Automatic injection molding system

An automatic system and injection molding machine technology, applied in coating and other directions, can solve the problems of high labor cost and labor intensity of workers, and achieve the effect of reducing labor cost, reducing labor pressure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

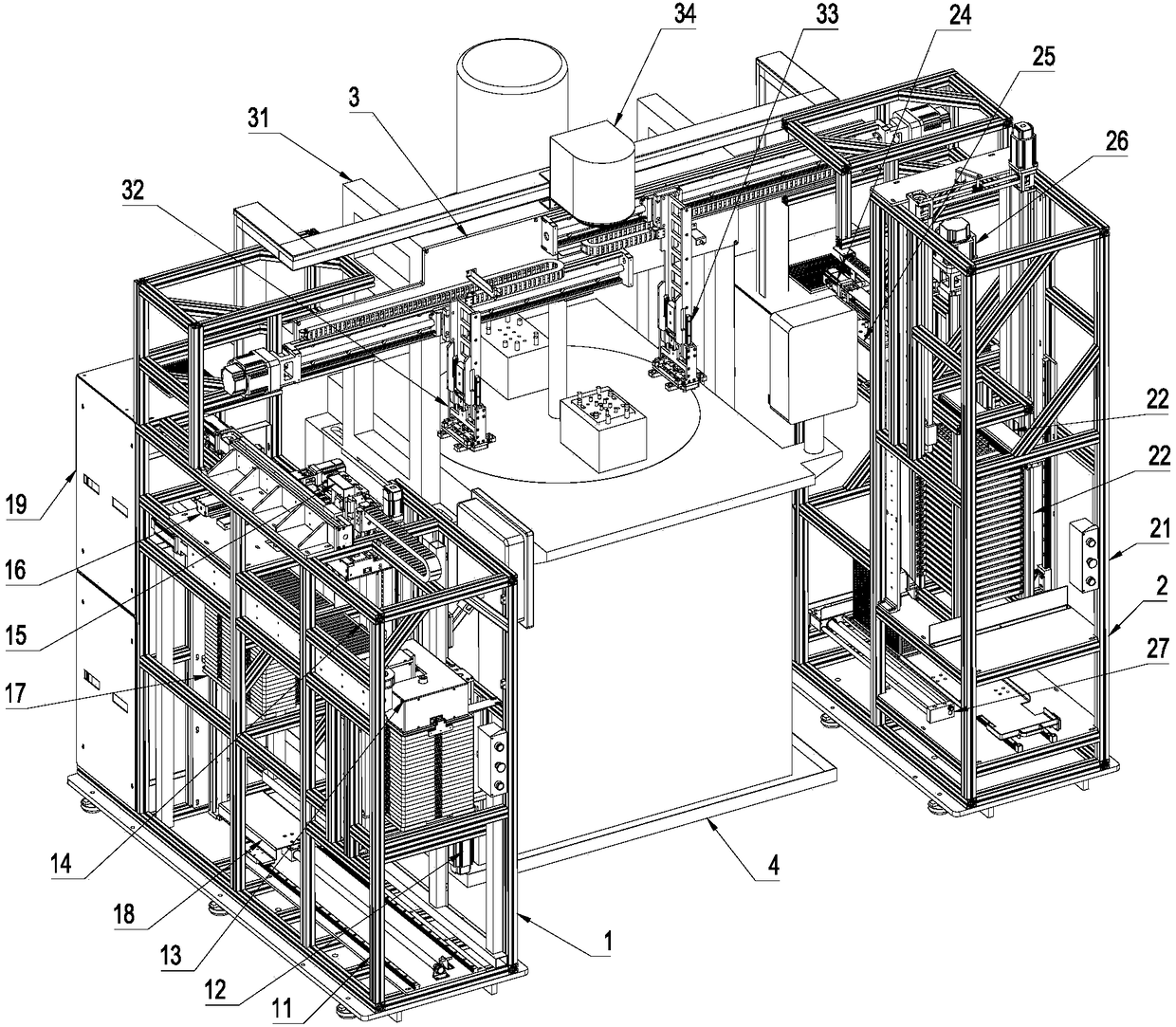

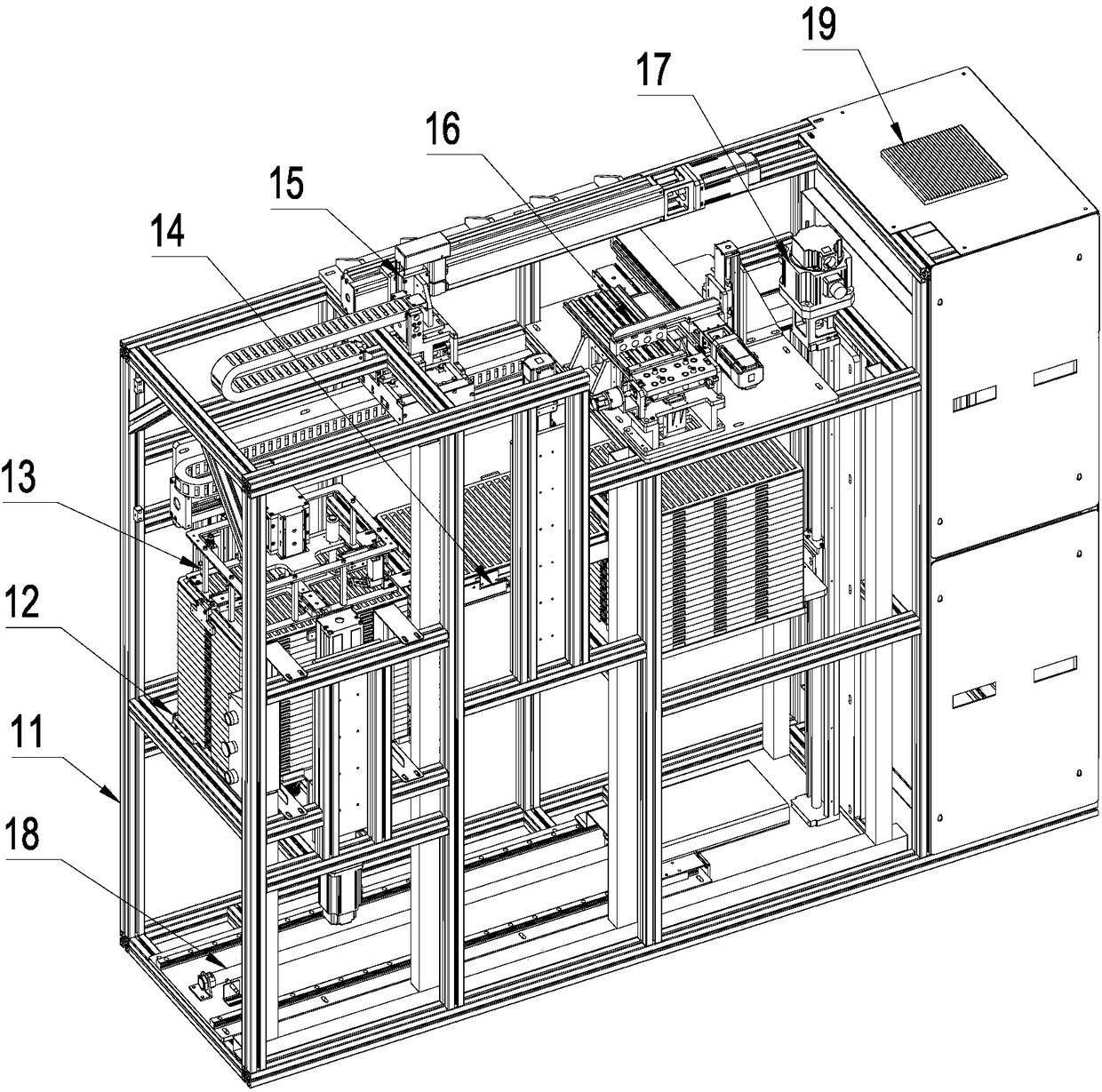

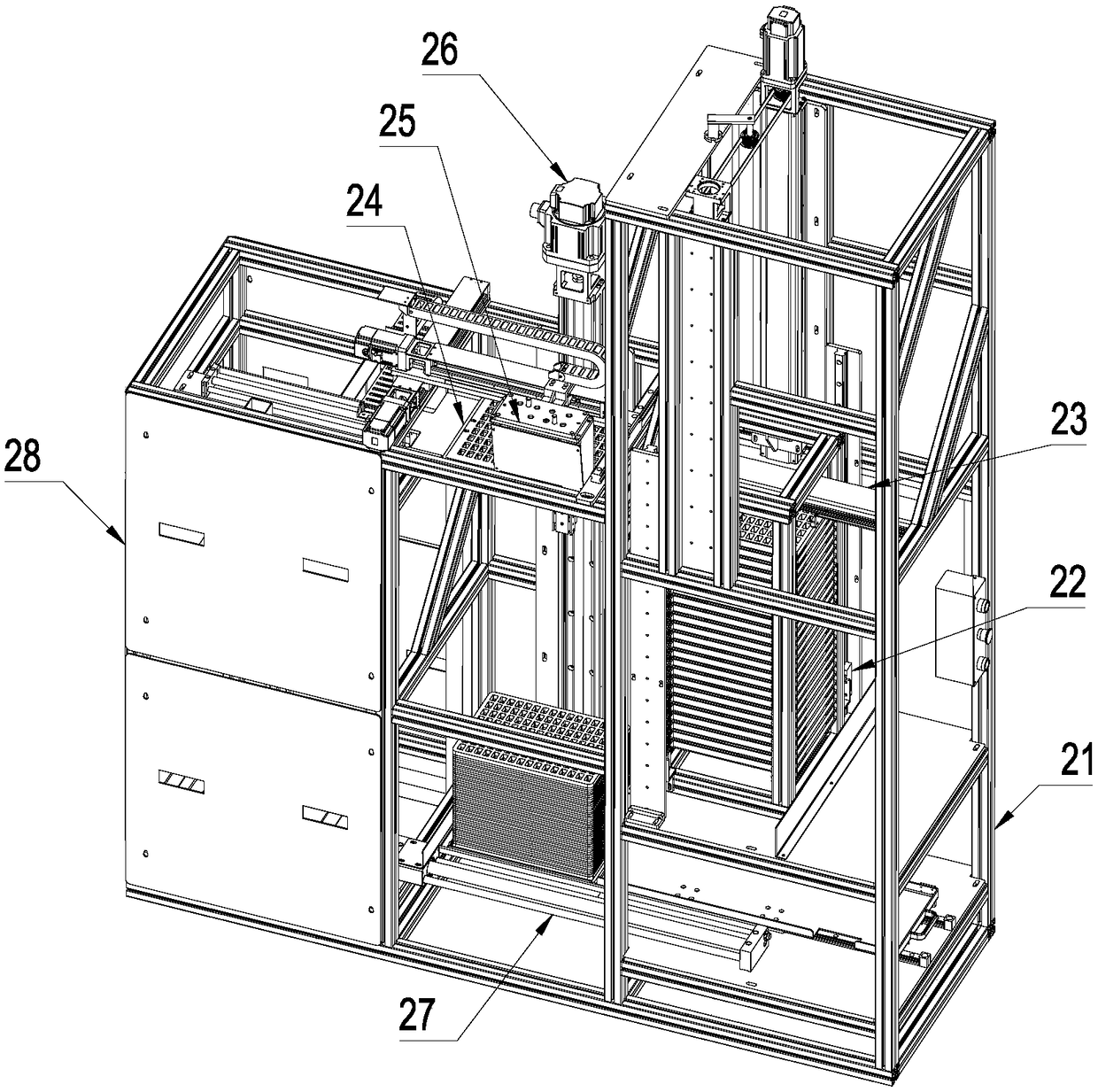

[0017] Such as Figure 1 to Figure 3 As shown, an automatic injection molding system includes an injection molding machine. The left side of the injection molding machine 4 is provided with a loading mechanism 1, and the right side is provided with a blanking mechanism 2. A loading and unloading robot gantry is provided between the loading structure and the blanking mechanism. Rack mechanism 3, feeding mechanism 1 includes feeding rack 11, magnetic ring full disk lifting mechanism 12, single disk clamping mechanism 13, single disk positioning lifting mechanism 14, magnetic strip pick and place arrangement mechanism 15, magnetic ring packing mechanism 16 , Empty tray stacking mechanism 17, empty tray transfer mechanism 18 and feeding mechanism electrical control part 19, unloading mechanism 2 includes unloading rack 21, finished empty tray lifting mech

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap