Electric linear actuator

An electric actuator, linear technology, applied in the direction of transmission, sliding contact bearings, bearings of rotary motion, etc., can solve the problems of electric motor size and power consumption increase, power loss increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

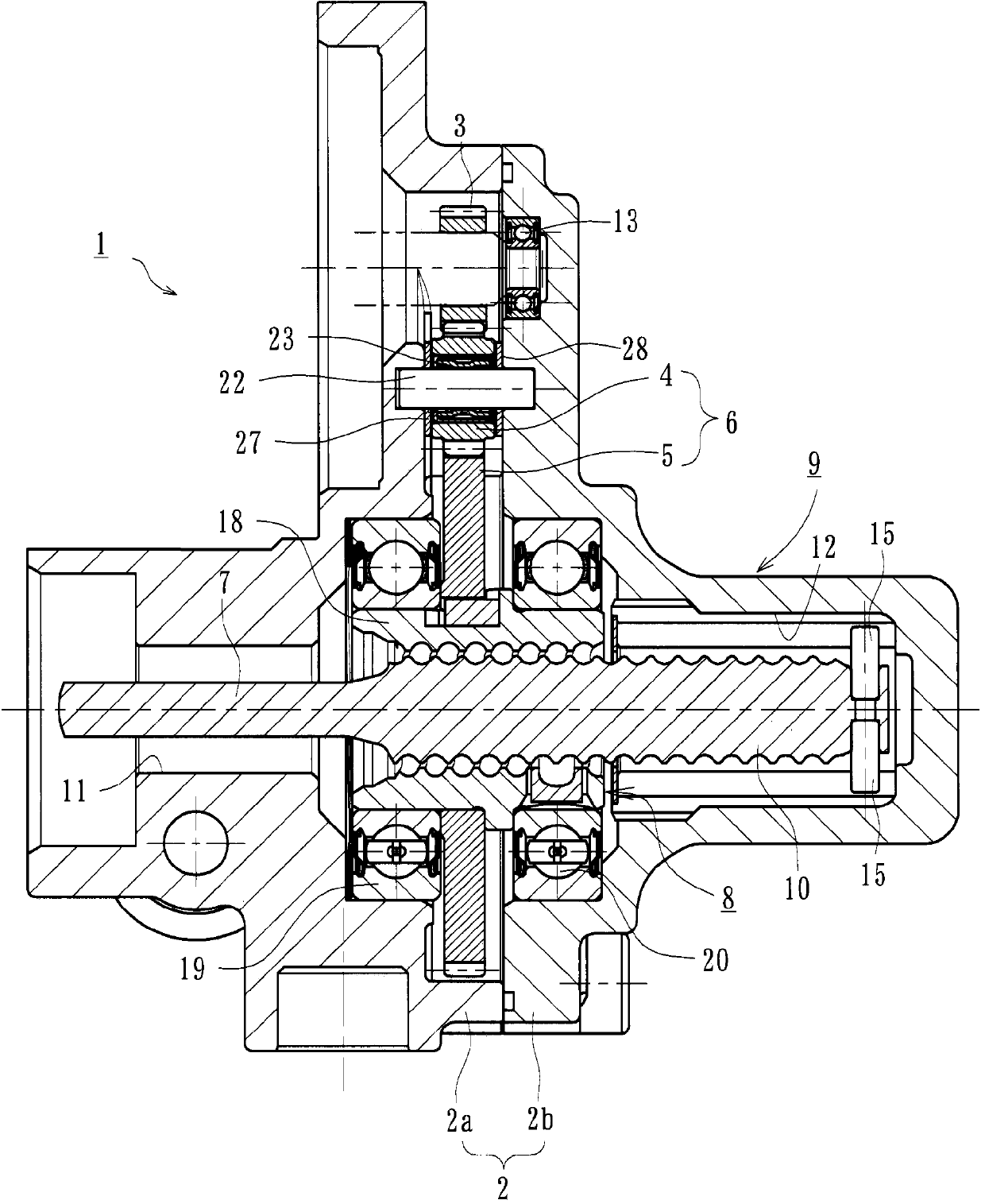

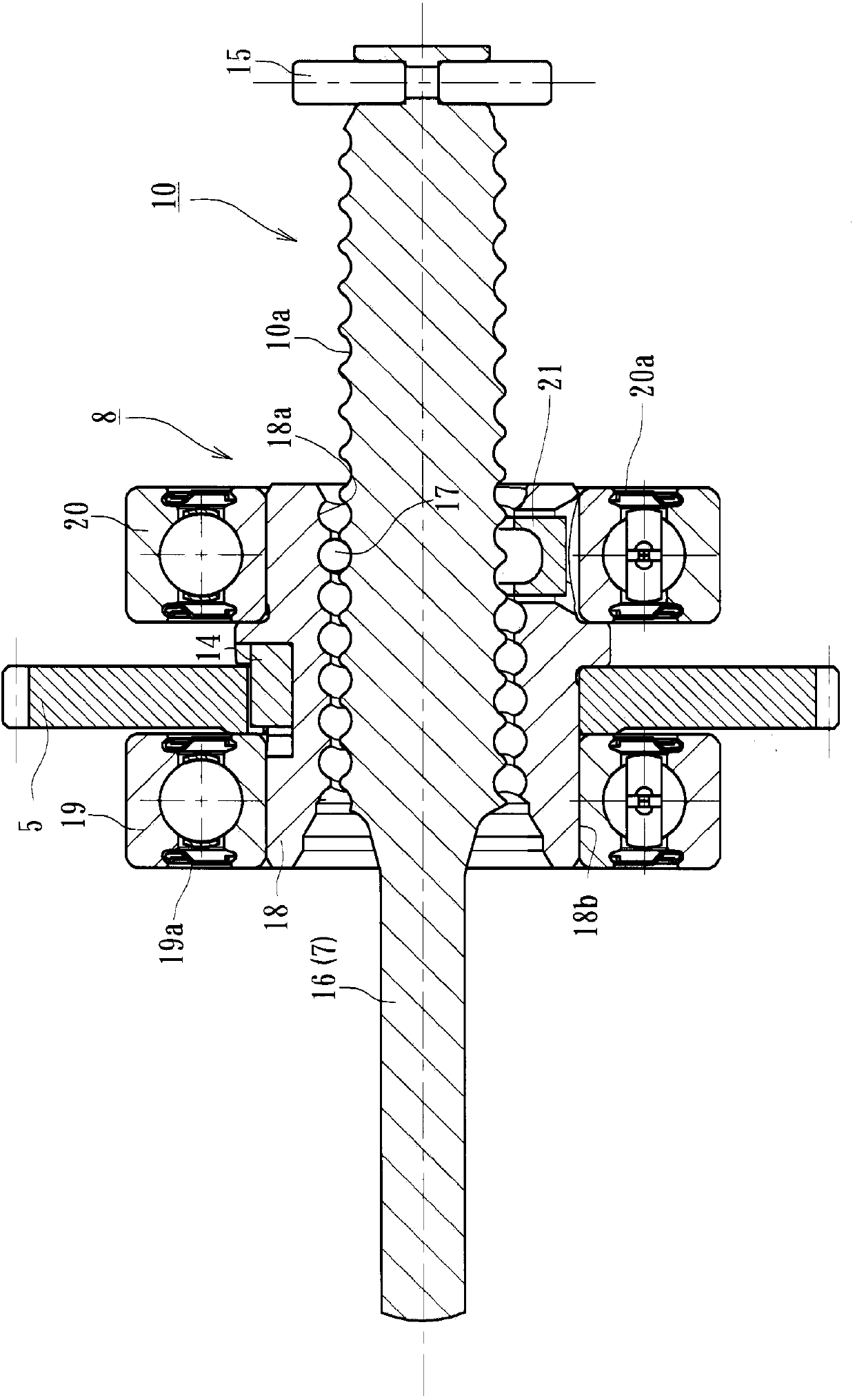

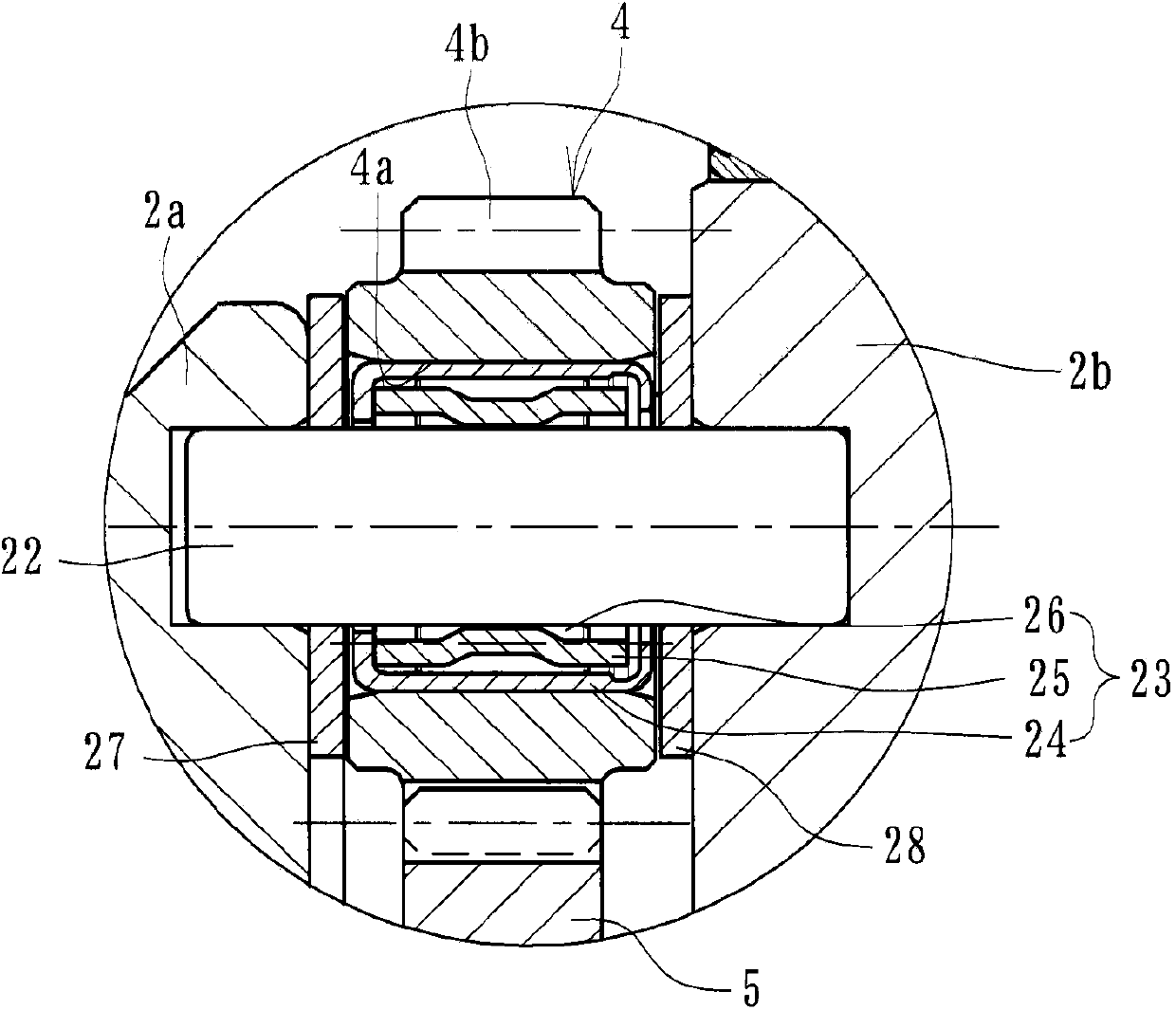

[0037] figure 1 is a longitudinal sectional view showing a preferred embodiment of the linear electric actuator of the present invention, figure 2 is shown figure 1 A longitudinal sectional view of the actuator body of the linear electric actuator, image 3 is shown figure 1 A partial enlarged view of the intermediate gear of the linear electric actuator, and Figure 4 is shown image 3 A partial enlarged view of the variant of the intermediate gear.

[0038] Such as figure 1 As shown, a linear electric actuator 1 comprises a housing 2 formed of a lightweight aluminum alloy, an electric motor (not shown), an intermediate gear mated to an input gear 3 mounted on a motor shaft (not shown) of the electric motor 4. A reduction mechanism 6 with an intermediate gear 4 and an output gear 5, a ball screw mechanism 8 that converts the rotary motion of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap