Push pin machining method and assembly machine used in cooperation with same

A processing method, the technology of H-shaped nails, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow speed and high cost of H-shaped nails, and achieve the effects of fast production speed, labor saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for processing H-shaped nails. First, an I-shaped cap with a large cap at one end and a small cap at the other end is produced in an injection molding machine, and a central hole is opened in the center of the large cap, and the central hole extends upward to the small cap. At the cap, a metal nail with a pointed end and a flat end is made on the forging equipment, and finally the I-shaped cap and the metal nail are assembled by a matching I-shaped nail assembly machine.

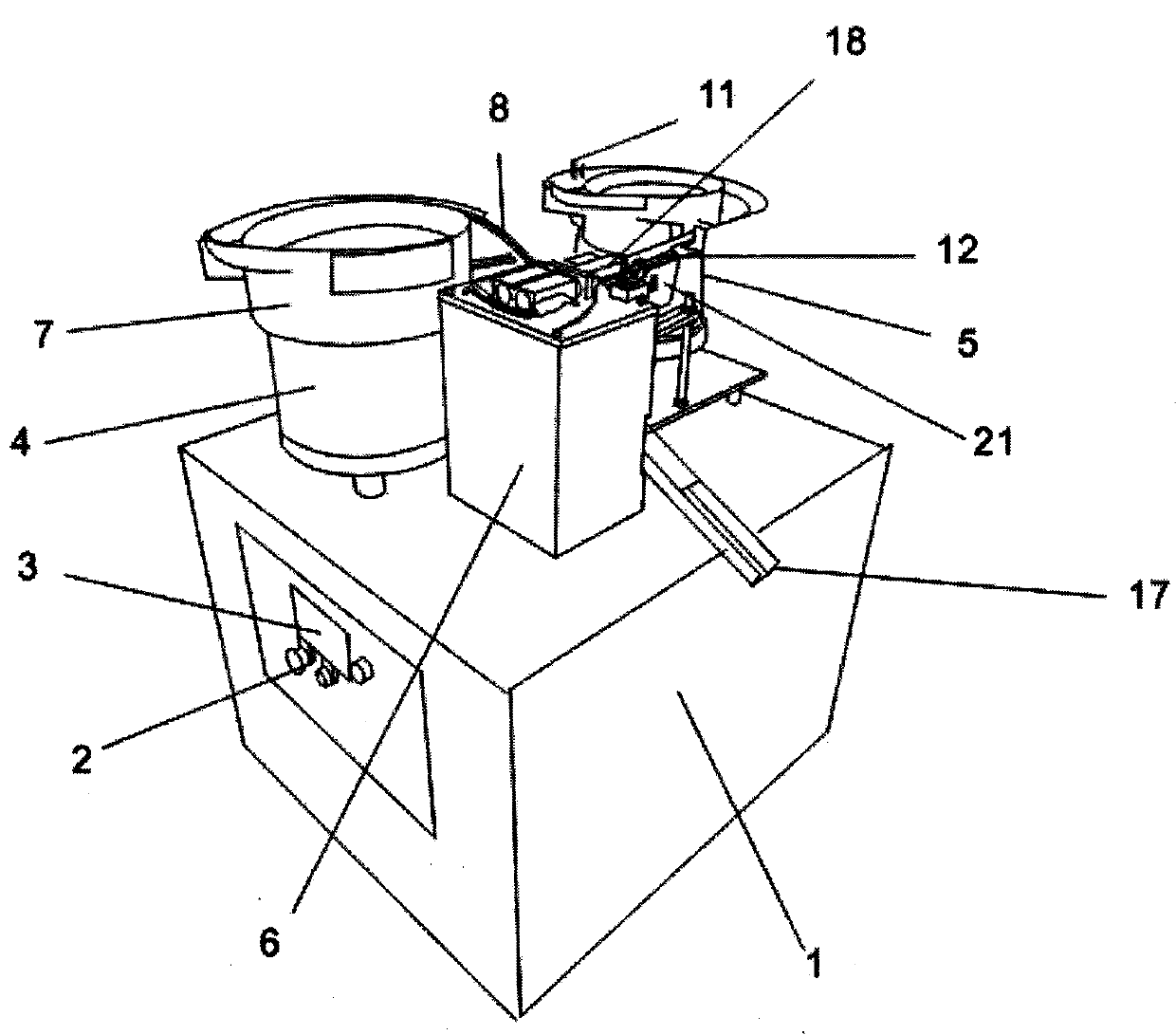

[0031] like Figure 1 to Figure 6 As shown, the H-shaped nail assembly machine used in conjunction with the processing method includes the H-shaped nail assembly machine body 1, and the control box located therein, the button 2 and panel 3 on the control box protrude from the body, and the H-shaped nails The top of the assembly machine body 1 is provided with an I-shaped cap conveyor 4, a metal nail conveyor 5 and a working box 6;

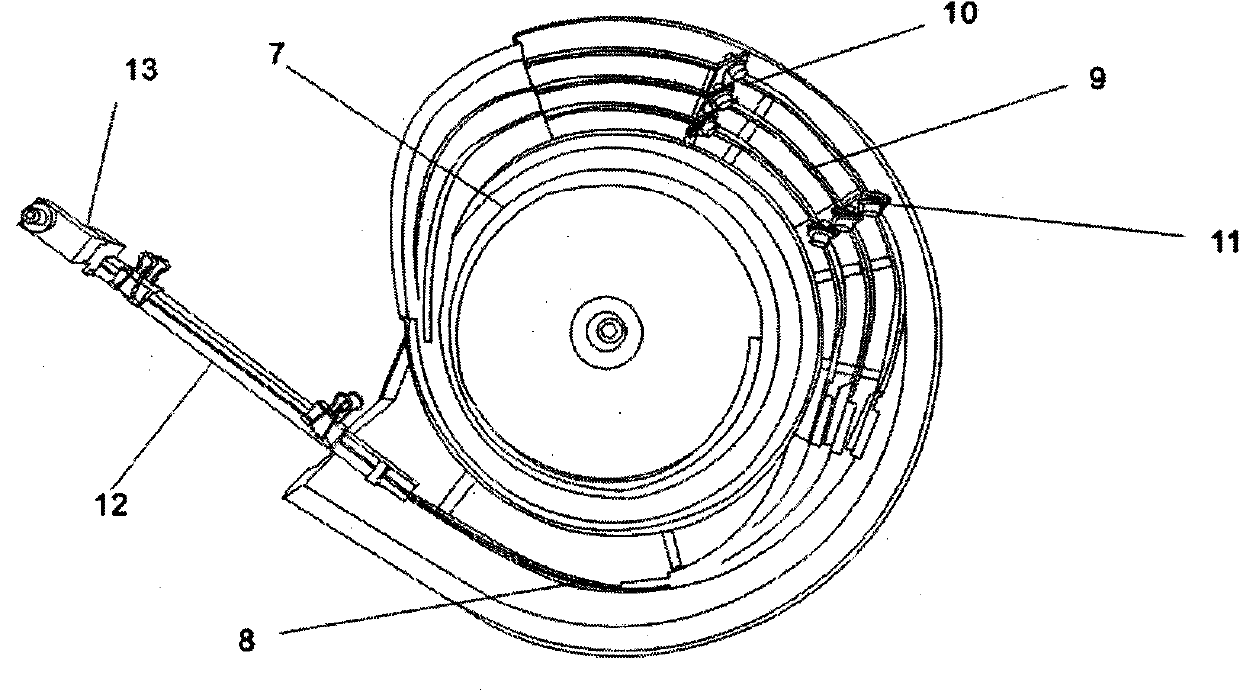

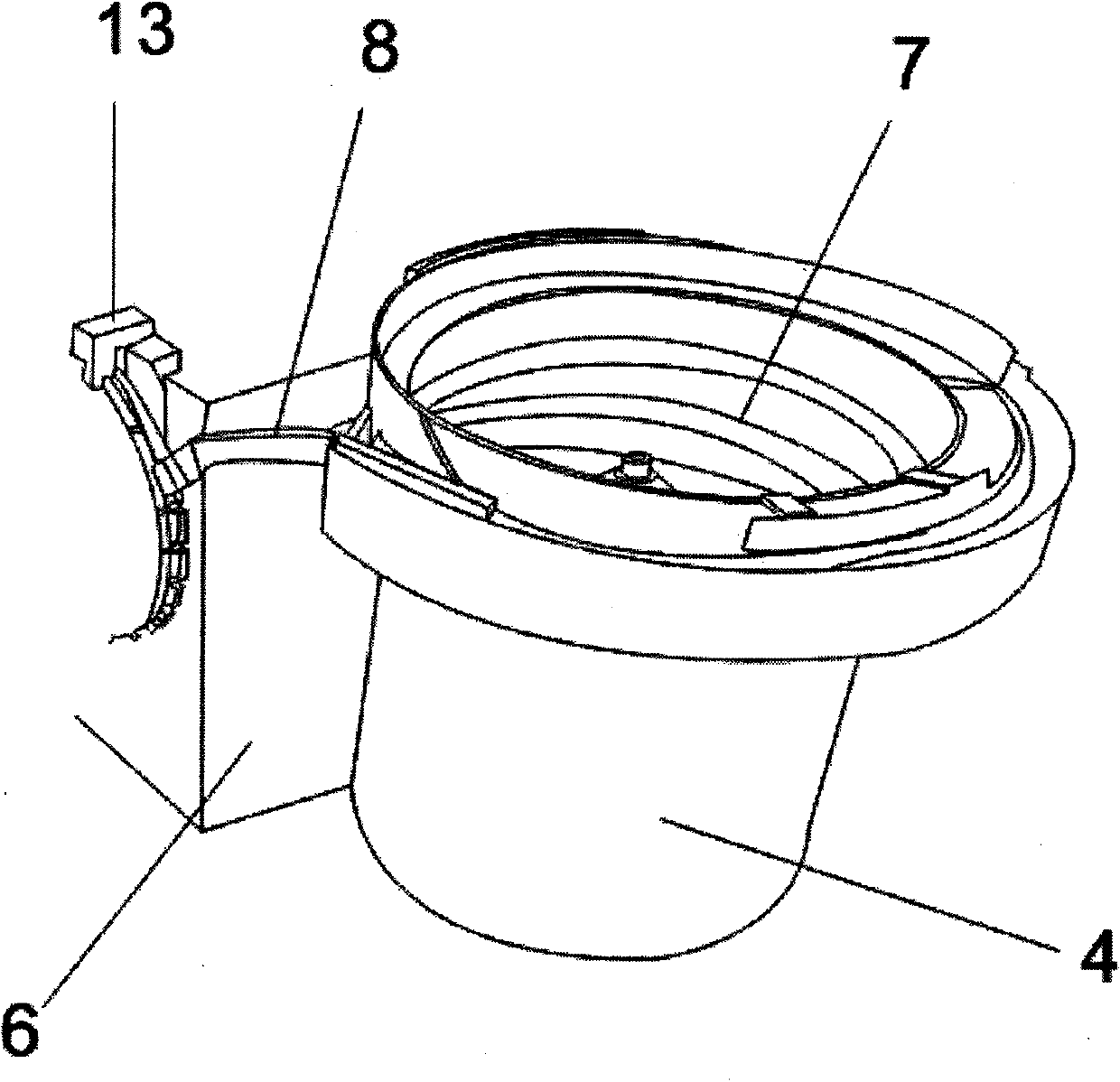

[0032] Both the I-shaped cap conveyor 4 and the metal nail con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap