Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Injection molding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

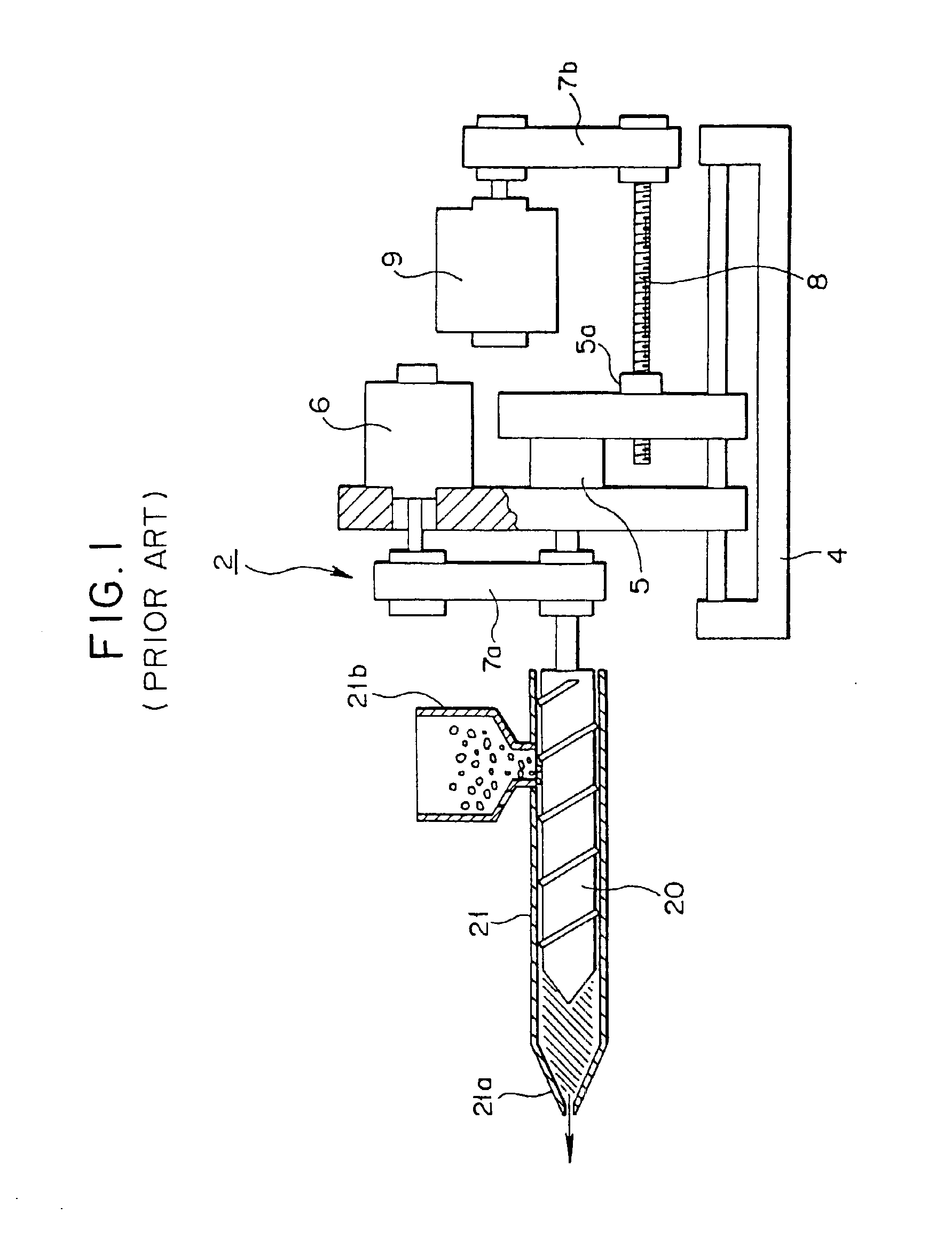

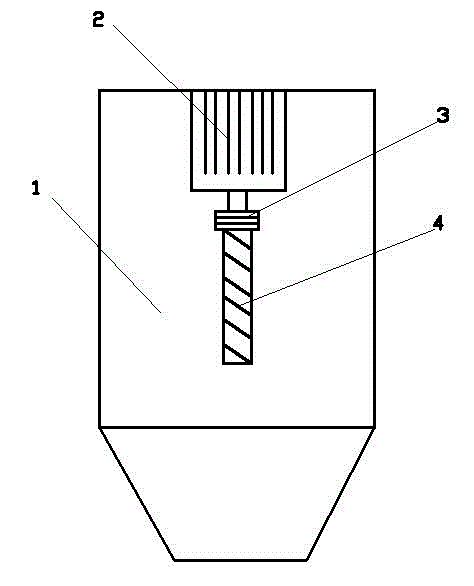

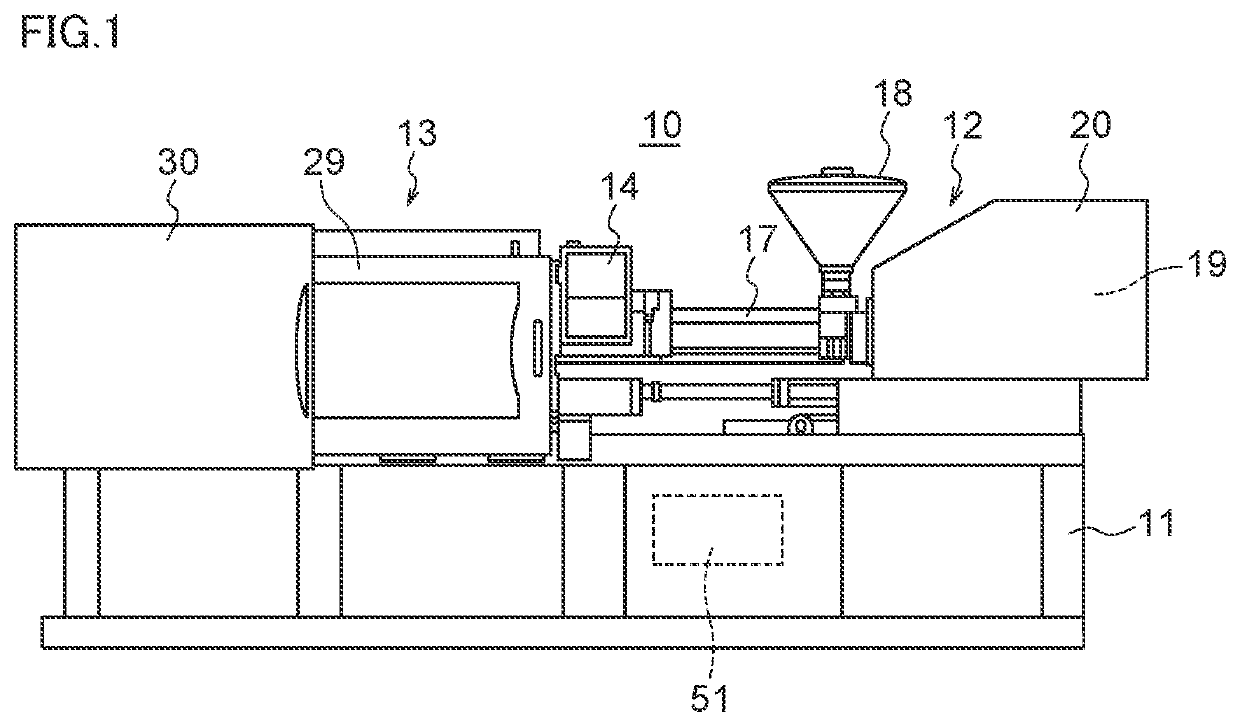

An Injection molding machine, or (Injection moulding machine BrE), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit.

Super-cold-resistant impact-resistant high-toughness PP-R pipe material and preparation method thereof

InactiveCN104910521AImprove low temperature resistanceSolve the problem of water deliveryRigid pipesWater deliveryInjection molding machine

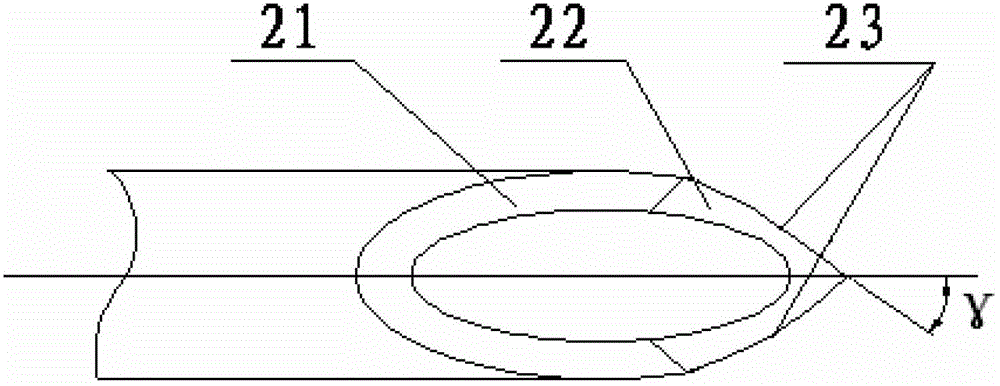

The invention relates to a super-cold-resistant impact-resistant high-toughness PP-R pipe material and a preparation method thereof, belonging to the field of macromolecules. The method comprises the following steps: preparing materials by virtue of a PP-R resin and a cold-resistant toughened color master batch; adding the prepared raw materials into a twin-screw extruder, mixing, molding, cooling, and performing grain-sized dicing, thereby obtaining a modified material A; drying the modified material A in a drying box, thereby obtaining a modified material B; and finally, putting the modified material B on an injection molding machine, and performing injection molding to obtain the PP-R pipe. The PP-R pipe disclosed by the invention can be used at the temperature of 50 DEG C below zero to 30 DEG C below zero, the low temperature resistance of the pipe is enhanced, the water delivery problem in the northern area in winter is solved, the toughness and impact resistance of the PP-R pipe are enhanced, the PP-R pipe is difficult to age, and the service life is prolonged.

Owner:CHANGZHOU UNIV

Microcellular foaming and in-mold decoration composite molding device with composite foaming agents and microcellular foaming and in-mold decoration composite molding method

InactiveCN107379388AImprove foaming efficiencyImprove surface qualityCoatingsFoaming agentGas cylinder

Owner:WUHAN UNIV OF TECH

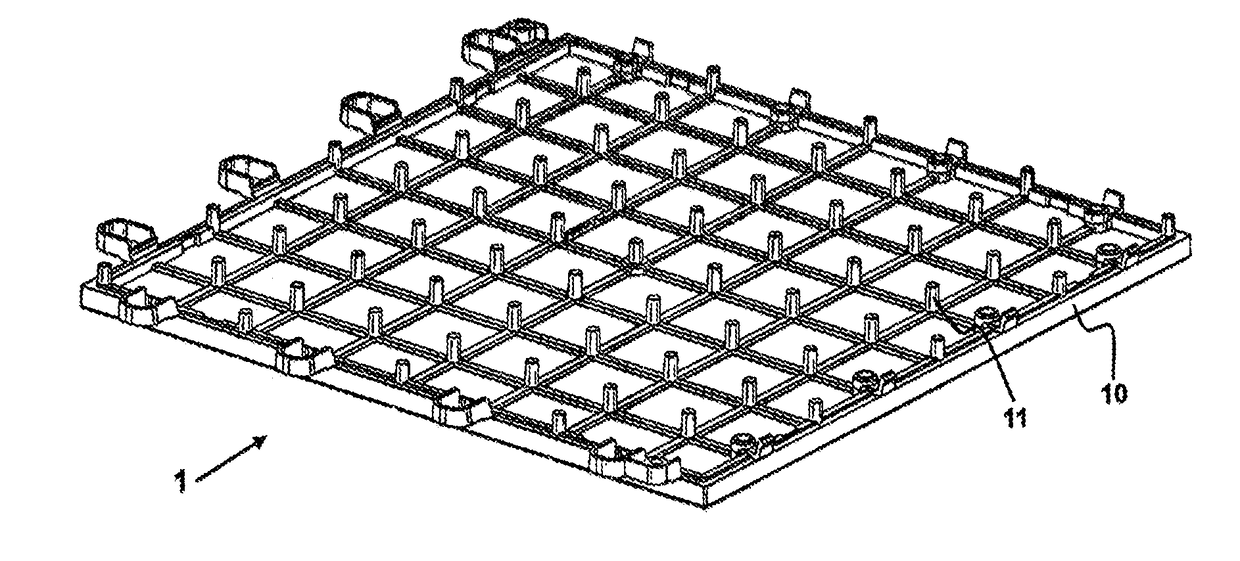

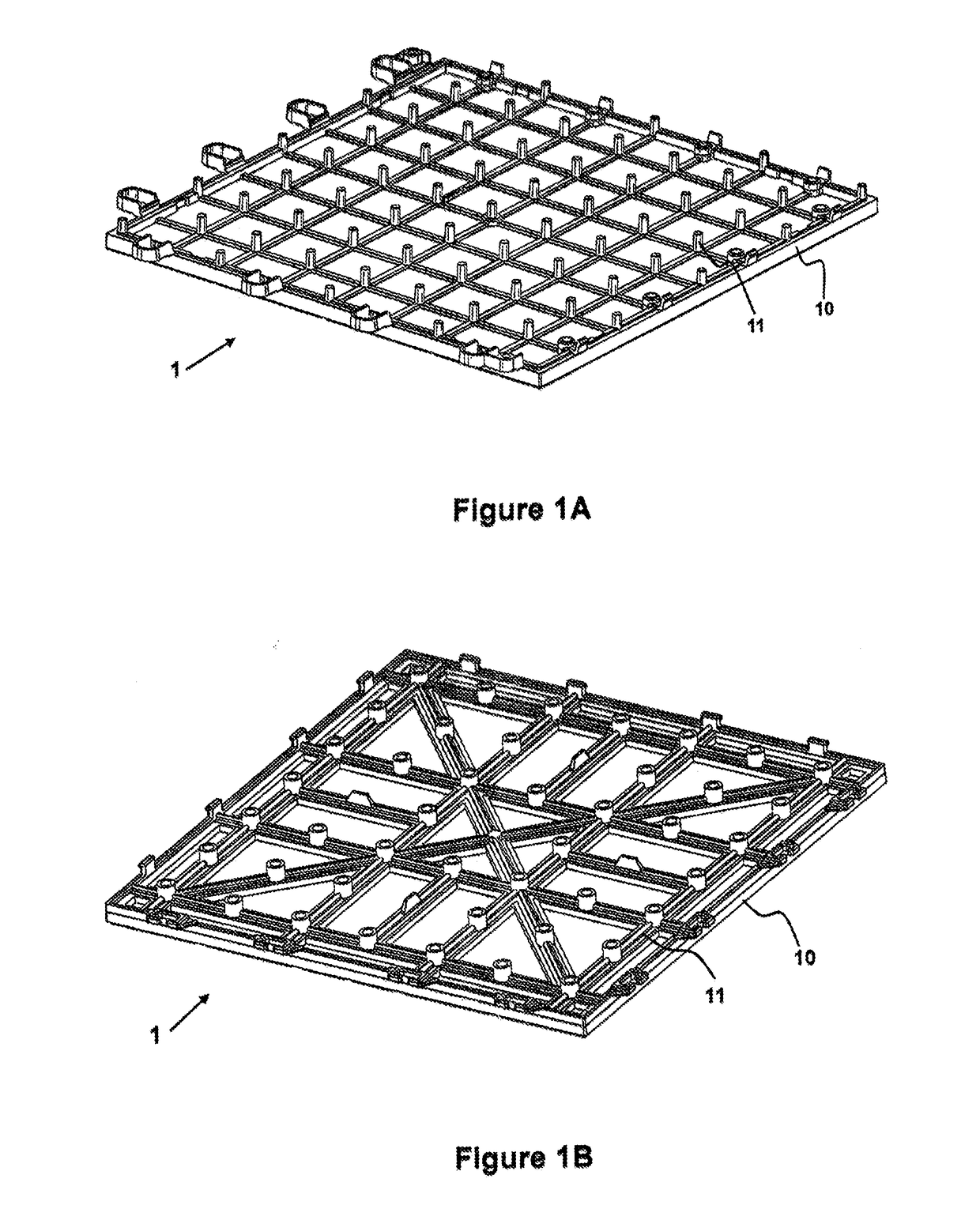

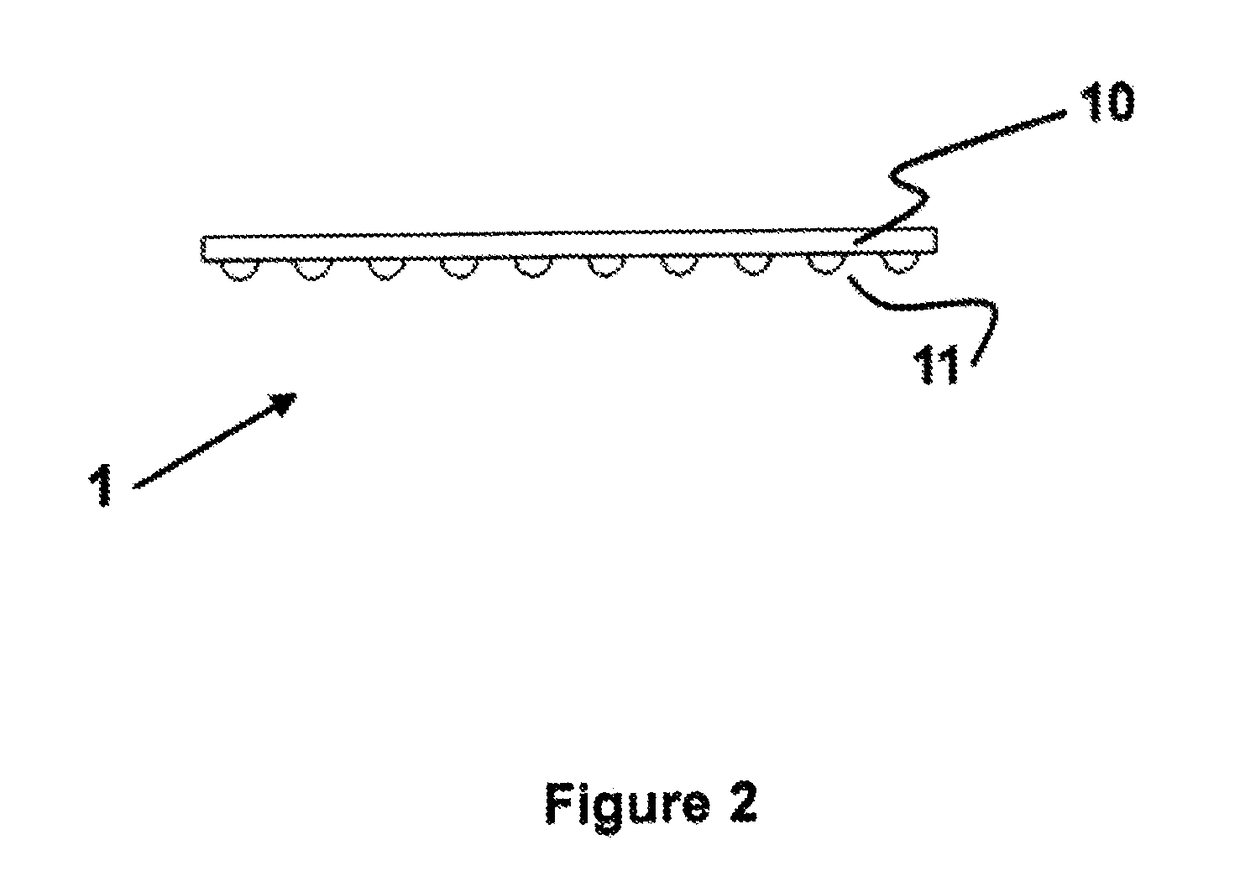

Production of two-layer composite deck tile by injection molding method

InactiveUS20170081862A1Eliminate disadvantagesEnhanced advantageSingle unit pavingsSynthetic resin layered productsOutdoor areaInjection moulding

Owner:SEMA PLASTIK KALIP VE MAKINE SANAYI VE TICARET LTD STI

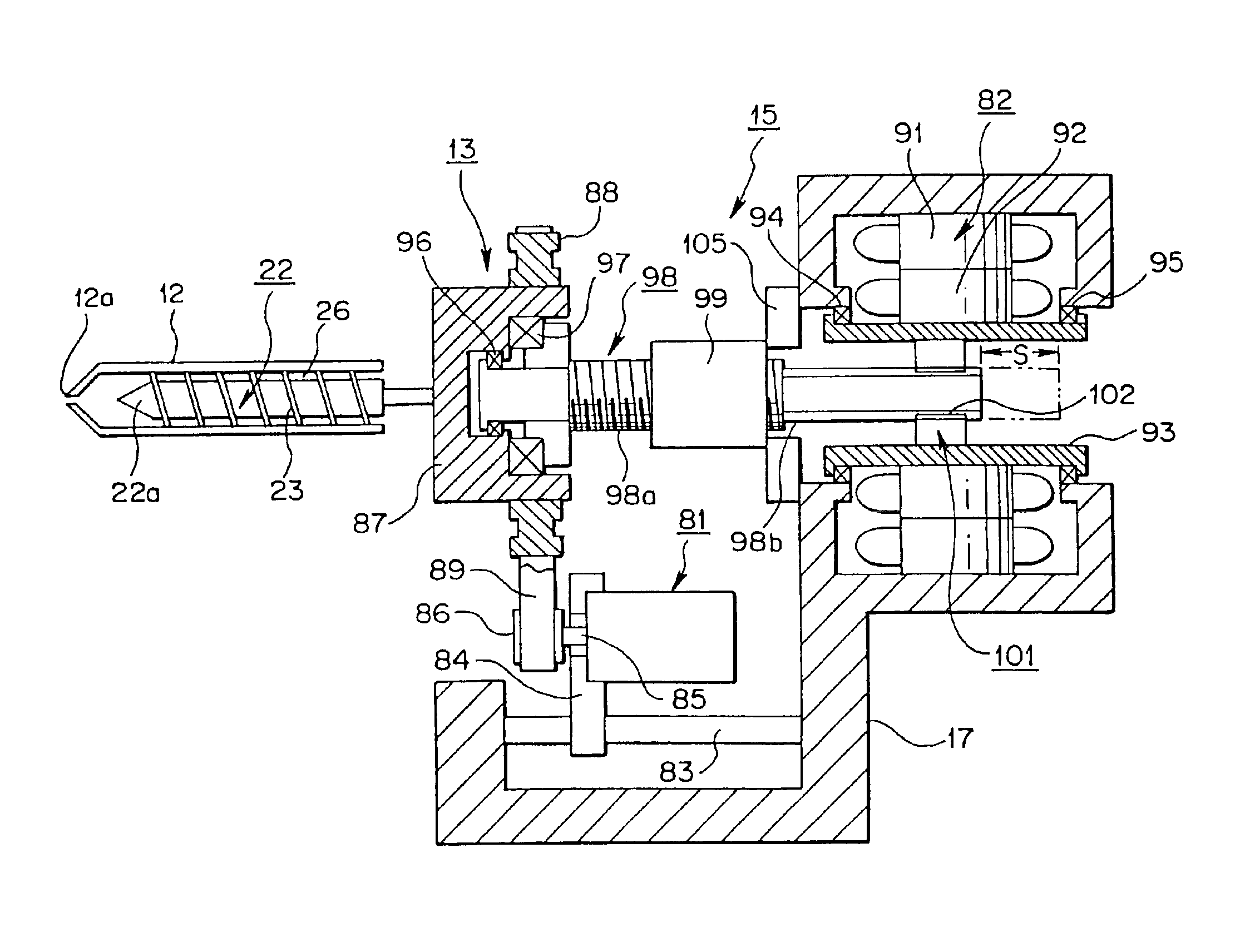

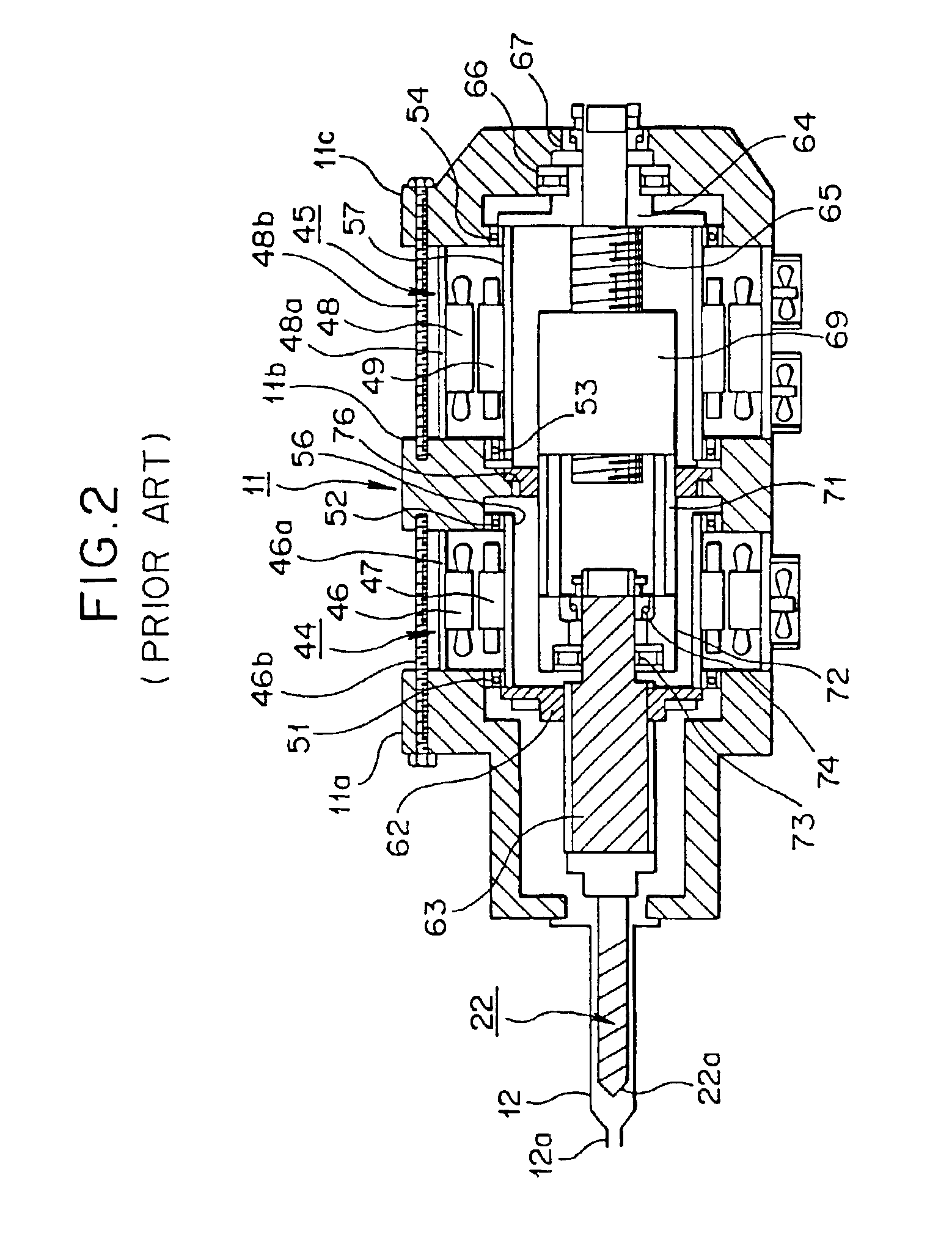

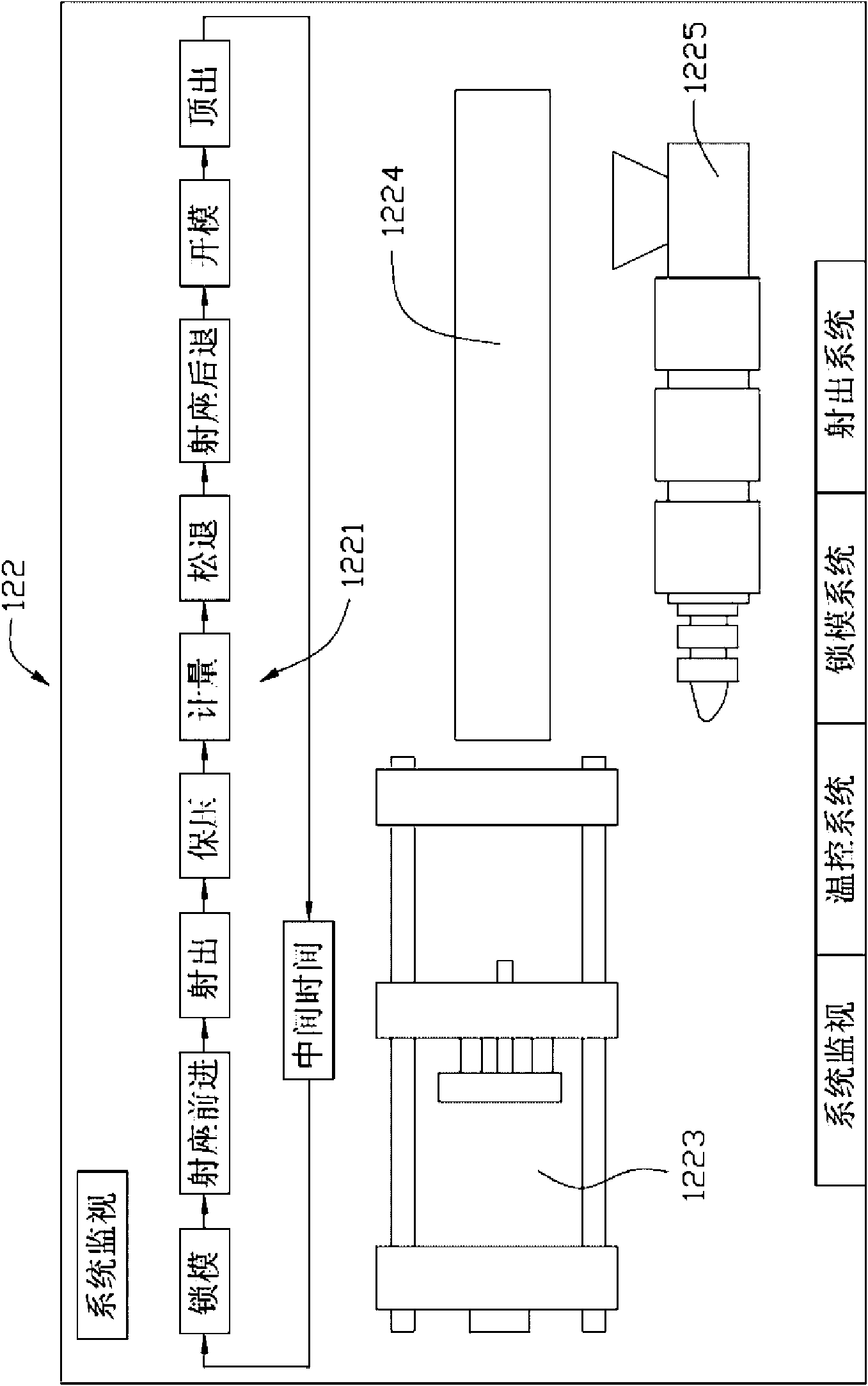

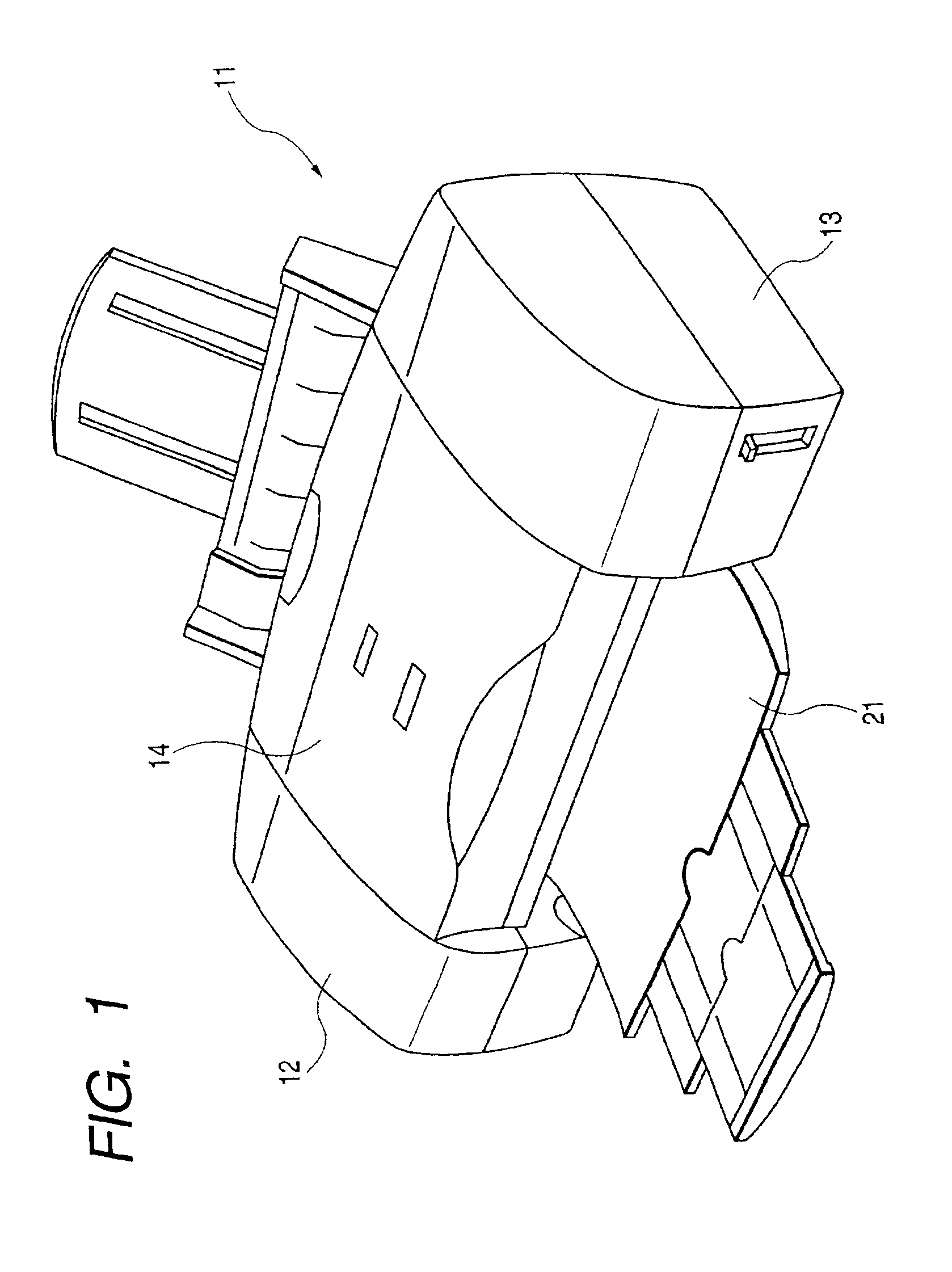

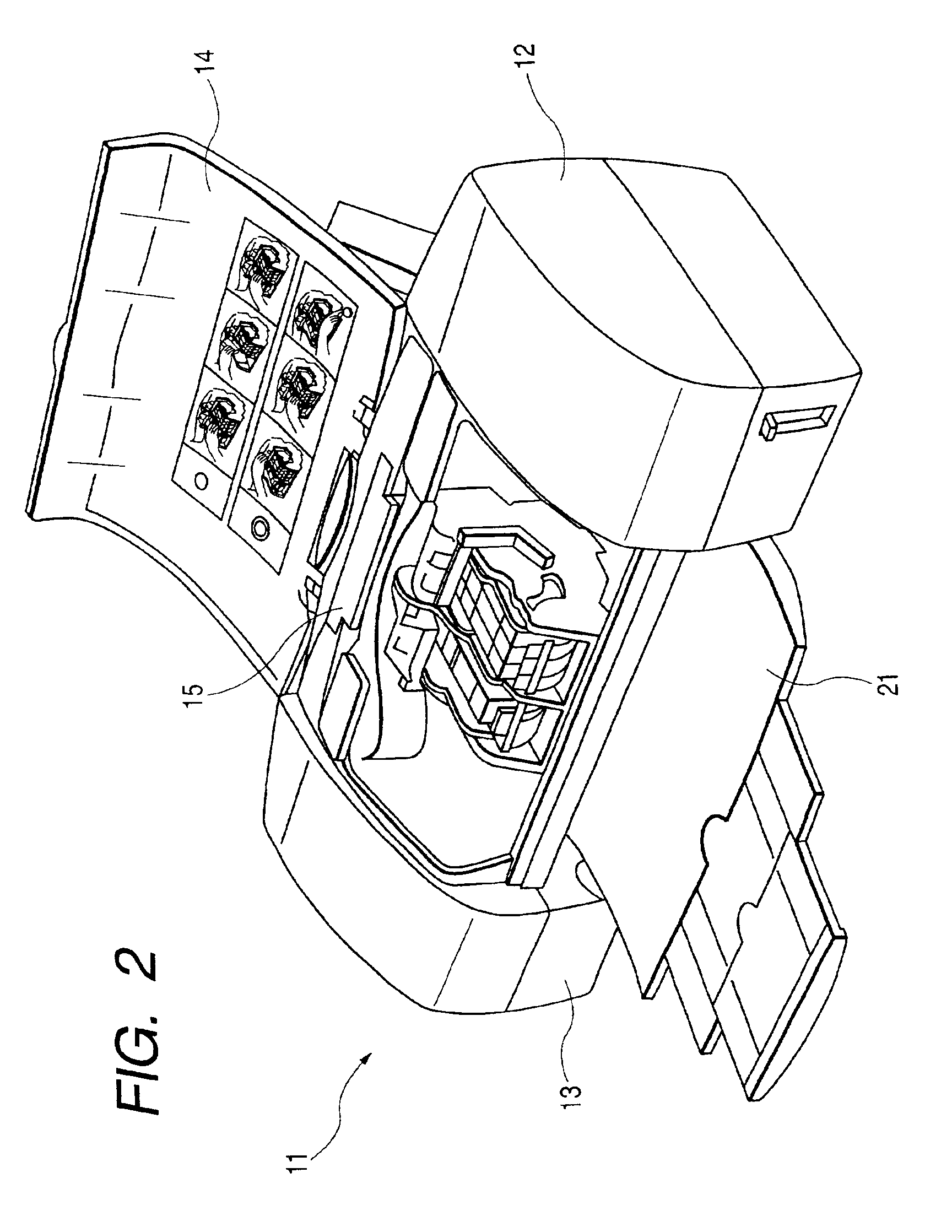

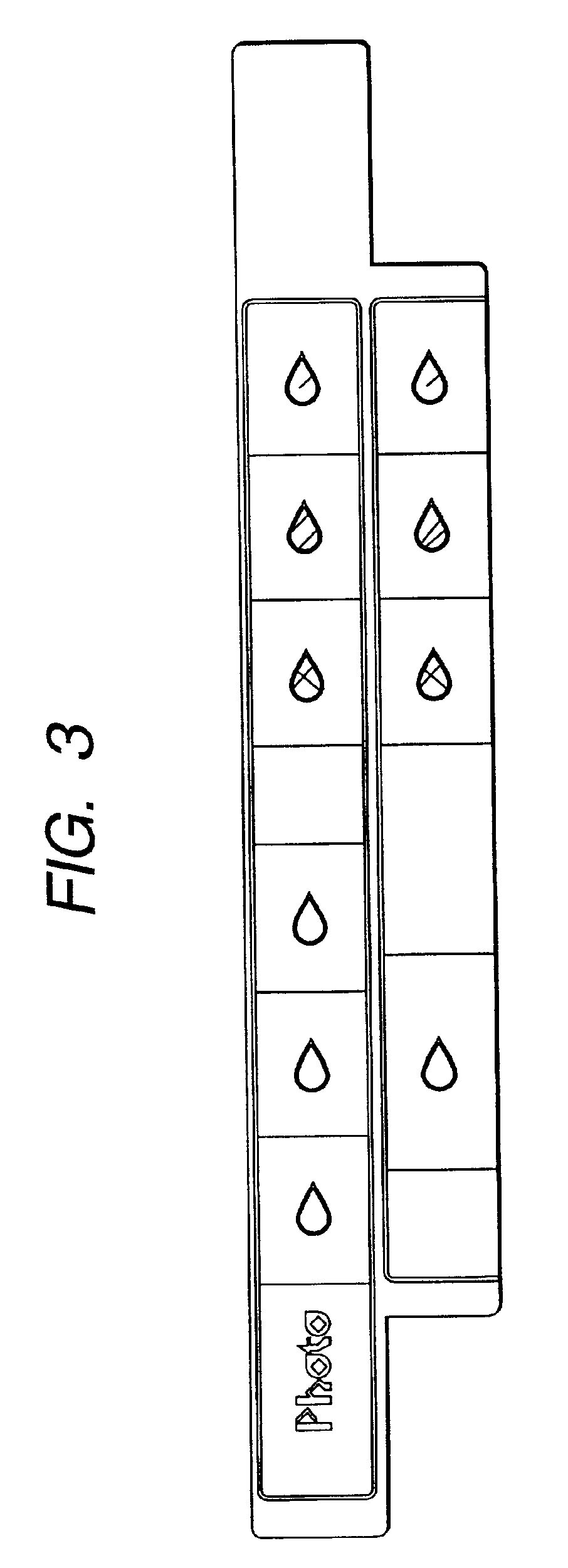

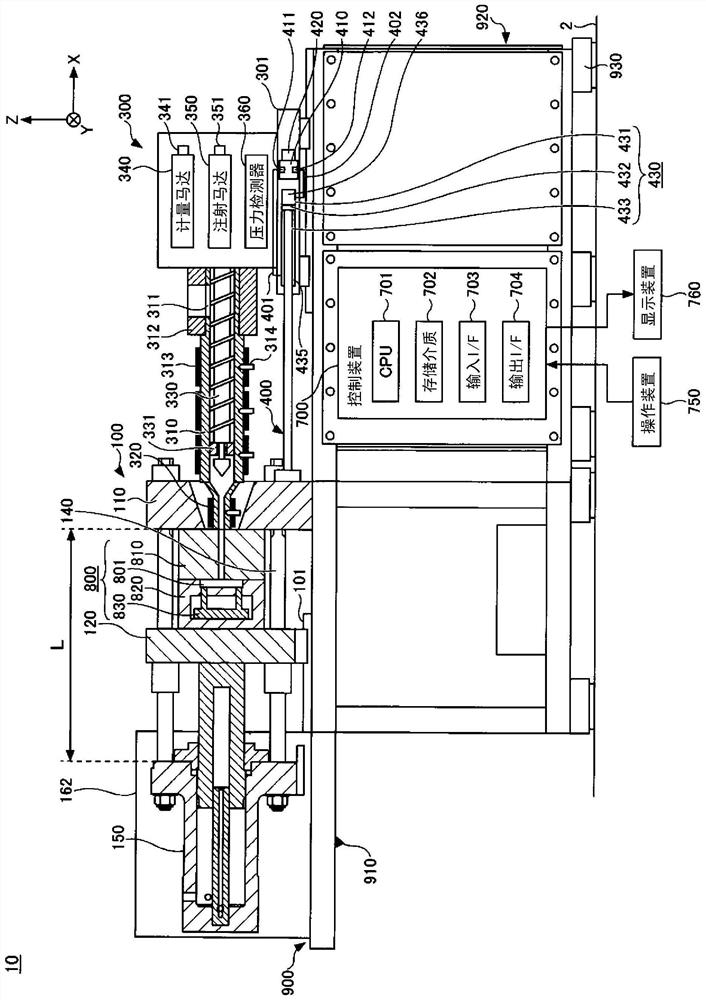

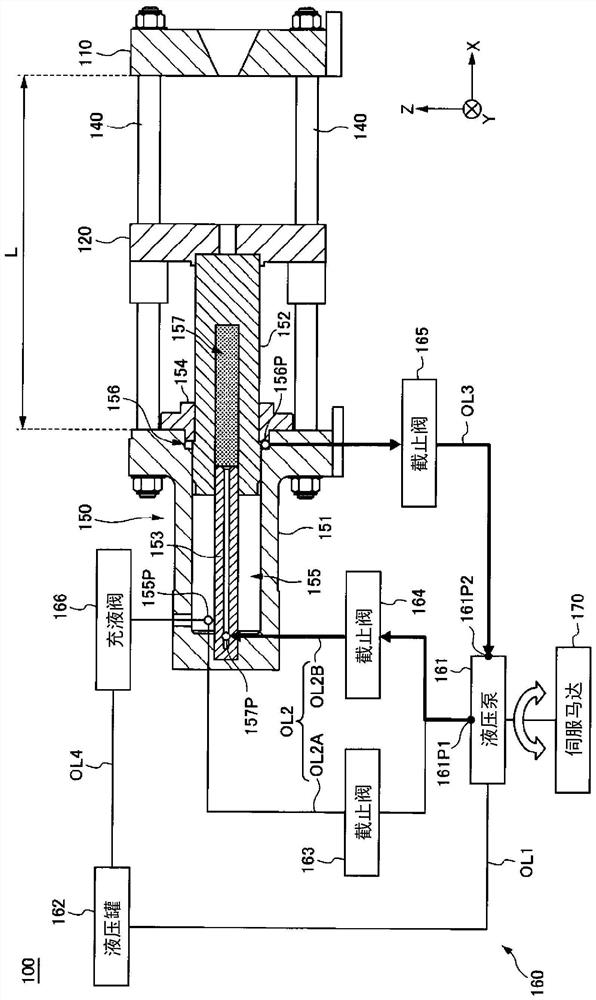

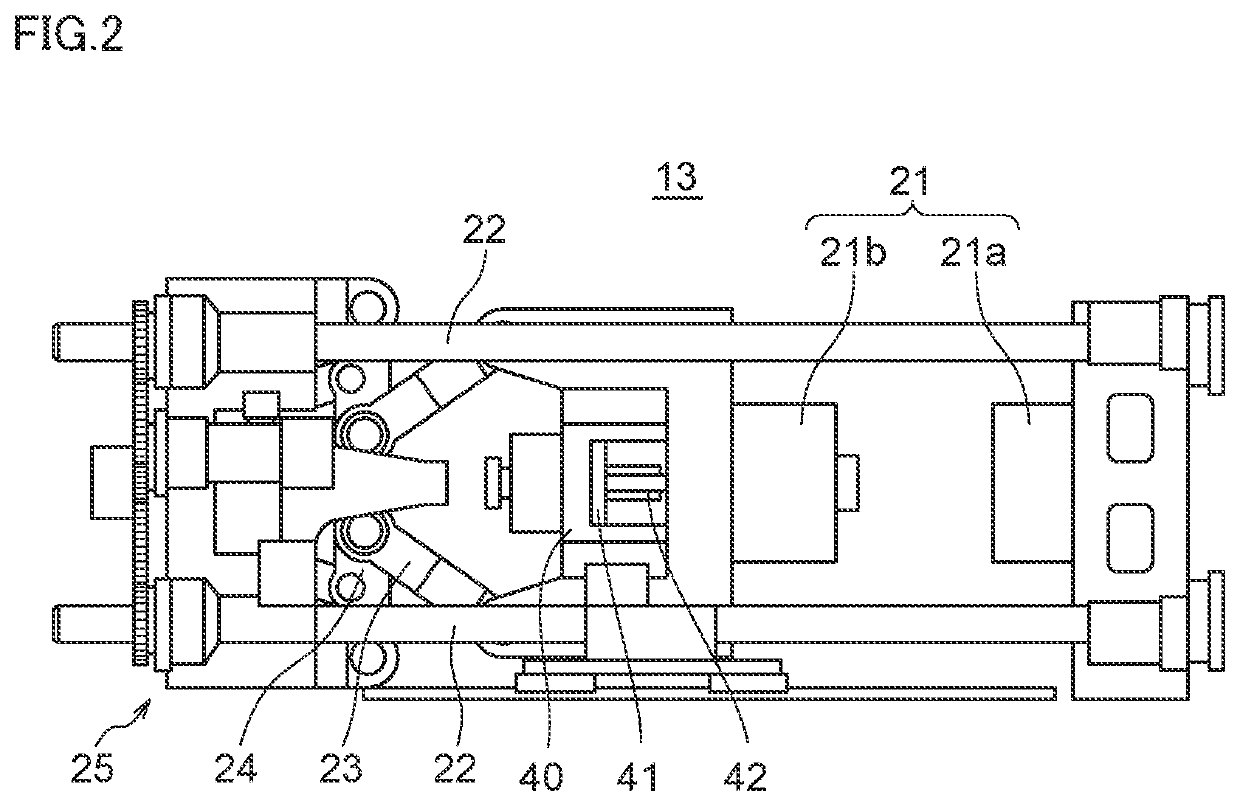

Injection molding machine

InactiveUS7234928B2Easy to assembleEasy maintenanceAuxillary shaping apparatusFood shapingLinear motionDrive shaft

Owner:SUMITOMO HEAVY IND LTD

Process for produicng stamper for direct mastering, and stamper produced by such process and optical disc

InactiveUS20060290018A1Increased durabilityWeaken energyOptical articlesRecord information storageEngineeringInjection molding machine

In producing a stamper for molding an optical disc, a master disc which can be obtained from the steps of forming a thermosensitive material layer capable of acting as a negative type by a laser beam on a substrate, irradiating a laser beam to predetermined areas of the thermosensitive material layer so as to partially perform exposure and wet-etching the partially exposed thermosensitive material layer so as to form a fine pits-and-bumps pattern is used as a stamper for injection molding machine. Therefore, minute pits each having a size smaller than the spot of the laser beam of optical limit are formed, thereby providing a stamper with the small number of deficiencies.

Owner:PANASONIC CORP

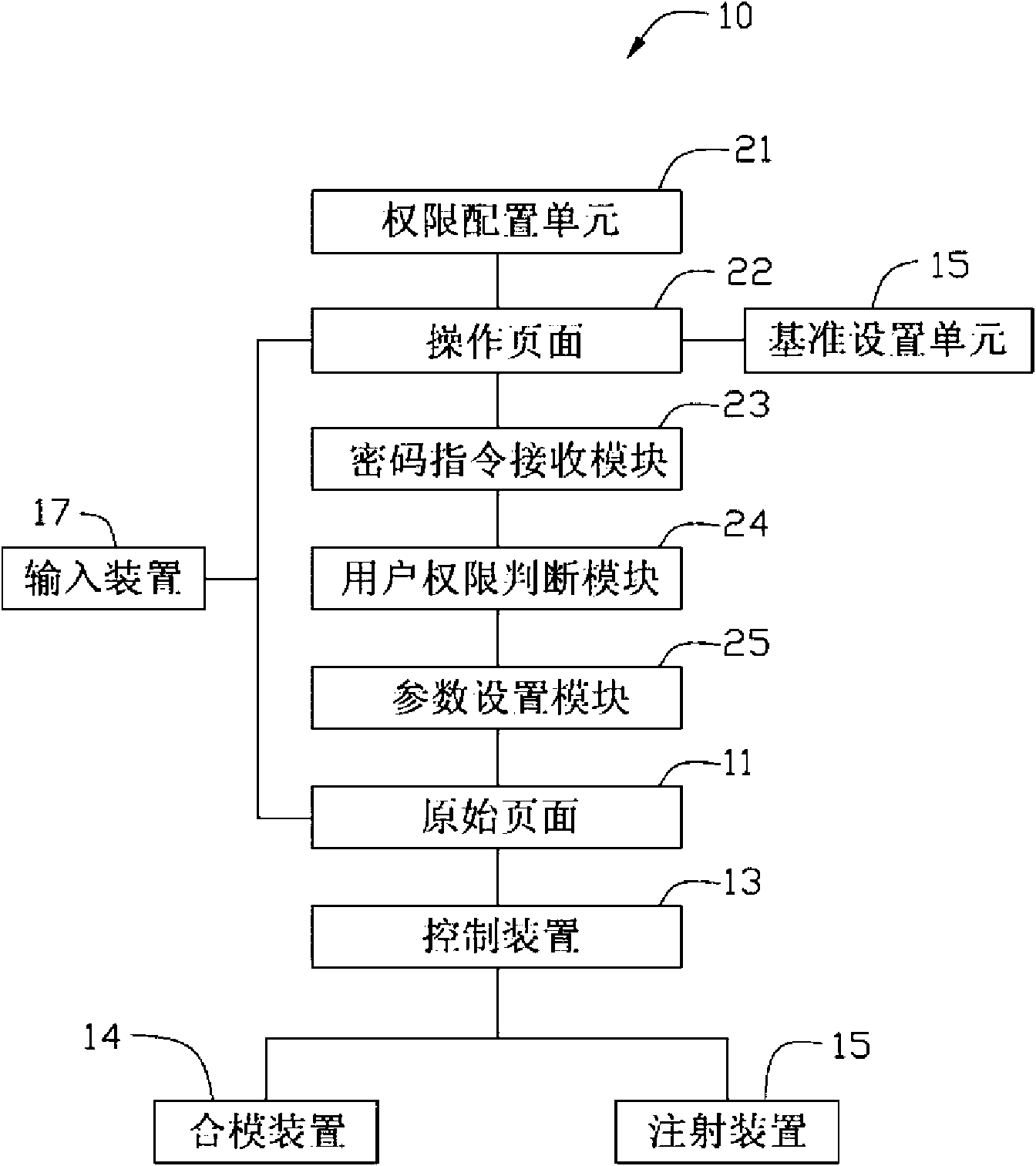

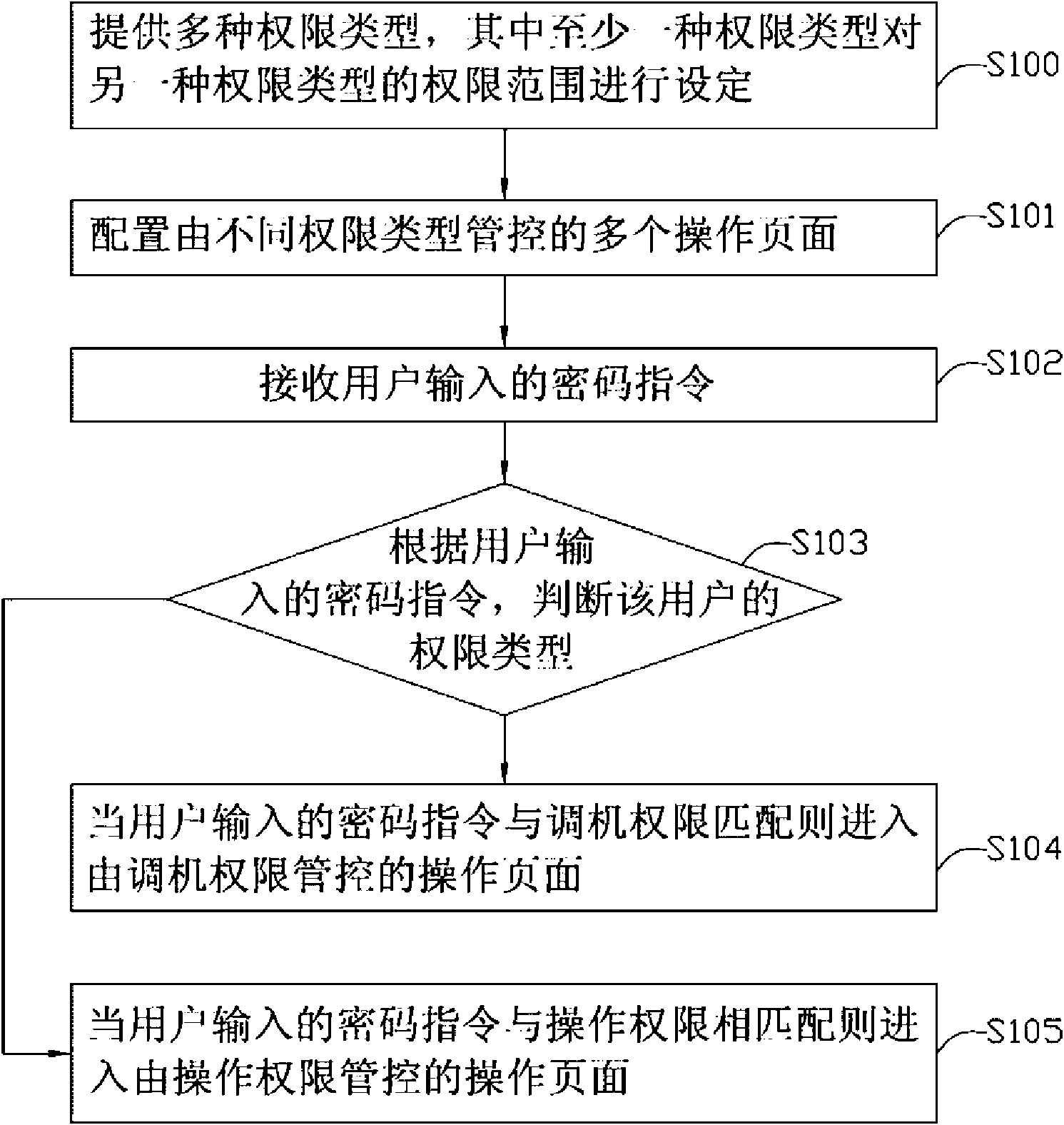

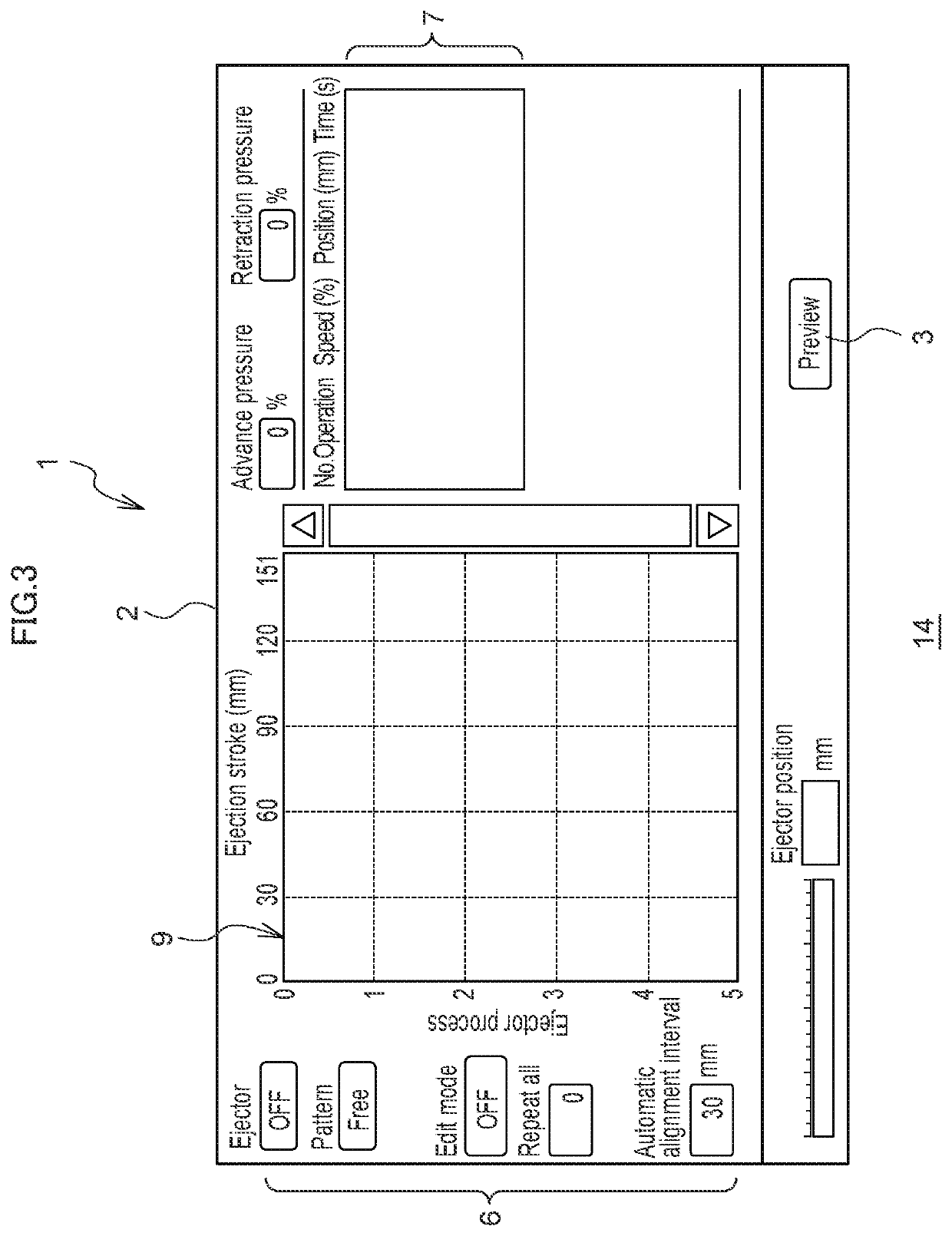

Method for setting control parameters of injection molding machine and injection molding machine

InactiveCN101941278AEasy to controlMeet needsNumerical controlInjection mouldingInjection molding machine

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

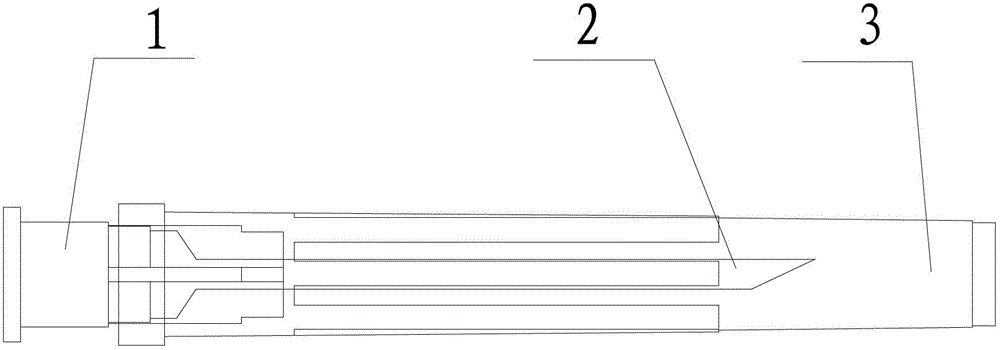

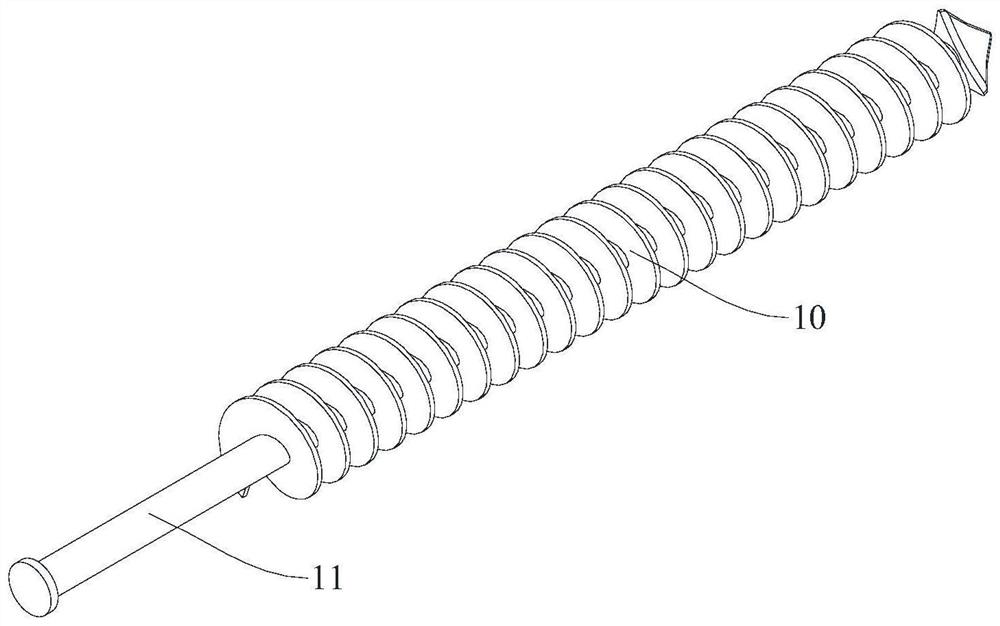

Disposable medical syringe needle

InactiveCN102716531AMeet production requirementsEasy to processInfusion needlesDiseaseInjection moulding

Owner:侯李明

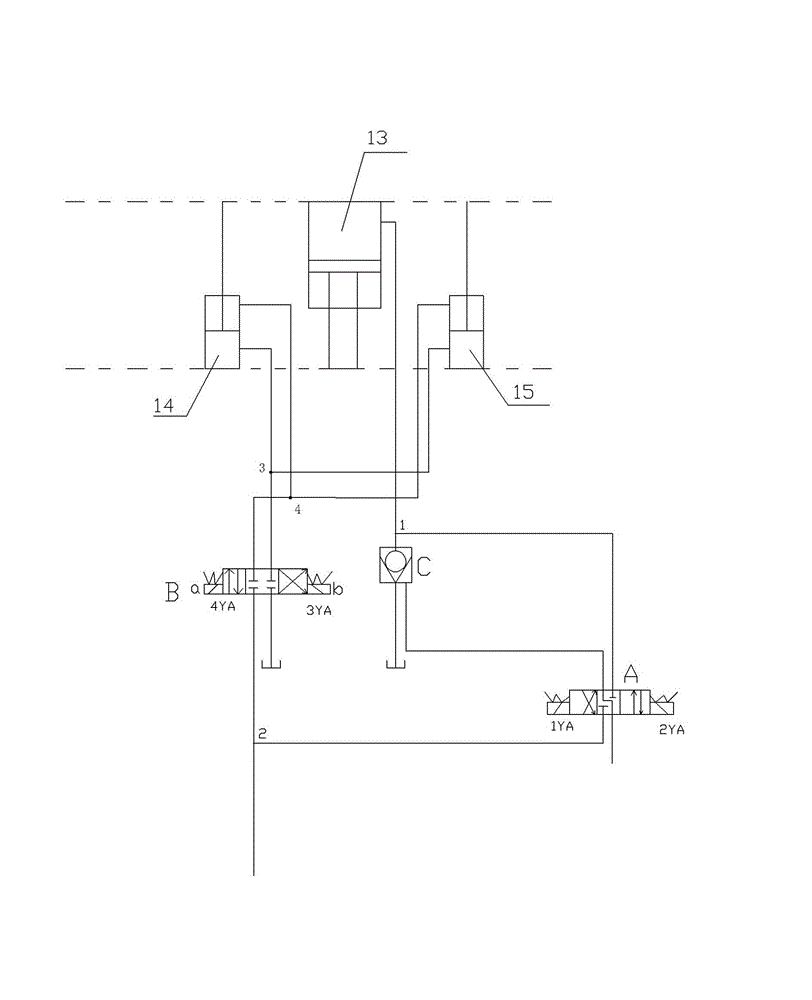

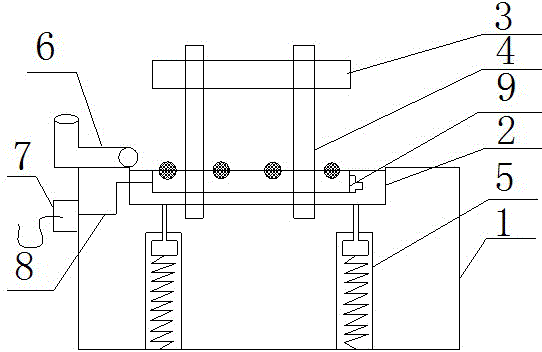

Mode locking system

Owner:珠海市凯顺自动化科技有限公司

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

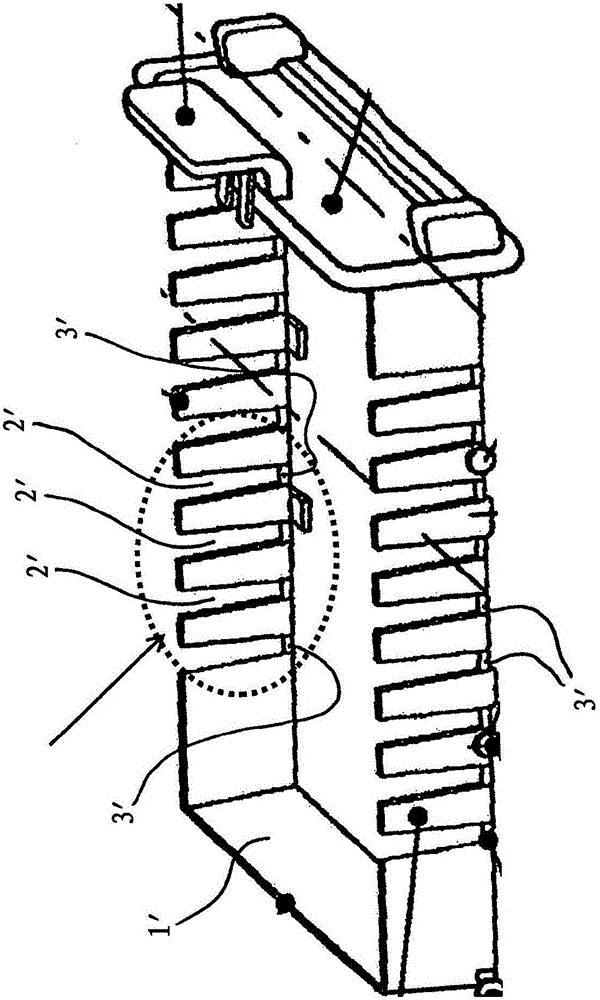

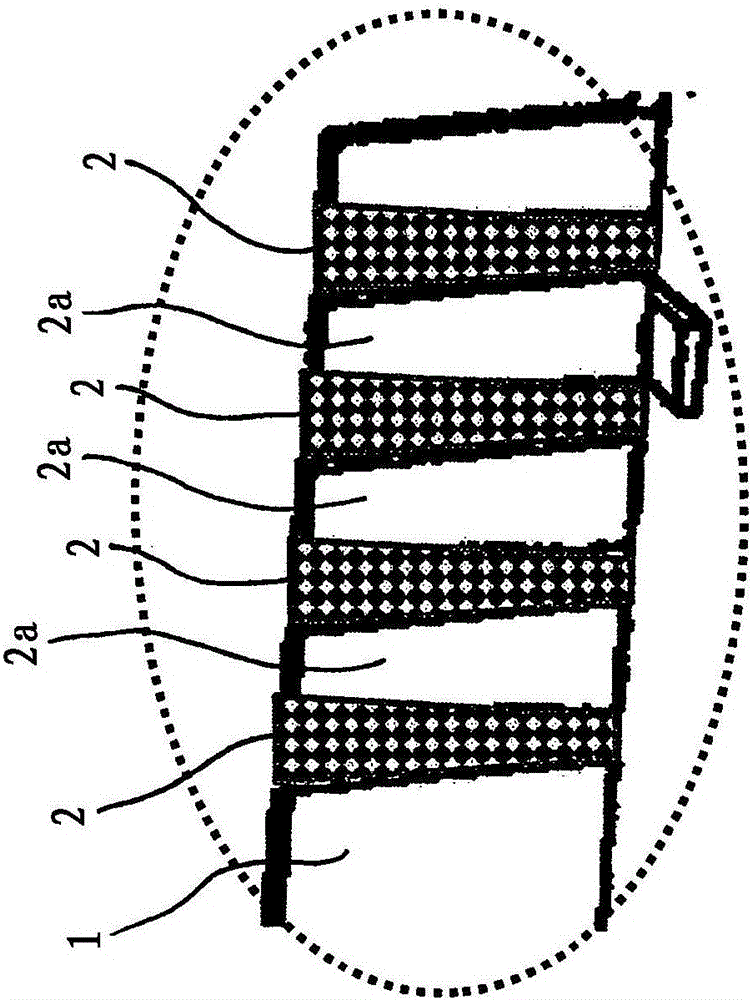

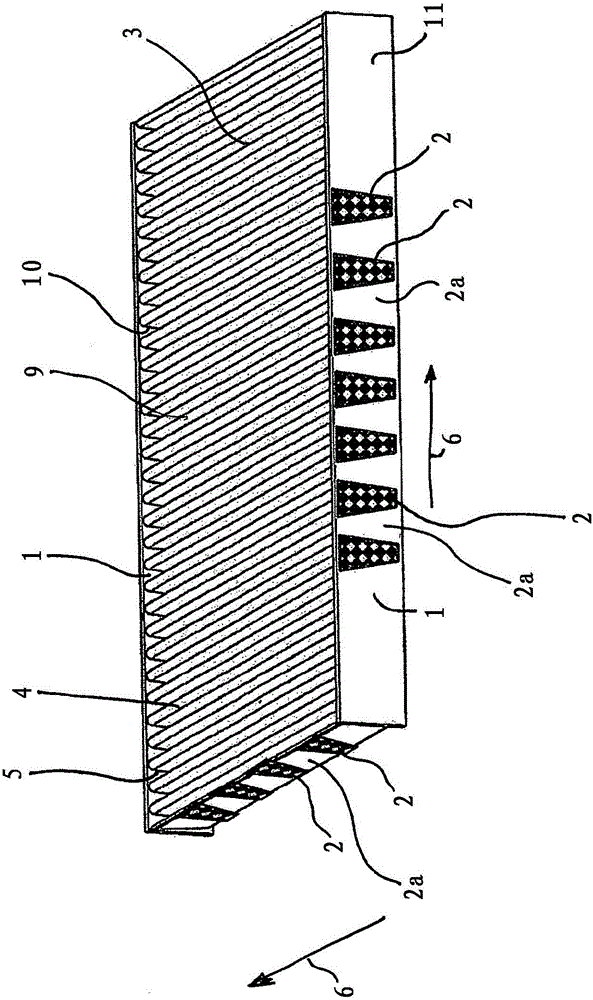

Flexible filter element with plastic frame formed thereon by injection molding

ActiveCN105999873ALossless deformationNo further processing steps requiredDispersed particle filtrationMembrane filtersFilter mediaHardness

Owner:CARL FREUDENBERG KG

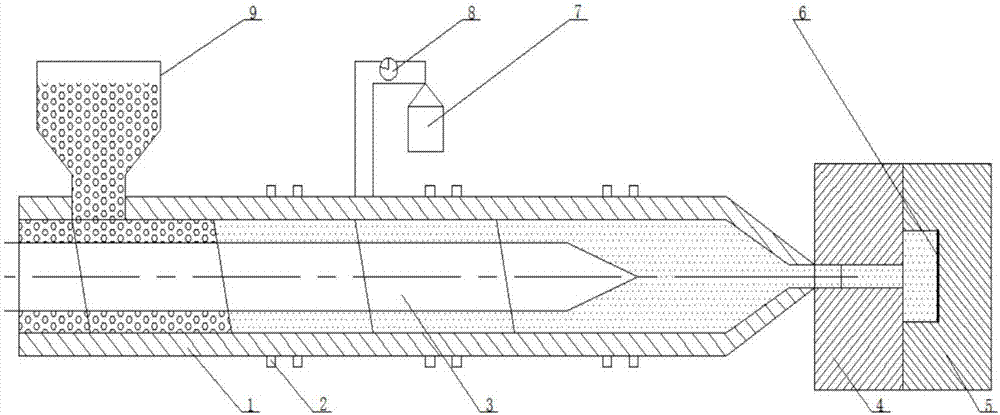

Glass tube cladding extrusion molding process

InactiveCN105729746ARealize automated productionDriven by automated productionCoatingsSemiconductor devices for light sourcesMolding machineEngineering

Owner:DONGGUAN HONG XIN PHOTOELECTRIC TECH CO LTD

Injection molding method

InactiveCN102127303AGood dispersionChemical stability stableCoatingsBlack spotInjection molding machine

Owner:NINGBO HENGFU AUTO PARTS DEV

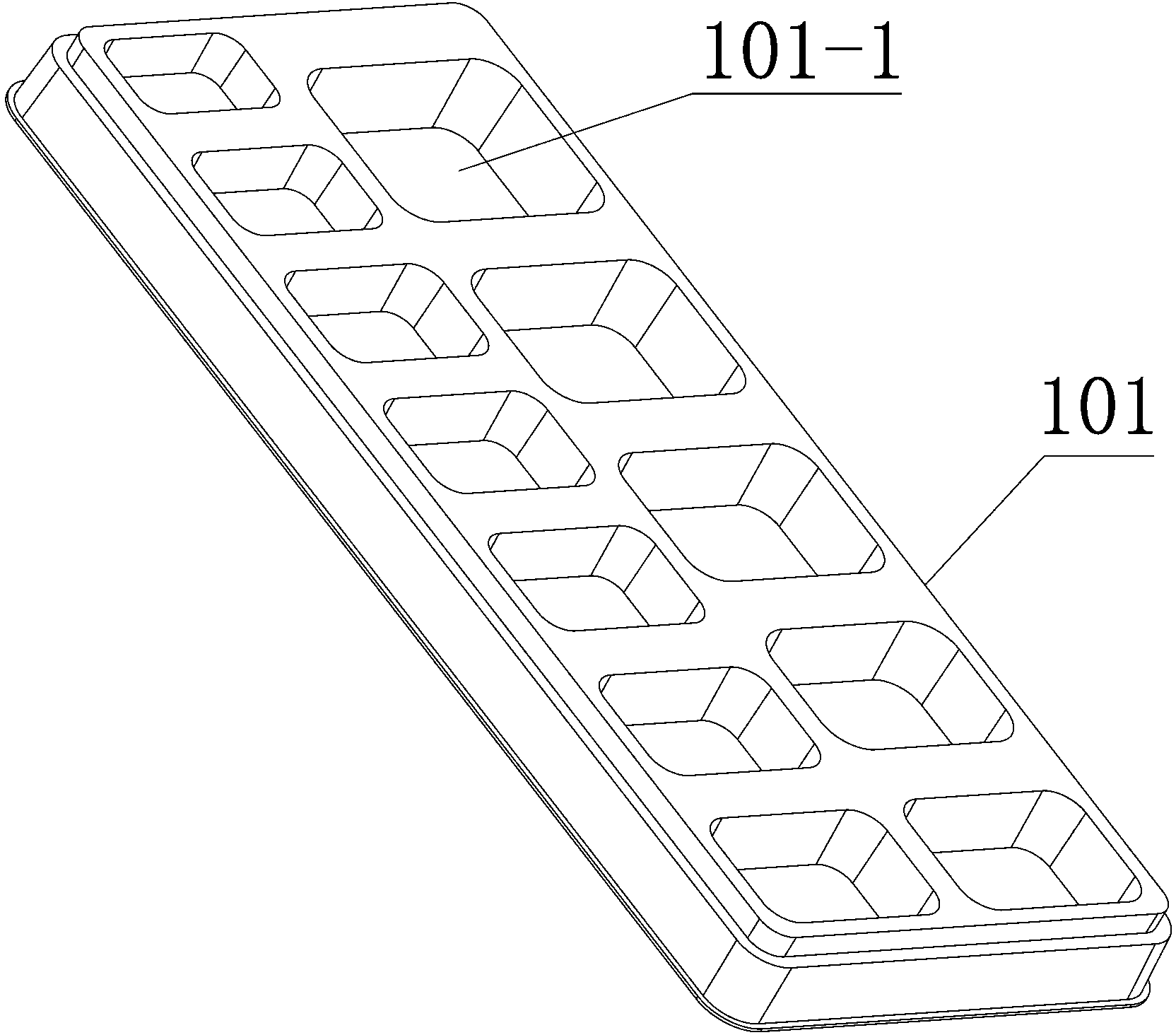

Blister and injection molding combined beautifying accessory packaging display box and box set

ActiveCN103640750AEasy to manageRich and diverseTray containersInternal fittingsEngineeringInjection molding machine

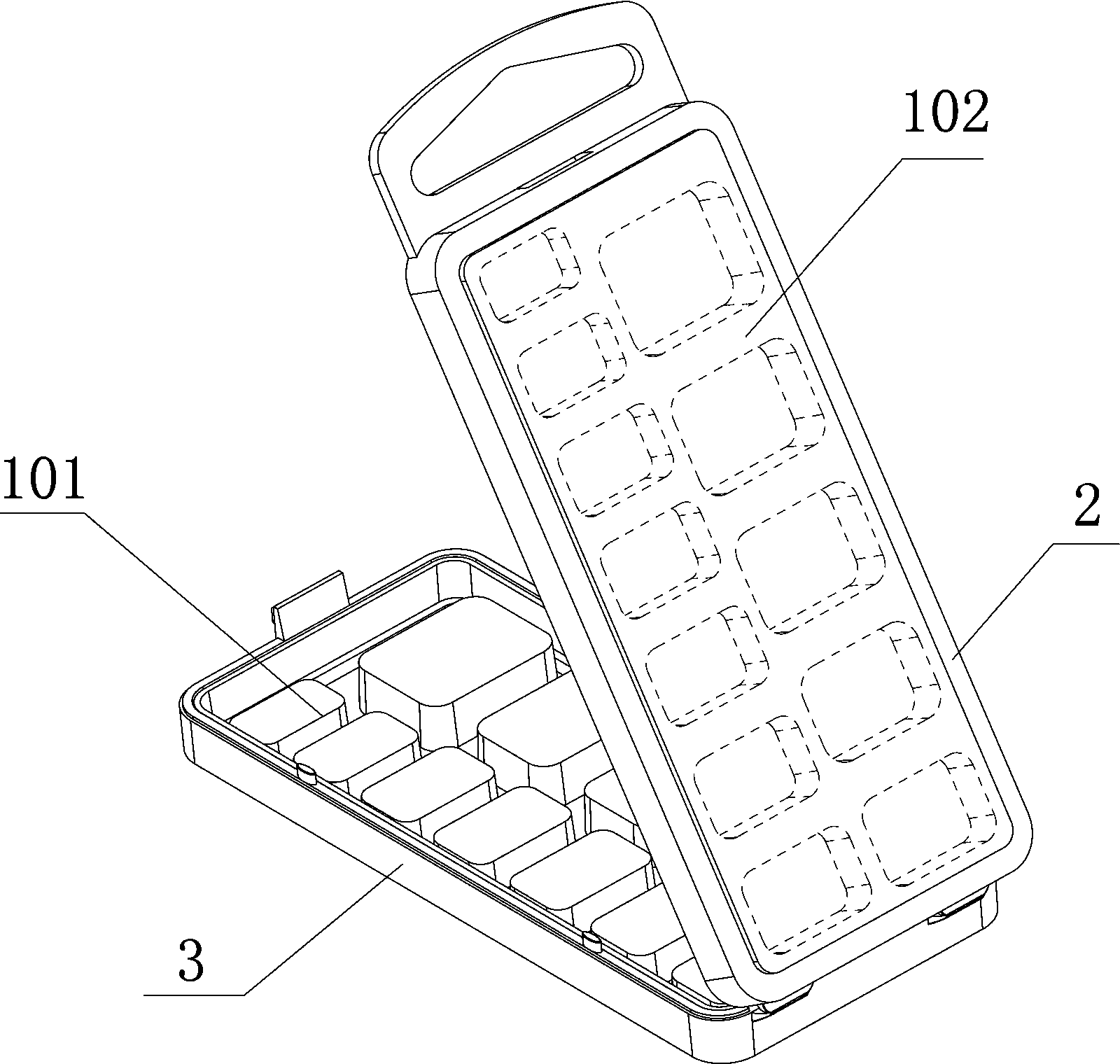

The invention provides a blister and injection molding combined beautifying accessory packaging display box and a box set. The packaging display box comprises blistered inner boxes, a first injection-molded packaging frame and a second injection-molded packaging frame, wherein side edges of the blistered inner boxes are sleeved with the first and second injection-molded packaging frames which are in closely-buckled connection; and the box set comprises a plurality of packaging display boxes, each packaging display box consists of the blistered inner boxes as well as the first and second injection-molded packaging frames forming inner seals of the side edges of the blistered inner boxes, and an easy-to-tear thin strip is molded between every two adjacent first injection-molded packaging frames and / or second injection-molded packaging frames. According to the beautifying accessory packaging display box and the box set, under the condition that the cost is basically not increased, the diversification of products is enriched, the overall texture and grades of the products are improved, meanwhile, consumers can see styles of beautifying accessories through the blistered inner boxes with higher transparency, a good display role is played, and the trouble in opening and closing of packaging boxes is omitted.

Owner:金文日

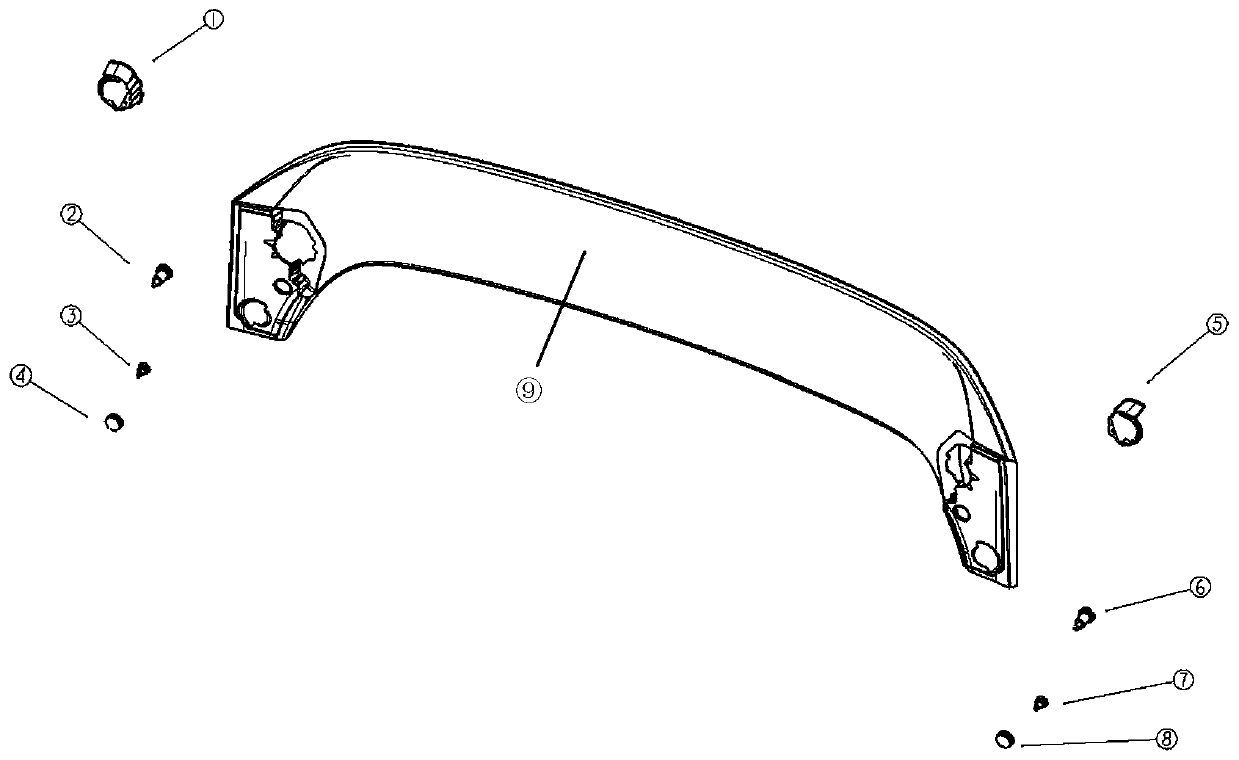

Device for injection molding

The present disclosure relates to a device for the injection molding of an item including at least one face, a protruding peripheral part provided with an edge for the connection with another face, said device including mold elements movable with respect to each other and jointly cooperating by delimiting therebetween joint planes as well as a cavity intended to be filled with liquid plastic material through injection channels to form said item after the ejection from the mold, characterized in that it includes a mold element to form the protruding part of the item, whose joint plane with the immediately adjacent front mold element is angularly oriented from said edge and on at least a portion of the length thereof, according to the direction of ejection.

Owner:AURAY PLAST

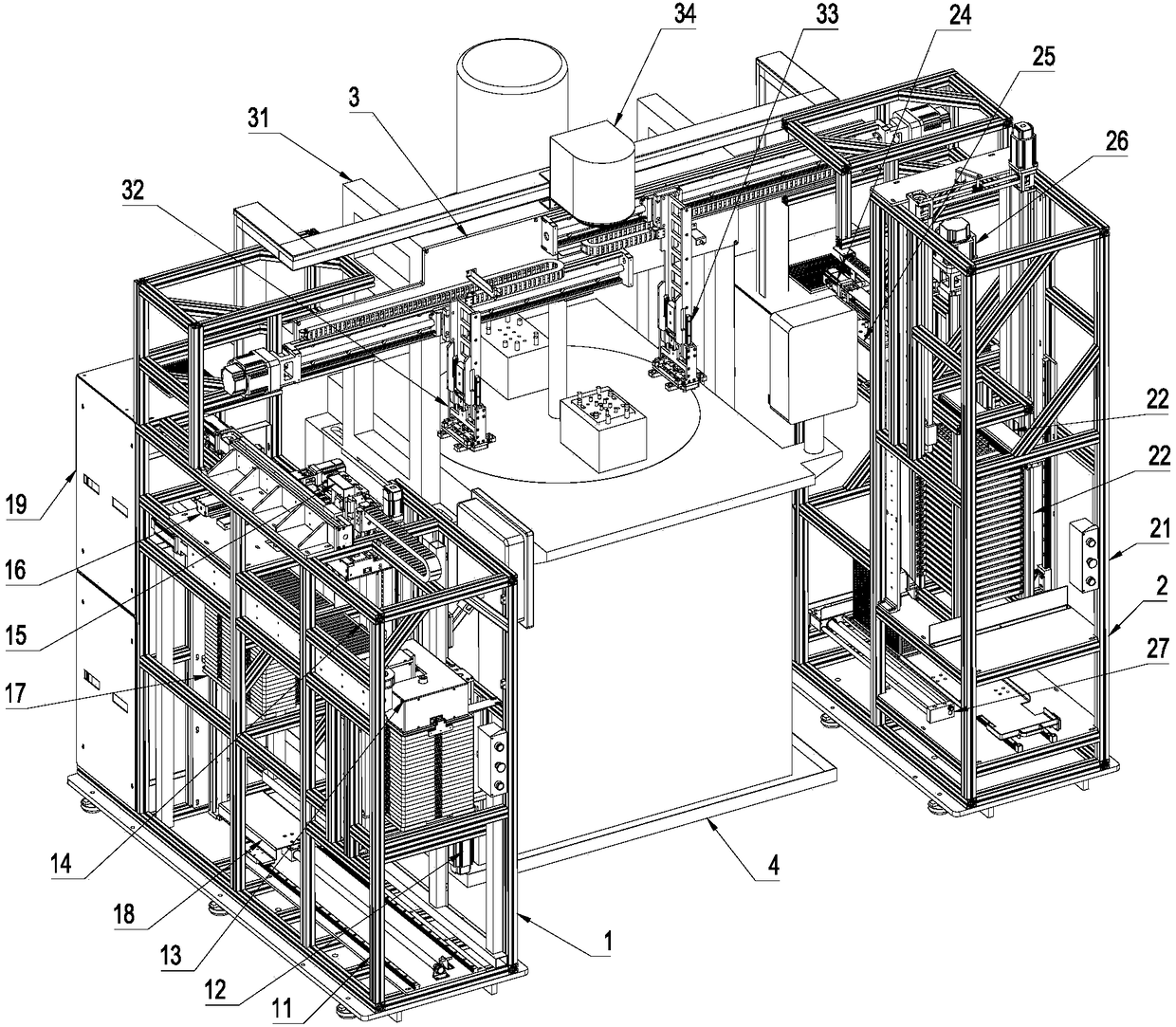

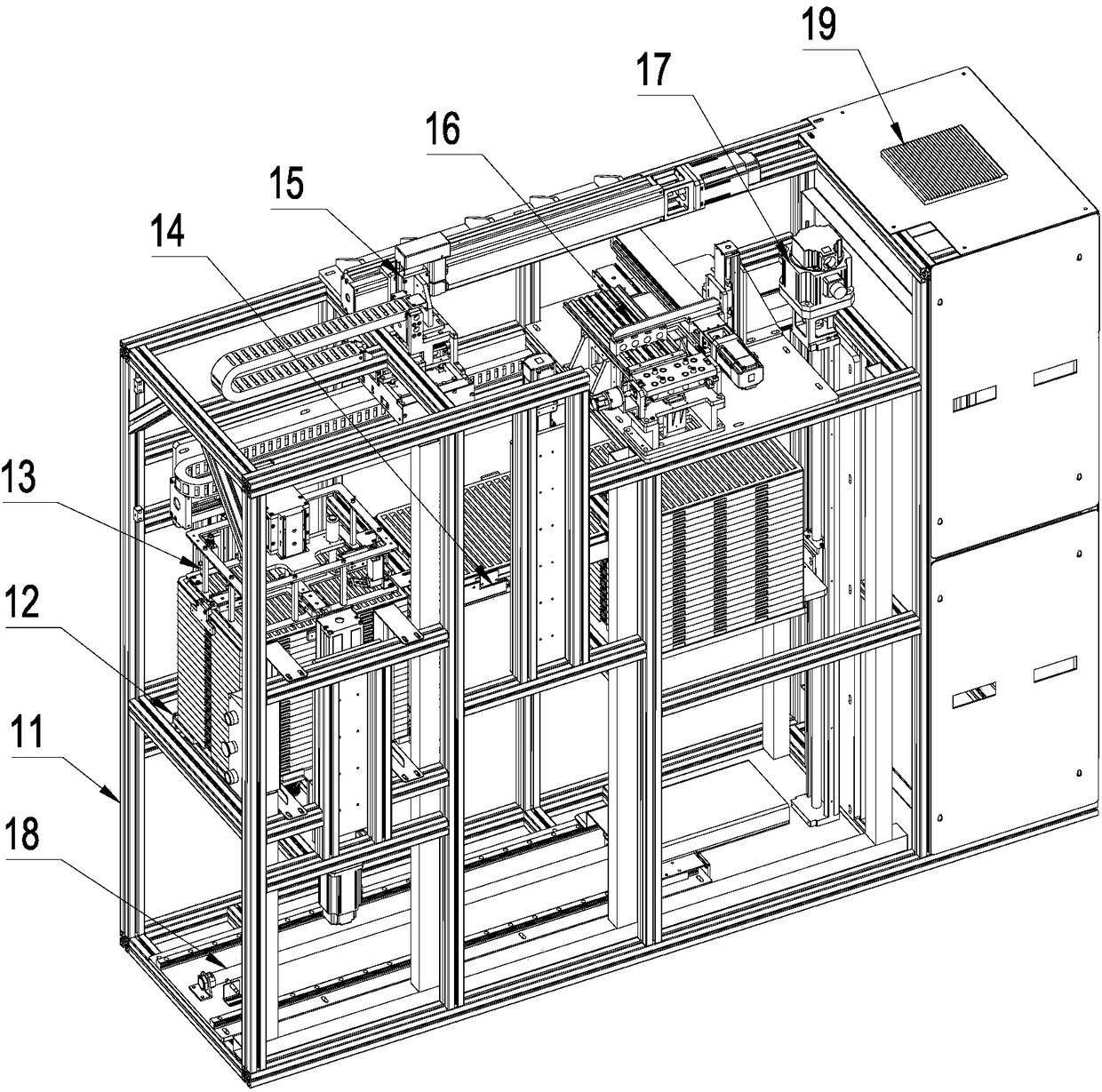

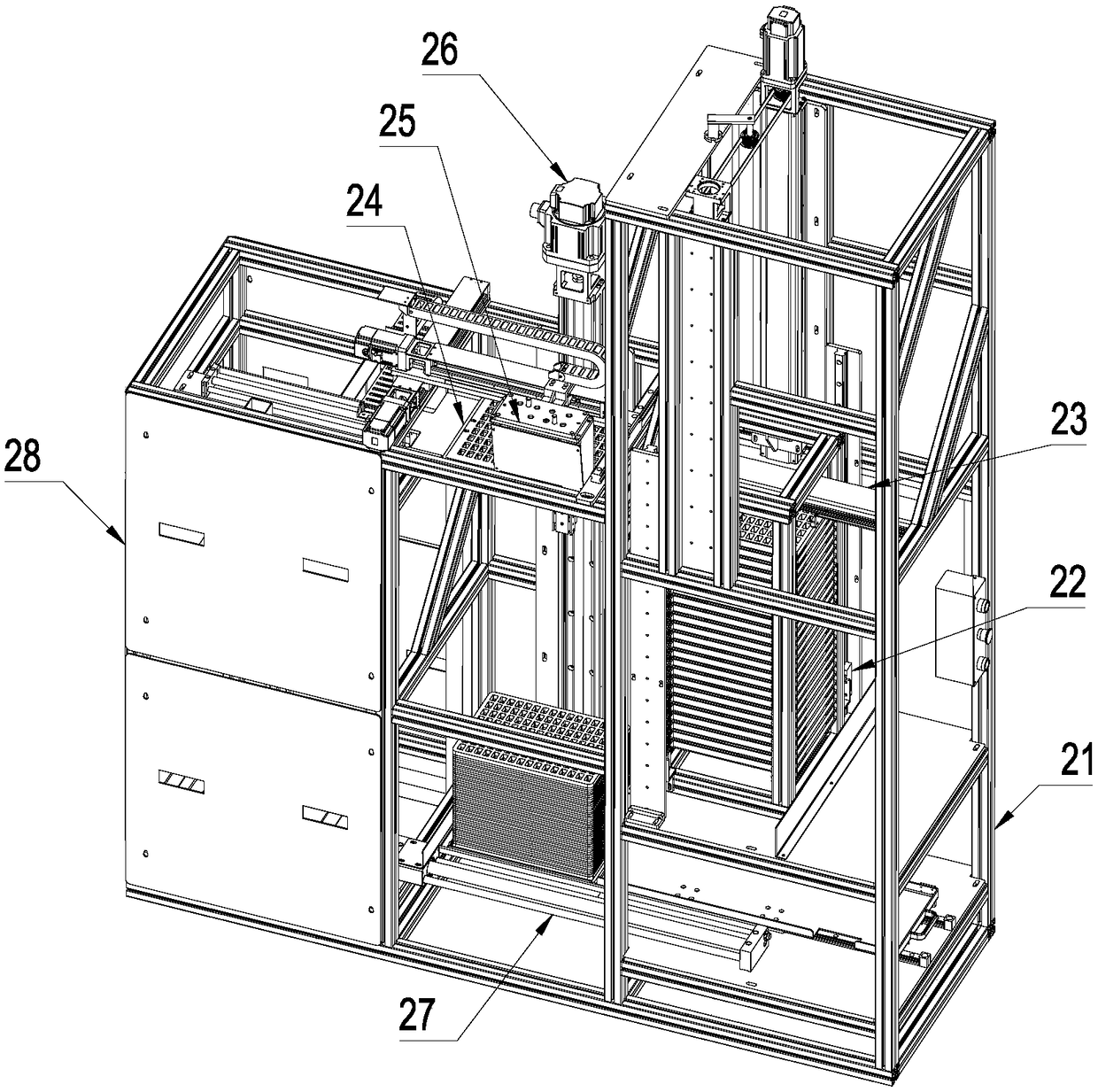

Automatic injection molding system

Owner:成都华聚科技有限公司

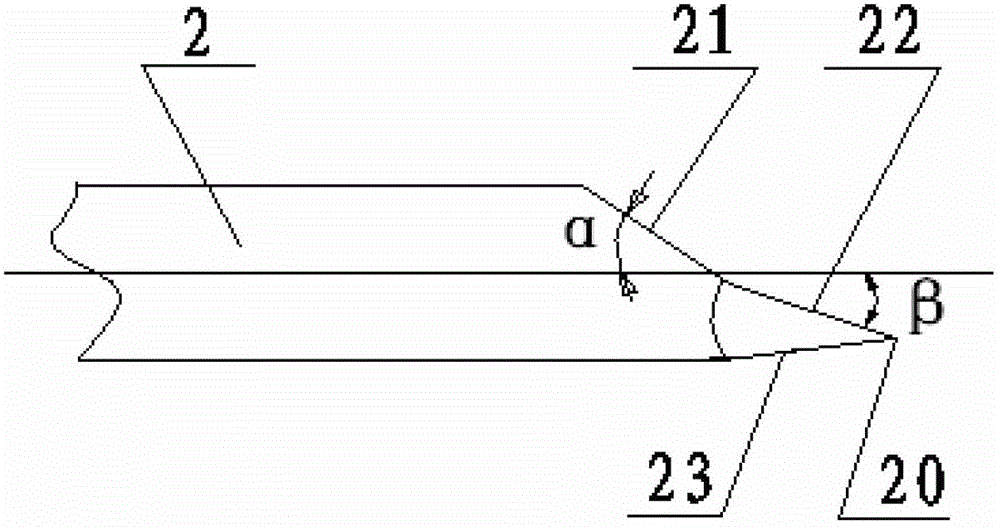

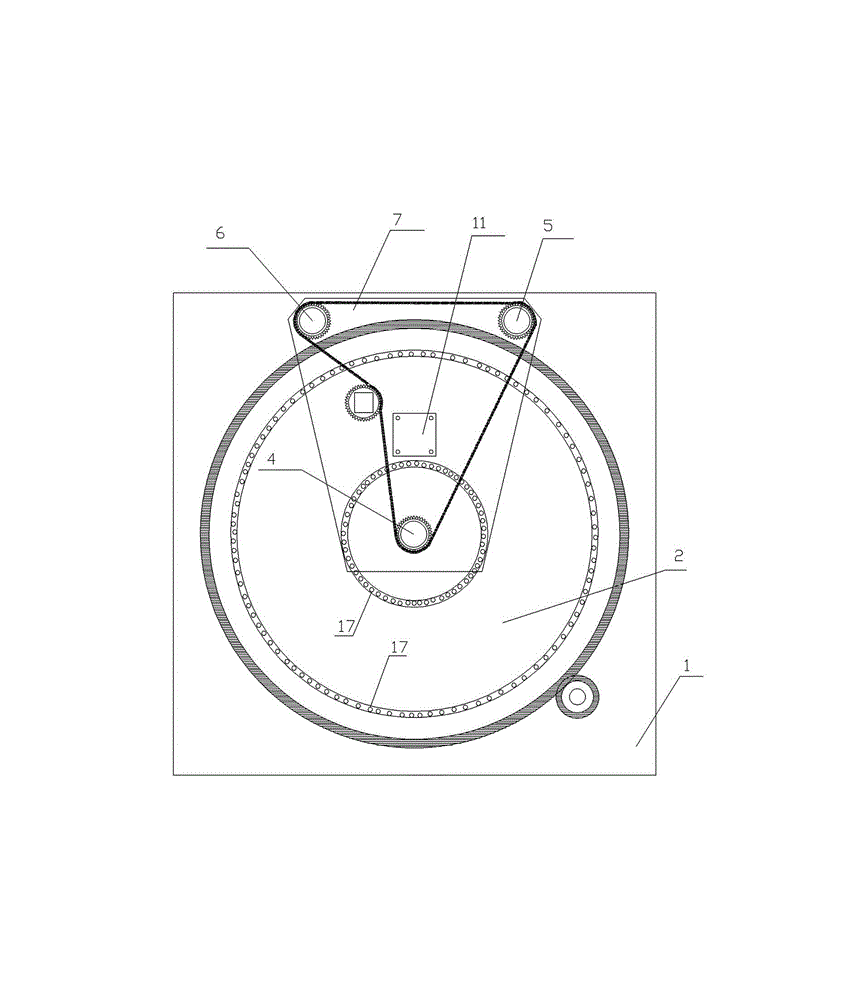

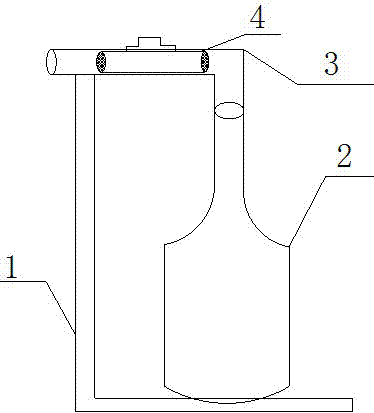

Sucking nozzle of injection molding sucker

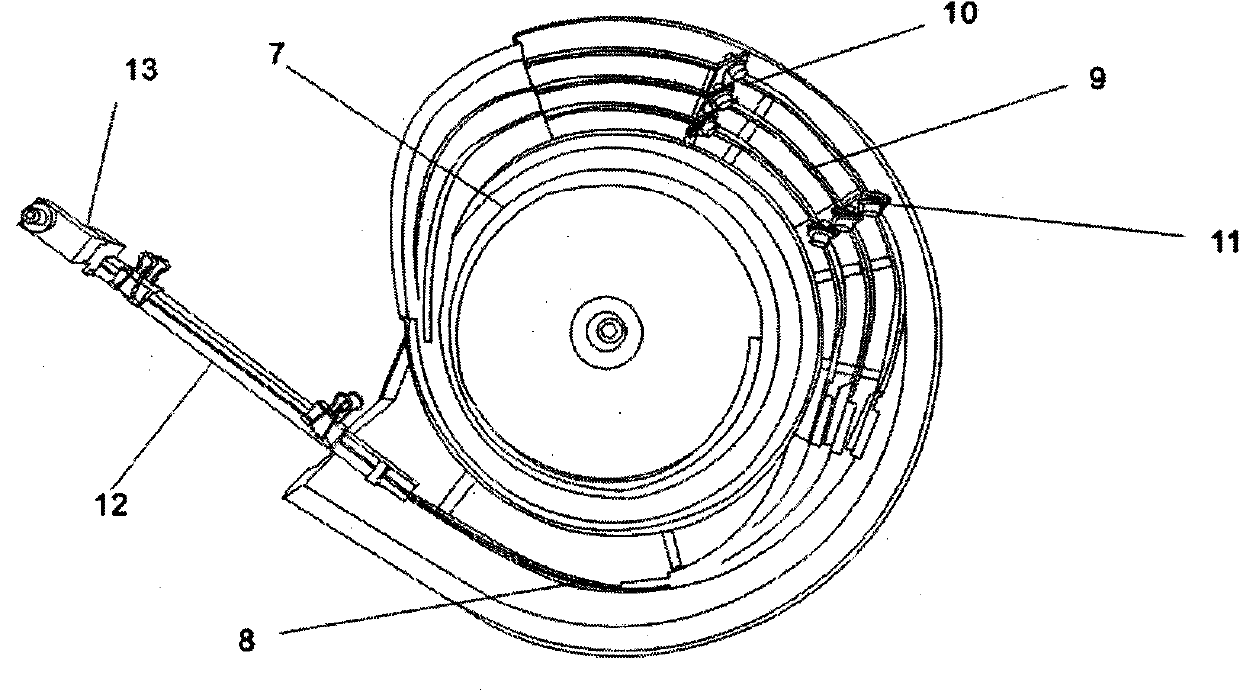

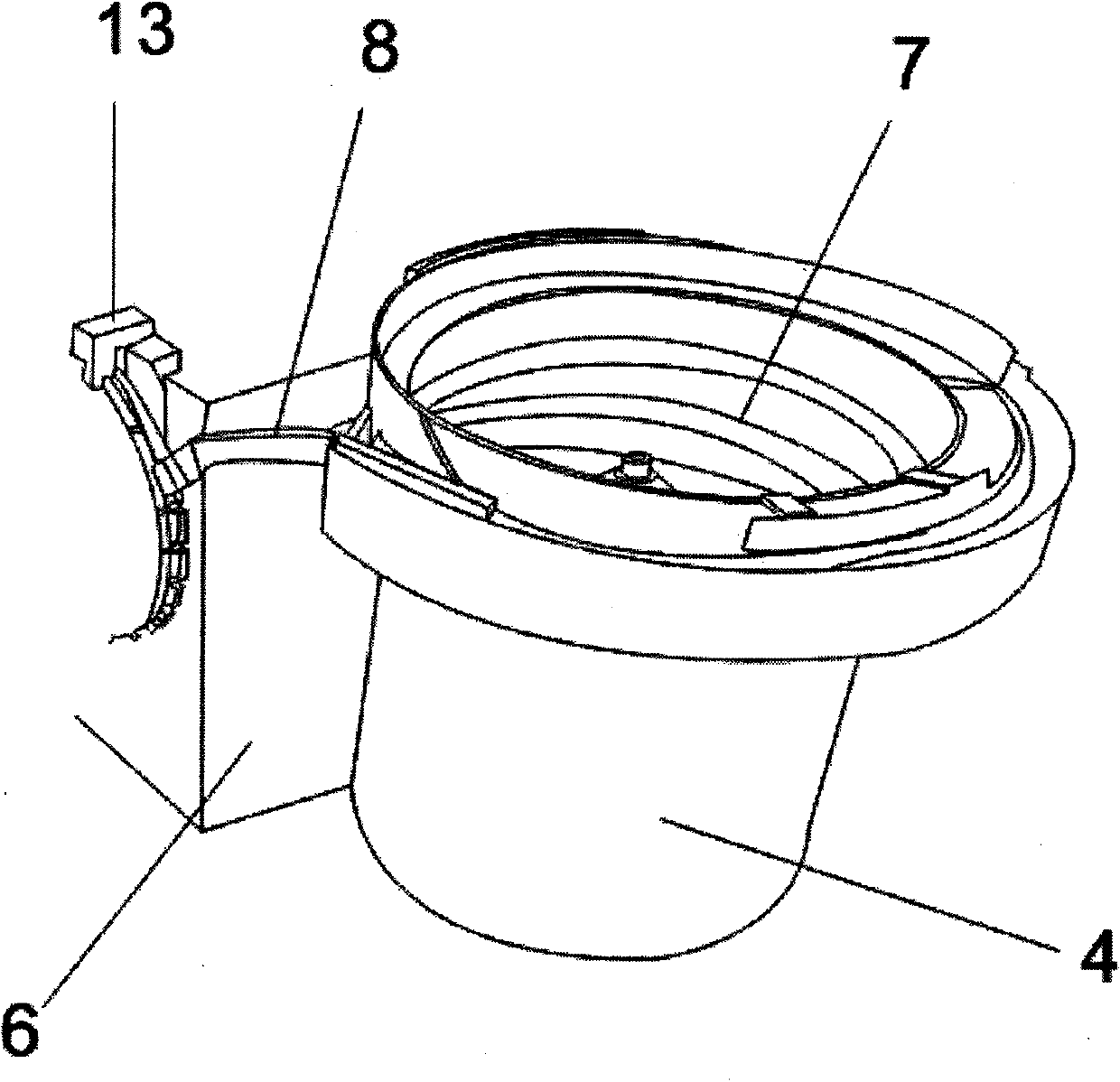

The invention discloses a sucking nozzle of an injection molding sucker. The sucking nozzle of the injection molding sucker comprises a sucking pipe, and further comprises a rotary sucking mechanism and a rotary driving mechanism; the rotary driving mechanism is arranged in the sucking pipe; one end of the rotary sucking mechanism is positioned in the sucking pipe and is in contact with the rotary driving mechanism, and the other end is positioned out of the sucking pipe; the rotary driving mechanism includes a cylindrical outer shell and a turbofan blade mounted in the outer shell; the outer wall of the outer shell is in contact with the inner wall of the sucking pipe, and can freely rotate around the axis thereof; a gear ring I is arranged on the right end surface of the cylindrical outer shell; the rotary sucking mechanism includes a cylindrical section sleeved with the sucking pipe, and an external sucking disc; the outer wall of the cylindrical section is matched with the inner wall of the sucking pipe, and can freely rotate around the axis of the sucking pipe; a gear ring II engaged with the gear ring I is arranged on the left end surface of the cylindrical section; the sucking disc is projected rightwards, and is provided with multiple stirring support rods on the peripheral surface; a feed hole is formed in the sucking disc; and stirring teeth are arranged on the stirring support rods. The sucking nozzle can realize stable feeding.

Owner:BISHAN BRANCH OF CHONGQING RUNTONG IND CO LTD

Recycled ABS resin, recycled ABS alloy resin and production process of ABS alloy resin

InactiveUS6881368B2Improve defectsMaintain good propertiesOther chemical processesPlastic recyclingAlloyInjection molding machine

Owner:CANON KK

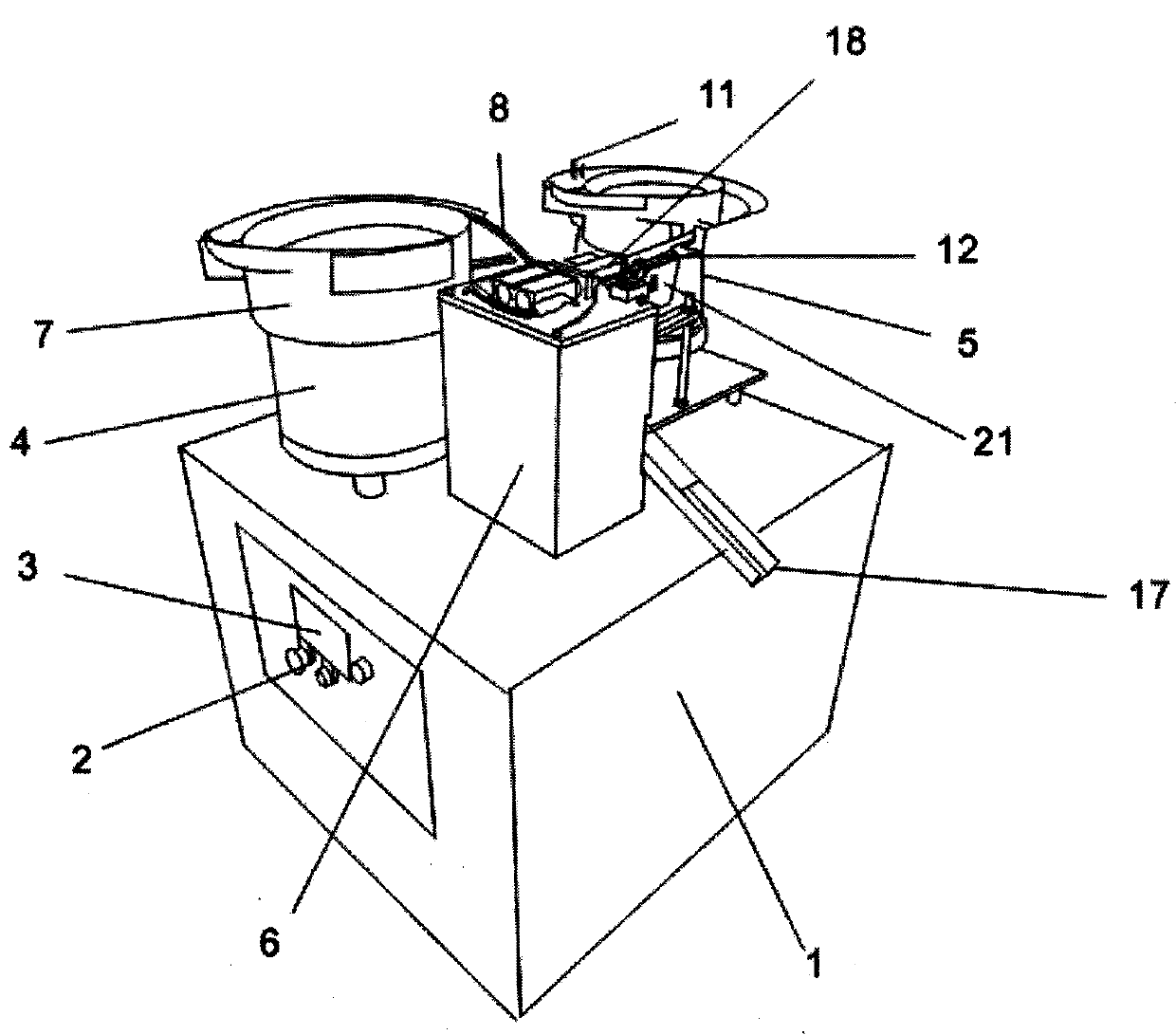

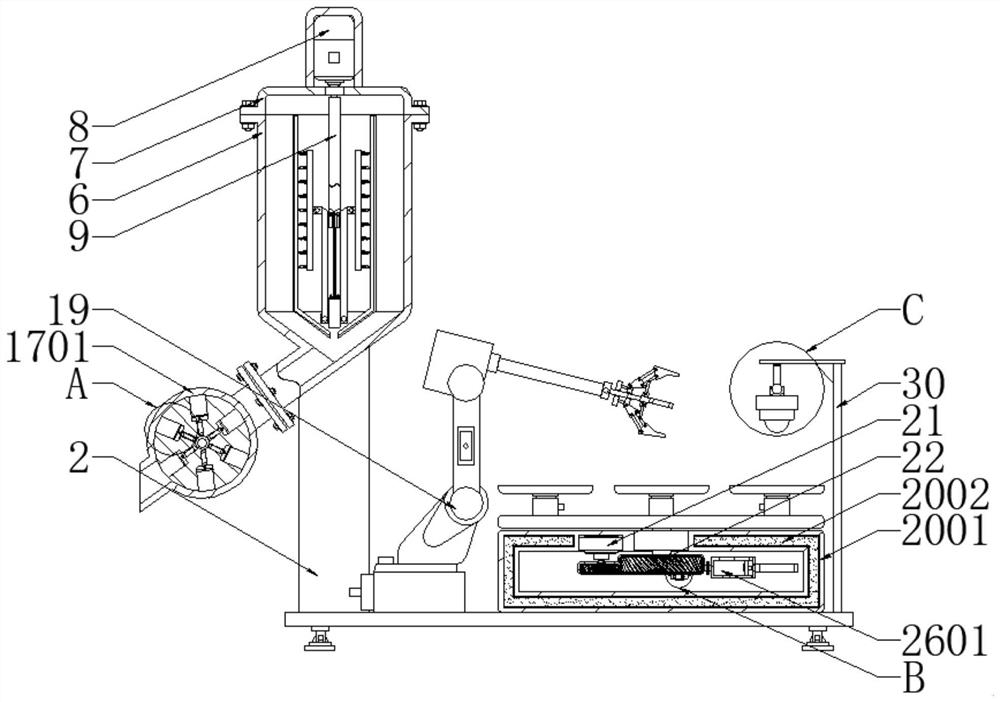

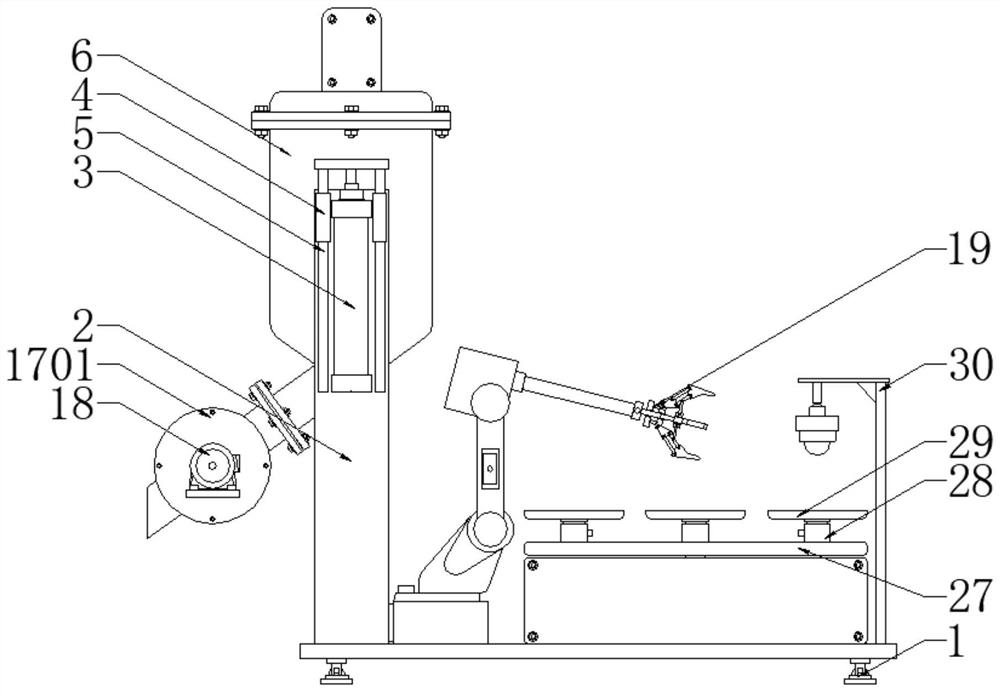

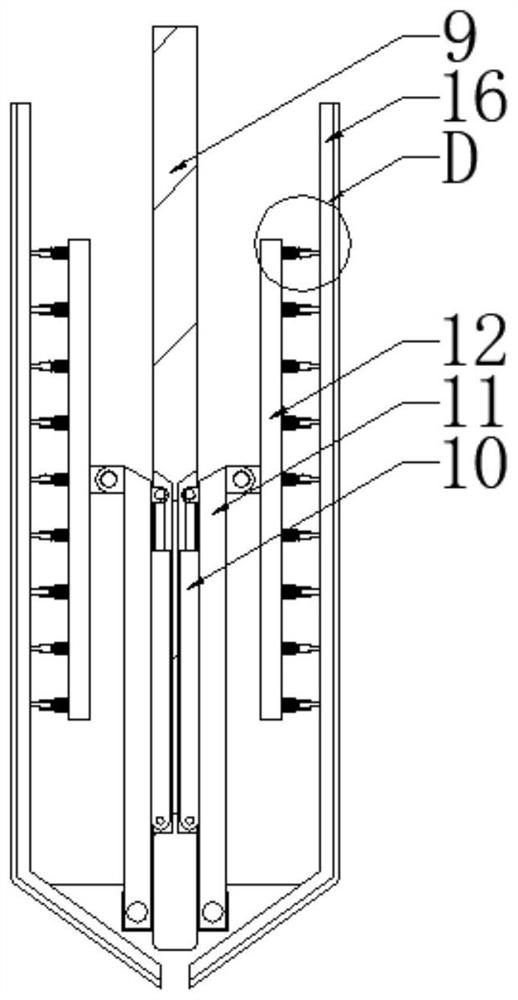

Automatic material taking and discharging mechanism of metal powder injection molding machine

ActiveCN114570928AEfficient cleaning structureWith structureSubsonic/sonic/ultrasonic wave measurementPlastic recyclingEngineeringMachine

Owner:扬州钰能精密机械科技有限公司

Efficient injection molding device for automobile bumper production

Owner:WUHU ECHOM SCI & TECH

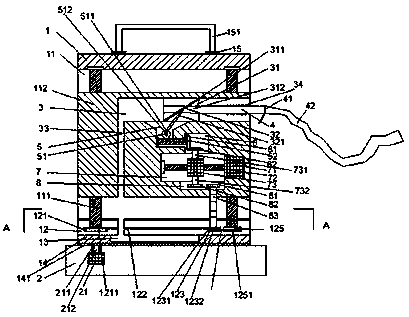

Injection molding machine

Owner:KUNSHAN JINHUAYUE MECHANICAL DESIGN

Injection molding machine

Owner:昆山慧星行机械设计有限公司

Intelligent injection molding machine

Owner:KUNSHAN XINWANMAO MOLD DESIGN

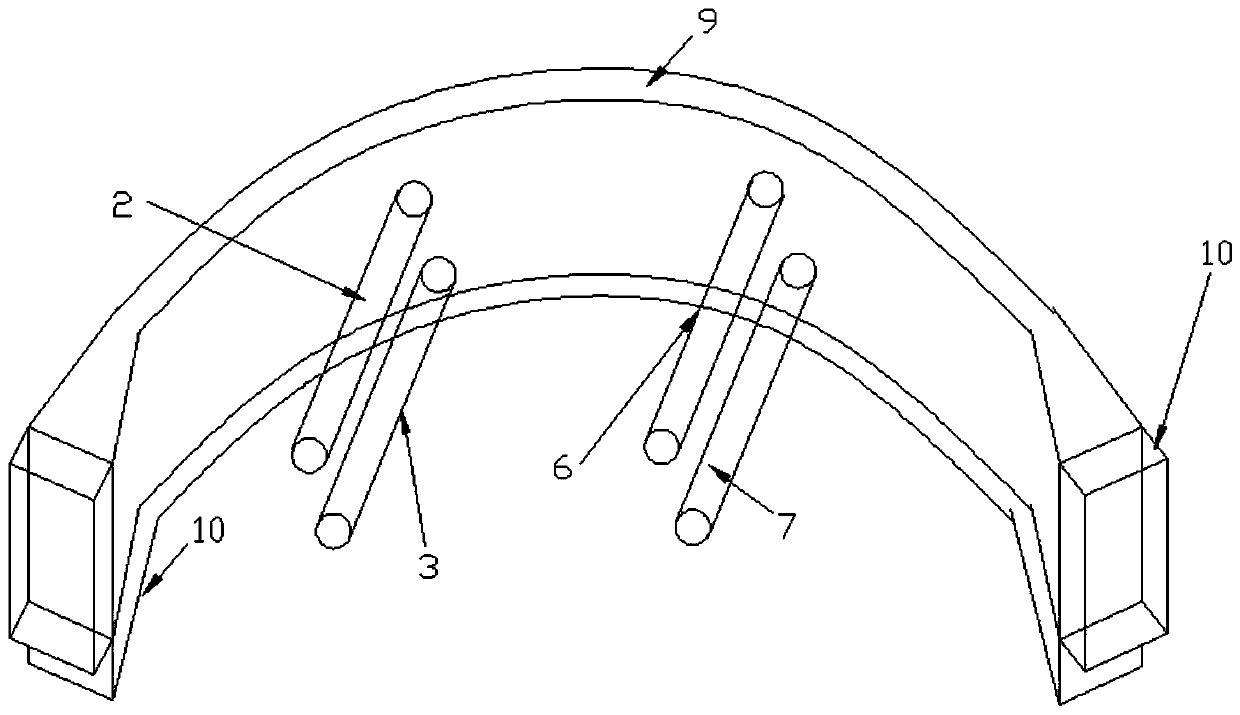

Blow molding process with effect of improving strength of flow guide plate by injection molding of inserts and prepared flow guide plate

PendingCN110216861AFirmly assembledEnhances refined perceptionAerodynamics improvementDomestic articlesBlow moldingEngineering

Owner:江阴名鸿车顶系统有限公司

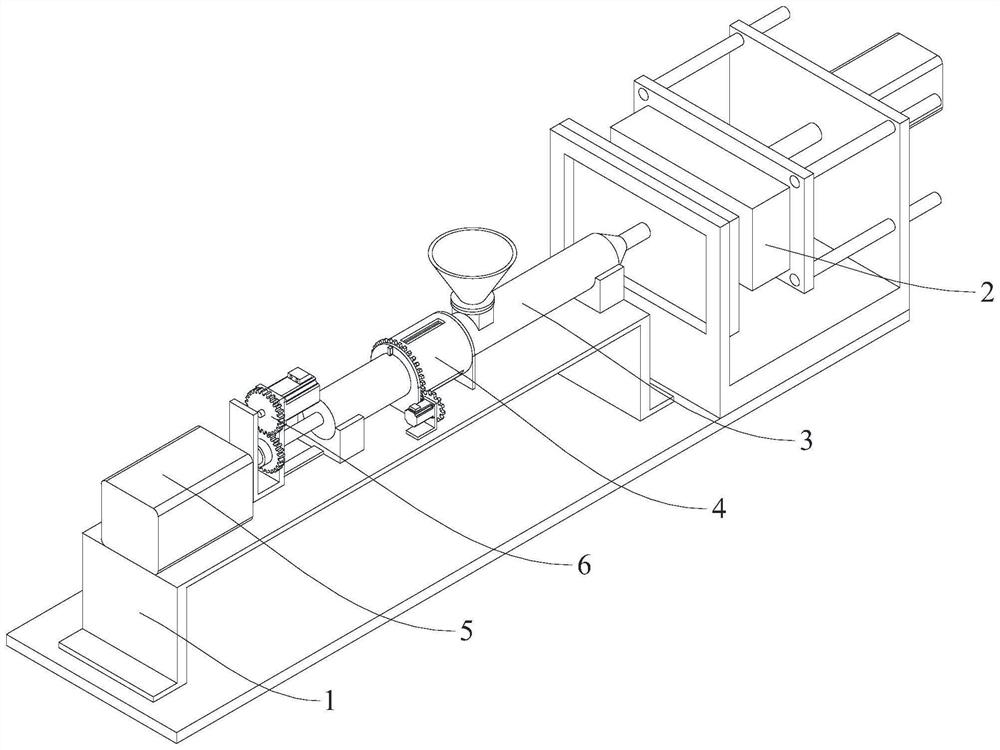

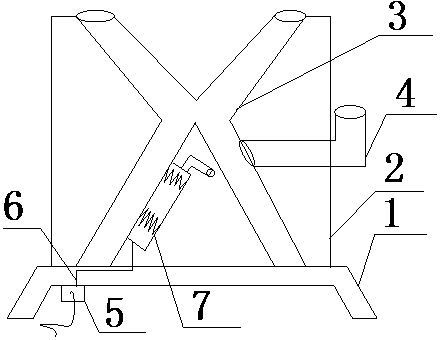

Micro-molding injection molding machine

InactiveCN109130066AReduce procurement costsSimple structureInjection molding machineComputer engineering

Owner:楼一

Automatic injection molding finished product sorting device

PendingCN110524818AImprove work efficiencyHigh discrimination accuracyEngineeringInjection molding machine

The invention provides an automatic injection molding finished product sorting device which is used for sorting first injection molding finished products and second injection molding finished productsof an injection molding machine and comprises a material frame, a first material basket, a second material basket, a first pipeline assembly, a second pipeline assembly and a manipulator mechanism; afirst material hole and a second material hole are formed in the top of the material frame, and a containing space is formed in the material frame; the manipulator mechanism is arranged between the injection molding machine and the material frame and can clamp the first injection molding finished product to the first material hole and clamp the second injection molding finished product to the second material hole at the same time. The first material basket and the second material basket are arranged in the containing space, the first pipeline assembly is communicated between the first material hole and the first material basket and used for conveying the first injection molding finished product to the first material basket, and the second pipeline assembly is communicated between the second material hole and the second material basket and used for conveying the second injection molding finished product to the second material basket. Two different injection molding finished products are automatically classified, the working efficiency is high, and the distinguishing correctness is high.

Owner:CHINA WONDERLAND NURSERYGOODS

Injection molding machine

Owner:SUMITOMO HEAVY IND LTD

Injection mold for engine cover plate

The invention provides an engine cover plate injection mold which comprises a fixed mold body, a first cavity formed in the fixed mold body and at least one second cavity communicated with the first cavity, a channel is formed in the position, at the bottom of each second cavity, of the fixed mold body, and an insert is slidably connected into each channel in a one-to-one correspondence mode. The outer peripheral wall of the insert is in sliding sealing fit with the inner peripheral wall of the channel; the bottom of the insert is connected with a driving mechanism used for driving the insert to move up and down in a reciprocating mode, when the insert is located at the highest point, the top of the insert fills the second cavity, and when the insert is located at the lowest point, the top of the insert is separated from the second cavity. According to the engine cover plate injection mold, secondary injection molding can be achieved only by using one set of mold to be matched with a common injection molding machine, the cost can be saved, and the injection molding efficiency is higher.

Owner:NINGBO FANGZHENG TOOL

Operation setting device and injection molding machine

PendingUS20220050589A1Easy to set upInput/output processes for data processingProcess engineeringInjection molding machine

Owner:NISSEI PLASTIC IND CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap