Screw type injection-molding-machine blanking apparatus structure

A device structure and injection molding machine technology, applied in the field of screw-type injection molding machine blanking device structure, can solve the problems of simple structure, bridging, etc., achieve the effect of low device cost, simple principle and structure, and improve molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

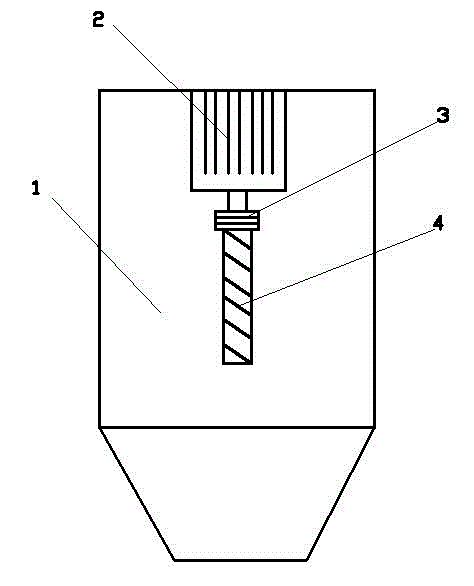

[0013] This embodiment provides a screw type injection molding machine blanking device structure, characterized in that: the screw type injection molding machine blanking device structure includes injection molding machine blanking hopper (1), power output device (2), coupling device (3), screw (4);

[0014] Wherein: a power output device (2) is installed on the top of the injection molding machine drop hopper (1), and the anti-bridging execution unit (4) is connected with the power output device (2) through a coupling (3).

[0015] According to claim 1, the screw type injection molding machine unloading device structure is characterized in that: said power output device (2) is a DC motor.

[0016] The screw type injection molding machine blanking device structure according to claim 1, characterized in that: said coupling (3) is an elastic coupling.

Embodiment 2

[0018] The invention provides a screw type injection molding machine blanking device structure, characterized in that: said injection molding machine blanking device with anti-bridging function includes injection molding machine blanking hopper (1), power output device (2) , coupling (3), screw (4);

[0019] Wherein: a power output device (2) is installed on the top of the injection molding machine drop hopper (1), and the screw rod (4) is connected with the power output device (2) through a coupling (3).

[0020] According to claim 1, the screw type injection molding machine unloading device structure is characterized in that: said power output device (2) is a DC motor.

[0021] The screw type injection molding machine blanking device structure according to claim 1, characterized in that: said coupling (3) is an elastic coupling.

Embodiment 3

[0023] The invention provides a screw type injection molding machine blanking device structure, which is characterized in that: the screw type injection molding machine blanking device structure includes an injection molding machine blanking hopper (1), a power output device (2), and a coupling (3), screw (4);

[0024] Wherein: a power output device (2) is installed on the top of the injection molding machine drop hopper (1), and the screw rod (4) is connected with the power output device (2) through a coupling (3).

[0025] The screw type injection molding machine blanking device structure according to claim 1, characterized in that: said coupling (3) is an elastic coupling.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap