Method for setting control parameters of injection molding machine and injection molding machine

An injection molding machine and parameter control technology, applied in the field of injection molding machines, can solve the problems of economic loss, single way of setting permissions, difficult control parameters, etc., and achieve the effect of easy management and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

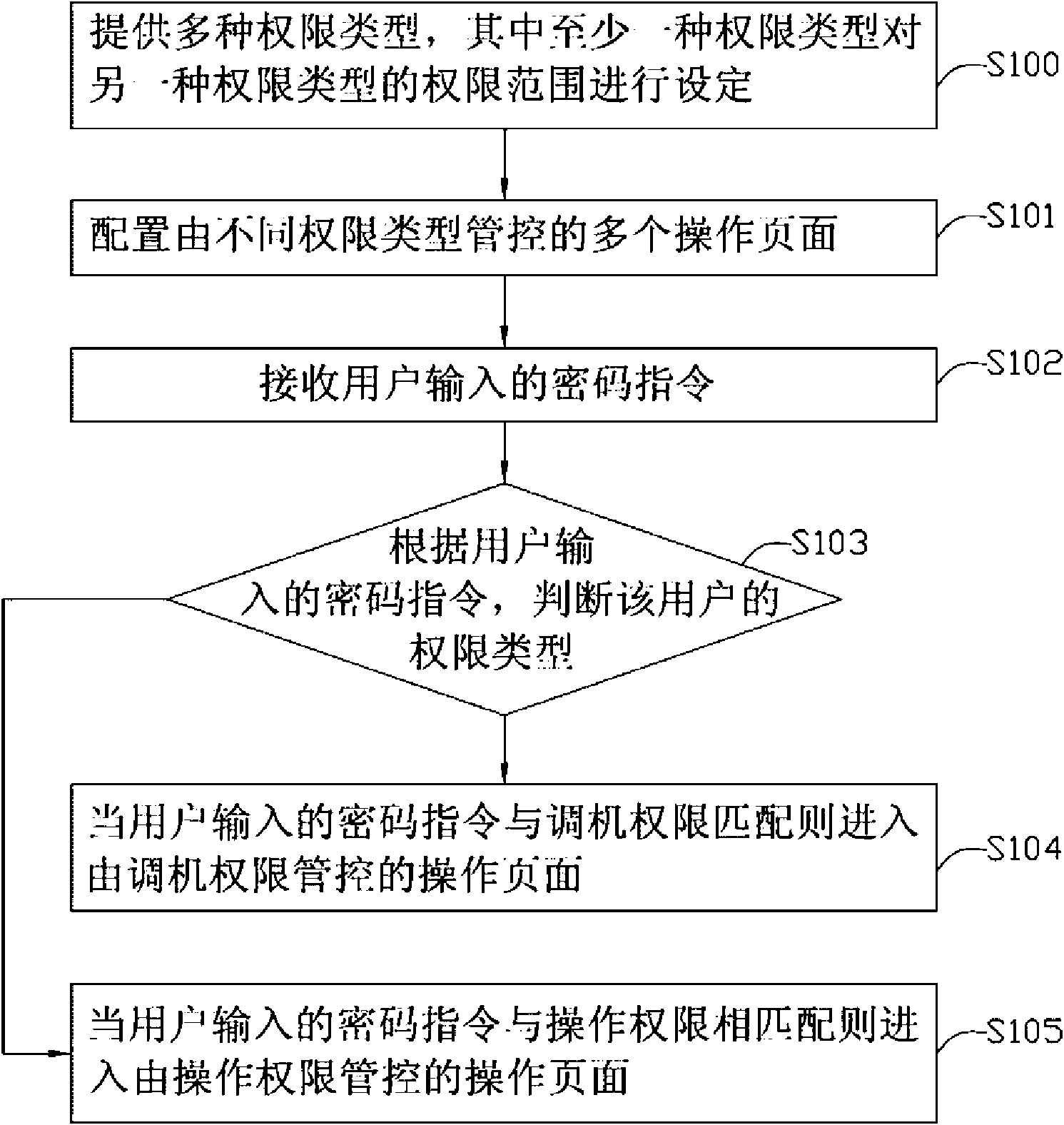

[0011] The method for setting the control parameters of the injection molding machine and the injection molding machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

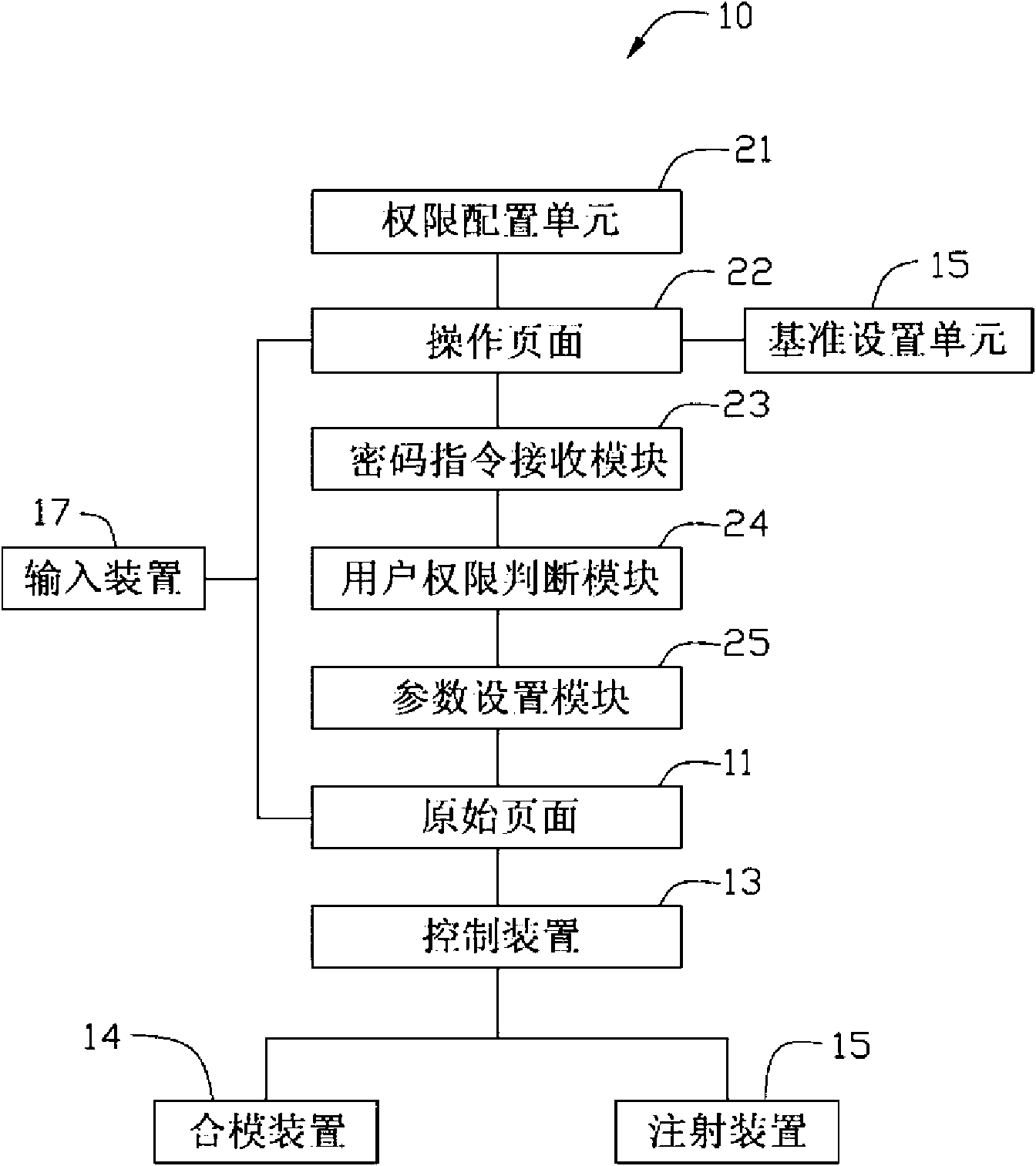

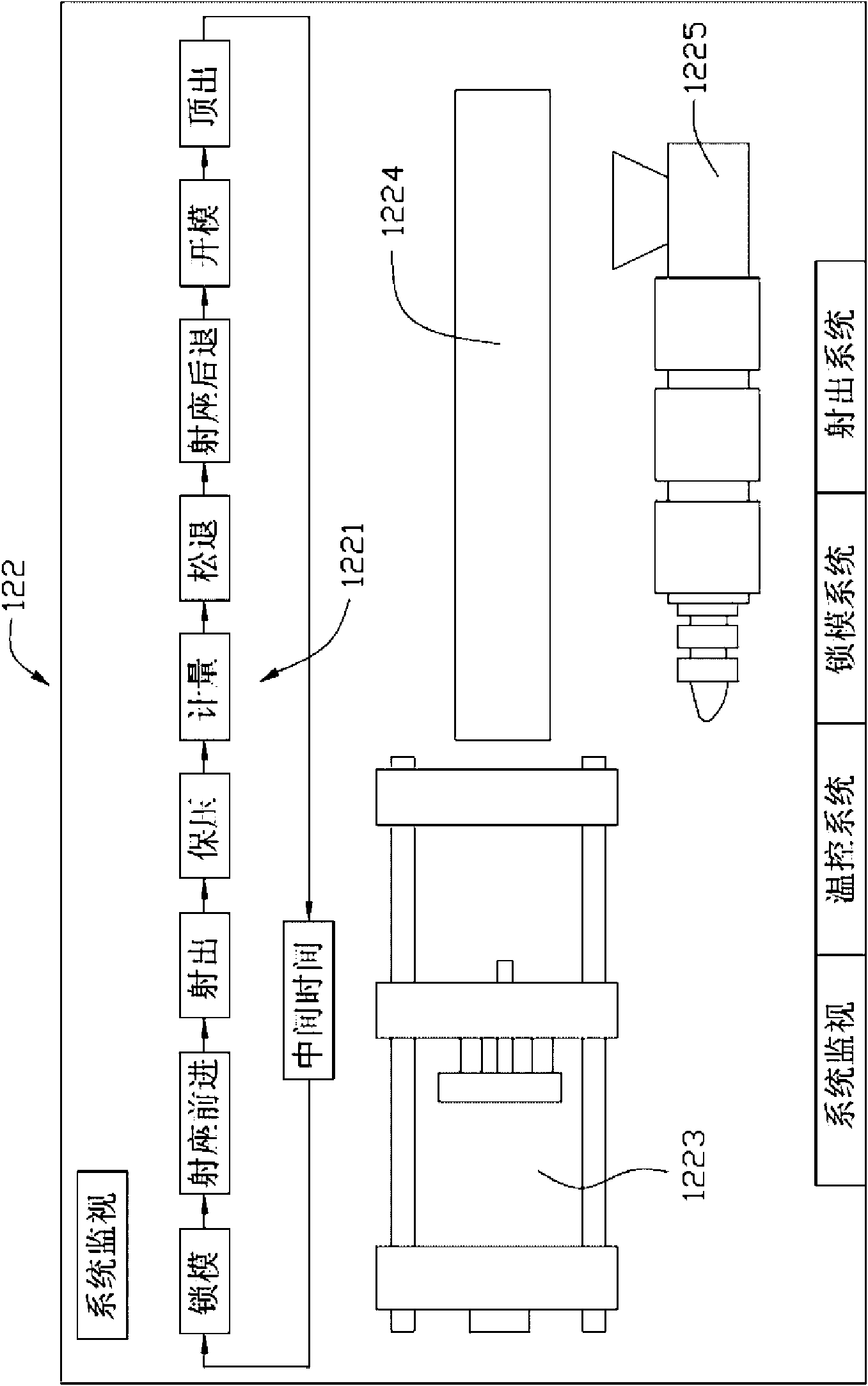

[0012] Such as figure 1 As shown, the injection molding machine 10 of the embodiment of the present invention includes an original interface 11, a control device 13, a mold clamping device 14, an injection device 15, an input device 17 and a display device (not shown). The original interface 11 is connected with the control device 13 and displayed by the display device, and is configured with characters or icons to describe corresponding setting items. The original interface 11 sets the control parameters of the injection molding machine 10 in response to the input from the input device 17 , and the control device 13 controls the actions of the mold clamping device 14 and the injection device 15 according to the control par

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap