Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Resource recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

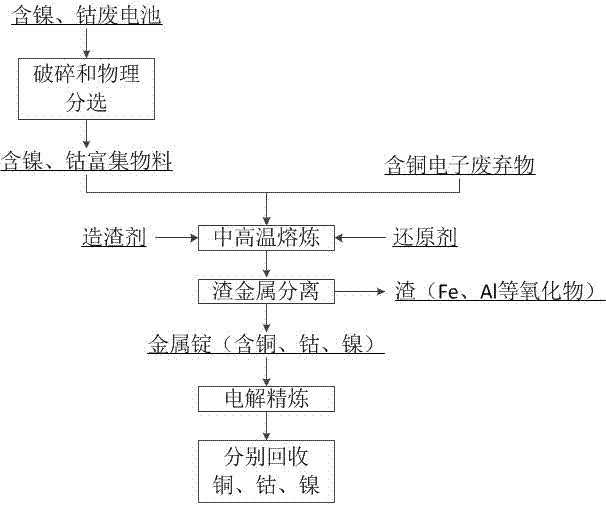

Synergetic metal recycling method for nickel and cobalt containing waste batteries and copper containing electronic waste

InactiveCN107012332AHigh purityAvoid efficiencyPhotography auxillary processesWaste accumulators reclaimingElectrolysisElectrical battery

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Method for enhancing hydrolysis and acid production by treating excess sludge by means of combined effect of pyrohydrolysis and surface active agent

InactiveCN105906178AIncrease the rate of hydrolysisIncrease productionSpecific water treatment objectivesBiological sludge treatmentSludgeResource recovery

The invention relates to a method for enhancing hydrolysis and acid production by treating excess sludge by means of a combined effect of pyrohydrolysis and a surface active agent, belonging to the fields of sludge treatment and resource recovery. According to the method, the excess sludge of a sewage treatment plant is taken as substrate, and the surface active agent is added into the excess sludge under the condition of heating, so that the processes of hydrolysis and acid production are promoted. The surface active agent not only inhibits the activity of methanogens, but also has functions of being amphiphilic and solubilizing, thus being capable of accelerating hydrolysis; when the surface active agent is combined with the pyrohydrolysis for treating the excess sludge, the pyrohydrolysis breaks cell walls, so that the function of the surface active agent is further enhanced, and the aim of enhancing the hydrolysis and acid production of the excess sludge is further achieved. Therefore, the method achieves the aims of accelerating the anaerobic fermentation hydrolysis speed of the excess sludge and enhancing the acid production by means of the combined effect of the surface active agent and the pyrohydrolysis, thus realizing reduction and resource recovery of the excess sludge.

Owner:BEIJING UNIV OF TECH

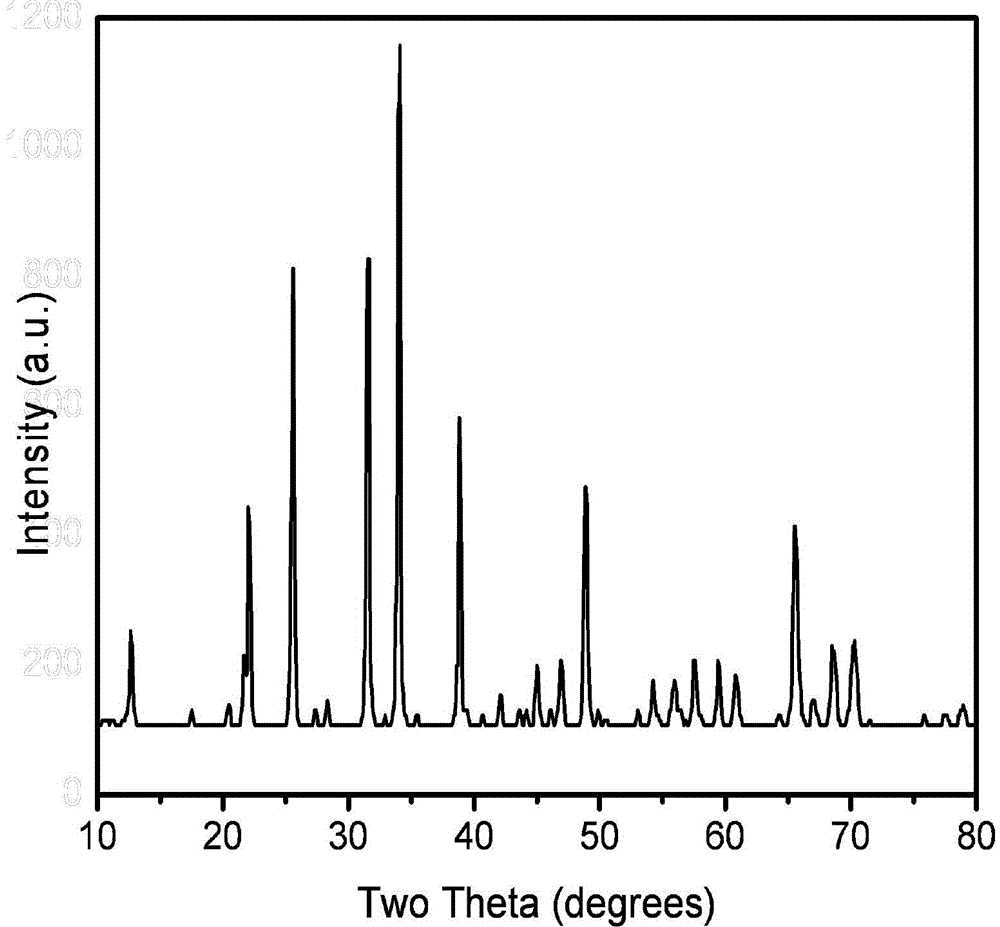

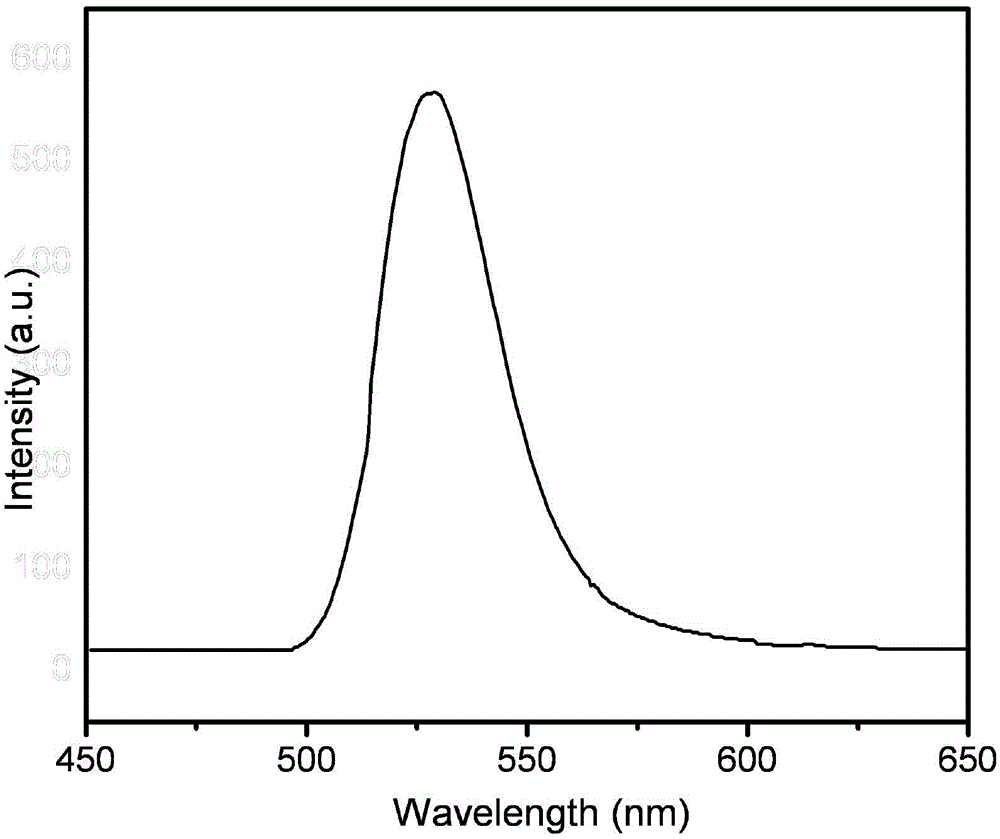

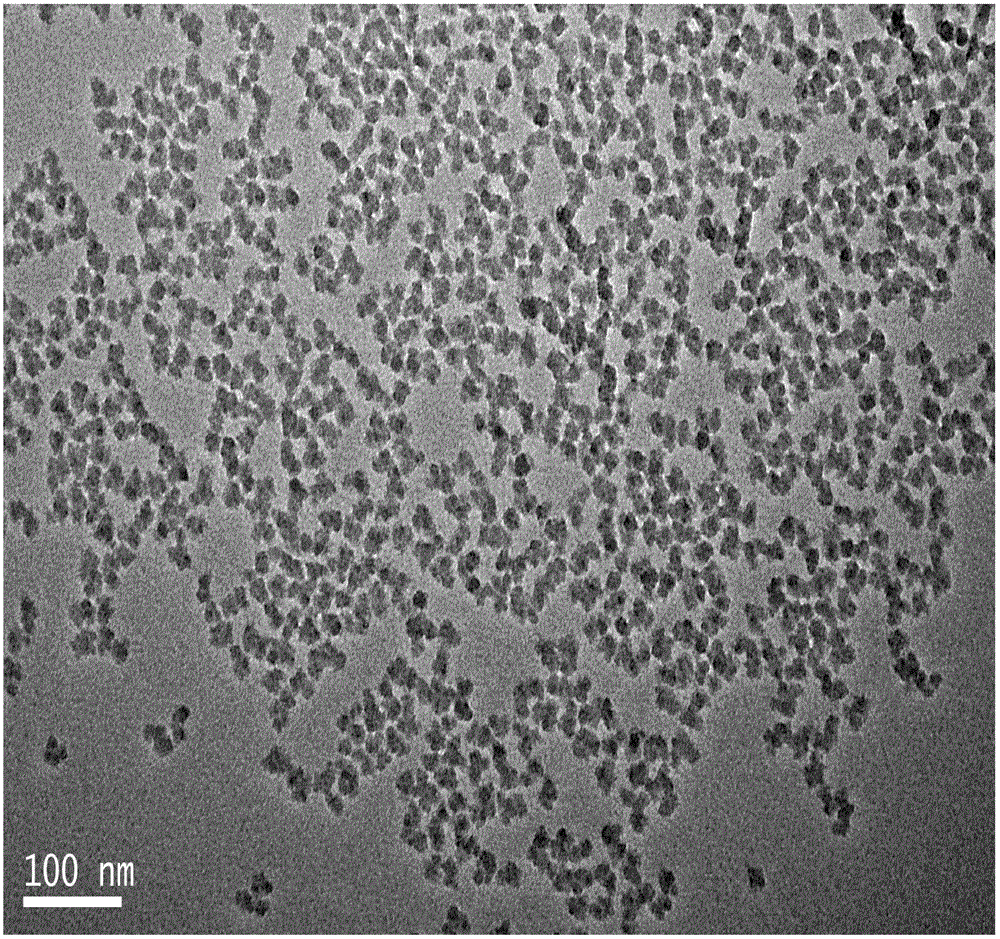

Method of synthesizing nano zinc silicate light emitting material by using waste silicon powder by hydrothermal method

InactiveCN104087289ATo achieve the purpose of resource recyclingSimple methodLuminescent compositionsPolytetrafluoroethyleneMaterials science

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for fully recycling and reproducing waste drip irrigation belts and waste greenhouse films

PendingCN114211640AQuality improvementOutstanding reproduction effectPlastic recyclingMechanical material recoveryBlow moldingMasterbatch

The invention relates to a waste drip irrigation tape and waste greenhouse film total recovery and reproduction method, and relates to the technical field of waste drip irrigation tape and waste greenhouse film resource recovery and reutilization, and the method comprises the following steps: waste material cleaning: putting waste drip irrigation tapes and waste greenhouse films into a cleaning pool for full cleaning; waste material drying, wherein the cleaned waste drip irrigation tape and the cleaned waste greenhouse film are dried; the waste materials are cut up, wherein the dried waste drip irrigation belts and the dried waste greenhouse films are cut up; mixing the raw materials: fully mixing the chopped waste materials with the new plastic material and the dyeing master batch; granulation: adding the mixed raw materials into an extruder for extrusion granulation; and film forming: performing blow molding and film forming on the raw material particles to finish reproduction of the waste materials. The waste drip irrigation tape and the waste greenhouse film can be utilized to the maximum extent, and the produced product is good in performance and good in application effect.

Owner:NINGXIA YURUN AGRI WATER SAVING IRRIGATION MFG CO LTD

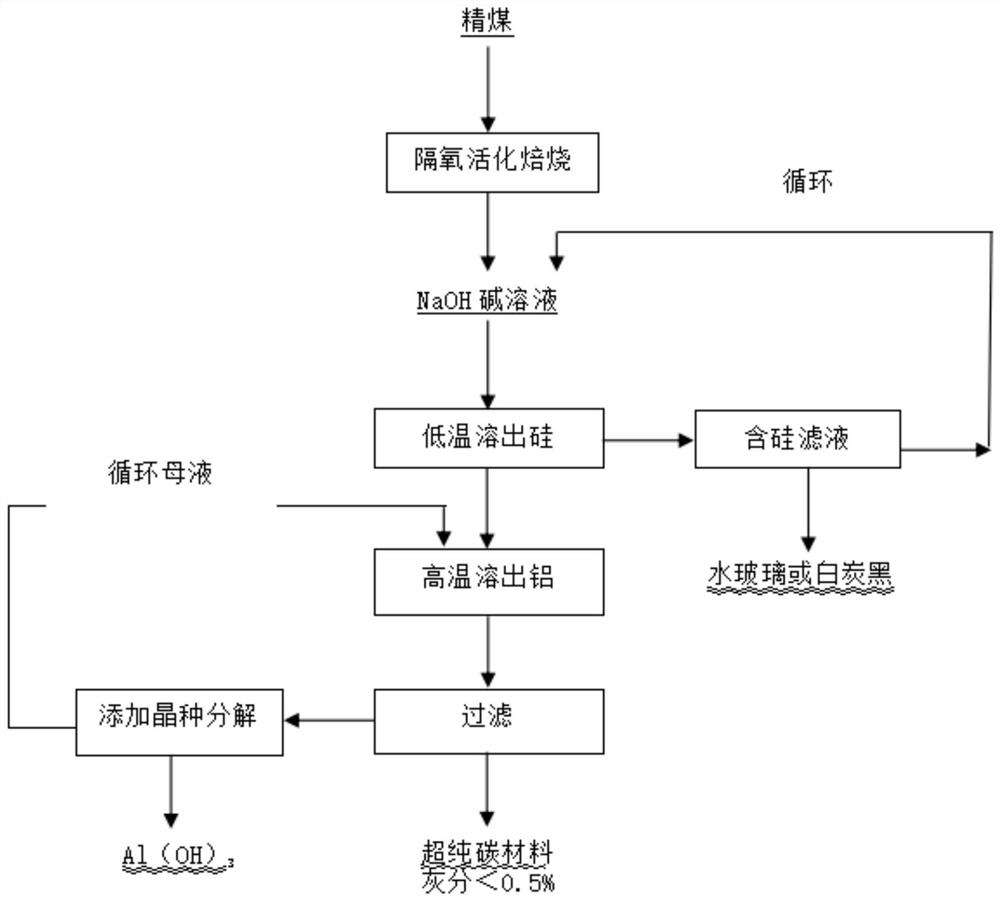

Chemical purification method for preparing ultralow ash content coal from clean coal

ActiveCN114317061ARealize recycling of resourcesAchieve recyclingSilicaSolid fuelsResource recoverySodium aluminate

Owner:HUAYANG NEW MATERIAL TECH GRP CO LT

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap