Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "DC motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A DC motor is any of a class of rotary electrical machines that converts direct current electrical energy into mechanical energy. The most common types rely on the forces produced by magnetic fields. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current flow in part of the motor.

Motor control device

InactiveCN101604945AHigh precisionCheap and simpleSingle motor speed/torque controlCurrent controllersElectrical resistance and conductanceEngineering

The present invention provides a motor control device, which realizes desired high-accuracy advanced angle control of brush-less DC motor with simple and low-cost structure. In the motor control device, a phase adjusting circuit is provided, which is composed of a combined circuit of resistances (R1-5) and diodes (D1-4), and processes the speed instruction into voltage similar to fold lien of optimum phase angle control characteristic corresponding to speed of the brush-less DC motor to form phase angle signal, and by adjusting the combination of resistances (R1-5) and diodes (D1-4), the speed instruction is processed into voltage similar to fold lien of optimum phase angle control characteristic corresponding to speed of the brush-less DC motor to form phase angle signal of the voltage corresponding to the optimum phase angle control characteristic, and execute high-accuracy advanced angle control for phase of power supply of the brush-less DC motor according to the phase angle signal.

Owner:NIDEC SHIBAURA CORP

Hybrid motor for transportation

A hybrid electric / piston driven motor may use a low voltage, high torque direct current (DC) motor to drive a vehicle, such as a motorcycle. The DC motor may be powered by a battery that may be charged by an alternator / DC generator. The alternator / DC generator may be driven by the movement of the vehicle. The motor may include springs that receive the kinetic energy of the pistons of the motor as the pistons rise in their upstroke. The springs may convert this upstroke kinetic energy to downstroke kinetic energy, minimizing the power needed from the battery.

Owner:STOVER BOBBY A

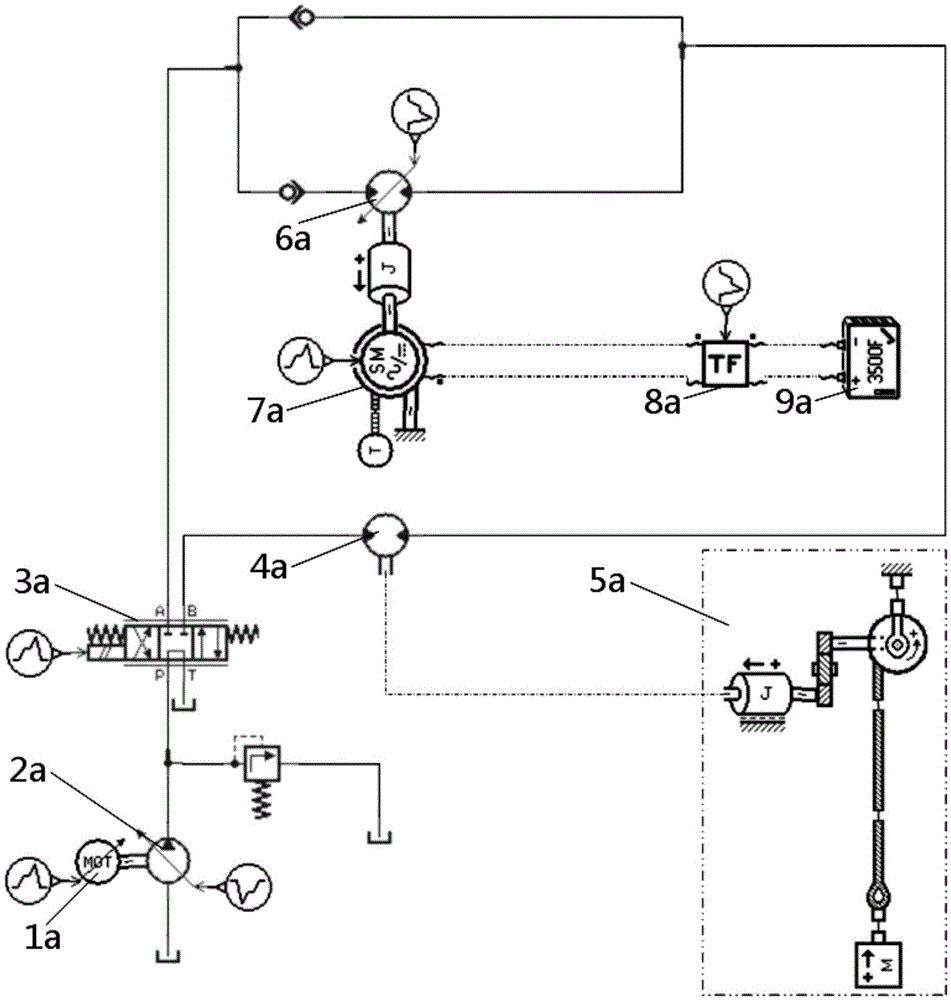

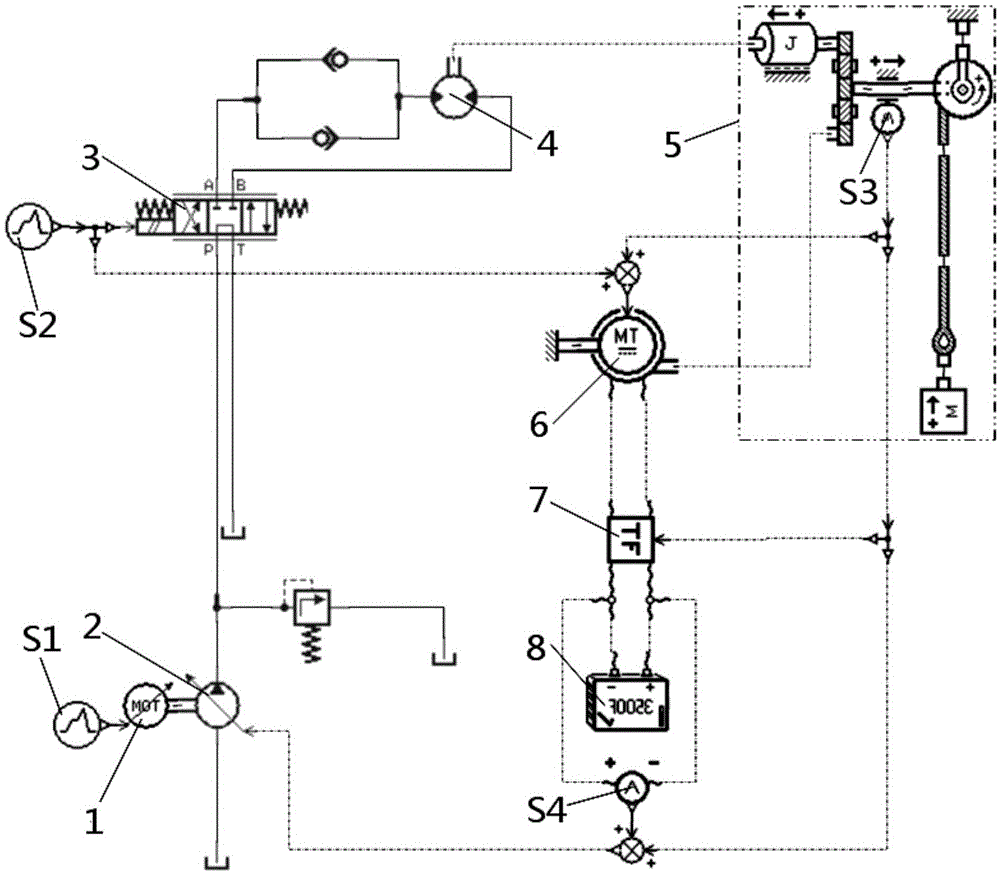

Potential energy recovery utilization system, control method and engineering machinery equipment

ActiveCN106560439AAchieve recyclingSimple structureMachines/enginesWinding mechanismsStored energyElectricity

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

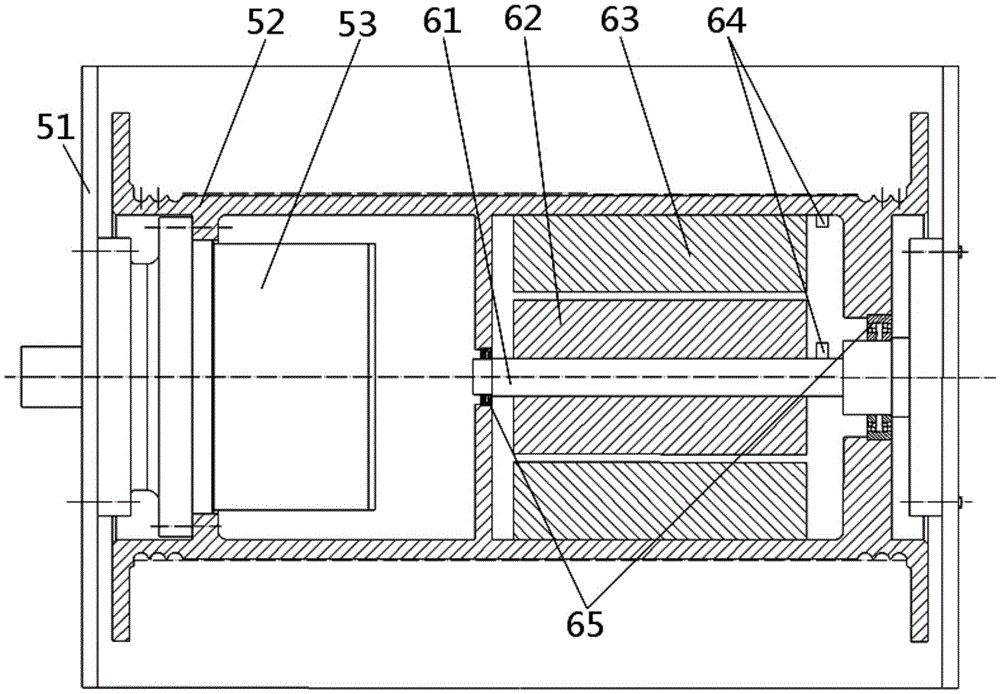

Stator core for an electronically commutated direct-current motor and method for producing a stator

InactiveCN105393434ASignificant mechanical damageReduce bending forceMagnetic circuit stationary partsManufacturing dynamo-electric machinesCurrent meterEngineering

The invention relates to a stator core (1) for an electronically commutated DC motor comprising an internal rotor, having several radially inwardly directed pole cores (2), which at their periphery are integral with back iron segments (3), and the back iron segments (3) are integral with adjacent back iron segments (3) via webs (4), wherein the back iron segments (3) alternate with the webs (4), and jointly form a seamlessly closed one-piece ring. The problem addressed by the invention is that of ensuring that in case of a stator core of this class, upon a reduction of the stator diameter and reduction of the pole distances after a winding, a clearly defined end position of the adjoining regions can be assumed, and that for this process step, only minimal forces are necessary, in which damage to the stator core is not to be expected, and that at the end of the process only a very small and uniform air gap remains at a lowest possible spring-back. This problem is solved by means of the characteristic of claim 1 and the method steps of claim 7.

Owner:BUHLER MOTOR GMBH

Vehicle-mounted monitor driving device

ActiveCN103085728AImprove noiseIncrease jitterNon-rotating vibration suppressionVehicle componentsElectric machineEngineering

The invention provides a vehicle-mounted monitor driving device. The vehicle-mounted monitor driving device comprises a direct current (DC) motor mechanically combined with a monitor, a transmission module, a spring assisting driving force of the DC motor and a shock absorber for reducing elasticity and bounce of the spring, wherein the transmission module is mechanically combined on the monitor together with the DC motor and used for converting rotating force of the DC motor into vertical motion force.

Owner:HYUNDAI MOBIS CO LTD

Intelligent control system for circuit breaker

PendingCN108063457ASolve the disadvantage of prone to island effectImprove stabilityPower network operation systems integrationSingle network parallel feeding arrangementsTime delaysSwitching power

The invention provides an intelligent control system for a circuit breaker. The intelligent control system comprises the components of a CPU control circuit; a grid voltage sampling circuit which is electrically connected with a grid power supply and is electrically connected with the CPU control circuit; a circuit breaker position sampling circuit which is electrically connected with the CPU control circuit; a motor driving circuit which is electrically connected with the CPU control circuit; a DC motor which is electrically connected with the motor driving circuit and is connected with the circuit breaker; and a switch power supply circuit which is electrically connected with the CPU control circuit, the circuit breaker position sampling circuit, the motor driving circuit and the DC motor. According to the intelligent control system, when power failure, voltage loss or over-voltage of a commercial power grid is detected and after time delaying by a certain period is performed, connection between the commercial power and a load is automatically switched off so that a distributed grid-connected power generating system is separated from the commercial power grid. When the voltage ofthe commercial power grid is normal, the commercial power grid is connected with the load, and furthermore the distributed grid-connected power generating system is connected with the power grid. Theintelligent control system settles a defect of easy islanding effect in the power grid when the distributed grid-connected power generating system is connected with the commercial power, thereby improving stability and safety in operation of the power grid.

Owner:SUZHOU FUTURE ELECTRICAL APP

Symmetric drive method for DC motor in elevator door motor system

The invention discloses a symmetric drive method for a DC motor in an elevator door motor system. An elevator continues to supply power to the DC motor after a door is opened or closed, gate signals of a switching component on an H bridge are converted to symmetric pulse signals with the duty ratio being 50%, and a rotation shaft of the motor is in a static state. Under the state, the torque direction of the rotation shaft of the DC motor is frequently and regularly switched between the forward direction and the backward direction, the motor is in the stalled state, and the stalled state can not be easily changed through external force. Due to the fact that when an elevator landing door is in an opened state and a closed state, the state of the landing door can not be changed by external force manually, the symmetric drive method meets the above requirements, and the reliability of the elevator landing door can be better guaranteed. When the motor is in the stalled state, only the inside resistance of the motor consumes energy, the energy loss is greatly reduced, the motor also has certain moment, and therefore the energy conservation performance of the elevator door motor system is improved.

Owner:CHANGZHOU UNIV

A low-speed delay on-time set method for a brushless DC motor

InactiveCN108988704AWeaken low-speed commutation torque rippleTorque ripple controlElectronic commutatorsLow speedSteady state

The invention discloses a low-speed delay on-time setting method for a brushless DC motor. The setting method includes setting that initial value of start-up phase delay opening time to 0 after brushless DC motor enter low-speed steady-state working state, ; in each subsequent commutation cycle, the on-phase delay on-time is incremented by one microsecond; Recording the rotational speed Sa of thebrushless DC motor before commutation of each commutation cycle; Brushless DC motor speed Sb in each commutation cycle is record; Subtracting the Sb from the Sa to obtain the rotational speed deviation Delta S of the brushless DC motor; The on-phase delay on-time corresponding to the minimum absolute value of Delta S / Sa is taken as the setting value of the low-speed delay on-time of the brushlessDC motor.

Owner:张懿

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap