Spin winding machine

A coiling machine and mechanical technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of deterioration of the tracking performance of the contact roller 143, failure to check the slide box 144 easily, and damage the slide box 144 smoothly In order to achieve the effect of easy lifting abnormality, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described below with reference to the drawings.

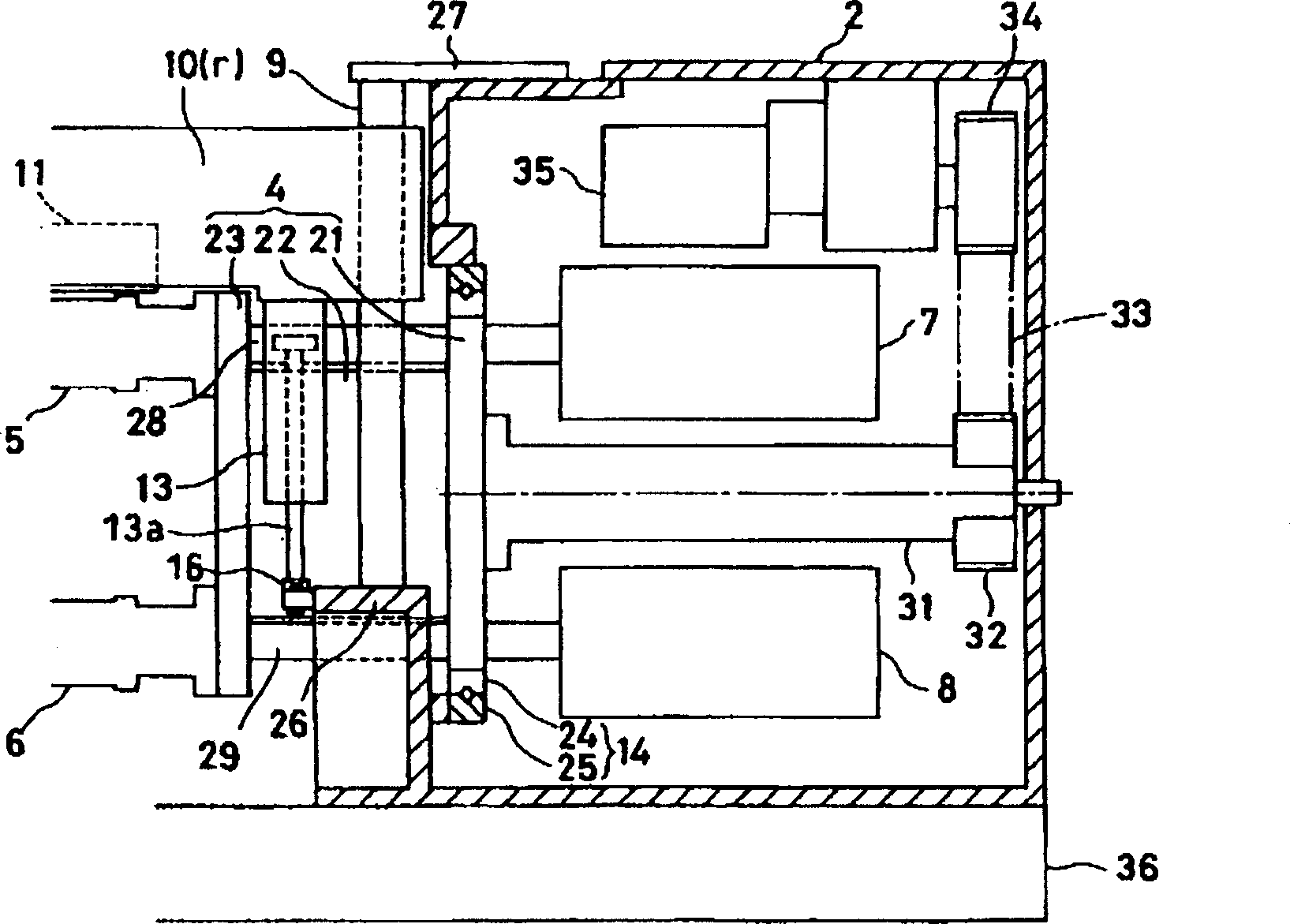

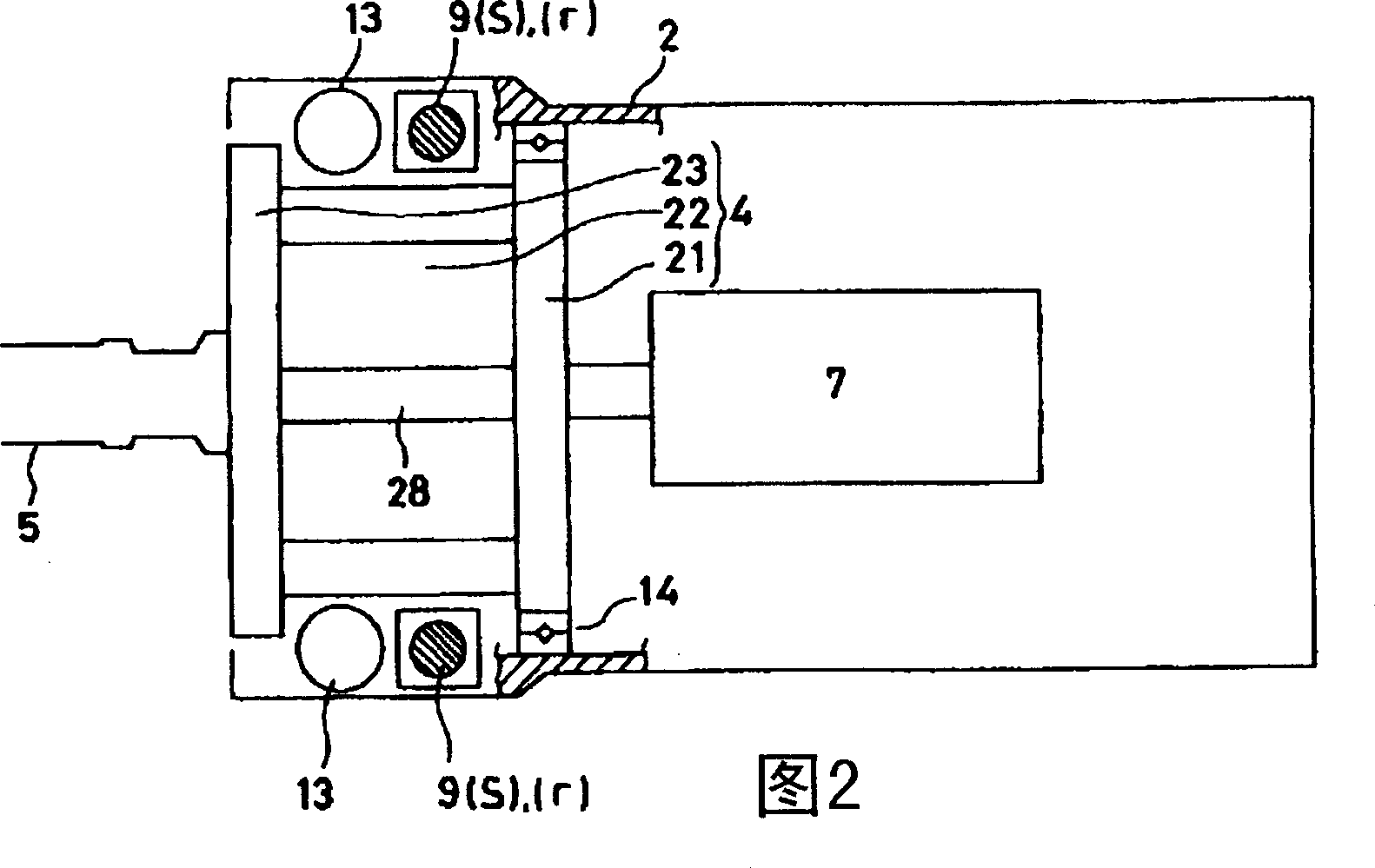

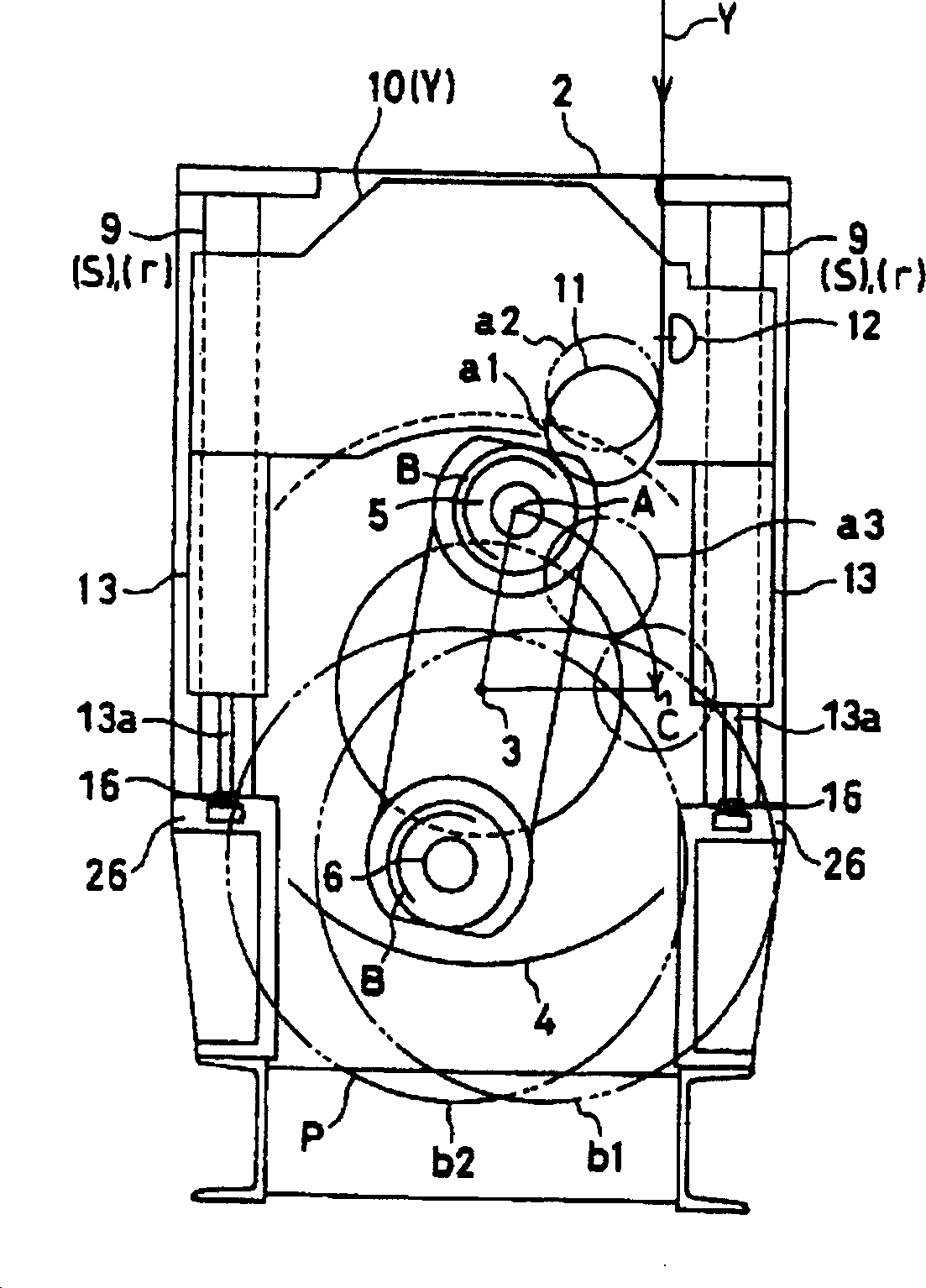

[0045] Such as Figure 4 , Figure 5 As shown, the spinning winder 1 is composed of the following parts: a turntable 4 that rotates around a central axis 3 relative to the machine body 2; two bobbin holders 5, 6 protruding from the turntable 4; The induction motors 7 and 8 driven by bobbin holders 5 and 6 on the back of the turntable 4; guided by the guide pillars 9 in the machine body 2, the lifting frame 10 that moves vertically up or down; the lifting frame 10 supported on the lifting frame 10 Contact roller 11; traverse device 12 supported on lifting frame 10.

[0046]The entire weight of the elevating frame 10 supporting the contact roller 11 and the traverse device 12 is supported by the contact pressure cylinder 13 provided between the elevating frame 10 and the machine body 2, and the difference between these weights and the upward thrust from the contact pressure cylin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap