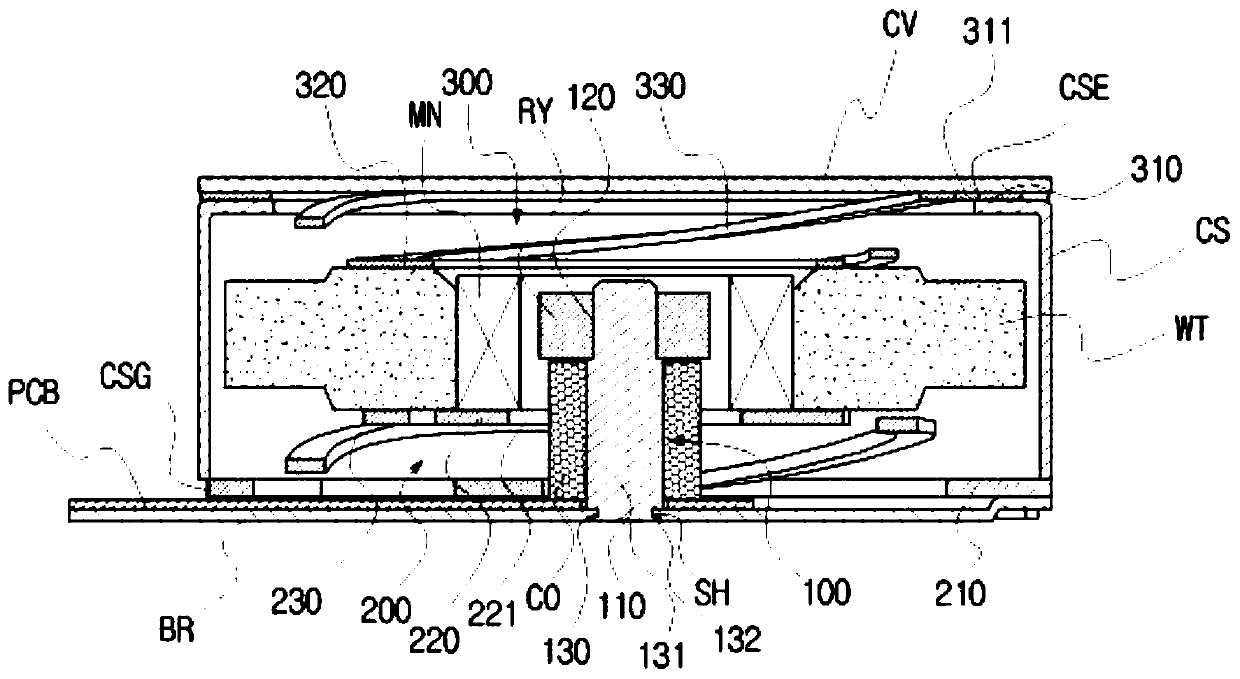

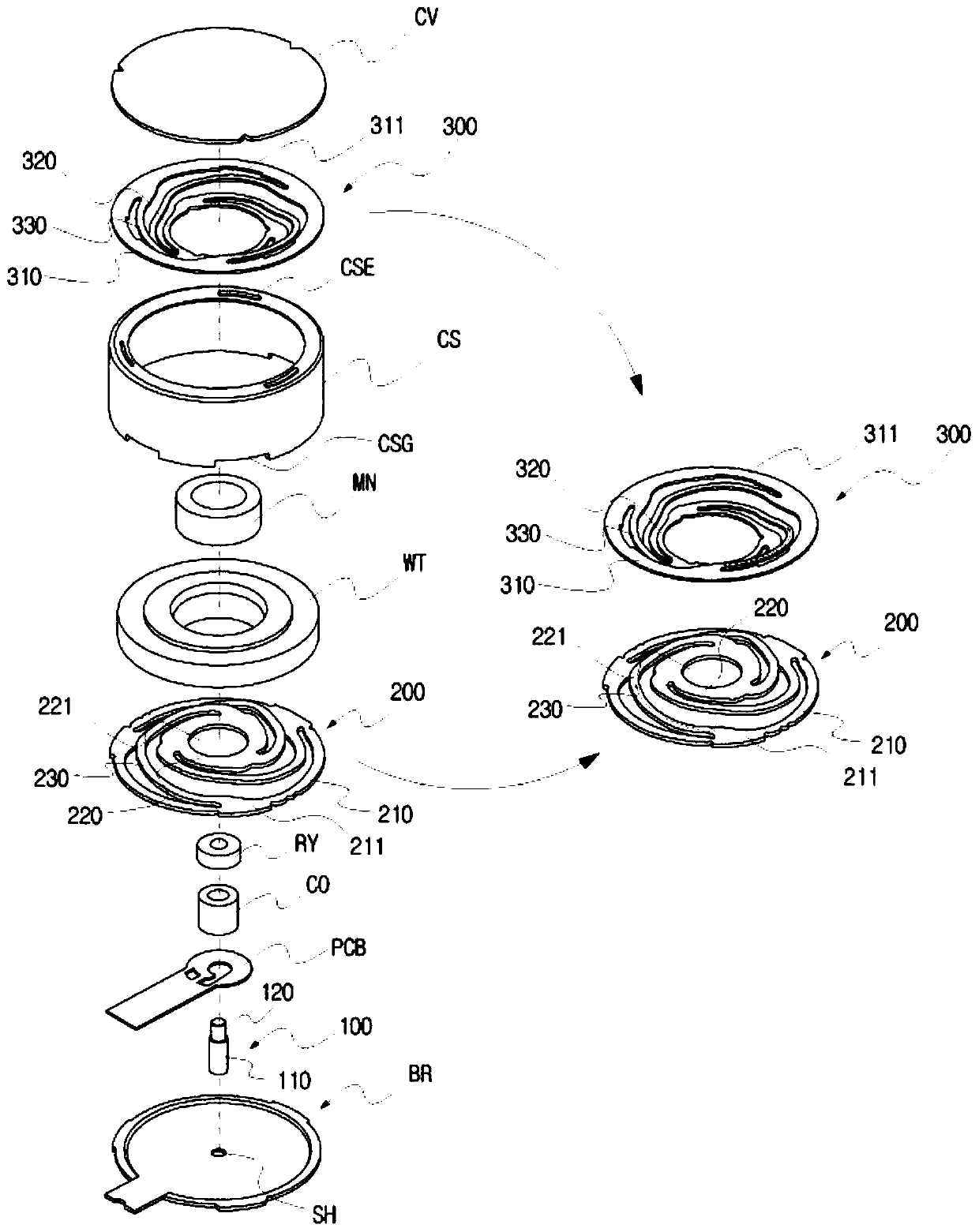

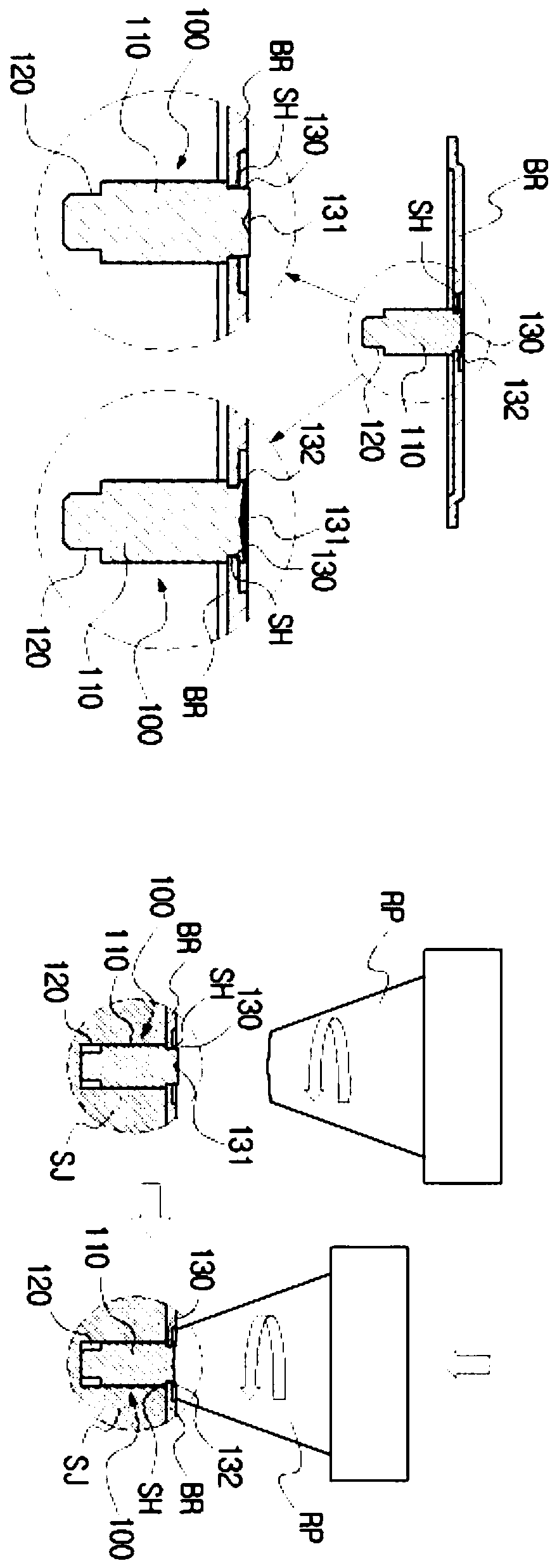

Linear vibration actuator

A linear vibration and actuator technology, used in electric components, telephone communication, control of mechanical energy, etc., can solve problems such as inability to guarantee life, high vibration difficulties, etc., to prevent partial vibration, improve touch feeling, and drive noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the present invention can be modified variously, and can have various embodiments. Hereinafter, specific embodiments are shown in the drawings and described in detail. However, the present invention is not limited to these specific embodiments, and includes all modifications, equivalents, and replacements included in the spirit and technical scope of the present invention.

[0035] These examples are provided for the purpose of explaining in more detail to those skilled in the art. Therefore, in order to clearly illustrate and emphasize, the form of each component shown in the drawings will be enlarged. When describing the present invention, if it is considered that the specific description of the related known technology will confuse the gist of the present invention, it will be omitted. description of it.

[0036] Terms such as first and second can be used when describing various constituent elements, and the constituent elements should not be limited

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap