Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Winding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A winding machine or winder is a machine for wrapping string, twine, cord, thread, yarn, rope, wire, ribbon, tape, etc. onto a spool, bobbin, reel, etc.

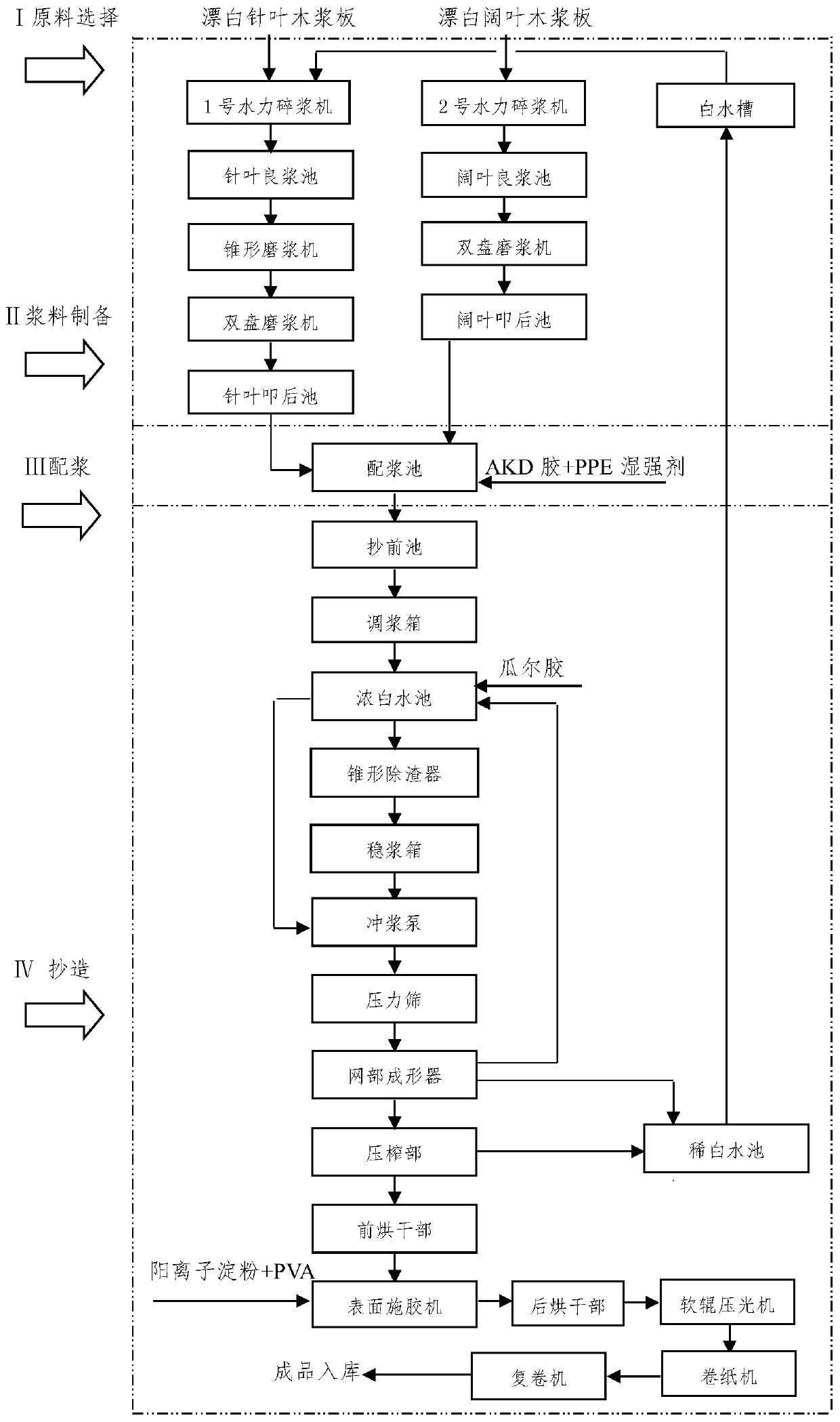

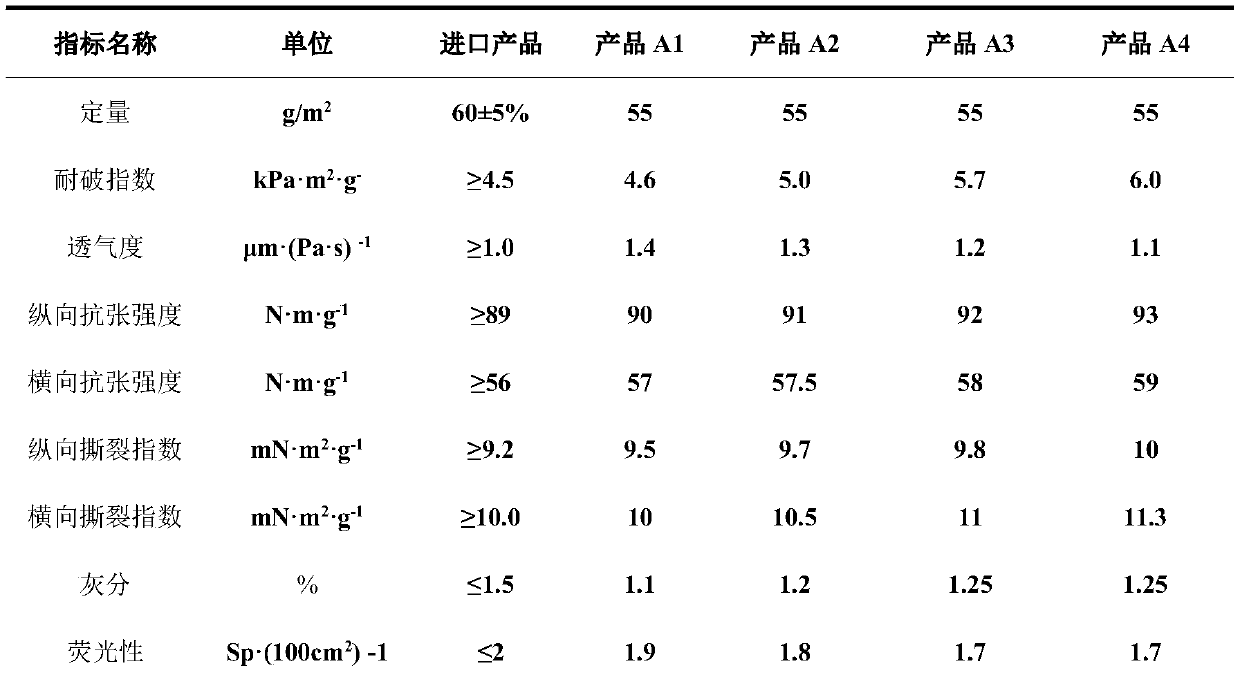

Medical dialysis body paper and production method thereof

InactiveCN109853297AHigh strengthImprove breathabilityWater-repelling agents additionSpecial paperWinding machinePulp and paper industry

Owner:NANJING FORESTRY UNIV

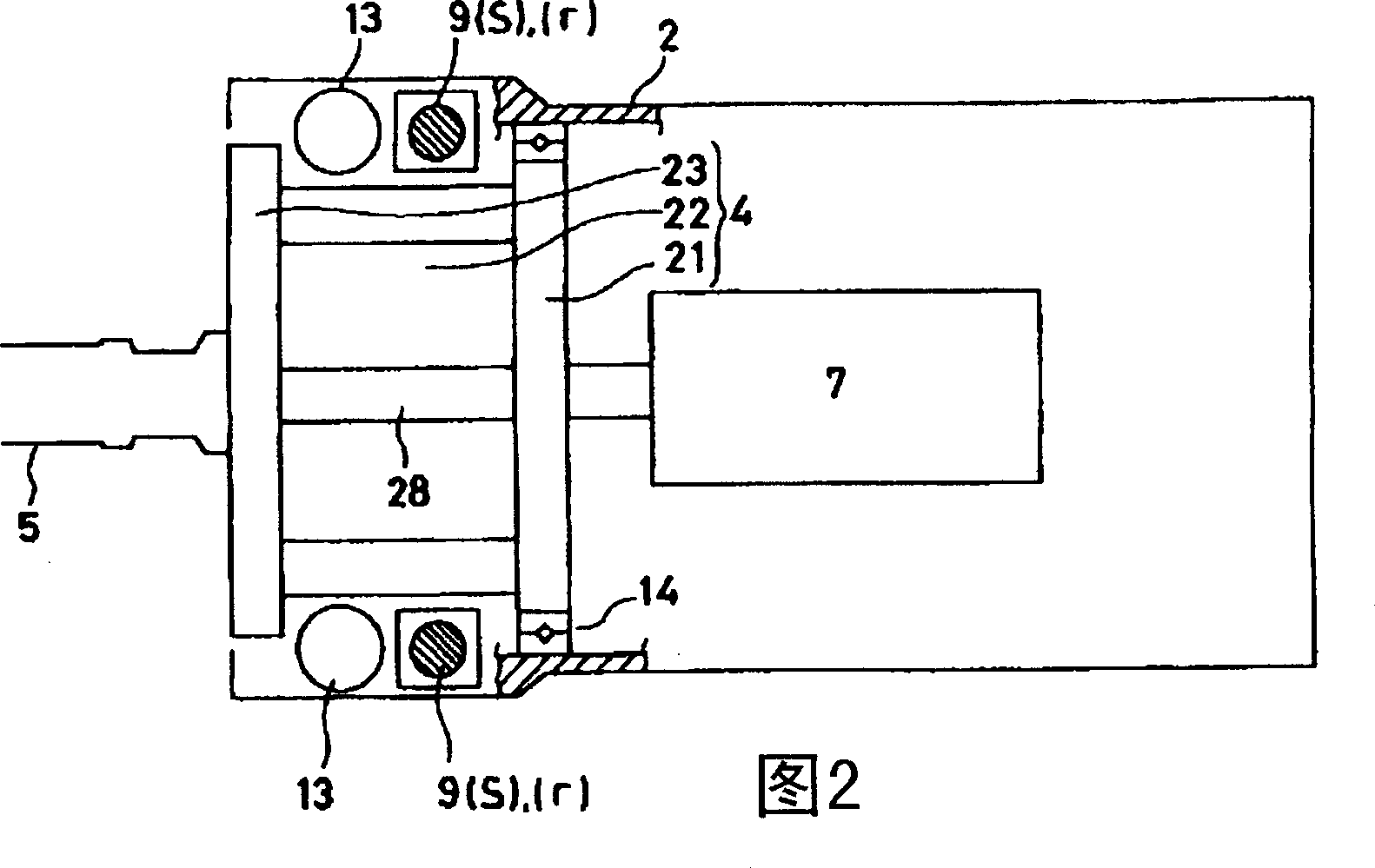

Yarn winding machine with yarn breakage auto-stop function

The invention discloses a yarn winding machine with a yarn breakage auto-stop function. The yarn winding machine comprises a bracket, a power device, a transmission device, yarn winding shafts and yarn reel loading parts, and further comprises yarn breakage auto-stop devices, wherein the power device, the transmission device, the yarn winding shafts and the yarn reel loading parts are mounted on the bracket; the yarn reel loading parts are used for loading of yarn reels; the power device is connected with and used for driving the transmission device; the transmission device is connected with and used for driving the yarn winding shafts; the yarn breakage auto-stop devices are arranged between the yarn winding shafts and the yarn reel loading parts, and comprise switches, detecting modules and processing modules; the detecting modules are electrically with the processing modules; the processing modules are electrically connected with the switches; the switches are connected in series with the power device; the detecting modules are used for detecting the status of yarns between the yarn winding shafts and the yarn reel loading parts, and feeding back signals; and the processing modules are used for controlling the on-off of the switches according to the signals. After a broken yarn is detected, the yarn winding machine disclosed by the invention is stopped in time, thereby preventing the continued running of the yarn winding machine and the waste of energy; and meanwhile, random yarn winding is avoided, the overall yarn quality is guaranteed, and the labor intensity of workers is reduced.

Owner:GUANGXI SISAL GRP SHANWEI SISAL PROD CO LTD

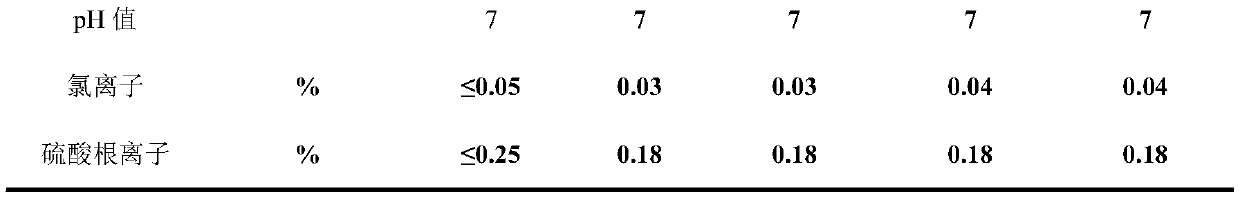

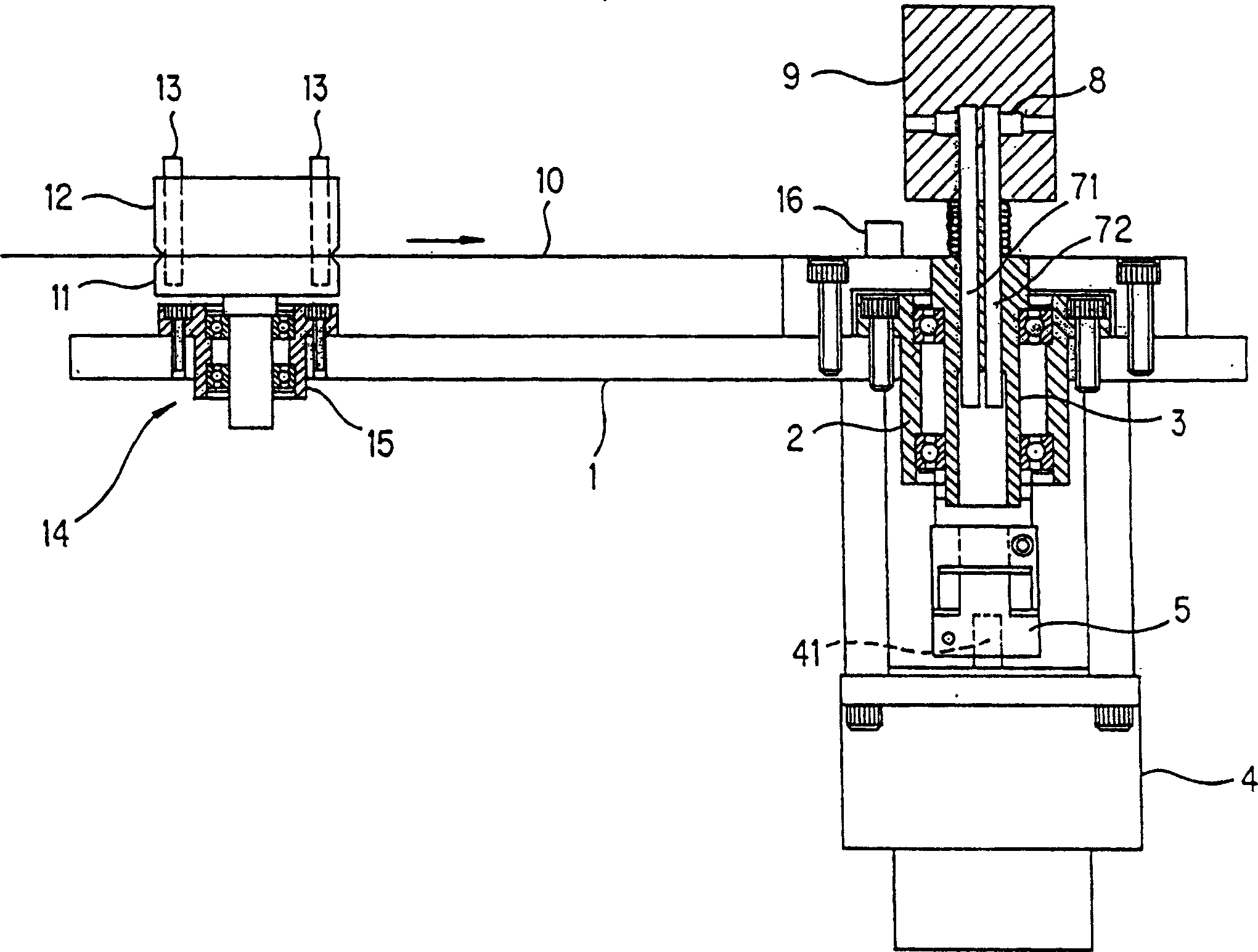

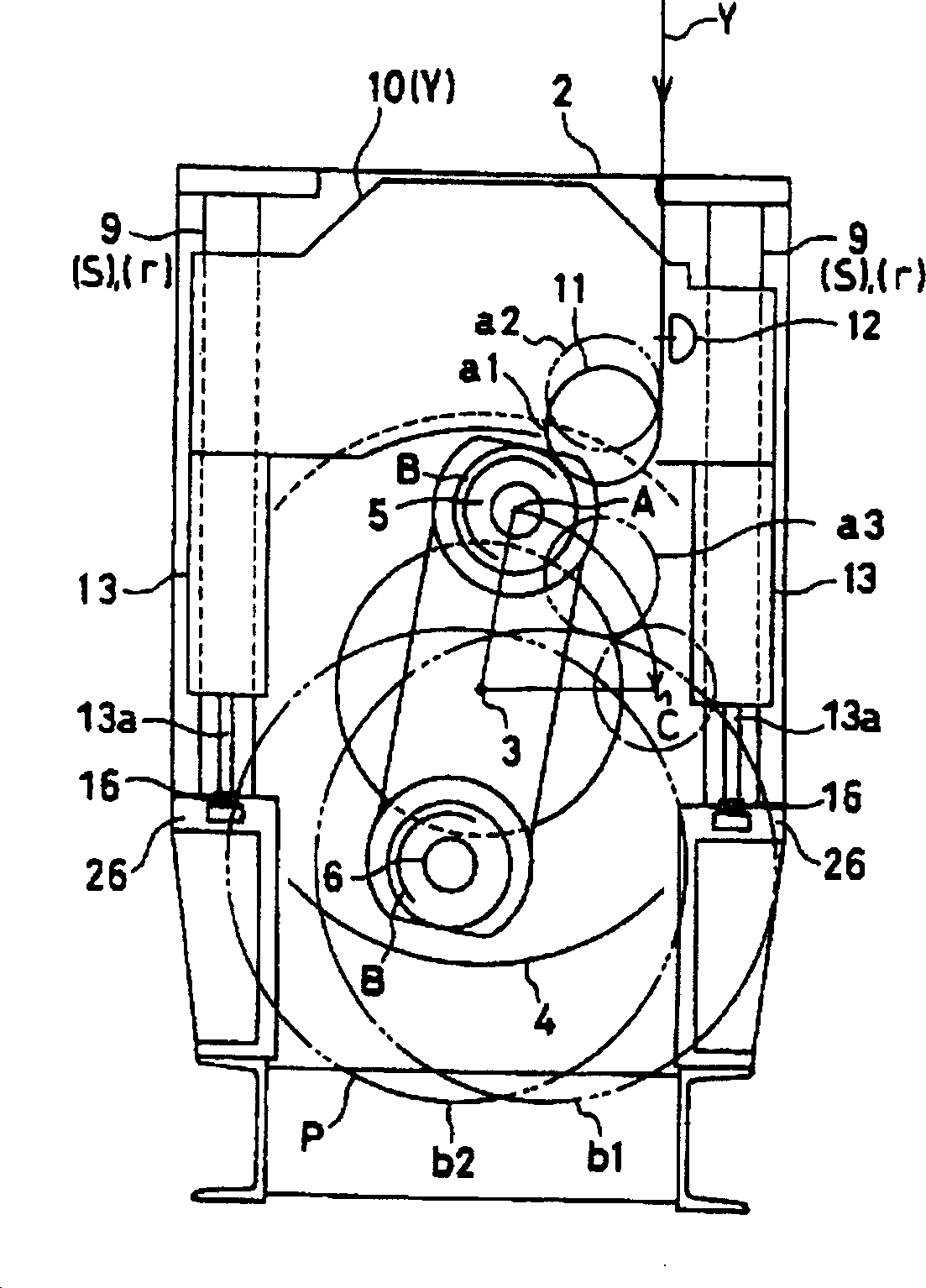

Edgewise coil winding machine

Owner:TOYO DENSO

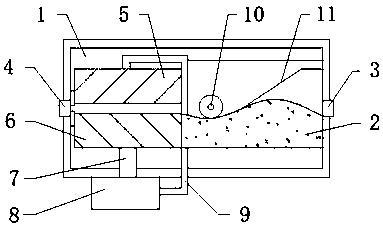

Building waste residue treatment device

InactiveCN111790477AAvoid damageImprove screening efficiencySievingScreeningWinding machineElectric machine

The invention discloses a building waste residue treatment device, and belongs to the technical field of building waste residue treatment tools. The building waste residue treatment device comprises ascreening device and a crushing device, wherein the screening device is arranged above the crushing device, the screening device is used for separating waste residues with different sizes, the crushing device is prevented from being damaged due to the fact that part of waste residues are too large in size and too hard, and the crushing device is used for crushing small waste residues; and the screening device comprises a screening shell, a screening net, a steel wire, a winding machine, a winding motor, a left side plate and a right side plate, after the screening net screens small waste residues in the waste residues, the winding machine is driven to rotate through work of the winding motor, the steel wire is lengthened, and the screening net is driven to turn over downwards, large wasteresidues left on the screening net are discharged, a part of overlarge and hard building waste residues are prevented from damaging the crushing device to a certain extent, and the service life of the crushing device is prolonged.

Owner:过蕊

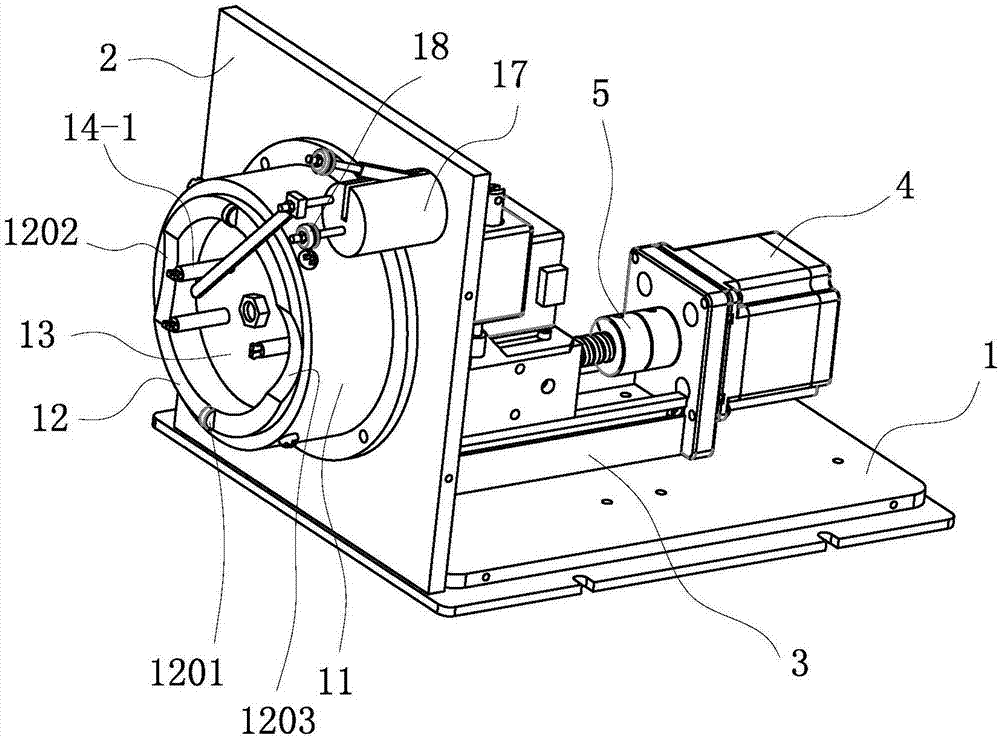

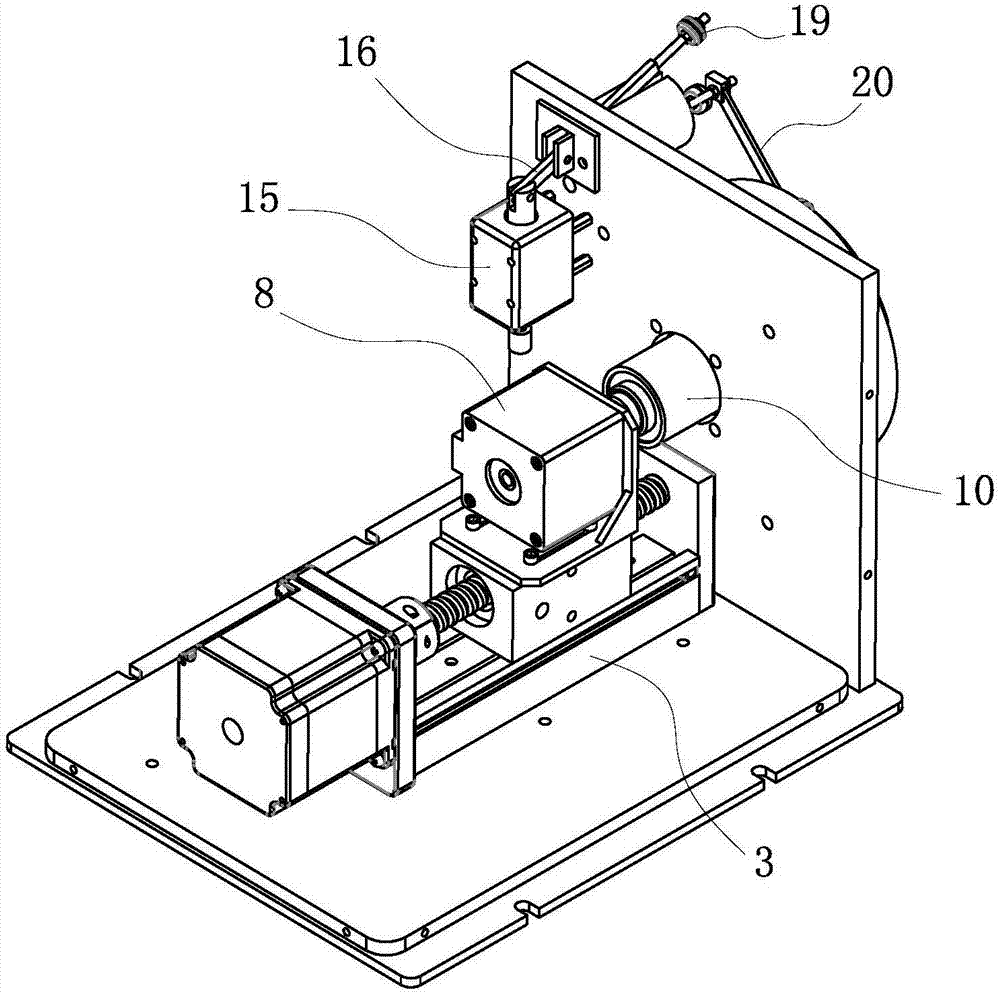

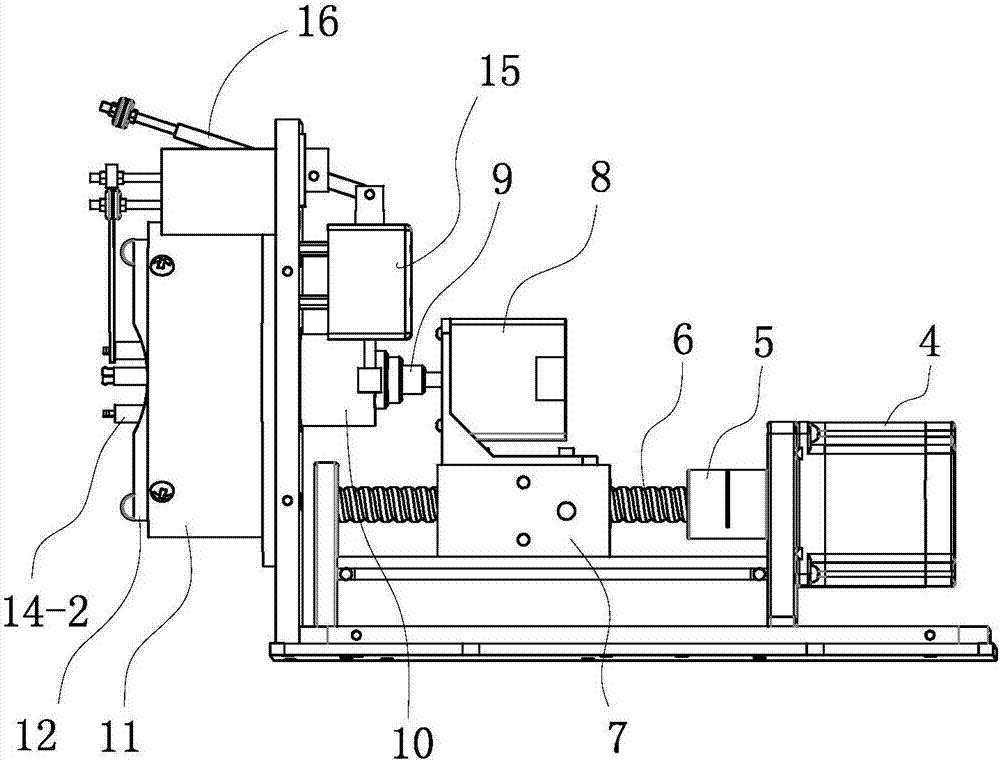

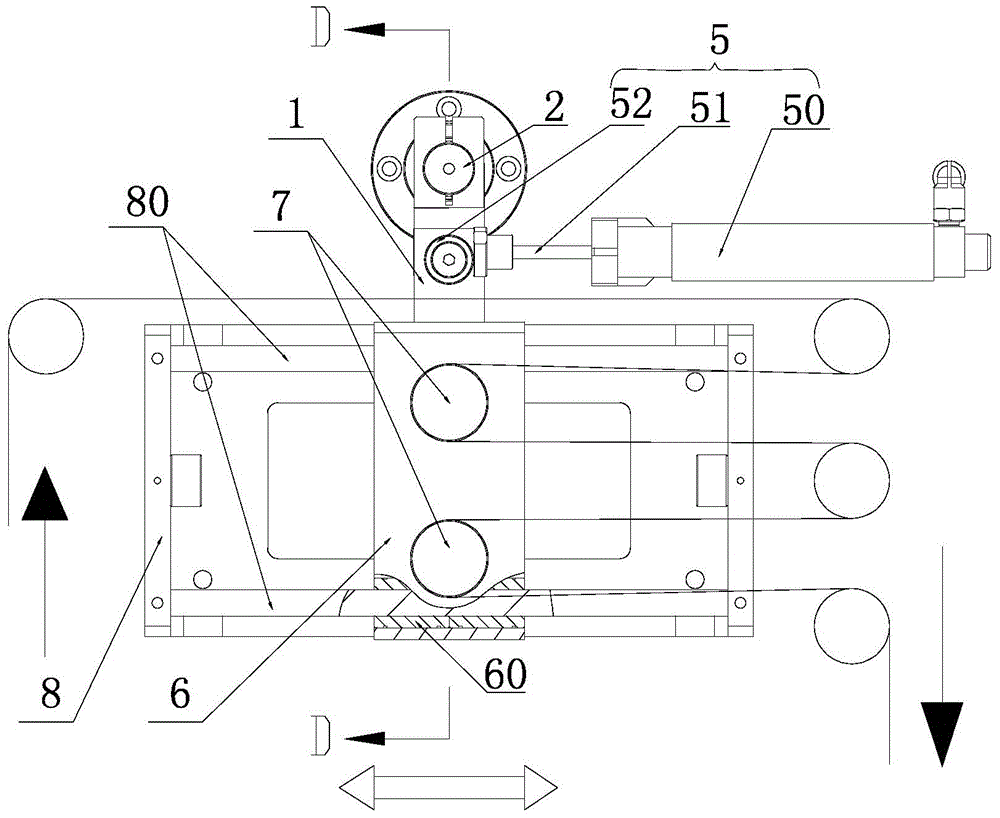

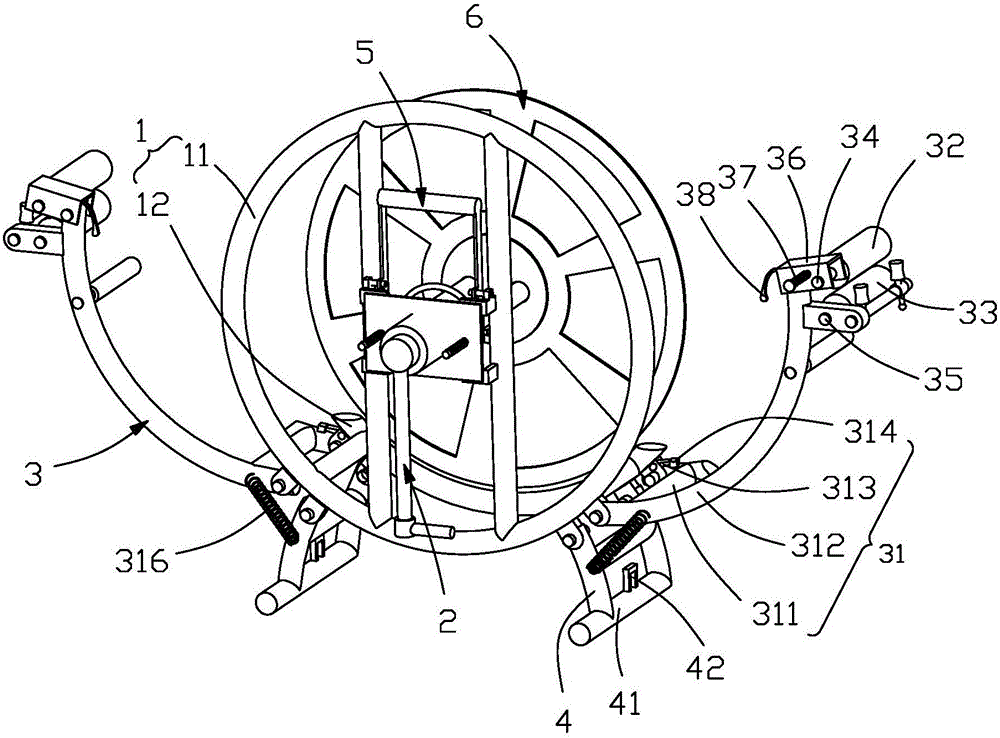

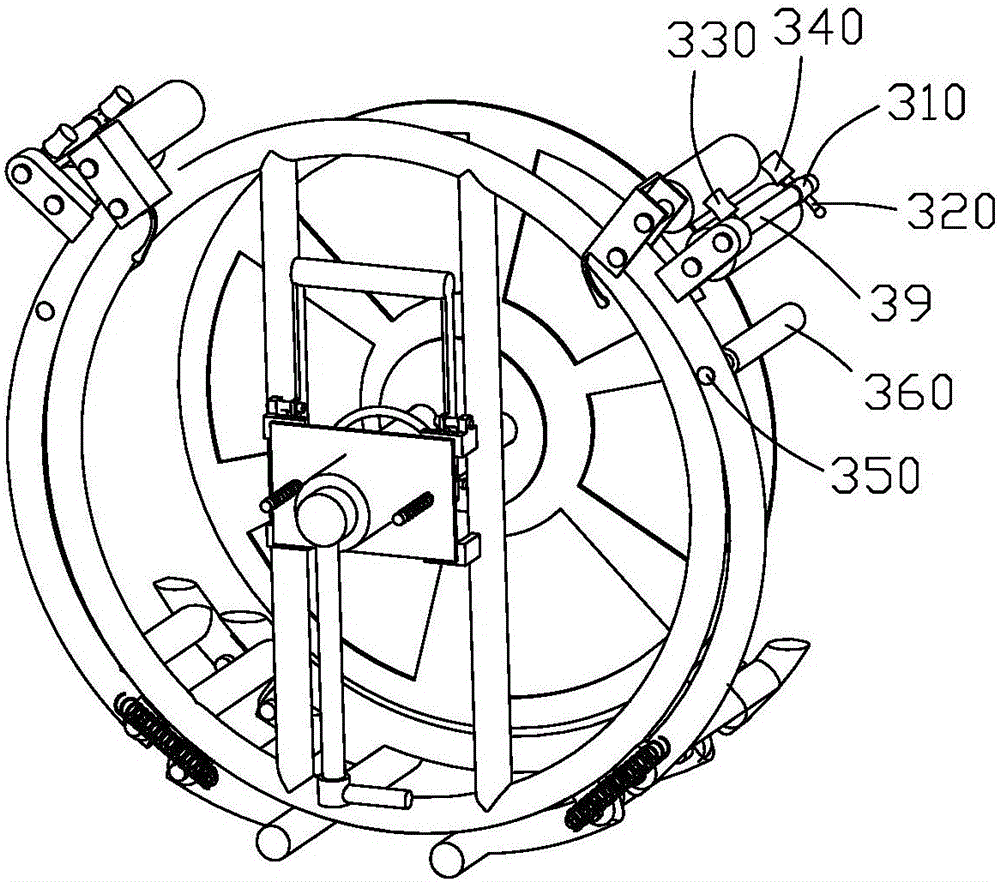

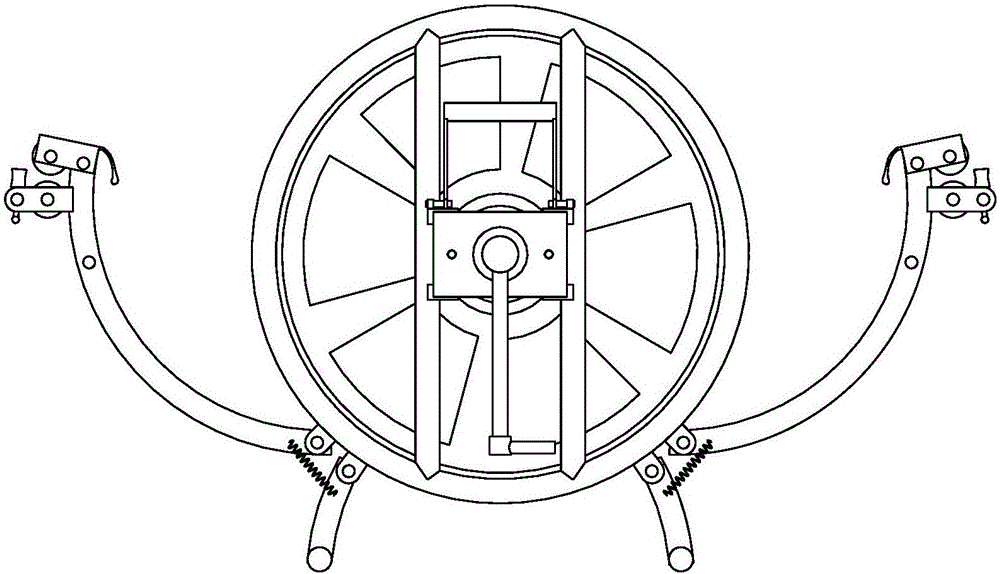

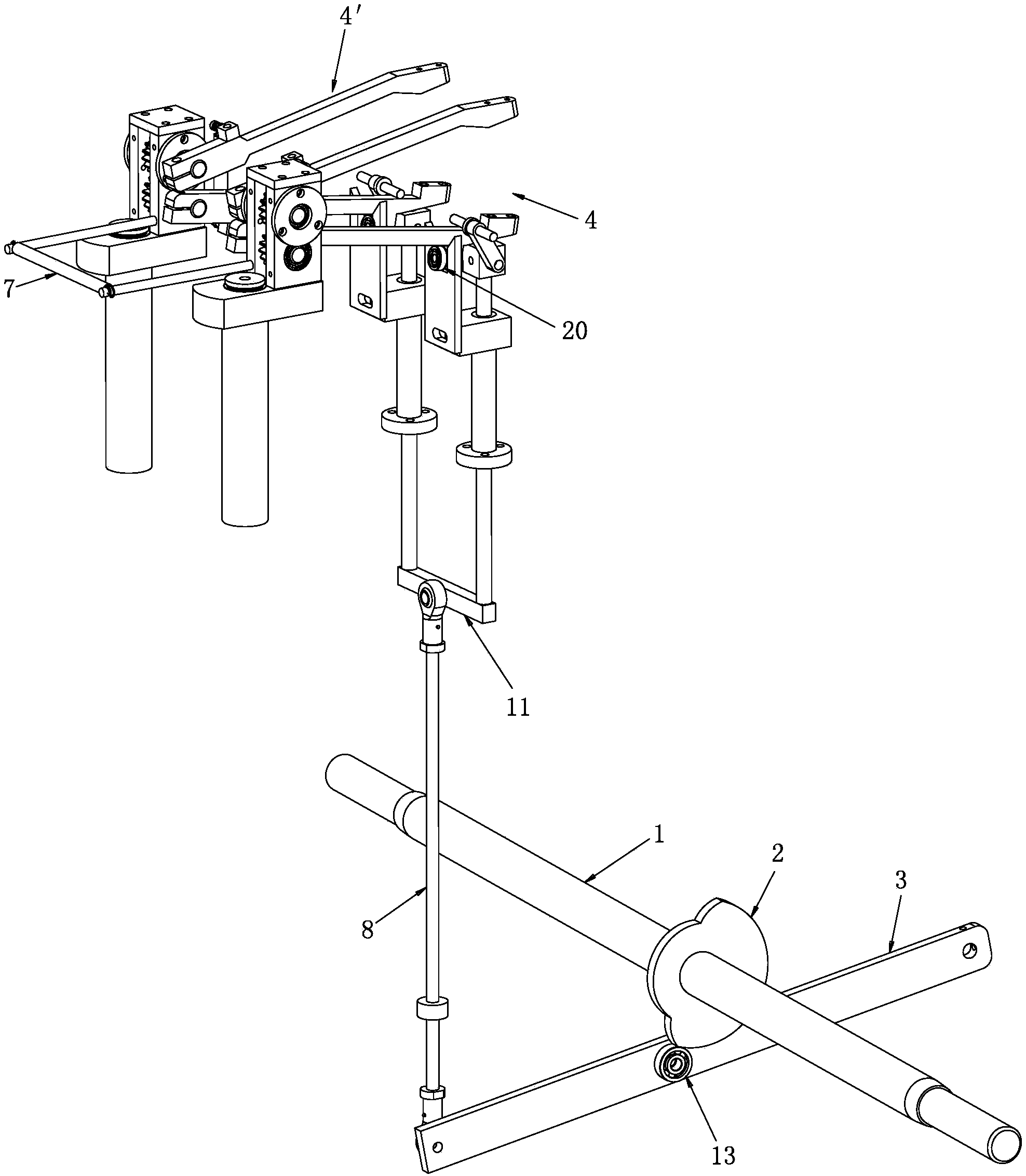

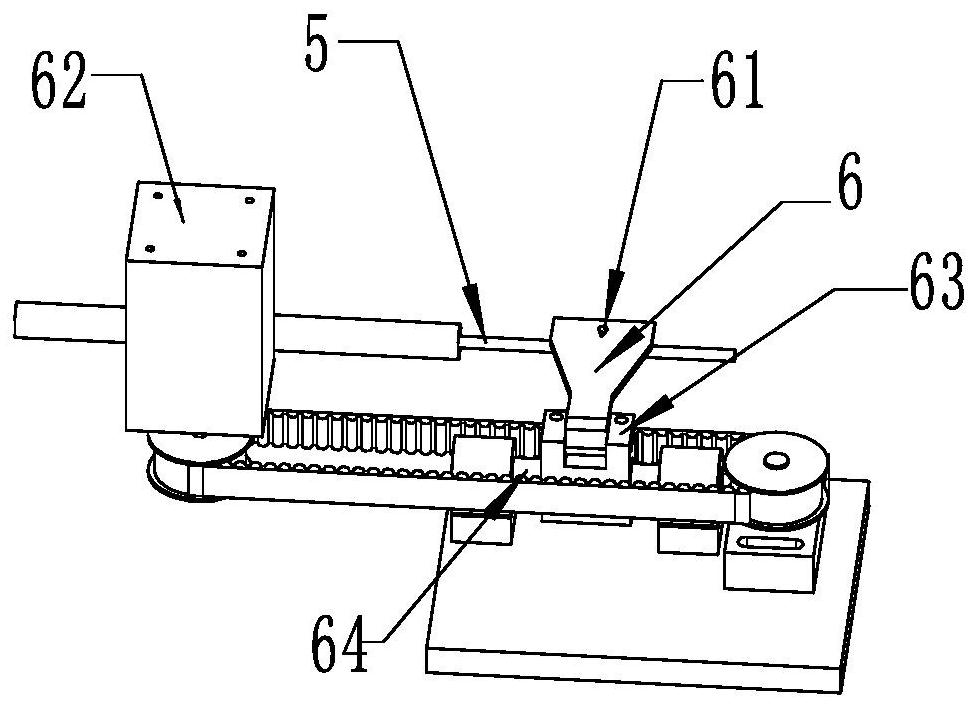

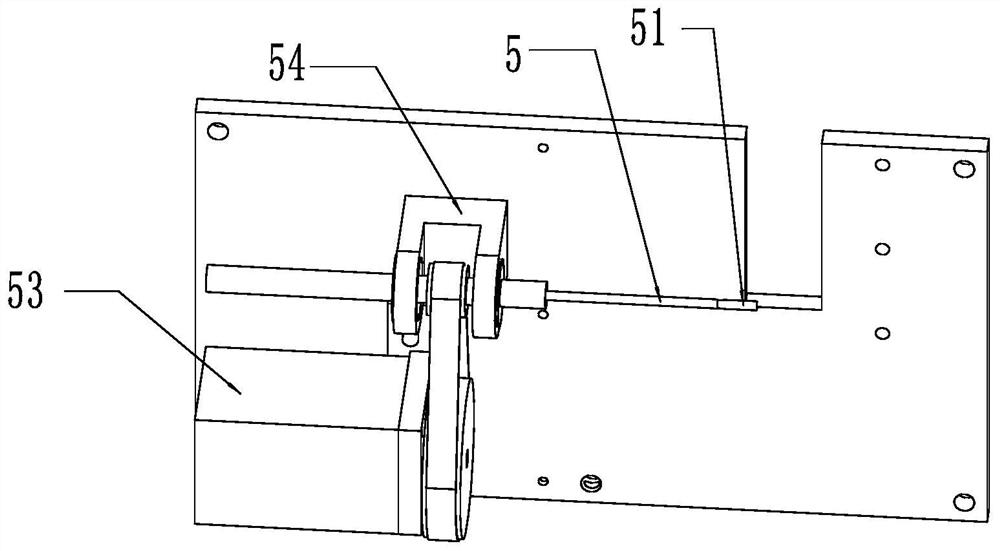

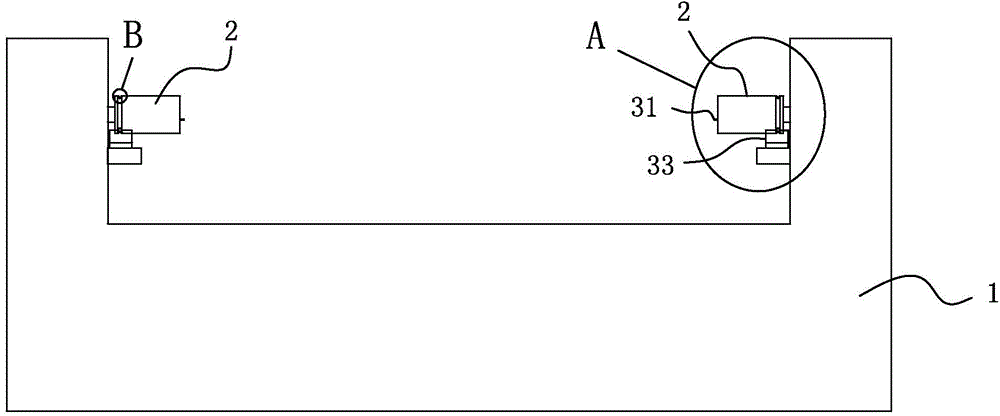

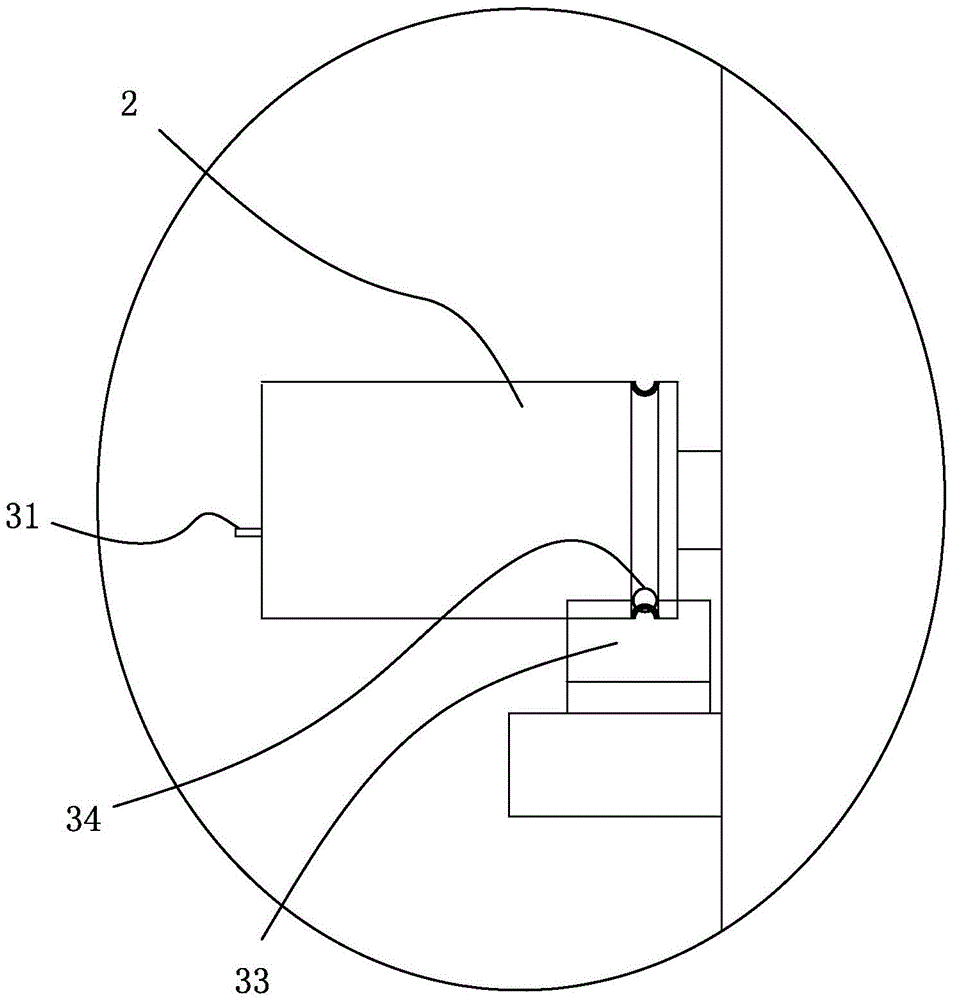

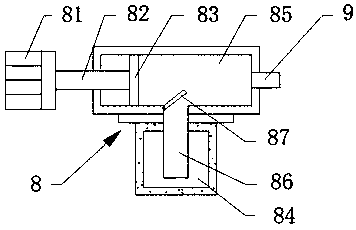

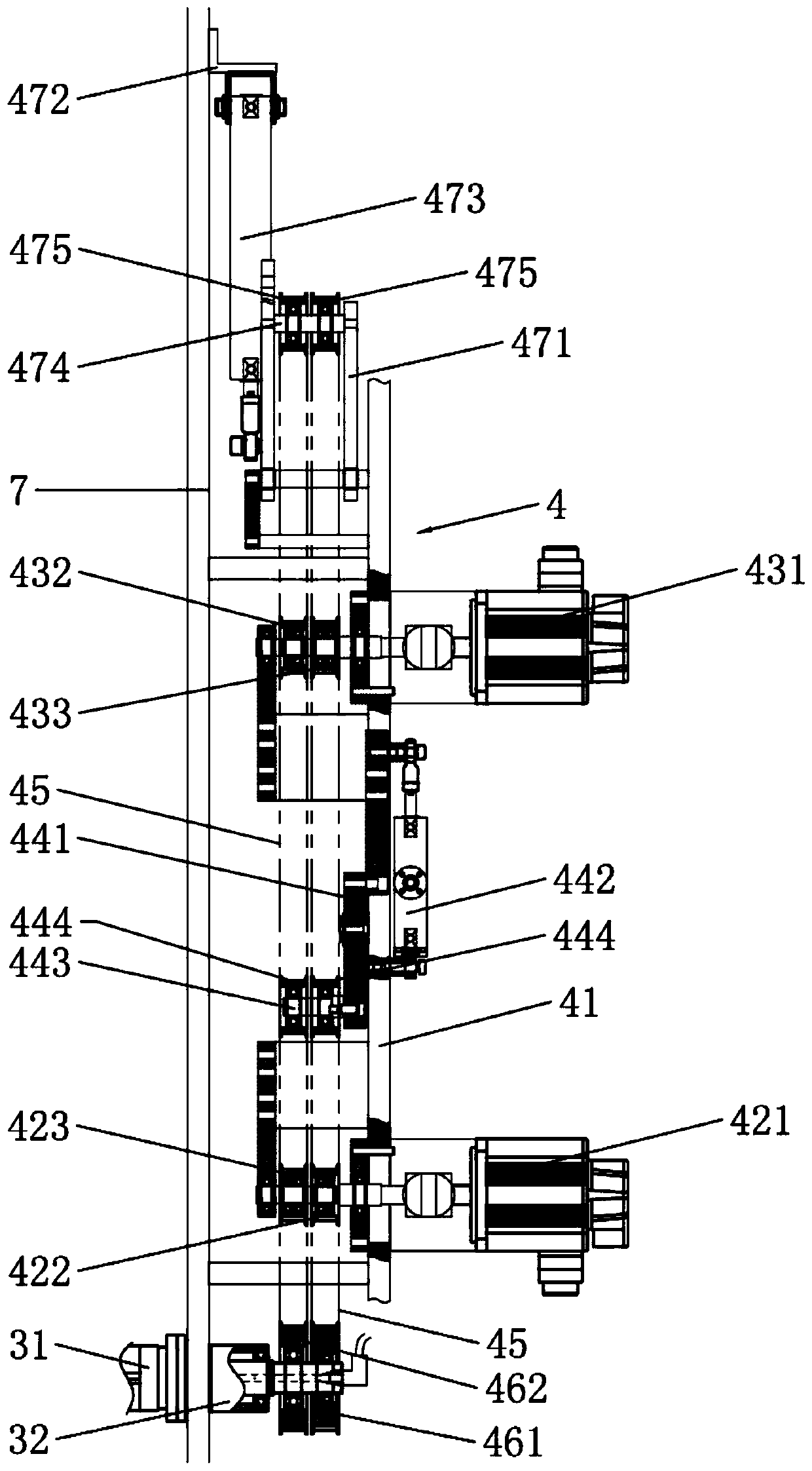

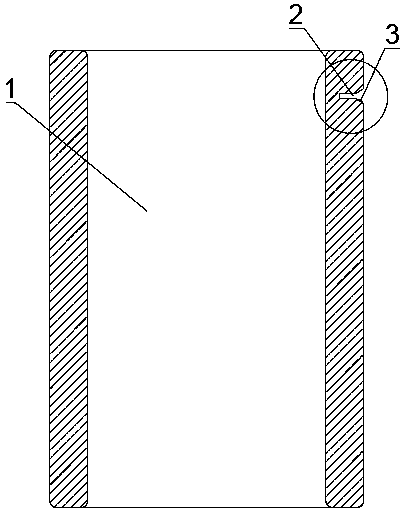

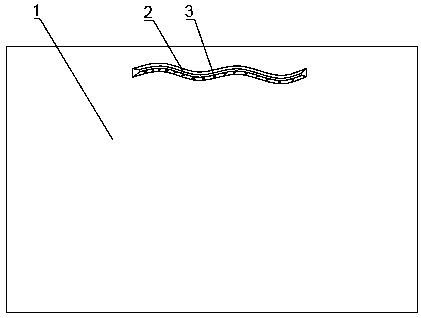

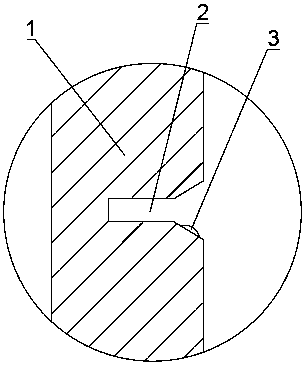

Suture winding machine and suture winding method

ActiveCN107265181ARealize automatic winding operationLow costFilament handlingWinding machineRotational axis

Owner:SHANDONG UNIV

Cloth winding machine for cloth processing production

Owner:安徽富贵服饰有限公司

Spin winding machine

Owner:MURATA MASCH LTD

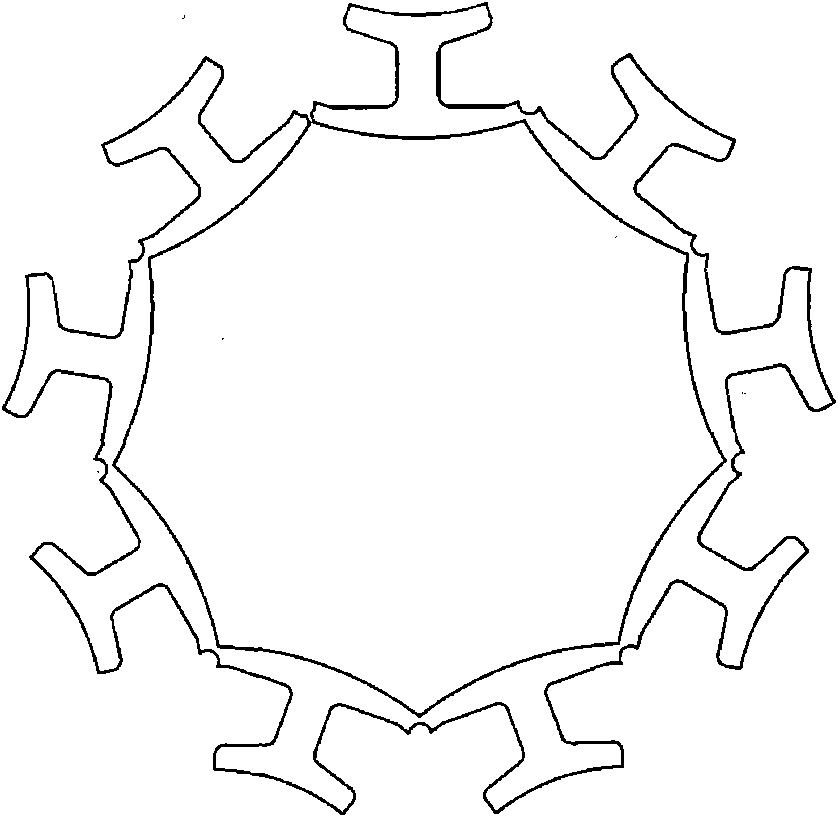

Stator coil winding process

InactiveCN102097899ACompact structureAvoid Stator Performance ImpactManufacturing dynamo-electric machinesBrushless motorsWinding machine

Owner:惠州龙德科技股份有限公司

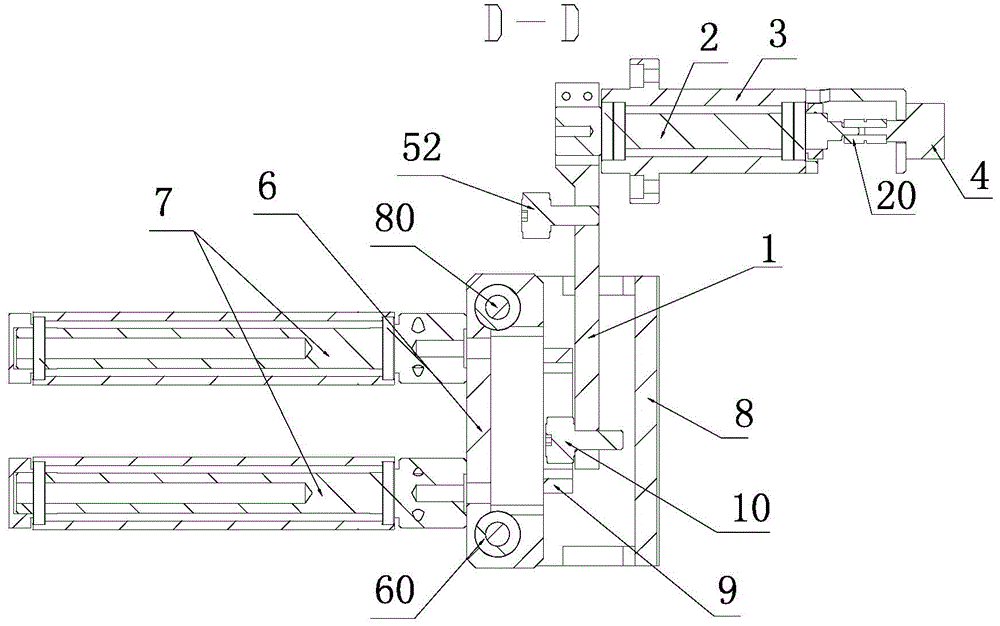

Tension mechanism of winding machine

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

Clamp for transformer winding machine

Owner:上科智能电气(苏州)有限公司

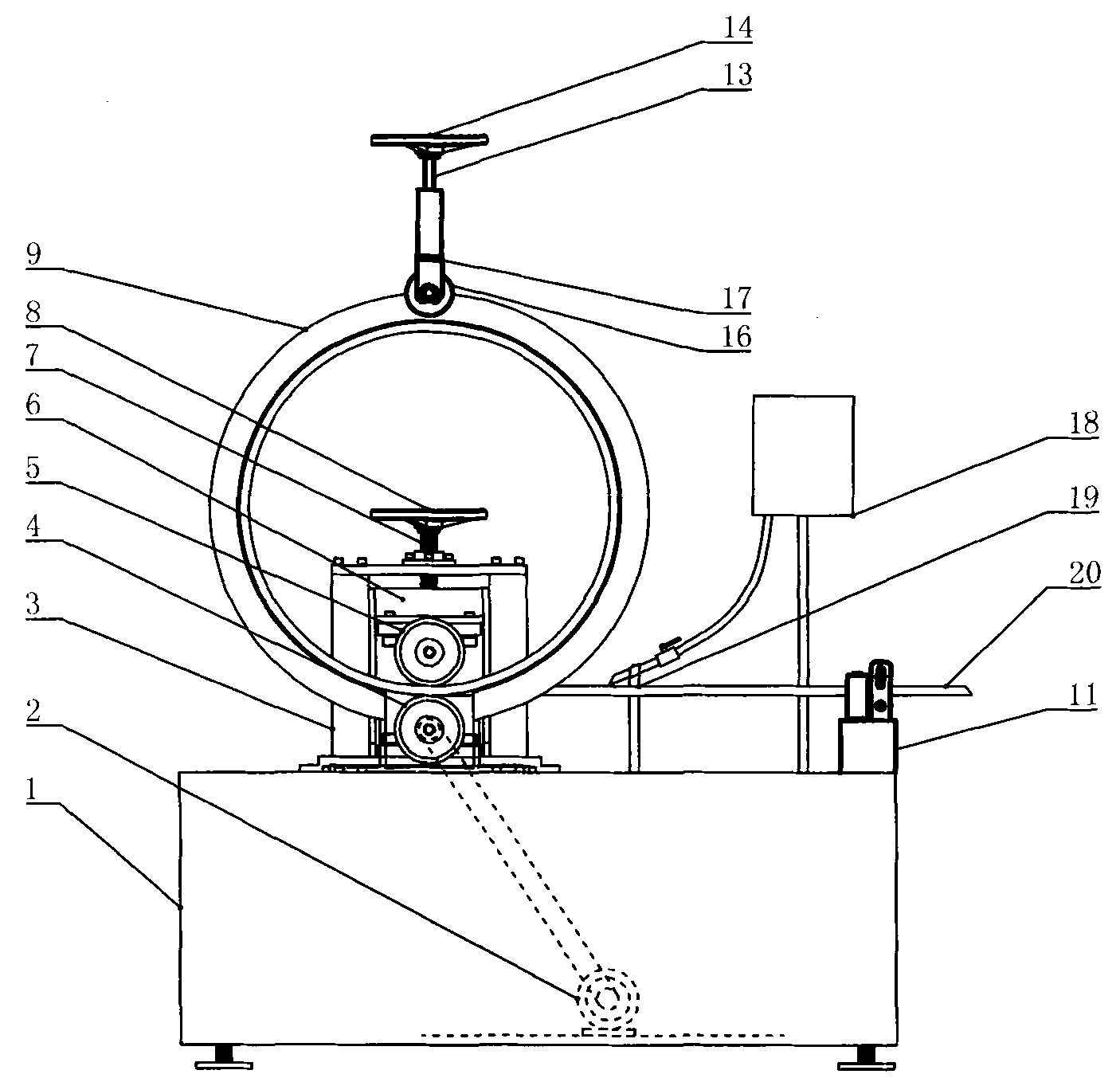

Portable fire hose winding machine

InactiveCN106185476AAutomatic and fast windingAvoid gas blockageFire rescueWinding machineConductor Coil

Owner:黄振灵

Steel tube sheet winding machine

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

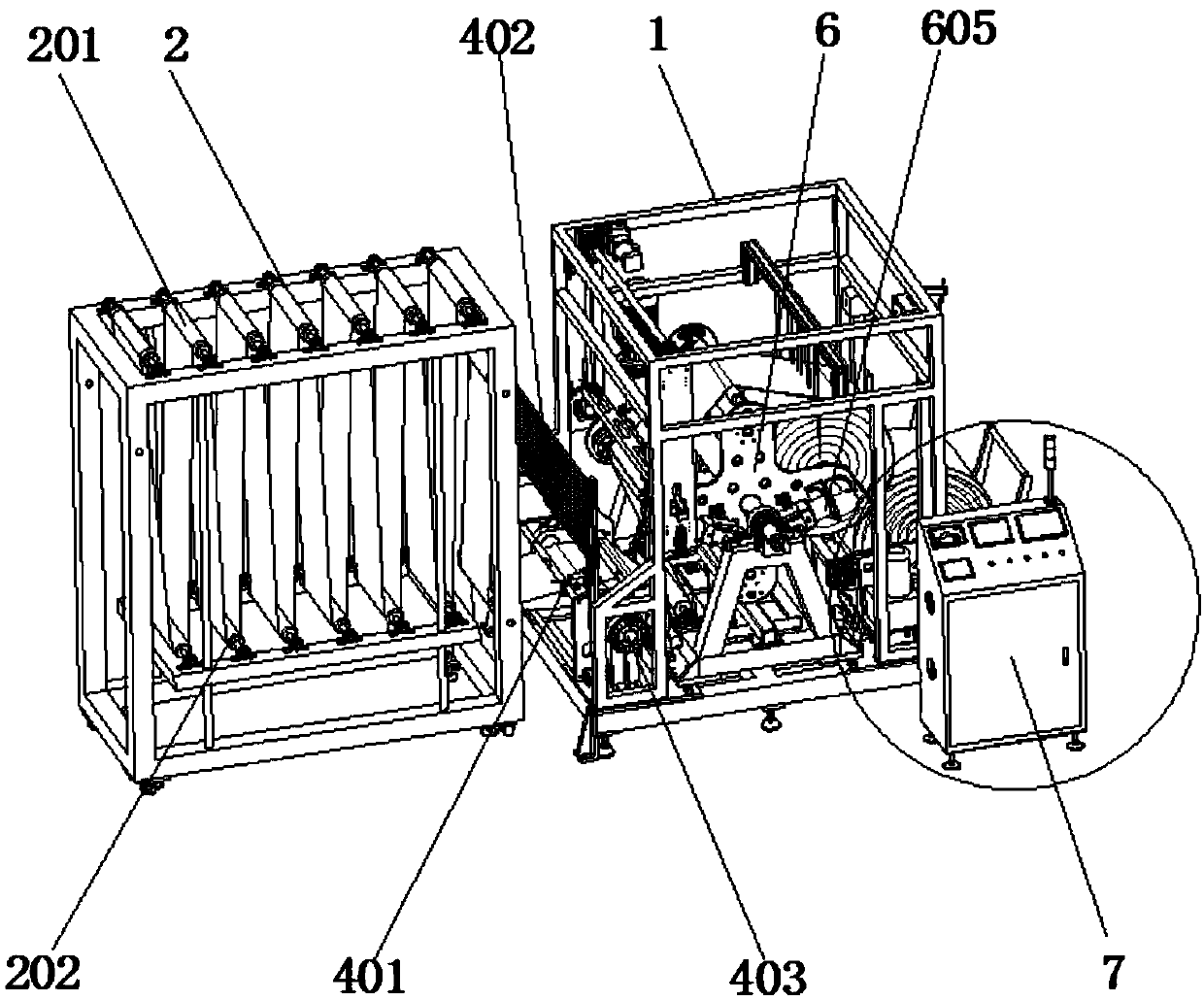

Automatic aluminum foil winding machine

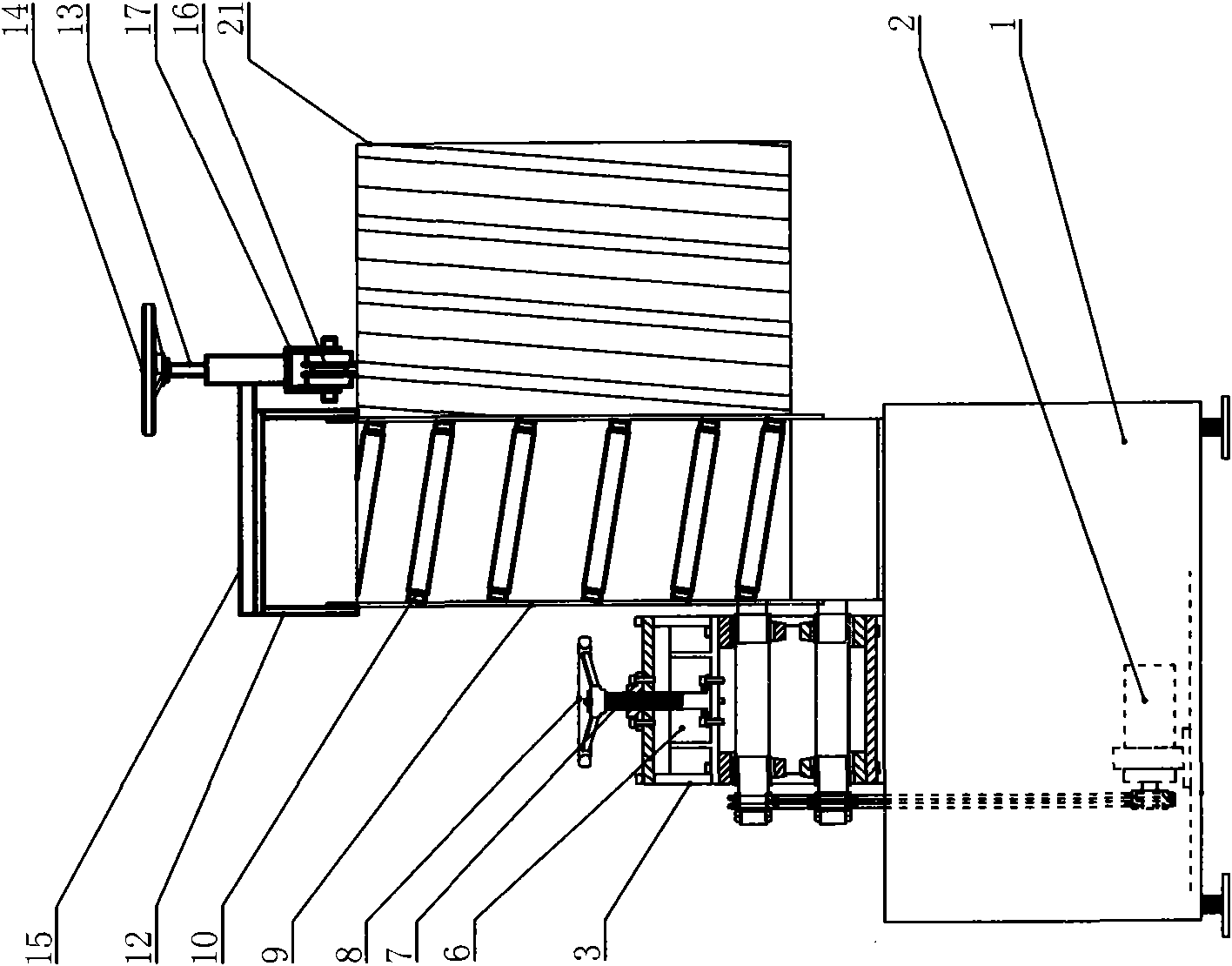

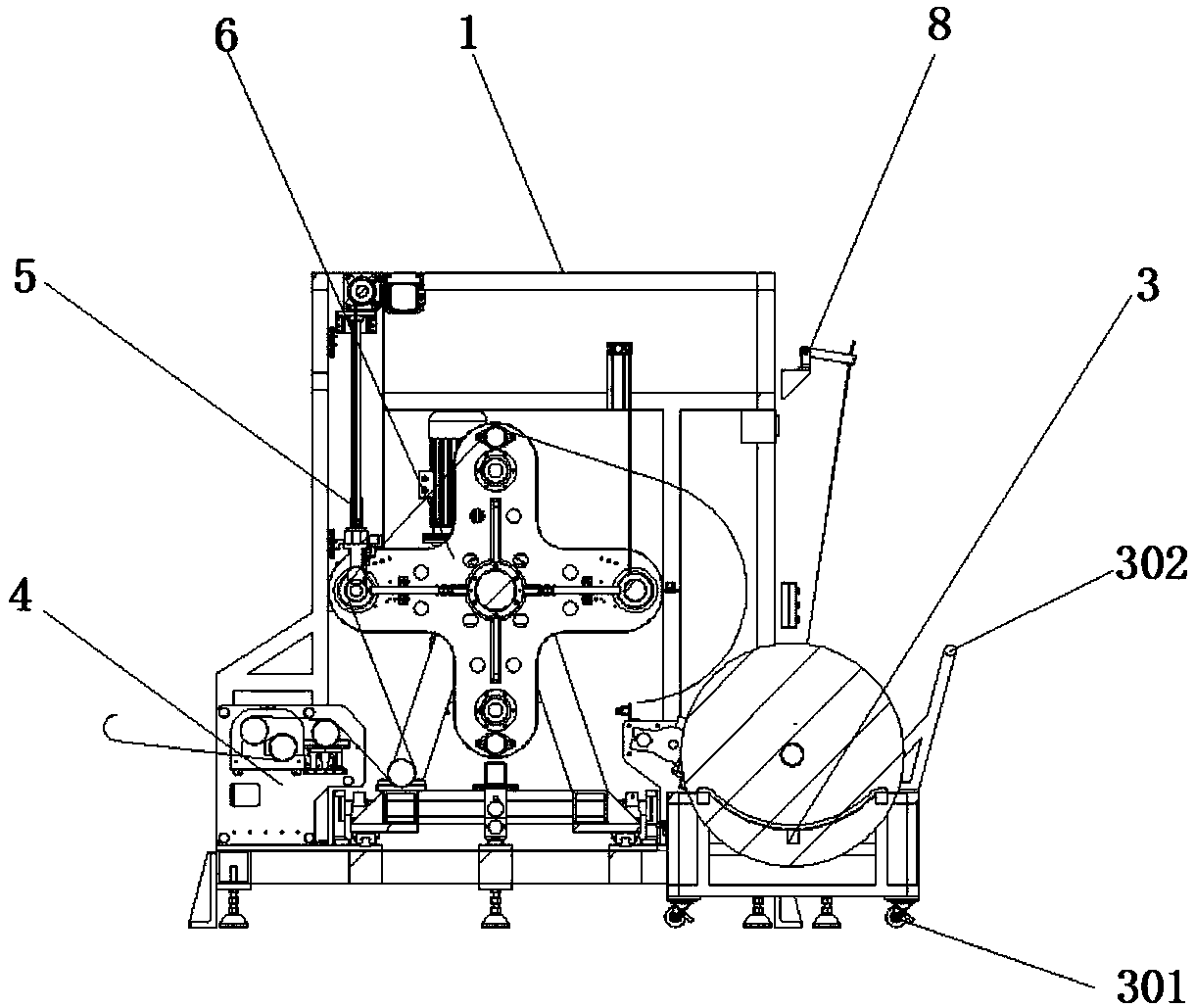

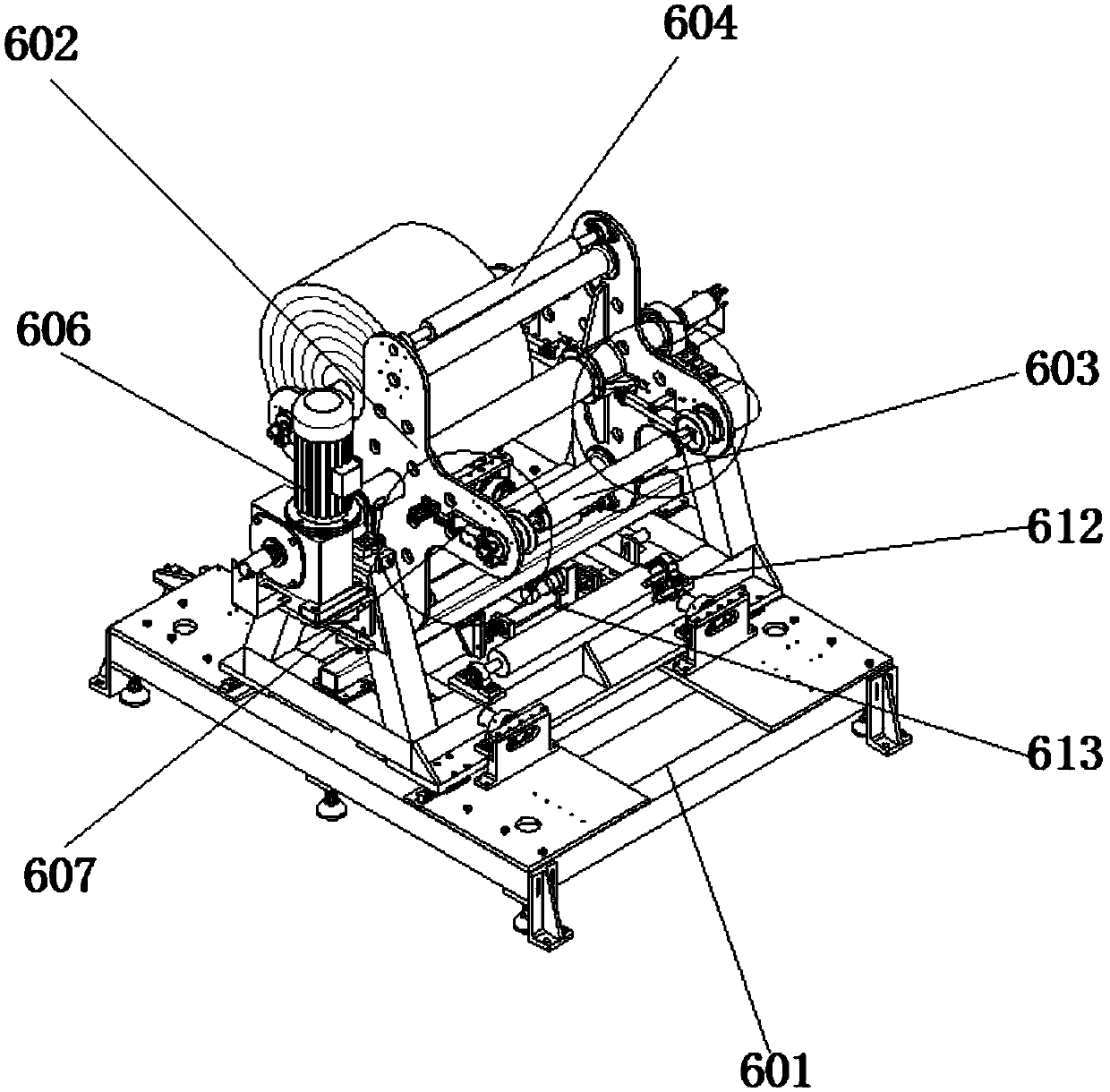

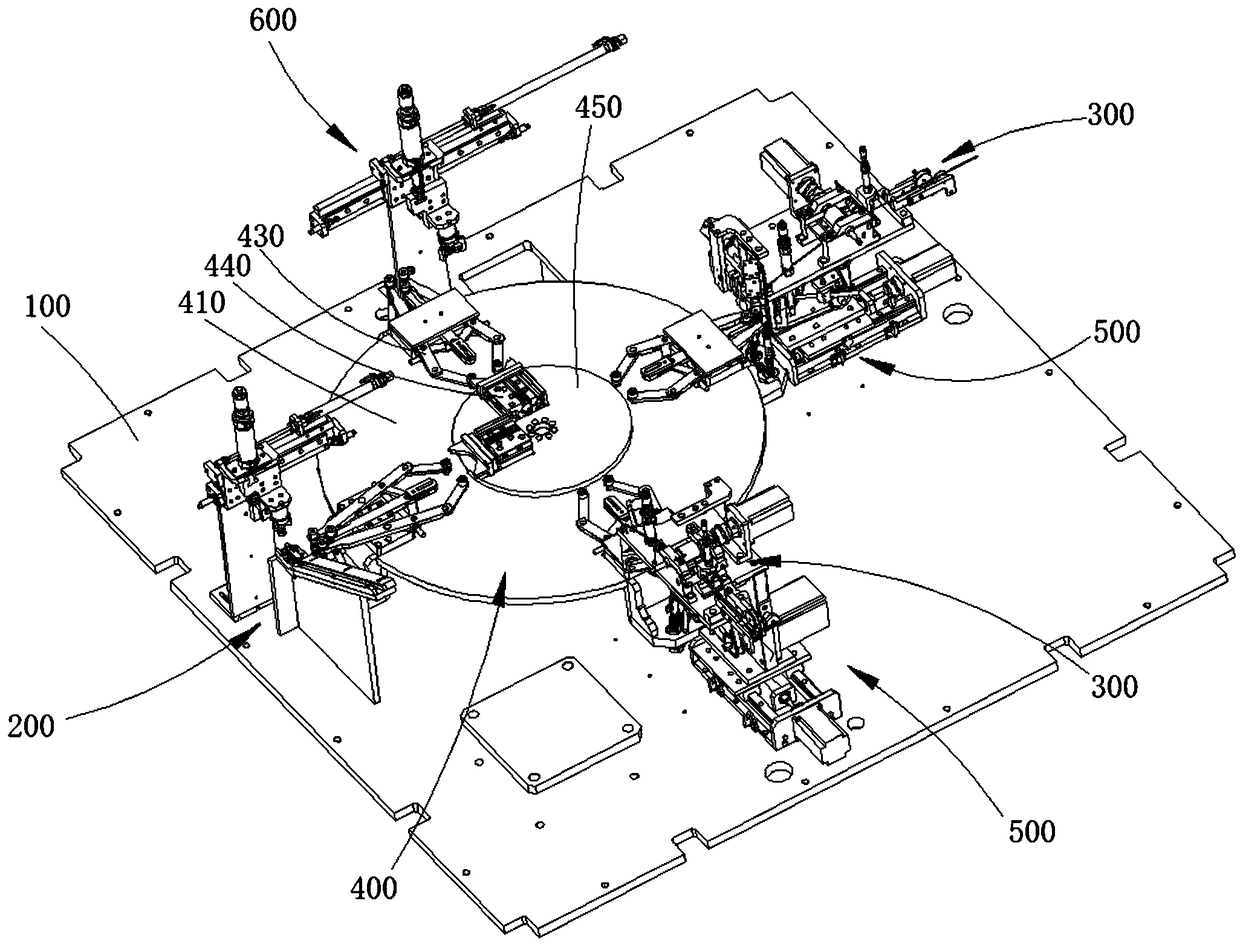

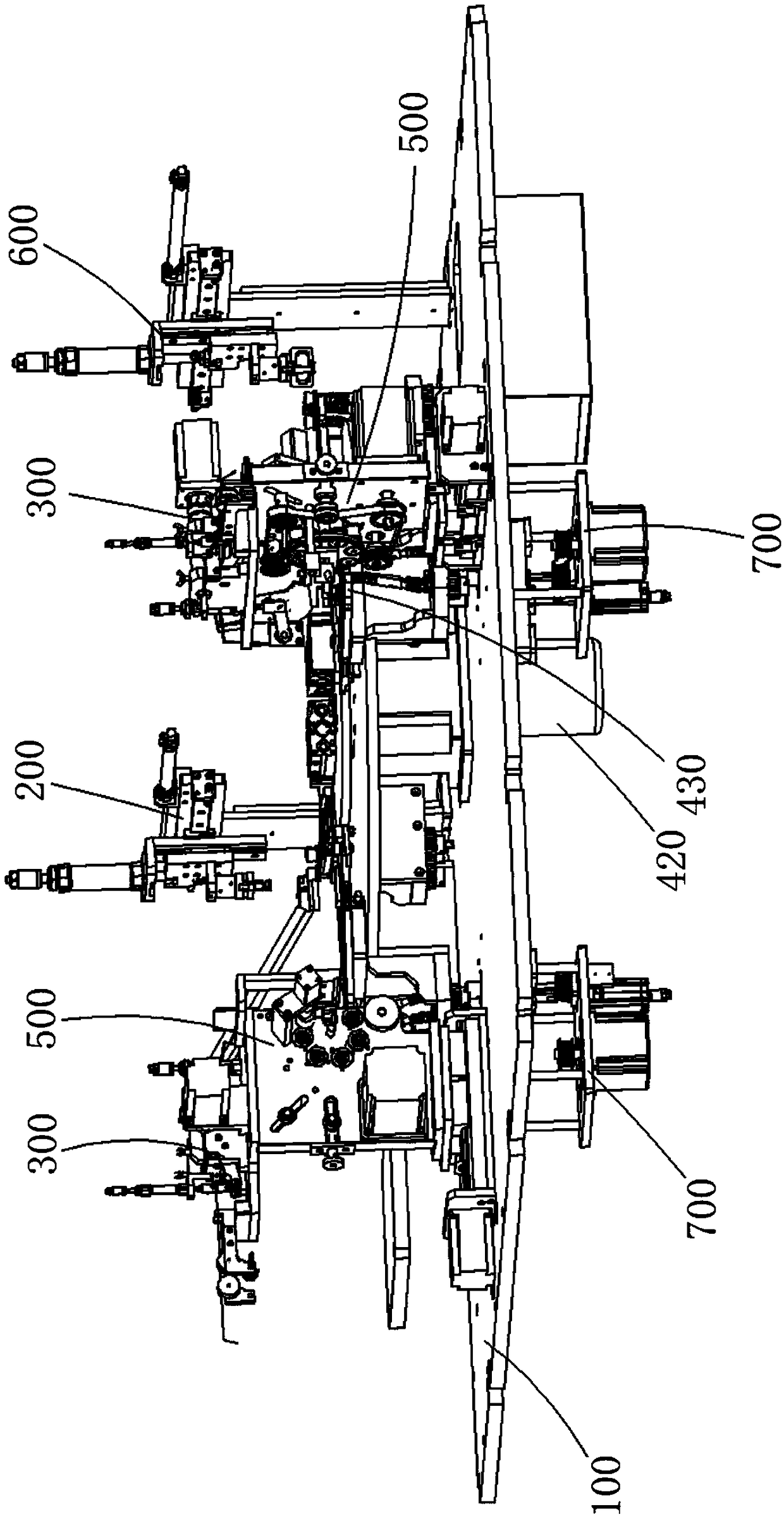

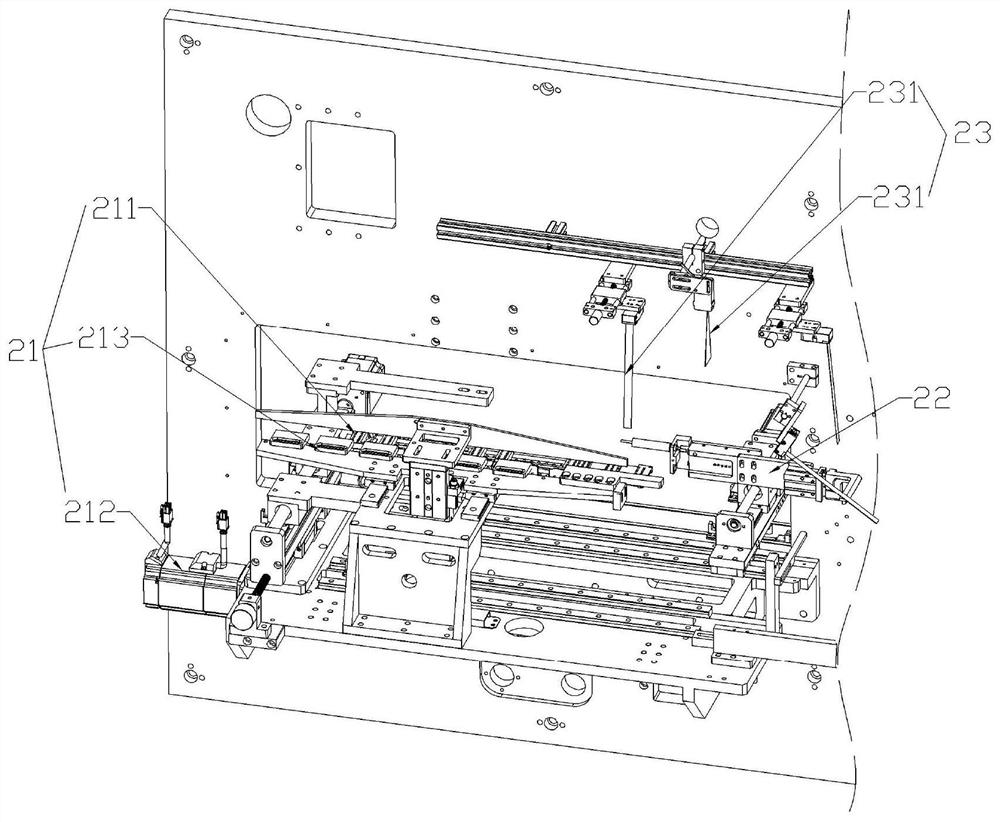

The invention discloses an automatic aluminum foil winding machine. The machine comprises a machine frame, a feeding mechanism, a discharging mechanism and an operation box, wherein the feeding mechanism, the discharging mechanism and the operation box can be detached from the machine frame; the feeding mechanism and the discharging mechanism are arranged at the front end and the rear end of the machine frame respectively; the machine frame is provided with a tension control mechanism, a cutting mechanism and a turnover large rotary plate mechanism; the tension control mechanism is arranged atthe front end of the machine frame and is matched with the feeding mechanism for feeding; the turnover large rotary plate mechanism is arranged between the tension control mechanism and the discharging mechanism; and the cutting mechanism is arranged between the tension control mechanism and the turnover large rotary plate mechanism and is located above the turnover large rotary plate mechanism.According to the automatic aluminum foil winding machine, the tension force can be flexibly controlled, and the winding position can be flexibly adjusted.

Owner:DONGGUAN XINLIANGDIAN AUTOMATION EQUIP TECH

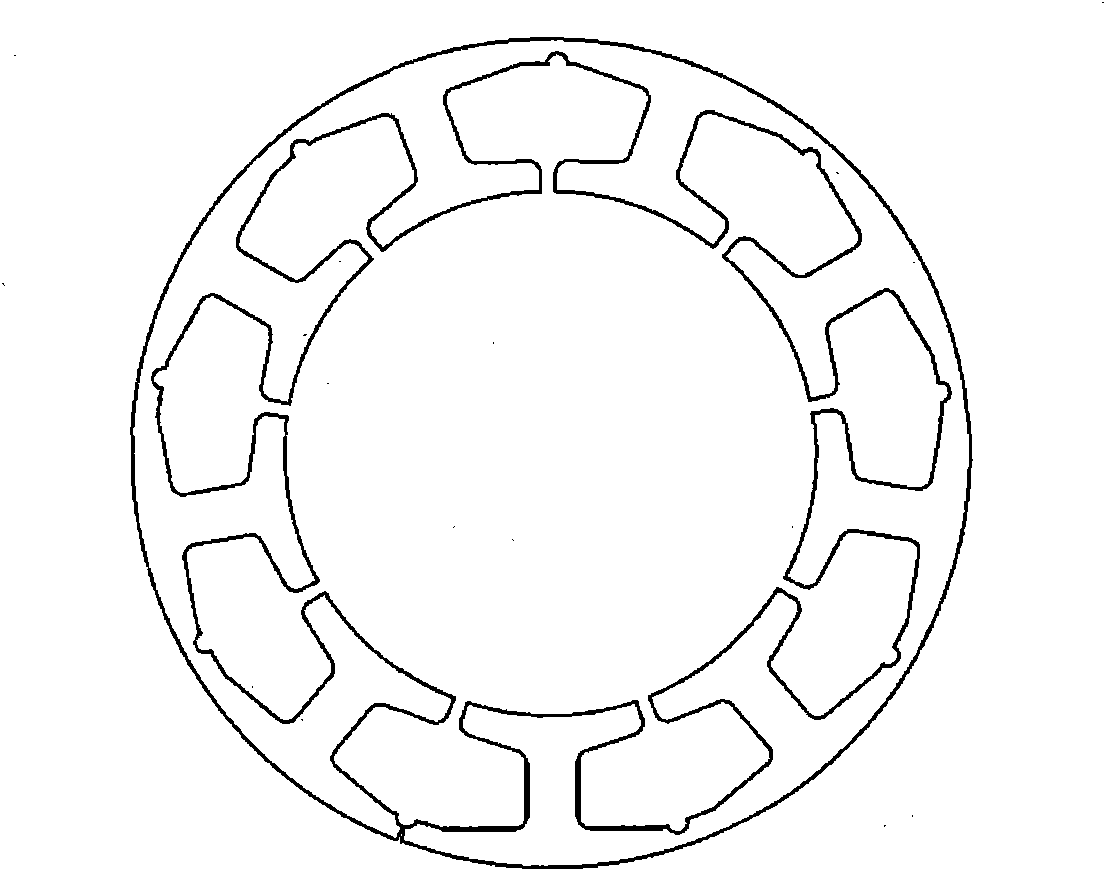

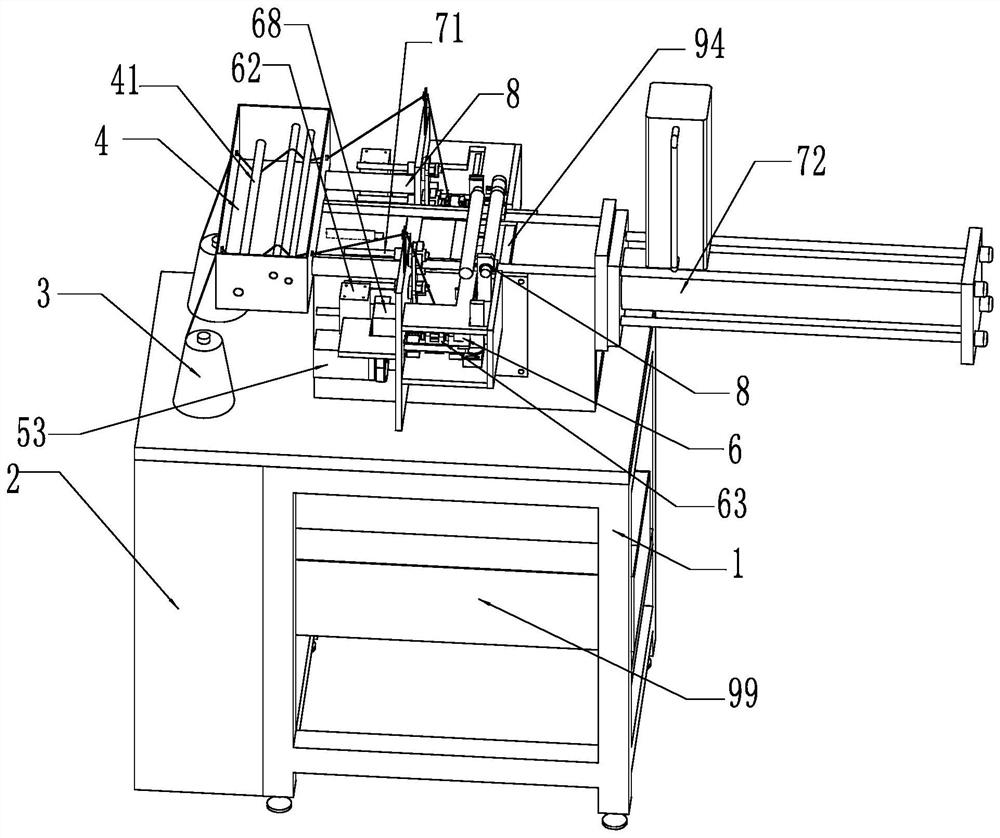

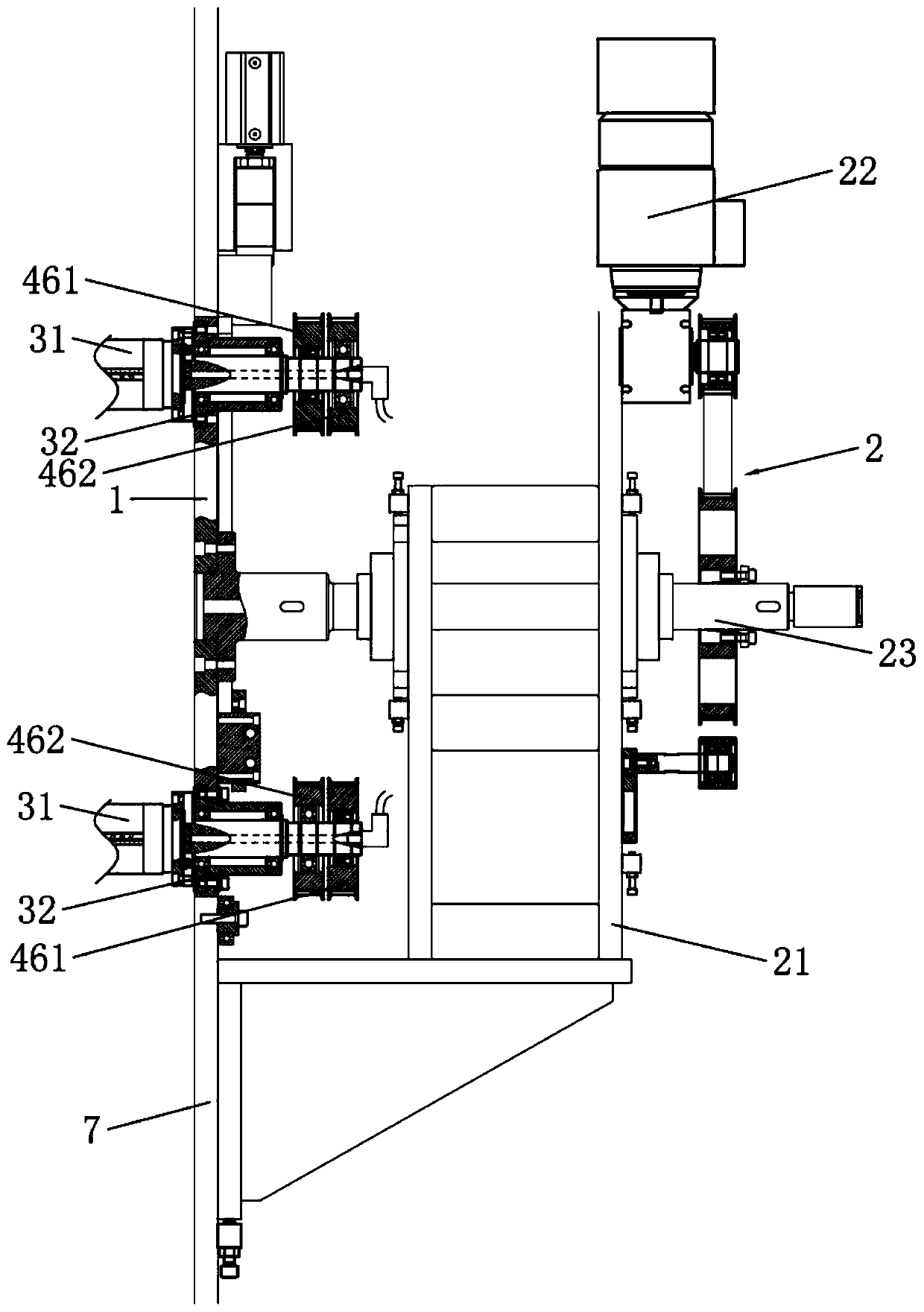

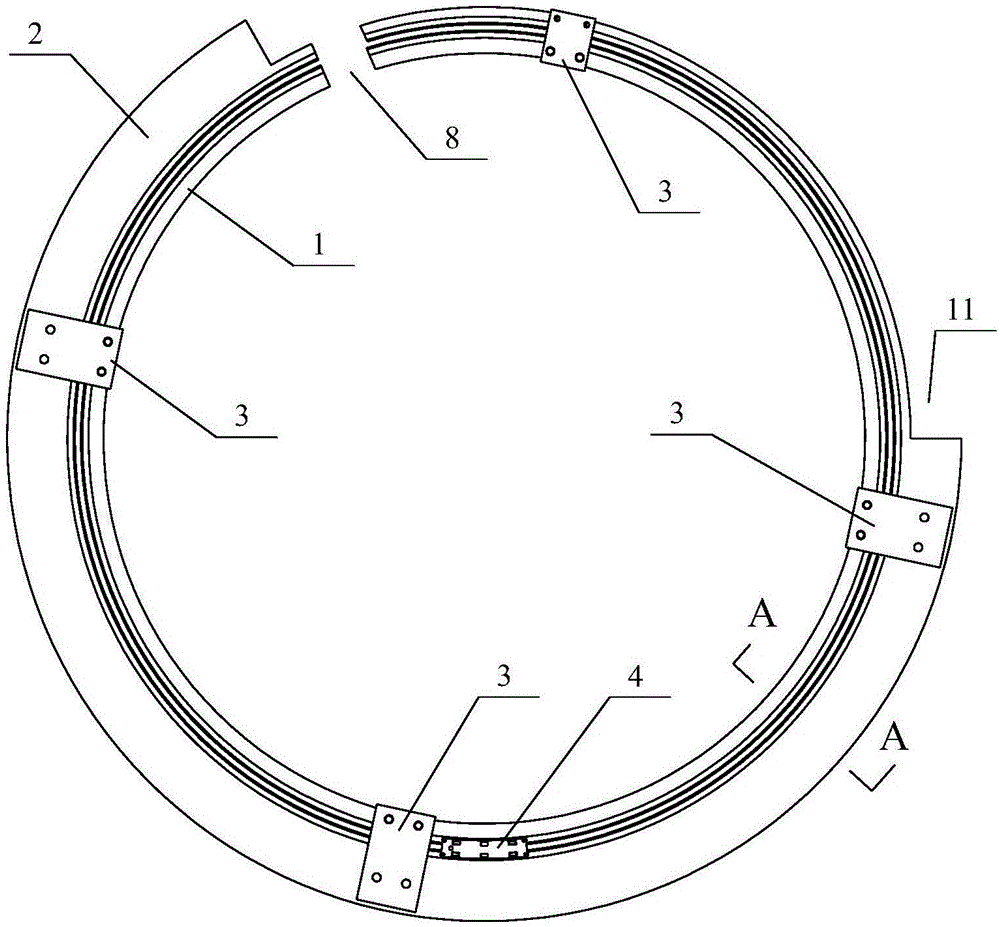

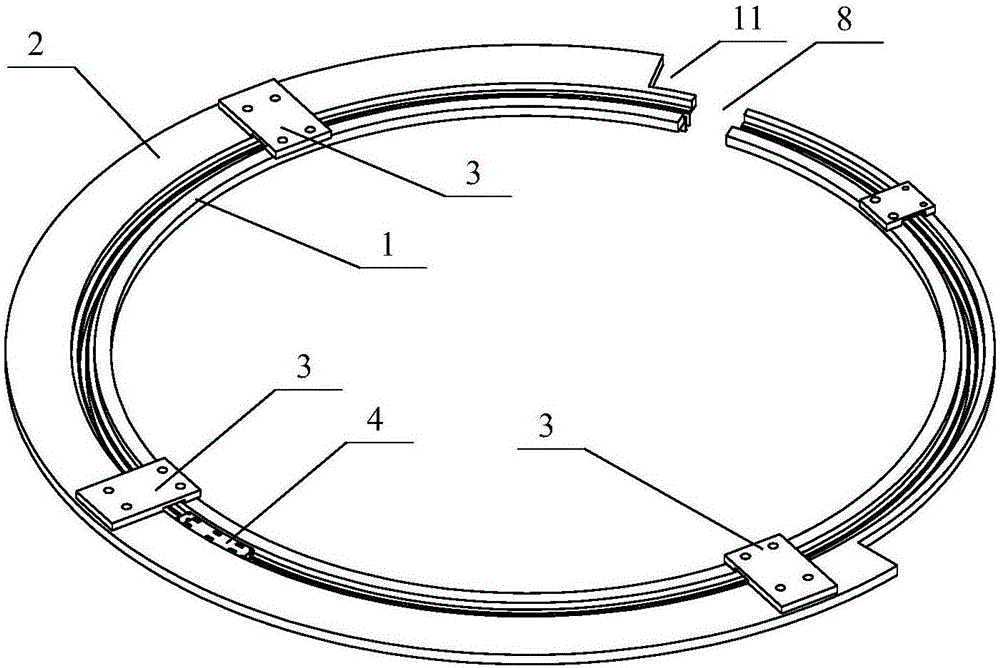

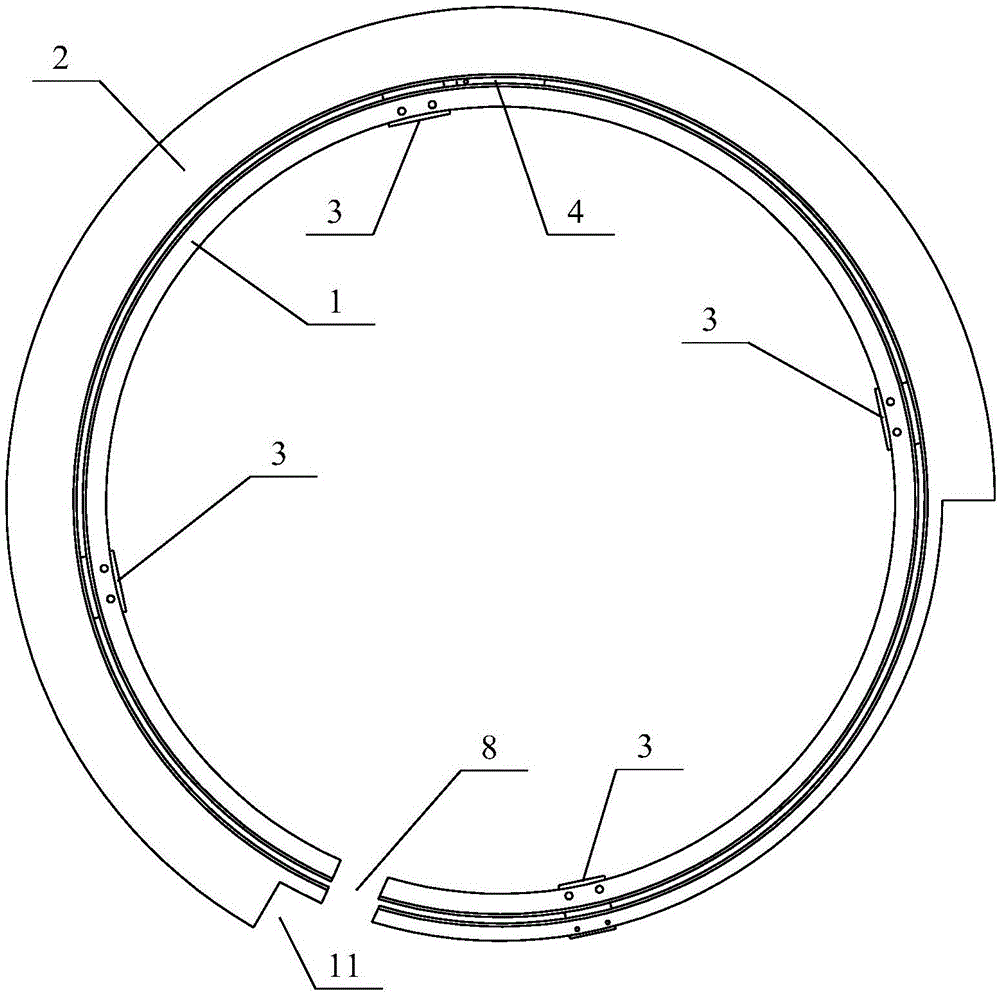

A magnetic ring winding machine

ActiveCN109103012AAchieve transshipmentReasonable transit distanceCoils manufactureWinding machineComputer module

Owner:SHENZHEN ZHIYUAN PENGFA SCI & TECH COMPANY

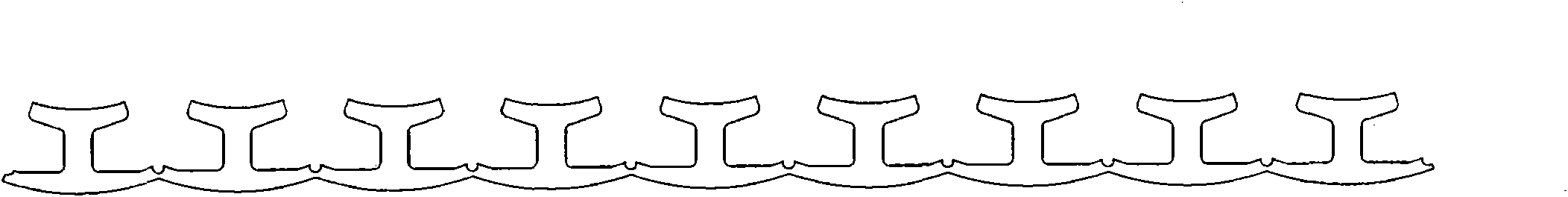

Energy-saving and consumption-reducing cable conductor manufacturing method

InactiveCN109698048AReduce gapQuality improvementCable/conductor manufactureWinding machineElectrical conductor

The invention provides an energy-saving and consumption-reducing cable conductor manufacturing method. The cable conductor manufacturing method includes the following steps: round copper rods are drawn into copper wires, the copper wires are continuously annealed into soft copper wires by using a continuous annealing copper wire drawing machine, and the soften copper wires are wound by an I-shapedwheel; a stranding machine can adjust pitch, rotation direction, PLC man-machine interface control, and polycrystalline drawing die on each segment; the copper wires on the I-shaped wheel wound wiresare on the frame type stranding machine, the pitch diameter ratio of each outer layer is not greater than the pitch diameter ratio of the inner layer, and the cable conductors are twisted into a strand; and the cable conductors twisted into a strand are stored in a cable tool disk by a tractor and a winding machine. The advantages of the energy-saving and consumption-reducing cable conductor manufacturing method are that the cable conductor is of a special-shaped single-filament stranded structure and has the advantages of reduced gaps between filaments, smooth, bright and round appearance, reduced diameter, improved density, more stable resistance and improved cable quality, and the method reduces the consumption of materials and increases the economic benefit of an enterprise.

Owner:SHANDONG JINYUAN COPPER CO LTD

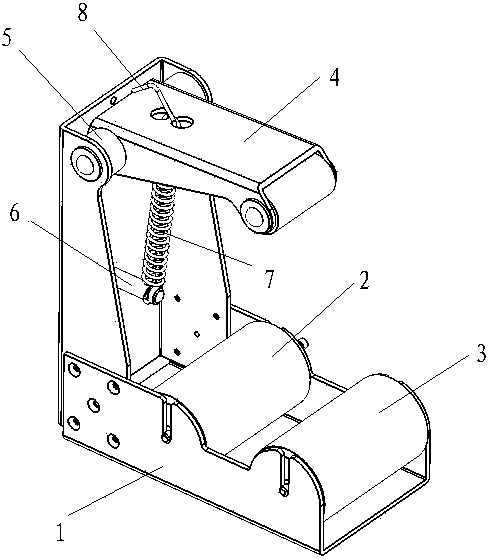

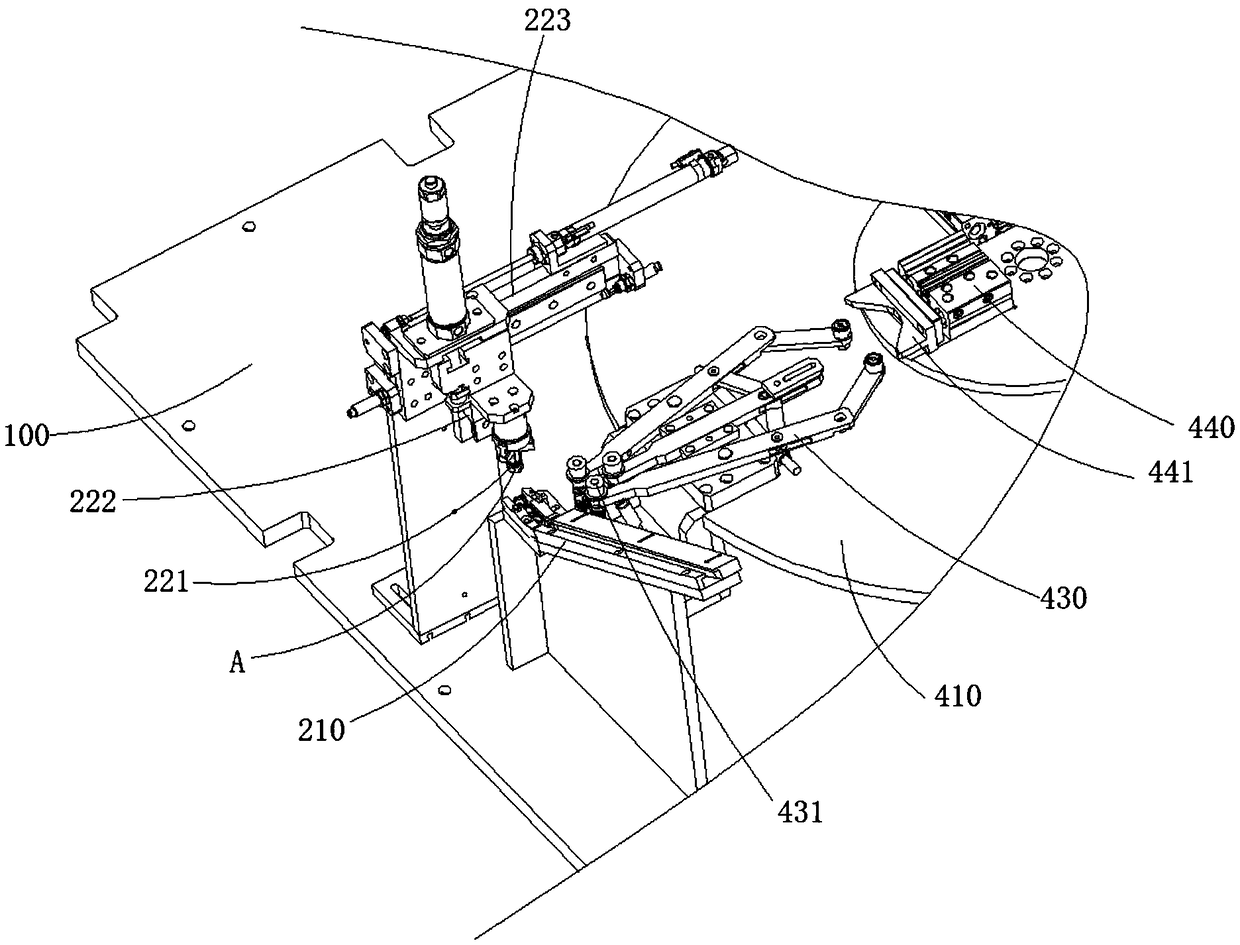

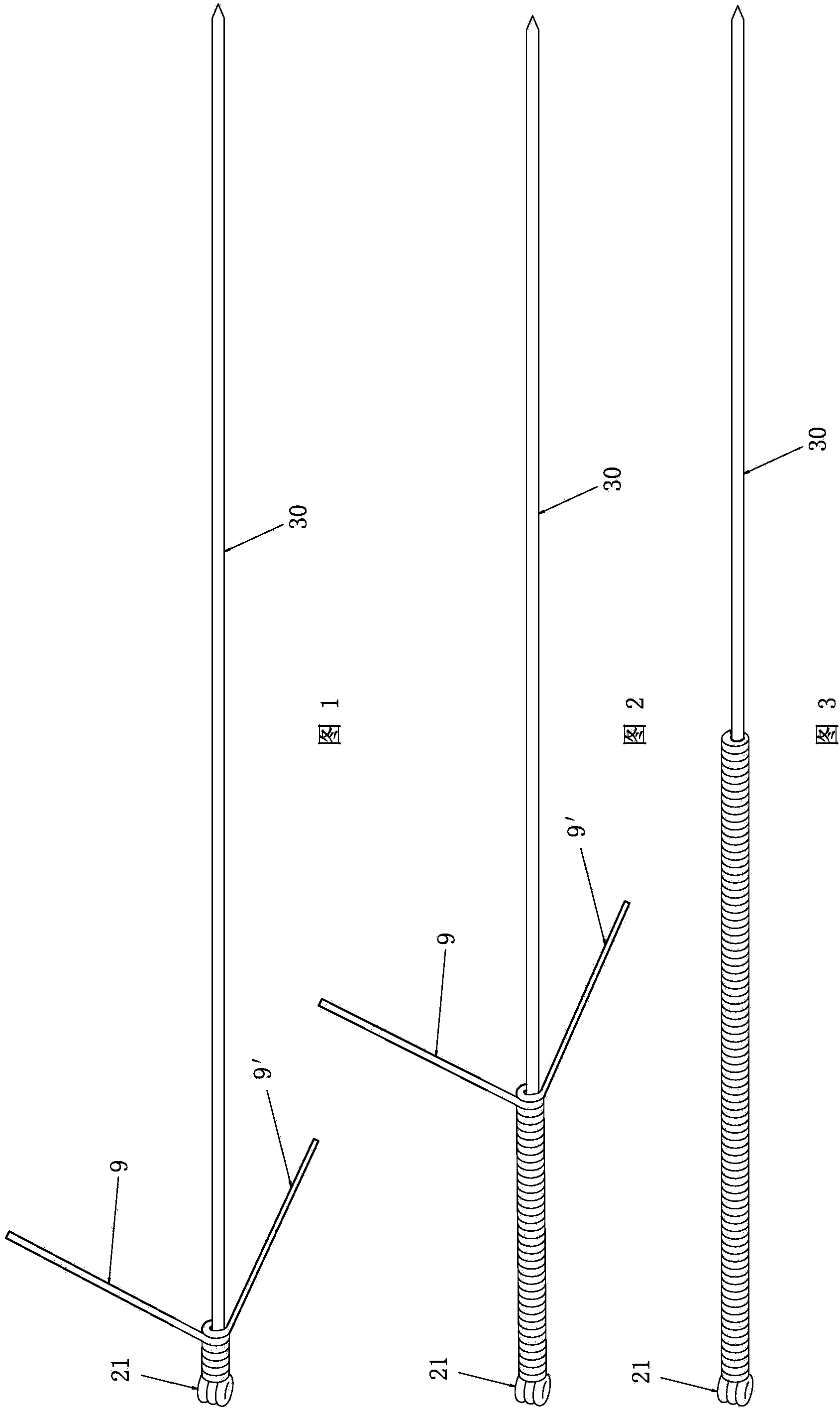

Metal wire clamping mechanism of acupuncture needle automatic handle winding machine

Owner:SUZHOU MEDICAL SUPPLY FACTORY CO LTD

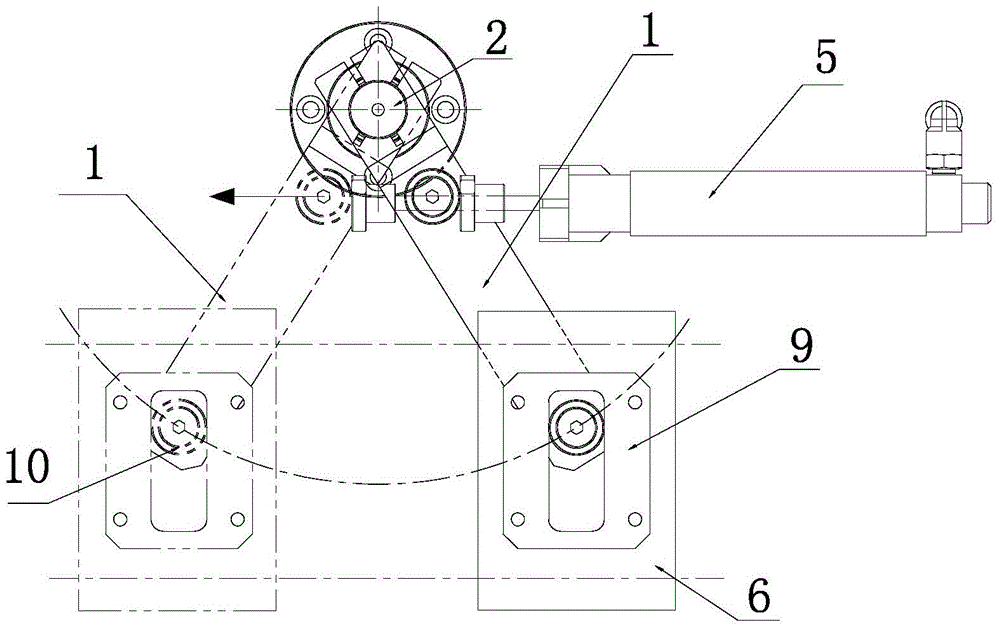

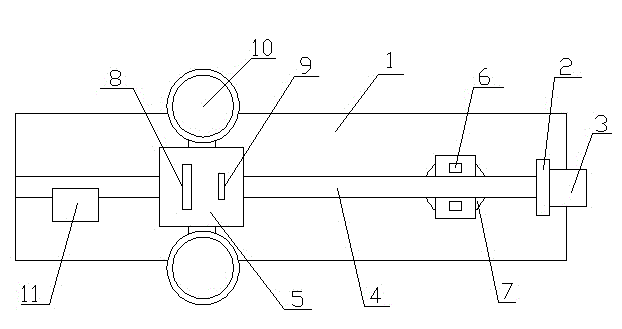

Winding force sensor for hard metal wire, and winding force detection method

InactiveCN110608836AHigh degree of automationIncrease productivityTension measurementWinding machineHard metal

The invention discloses a winding force sensor for a hard metal wire, and the winding force sensor comprises a wire-passing guide wheel, a cantilever pressure sensor, and wire-pressing guide wheels, wherein the wire-pressing guide wheels are divided into left and right groups, which are respectively installed on support platforms on left and right sides of the cantilever pressure sensor. The invention also discloses a winding force detection method of the winding force sensor for the hard metal wire, and the method firstly makes the hard metal wire sequentially pass through the wire-pressing guide wheel on the left side, the wire-passing guide wheel and the wire-pressing guide wheel on the right side, starts the winding machine to tension and wind the metal wire that will generate downwardpressure on the wire-passing guide wheel and the detection axis of the cantilever pressure sensor, obtains the relationship between the pressure and winding force by the trigonometric function operation, and calculates the winding force of the metal wire, so that the real-time monitoring of the winding force of the hard metal wire during the winding process is realized, and the installation is flexible and convenient, which is suitable for the upgrade and reconstruction of large cable production equipment.

Owner:BENGBU COLLEGE

Upward continuous casting machine of superwide copper strip blank

The invention discloses an upward continuous casting machine of a superwide copper strip blank, comprising a smelting furnace, heat preserving furnaces, the upward continuous casting machine arranged above the heat preserving furnaces, inductors, a variable frequency coreless winding machine and a graphite mould. The upward continuous casting machine of the superwide copper strip blank is characterized in that both sides of the smelting furnace are respectively provided with the heat preserving furnaces; the inductors are respectively arranged at the bottoms of the heat preserving furnaces and the smelting furnace; the upward continuous casting machine is provided with two drawing heads; each drawing head is connected with a crystallizer; the graphite mould is in a rectangular shape, and a C-shaped clamp is arranged on the graphite mould and fixed by using a bolt. The invention has the advantages of simple structure and long service life, realizes the short process of the superwide copper strip blank, achieves the energy saving, the emission reduction and the low carbon; in addition, the superwide copper strip blank produced by using the upward continuous casting machine has uniform thickness and stable quality.

Owner:李福金

Coreless bottom line winding and shaping automatic all-in-one machine and method thereof

Owner:DONGYANG TAIJI PRECISION MFG

Resistance detection device for wire winding machine

InactiveCN104525626AEasy to detectImprove detection efficiencyResistance/reactance/impedenceMetal working apparatusElectricityWinding machine

Owner:何雲彬

Novel winding machine

Owner:YIZHENG SIFANG LIGHT TEXTILE MACHINERY

Oiling device for winding machine

InactiveCN107804753AScientific and reasonable designApply evenlyFilament handlingWinding machineAdhesive

Owner:WUJIANG HONGRUI PRECISION MASCH FACTORY

Rotary winding structure applied to self-adhesive label winding machine

PendingCN111153254AImprove work efficiencyNovel structural designWebs handlingWinding machineCircular disc

Owner:博泰数码智能技术(江苏)有限公司

Buzzer coil winding device with winding arrangement function

The invention provides a buzzer coil winding device with a winding arrangement function. The buzzer coil winding device comprises a workbench, a clamping device is arranged on the workbench, and a winding mechanism is arranged on the workbench; the clamping device comprises a first fixing plate, the first fixing plate is fixedly installed on the workbench, a servo motor is fixedly installed on one side of the first fixing plate, a connecting rod is rotatably inserted into the first fixing plate, and the output end of the servo motor is fixedly connected with one end of the connecting rod; a first mounting plate is fixedly mounted at the end, away from the servo motor, of the connecting rod, a first clamp is fixedly mounted on the first mounting plate, an adjusting lead screw is rotatably inserted into the first mounting plate, and a limiting ring is fixedly mounted at the end, away from the first clamp, of the adjusting lead screw; the magnetic core is clamped through the clamping device, so that the stability of the magnetic core is improved, the magnetic core is prevented from loosening in the winding process, and the phenomenon of incomplete winding of the magnetic core is avoided.

Owner:JIANGSU HUANENG ELECTRONICS CO LTD

One-time molding composite pipe used for high-speed winding head

Owner:桐乡市凤鸣恒益塑胶制品厂

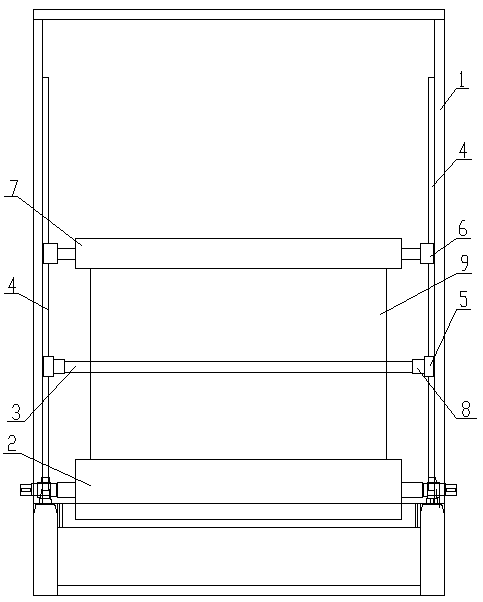

Narrow non-woven fabric multi-shaft winding machine and winding method thereof

ActiveCN114194944AAvoid frequent replacementIncrease winding lengthWebs handlingWinding machineReciprocating motion

The invention discloses a narrow non-woven fabric multi-shaft winding machine. The narrow non-woven fabric multi-shaft winding machine comprises a winding rack, a winding device, a tensioning adjusting device, an elastic pressing device and a first power piece. The winding device comprises a sliding frame, an air swelling shaft, a winding mandrel and a second power piece, the sliding frame is slidably connected to one end of the winding rack, one end of the air swelling shaft is rotatably connected to the sliding frame, the outer wall of the air swelling shaft is sleeved with the winding mandrel, and the second power piece is used for driving the air swelling shaft to rotate; the cross section of the winding core shaft is in a reuleaux triangle shape, and the winding core shaft comprises a conical part and a columnar part; the tensioning adjusting device comprises a tensioning displacement driving mechanism and a tensioning roller set, and the tensioning displacement driving mechanism is arranged at the other end of the winding rack; the elastic pressing device is used for pressing the non-woven fabric against the surface of the winding mandrel; the first power piece is used for driving the winding device to do reciprocating motion in the direction perpendicular to the non-woven fabric winding direction; according to the non-woven fabric winding device, non-woven fabric with longer length can be wound, frequent replacement of the mandrel is avoided, and the winding efficiency is improved.

Owner:GUANGDONG BIAODIAN NONWOVENS TECH CO LTD

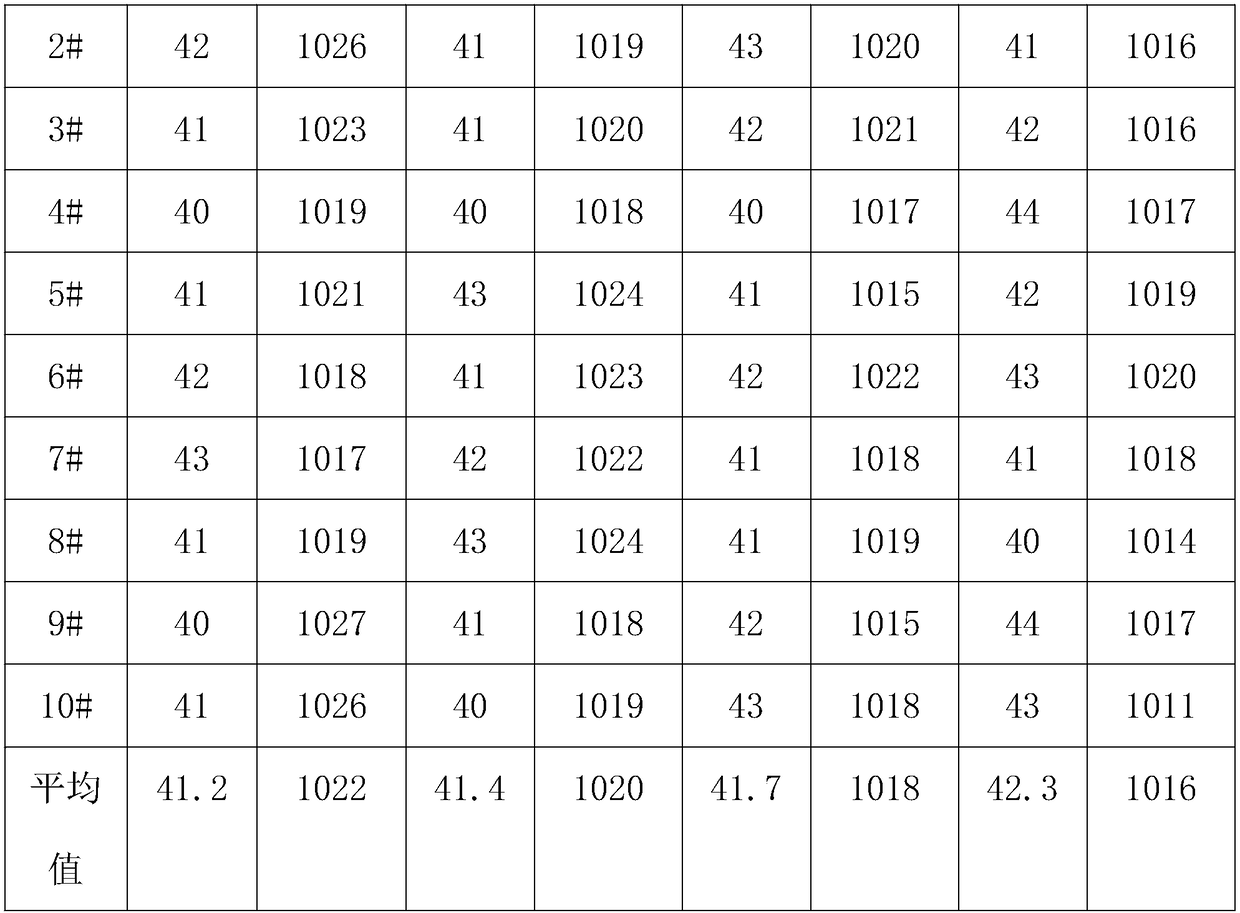

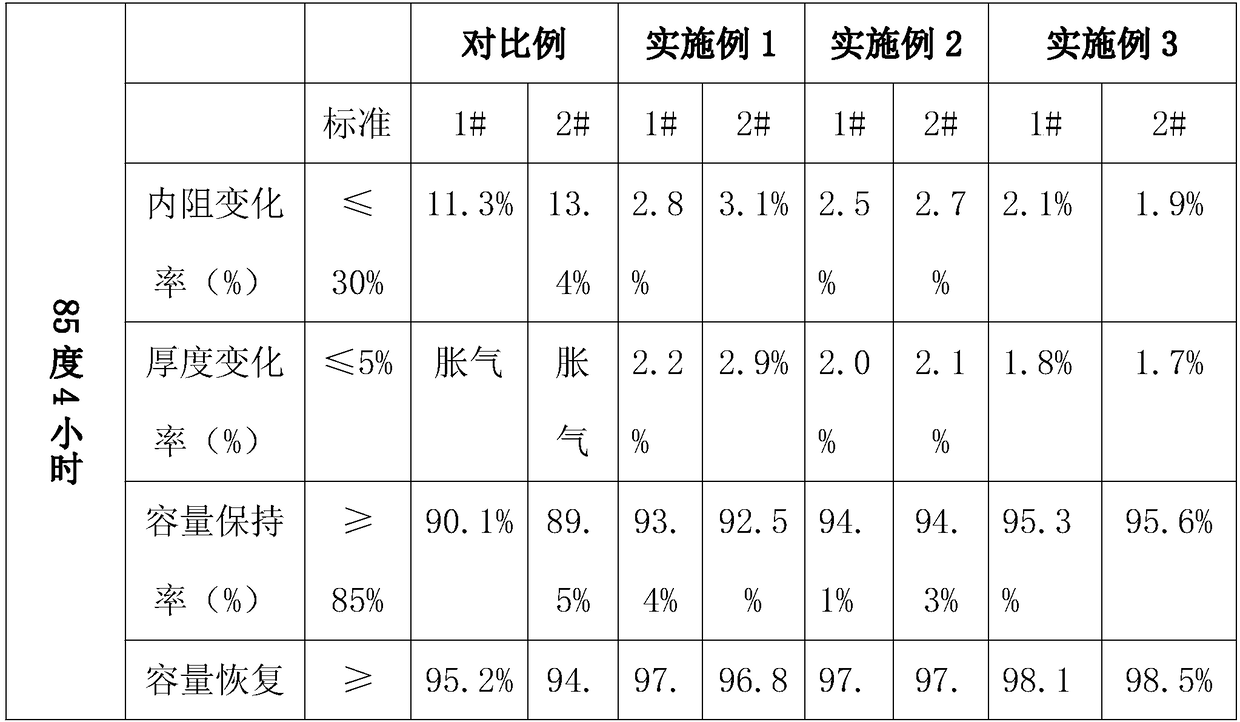

Manufacturing method of high-temperature resistant ternary lithium ion battery

InactiveCN108400389AImprove pass rateImprove high temperature resistanceFinal product manufactureElectrolyte accumulators manufactureManufacturing technologyMetal foil

Owner:MEIZHOU LIANGNENG NEW ENERGY SCI & TECHCO

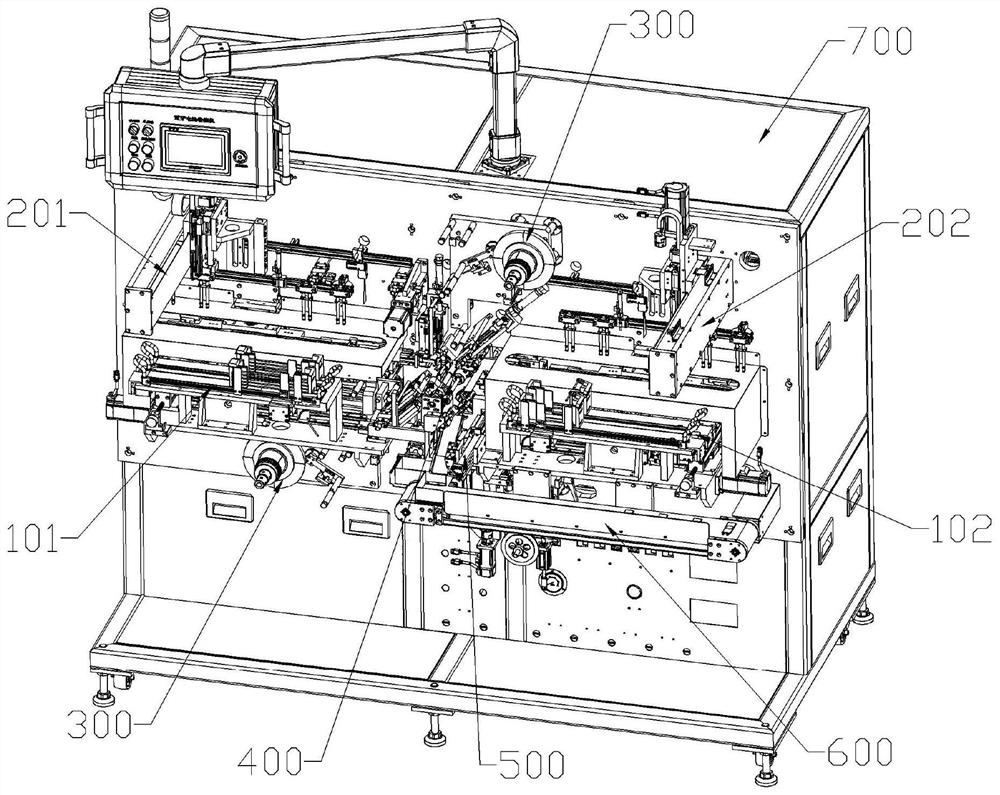

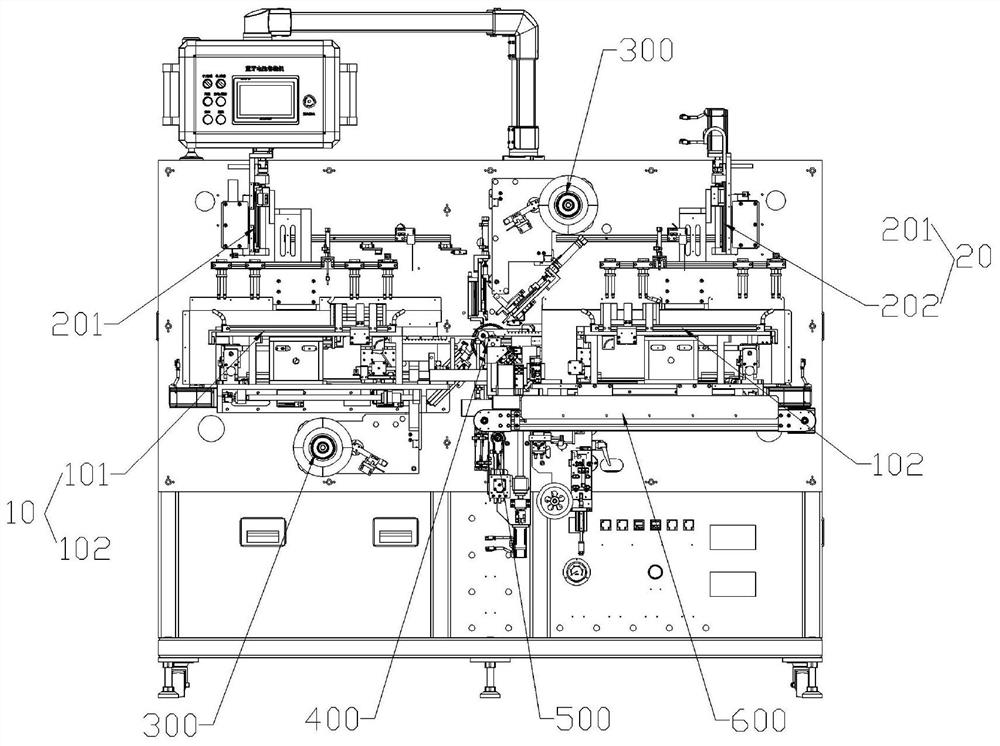

Automatic winding machine for micro battery

PendingCN112271319ARealize the winding processImprove operating precisionPrimary cell manufactureFinal product manufactureWinding machinePole piece

Owner:深圳市鸿德机电科技有限公司

Initial point fixing device of steel wire coil winding machine

Owner:哈尔滨工大宏图橡塑科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap