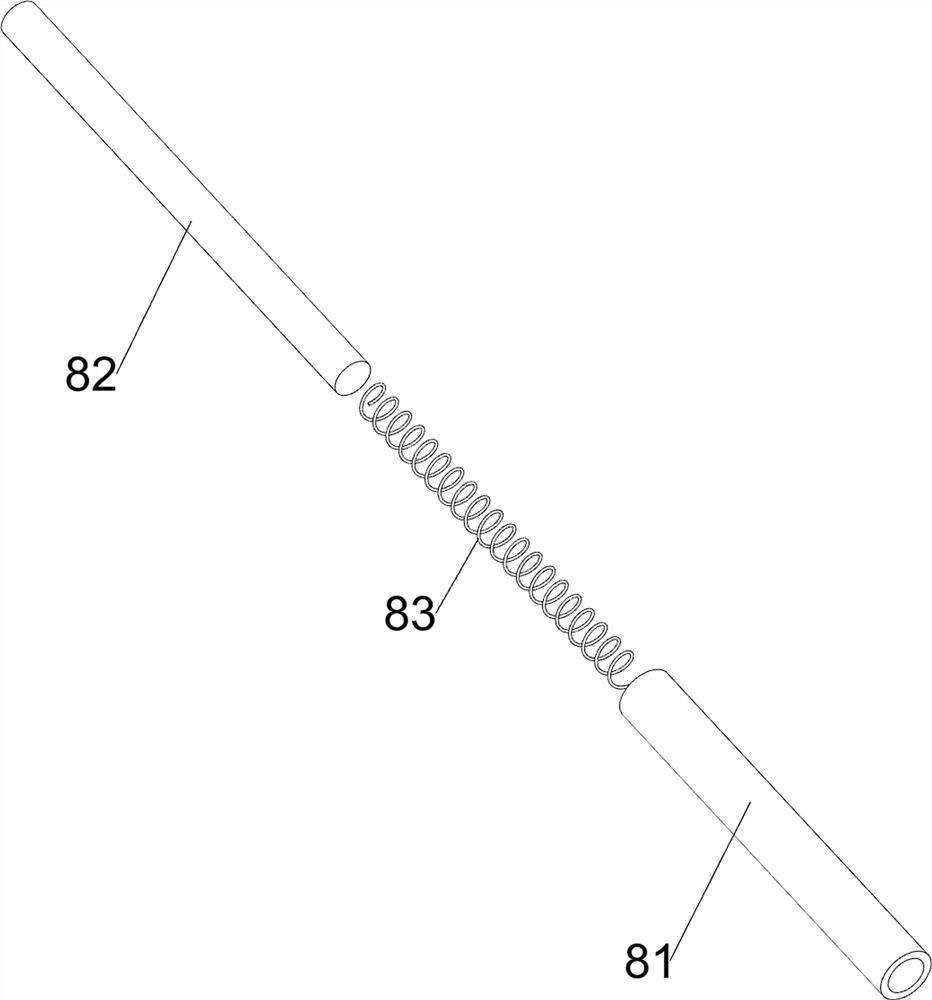

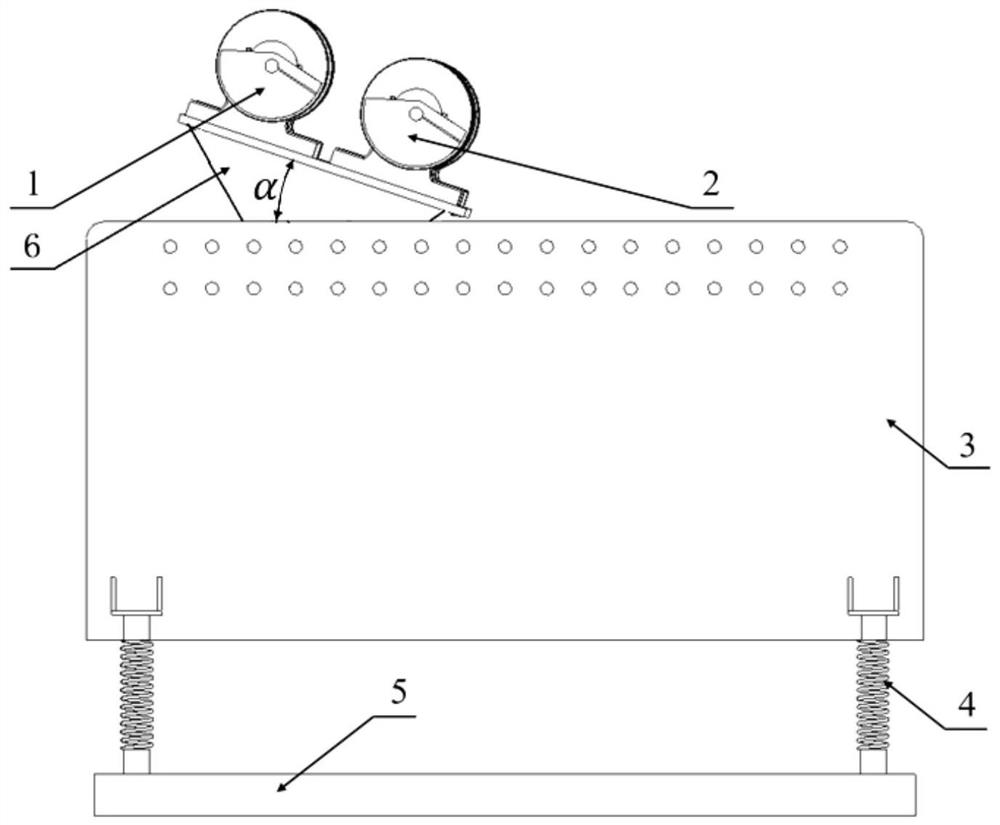

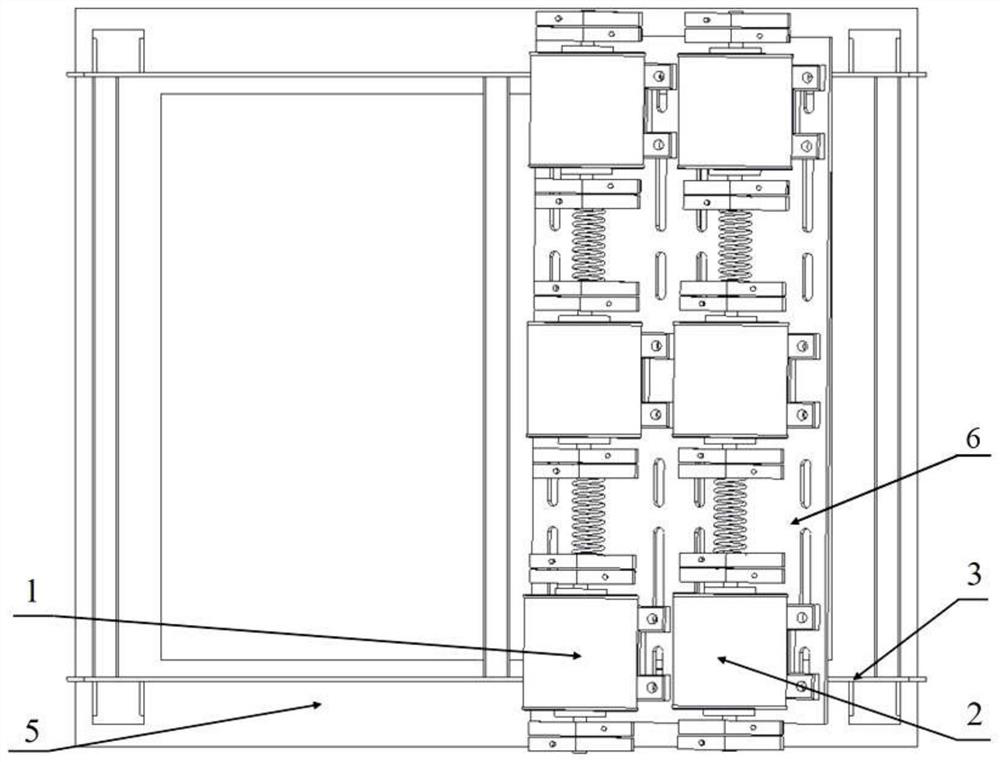

Torsion spring coupled double-shaft six-excitation-motor linear or elliptical vibrating screen

Owner:SOUTHWEST PETROLEUM UNIV

Robot device for polishing casting parts

Owner:ANHUI HISEED ROBOT CO LTD

Singe motor driven double-axis control mechanism and feeding device thereof

Owner:MEISHAN HUACHEN TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap