Steel-plastic composite winding pipe winding machine

A technology of steel-plastic composite and winding pipes, which is applied in the field of devices for winding plastic winding pipes, can solve the problems of many driving wheels, high cost, and low production efficiency, and achieve the effects of meeting design requirements, improving ring stiffness, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

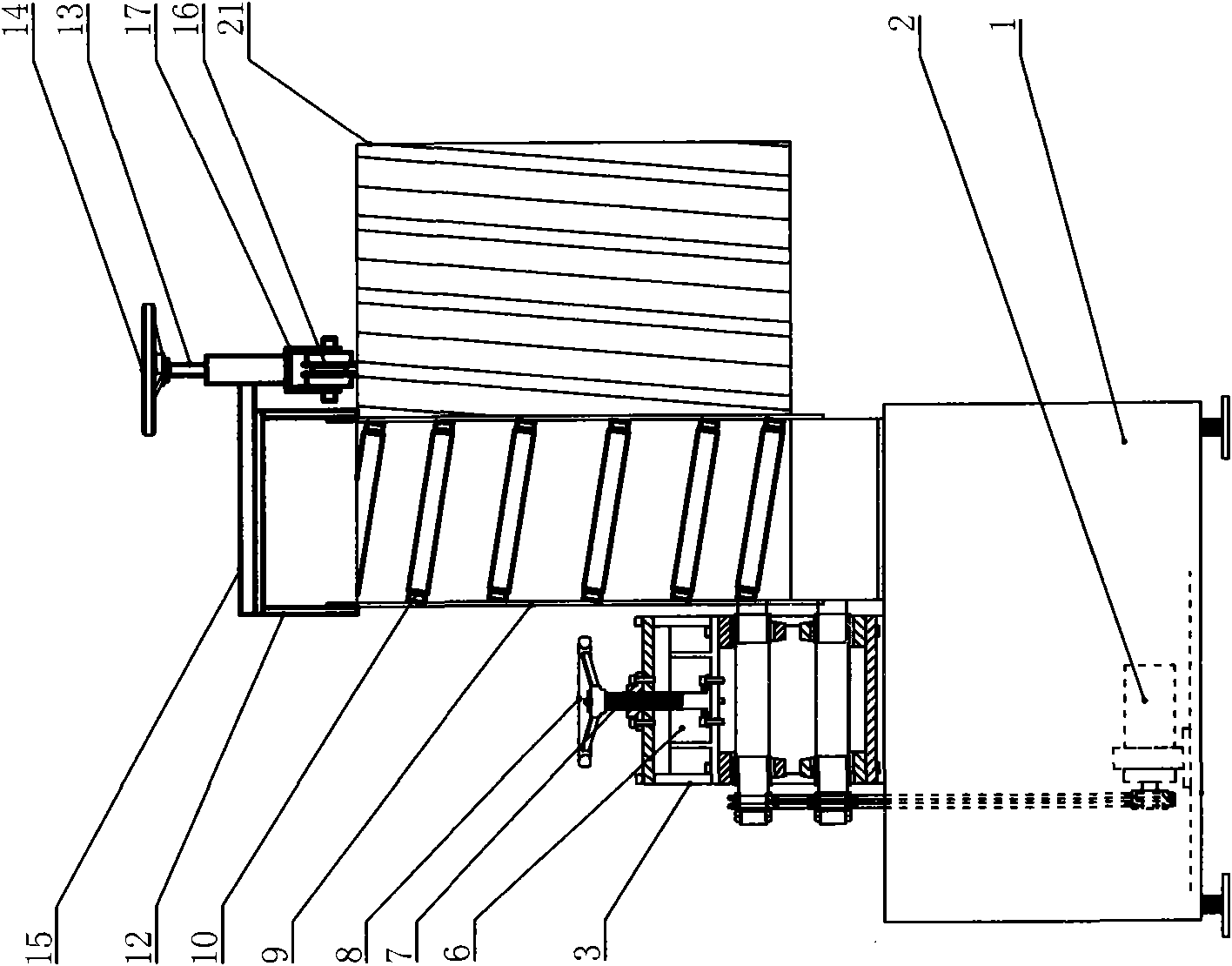

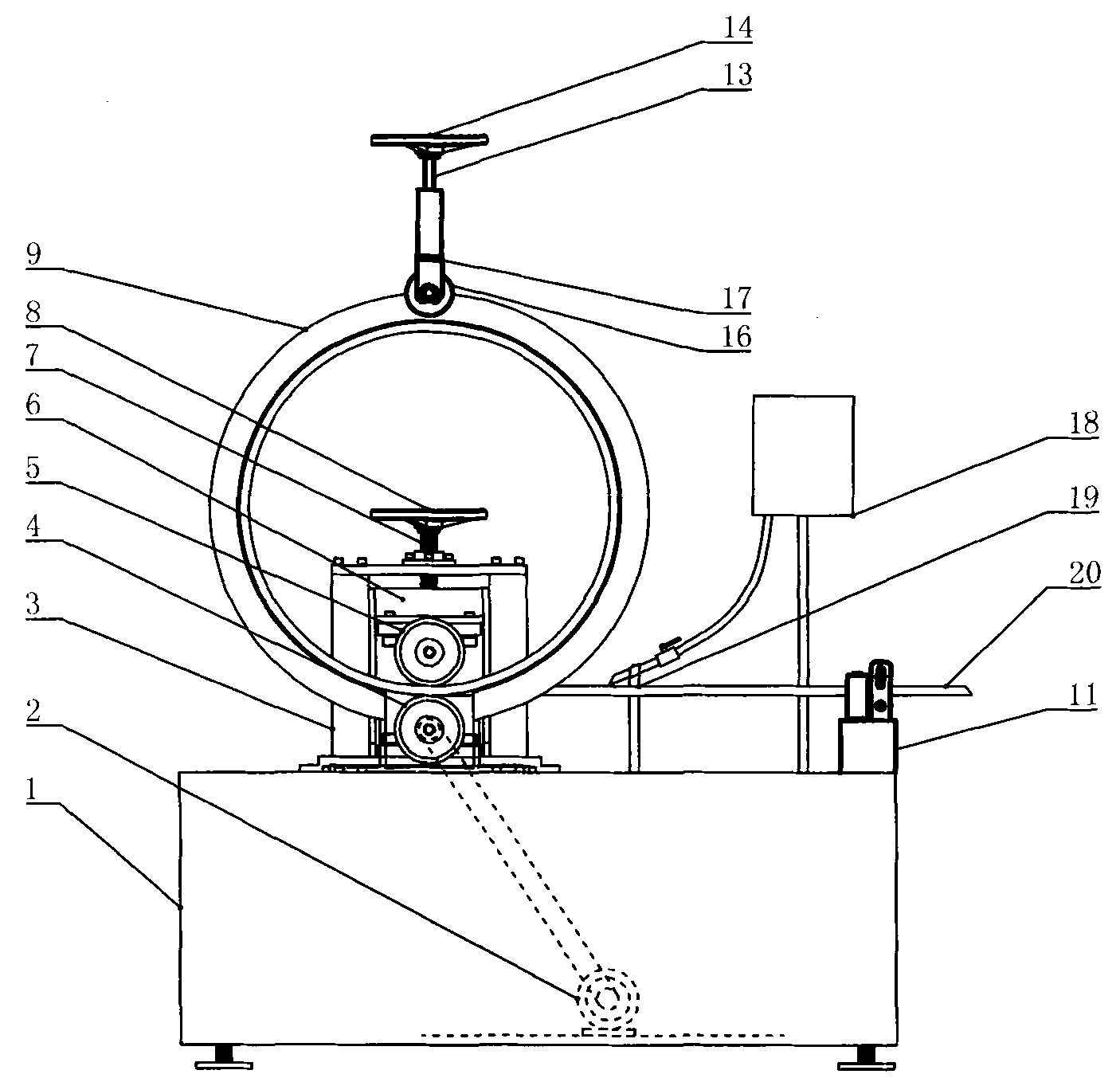

[0009] refer to figure 1 , 2 , it includes a machine base 1, a motor 2 is installed on the machine base, a box body 3 is fixed on the machine base 1, a slider 6 is arranged in the box body, the slider 6 is installed on the slideway on the inner wall of the box body, and an upper power roller is arranged on the box body 5 and the lower power roller 4, the upper power roller is installed on the slider 6, the lower power roller is fixed on the box, the lower power roller is connected with the motor through the chain, the upper power roller is connected with the lower power roller through the chain, and the lead screw 7 passes through The screw nut is installed on the box and connected with the slider 6. The upper end of the screw is equipped with a hand wheel 8, and the ring gauge is installed on the base. The ring gauge is replaceable, and its diameter is 300cm-3000cm. The edge is at the same height as the upper edge of the outer diameter of the lower power roller. Several rotatin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap