Manufacturing method of high-temperature resistant ternary lithium ion battery

A technology of lithium-ion battery and production method, which is applied in the production field of high-temperature-resistant ternary lithium-ion batteries, can solve the problems of battery loss of use function, battery cell swelling, etc., and achieve improved pass rate, good high-temperature resistance performance, and product pass rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: positive and negative electrode sheet production method is the same as comparative example, positive electrode sheet is soaked 3mins with the acetone solution that contains 1% vinyltriethoxysilane, 0.3%HOAc after making sheet, then takes out positive electrode sheet and puts Put it in a 60-degree oven for 5 minutes. After the acetone on the surface of the positive electrode is completely evaporated, take it out and make the battery according to the normal process of lithium-ion batteries.

Embodiment 2

[0029] Embodiment 2: the method for making the positive and negative plates is the same as that of the comparative example. The positive plate is soaked for 3mins with the acetone solution containing 2% vinyltriethoxysilane and 0.3% HOAc after the film is finished, and then the positive plate is taken out and placed in Put it in a 60-degree oven for 5 minutes. After the acetone on the surface of the positive electrode is completely evaporated, take it out and make the battery according to the normal process of lithium-ion batteries.

Embodiment 3

[0030] Embodiment 3: the positive and negative electrode sheet production method is the same as the comparative example, and the positive electrode sheet is soaked for 3mins with the acetone solution containing 3% vinyltriethoxysilane and 0.3% HOAc after making the sheet, and then the positive electrode sheet is taken out and placed in Put it in a 60-degree oven for 5 minutes. After the acetone on the surface of the positive electrode is completely evaporated, take it out and make the battery according to the normal process of lithium-ion batteries.

[0031] test:

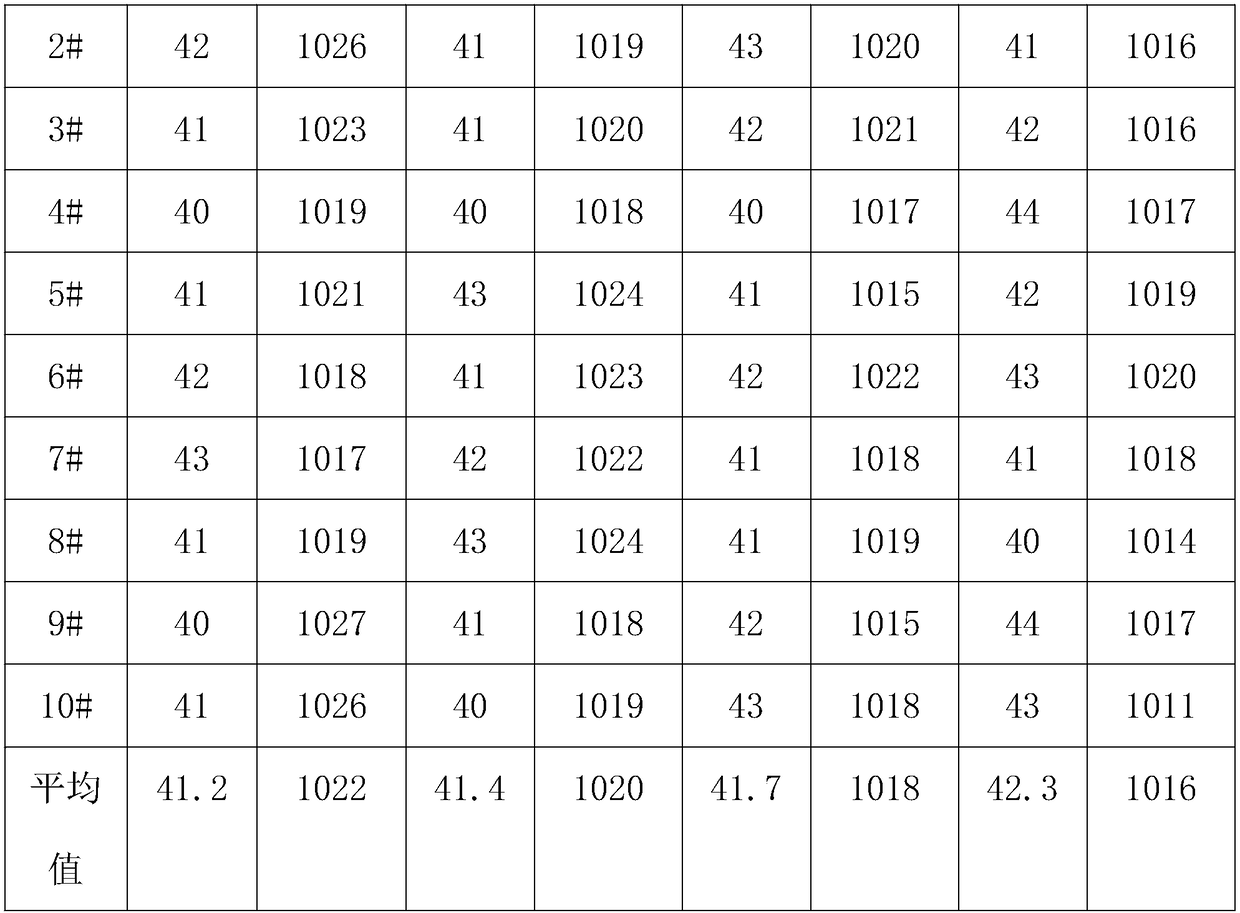

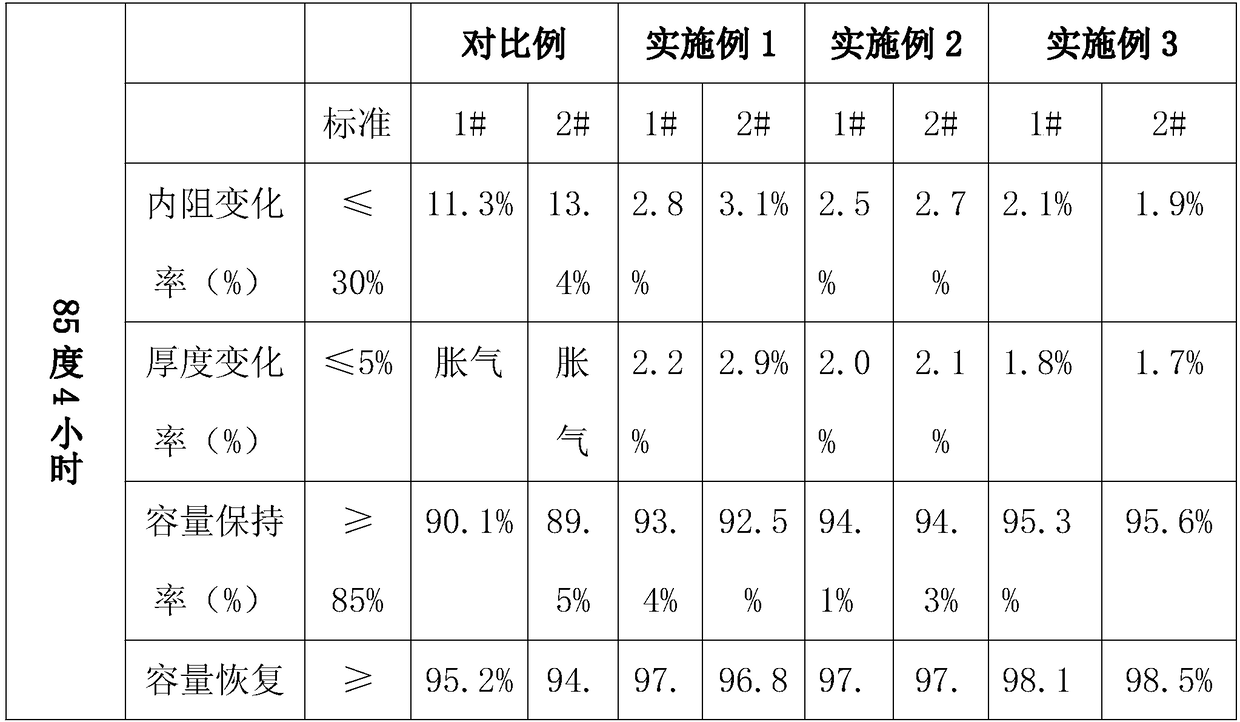

[0032] Take each group of comparative example and embodiment batteries, and test the capacity, voltage, internal resistance, and thickness of the batteries. After fully charging (charging to 4.2V), store them at a high temperature of 85 degrees for 4 hours and 24 hours respectively. The test data are as follows:

[0033]

[0034]

[0035] Judging from the capacity and internal resistance of the fabricated cells,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap