Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about "Mechanical energy handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

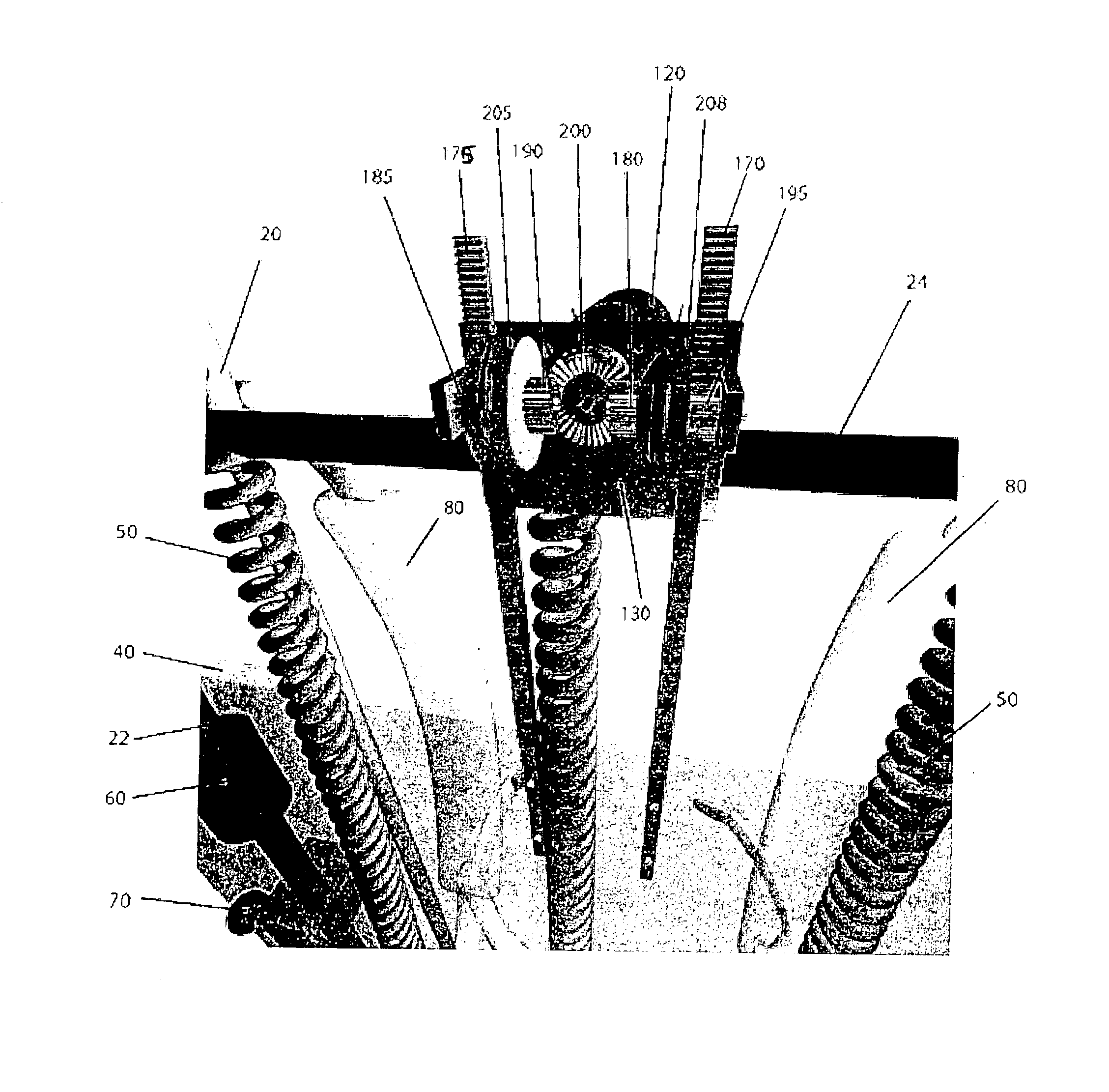

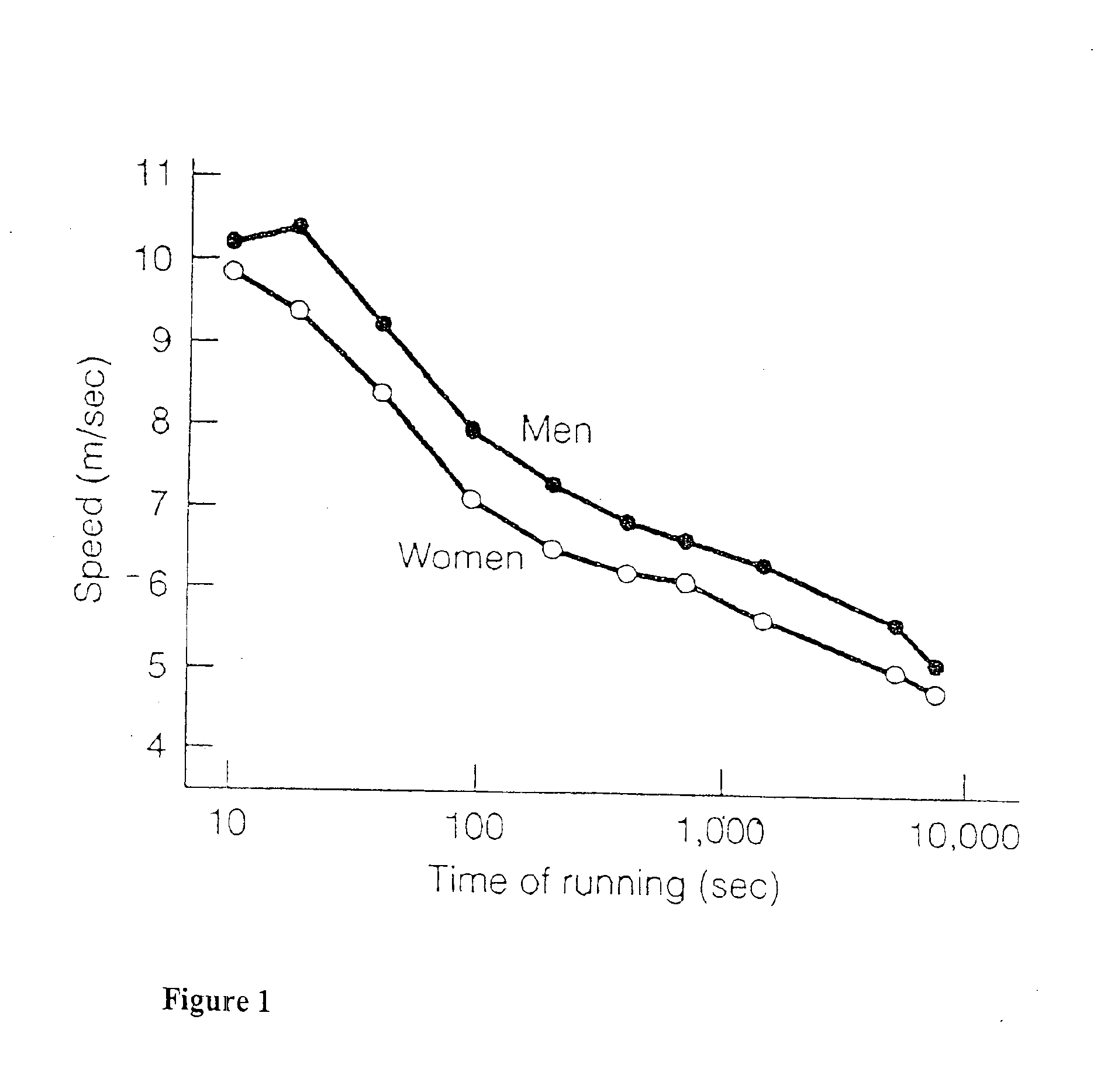

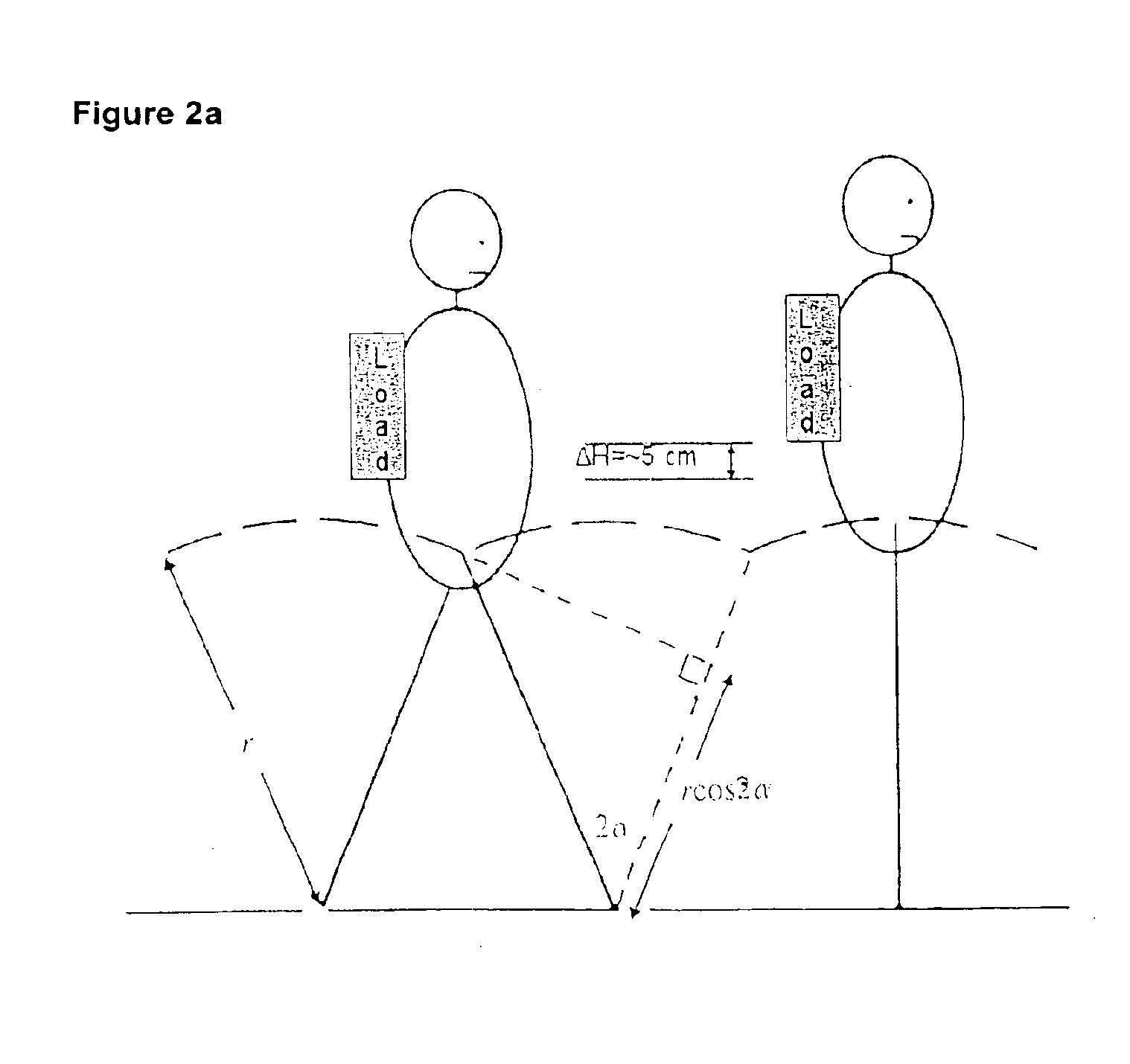

Backpack for harvesting electrical energy during walking and for minimizing shoulder strain

ActiveUS6982497B2Large movementReduce absolute vertical motionTravelling sacksPiezoelectric/electrostriction/magnetostriction machinesGear wheelShoulder strain

Owner:LIGHTNING PACKS

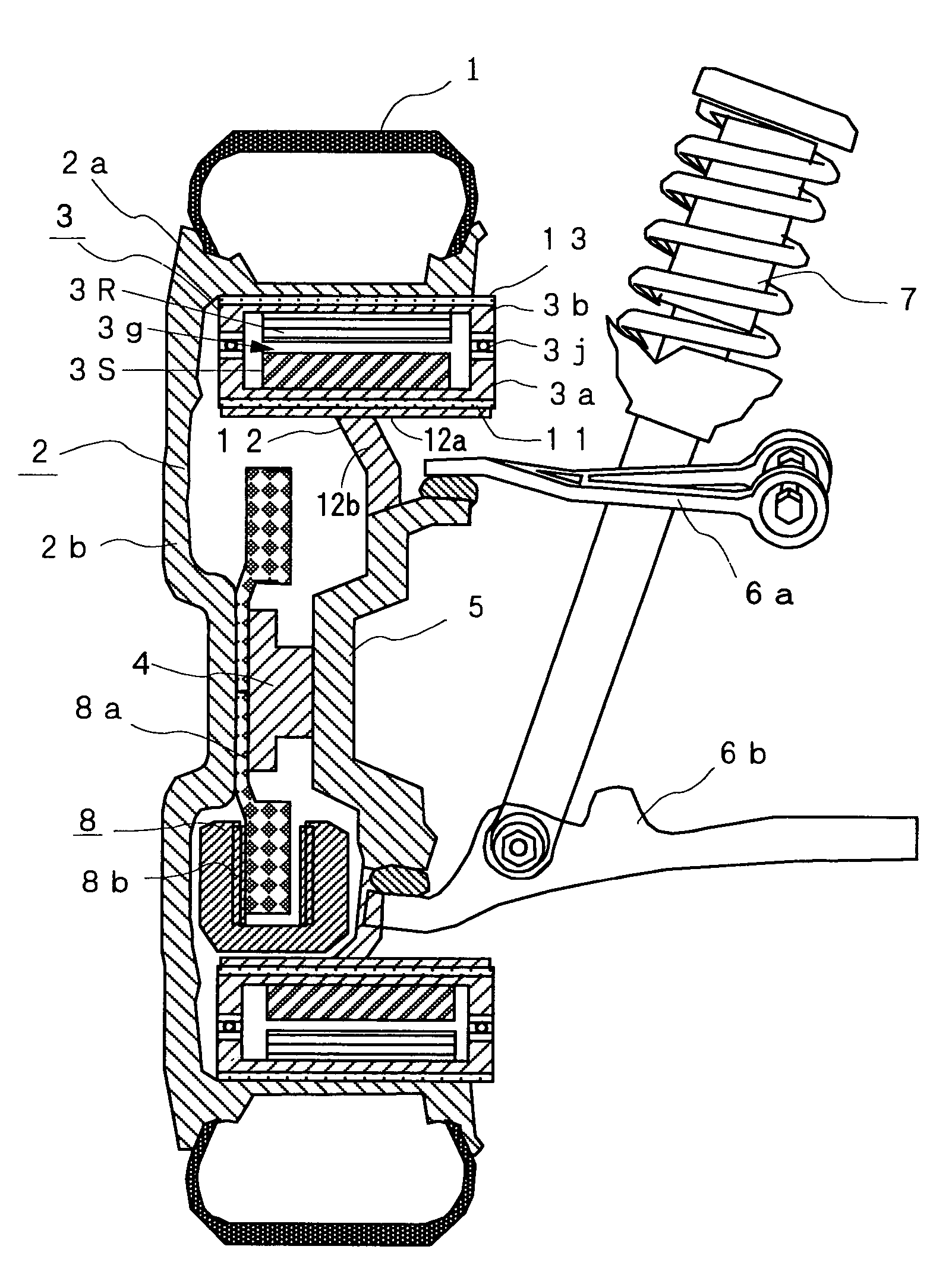

Fixing method of in-wheel motor and in-wheel motor system

InactiveUS7306065B2Reduce contact forceImprove road holding propertyRotating vibration suppressionNon-rotating vibration suppressionEngineeringElectric motor

Owner:BRIDGESTONE CORP

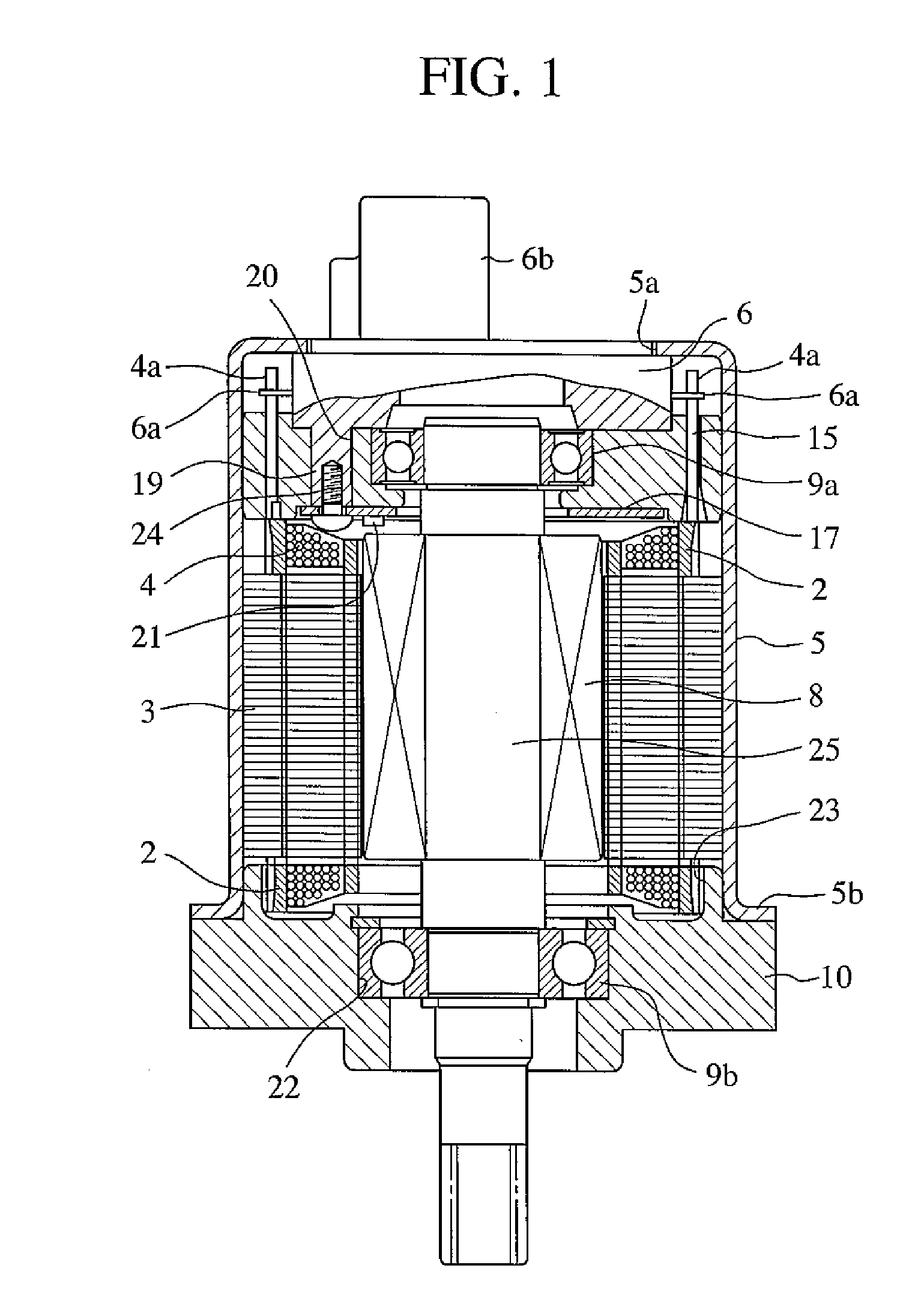

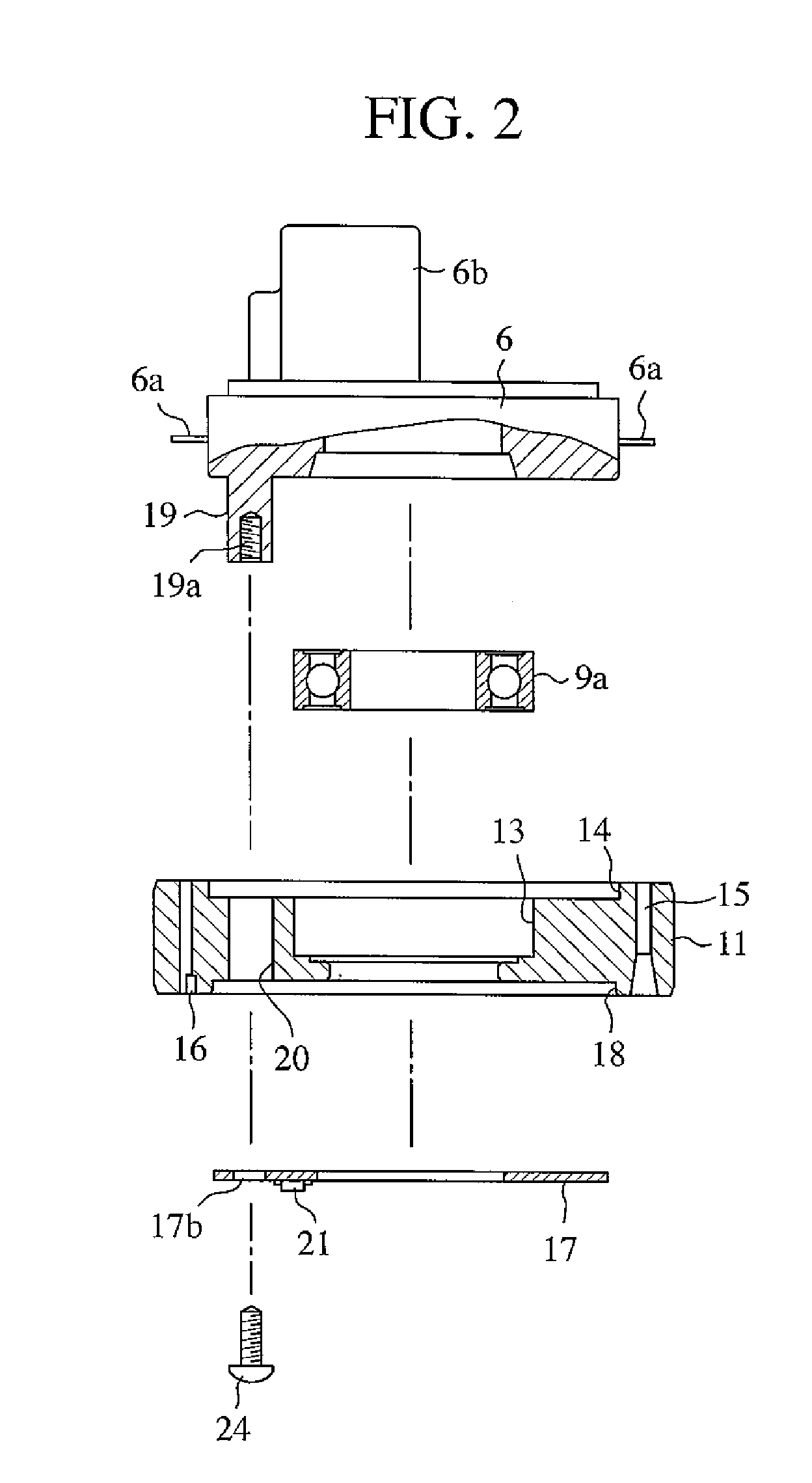

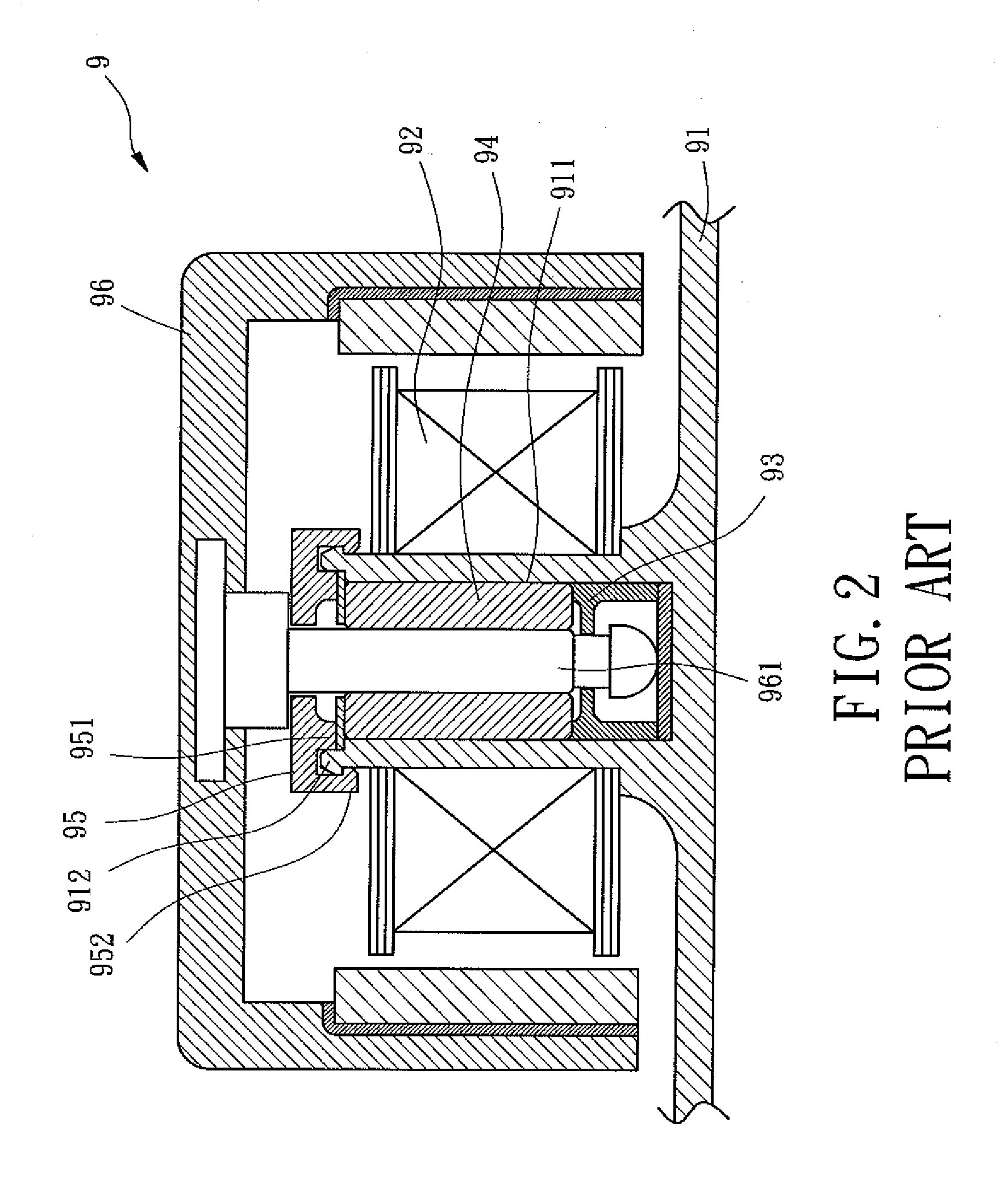

Motor

InactiveUS20050035670A1Reduce noiseExtended service lifePump componentsMagnetic circuitPhysicsMagnetic structure

Owner:DELTA ELECTRONICS INC

Brushless motor

ActiveUS20100133935A1High positioning accuracyProlonging permanent magnetWindingsMechanical energy handlingBrushless motorsMagnetic poles

Owner:MITSUBISHI ELECTRIC CORP

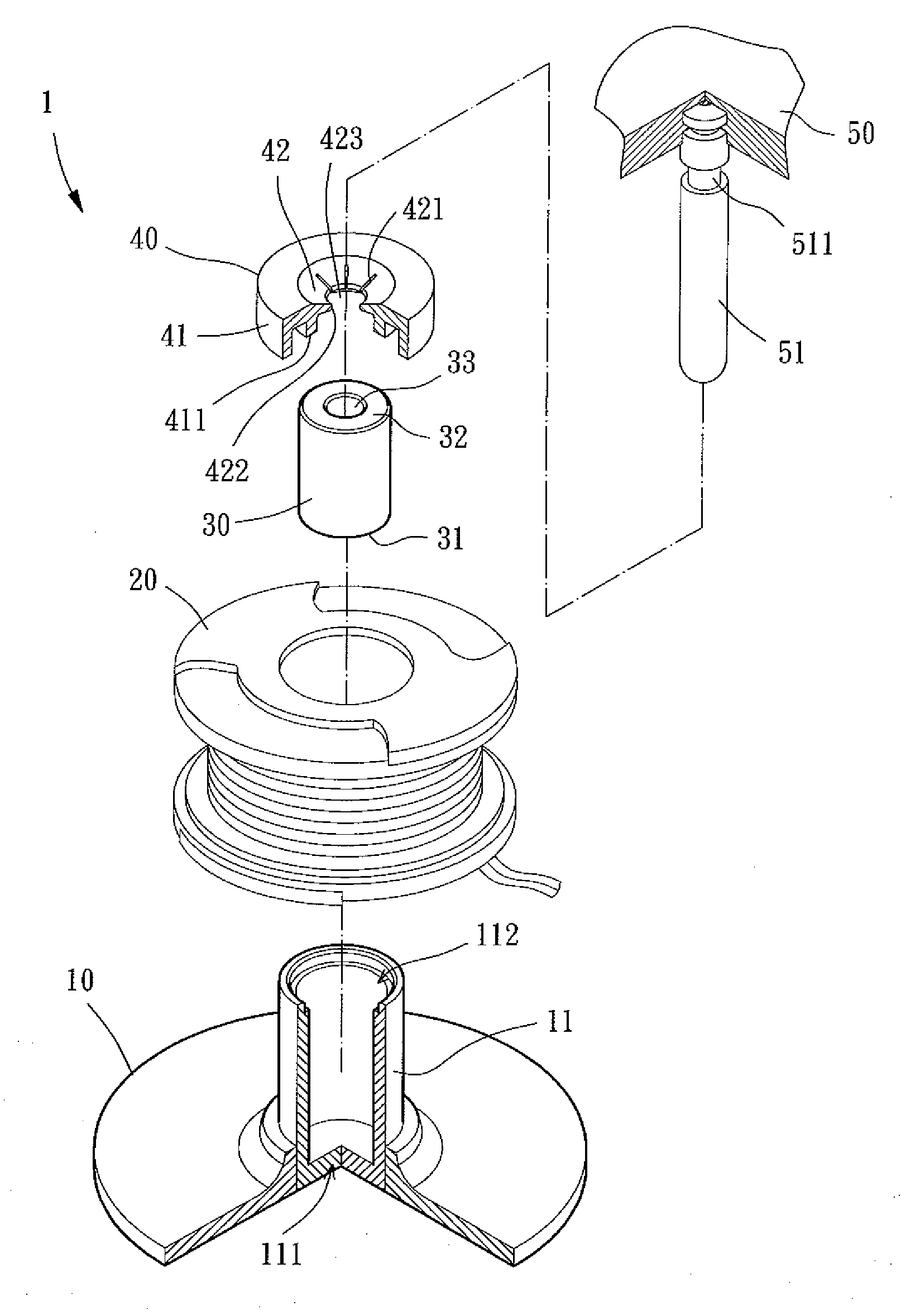

Motor

InactiveUS20100127588A1Prevent disengagementMagnetic circuit rotating partsPump componentsEngineeringSingle component

Owner:SUNONWEALTH ELECTRIC MACHINE IND

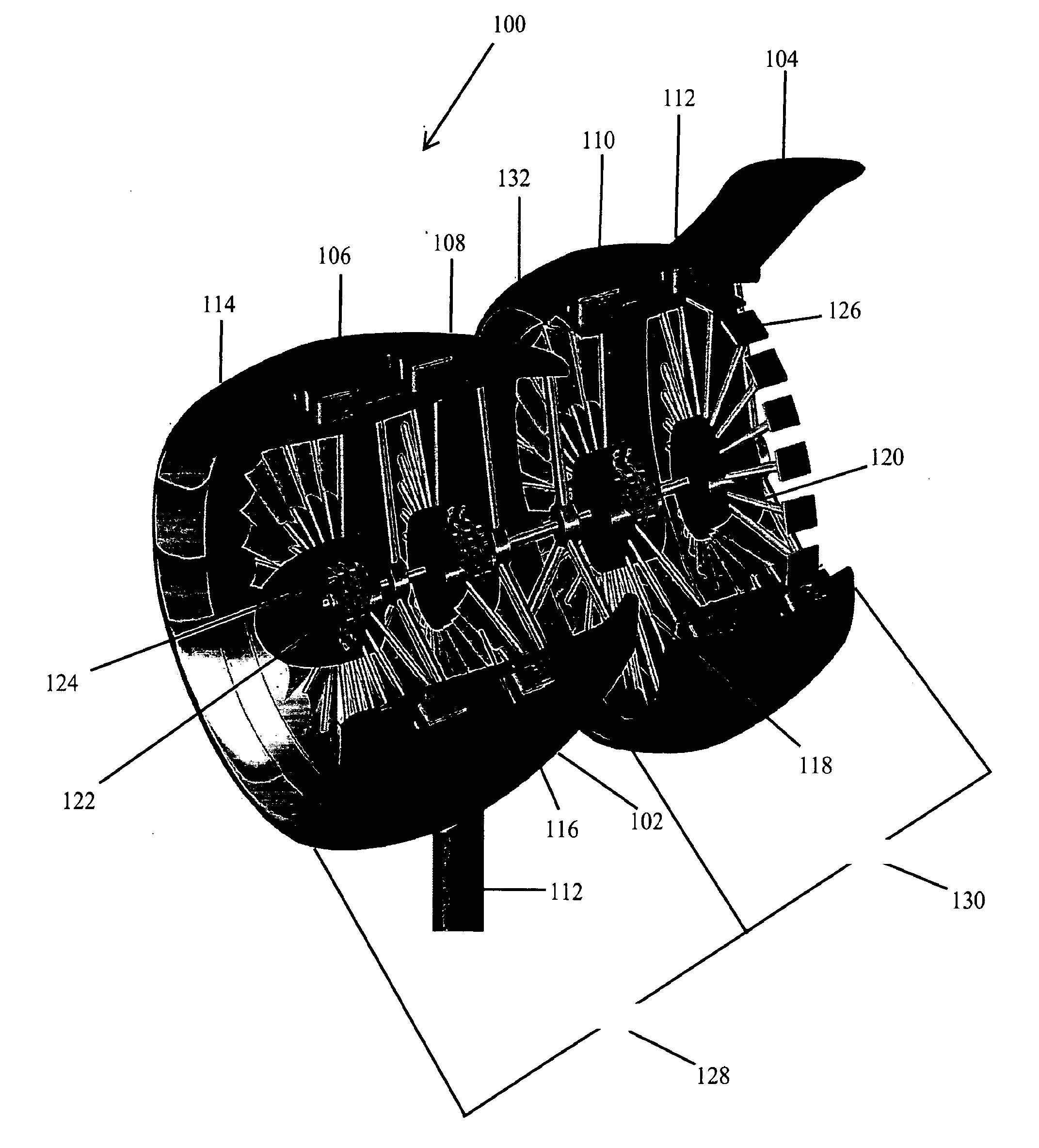

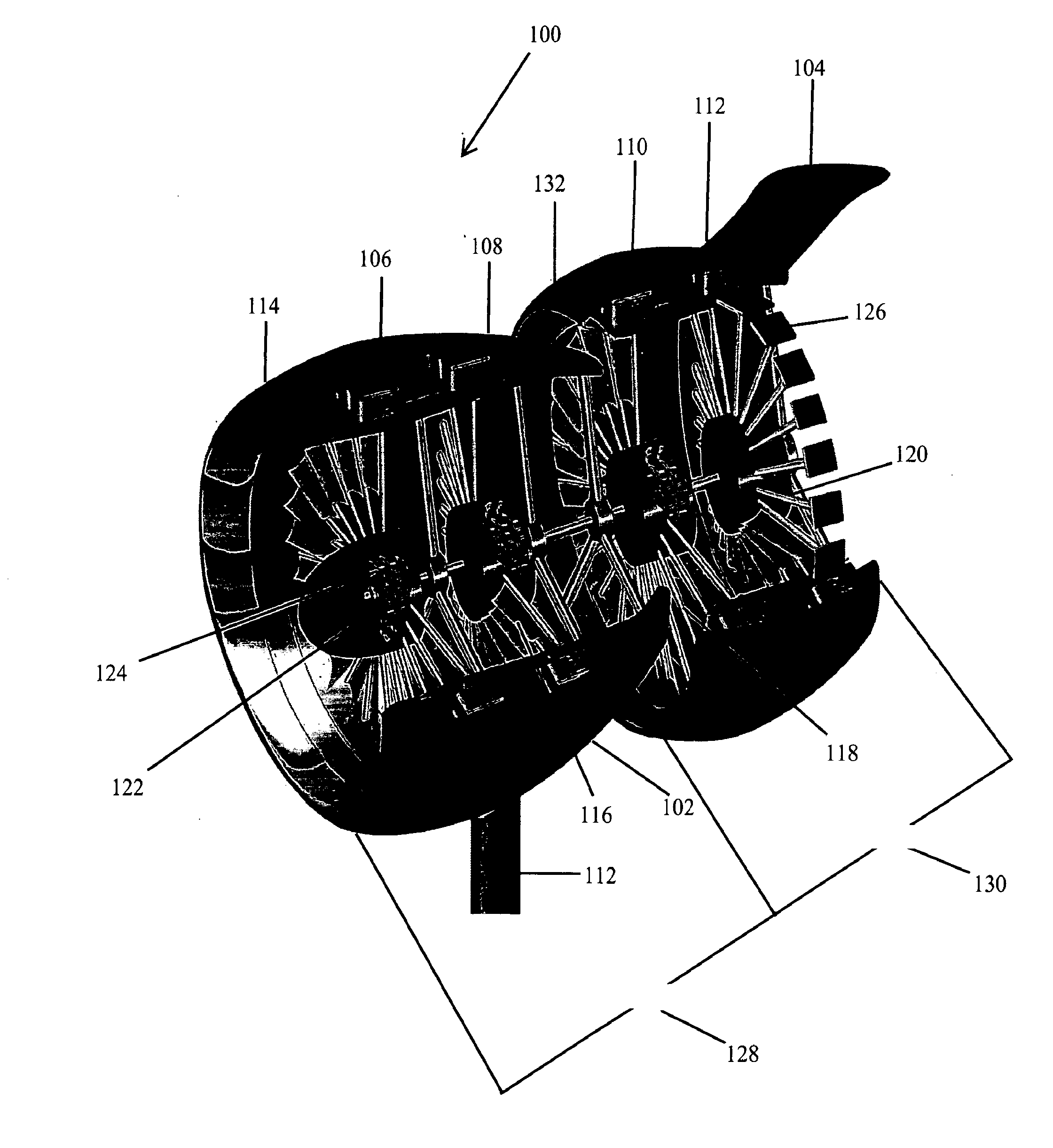

System and method for power production using a hybrid helical detonation device

InactiveUS20090102203A1Shorten the lengthFast fillEngine manufactureTurbine/propulsion fuel valvesCombustion chamberDeflagration to detonation transition

The system and method described herein uses a hybrid pulsed detonation engine (PDE) system to drive a turbine that powers an electric generator. The combustion chamber of the PDE is shaped in a helical form, so that the external length of the section is reduced, while maintaining the distance for acceleration to detonation. This allows the achievement of deflagration to detonation transition without the help of turbulence enhancing obstacles, while keeping the overall size of the detonation tube small. The PDE output can be scaled by: increasing the cross sectional area of the detonation chamber; increasing the number of detonation tubes; and increasing the frequency of operation of the PDE. The replacement of conventional deflagrative internal combustion engines, including gas turbines and reciprocating engines, with pulsed detonation engines for electric power generation, may provide fuel savings and have a lower environmental impact.

Owner:LU FR K +4

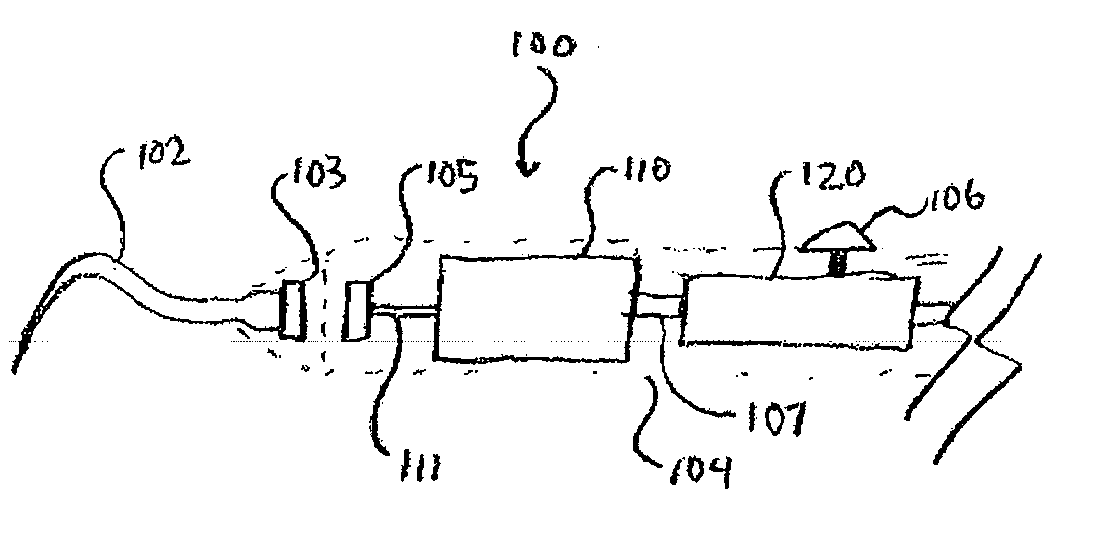

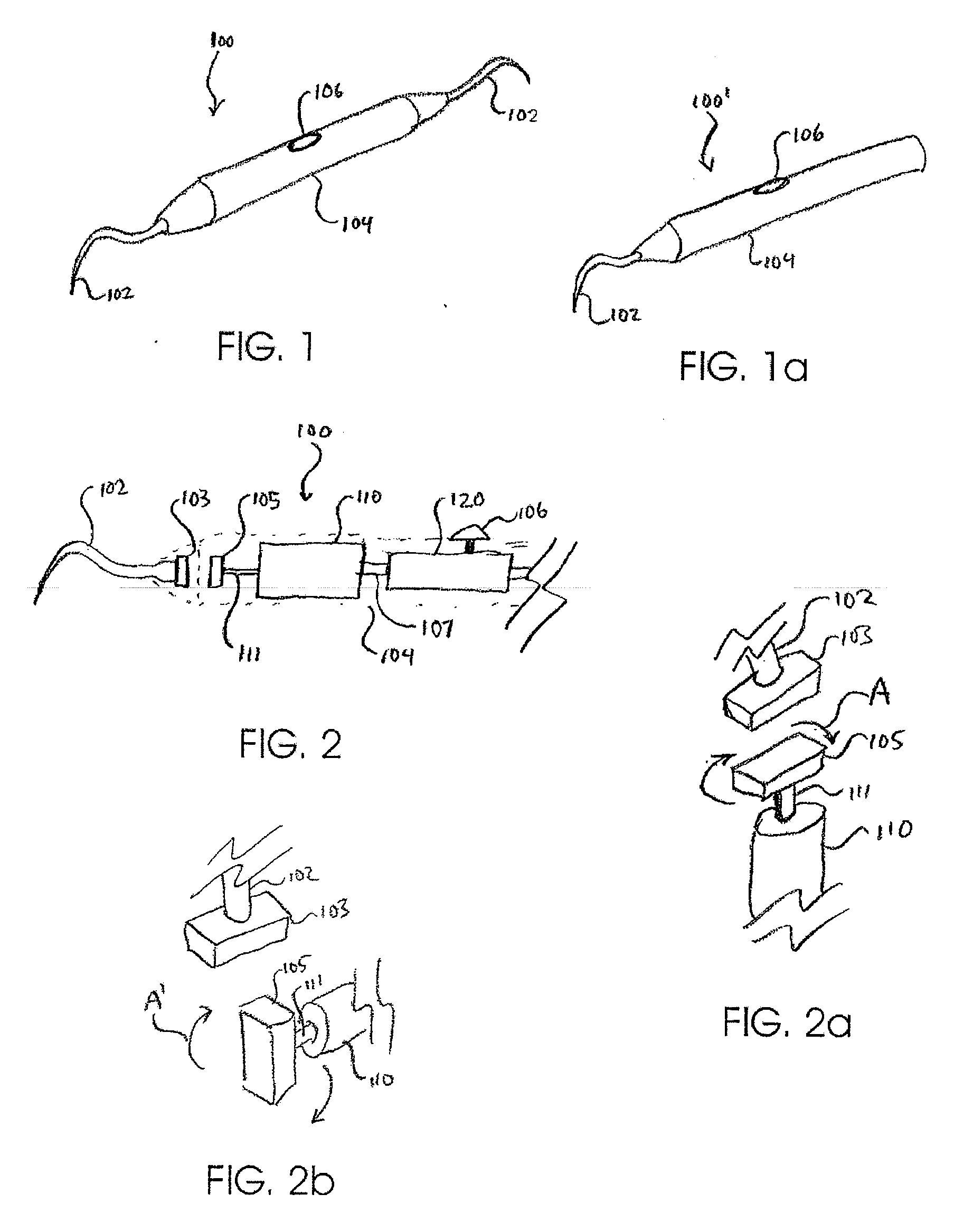

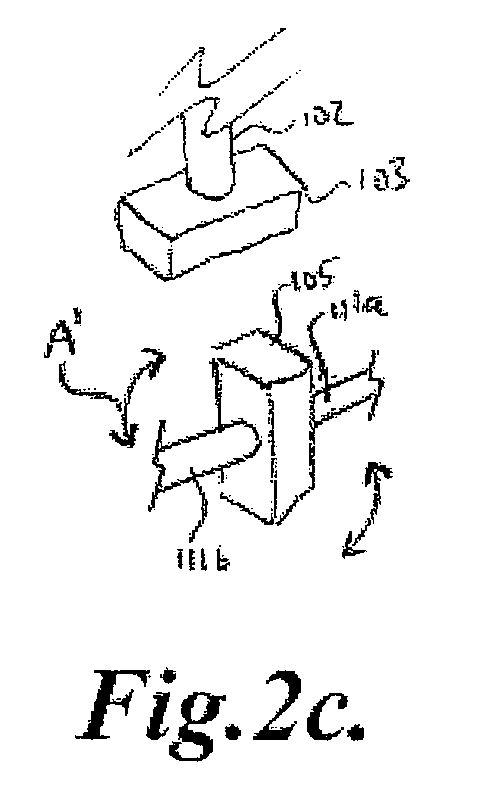

Vibratory Dental Tool

InactiveUS20080318184A1Easy to repositionDynamo-electric brakes/clutchesTooth pluggers/hammersReciprocating motionEngineering

Owner:DISCUS DENTAL LLC

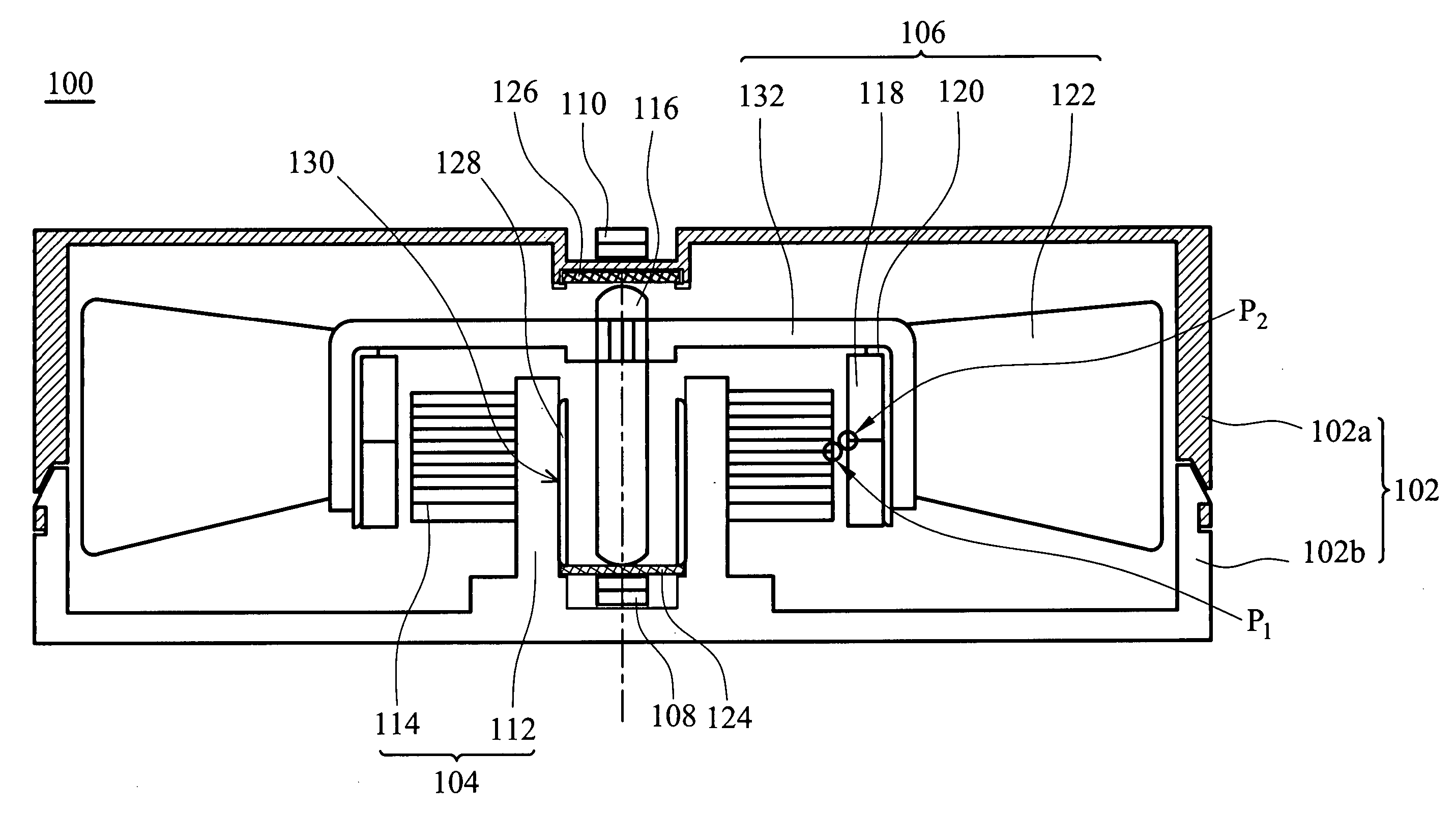

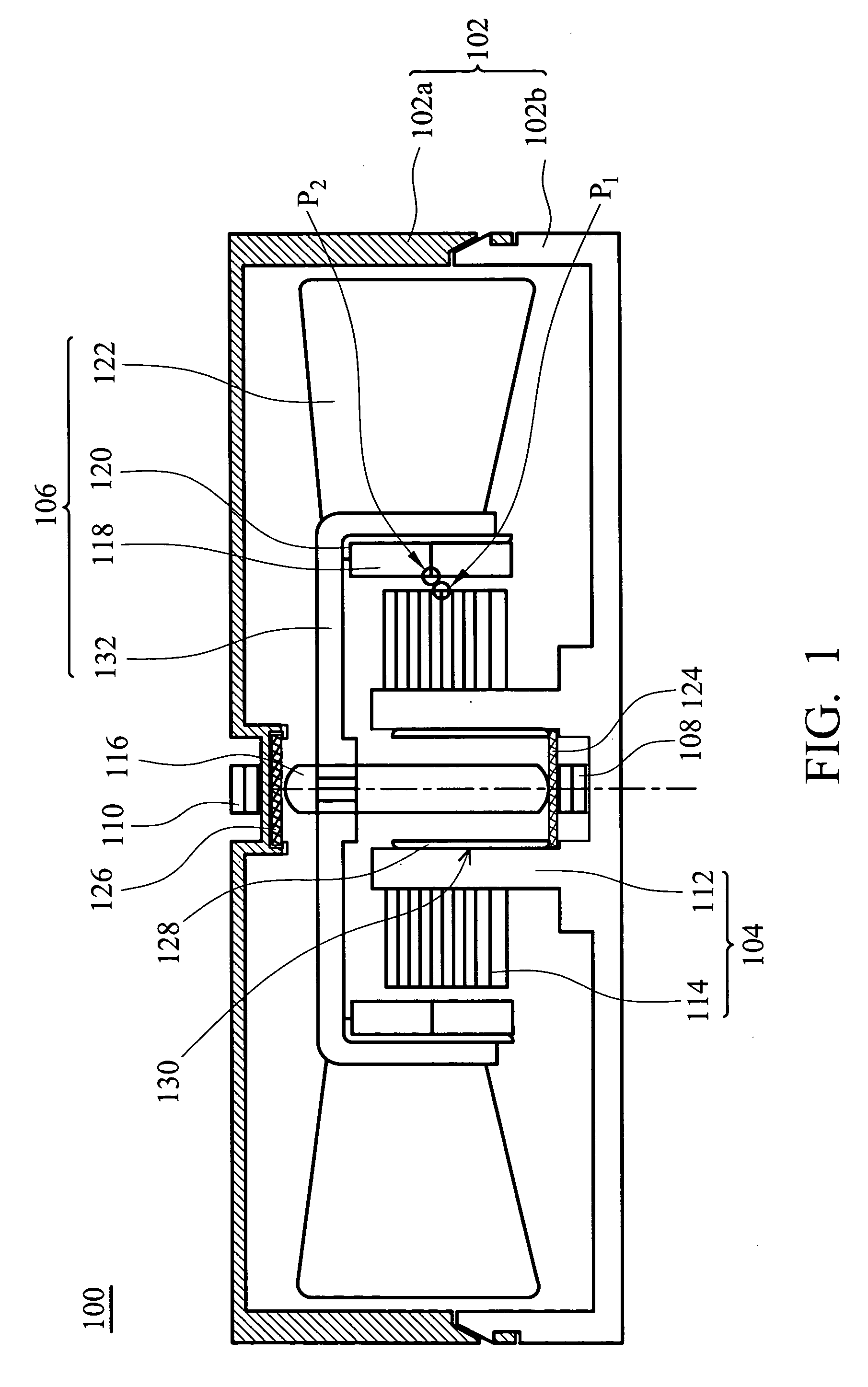

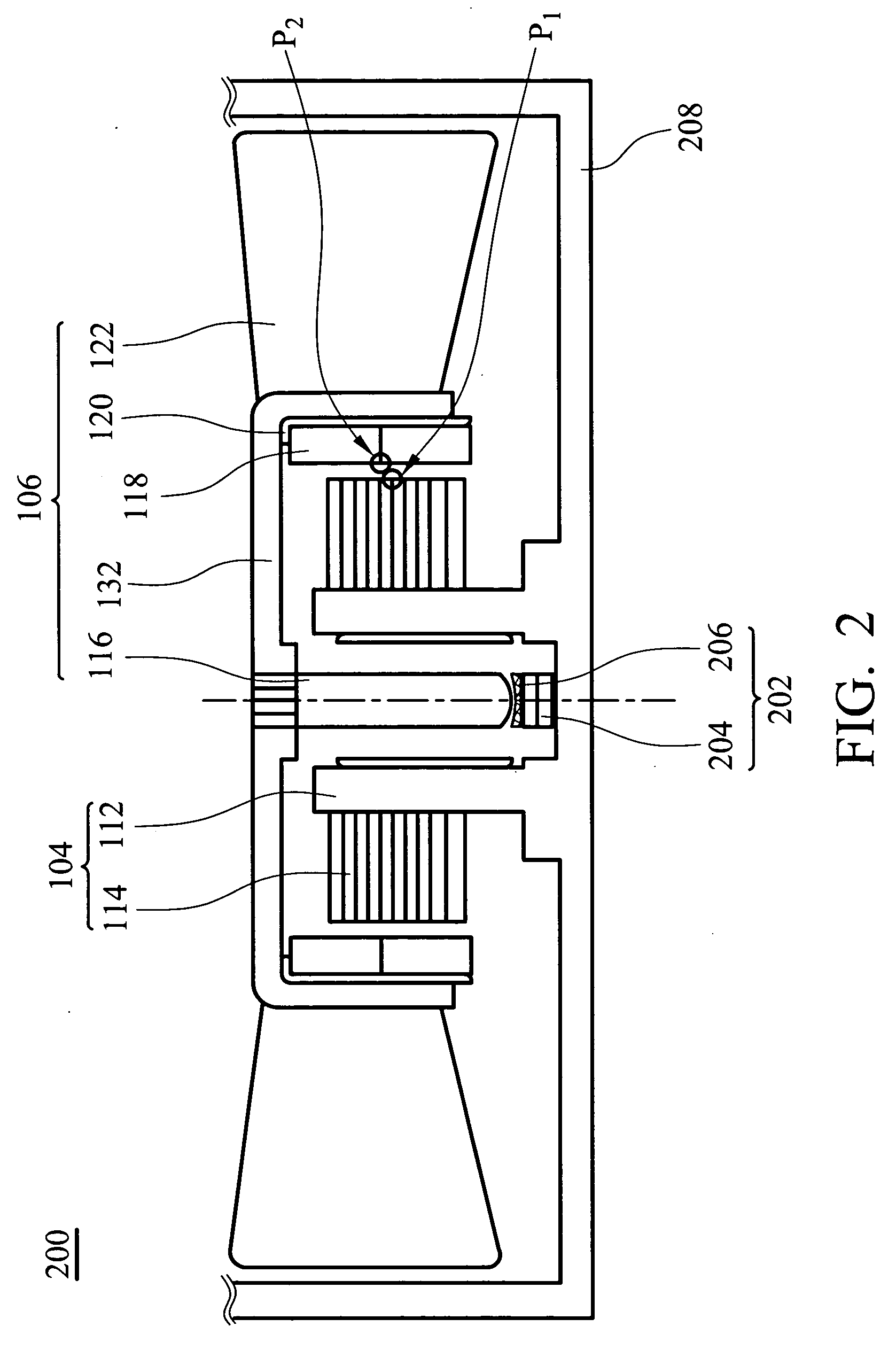

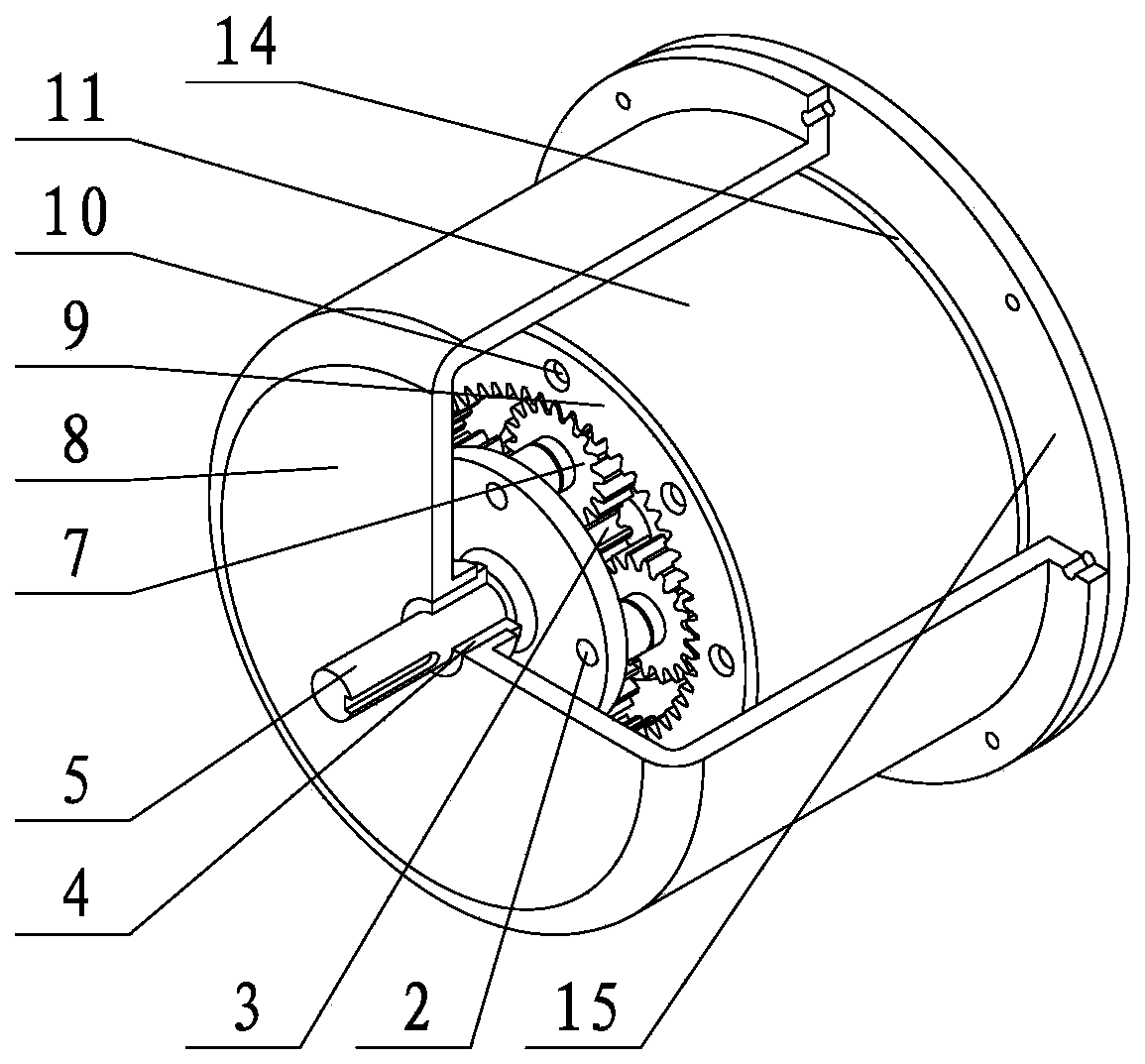

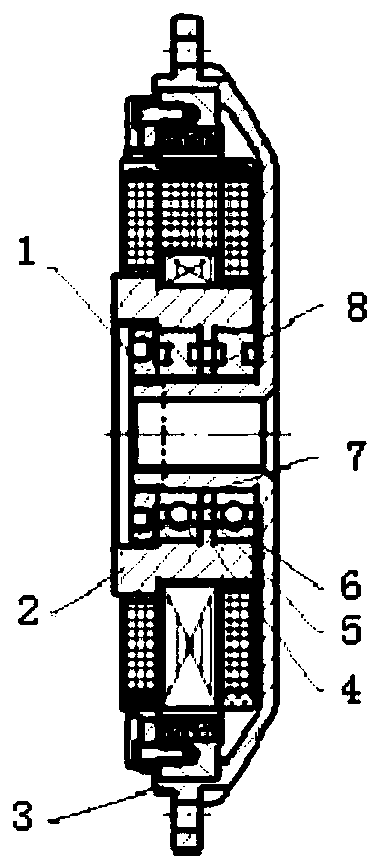

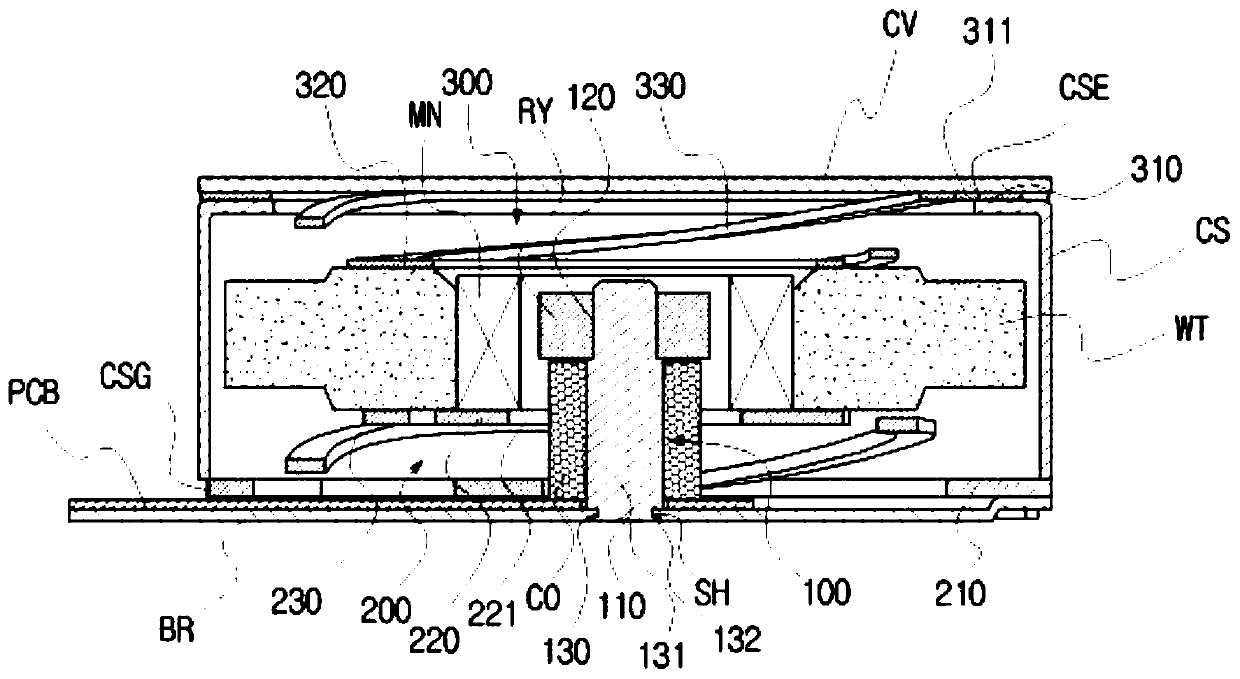

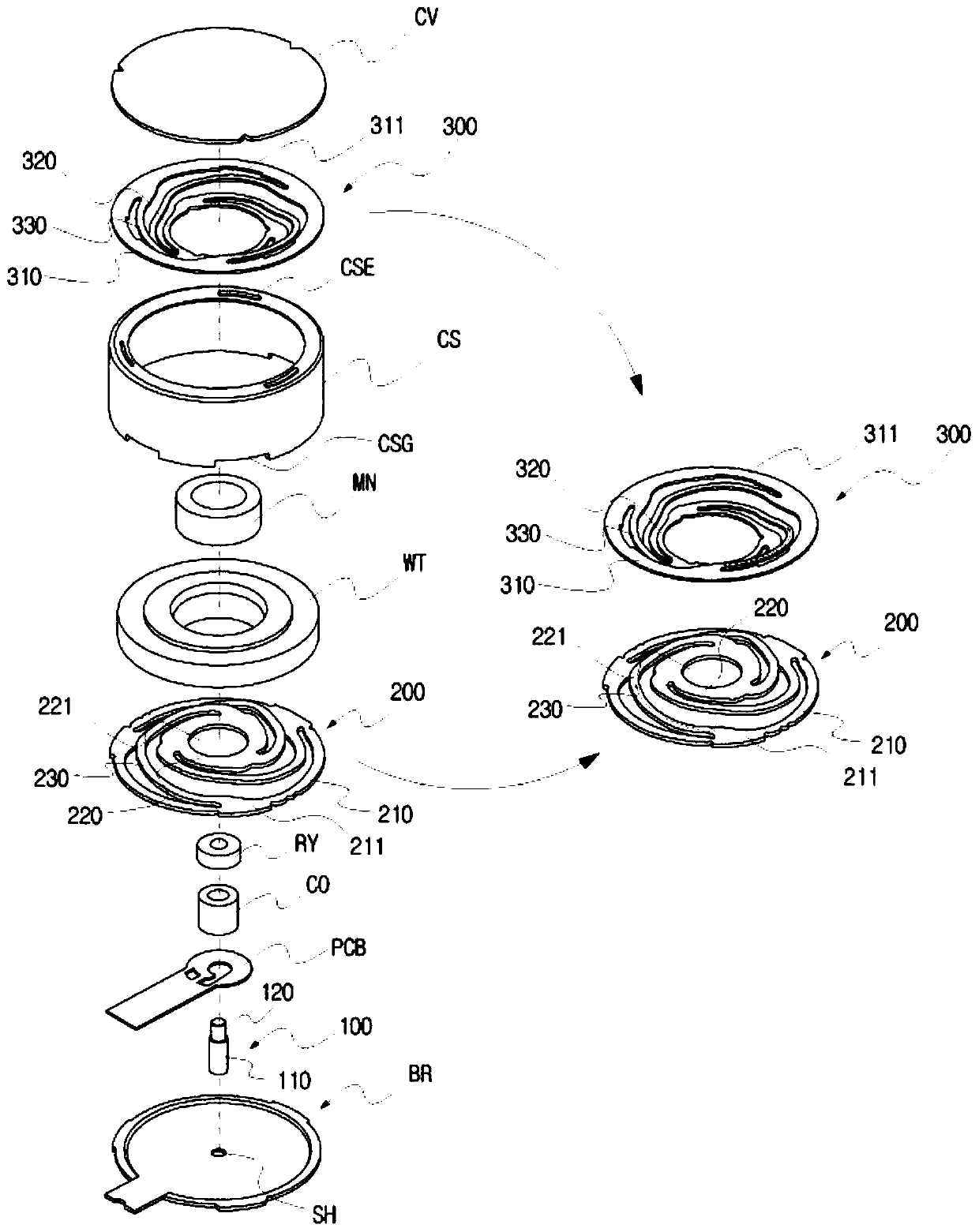

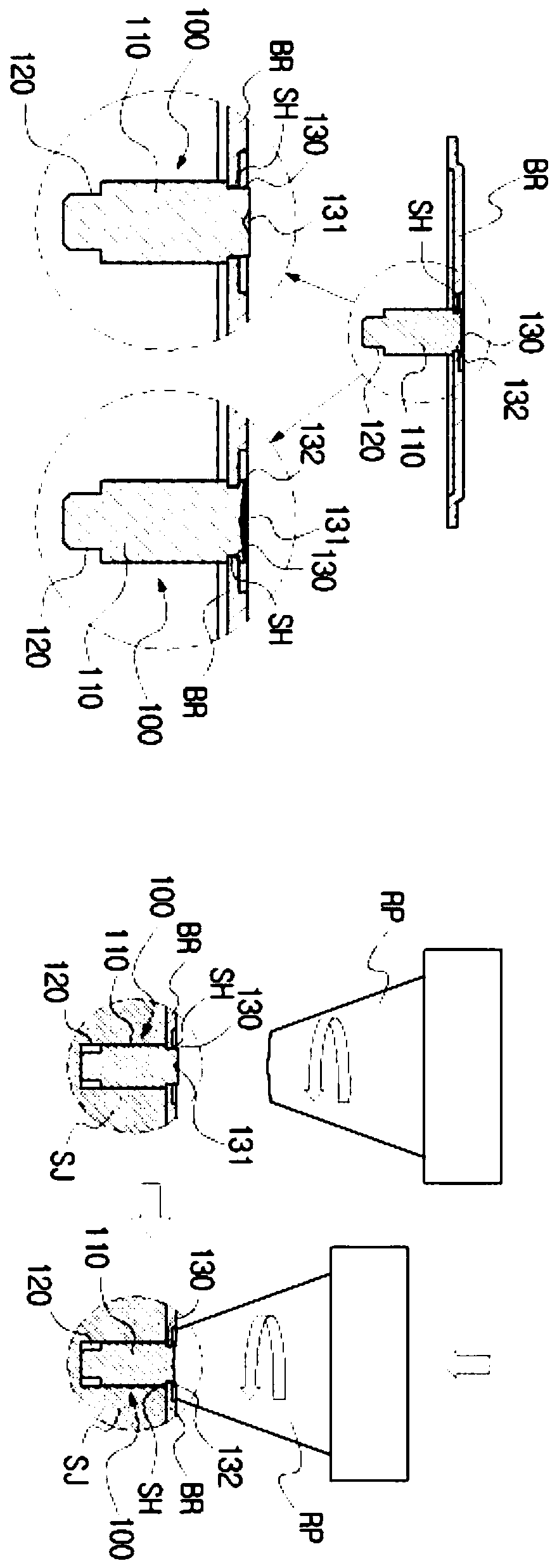

In-wheel actuator and in-wheel assembly comprising the same

An in-wheel assembly is provided, and the in-wheel assembly includes an in-wheel actuator and a wheel. The in-wheel actuator includes a driving motor; a decelerator which is disposed inside the driving motor and configured to reduce a rotational speed of the driving motor; and a hollow shaft which is disposed inside the driving motor and configured to transfer a rotational force of the driving motor to the decelerator, which is accommodated in a hollow of the hollow shaft, and circulates fluid inside of the driving motor with respect to a surface of the decelerator when driven to rotate by the driving motor. The wheel accommodates the in-wheel actuator and receives a rotational speed reduced by the decelerator to rotate.

Owner:SAMSUNG ELECTRONICS CO LTD

Exhaust gas turbocharger for an internal combustion engine and method of operating an exhaust gas turbocharger

InactiveUS20070101714A1Improve responseImprove power densityInternal combustion piston enginesExhaust apparatusTurbochargerElectric machine

In an exhaust gas turbocharger for an internal combustion engine comprising a compressor and a turbine interconnected by a shaft in a rotationally fixed manner, and an electric machine which can be connected to the exhaust gas turbocharger via a clutch, the exhaust gas turbocharger can be driven at least temporarily by a disk-shaped flywheel rotatably supported on the shaft and being operable selectively by the turbine and by an electro-dynamic structure for improving the response behavior of the exhaust gas turbocharger.

Owner:DAIMLER AG

Wind jet turbine

InactiveUS20120068670A1Reduce weightIncrease wind speedEmergency protective circuit arrangementsDynamo-electric converter controlEngineeringTurbine

Owner:BERSIEK SHAMEL A

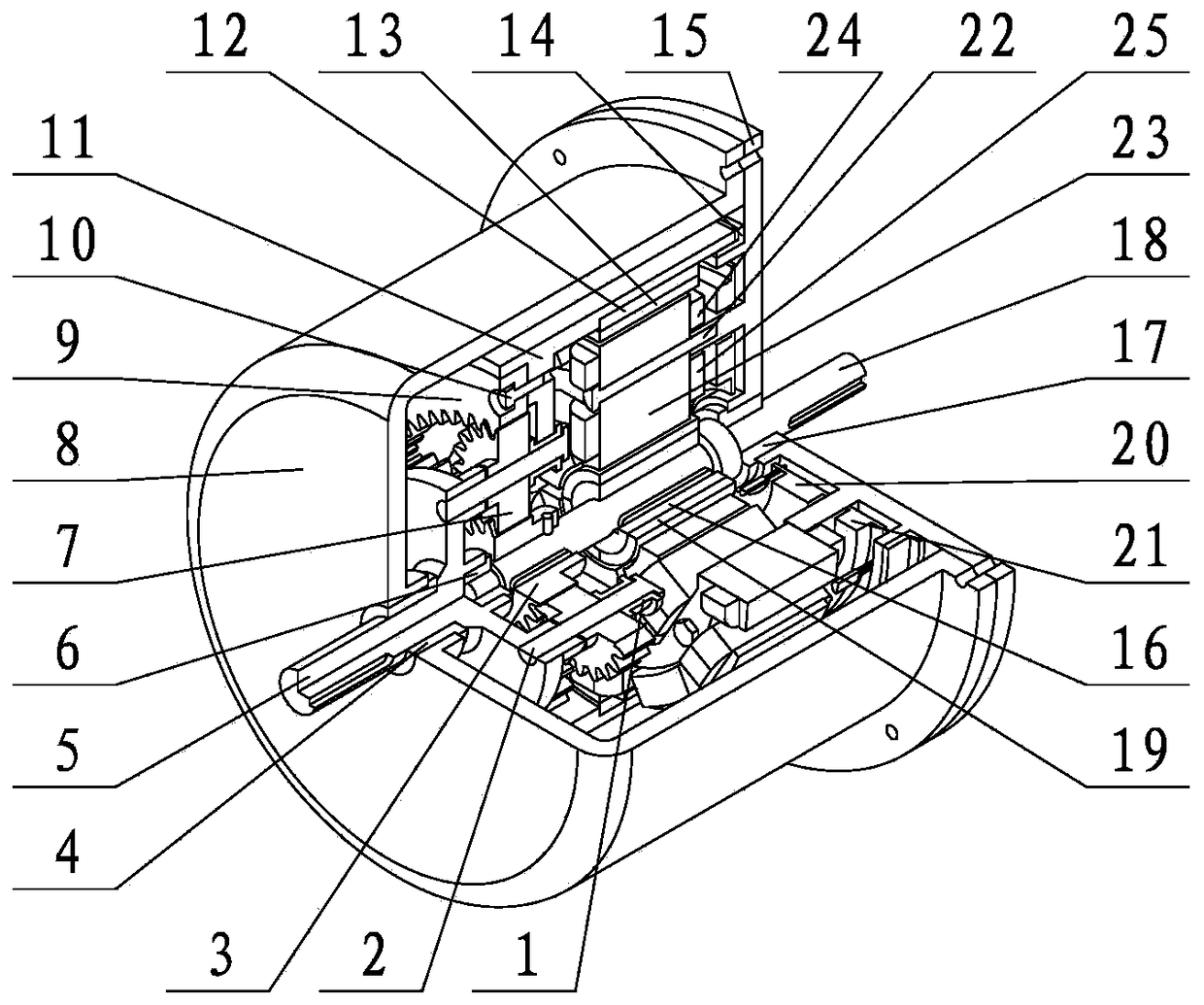

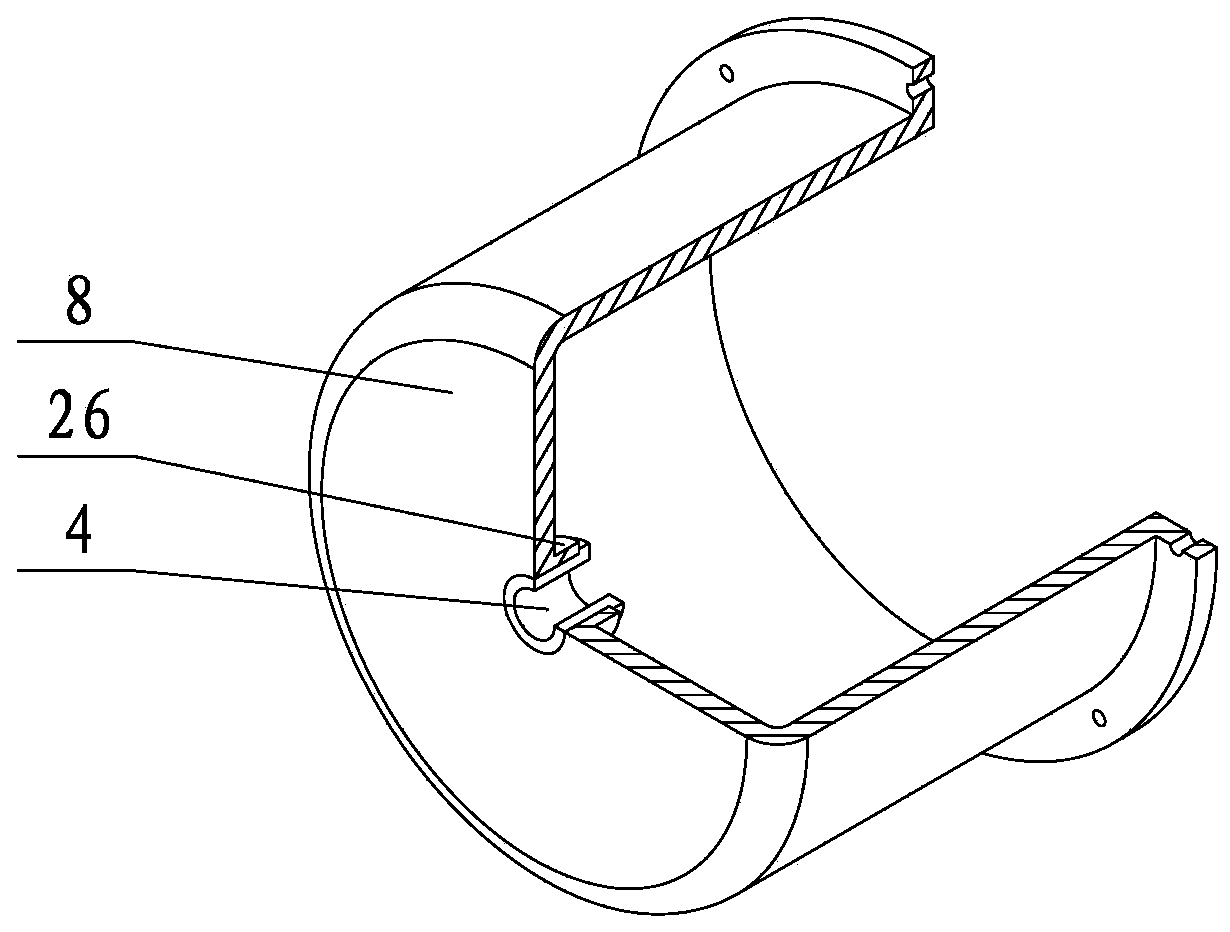

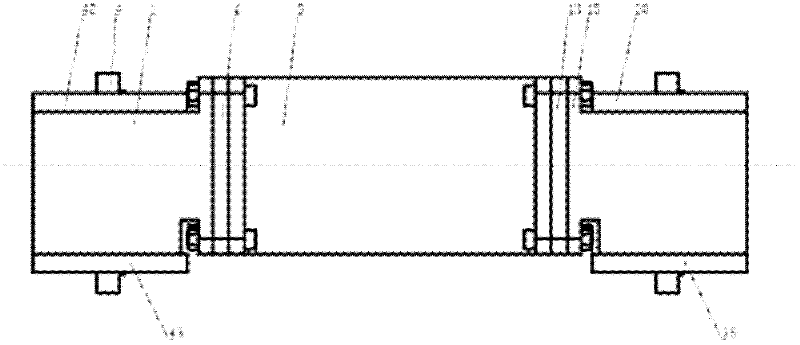

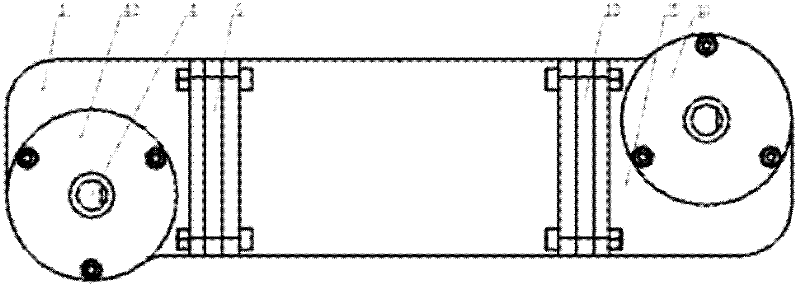

Dual-rotor input planet-gear speed reducer

The invention discloses a dual-rotor input planet-gear speed reducer, and relates to a speed reducer. The speed reducer comprises a shell component, an engine base component, a controller one, a controller two, a stator component, an external rotor component, an internal rotor component, a rotating shaft component, a gear ring, and a planet-gear component; in the operation process of the speed reducer, the output rotation speed of an output shaft one is related to rotation speed difference between two motor rotors; two motor rotors are always in the high-speed operation state, the rotating direction of the output shaft one of the speed reducer can be changed under the state of maintaining the unchanged rotation directions of two motor rotors, thereby driving a load device to realize the functions of frequently accelerating and reducing speed, frequently starting and stopping, even frequently changing the rotation direction of the load device. The speed reducer disclosed by the invention can ensure the motor to operate under the working state with high frequency, and improve the response speed when the speed reducer changes the rotation direction of the load device.

Owner:如皋久源传动机械有限公司

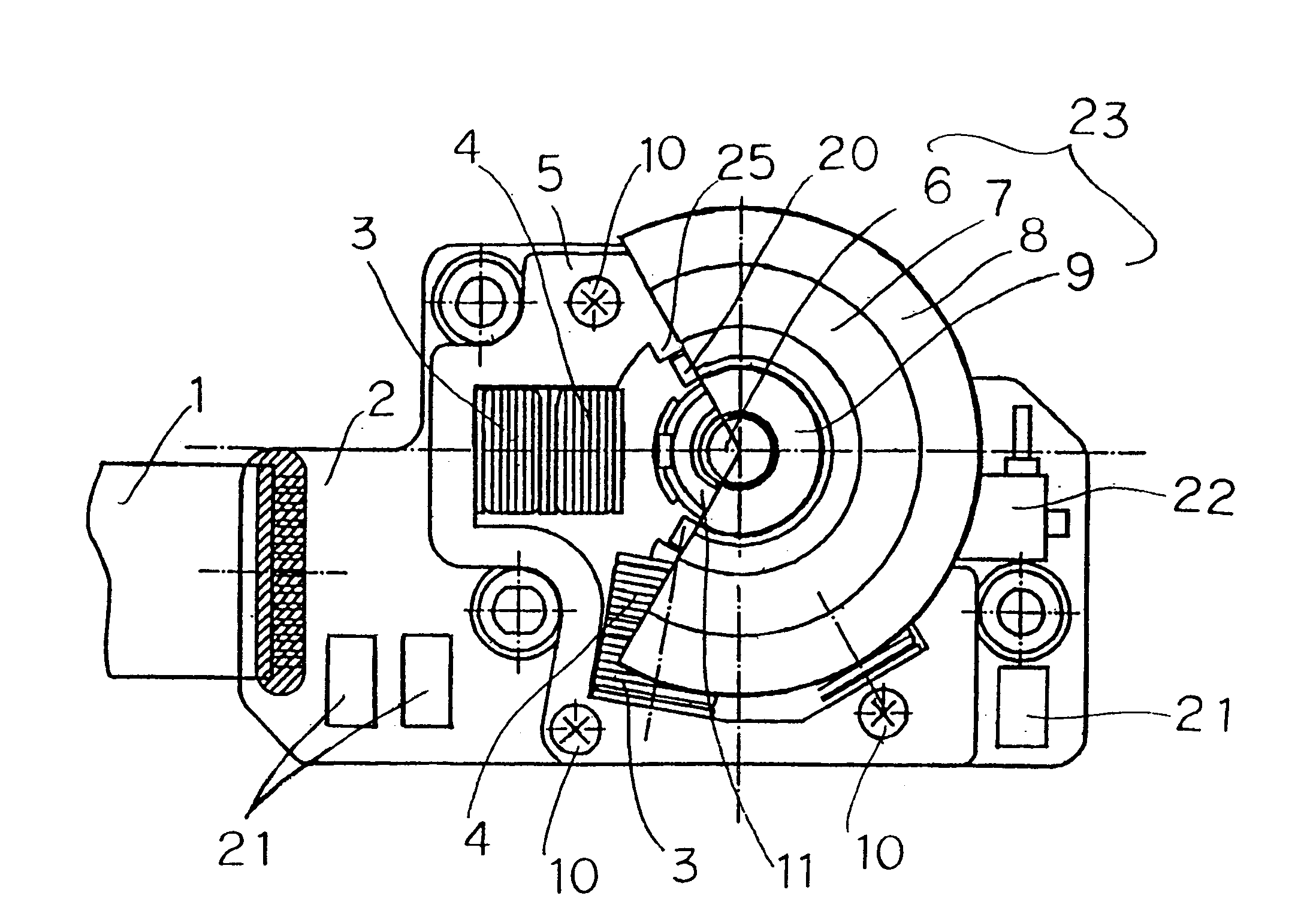

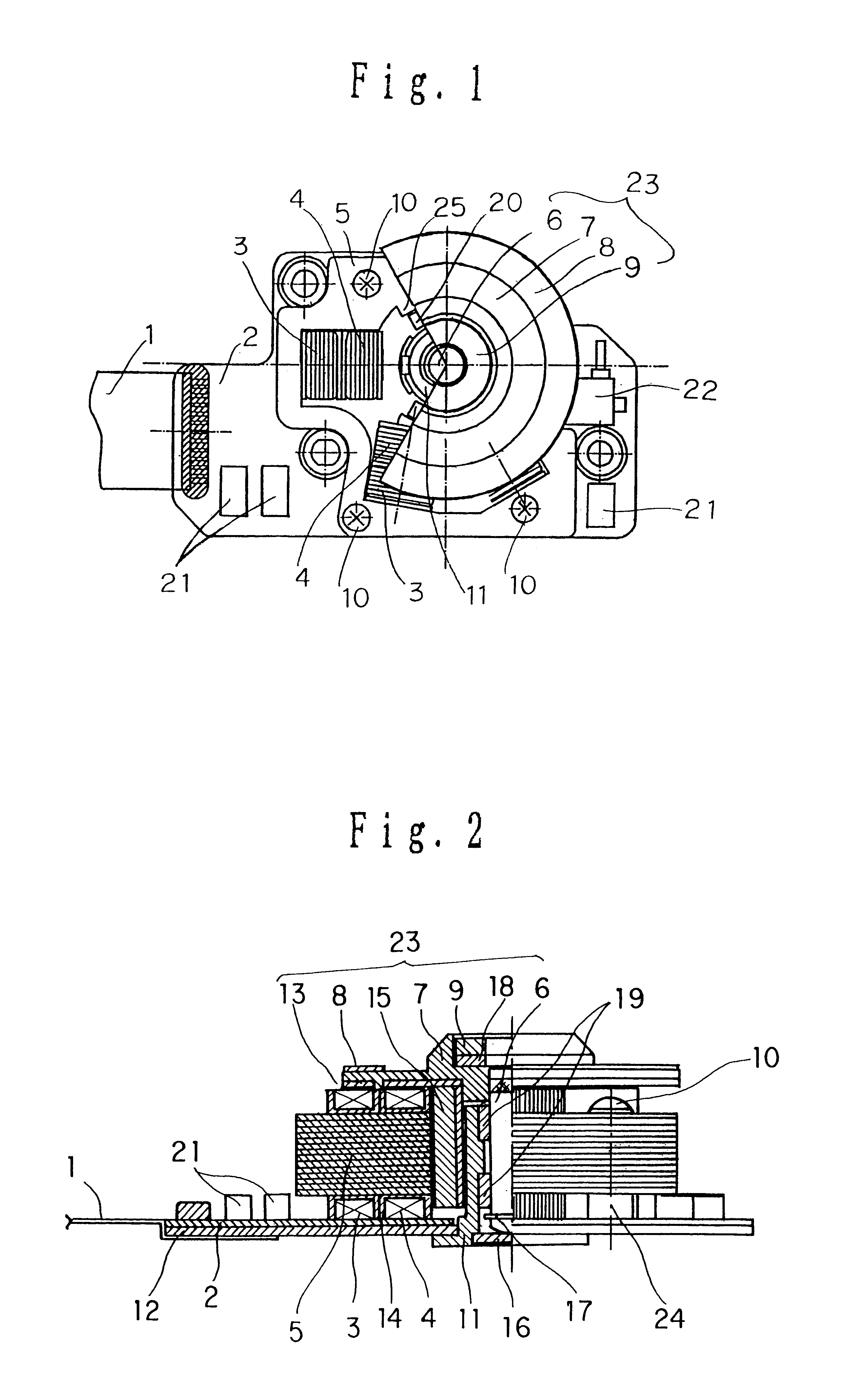

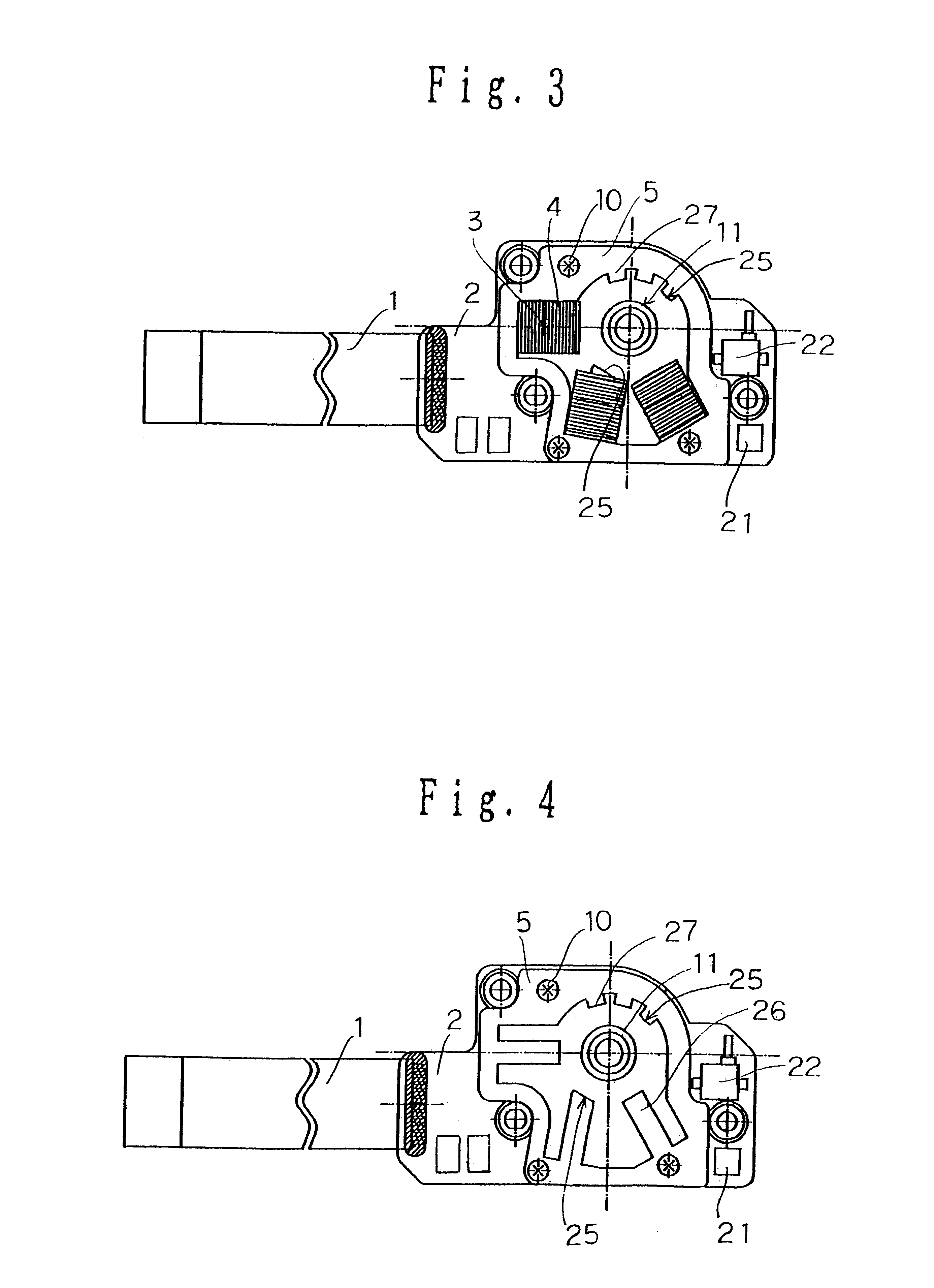

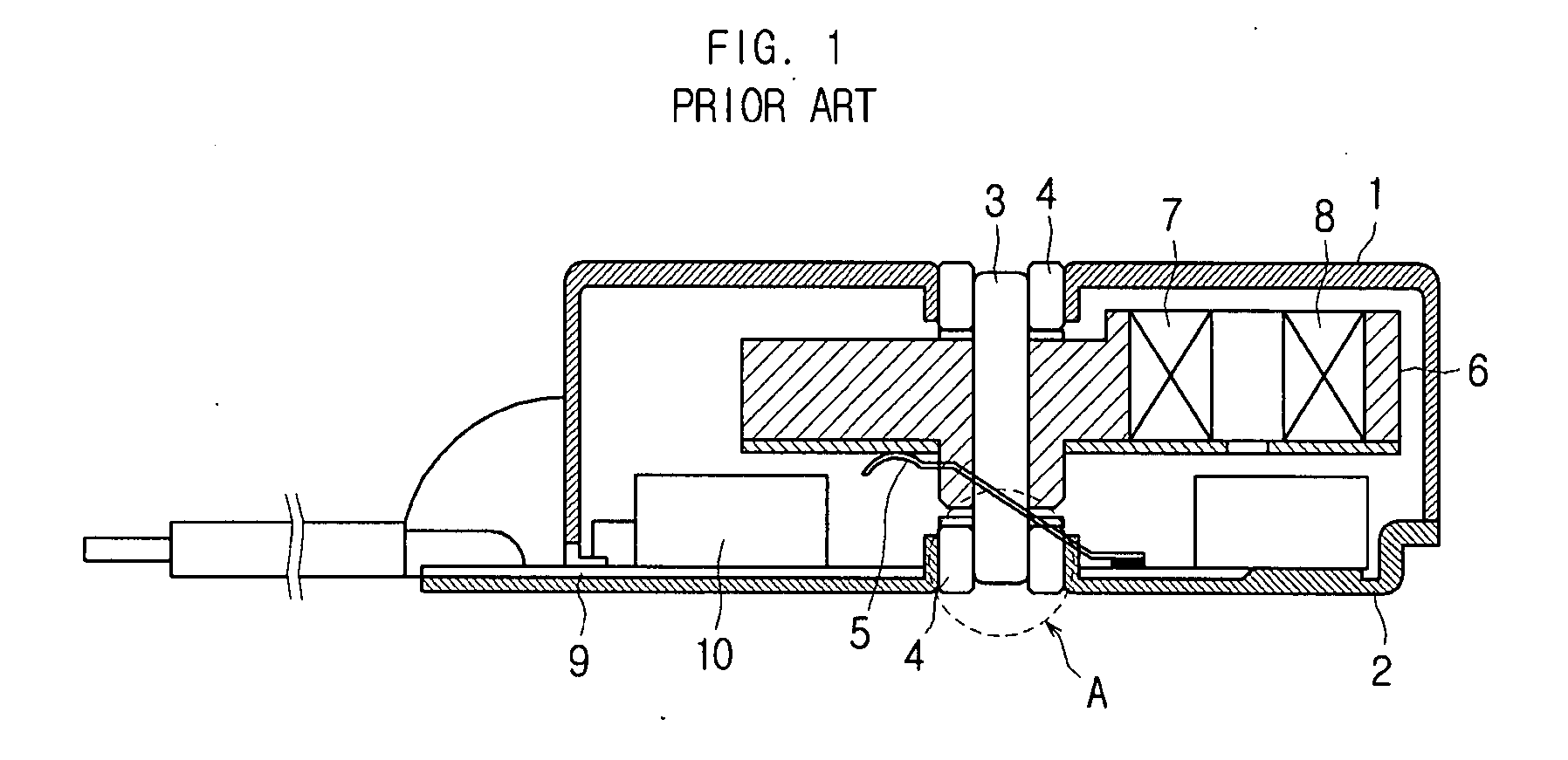

Motor structure for use with optical disks

InactiveUS6603635B1Improved in accelerating/decelerating characteristicSmall currentRecord information storageMagnetic circuit stationary partsRotor magnetsMagnetic poles

Owner:MINEBEA CO LTD

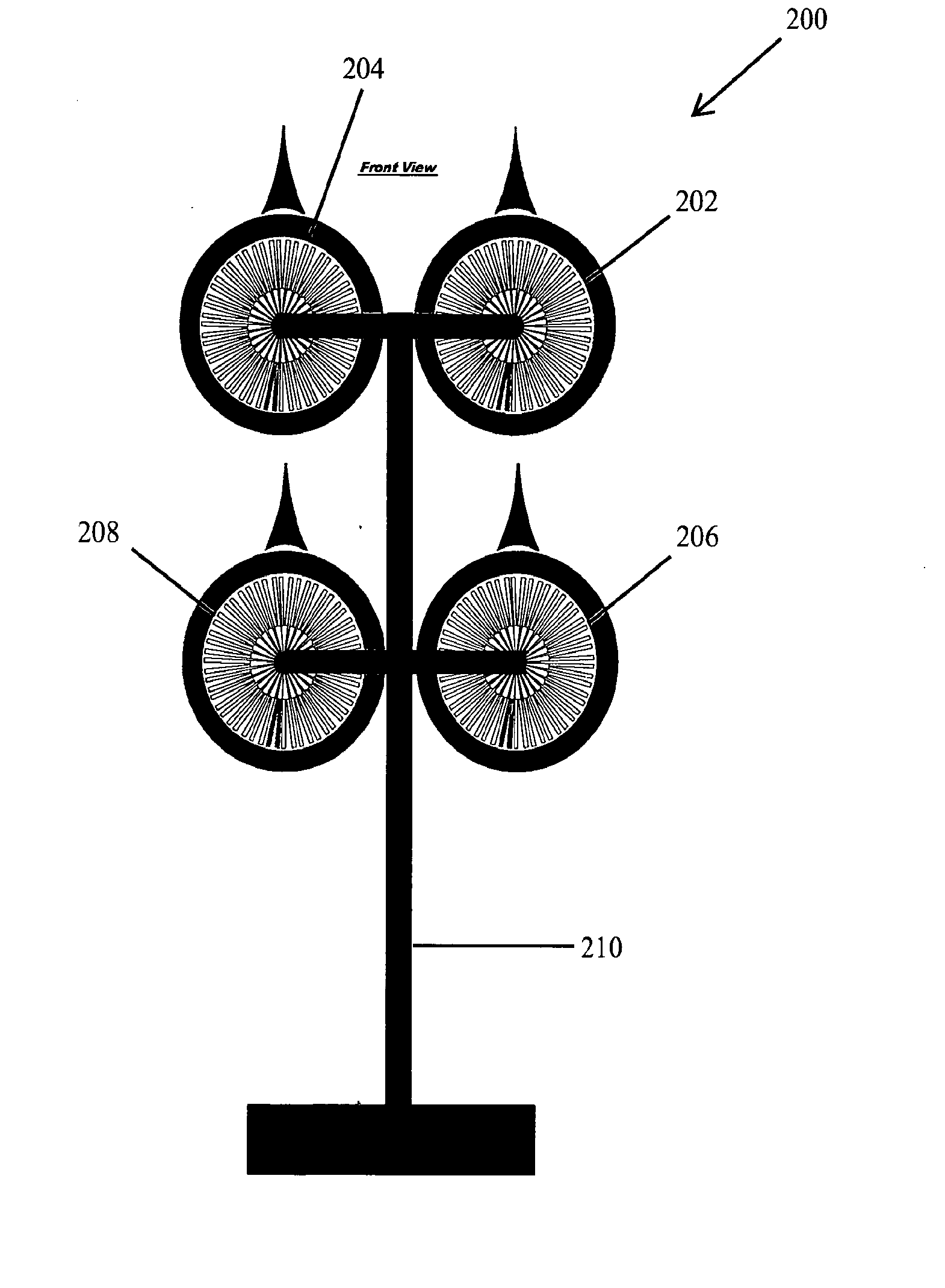

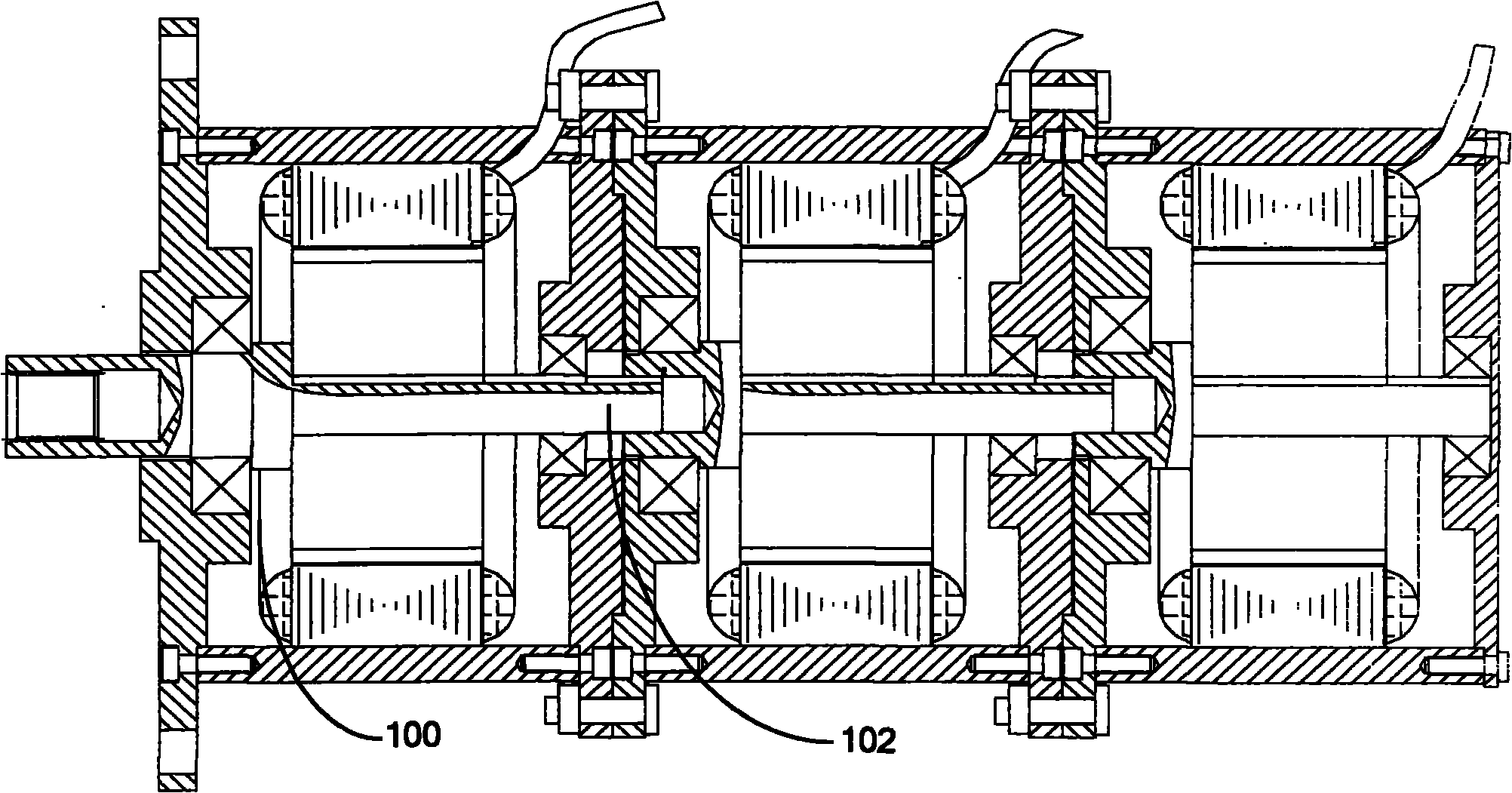

Vehicle Energy Harvesting System

InactiveUS20190044413A1Piezoelectric/electrostriction/magnetostriction machinesMachines/enginesReciprocating motionDrive shaft

An energy harvesting system (100) for harvesting energy from vehicles travelling on a road (102). The system (100) includes a plurality of flexible hoses (104) which are embedded in a road overlay (106). Each hose (104) holds a hydraulic fluid, e.g. water, such that, when a vehicle wheel (108) passes over the hose (104), the fluid is displaced. The system (100) further comprises a plurality of double-acting hydraulic fluid cylinders (109) which are in fluid flow communication with the fluid in the hoses (104) and are configured to convert pressure applied to the fluid into rotary motion which drives an electrical generator. One hose is connected to each end of the cylinder (109) to drive it in opposite directions to induce linear reciprocating motion which is converted to rotary motion by way of a mechanical drivetrain. Due to the double action, it drives at least two drive shafts simultaneously.

Owner:EPITOME PROPERTY INVESTMENTS PTY LTD

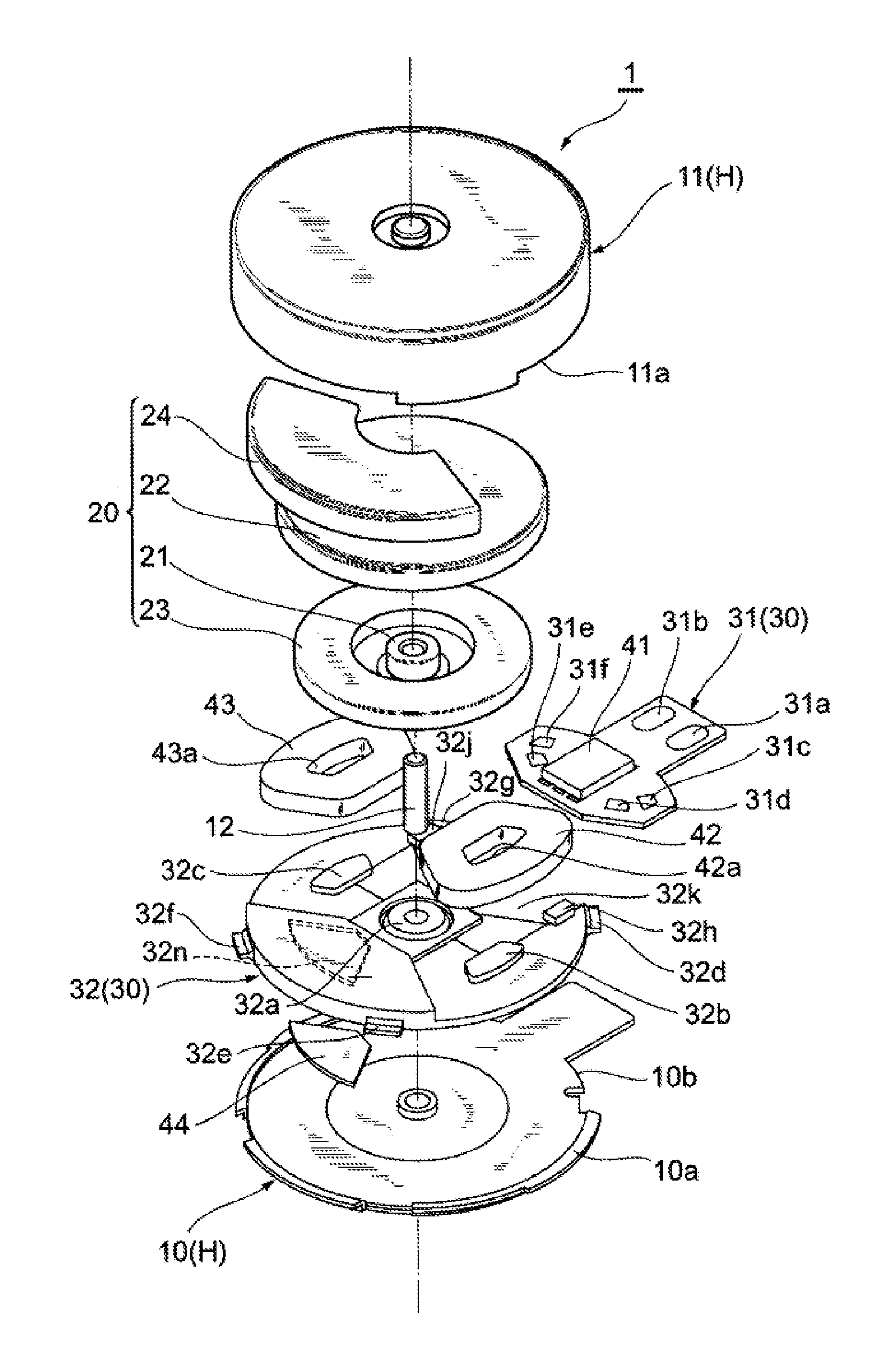

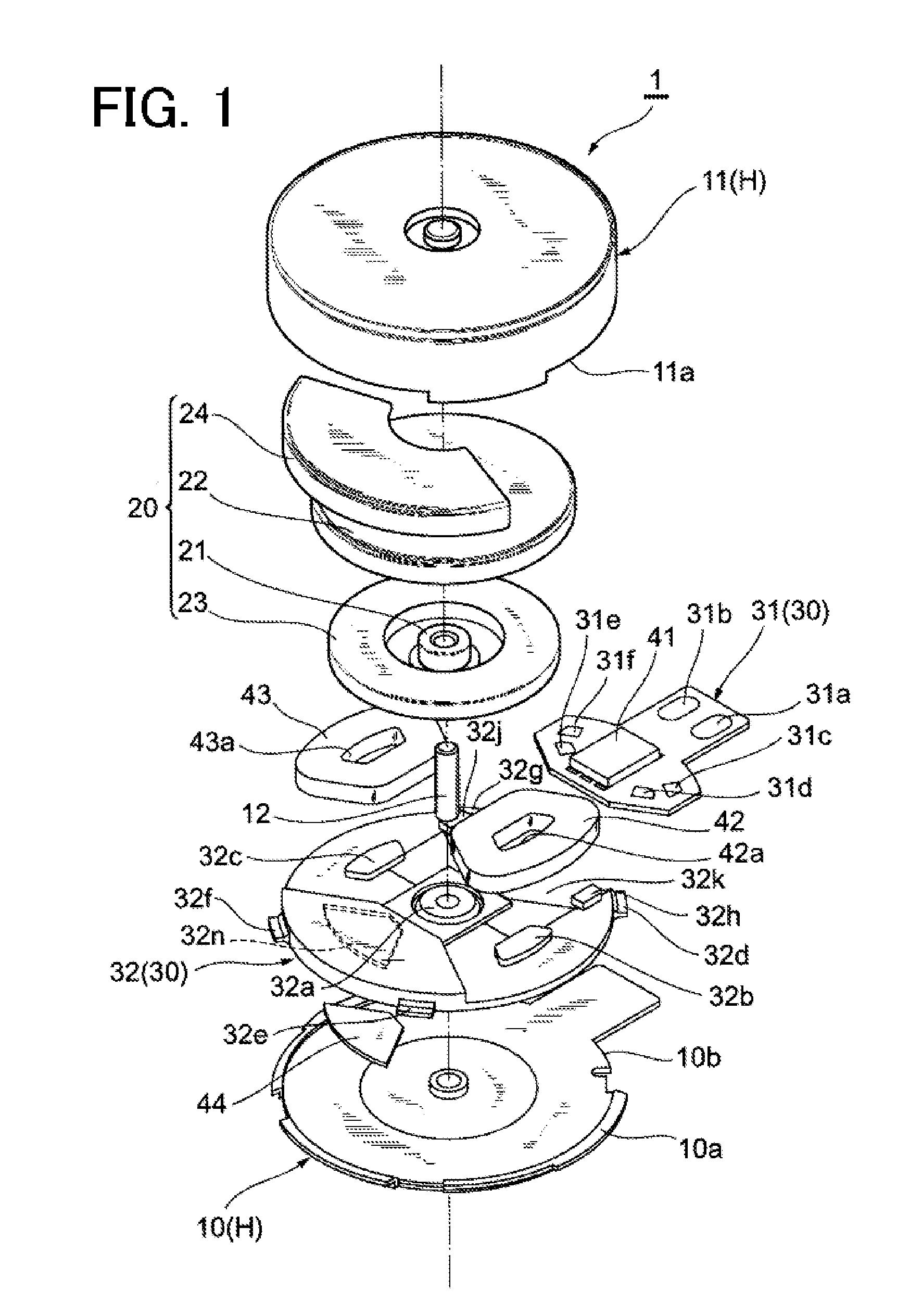

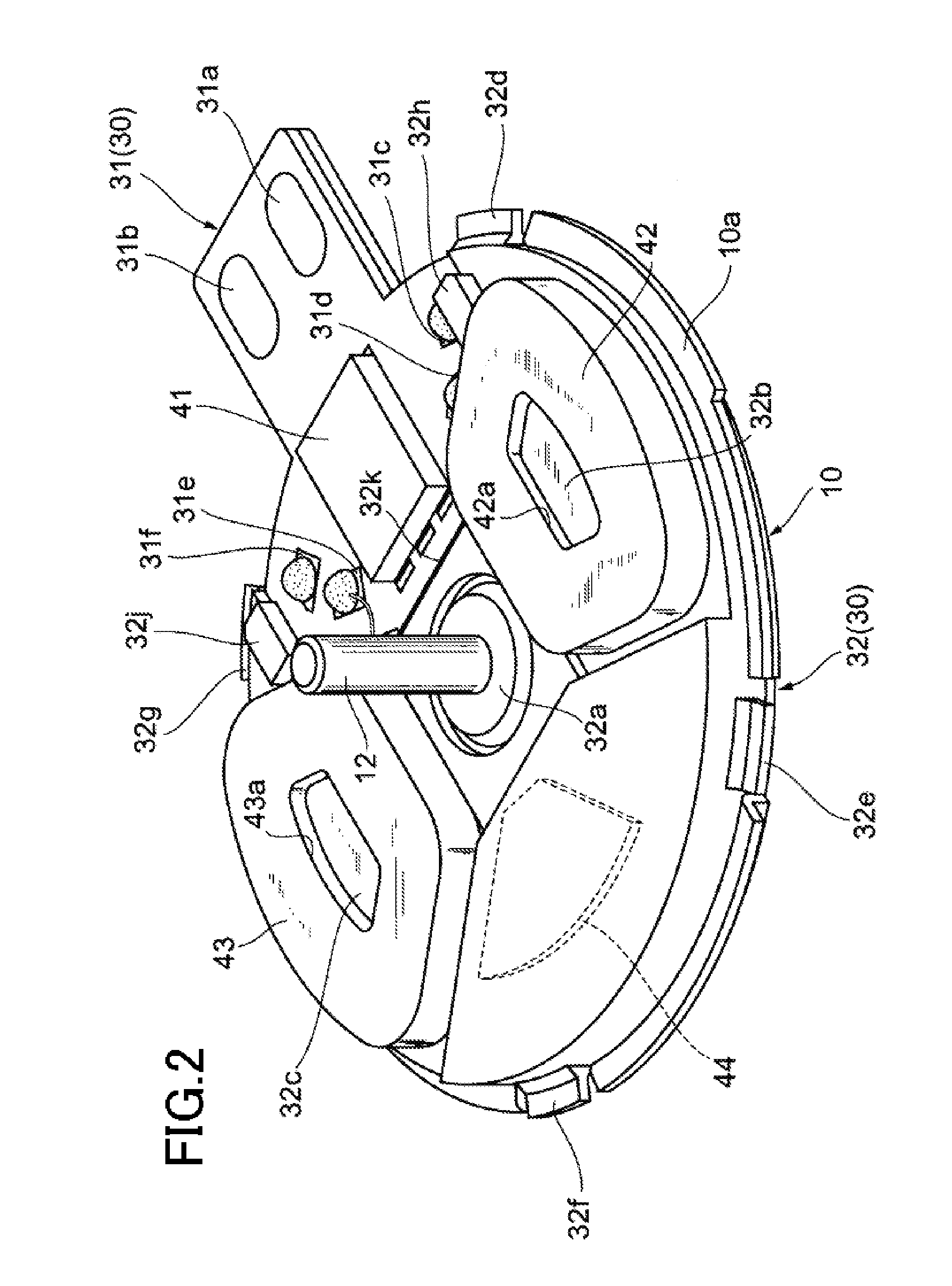

Brushless motor

InactiveUS20110001385A1Error proneReduce output torqueWindingsMechanical energy handlingBrushless motorsMiniaturization

Owner:COPAL CO LTD

Motor brake system

ActiveUS20200132149A1Association with control/drive circuitsAxially engaging brakesElectric machineControl theory

A motor includes a housing containing a rotor and stator. A brake assembly is adapted to restrain rotation of the rotor. A brake controller includes a brake diagnostics system. At least one vibration sensor is located in the housing and provides vibration data to the brake diagnostics system in response to a brake operation cycle of the brake assembly. The vibration data is used by the brake diagnostics system to assess an operative condition of the brake assembly.

Owner:ROCKWELL AUTOMATION TECH

Hybrid motor for transportation

A hybrid electric / piston driven motor may use a low voltage, high torque direct current (DC) motor to drive a vehicle, such as a motorcycle. The DC motor may be powered by a battery that may be charged by an alternator / DC generator. The alternator / DC generator may be driven by the movement of the vehicle. The motor may include springs that receive the kinetic energy of the pistons of the motor as the pistons rise in their upstroke. The springs may convert this upstroke kinetic energy to downstroke kinetic energy, minimizing the power needed from the battery.

Owner:STOVER BOBBY A

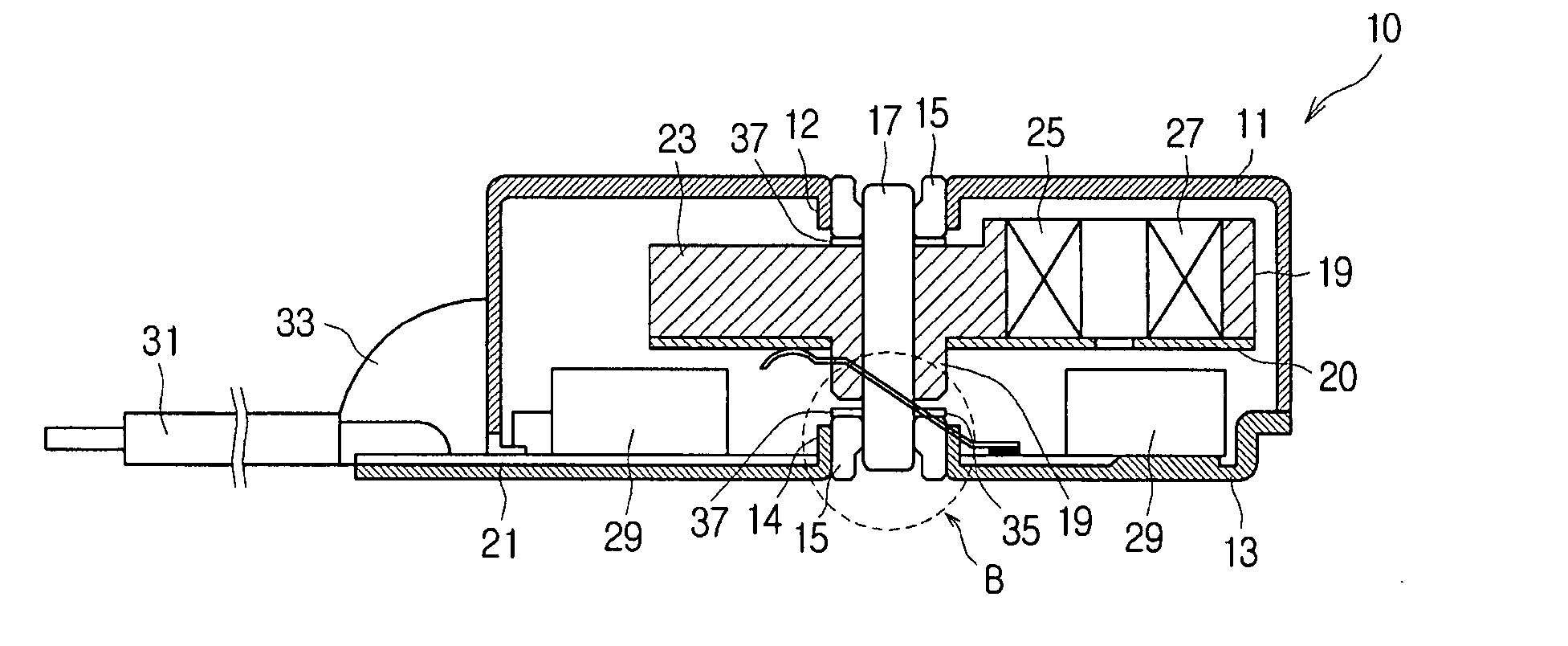

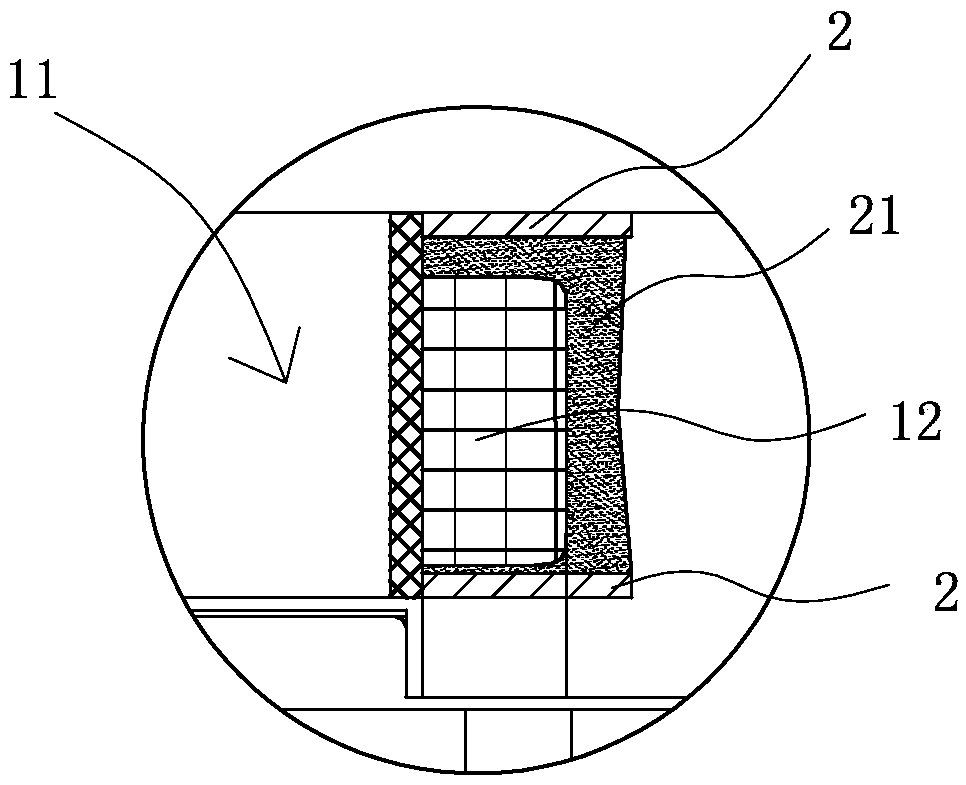

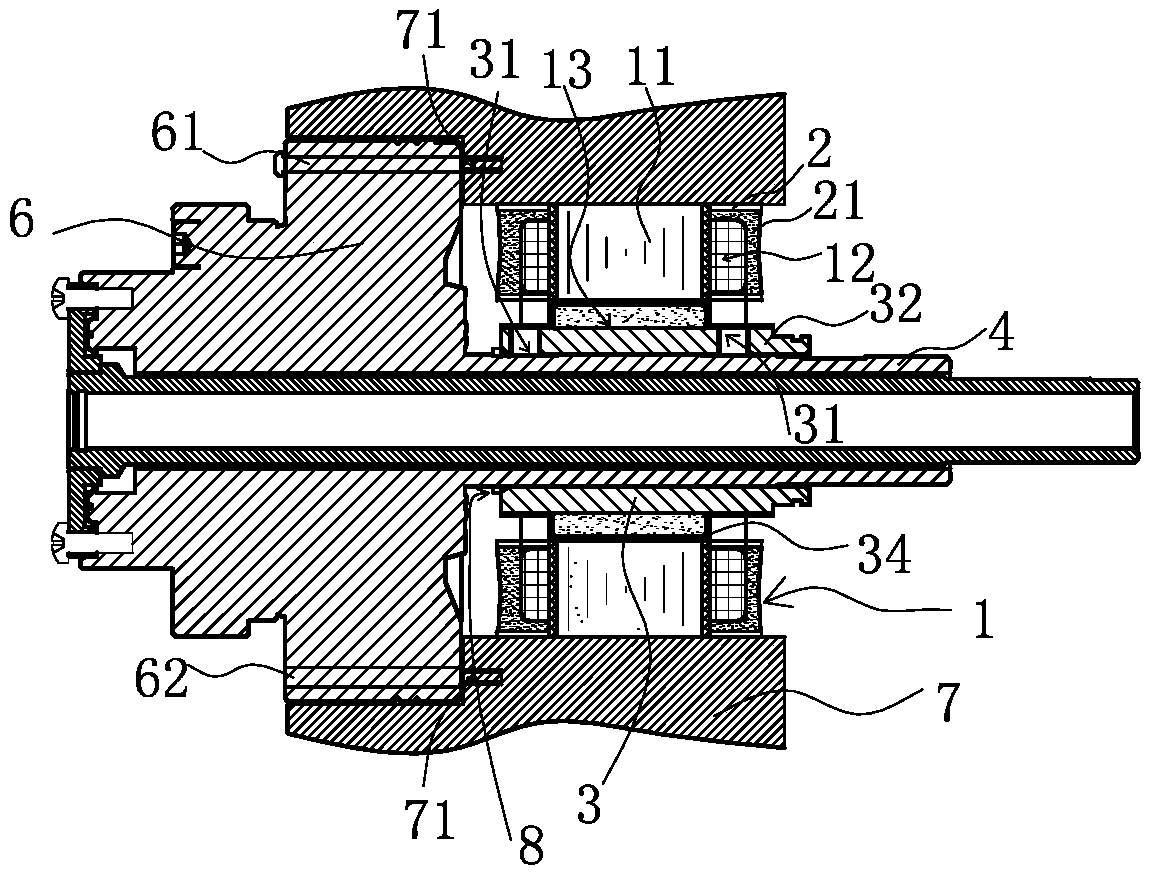

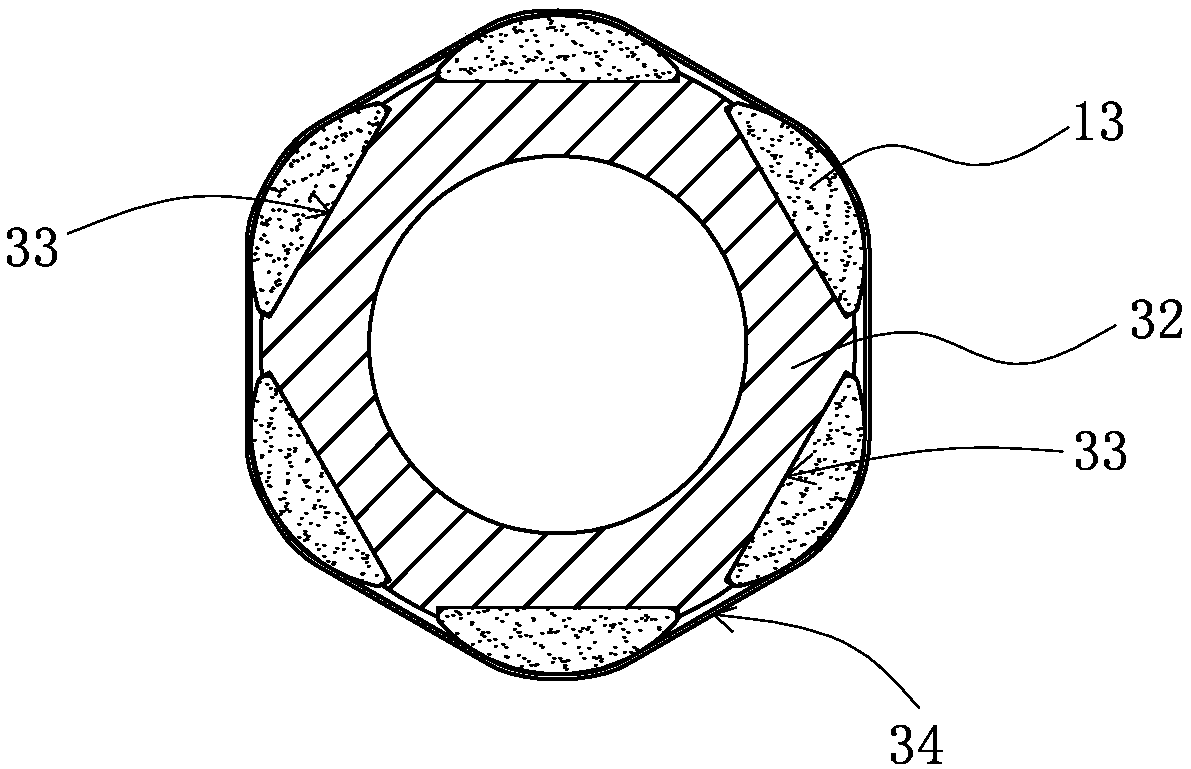

Pan-tilt motor and pan-tilt

ActiveCN104756373AShooting stabilityEnsure consistencyAircraft componentsMechanical energy handlingEngineeringMotor shaft

The invention discloses a pan-tilt motor (10), comprising a rotor component (11), a motor shaft (12) and a stator component (13). The motor shaft (12) comprises a shaft body (122), a first end (124) and a second end (126). The first end (124) if fixedly connected to the rotor component (11). The stator component (13) sleeves the periphery of the shaft body (122) and is connected to the motor shaft (12) in a rotating manner through a pair of bearings (15). The pair of bearings (15) are disposed near the first end (124) and the second end (126). The pan-tilt motor (10) also comprises a compressing piece (16) and an elastic body (18). The compressing piece (16) matches with the second end (126), and thereby the stator component (13) is positioned at the motor shaft (12) in an axial direction. The elastic piece (18) and a bearing pad (152) are both disposed between the compressing piece (16) and the bearing (15) adjacent to the second end (126). The bearing pad (152) clings to the bearing (15). The elastic piece (18) is disposed between the bearing pad (152) and the compressing piece (16). The elastic body (18) is elastically deformed through the compressing piece (16), and thereby the axial pretightening force of the pan-tilt motor (10) can be ensured.

Owner:SZ DJI OSMO TECH CO LTD

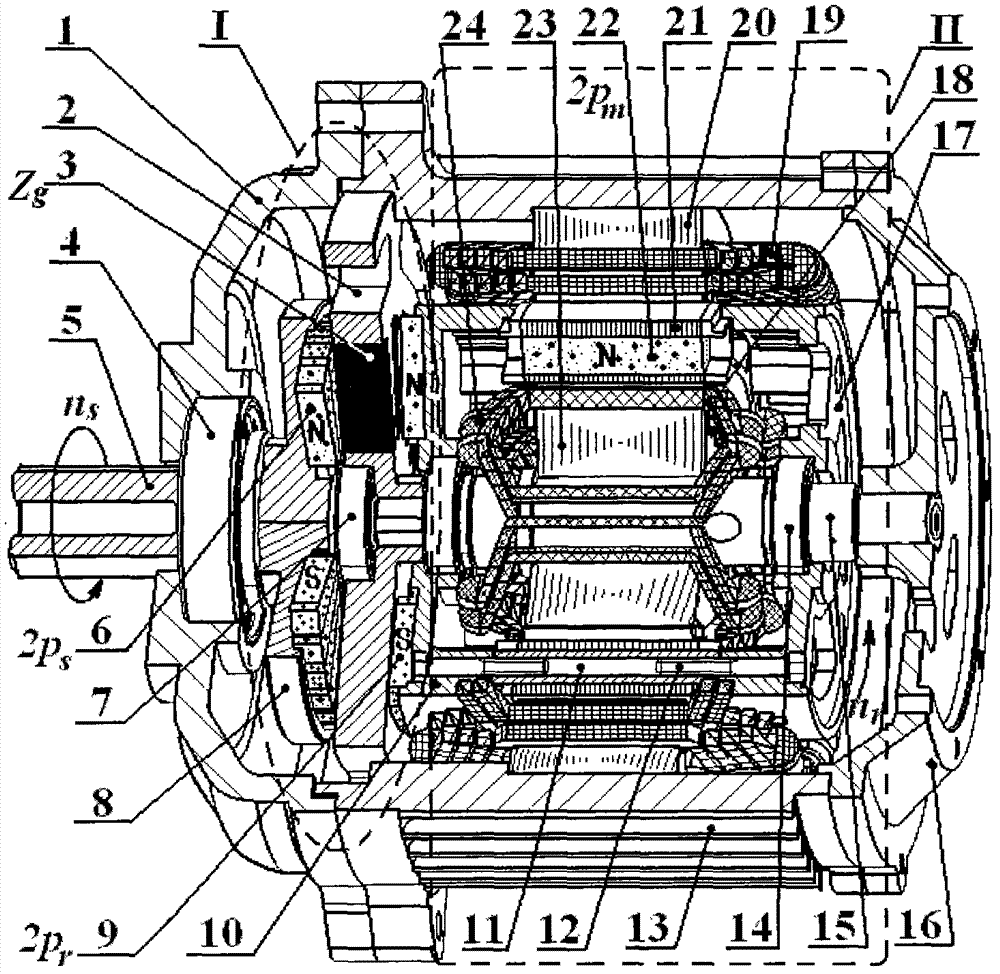

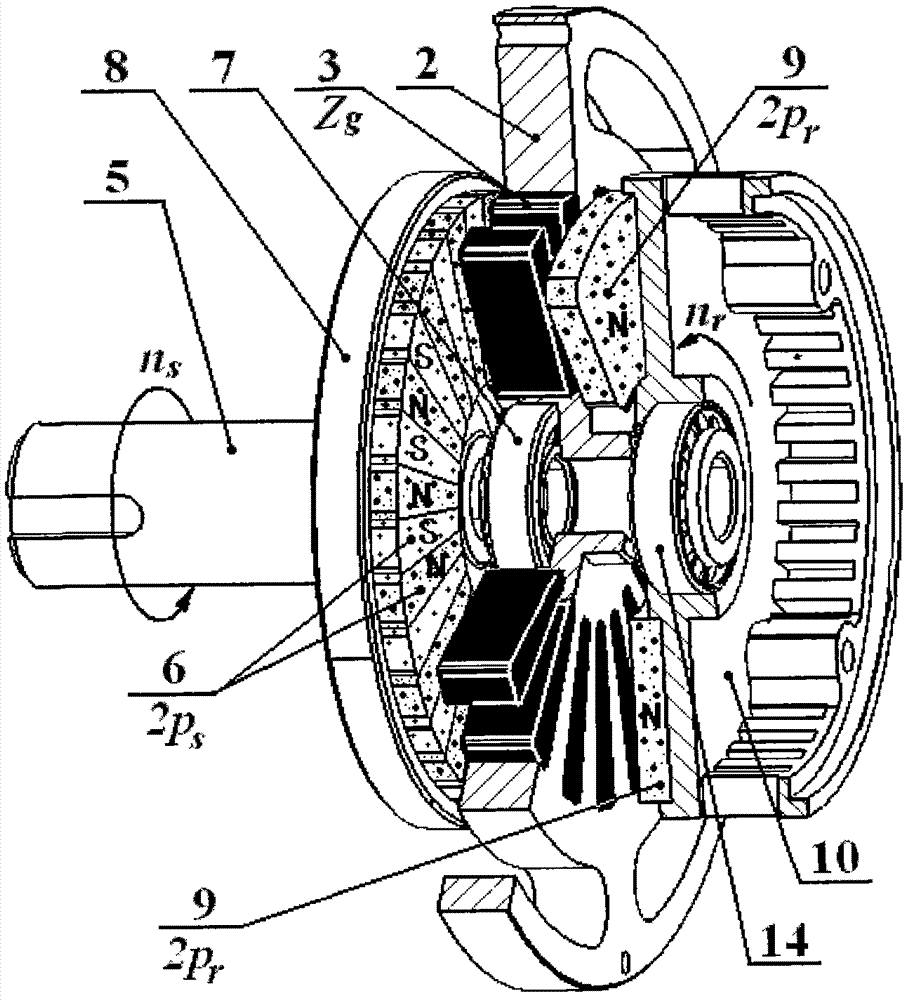

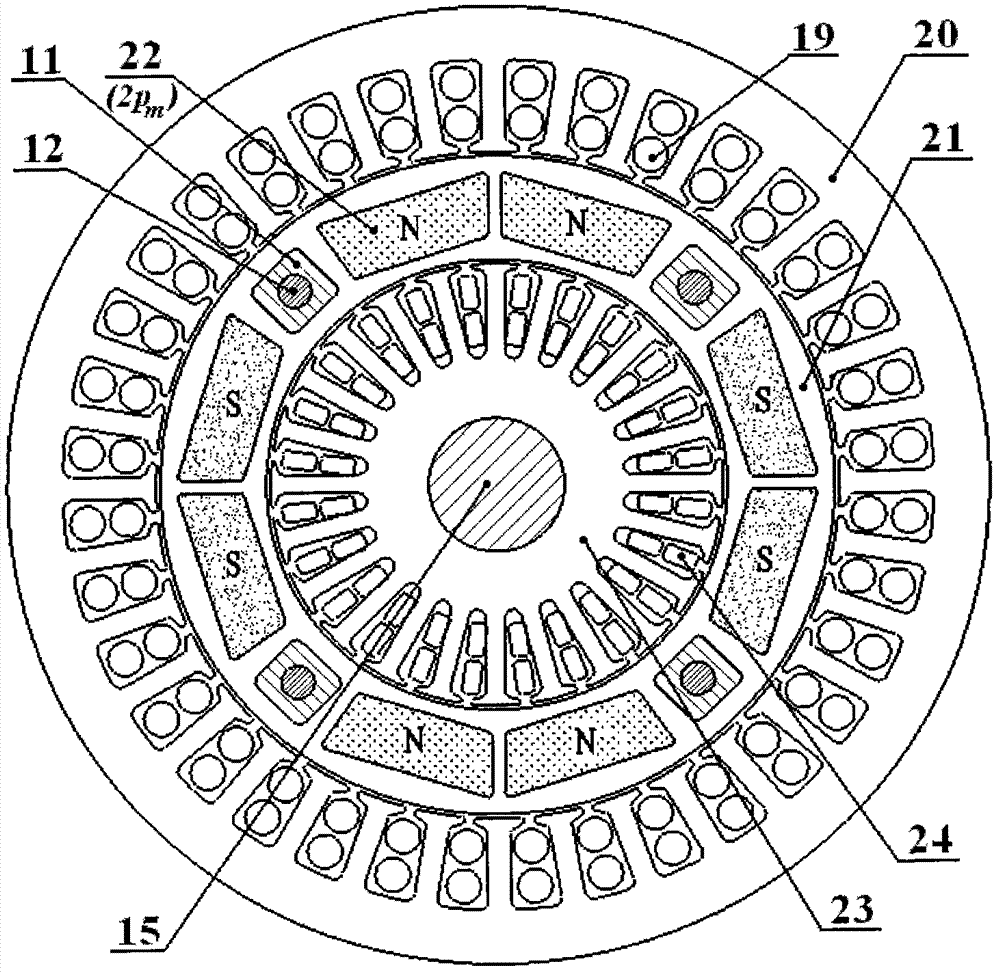

Direct-drive composite permanent magnet motor with magnetic transmission and dual-stator structure

InactiveCN102957260ATo achieve technical and economic effectSimple structureElectric machinesDynamo-electric gearsLow speedTransmission technology

Owner:余虹锦

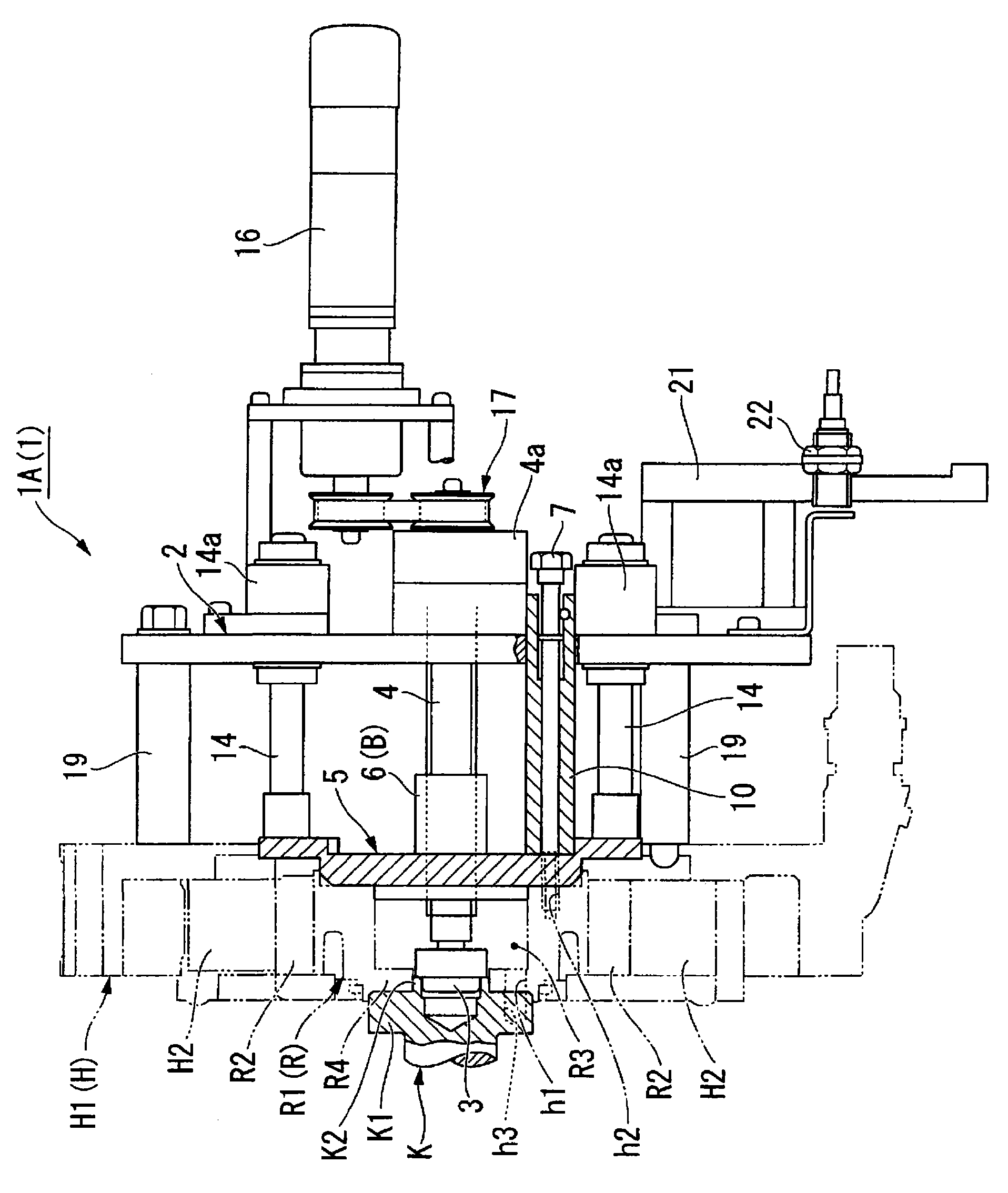

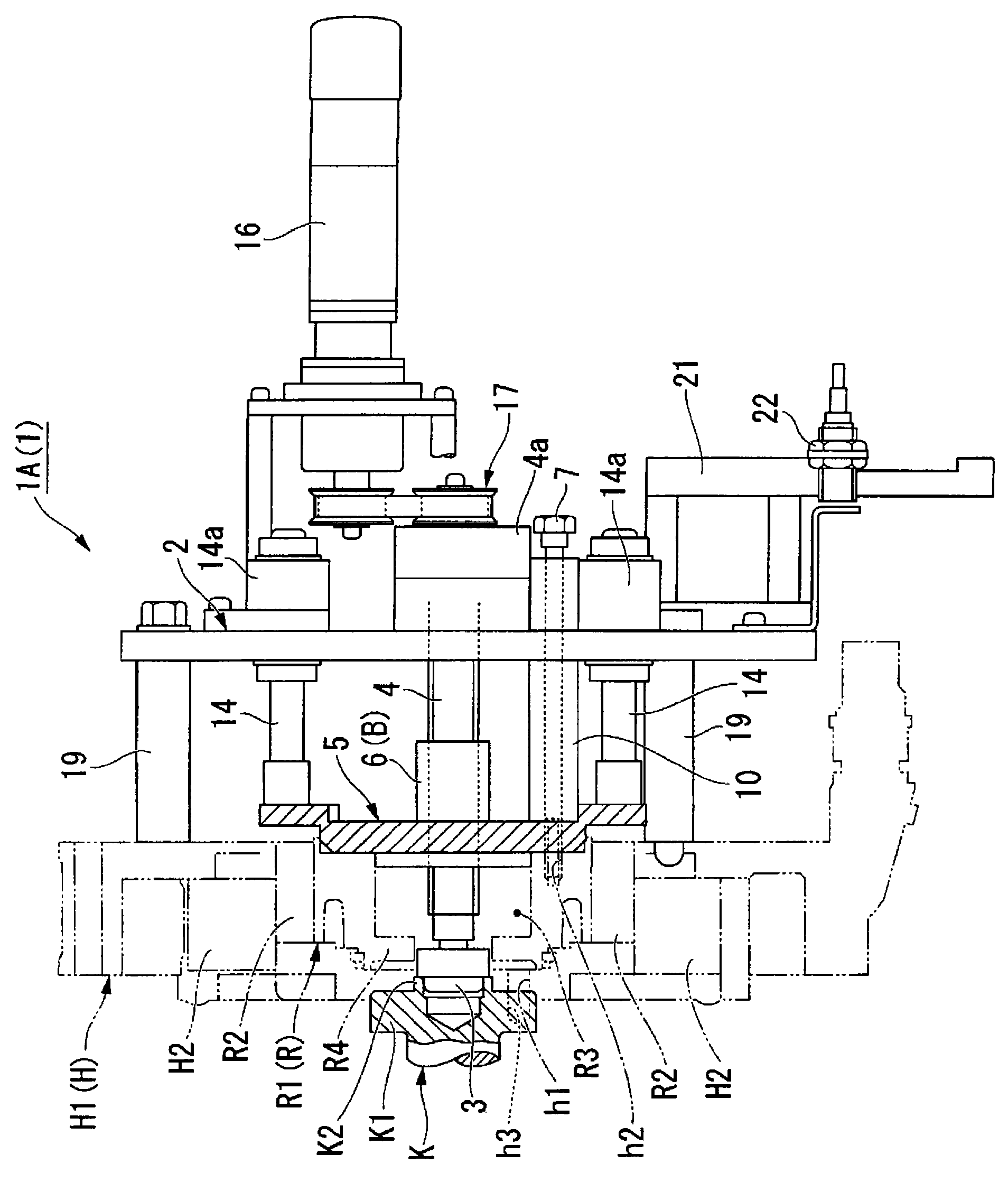

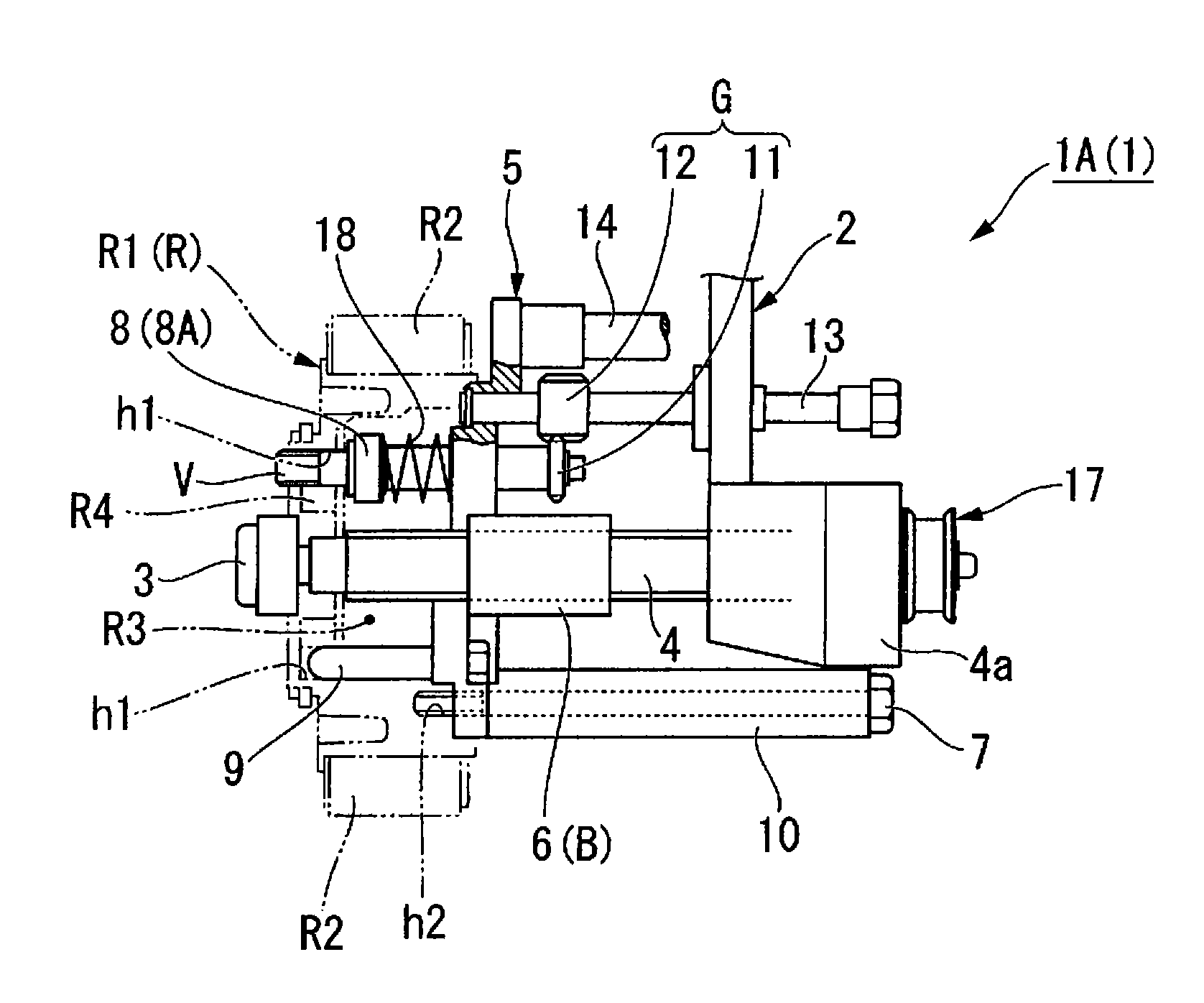

Machine tool and machine tool unit

ActiveUS20170326697A1No errors or impairmentsEasy to operateElectric/magnetic position measurementsMeasurement/indication equipmentsElectric power transmissionMotor drive

A motor-driven machine tool unit having a stator unit and at least one rotor unit having a rotor shaft that is rotatable about an axis of rotation. The rotor unit includes at least one first bearing unit arranged in the end region of a tool and / or workpiece receptacle, and a second bearing unit arranged at the opposite end region for mounting the rotor shaft in the stator unit. At least one electrical power transmission unit for transmitting electrical power between the stator unit and the rotor unit is provided. The problem addressed by the invention is that of better satisfying the increasing demands on modern machine tools or machine tool units. This problem is solved by the electrical power transmission unit is arranged in the end region opposite the tool and / or workpiece holder and / or on the second bearing unit.

Owner:FRANZ KESSLER GMBH

Vibration motor and oilless bearing

InactiveUS20070273224A1Improve propertiesReduce mechanical noiseManufacturing dynamo-electric machinesMechanical vibrations separationMotor vibrationElectric machinery

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Rotor mounting device and rotor mounting method

InactiveCN101689792AManufacturing stator/rotor bodiesMechanical energy handlingCrankshaftDrive shaft

Owner:HONDA MOTOR CO LTD

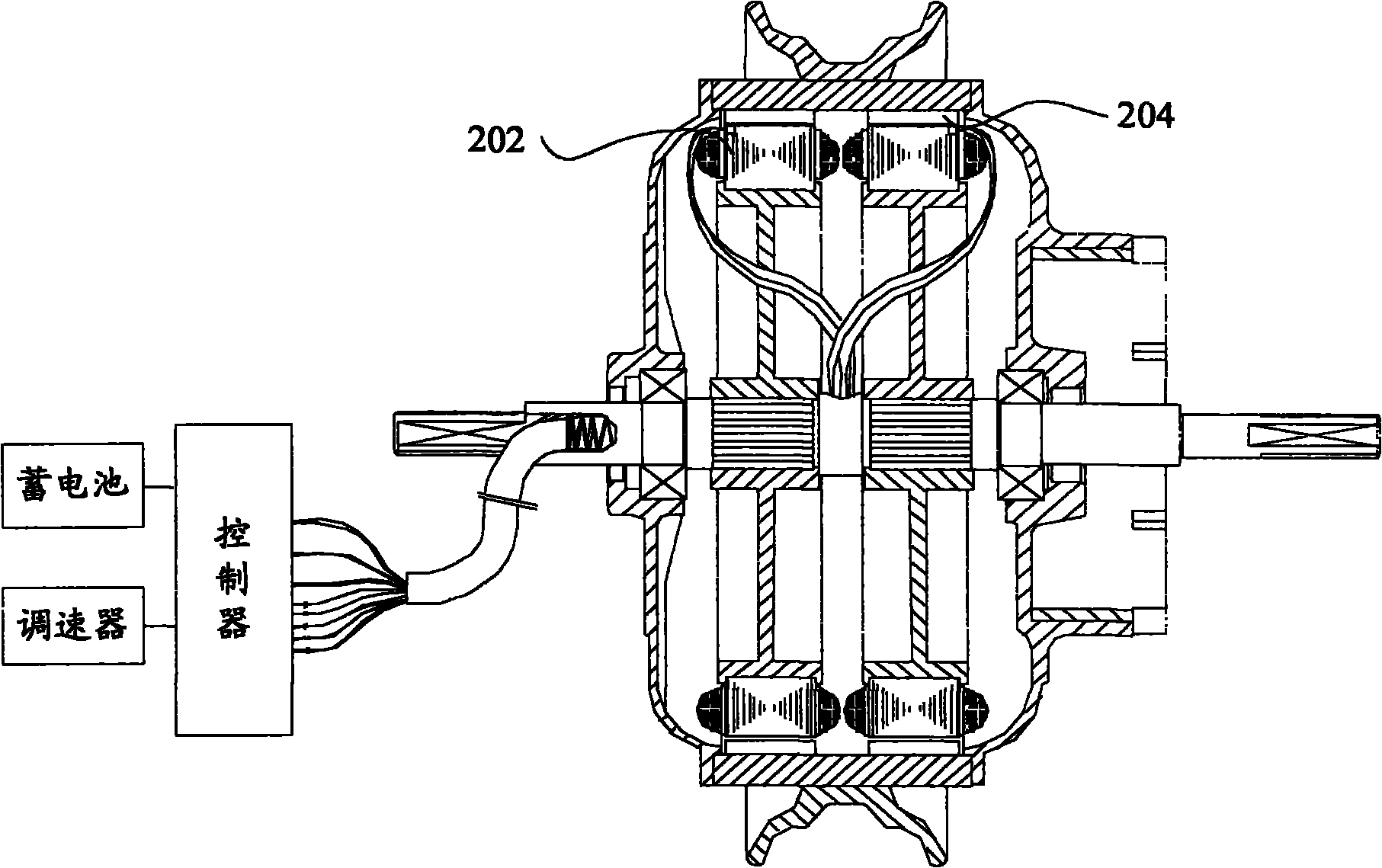

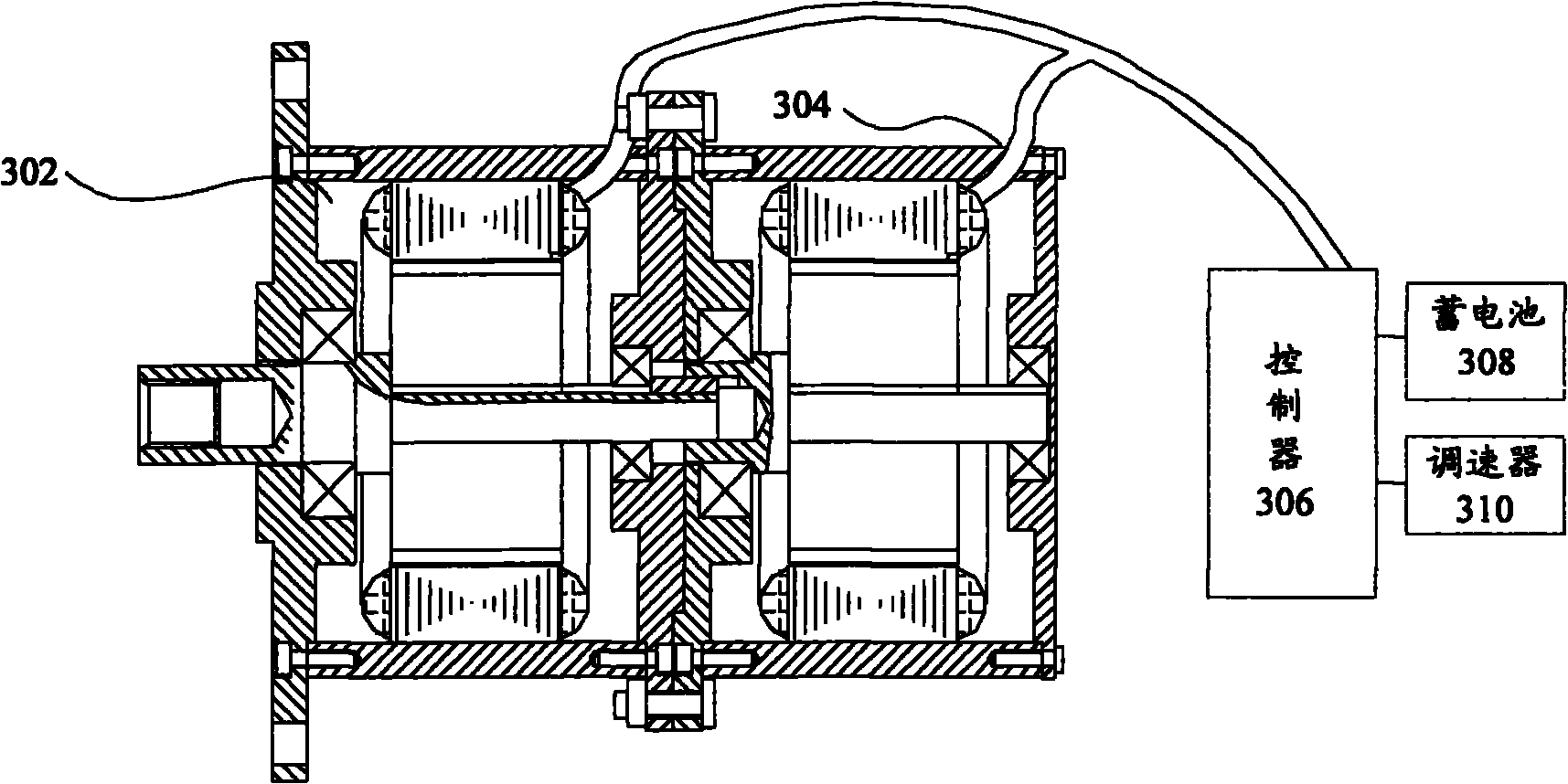

Electromagnetic force engine

InactiveCN105186821ALower friction temperatureExtended service lifeMechanical energy handlingCooling/ventillation arrangementDrive motorControl switch

The invention discloses an electromagnetic force engine. The engine comprises a magnetic force driving device and a control box. A control circuit and a storage battery are arranged in the control box. The magnetic force driving device comprises a plurality of electromagnetic iron core driving pistons which are arranged side by side. Output shafts of the plurality of electromagnetic iron core driving pistons are connected to one output crankshaft respectively. The control circuit makes the magnetic force driving device generate an electromagnetic driving force so as to drive the output crankshaft to output power. One end of the output crankshaft is provided with a heat dissipation fan used for heat dissipation. A connection shaft of the output crankshaft and the heat dissipation fan is provided with a driven belt pulley. The driven belt pulley is connected to an active belt pulley through a belt. The active belt pulley is installed on an output shaft of an electric generator. The other end of the output crankshaft is provided with a driving motor. The driving motor drives the output crankshaft to rotate. An output power supply of the electric generator is connected to the storage battery. One side of the magnetic force driving device is provided with a power output shaft. By using the engine of the invention, through a control switch on the control box, on-key starting control is realized; electricity generation power can be rapidly provided; a usage scope is wide and a service life is long; and control is convenient and sensitive.

Owner:戢平

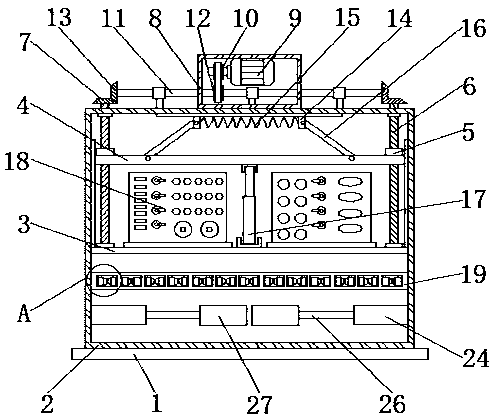

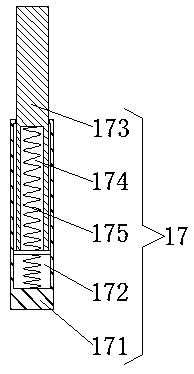

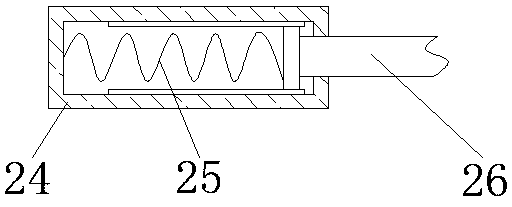

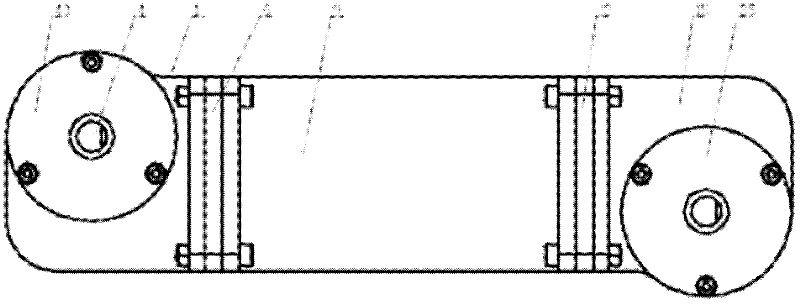

Switchgear with adjustable internal space

InactiveCN108199269AMeet the needs of separate placementEasy to useBus-bar/wiring layoutsMechanical energy handlingEngineeringSwitchgear

Owner:HANGZHOU QICHENG TECH CO LTD

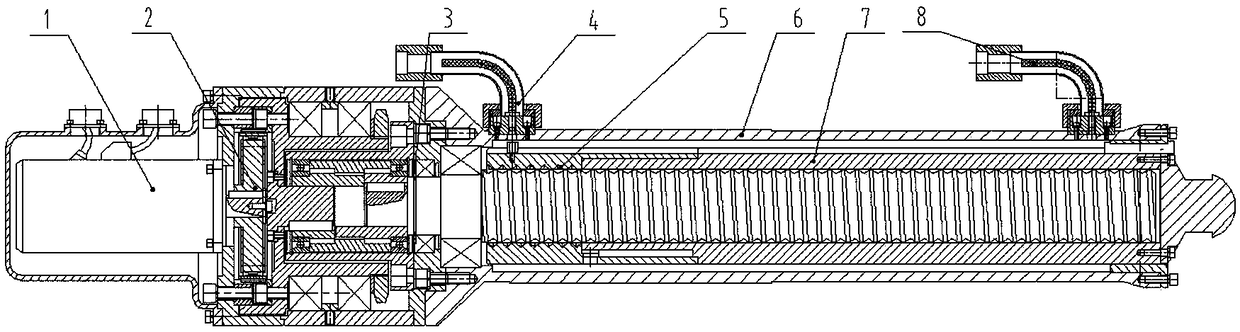

Secondary oscillating joint structure of underwater electric manipulator

InactiveCN102229145ALarge transmission ratioPlay a role in boostingJointsMechanical energy handlingStructure of the EarthElectric machine

Owner:HARBIN ENG UNIV

Motor device

ActiveCN101917086AReduce manufacturing costBatteries circuit arrangementsMultiple motor speed/torque controlControl theoryEffective energy

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE

Supporting leg control device

Owner:WUHAN BINHU ELECTRONICS

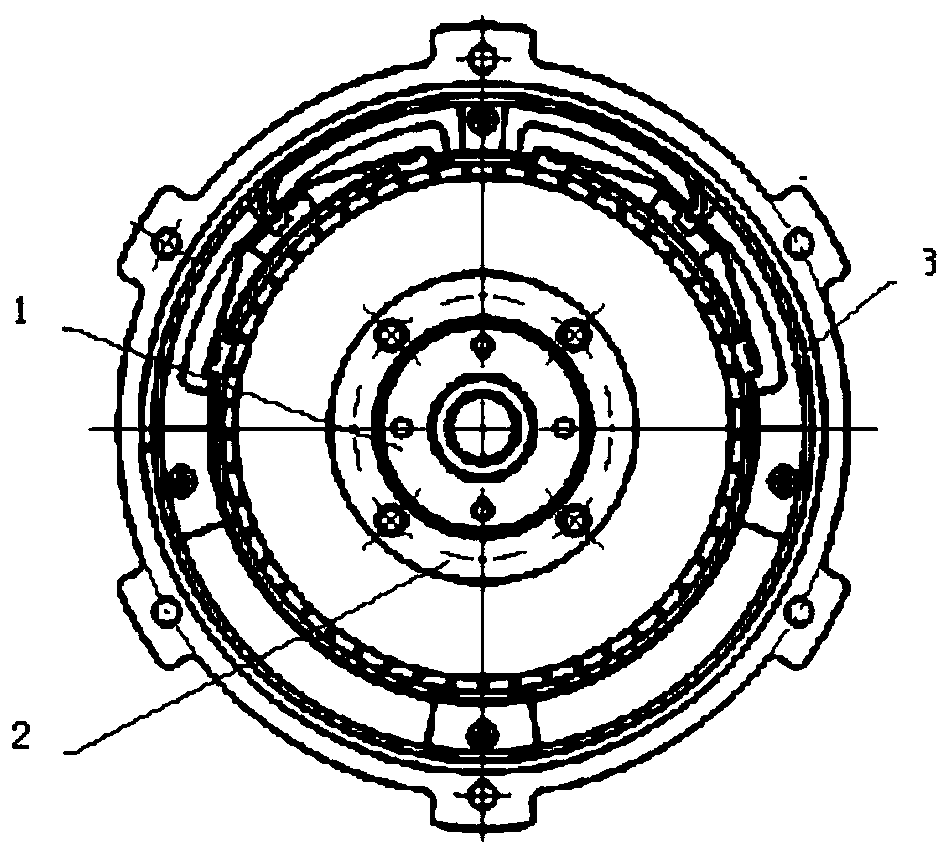

Bearing preload adjusting and locking structure for a small and special electrical machine and implementation method

ActiveCN110867984ARealize imposingRealize mass productionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMachine

Owner:TIANJIN NAVIGATION INSTR RES INST

Oil pollution prevention motor

Owner:杨庆华

Linear vibration actuator

PendingCN110266172AIncrease in sizeGood touchSpringsCurrent supply arrangementsActuatorLinear vibration

Owner:天津富禄通信技术有限公司

Rotor assembly for motor

A rotor assembly for a motor includes a rotor shaft having a journal portion formed in an axial direction and having a predetermined radius about an axis, and a center shaft portion extending along the axial direction from the journal portion and having a radius smaller than a radius of the journal portion about the axis; a cylindrical, integral permanent magnet inserted into the center shaft portion to surround an outer circumferential surface of the center shaft portion and being supported by the journal portion; and a sleeve inserted into the rotor shaft to surround an outer circumferential surface of the journal portion and an outer circumferential surface of the integral permanent magnet, supporting the integral permanent magnet in the axial direction, and supporting the outer circumferential surface of the center shaft portion in the radial direction.

Owner:HYUNDAI MOTOR CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap