Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Blow molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blow molding (BrE moulding) is a specific manufacturing process by which hollow plastic parts are formed and can be joined together. It is also used for forming glass bottles or other hollow shapes.

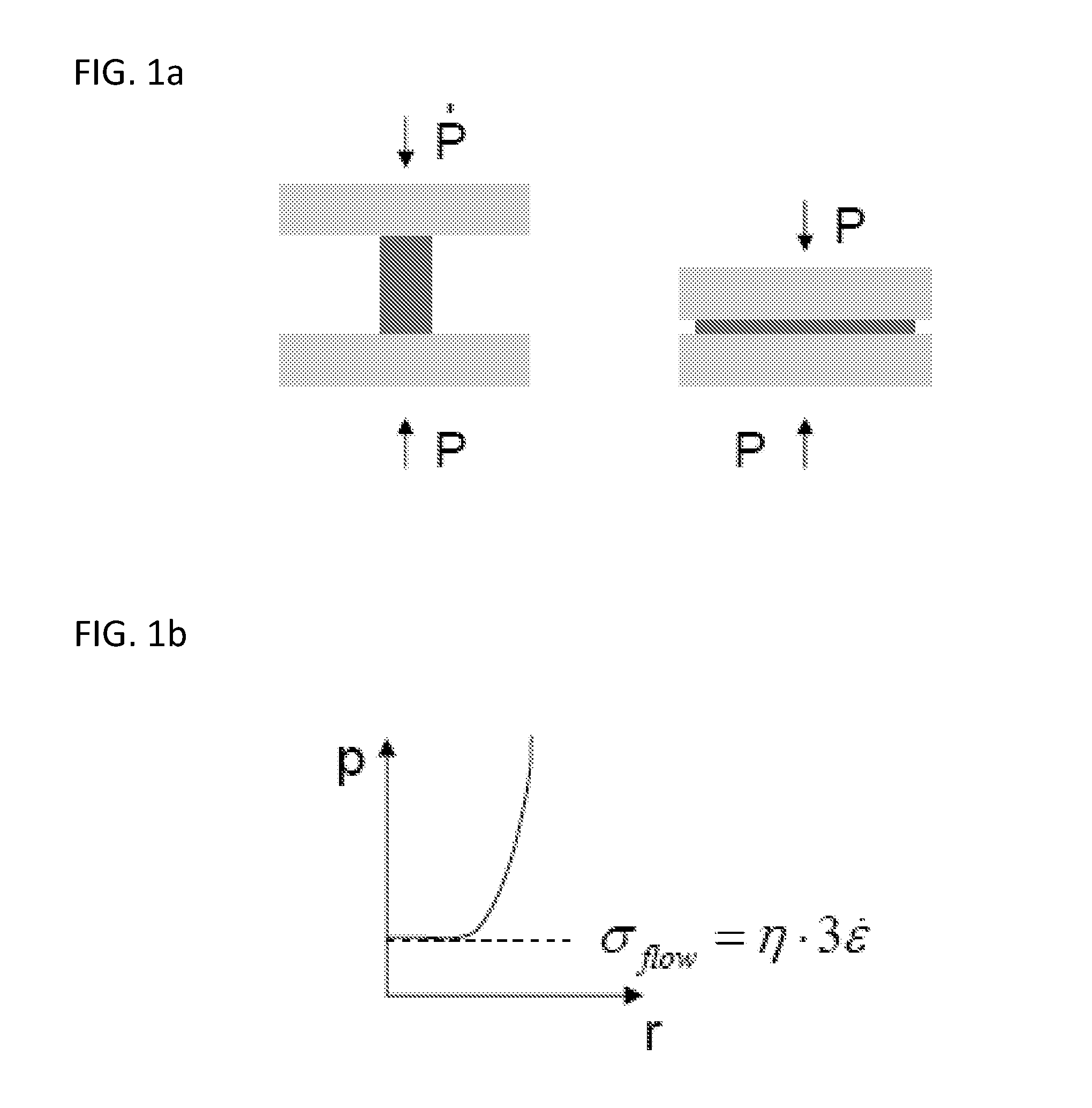

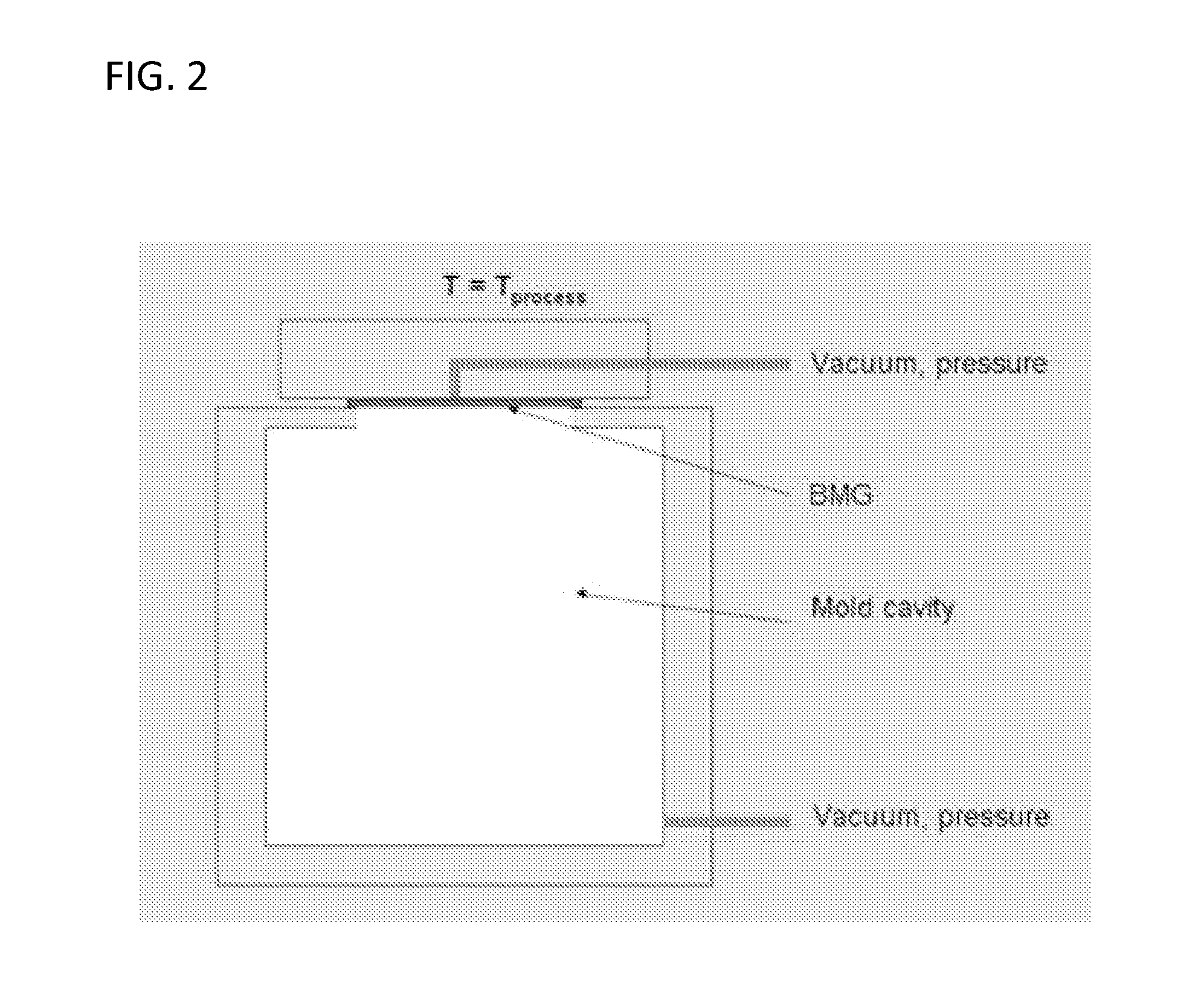

Method of blow molding a bulk metallic glass

Owner:YALE UNIV

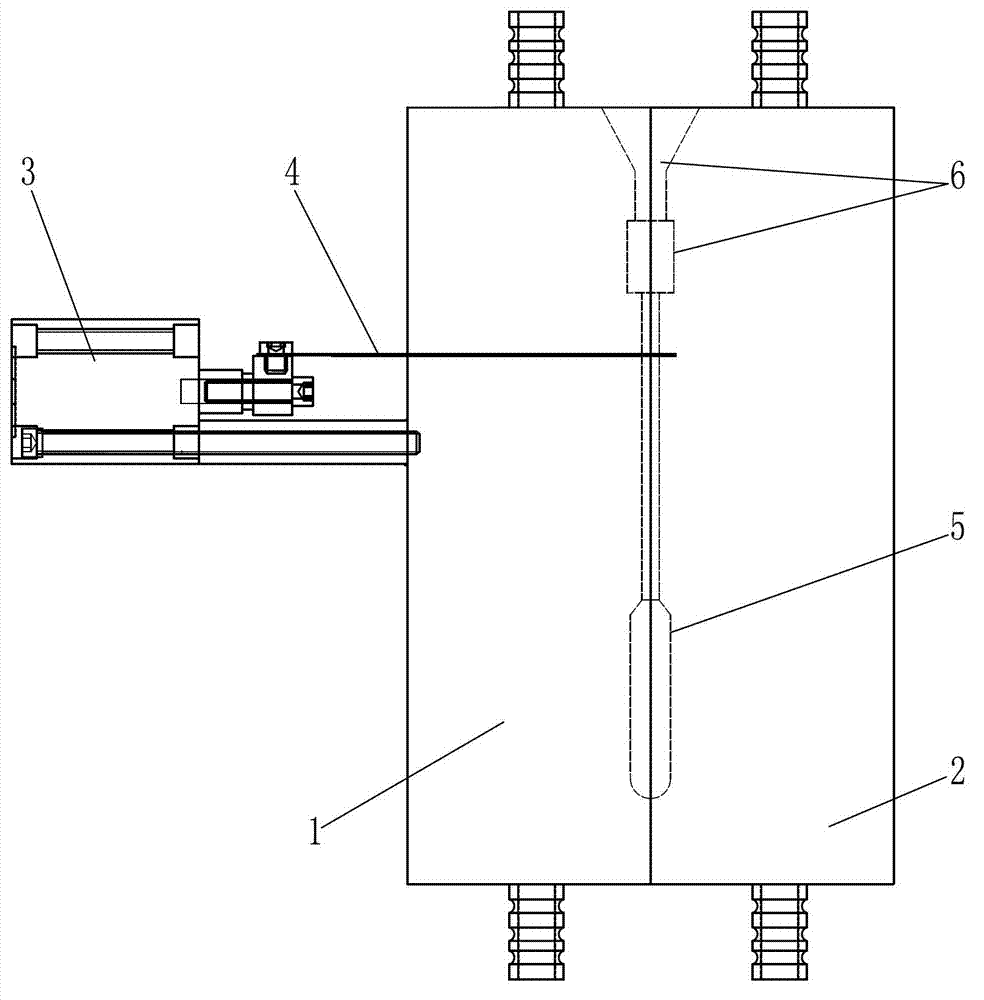

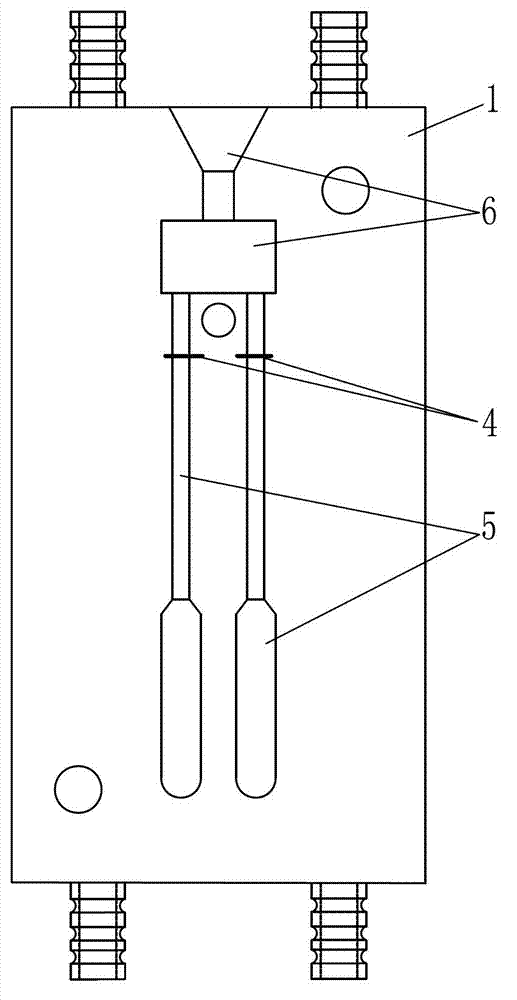

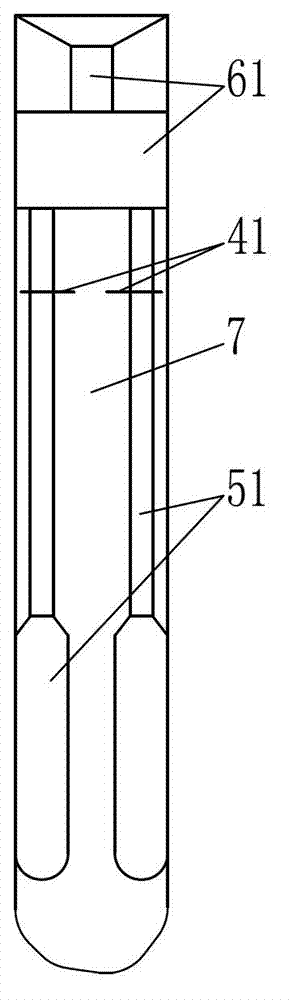

Pasteur pipette semi-finished product

ActiveCN102847566AImprove processing efficiencyGuarantee product qualityBurettes/pipettesBlow moldingWork in process

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

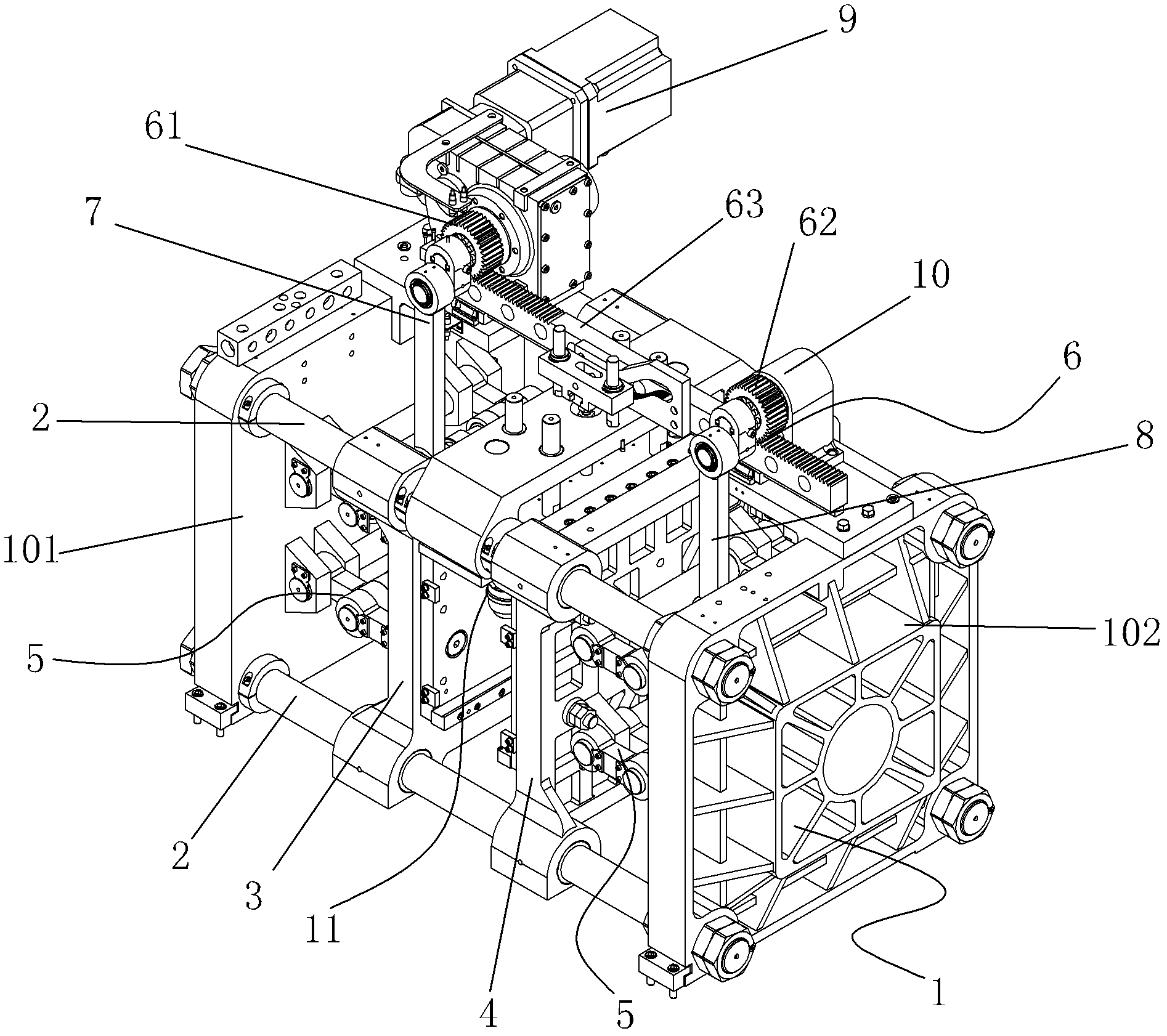

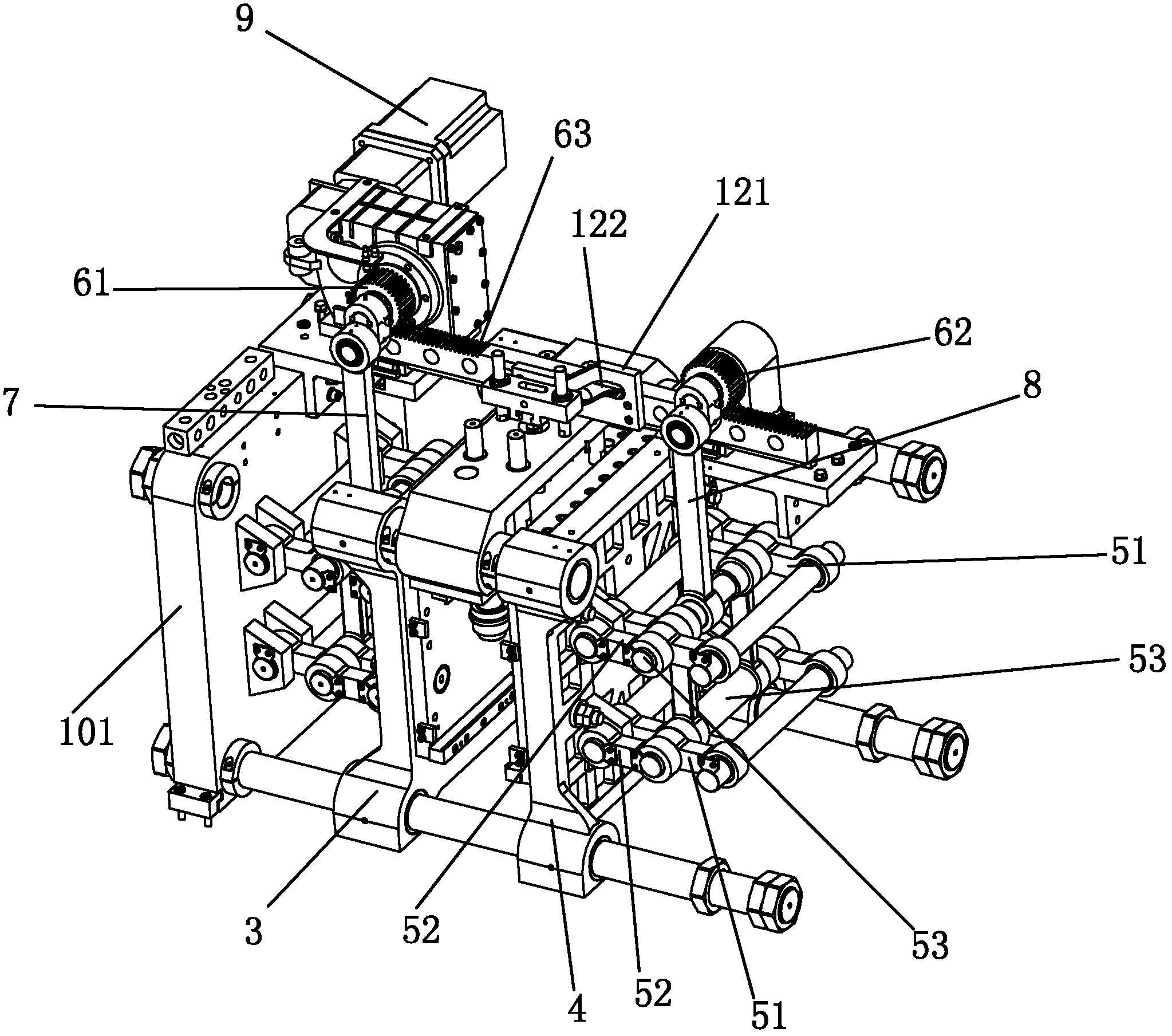

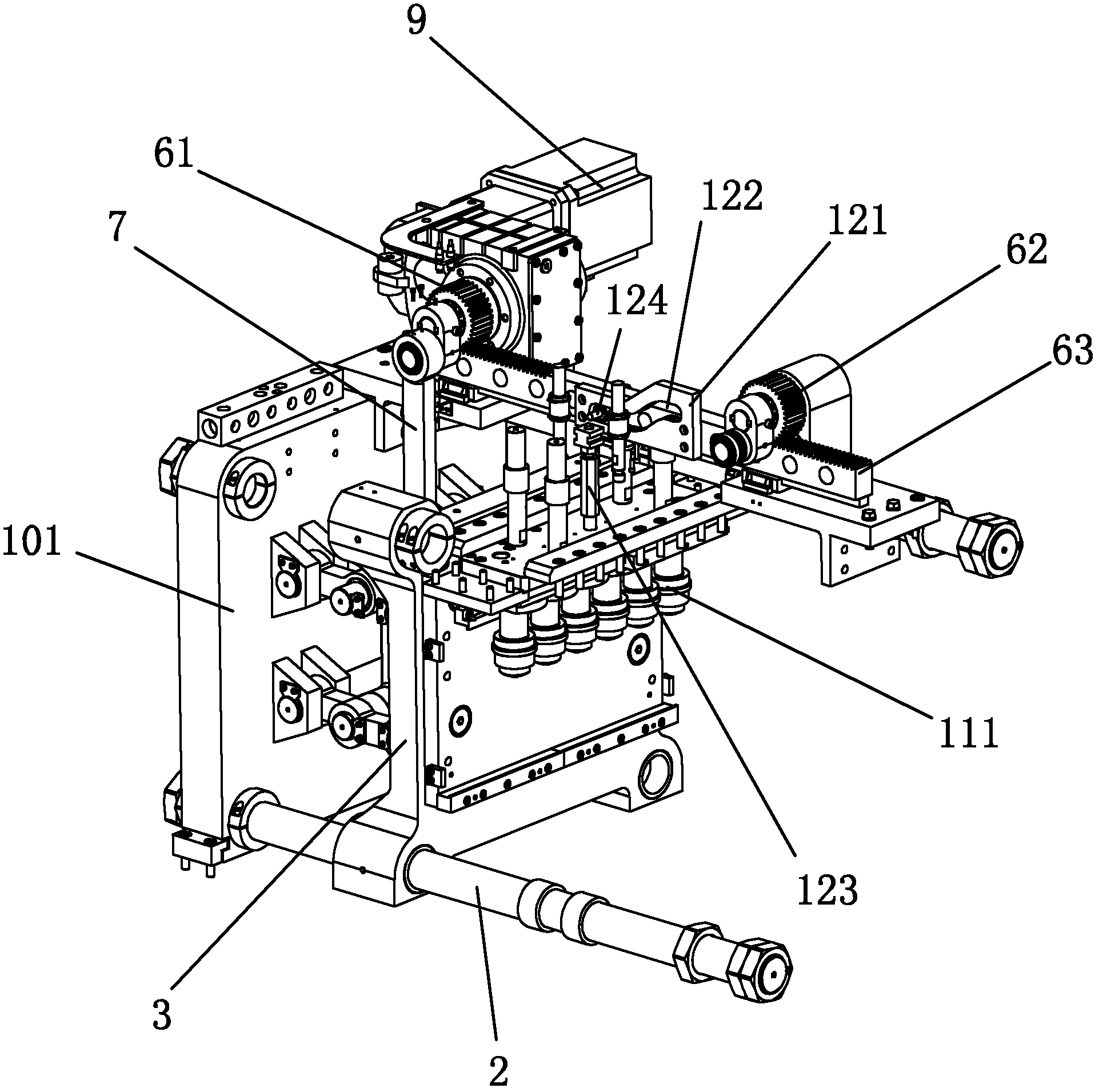

Mold opening and closing mechanism of blow molding machine

Owner:GUANGDONG FRIEND MACHINERY

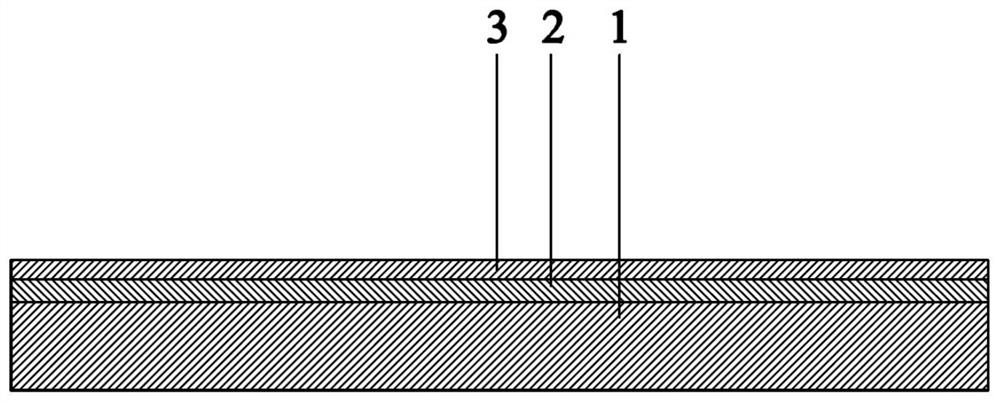

Environment-friendly film for home decoration

PendingCN114058106AEasy to stretchEasy to useAntifouling/underwater paintsInksBlow moldingPolymer science

Owner:佛山高明凯盛新材料科技有限公司

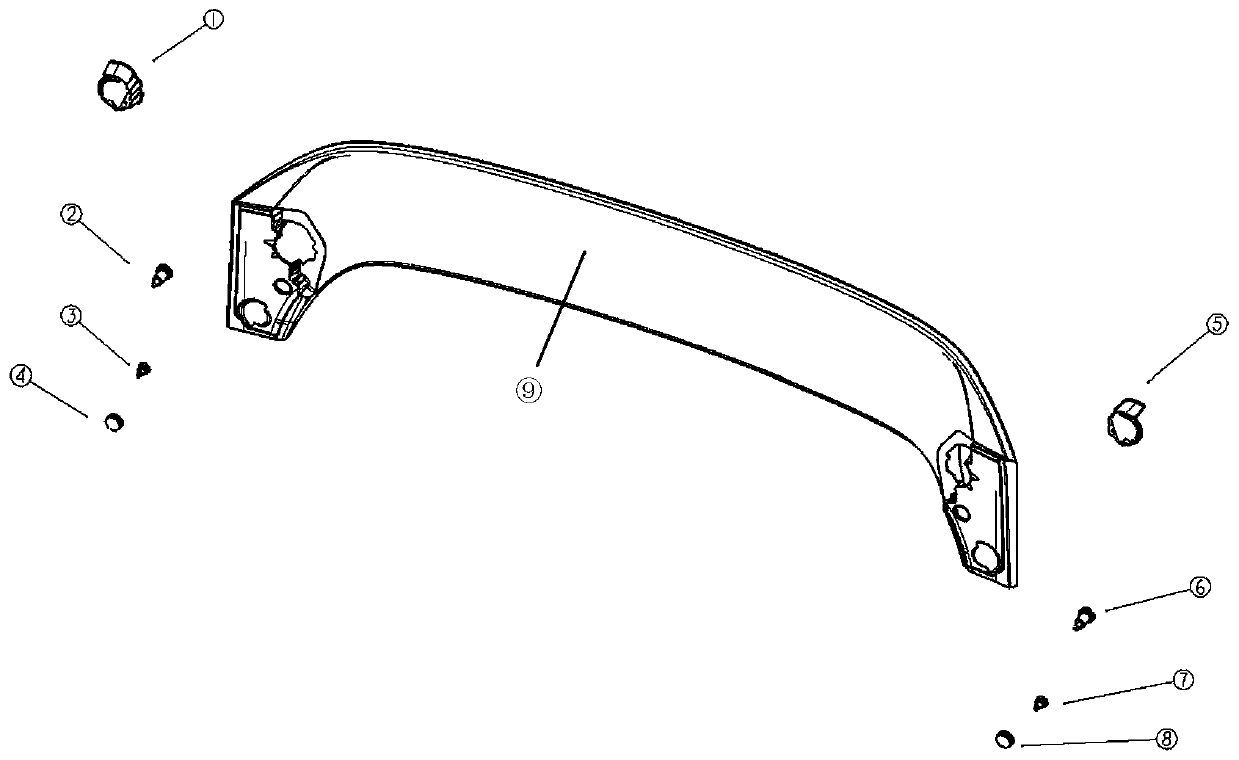

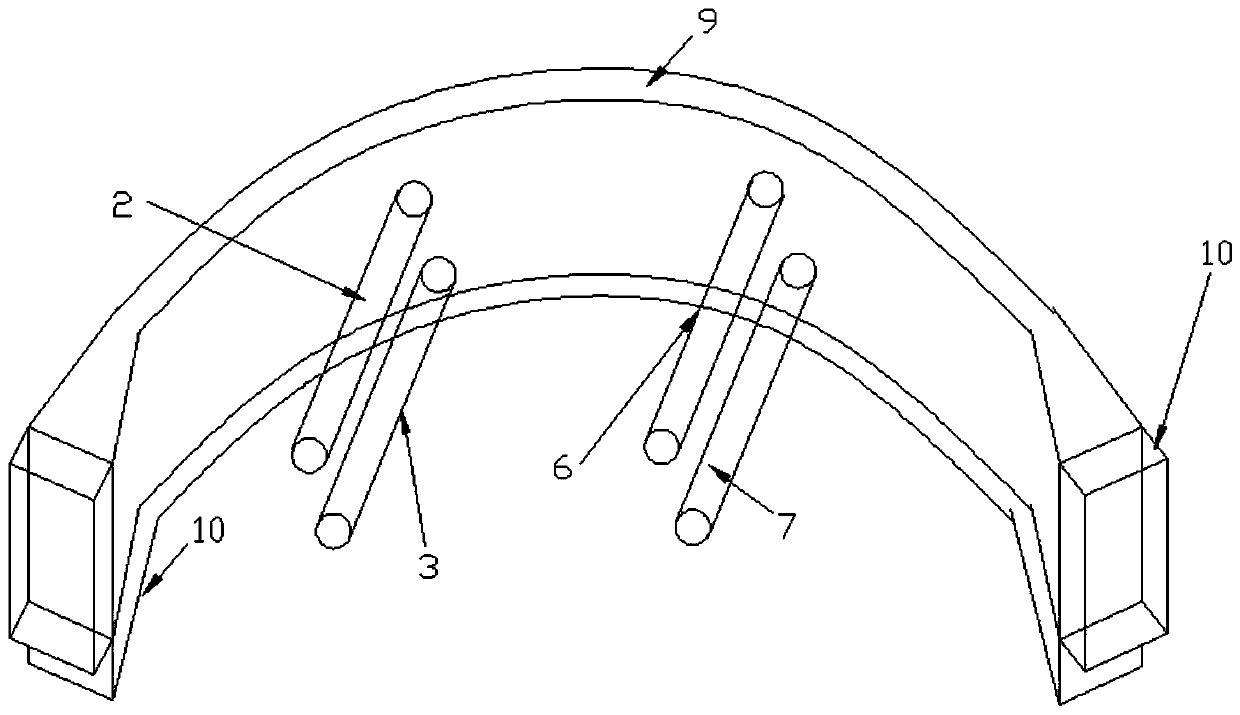

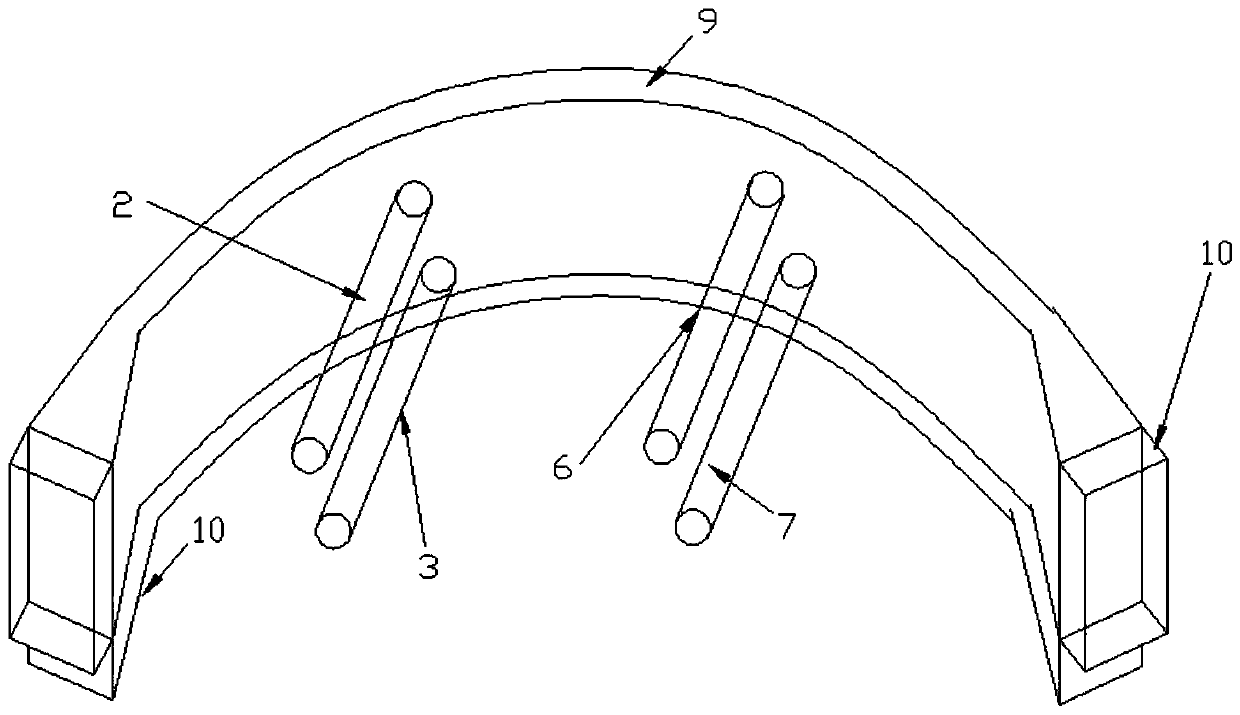

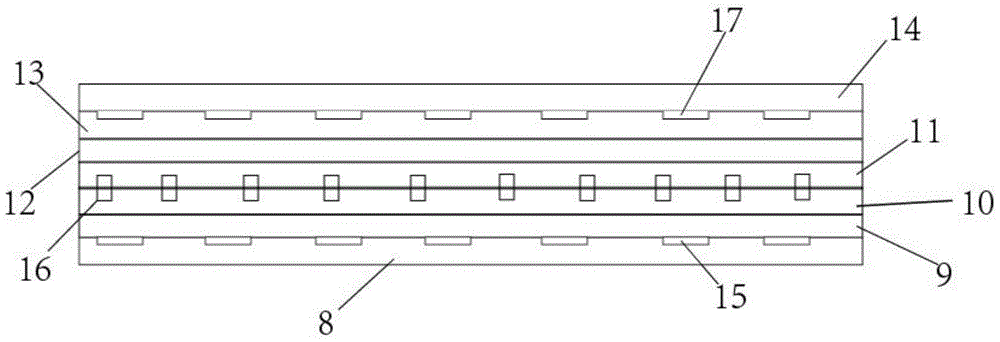

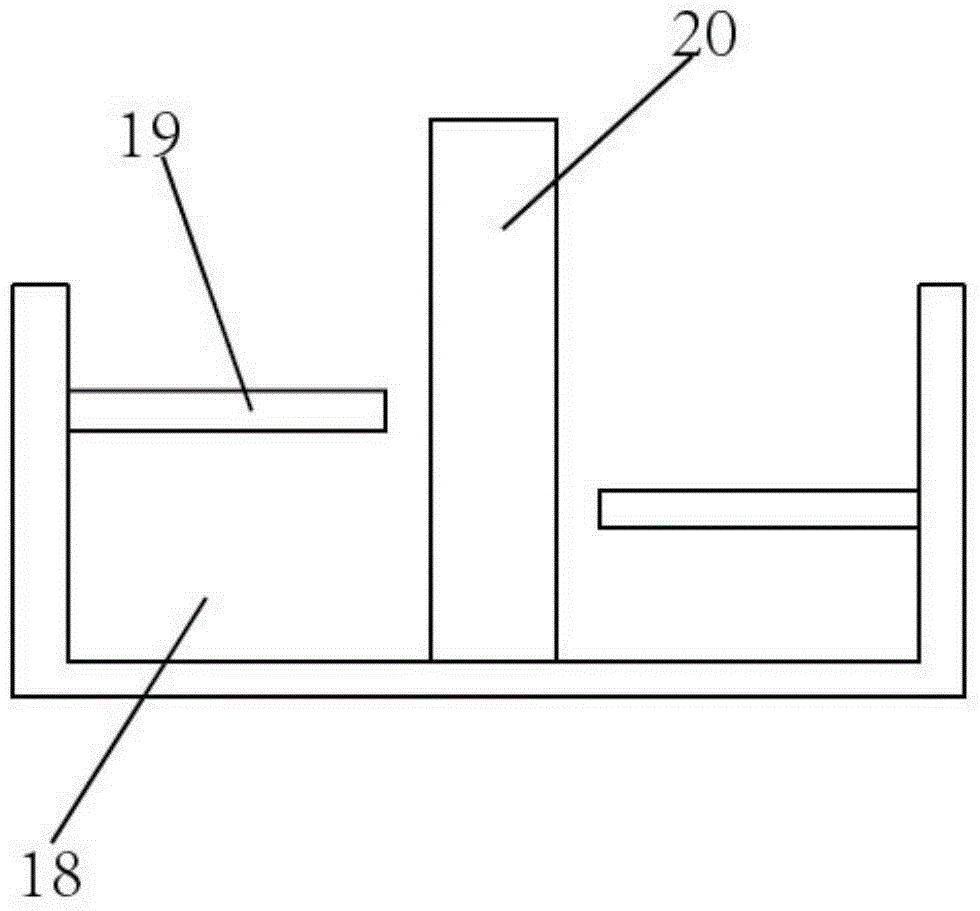

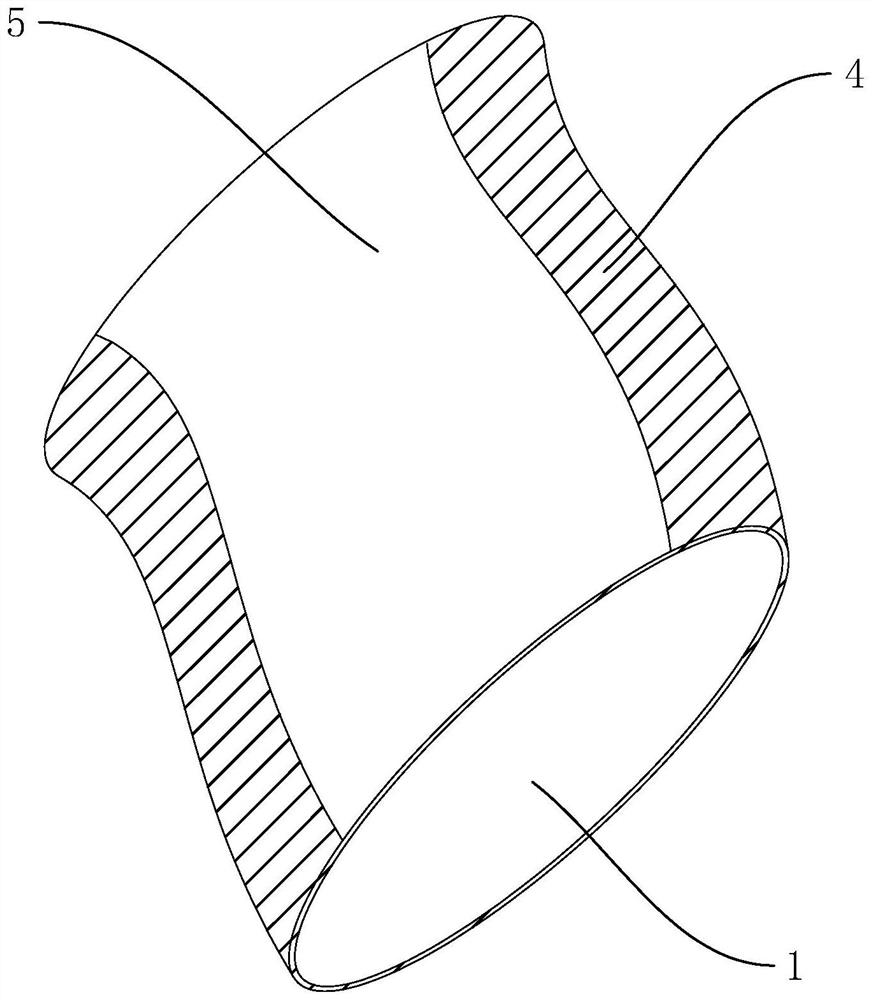

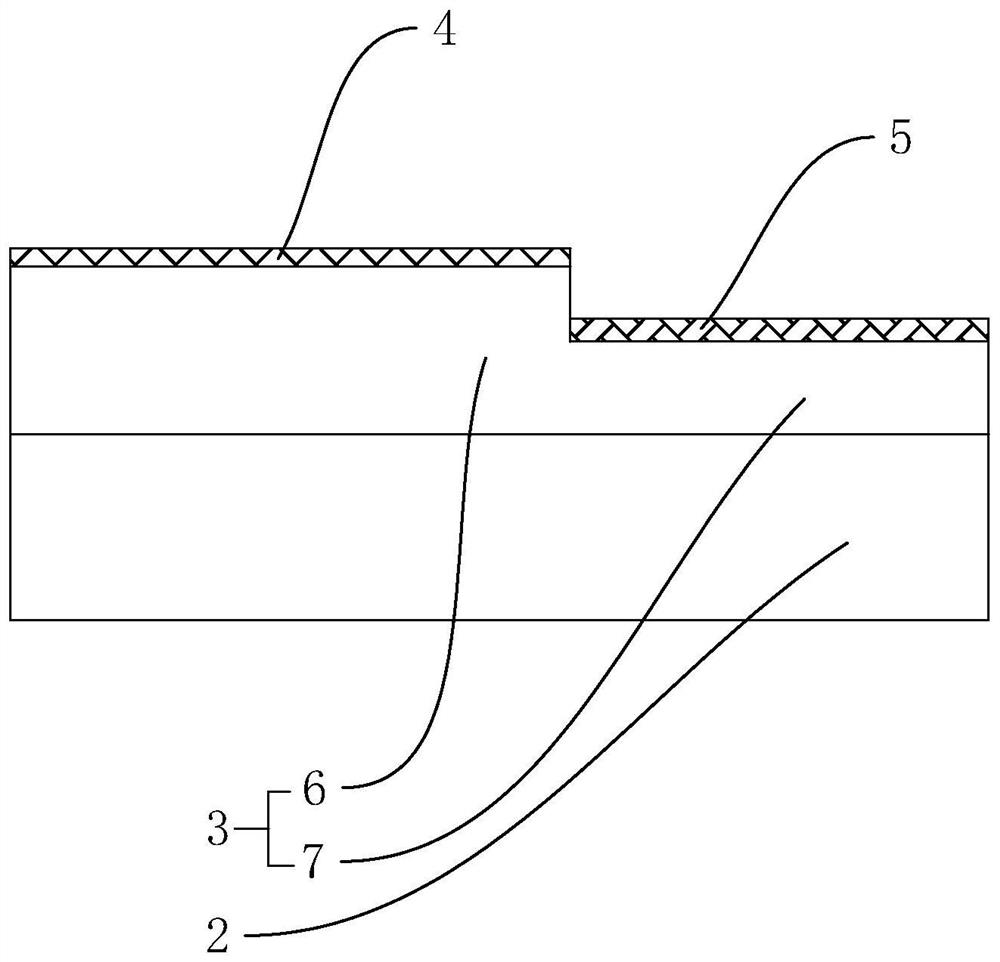

Blow molding process with effect of improving strength of flow guide plate by injection molding of inserts and prepared flow guide plate

PendingCN110216861AFirmly assembledEnhances refined perceptionAerodynamics improvementDomestic articlesBlow moldingEngineering

Owner:江阴名鸿车顶系统有限公司

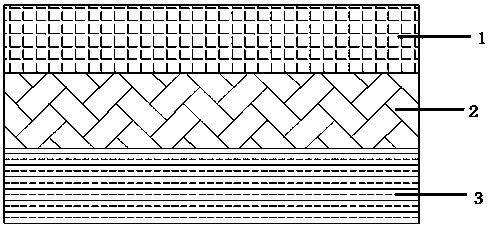

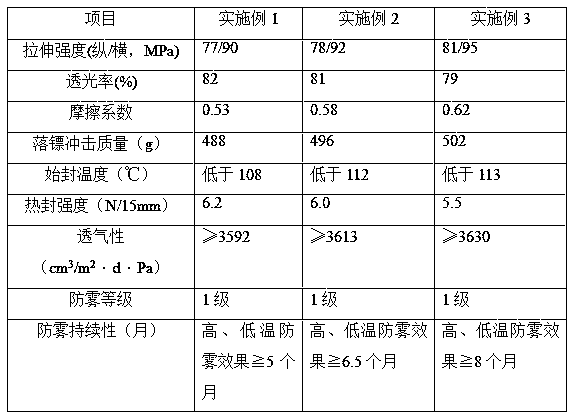

High-low-temperature anti-fog breathable polyethylene heat-sealing film for fruit and vegetable packaging and preparation method of high-low-temperature anti-fog breathable polyethylene heat-sealing film

InactiveCN110948974AReduce precipitationProlong the action timeSynthetic resin layered productsDomestic containersBlow moldingPolymer science

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV +1

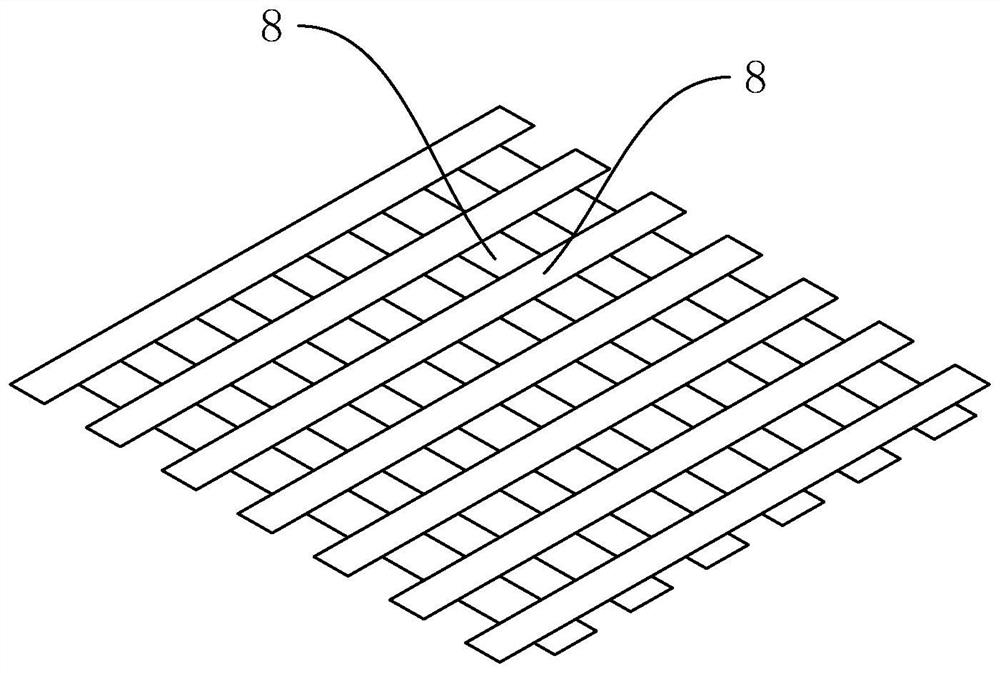

Method for fully recycling and reproducing waste drip irrigation belts and waste greenhouse films

PendingCN114211640AQuality improvementOutstanding reproduction effectPlastic recyclingMechanical material recoveryBlow moldingMasterbatch

The invention relates to a waste drip irrigation tape and waste greenhouse film total recovery and reproduction method, and relates to the technical field of waste drip irrigation tape and waste greenhouse film resource recovery and reutilization, and the method comprises the following steps: waste material cleaning: putting waste drip irrigation tapes and waste greenhouse films into a cleaning pool for full cleaning; waste material drying, wherein the cleaned waste drip irrigation tape and the cleaned waste greenhouse film are dried; the waste materials are cut up, wherein the dried waste drip irrigation belts and the dried waste greenhouse films are cut up; mixing the raw materials: fully mixing the chopped waste materials with the new plastic material and the dyeing master batch; granulation: adding the mixed raw materials into an extruder for extrusion granulation; and film forming: performing blow molding and film forming on the raw material particles to finish reproduction of the waste materials. The waste drip irrigation tape and the waste greenhouse film can be utilized to the maximum extent, and the produced product is good in performance and good in application effect.

Owner:NINGXIA YURUN AGRI WATER SAVING IRRIGATION MFG CO LTD

Packaging bag and application thereof

InactiveCN106477146AExtended shelf lifeExtended storage timeBagsSynthetic resin layered productsBlow moldingPlastic film

Owner:TIANJIN HAIJING PLASTIC PROD

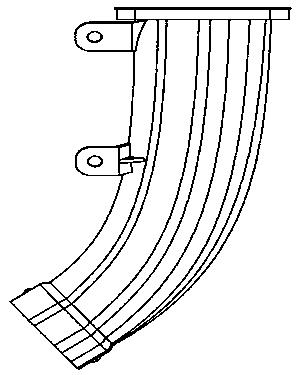

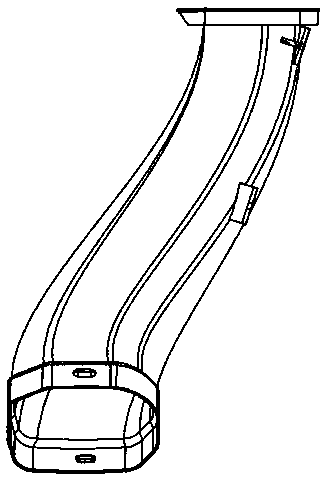

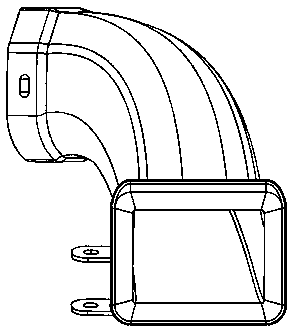

Manufacturing method of blow molding and foaming air channel

Owner:JIANGSU XINGCHENXING AUTO ACCESSORIES

Tear-resistant blown film and preparation process thereof

PendingCN114851665AImprove tear resistanceImprove puncture abilityWrappersFlexible coversBlow moldingPolymer science

Owner:绍兴新航塑料制品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap