Flexible filter element with plastic frame formed thereon by injection molding

A technology of filter element and injection molding technology, which is applied in the field of filter elements, can solve the problems of filter elements such as leaking, thin area breaking, and unsuitable hinges, etc., and achieve the goal of improving particle filter elements, good adhesion, and realizing flexibility and bendability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

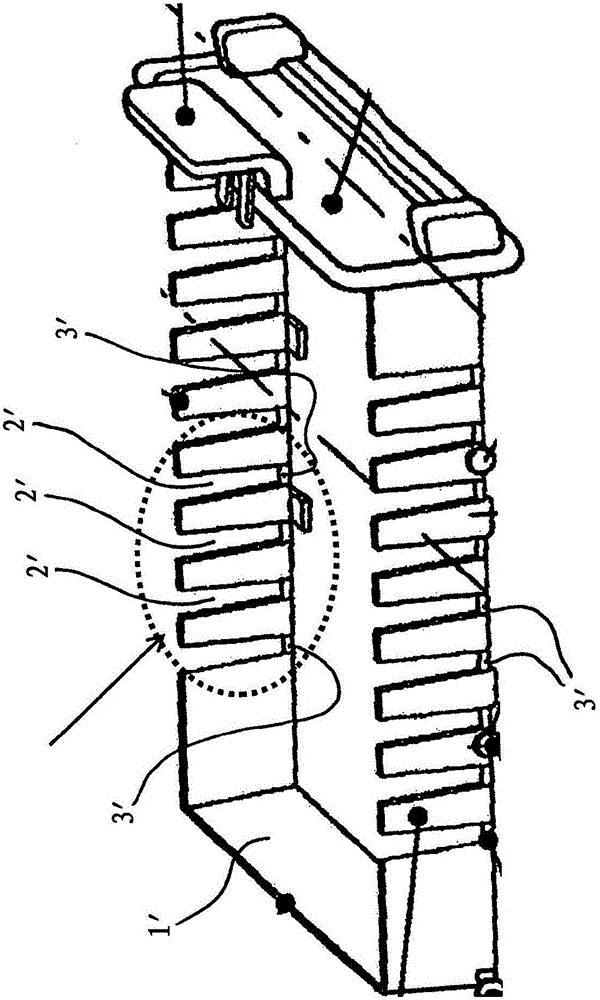

[0045] figure 1 A prior art frame element 1' is shown, which has a gap 2' and a thin area 3'.

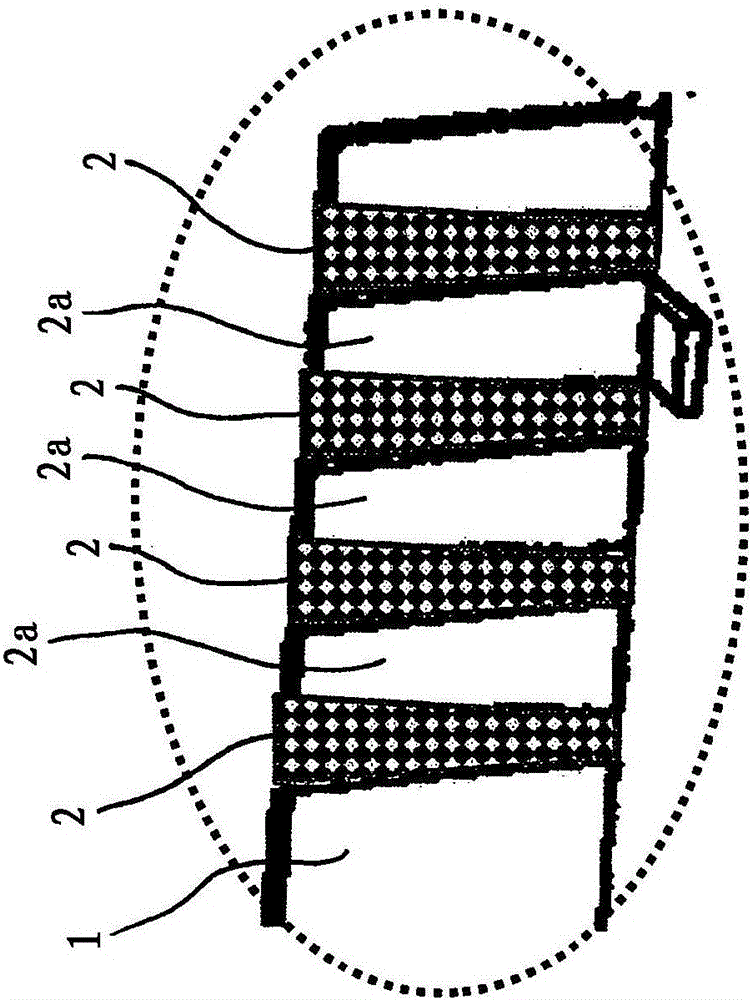

[0046] figure 2 A frame element 1 is shown in which some frame regions 2 a are made of a harder plastic and some frame regions 2 are made of a softer plastic.

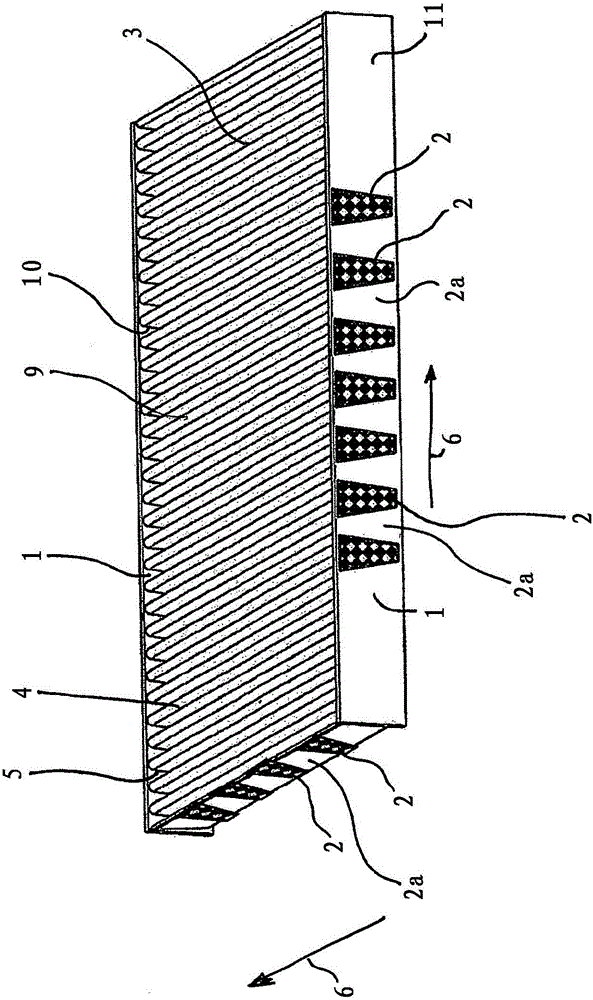

[0047] image 3 A filter element for insertion into a filter housing is shown, which comprises a filter medium 9 with a rim 10 which is connected to at least one injection-molded frame element 1 .

[0048] The frame element 1 is made of plastics of different hardness alternately in at least one direction of extension 6 in such a way that the filter element can be at least partially flexibly bent when the filter medium 9 and the frame element 1 are deformed.

[0049] Frame regions 2 made of softer plastic are attached to one or more frame regions 2 a of harder plastic of the frame element 1 , wherein the frame regions 2 of softer plastic form a defined curvature parts.

[0050] Plastics of different hardness can be configu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap