Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Plastic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

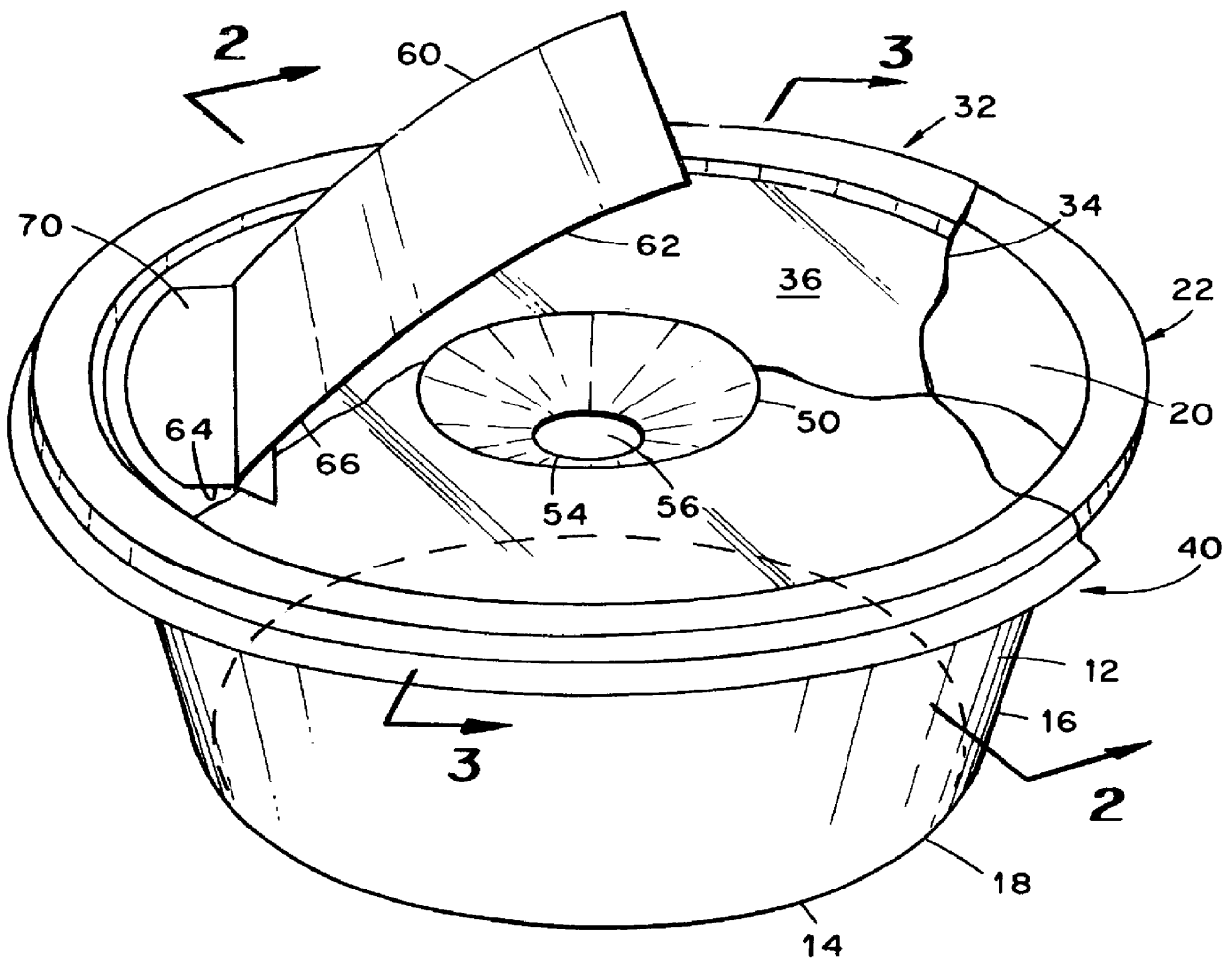

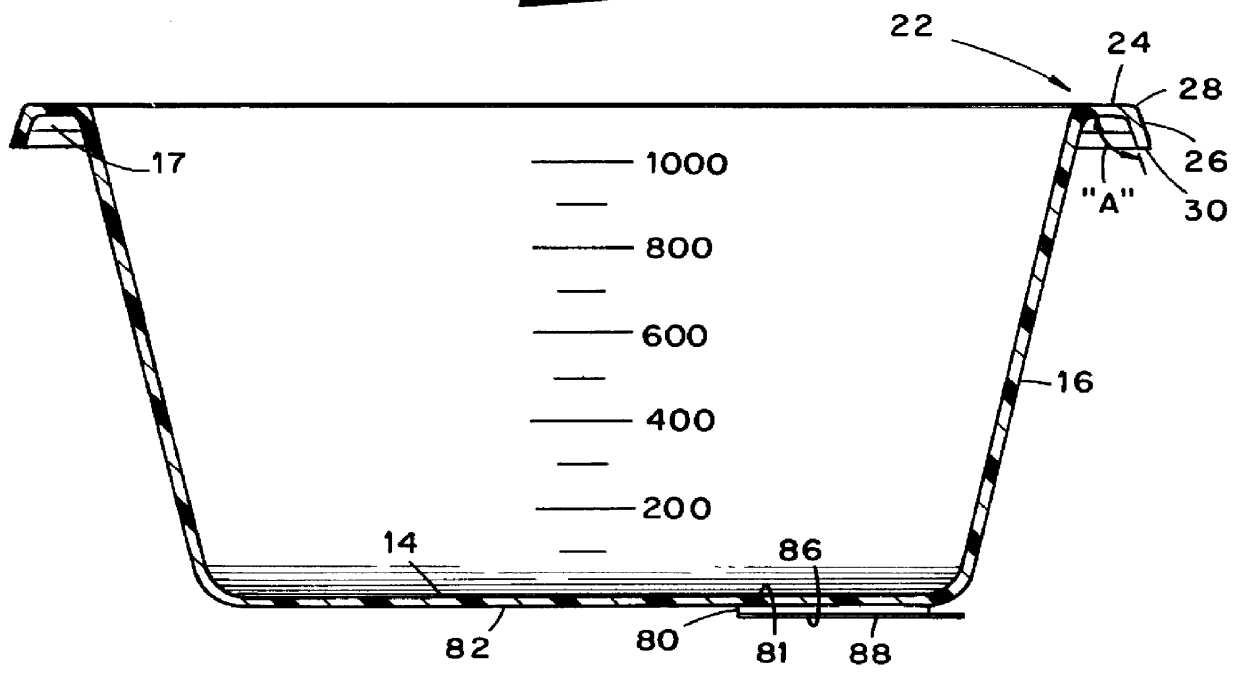

Receptacle for contaminated wastes

Owner:DEROYAL INDUSTRIES INC

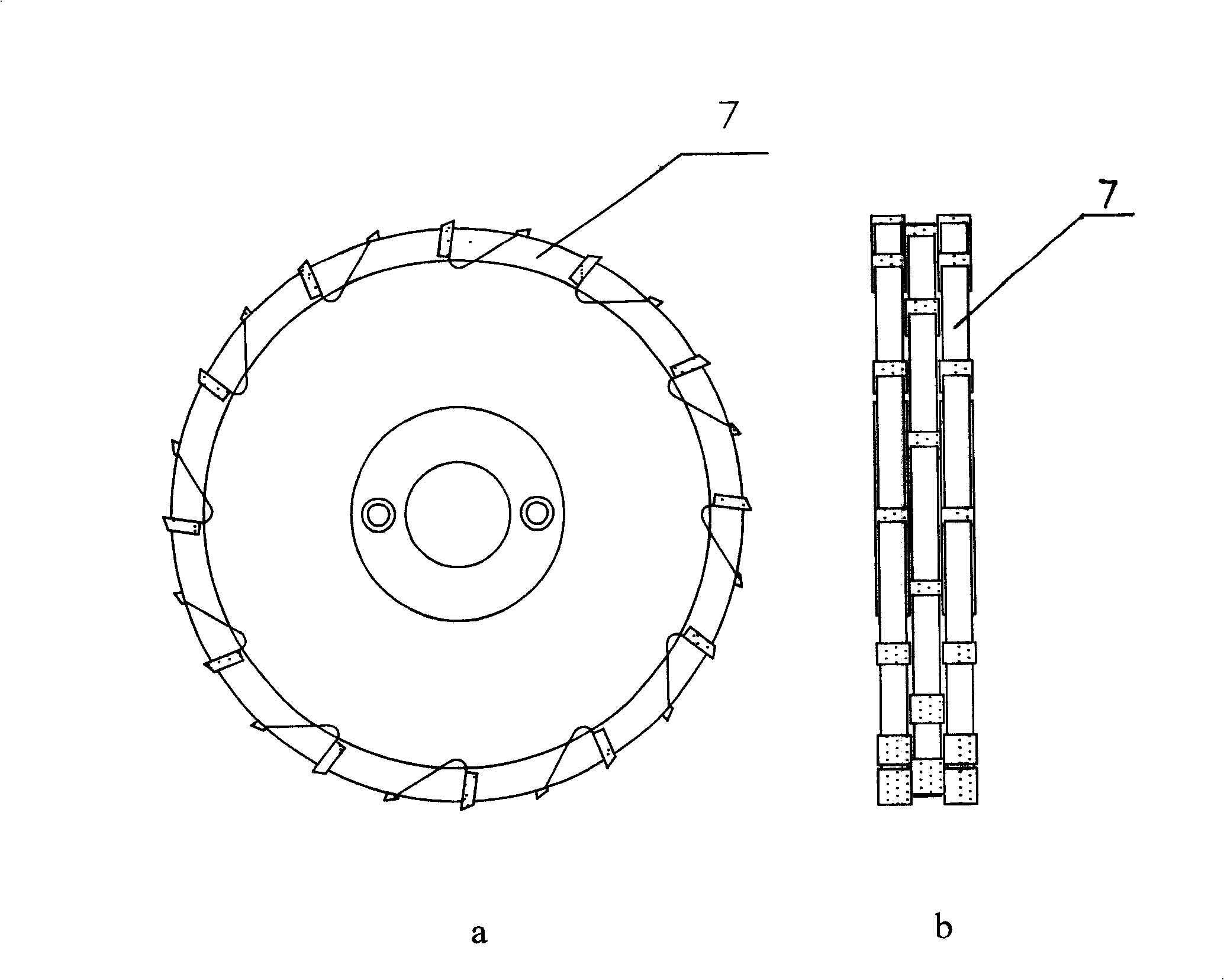

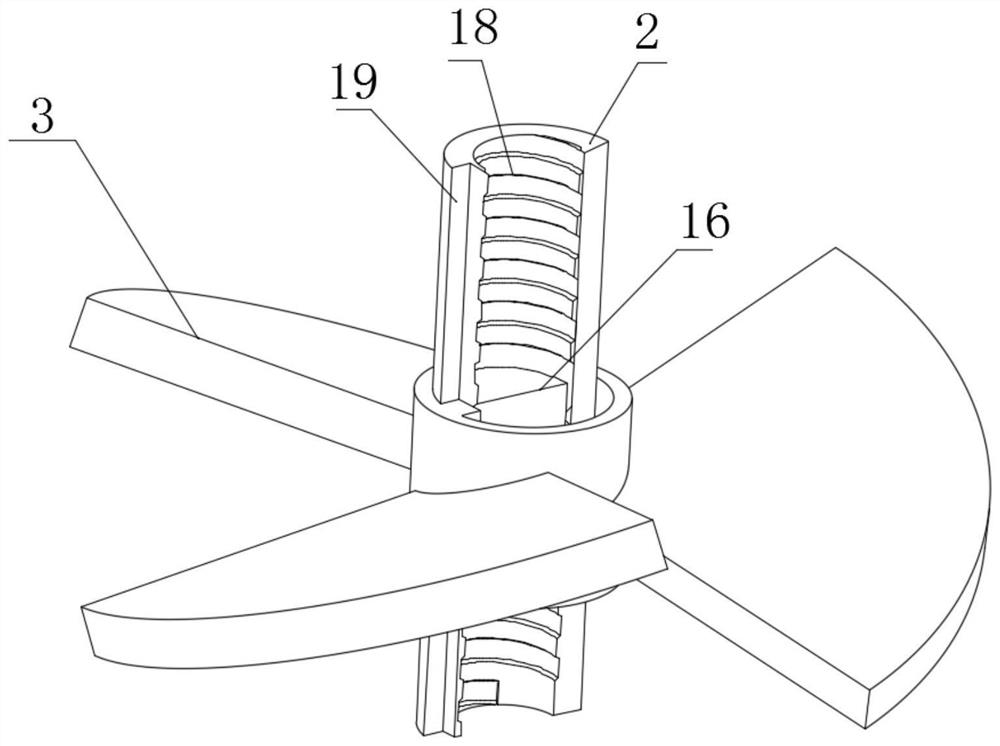

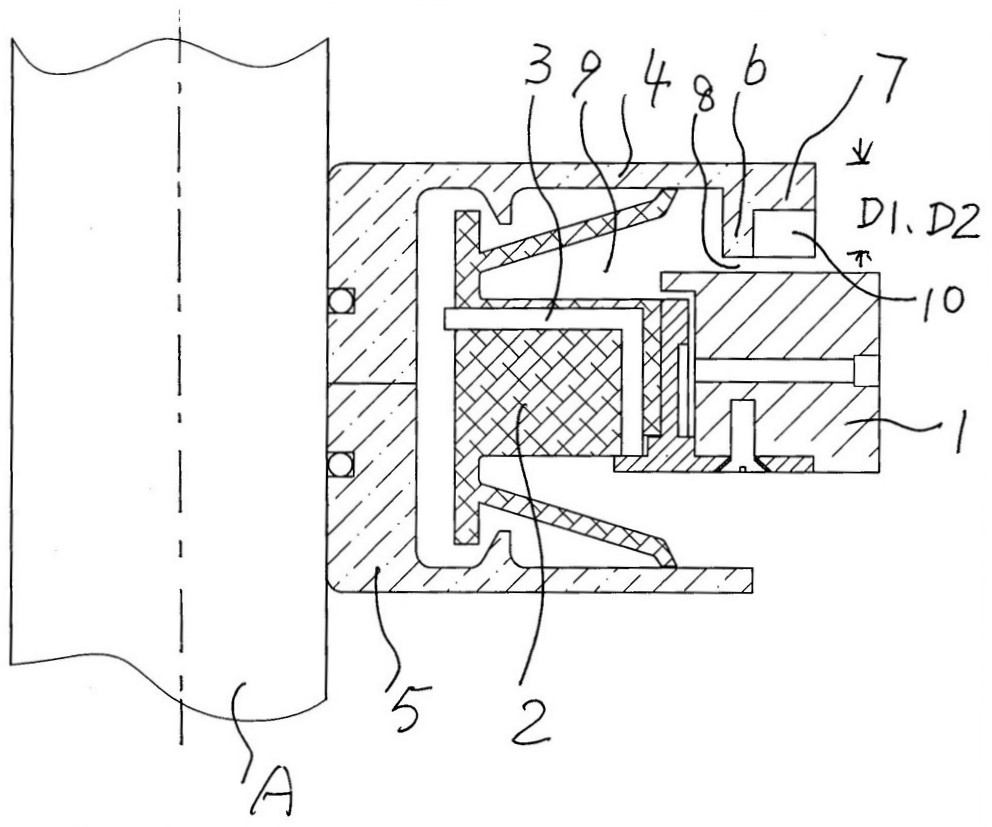

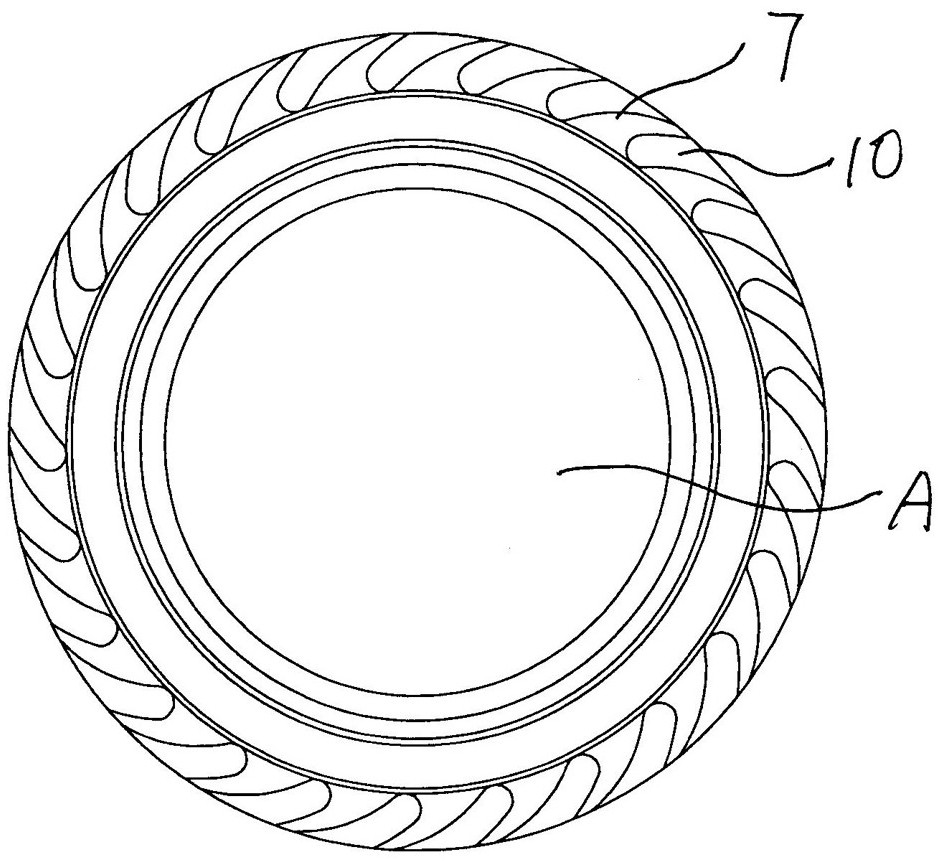

Alternator fan

InactiveUS20050106024A1High mechanical strengthImprove homogeneityPropellersPump componentsMobile vehicleAlternator

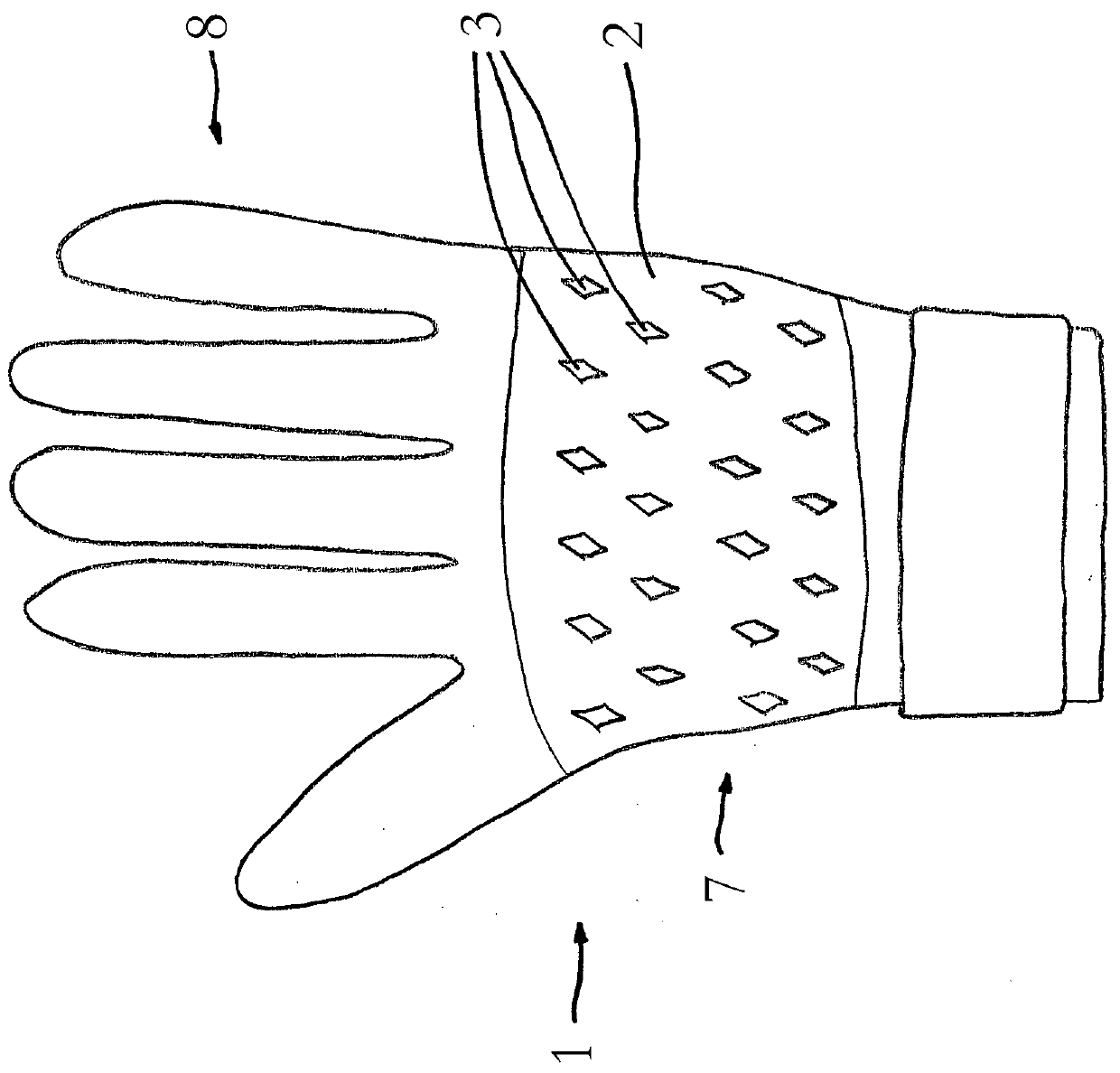

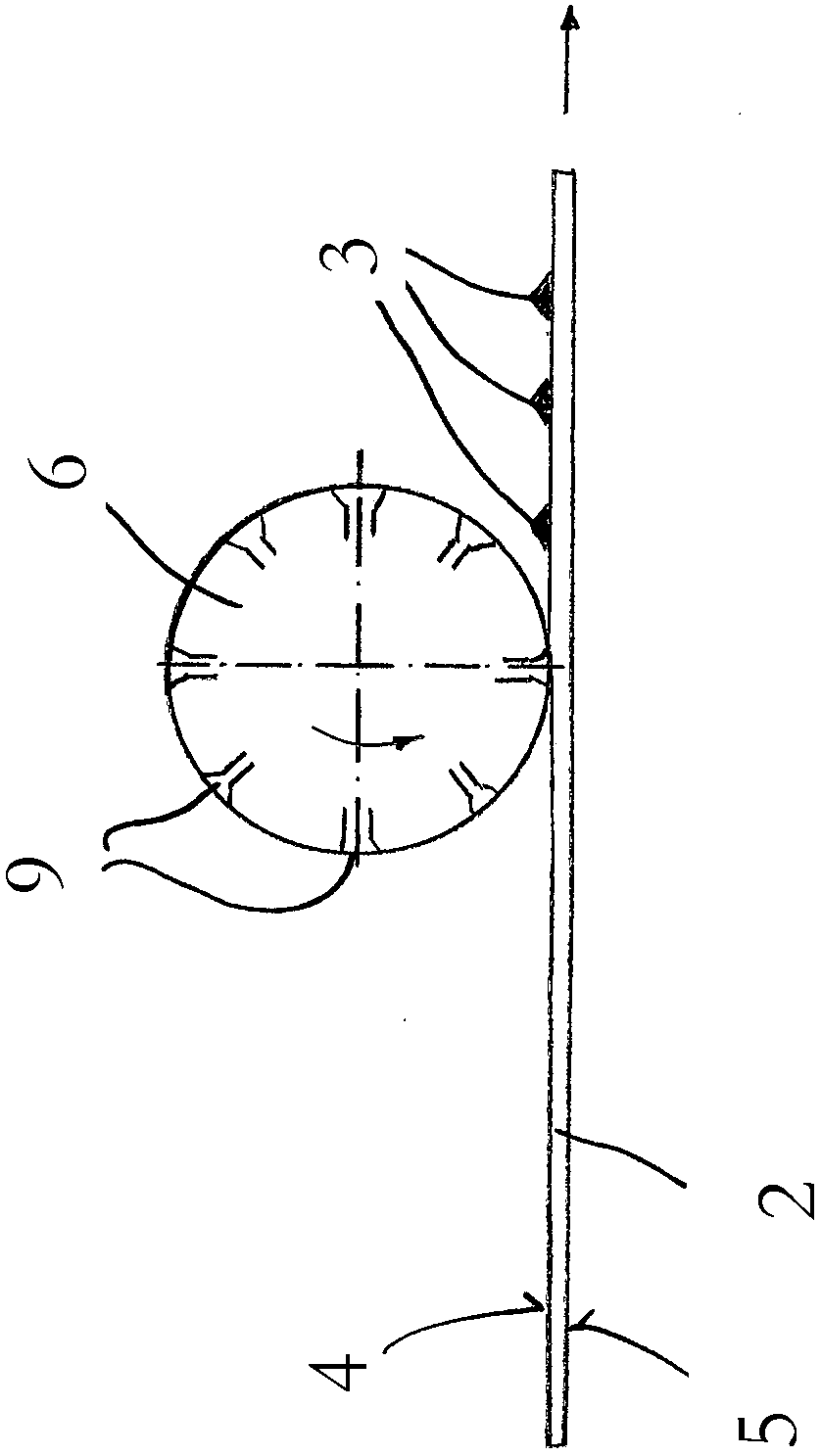

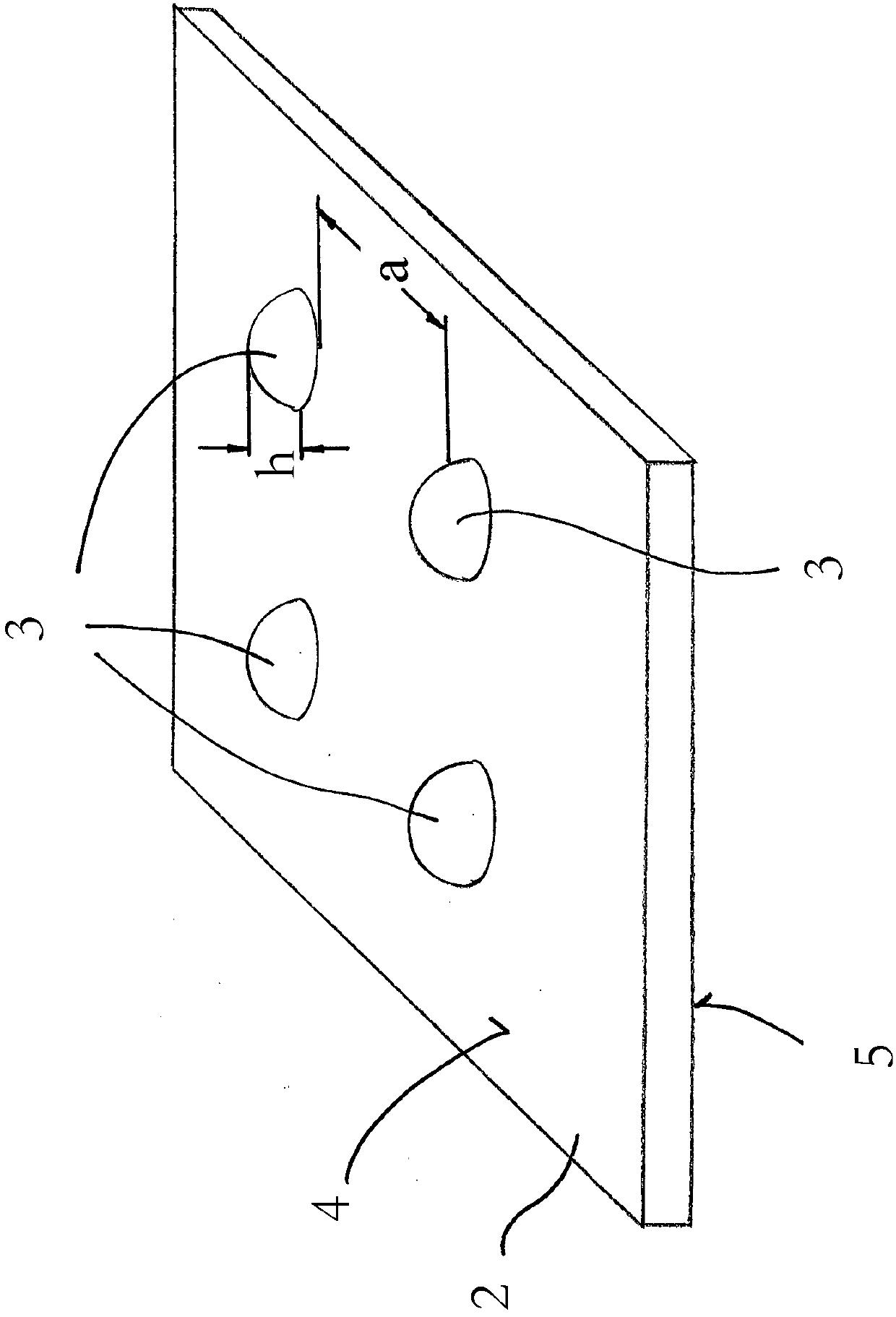

The invention is a fan for an alternator adapted to be coupled in rotation to the alternator rotor, and being of the type comprising a wheel part and a plurality of fan blades (47, 48) extending from the latter, the fan being moulded in a plastics material on an insert (50) which is preferably of metal and which constitutes the wheel part of the fan and is arranged to provide fastening of the fan on the rotor, being configured so as to constitute a means for increasing the mechanical strenght of the fan; the insert (50, 65) includes at least a portion of a blade (48, 69) of the fan. The invention is useful in the manufacture of a high power cooling fan for a motor vehicle alternator.

Owner:VALEO EQUIP ELECTRIC MOTEUR

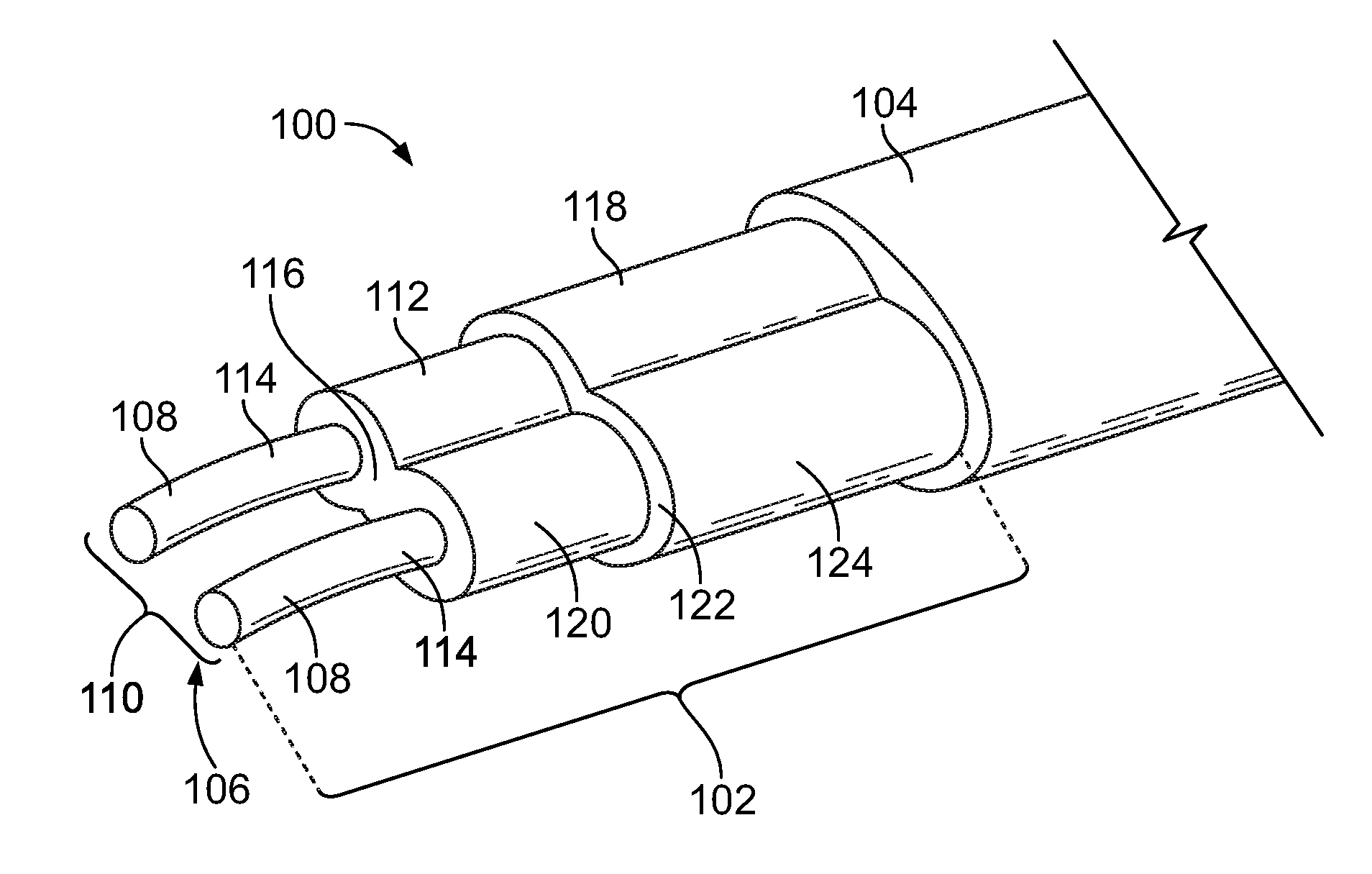

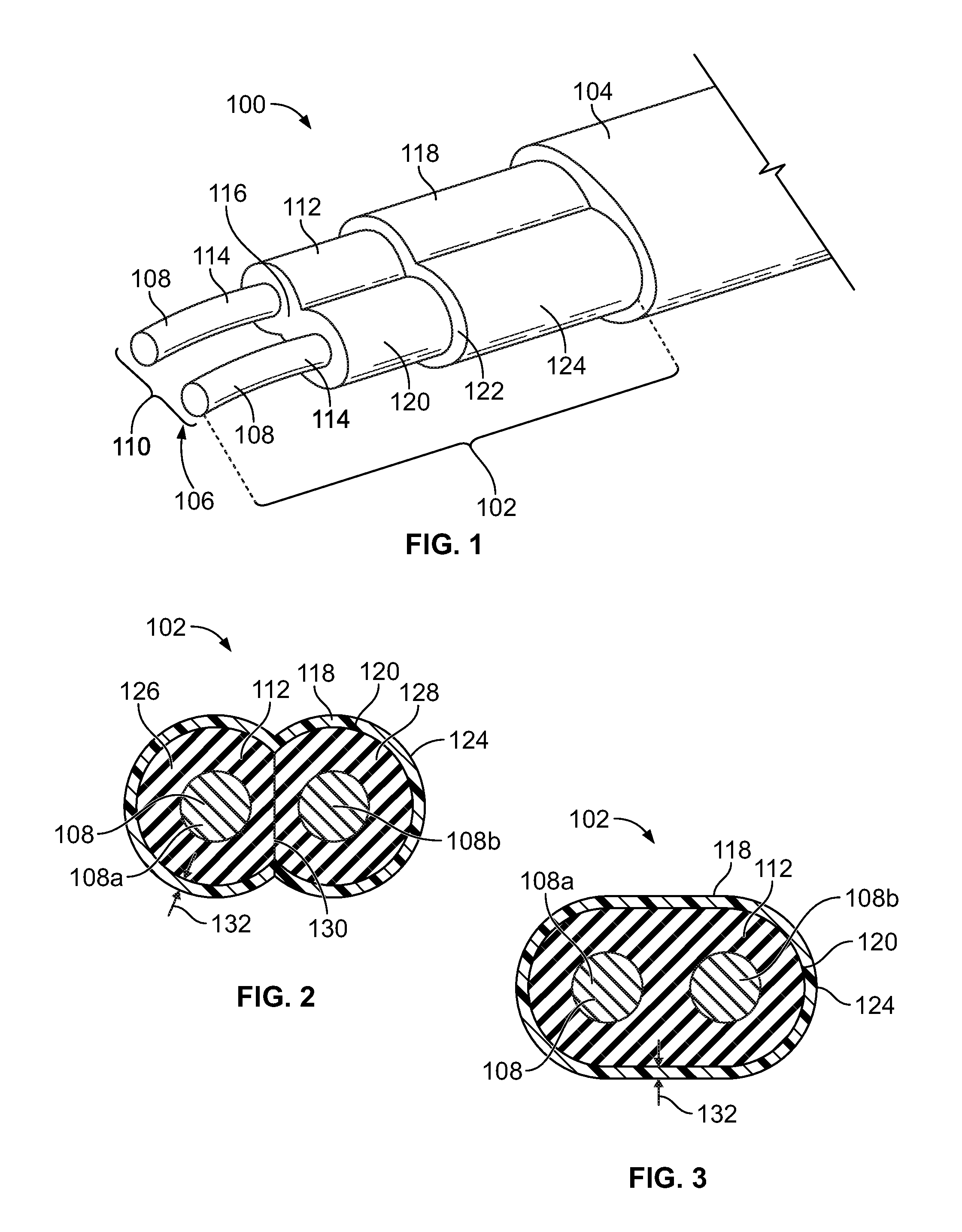

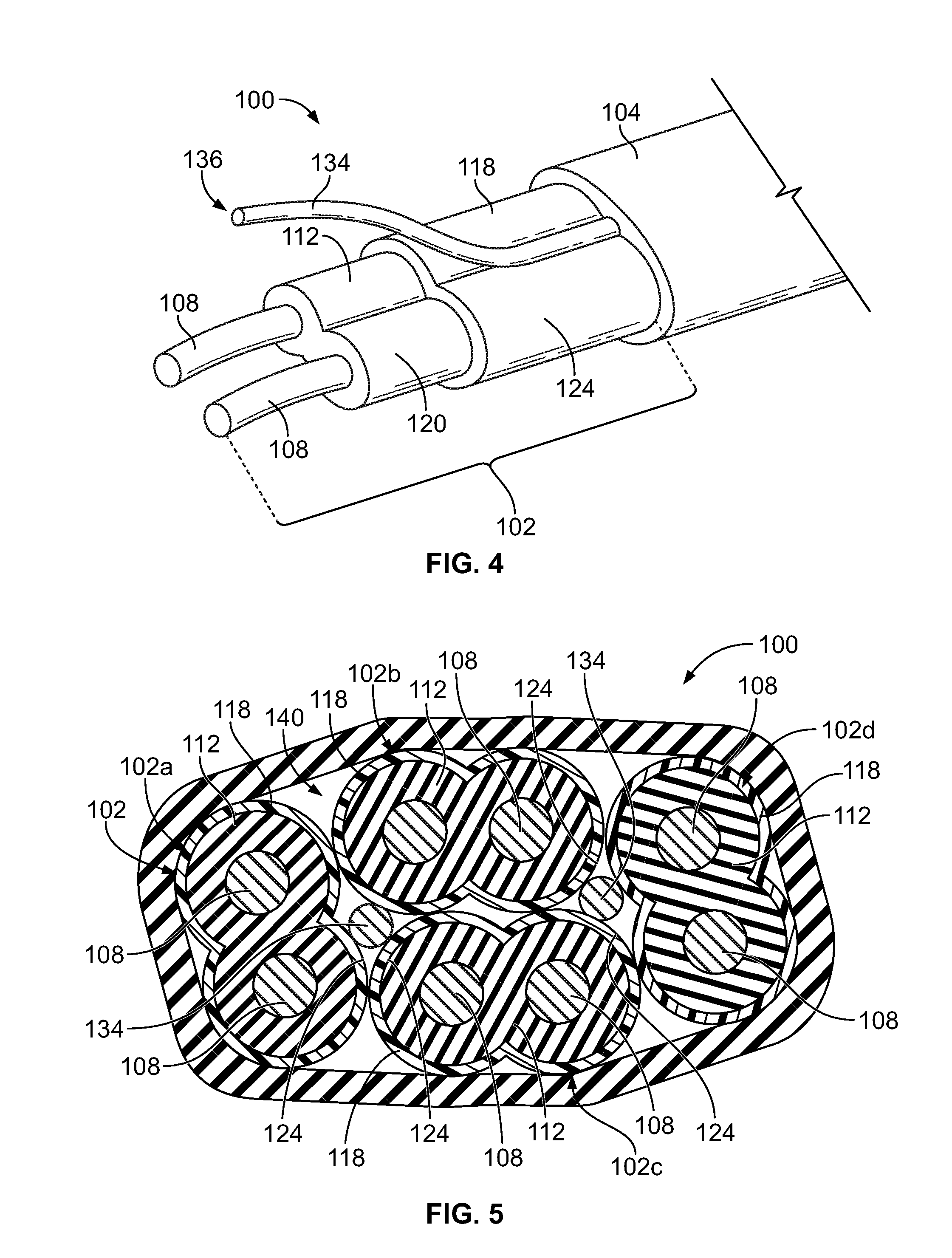

Electrical cable with shielded conductors

ActiveUS20160343474A1Coaxial cables/analogue cablesMagnetic/electric field screeningPlastic materialsElectrical conductor

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

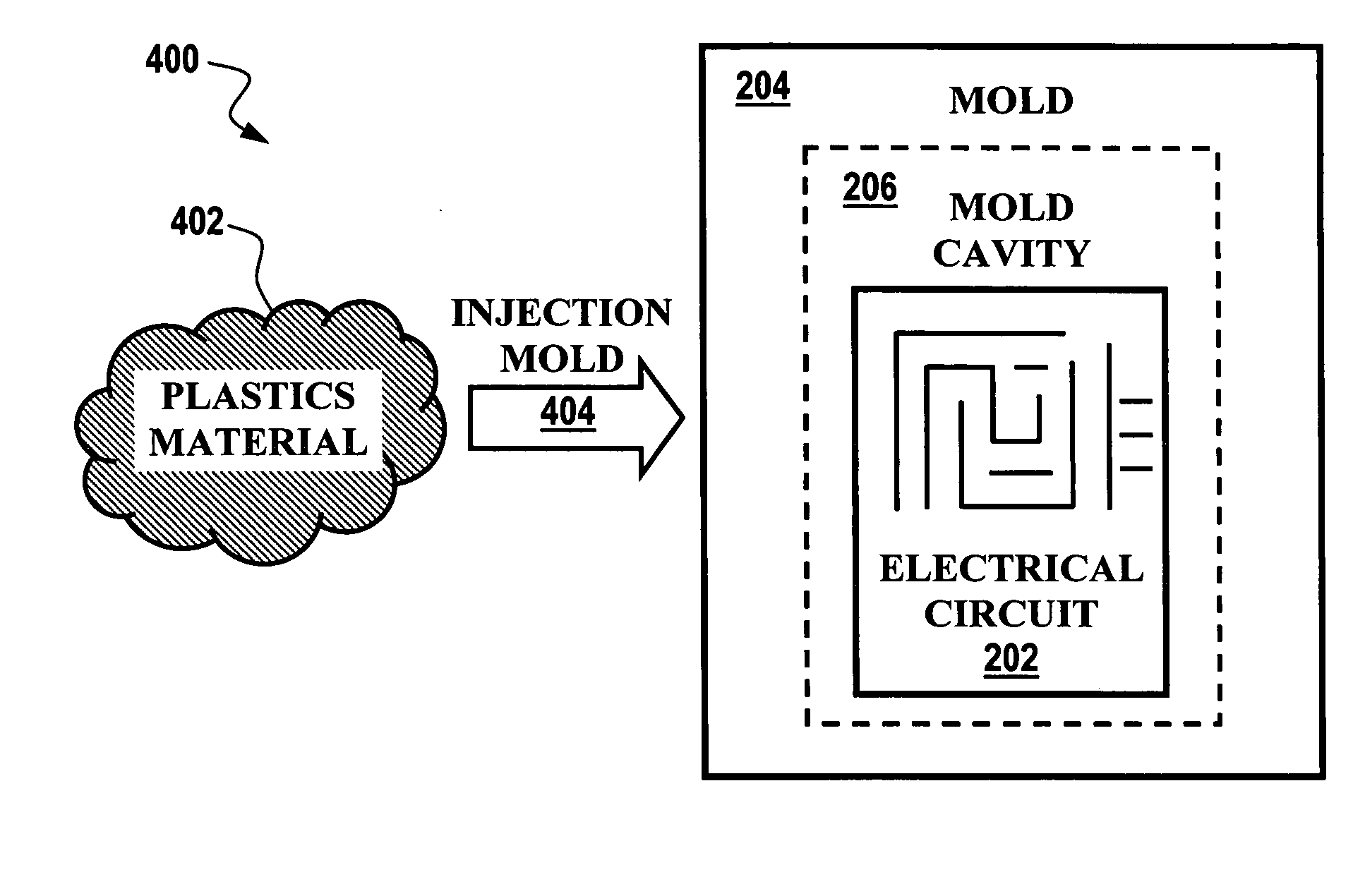

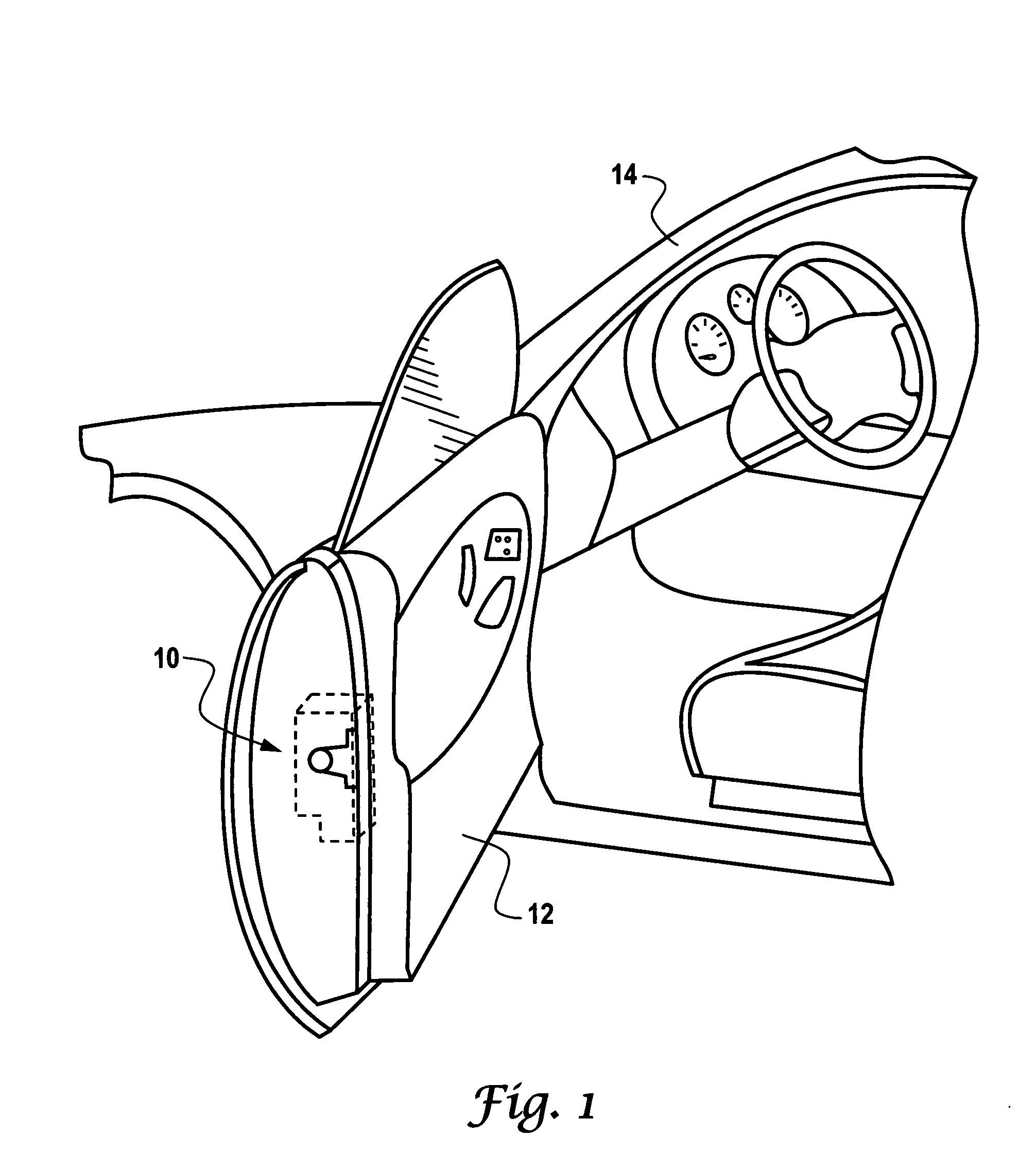

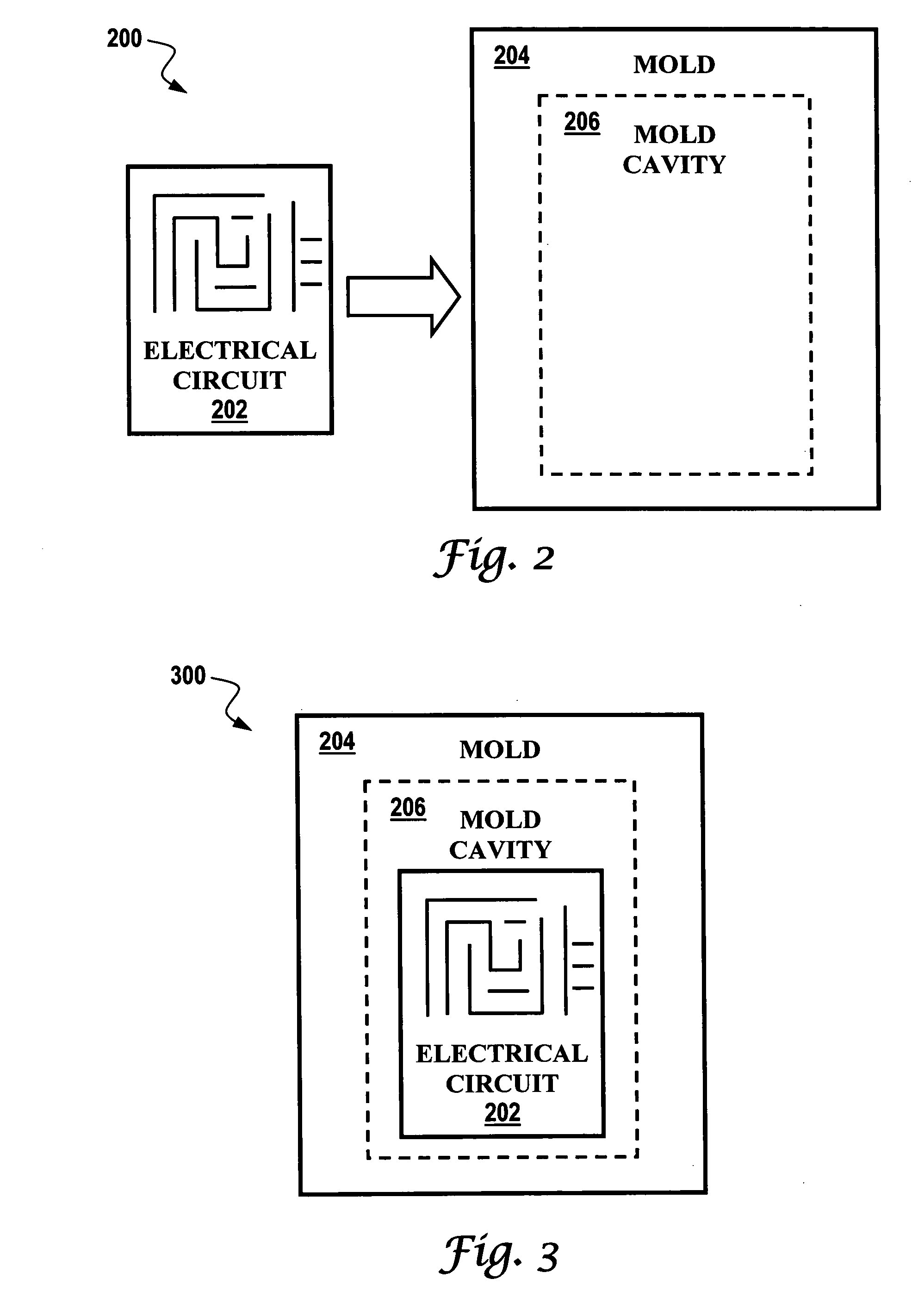

Circuit insulation methods and systems for vehicle door latches

Owner:HONEYWELL INT INC

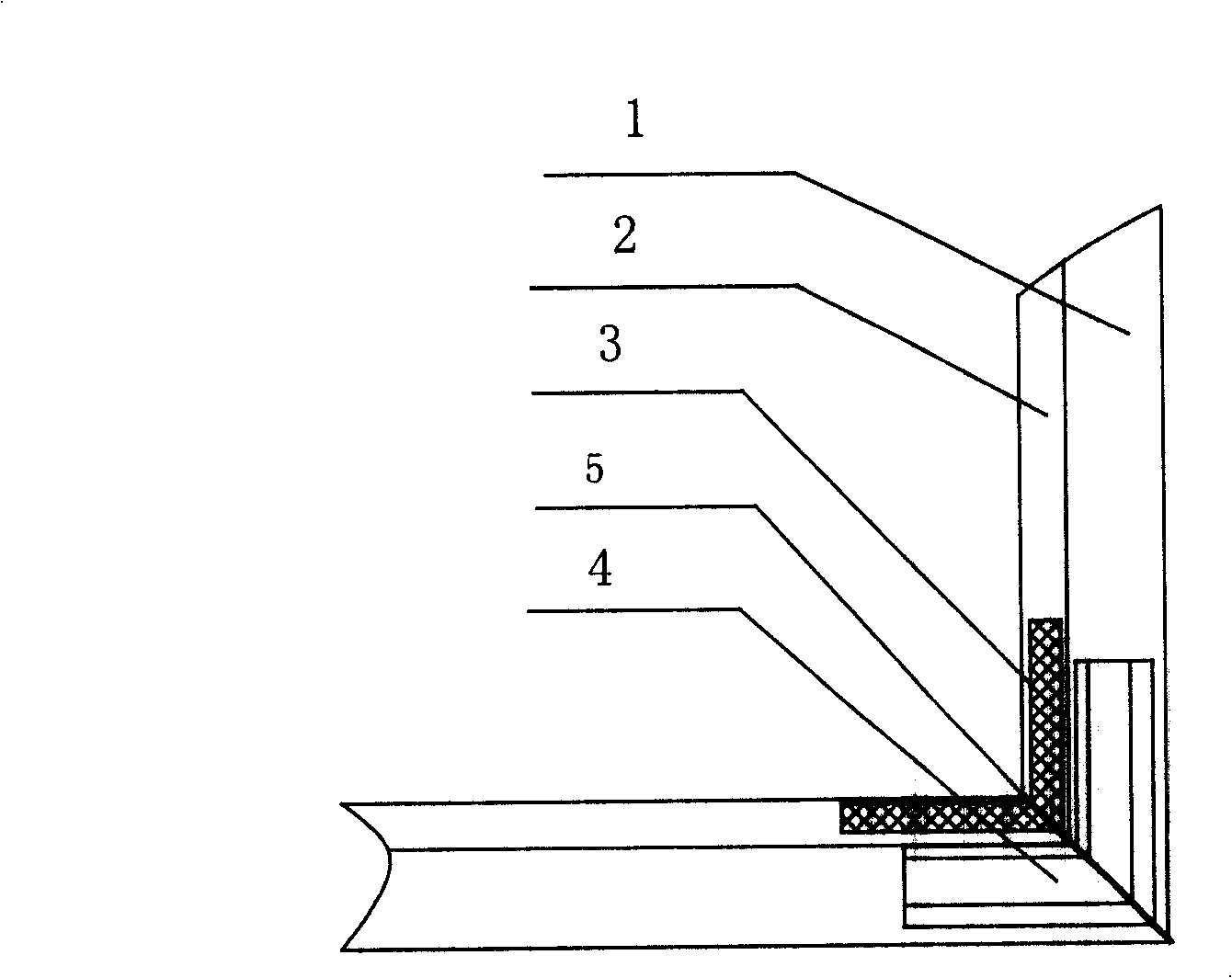

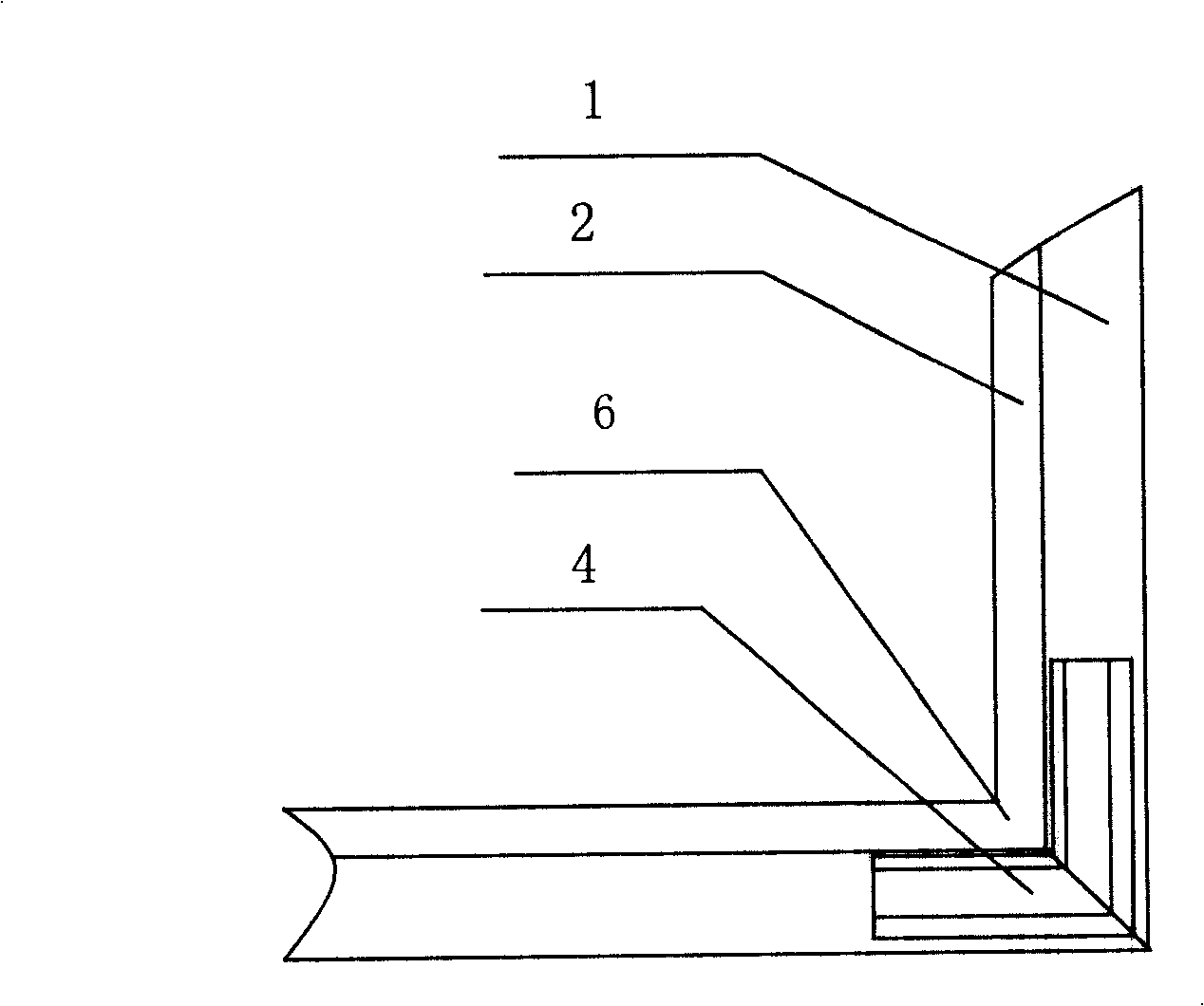

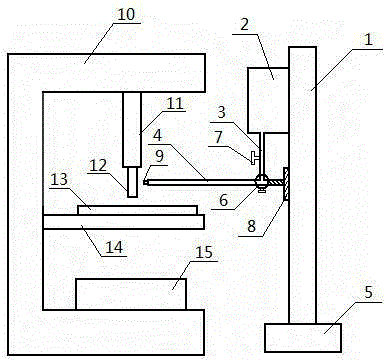

Welding process for aluminum plastics door and window

InactiveCN101244628AEliminate worriesIncrease productivityMilling cuttersMilling equipment detailsMilling cutterPlastic materials

Owner:CHANGZHI HUIFENG ELECTROMECHANICAL INDAL TRADE

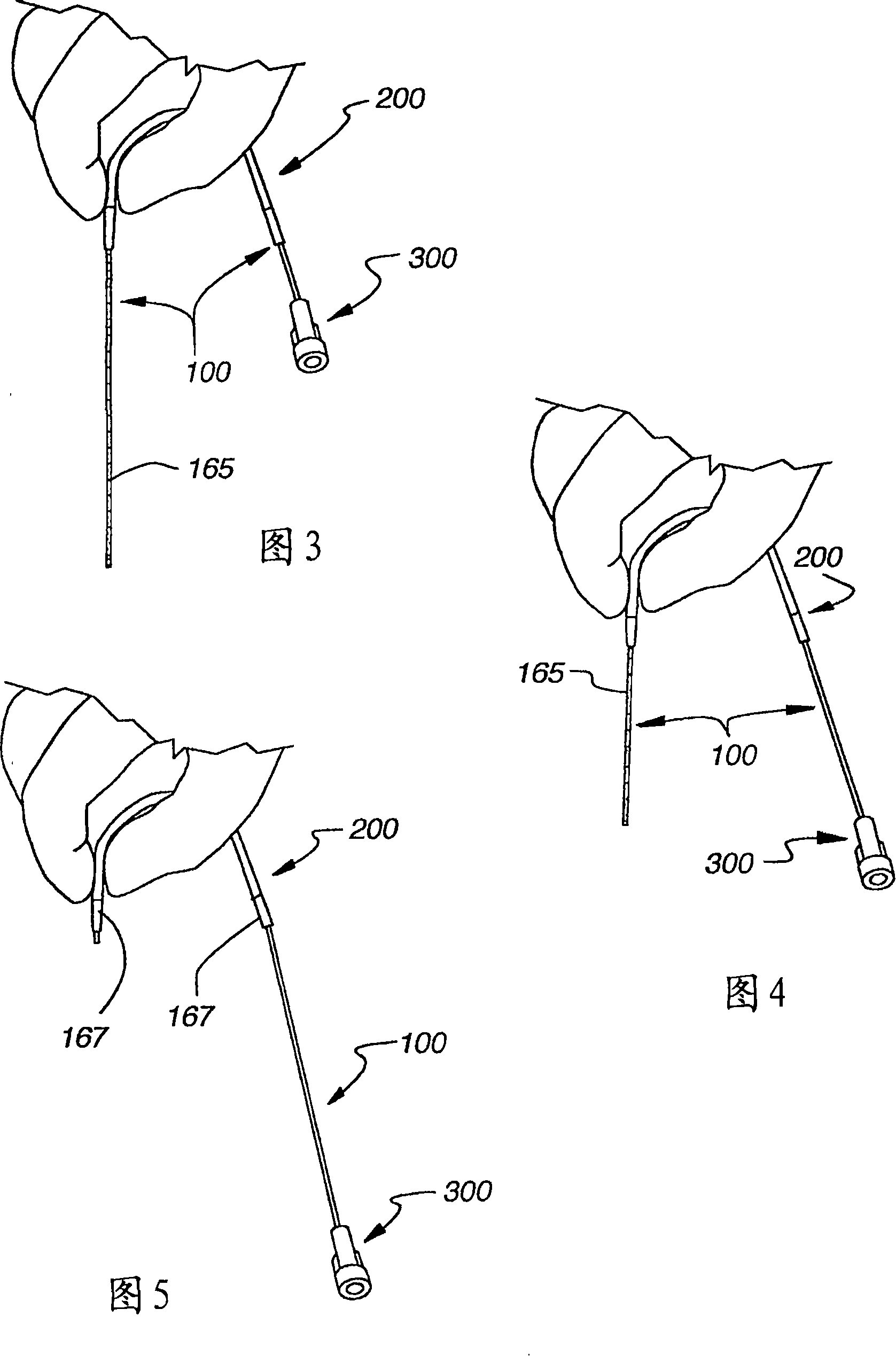

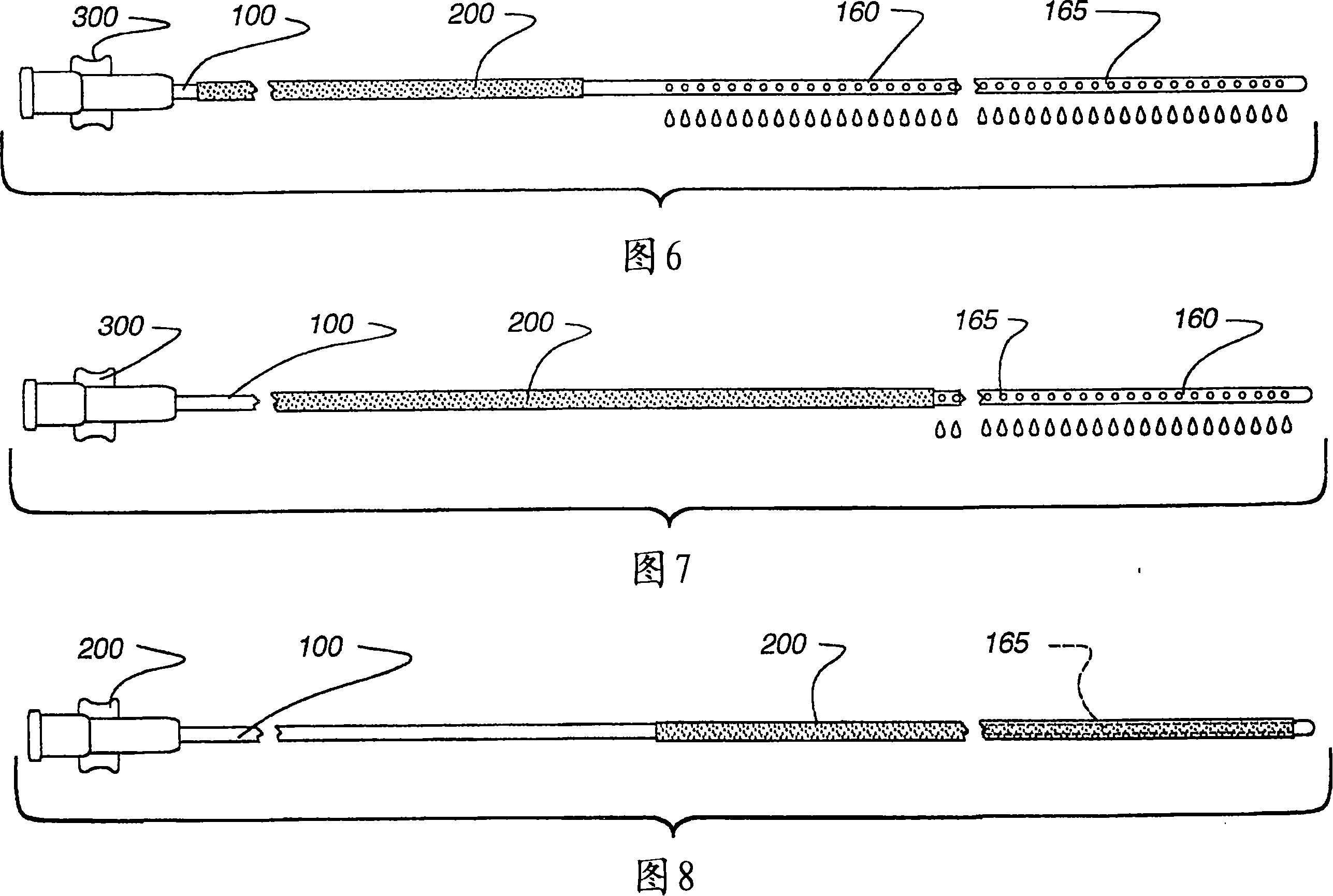

Adjustable infusion catheter

Owner:CURLIN MEDICAL INC

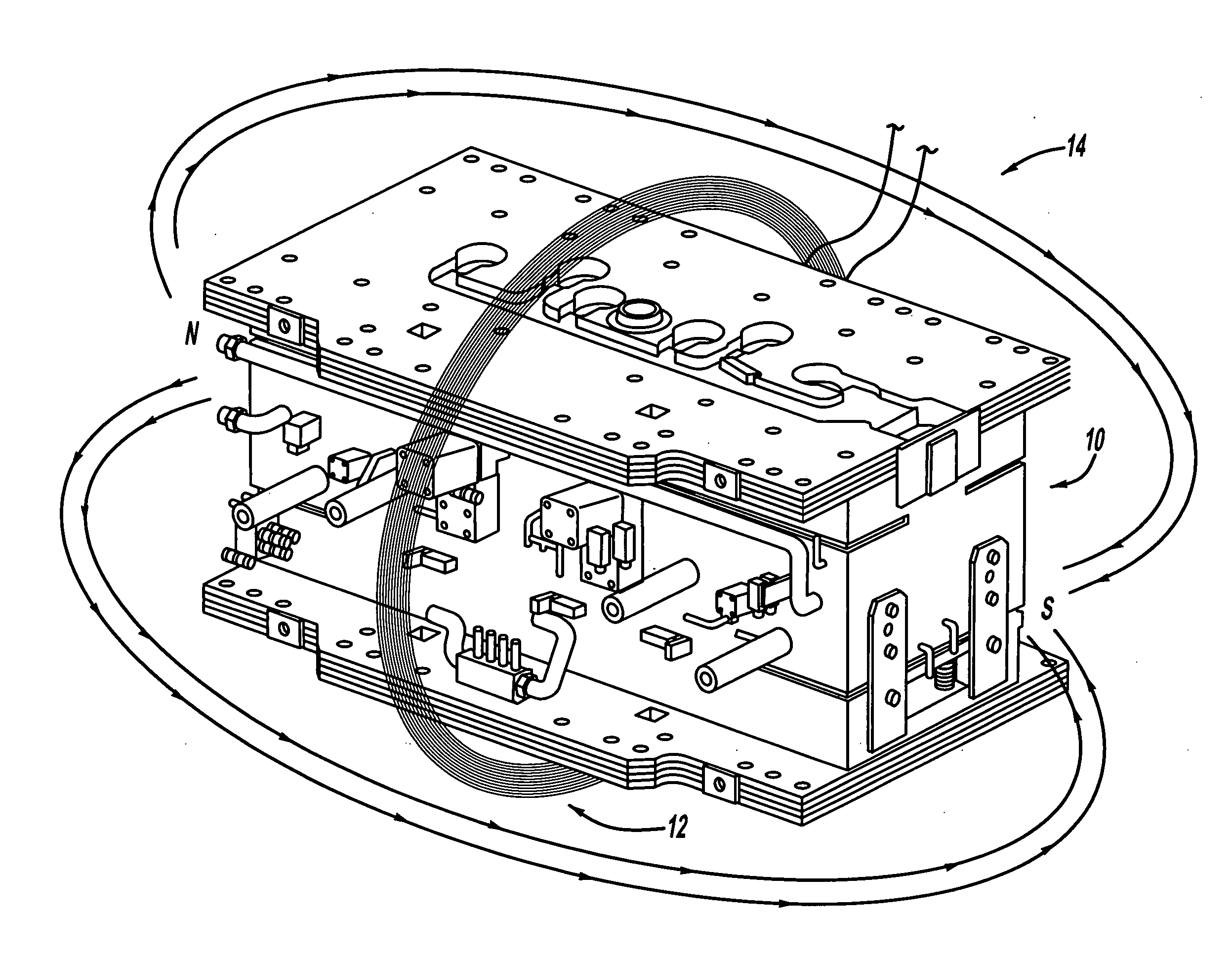

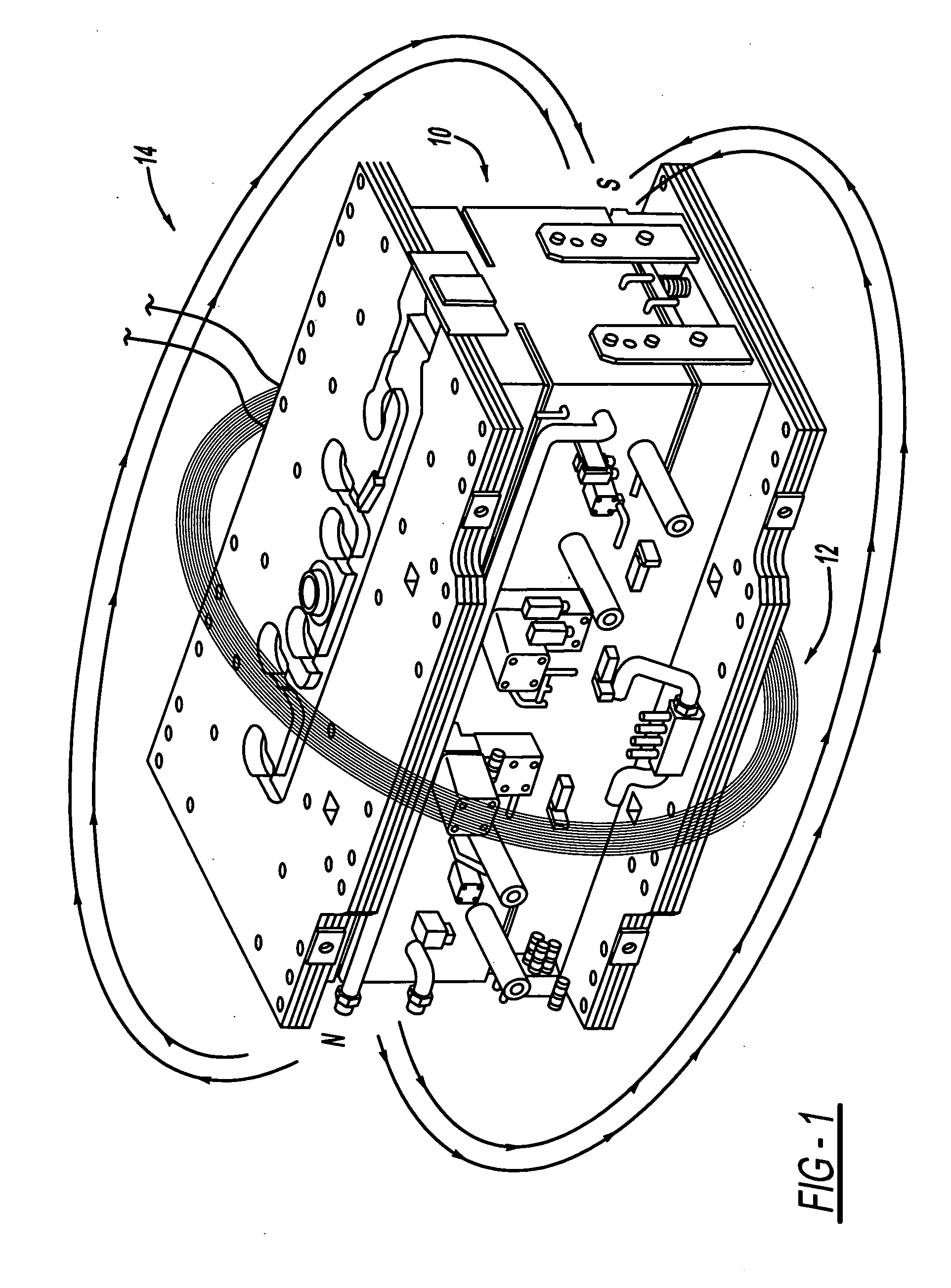

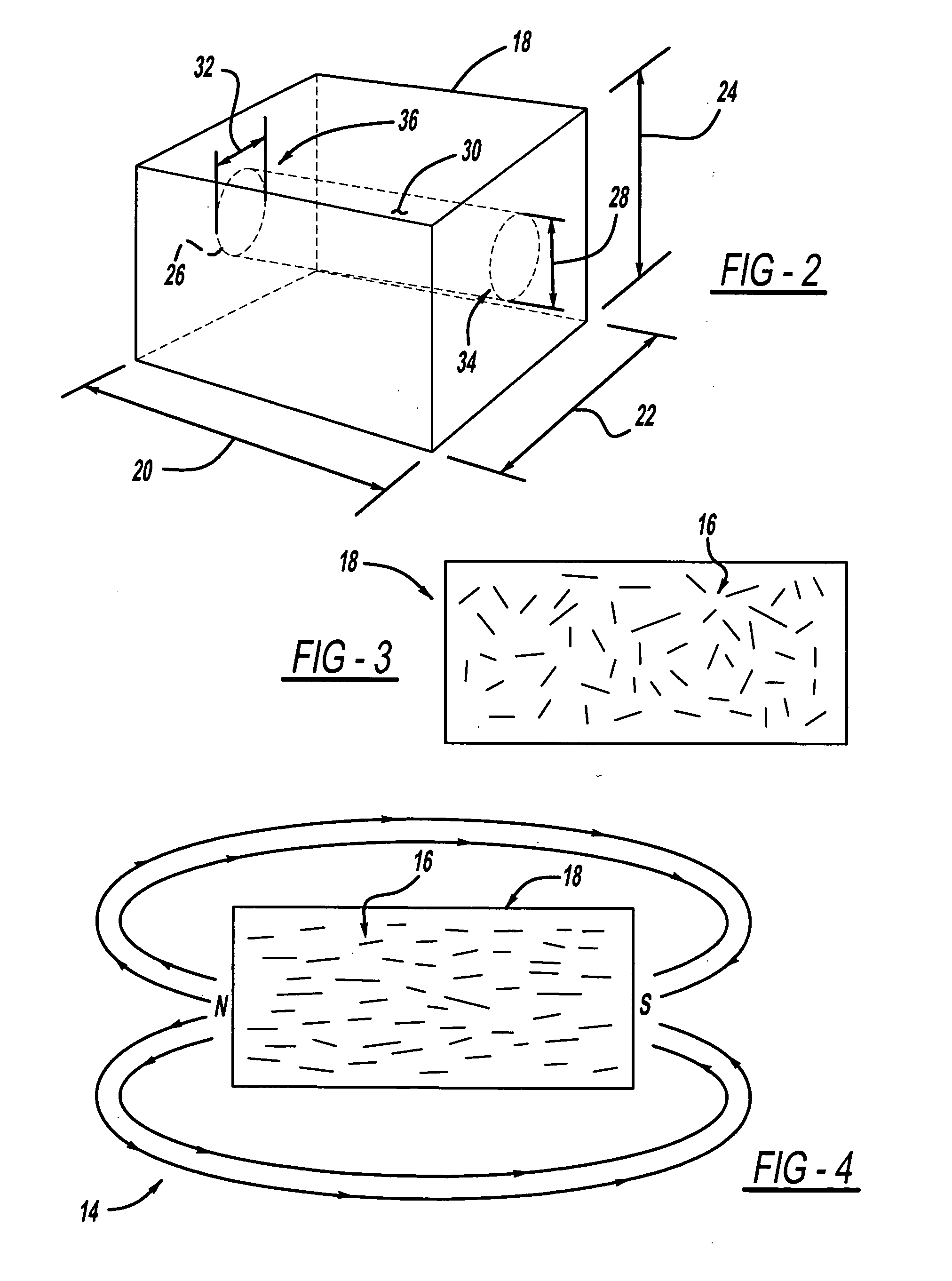

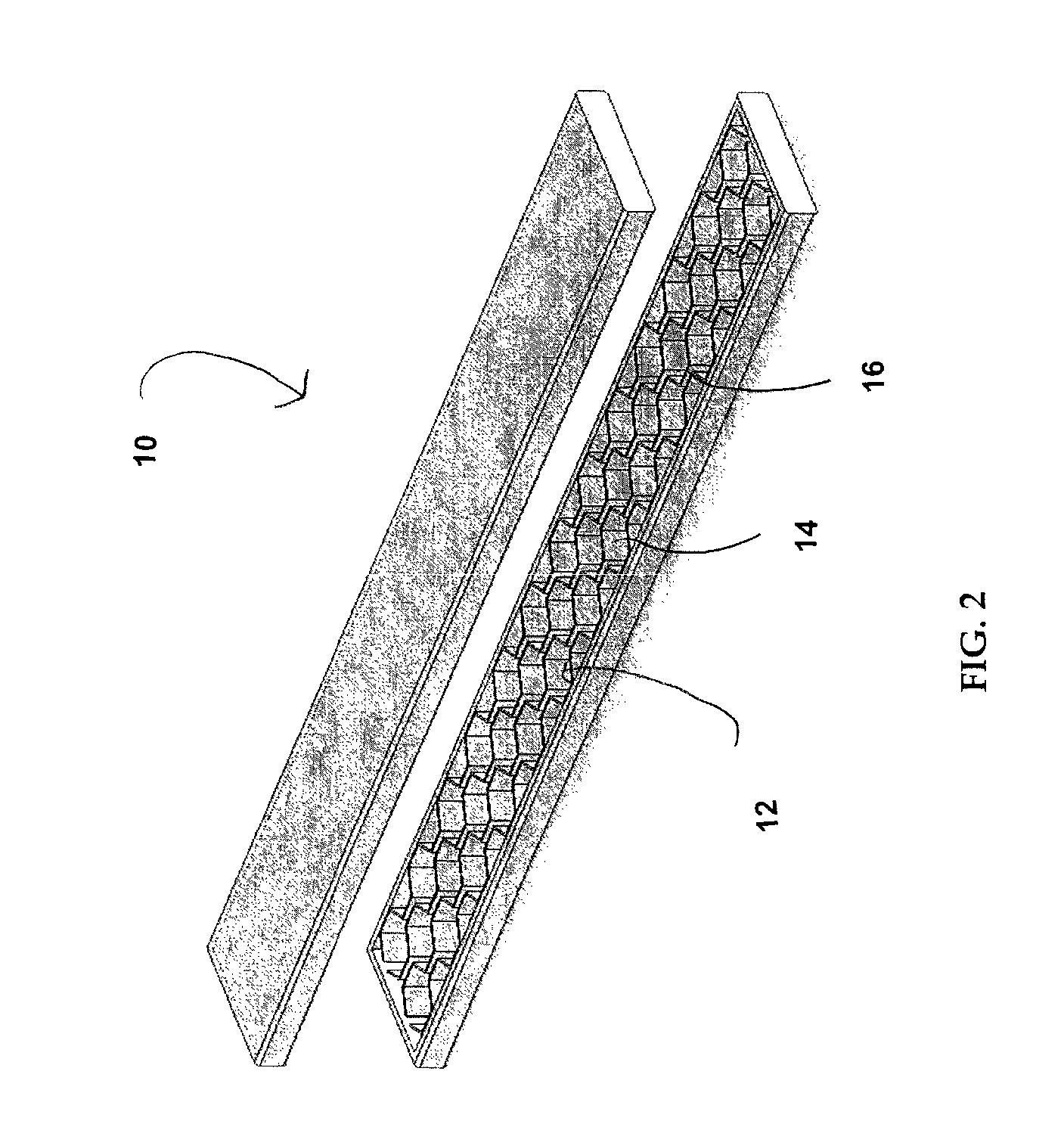

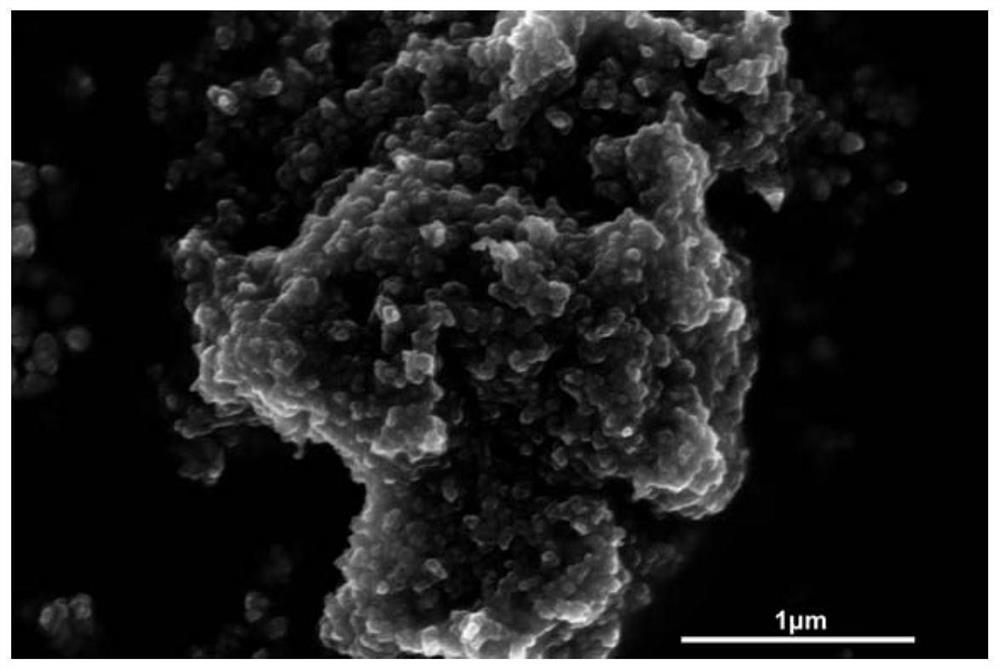

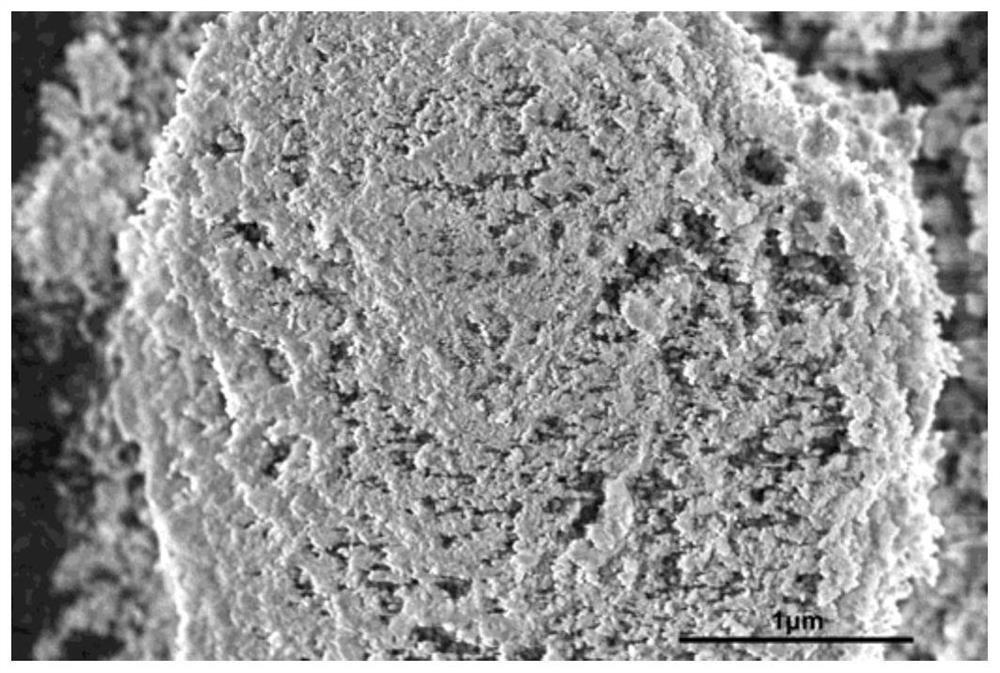

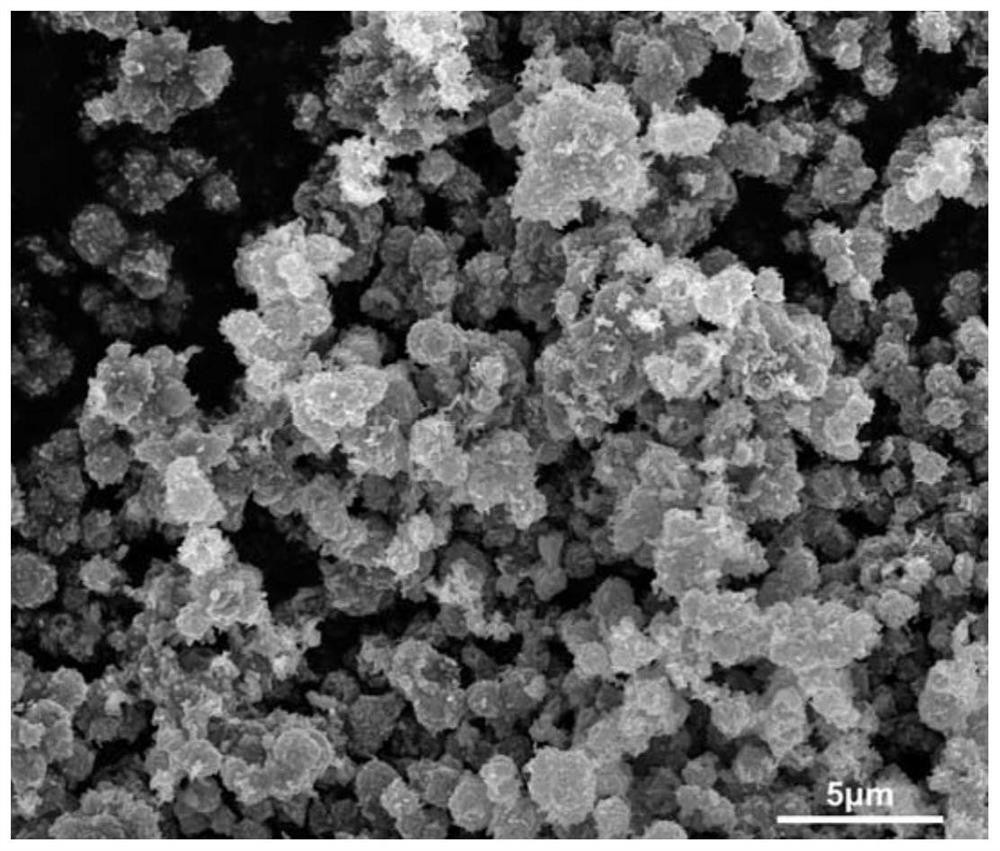

Magnetic alignment of nanoparticles within a polymer

InactiveUS20120183762A1Uniform sizeMaterial nanotechnologyLayered productsThermoplasticPlastic materials

Owner:MAGNA INTERNATIONAL INC

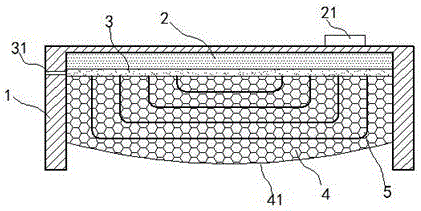

Lock It!

InactiveUS20160051084A1Easy to operateMaintaining food moistureCooking-vessel materialsClosuresPlastic materialsFood storage

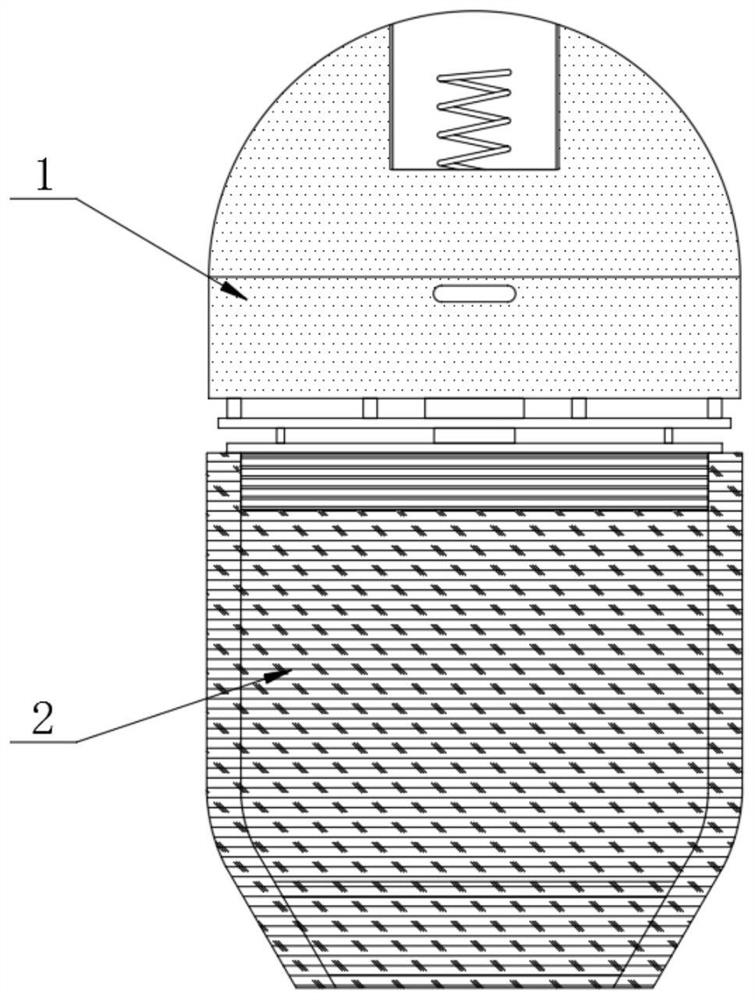

A food storage container comprising a bottom container for storing food, an easy to lift ventilation cover and a locking lid for securing the contents of the food storage container. The locking lid is provided at the top portion thereof with a combination lock. The combination lock having a plurality of wheels and notches being aligned with numbers on a rotatable dial. The combination lock is provided with lock bolts and engageable locking cases on both sides preventing the food storage container from opening. The food storage container is preferably formed from dishwasher-safe and microwave-safe materials. The combination lock of the present invention can be formed from a metal, glass or plastic material.

Owner:MARTINEZ SHAINA

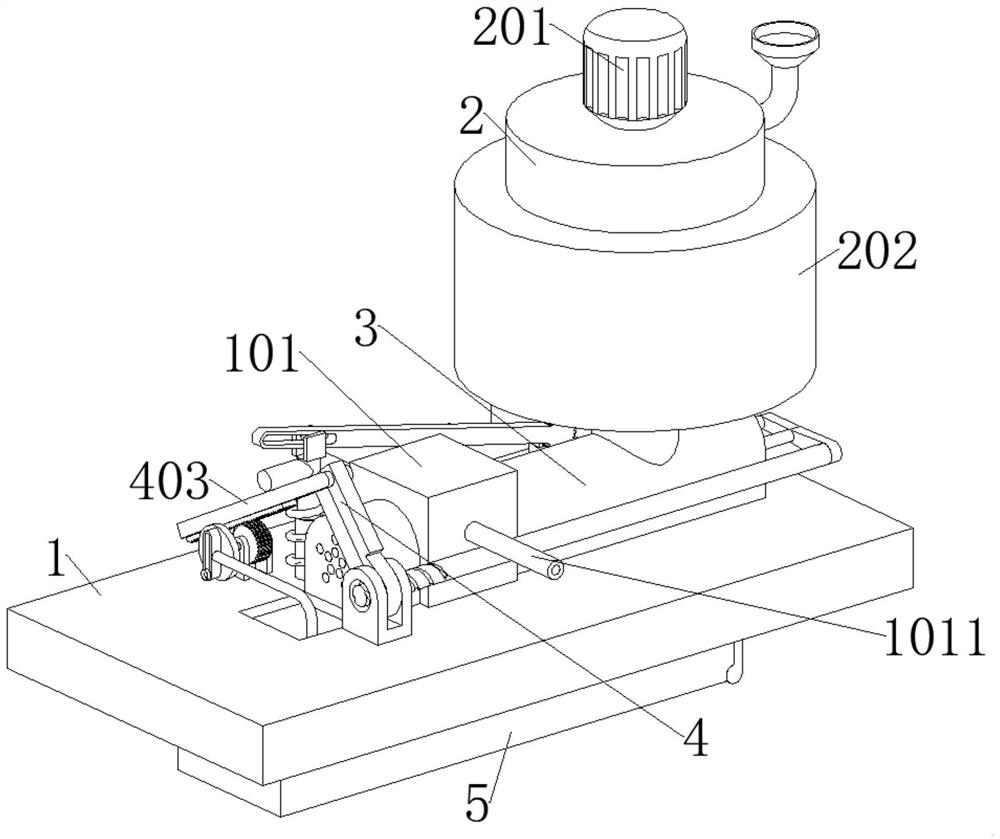

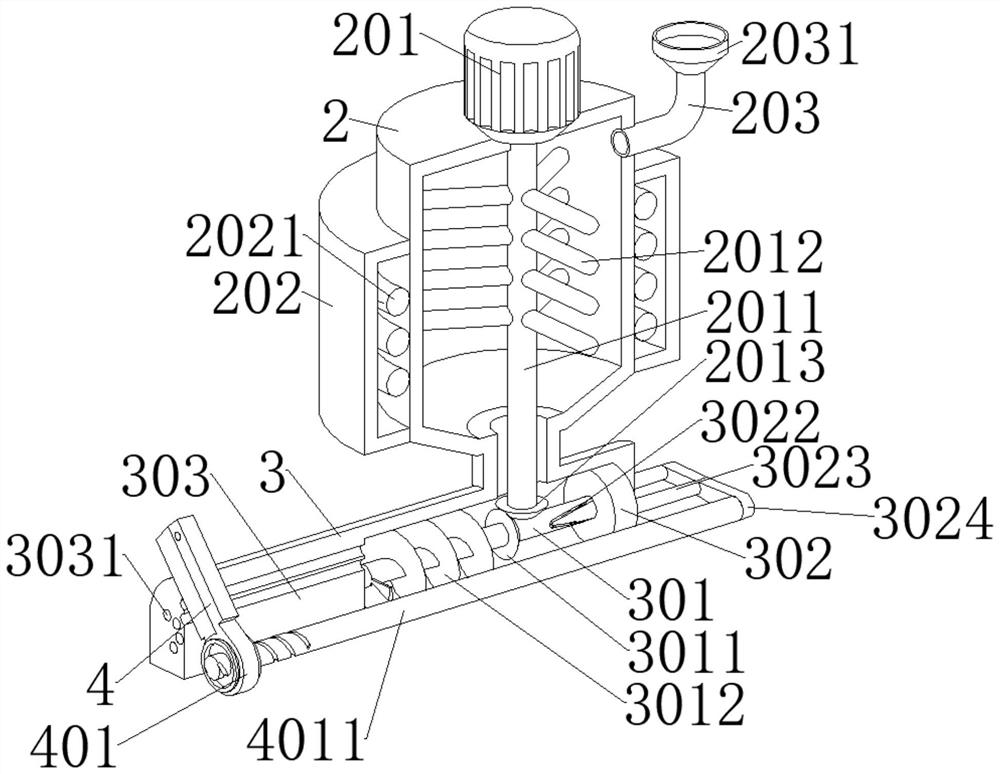

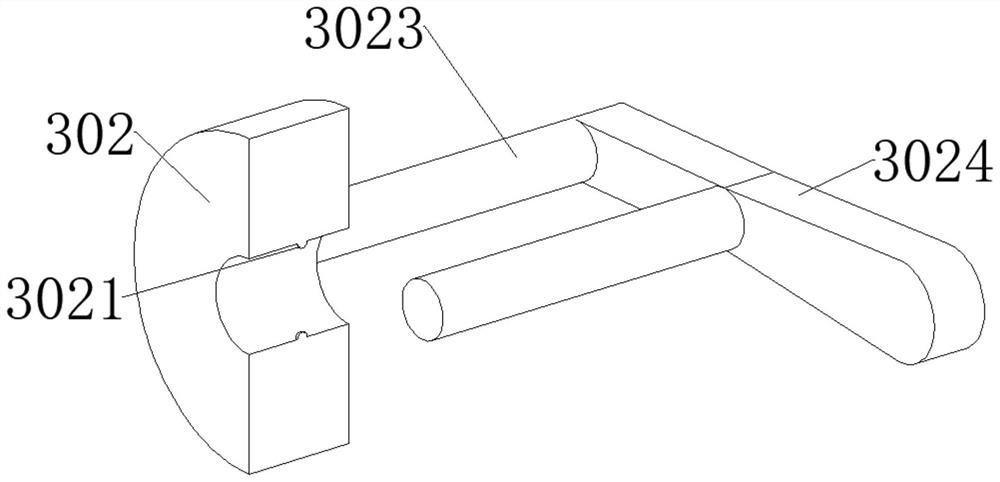

Mechanical device for automatic pouring of cutting fluid

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

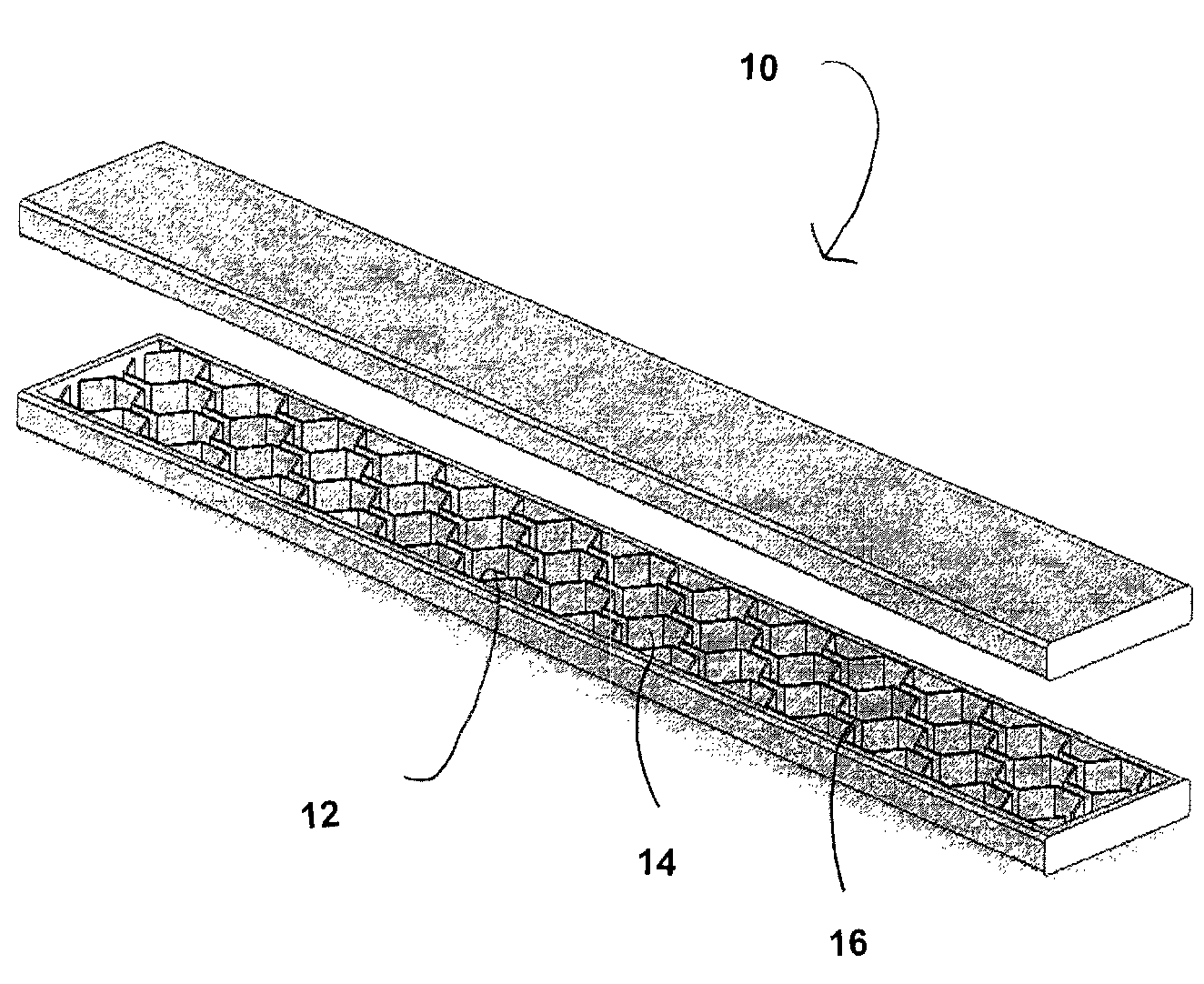

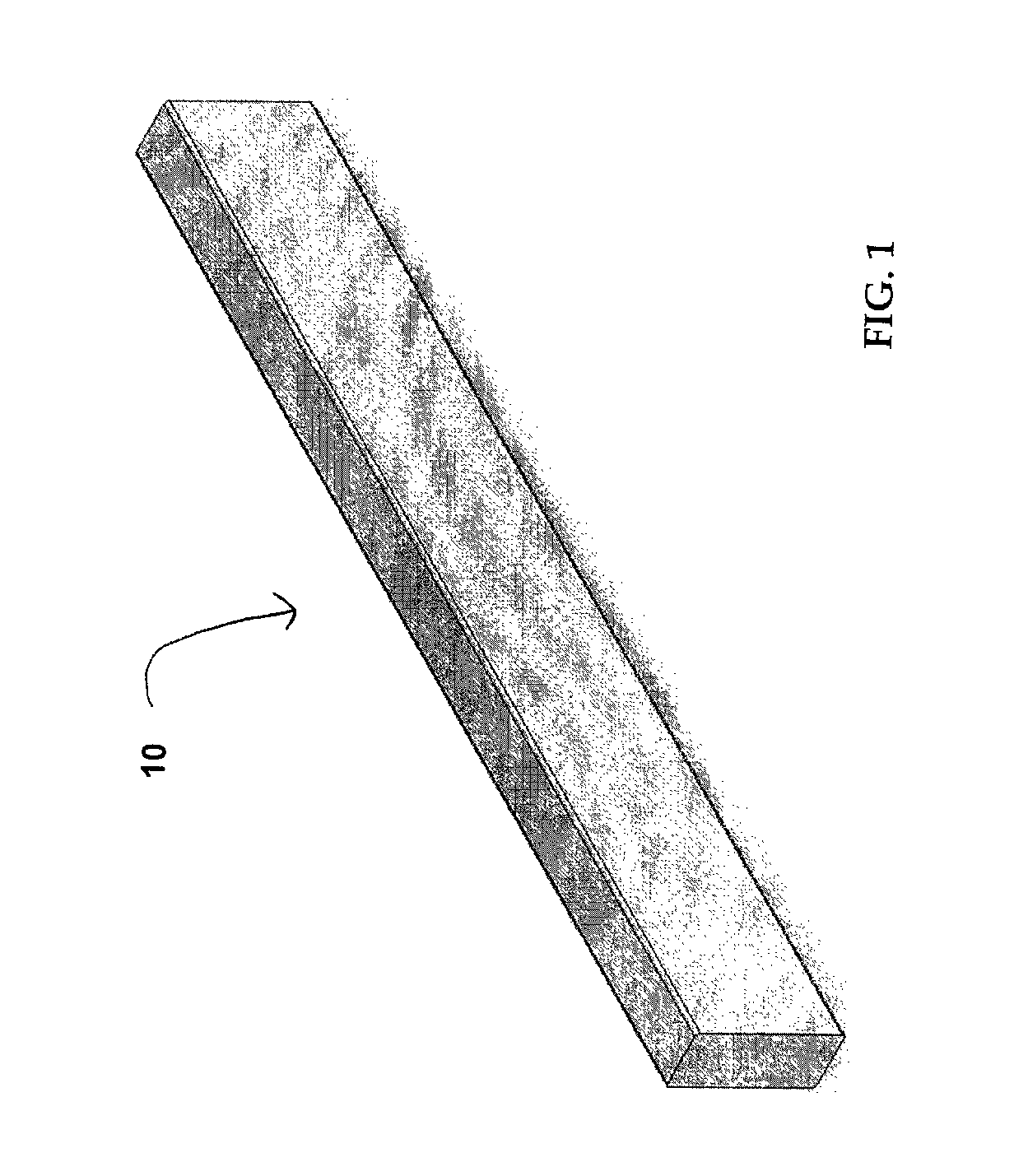

Rigid structure lubricant

InactiveUS7449433B1Increase and decrease rigidityIncrease and decrease and wear rateBearing componentsRail lubricationFiberPlastic materials

Owner:ENVIRONMENTAL LUBRICANTS MFG

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

Circular universal spanner

Owner:江苏龙胜机床制造有限公司

Device for injection molding

The present disclosure relates to a device for the injection molding of an item including at least one face, a protruding peripheral part provided with an edge for the connection with another face, said device including mold elements movable with respect to each other and jointly cooperating by delimiting therebetween joint planes as well as a cavity intended to be filled with liquid plastic material through injection channels to form said item after the ejection from the mold, characterized in that it includes a mold element to form the protruding part of the item, whose joint plane with the immediately adjacent front mold element is angularly oriented from said edge and on at least a portion of the length thereof, according to the direction of ejection.

Owner:AURAY PLAST

Extrusion device for mold production

Owner:苏州巨模模具有限公司

Flame-retardant wood-plastic material and preparation method thereof

InactiveCN106009170AImprove flame retardant performanceImprove waterproof performancePlastic materialsMelamine formaldehyde resin

The invention discloses a flame-retardant wood-plastic material, which is composed of the following raw materials in parts by weight: pentaerythritol 1-2, high-density polyethylene 170-200, ammonium polyphosphate 10-16, melamine 2-3, titanium Tetrabutyl acetate 6‑9, methyl triethoxysilane 30‑40, dimethyldiethoxysilane 27‑30, acetylacetone 0.3‑0.4, straw powder 120‑130, tributyl citrate 6‑ 8. Zinc borate hydrate 3‑4, ethylene bisstearamide 0.2‑1. The invention prepares silicon resin containing titanium, and mixes and modifies it with ammonium polyphosphate-coated melamine formaldehyde resin, so that the finished product not only has good flame retardancy, but also has good waterproof and heat resistance.

Owner:刘莹莹

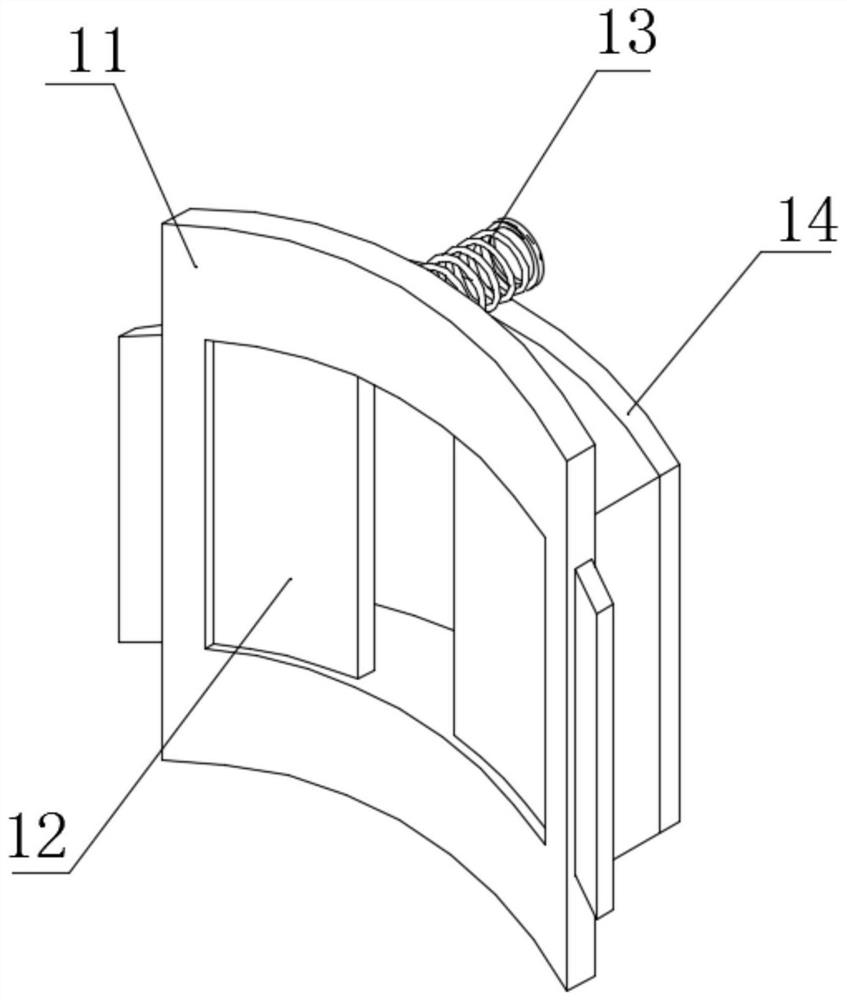

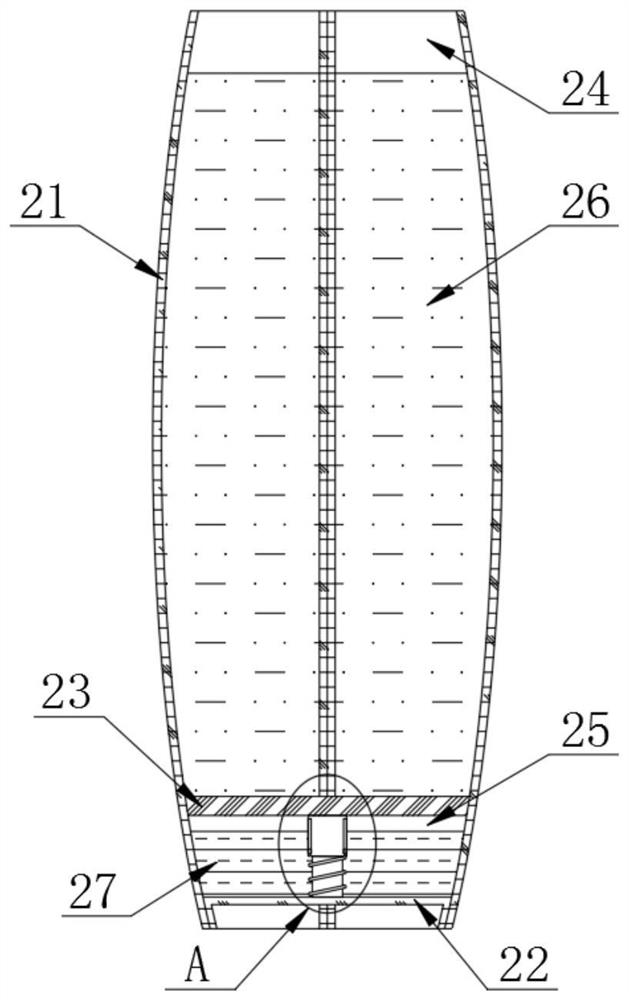

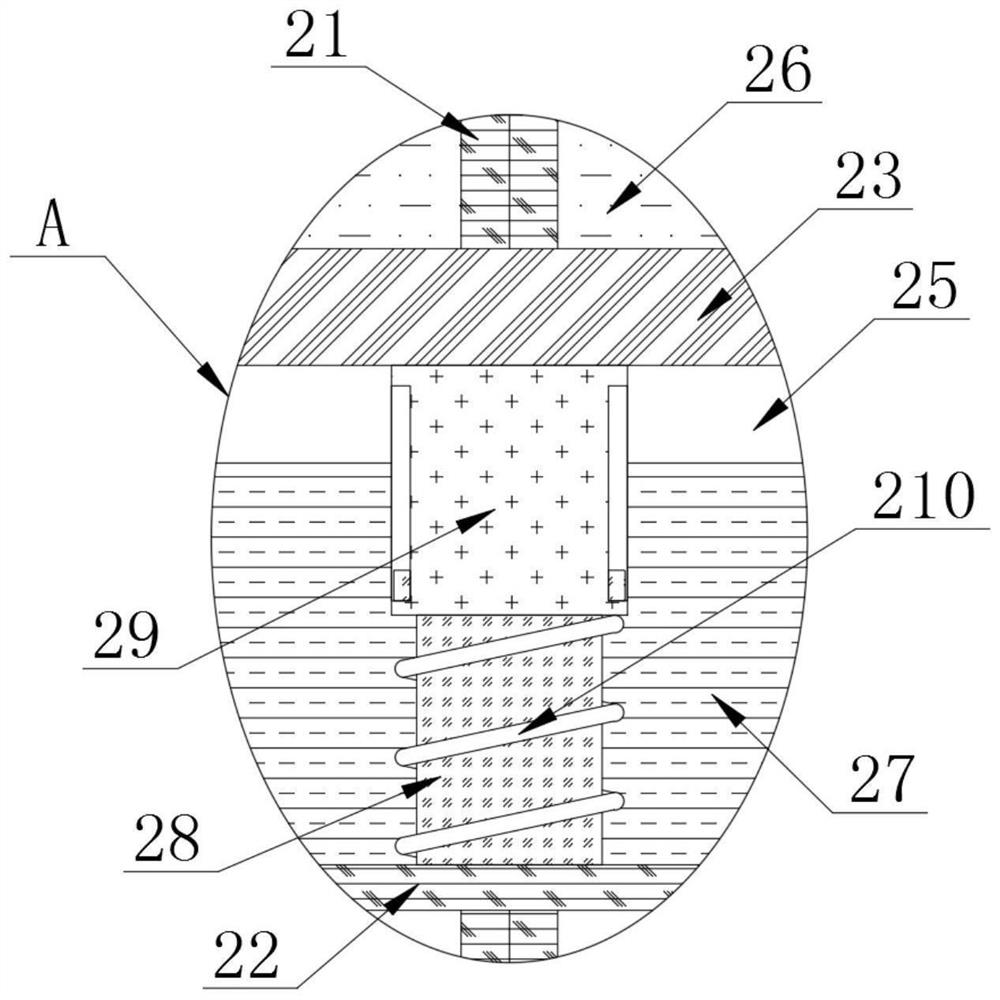

Cylinder sleeve inner hole processing clamp

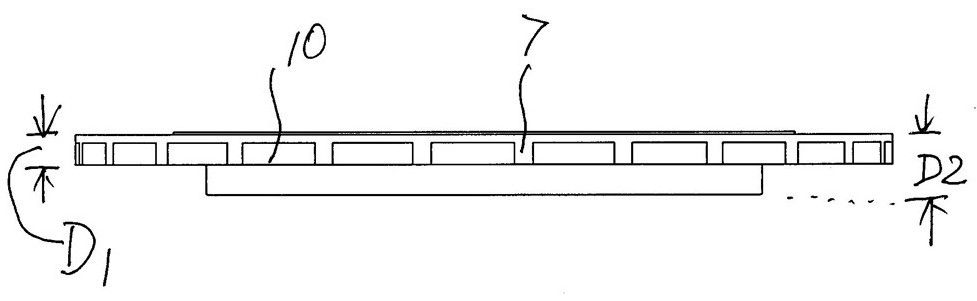

InactiveCN108747515ASimple structureReasonable designPositioning apparatusMetal-working holdersPlastic materialsArchitectural engineering

The invention relates to a cylinder sleeve inner hole processing clamp. The cylinder sleeve inner hole processing clamp comprises a clamp main body which is composed of a metal cylindrical housing andan ultrathin metal barrel, wherein two openings of the metal cylindrical housing are symmetrically equipped with circular ring baffle plates; the outer diameters of the circular ring baffle plates are fixedly connected with the metal cylindrical housing; the ultrathin metal barrel is fixedly connected to the inner diameters of the circular ring baffle plates; the inner cavity of the ultrathin metal barrel is equipped with a cylinder sleeve; the outer part of the ultrathin metal barrel is wound with a plastic material; the two ends of the plastic material are fixedly connected to sides of thecircular ring baffle plates; the bottom of the metal cylindrical housing is connected with a base; the bottom of the base is fixedly connected with a supporting plate through a screw; and piston barrels are symmetrically arranged at the two sides of the metal cylindrical housing. The cylinder sleeve inner hole processing clamp is simple in structure, is reasonable in design, can prevent the cylinder sleeve from being deformed and worn in a processing process, also can accurately position, reduces a rejection rate, improves production efficiency, can process cylinder sleeves of different specifications, can perform thick boring and fine boring, and reduces the cost.

Owner:JIANGSU ZIJIN POWER

Pet basin with handle

Owner:INNOVATIVE CREATIONS

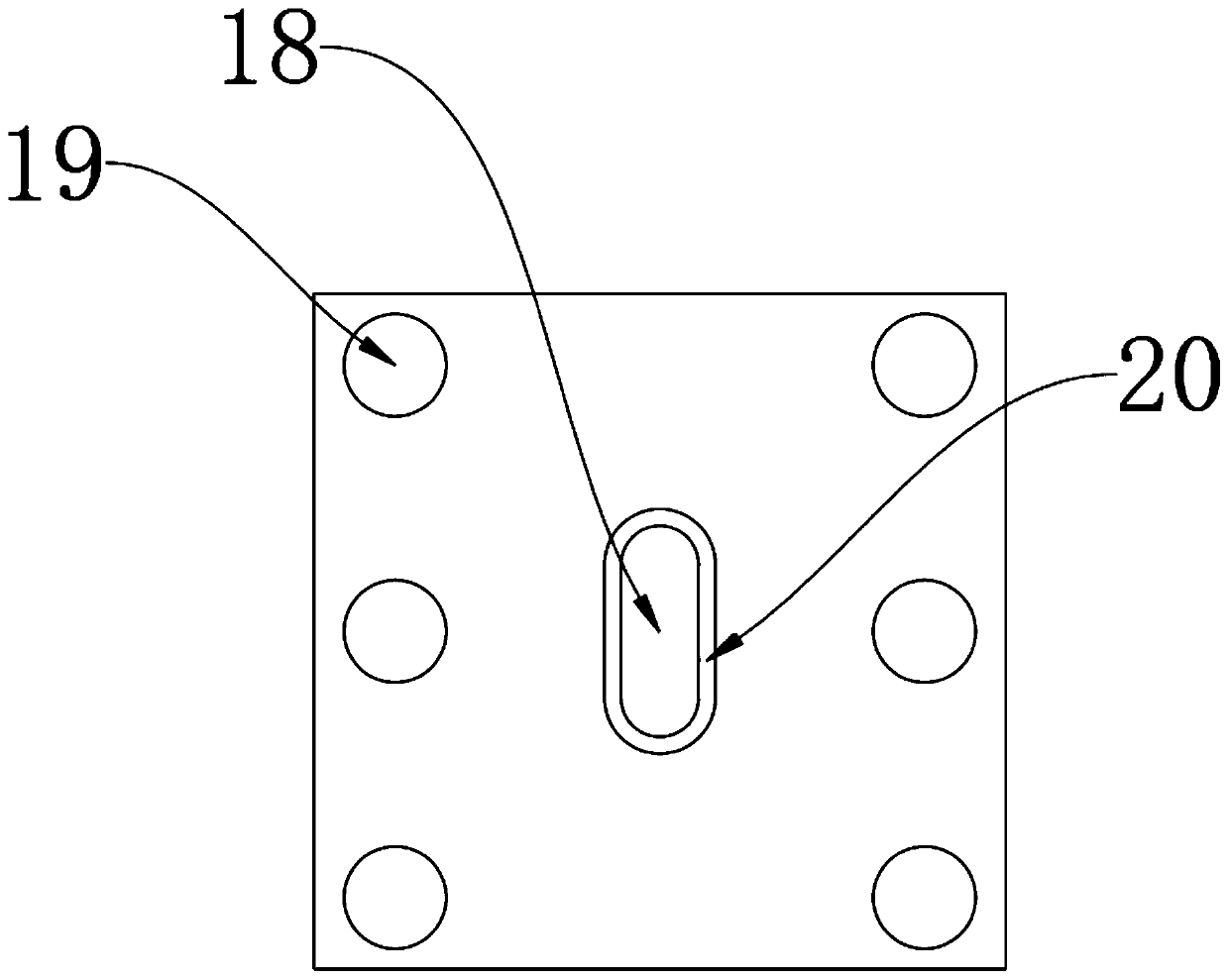

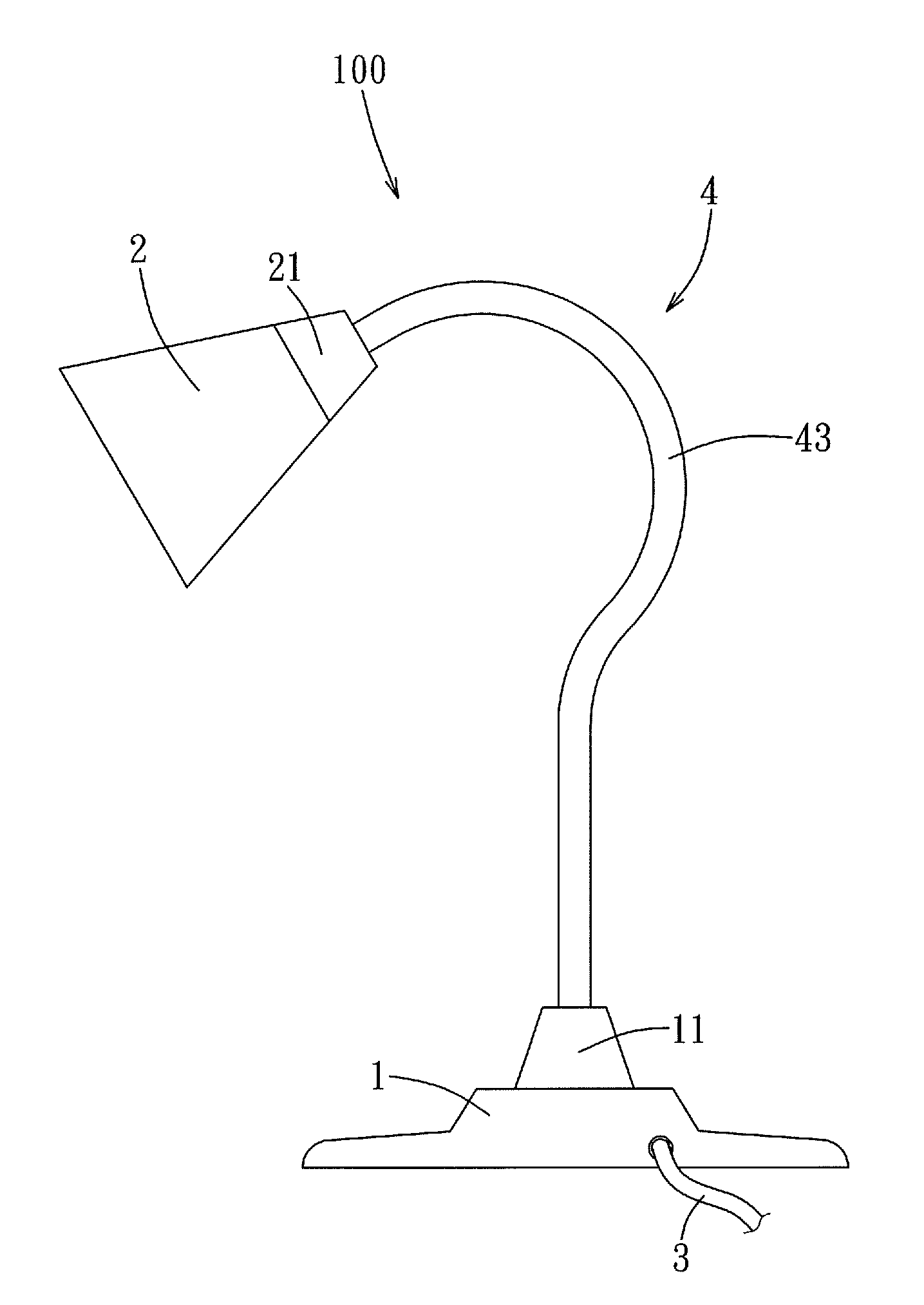

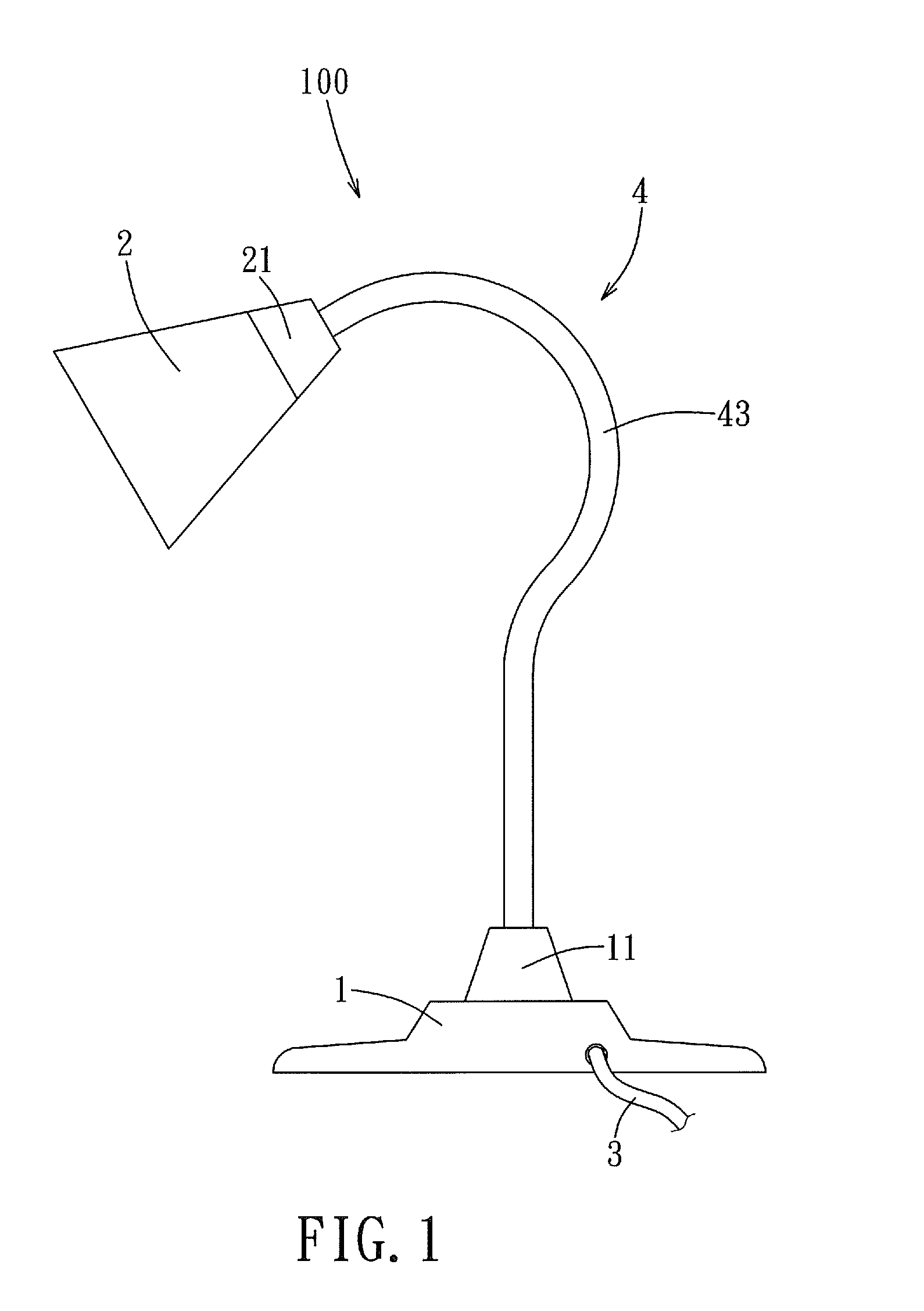

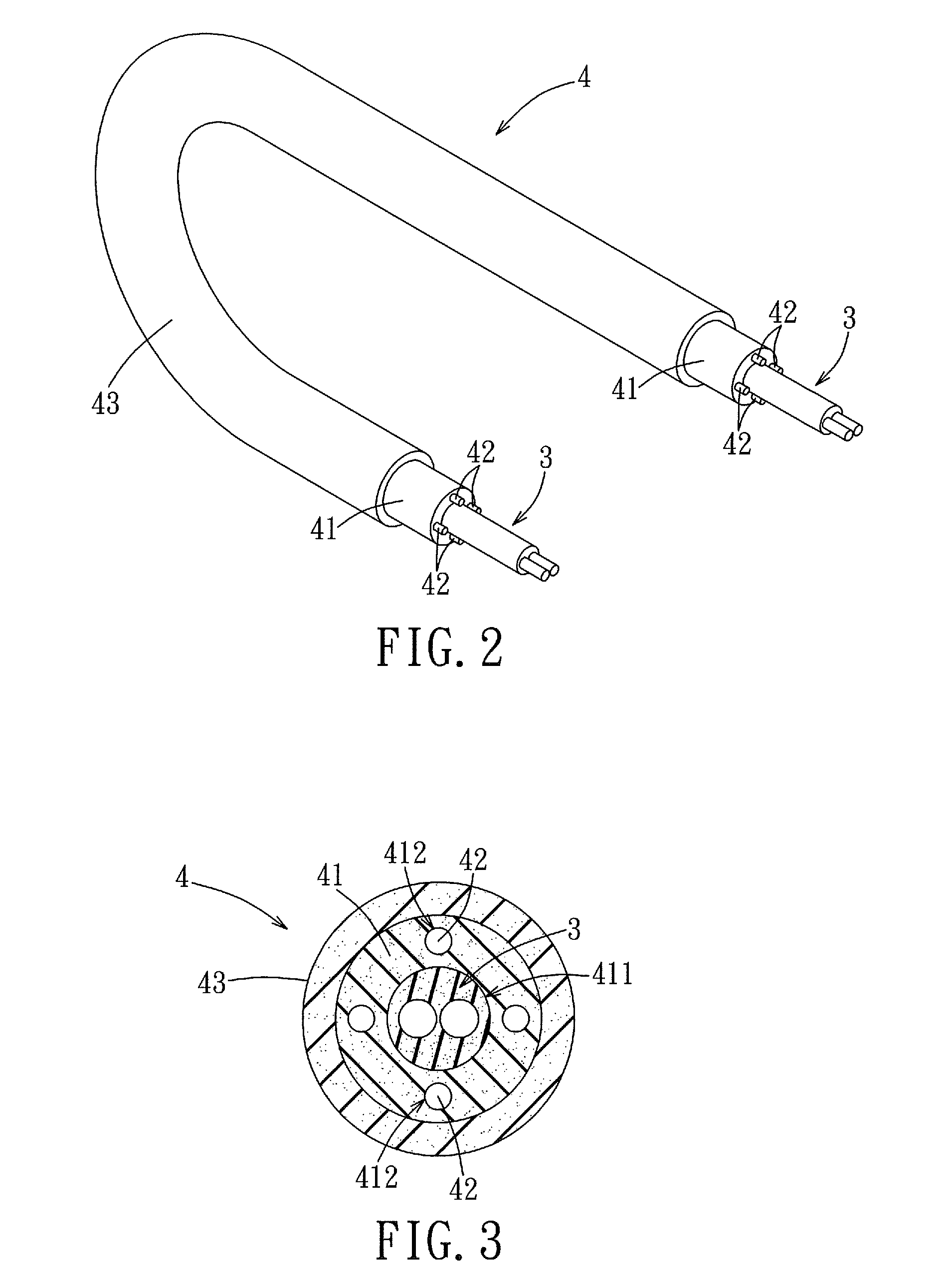

Flexible tube and lamp having the same

InactiveUS20130294099A1Low costSufficient supportLighting support devicesElectrical apparatusPlastic materialsMechanical engineering

Owner:HABITEX

Method for producing ethylene raw material

ActiveCN112708439AExpand sourceAchieve reuseLiquid hydrocarbon mixture productionPolymer sciencePolyolefin

Owner:SINOCHEM QUANZHOU PETROCHEM CO LTD +1

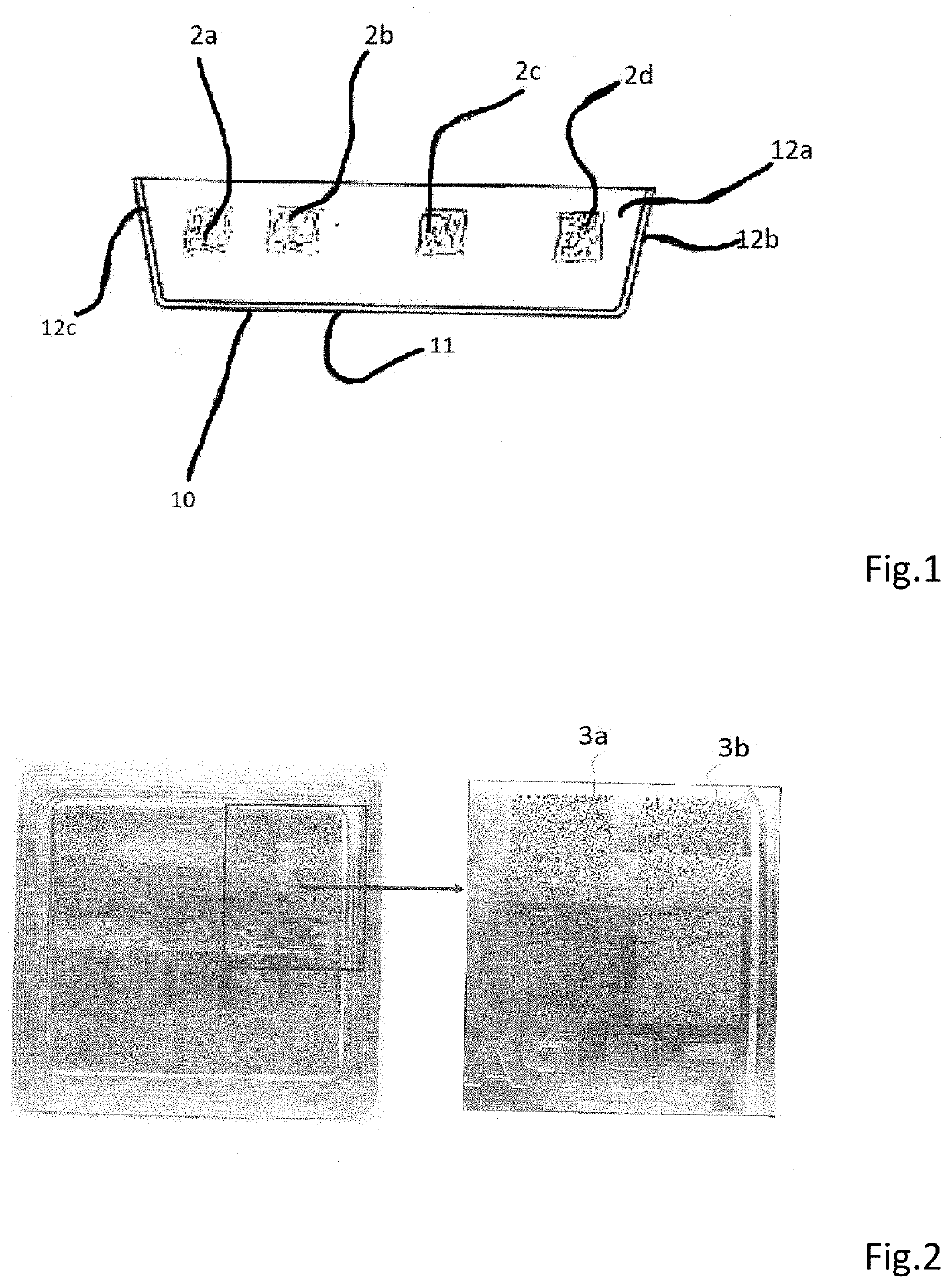

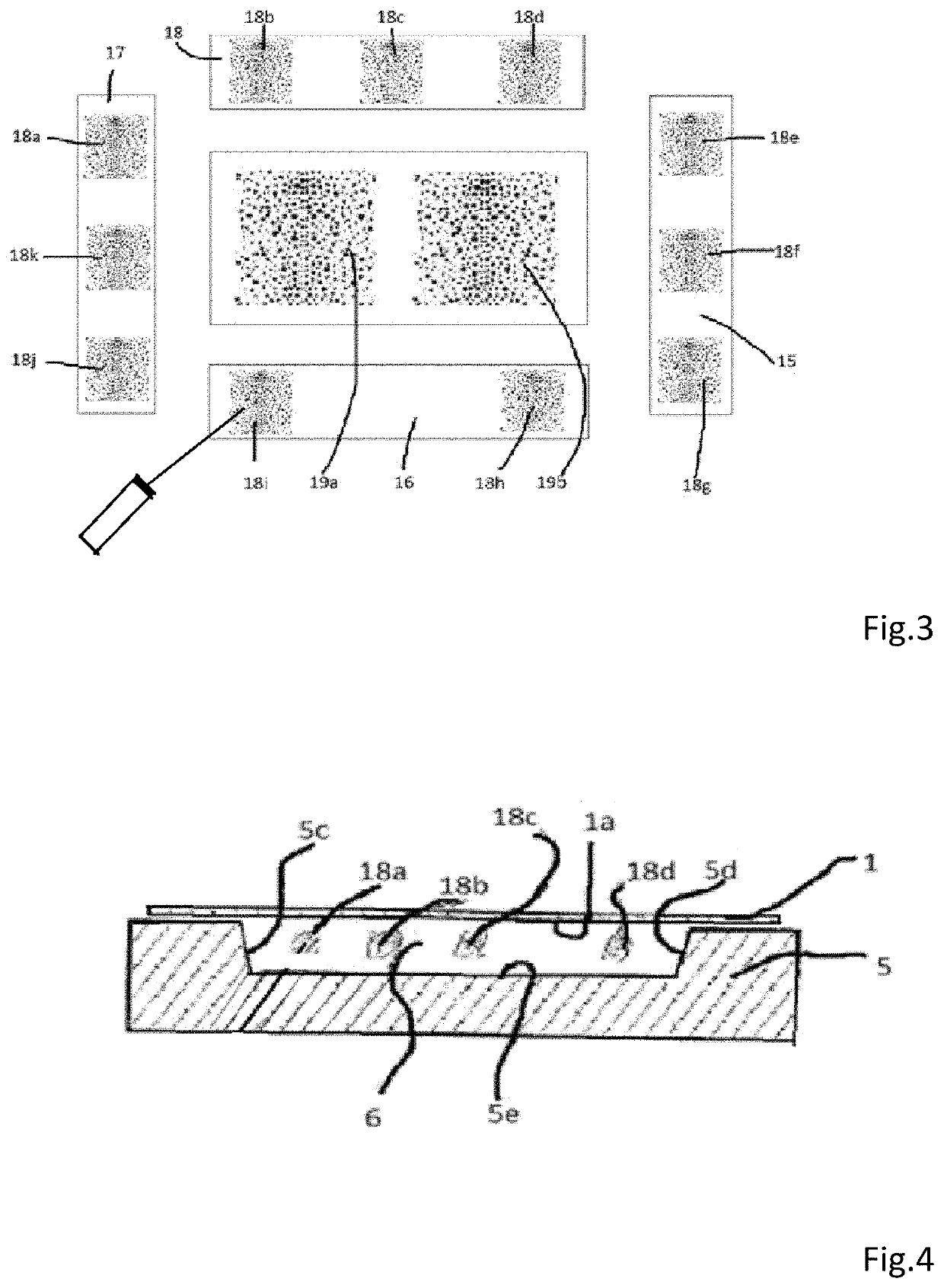

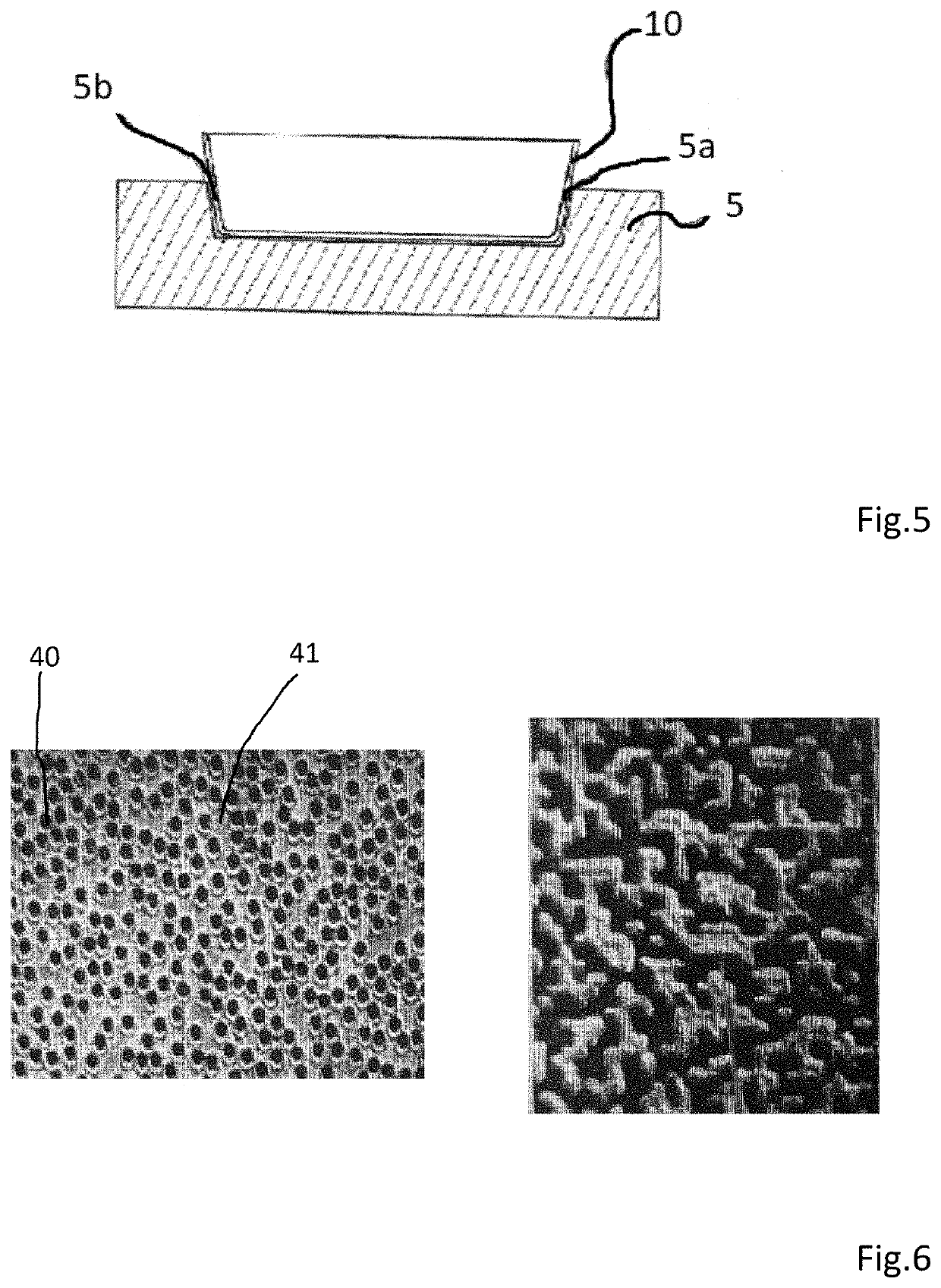

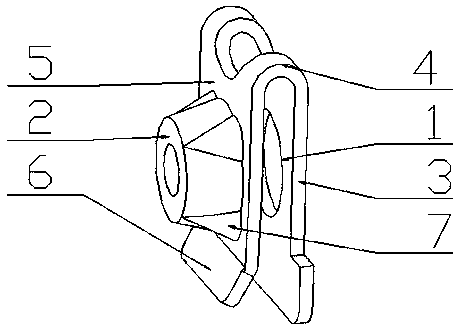

Method for encoding a packaging container, and encoded packaging container for consumer goods

PendingUS20220097436A1Quality improvementDomestic articlesRecord carriers used with machinesPlastic materialsEngineering

Owner:PACCOR PACKAGING GMBH

Multifunctional condensing projection cylinder

The invention discloses a multifunctional condensing projection cylinder which comprises a fixed loop, a convex lens, a connecting ring and a focusing ring. The multifunctional condensing projection cylinder has the advantages that the condensing projection cylinder can realize condensing projection via a convex lens and condensing projection via a single-lens reflex lens, two lenses are integrated, and the cost of a photographic condensing projection cylinder is reduced substantially; the condensing projection cylinder is simple in structure and principle, the manufacture cost is reduced greatly, a cold light source is used, a plastic material can be used, problems as heating can be avoided, the production difficulty is reduced greatly, and the production technology is simplified; and thecondensing projection cylinder can be fixed to a small cylinder in the front end of an existing light limiting cylinder in the market, and compared with a condensing projection cylinder of a traditional similar product, the production cost is reduced, the manufacturing difficulty is reduced, and the utilization efficiency of equipment is improved.

Owner:向茂勇

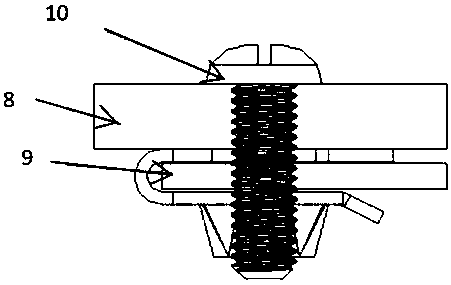

Mounting nut for automobile plastic part

PendingCN111102274AReduce weightIncrease elasticitySheet joiningOptical signallingPlastic materialsMechanical engineering

Owner:QINGDAO ZHIKE MACHINERY MFG CO LTD

Vacuum soft package pump pressure double compartment type cosmetic container

PendingCN111703695AEasy to finishSolve remaining problemsClosuresBottlesPlastic materialsEngineering

Owner:上海秀枝雪包装有限公司

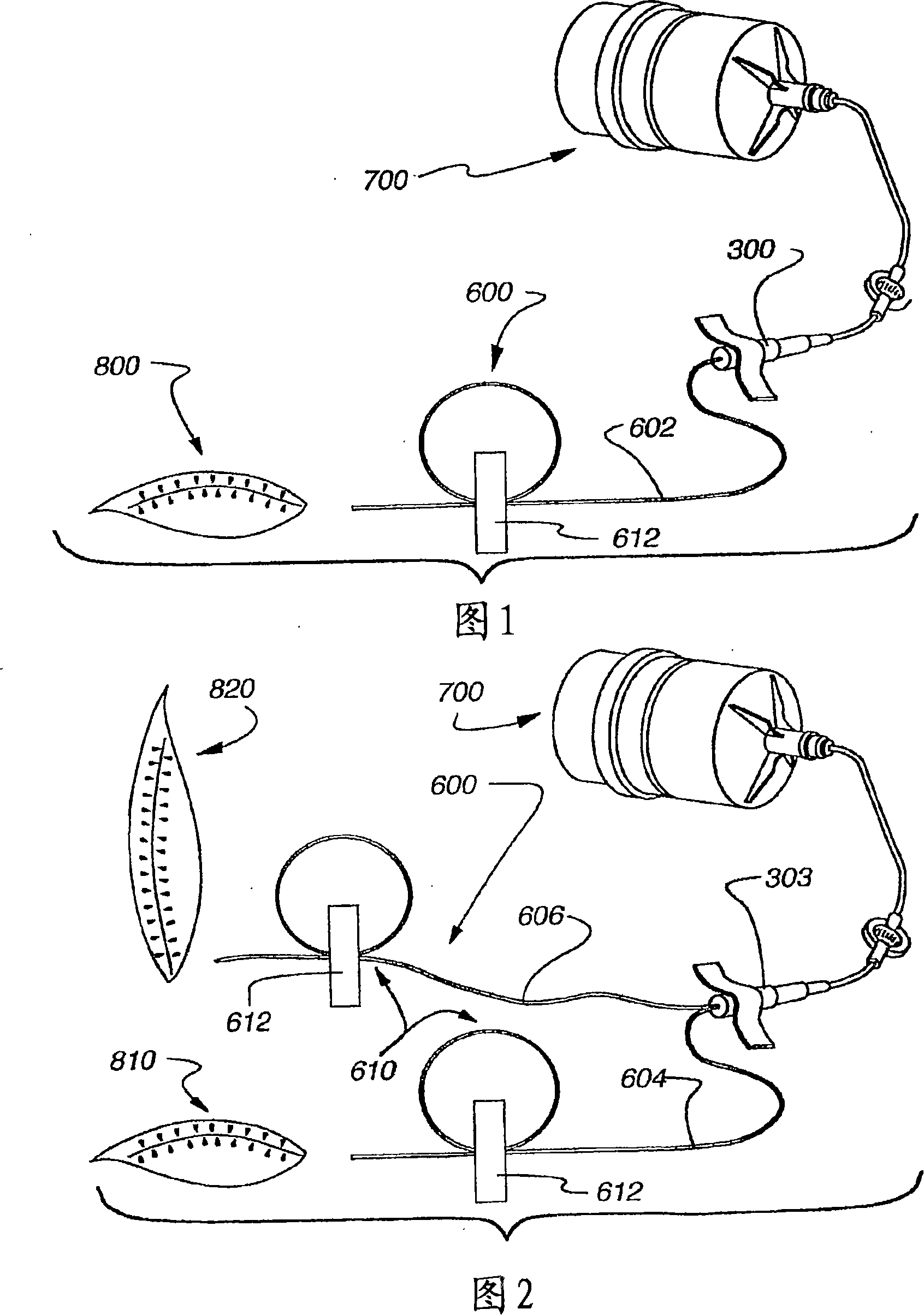

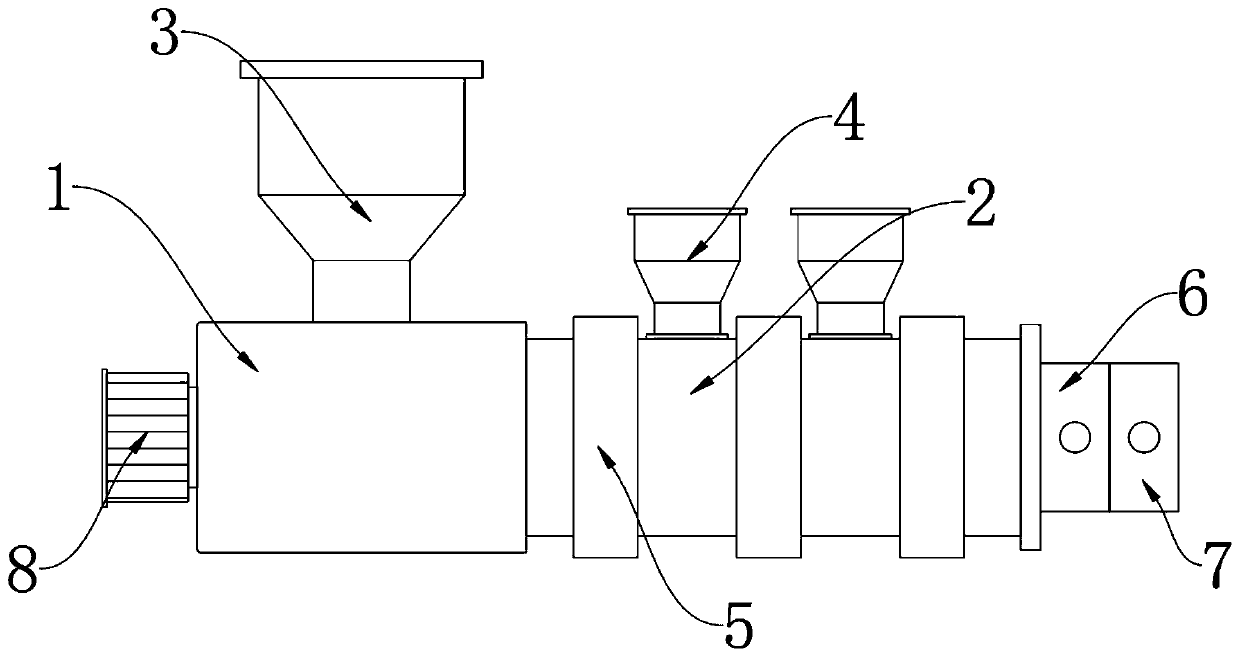

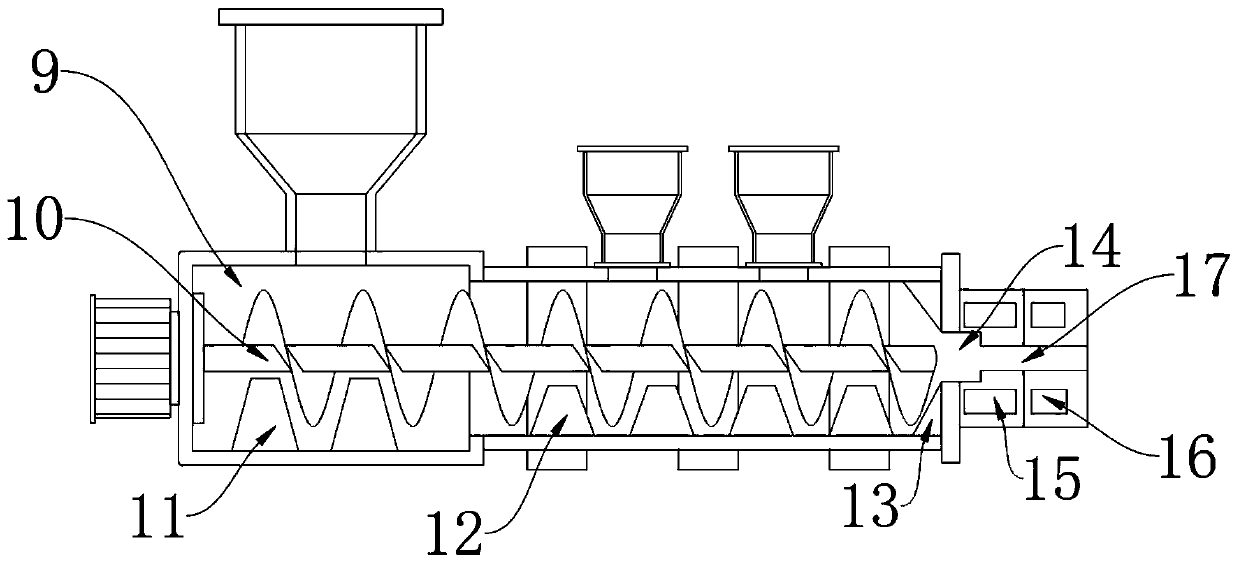

Method for fully recycling and reproducing waste drip irrigation belts and waste greenhouse films

PendingCN114211640AQuality improvementOutstanding reproduction effectPlastic recyclingMechanical material recoveryBlow moldingMasterbatch

The invention relates to a waste drip irrigation tape and waste greenhouse film total recovery and reproduction method, and relates to the technical field of waste drip irrigation tape and waste greenhouse film resource recovery and reutilization, and the method comprises the following steps: waste material cleaning: putting waste drip irrigation tapes and waste greenhouse films into a cleaning pool for full cleaning; waste material drying, wherein the cleaned waste drip irrigation tape and the cleaned waste greenhouse film are dried; the waste materials are cut up, wherein the dried waste drip irrigation belts and the dried waste greenhouse films are cut up; mixing the raw materials: fully mixing the chopped waste materials with the new plastic material and the dyeing master batch; granulation: adding the mixed raw materials into an extruder for extrusion granulation; and film forming: performing blow molding and film forming on the raw material particles to finish reproduction of the waste materials. The waste drip irrigation tape and the waste greenhouse film can be utilized to the maximum extent, and the produced product is good in performance and good in application effect.

Owner:NINGXIA YURUN AGRI WATER SAVING IRRIGATION MFG CO LTD

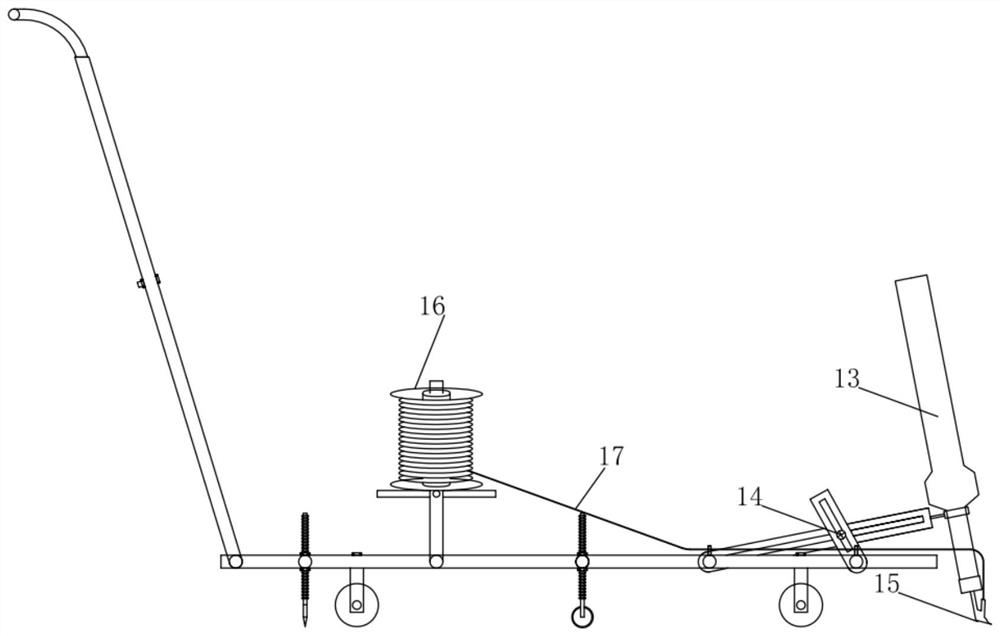

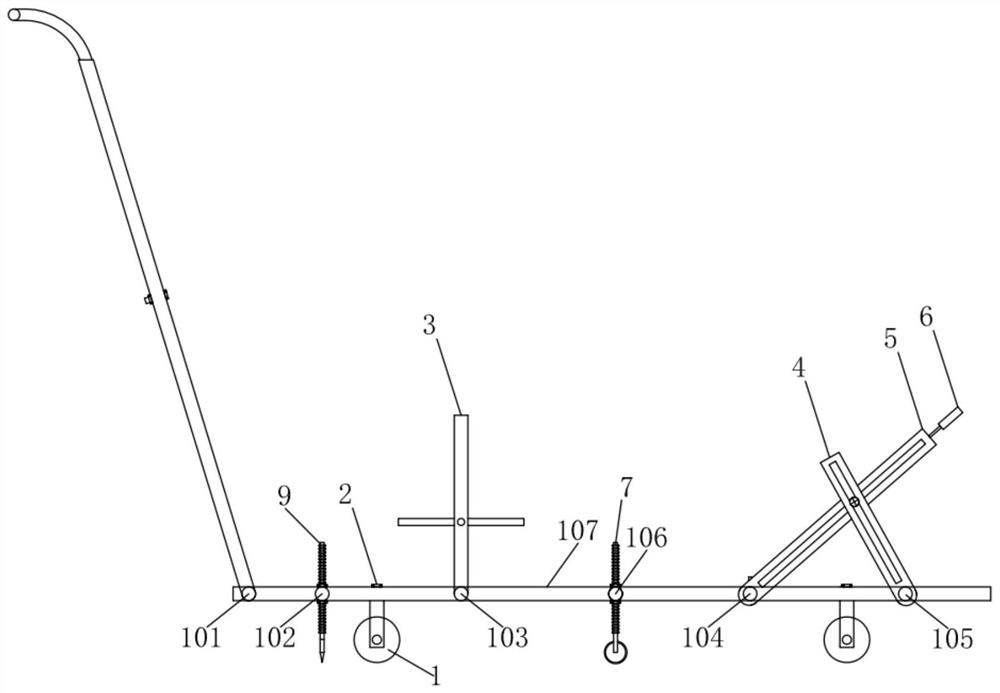

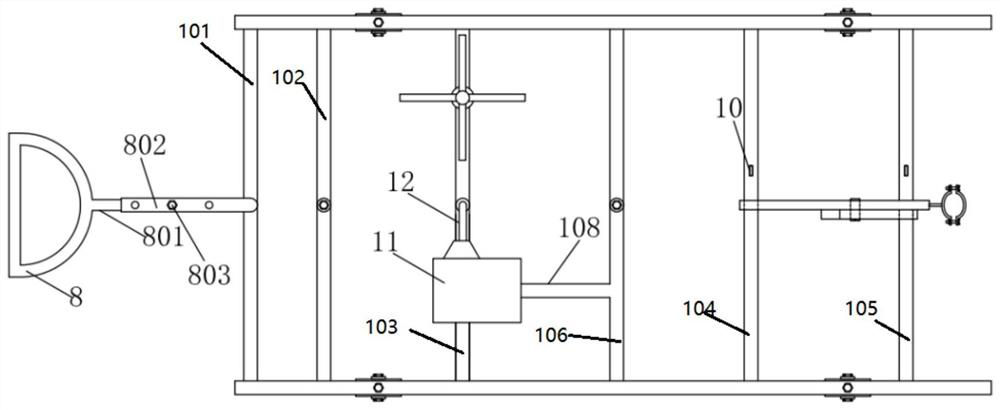

Multifunctional hard PVC plastic material welding vehicle and construction method thereof

Owner:CHINA FIRST METALLURGICAL GROUP

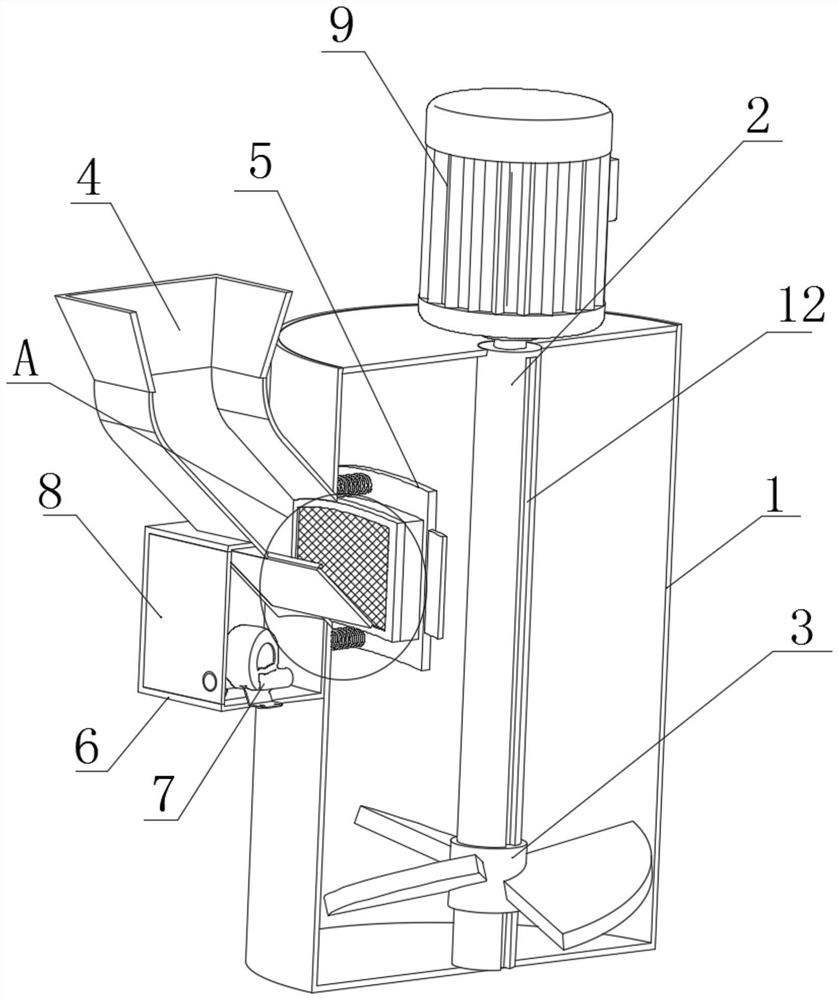

Plastic product production-based material treatment equipment

ActiveCN113580528ANo deformationWill not lead to qualitative changePlastic recyclingPlastic materialsDrive shaft

Owner:深圳市合盛隆塑胶制品有限公司

Plastic fuel cell system

PendingCN114361493AAchieve complete oxidationCatalytic cleavageCell electrodesFuel cell detailsFuel cellsPlastic materials

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap