Mode locking system

A technology of clamping and clamping device, applied in the field of clamping system, can solve the problems of low production efficiency, small overall height, not enough humanization, etc., and achieve the effect of high degree of automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The clamping system of the present invention is compact in structure, high in automation and productivity, and reasonable in design, and is suitable for vertical injection process environments with special requirements, such as plastic magnetic injection motor rotors (integrated injection molding with extended motor shafts), various stainless steels, various Copper parts and other occasions that need to be pre-embedded. The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides:

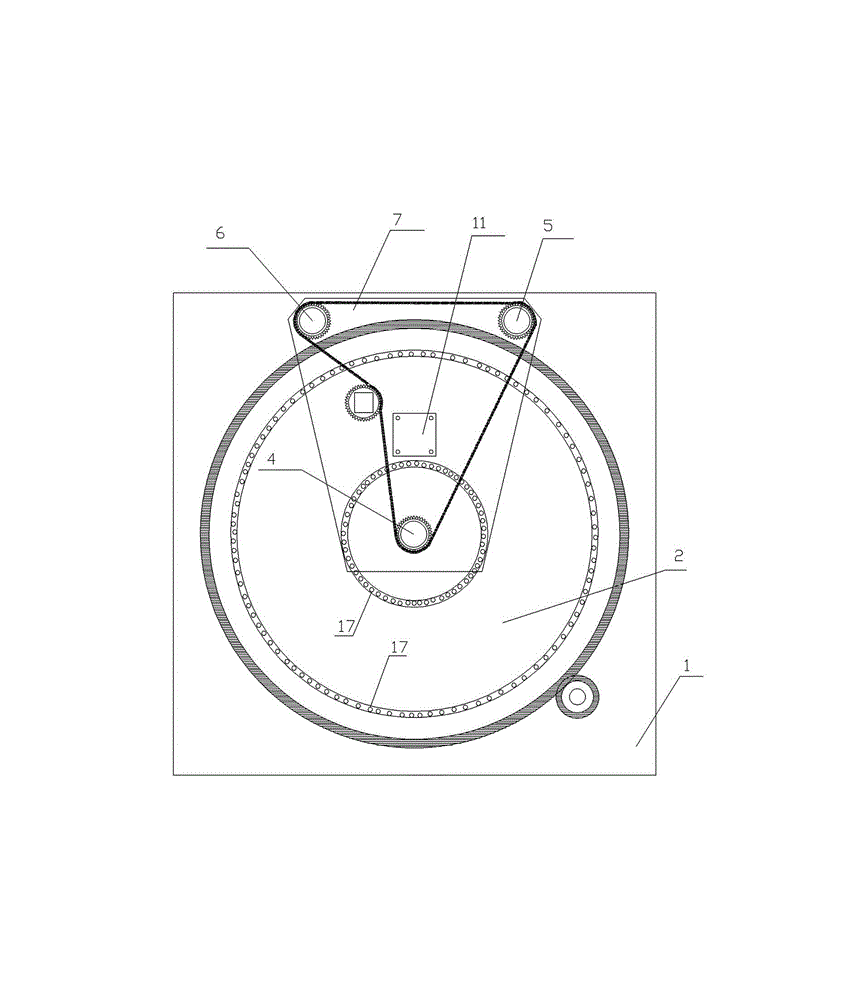

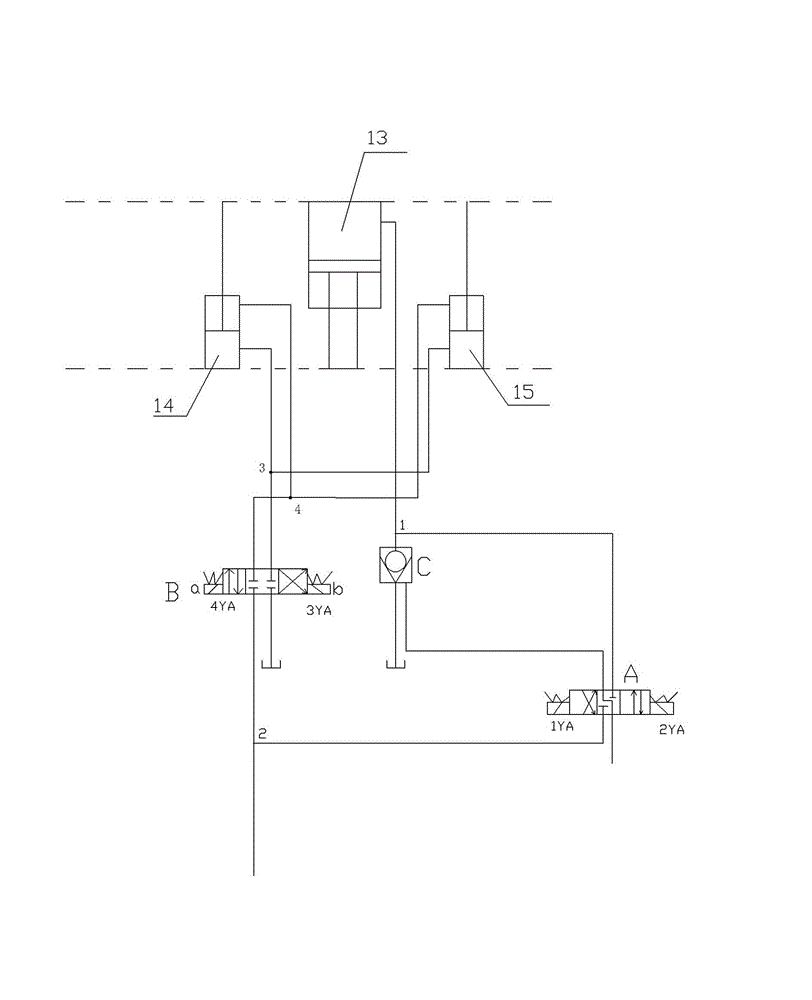

[0016] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes that the mold clamping system includes a workbench 1, a turntable 2 arranged on the workbench 1, a turntable motor 3 for driving the turntable 2 to rotate, and a second wheel passing through the workbench 1. A guide post 4, a second guide post 5 and a third guide post 6, the three guide posts can be lifted up and down in the vertical dire

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap