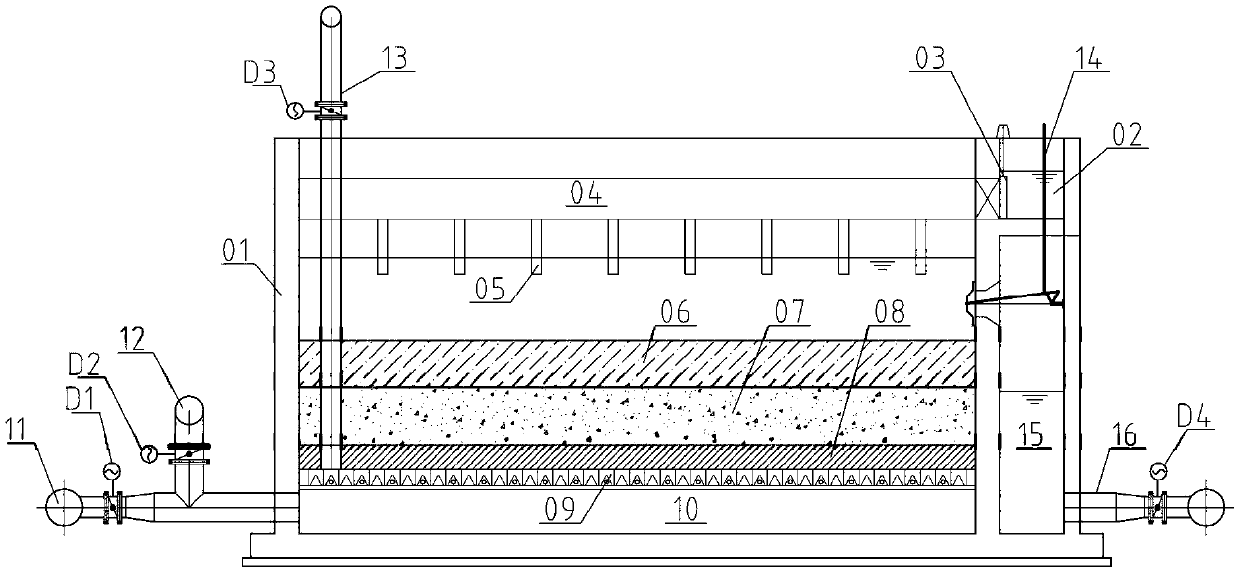

Organic polymer carrier-based novel denitrification filter tank process and device

An organic polymer and denitrification filter technology, which is applied in the field of water treatment, can solve the problems of small specific surface area of the filter material layer, low denitrification capacity load, and less denitrification biofilm, so as to reduce the total height of the filter, The effect of reducing head loss and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0029] A kind of novel denitrification filter process based on organic polymer carrier of the present invention comprises the following steps:

[0030] (1) Close the electric valve D2 of the backwash water inlet pipe, the electric valve D3 of the backwash air pipe, the electric valve D4 of the backwash water outlet pipe, and the drain flap valve 14, and filter the sewage to adjust the carbon source before entering the water inlet channel 02;

[0031](2) Open the water inlet valve 03, the filtered sewage is distributed into the water distribution channel 04, and then enters the filter pool body 01 through a plurality of short water distribution pipes 05 evenly arranged below the water distribution channel 04, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap