Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Optical articles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

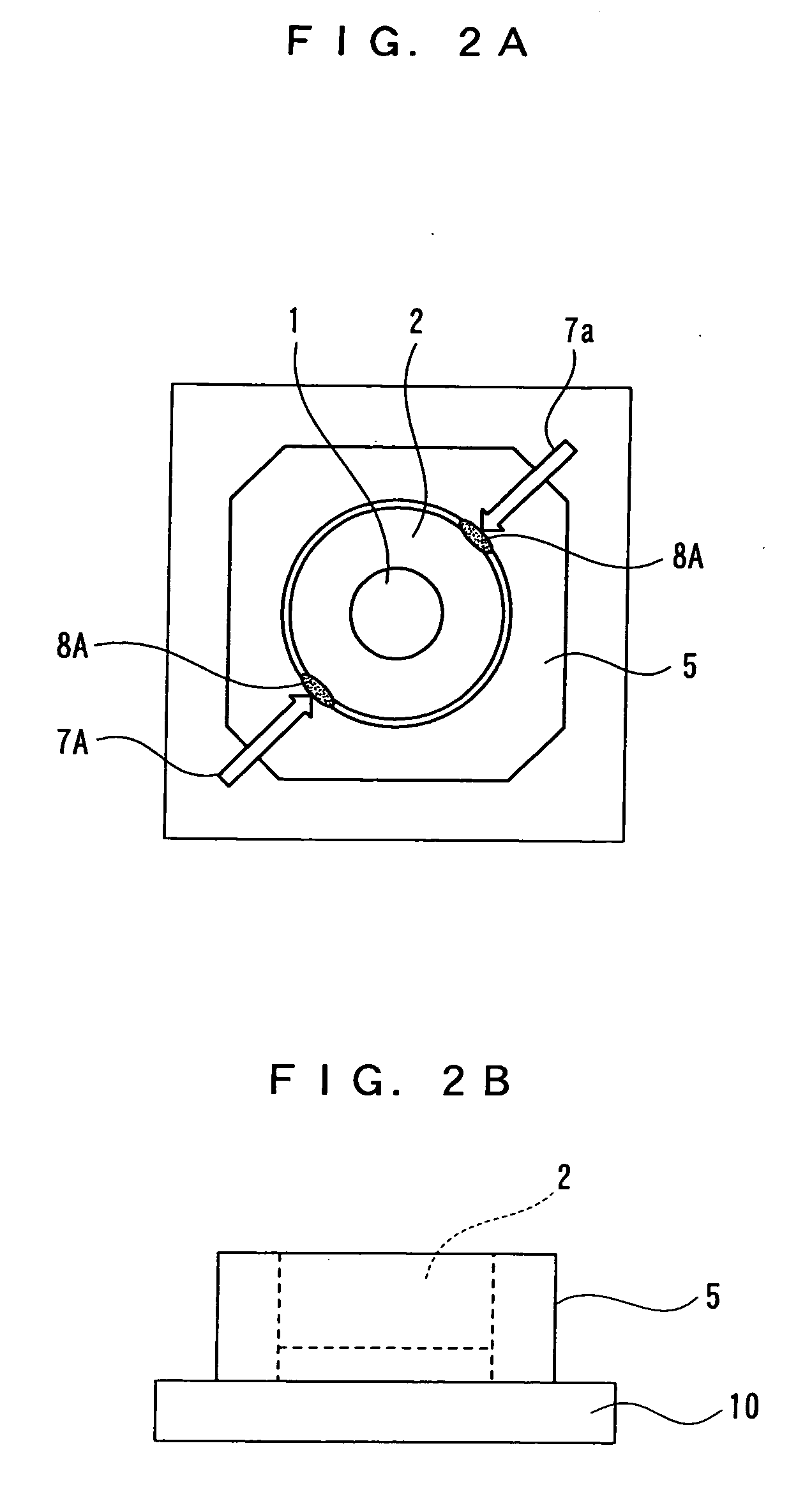

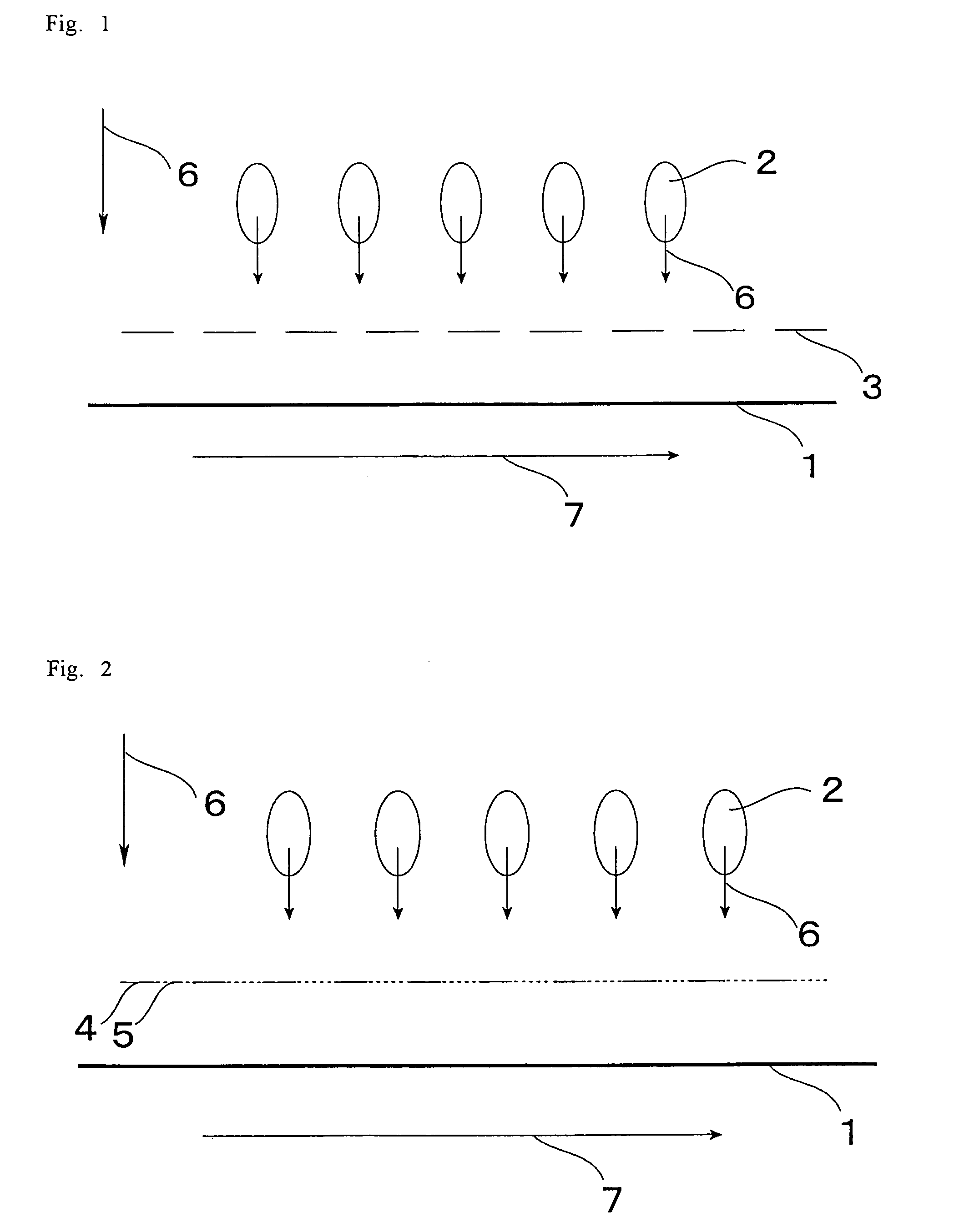

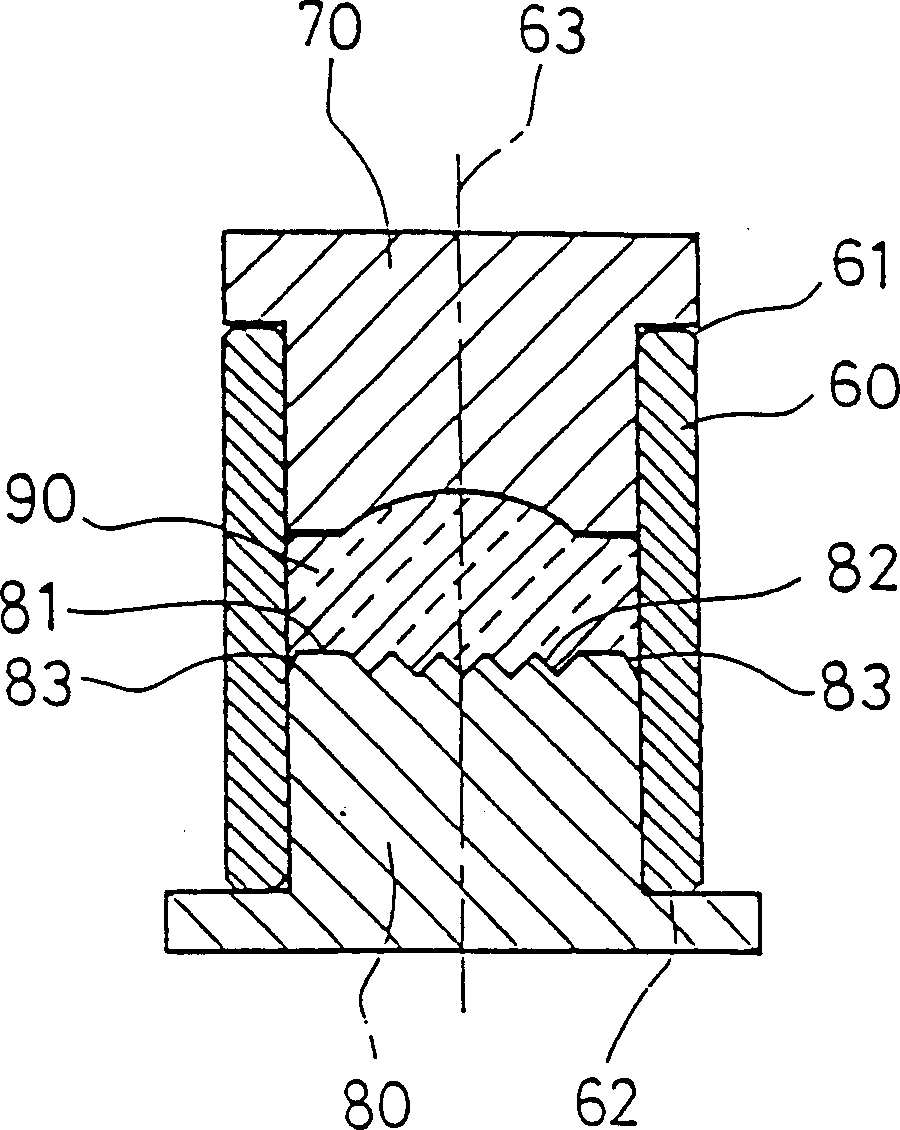

Manufacturing method of optical component and camera module

InactiveUS20060077575A1Slow changeAccurate fixing methodTelevision system detailsOptical articlesCamera moduleOptoelectronics

Owner:PANASONIC CORP

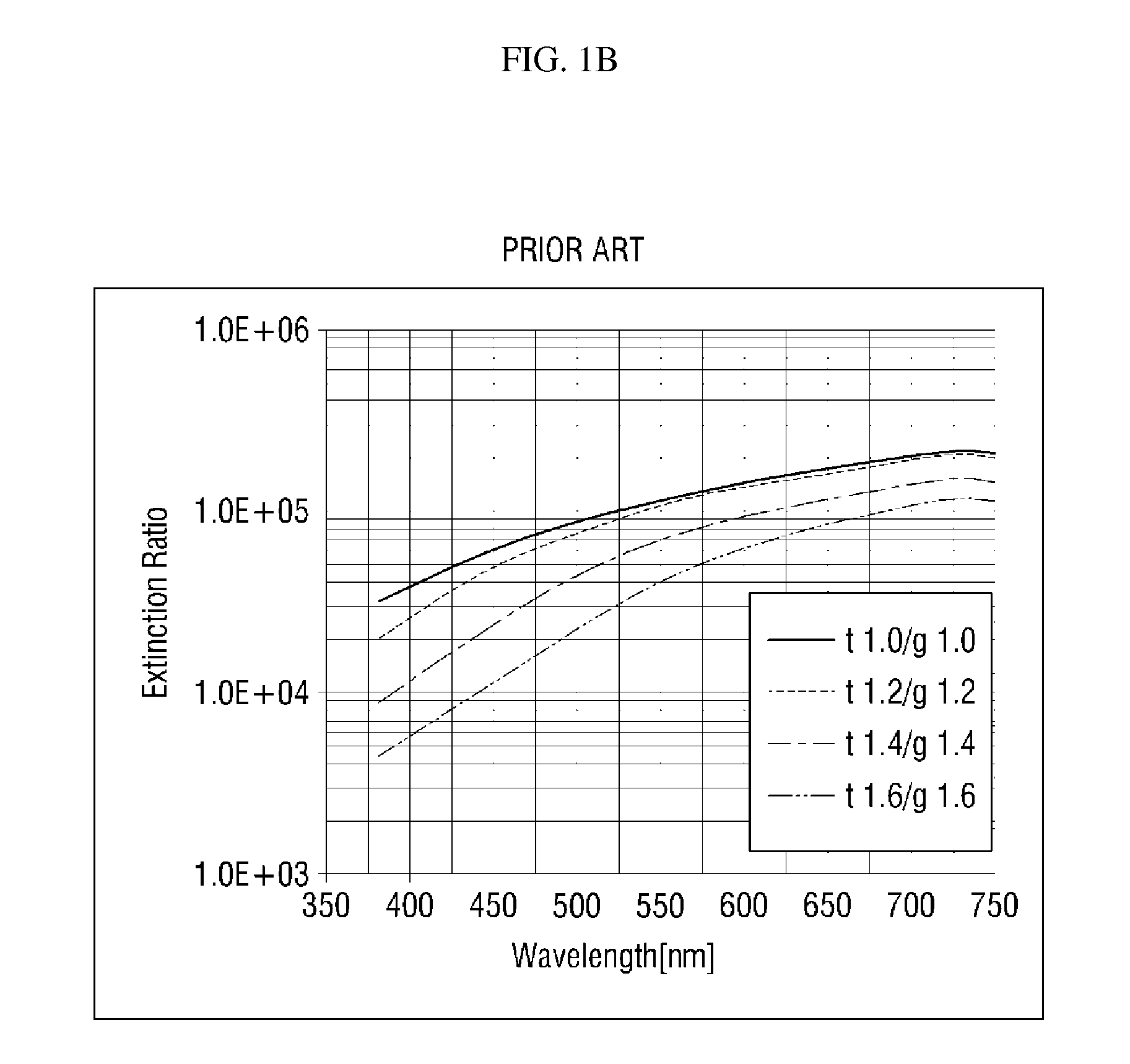

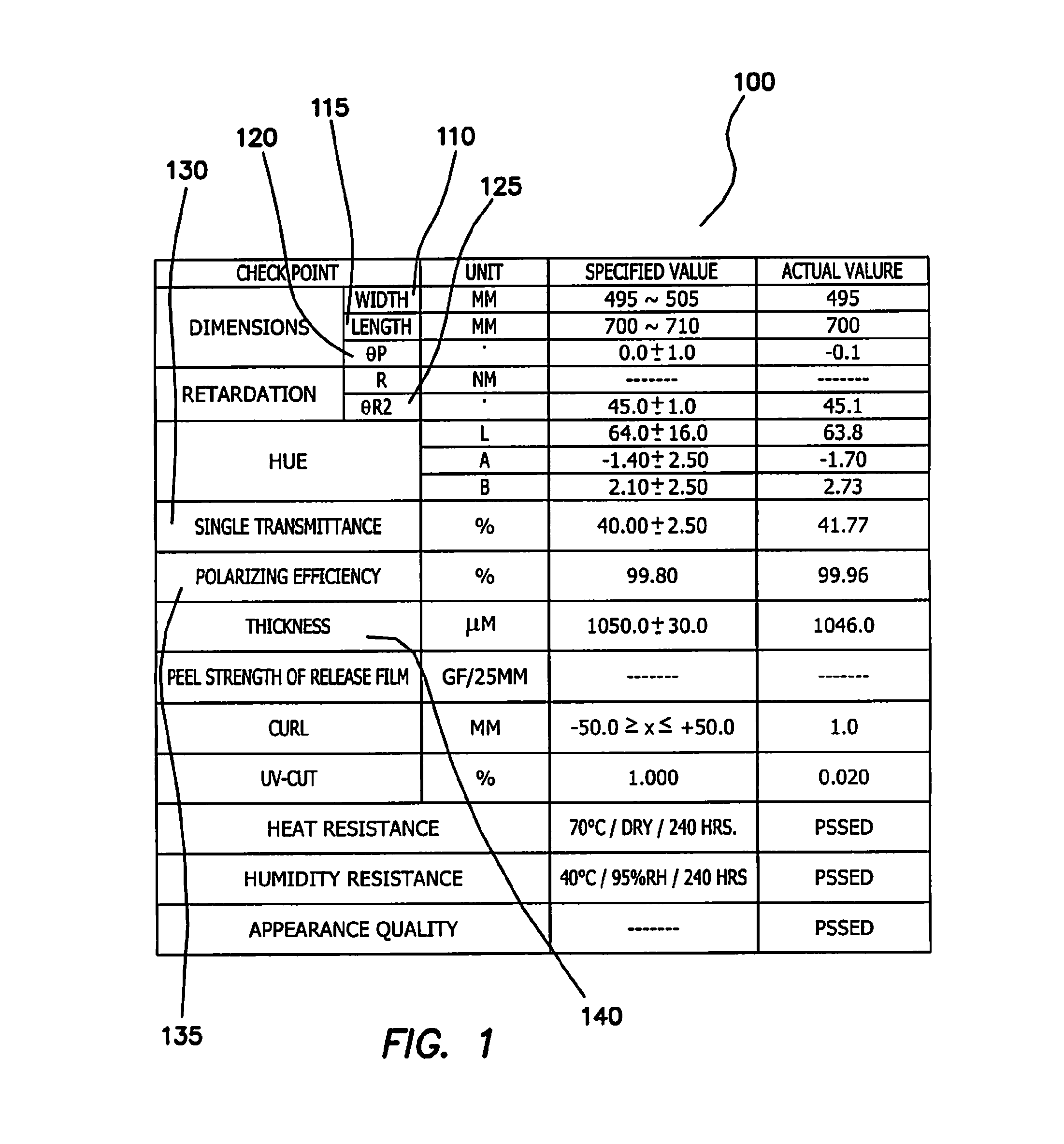

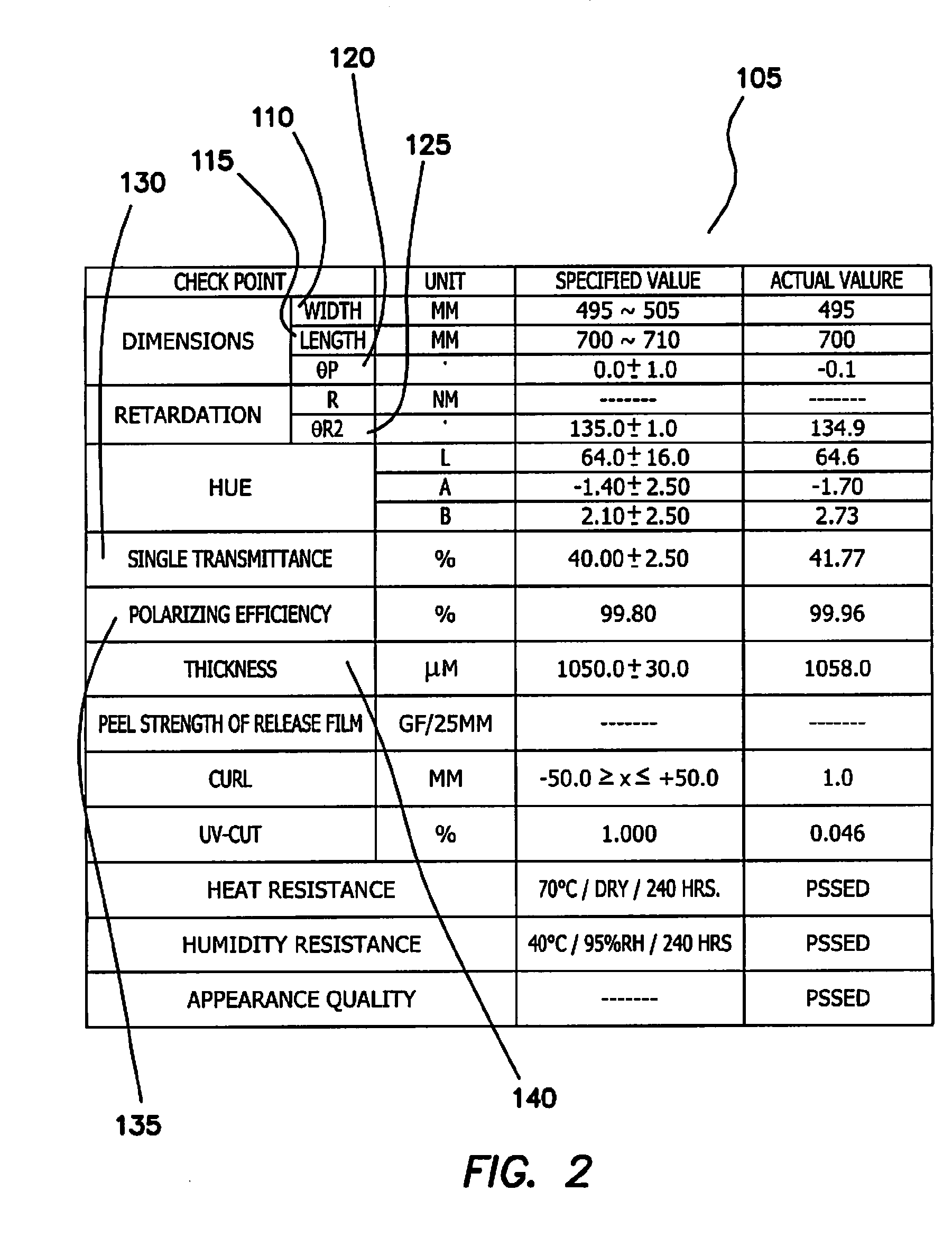

Composition for polarizing film, polarizing film, method of manufacturing the same, and liquid crystal display provided with the polarizing film

Owner:SAMSUNG ELECTRONICS CO LTD

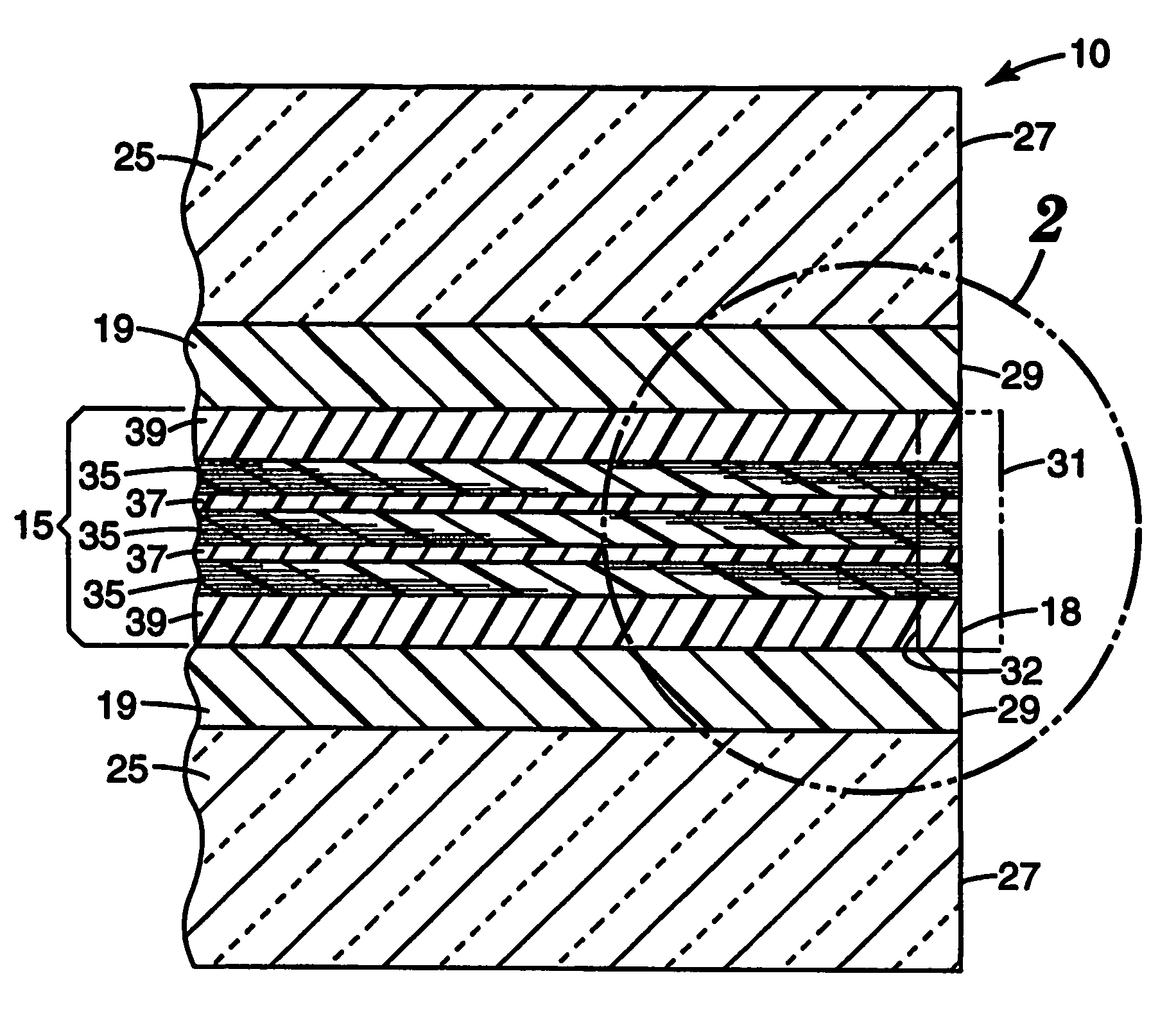

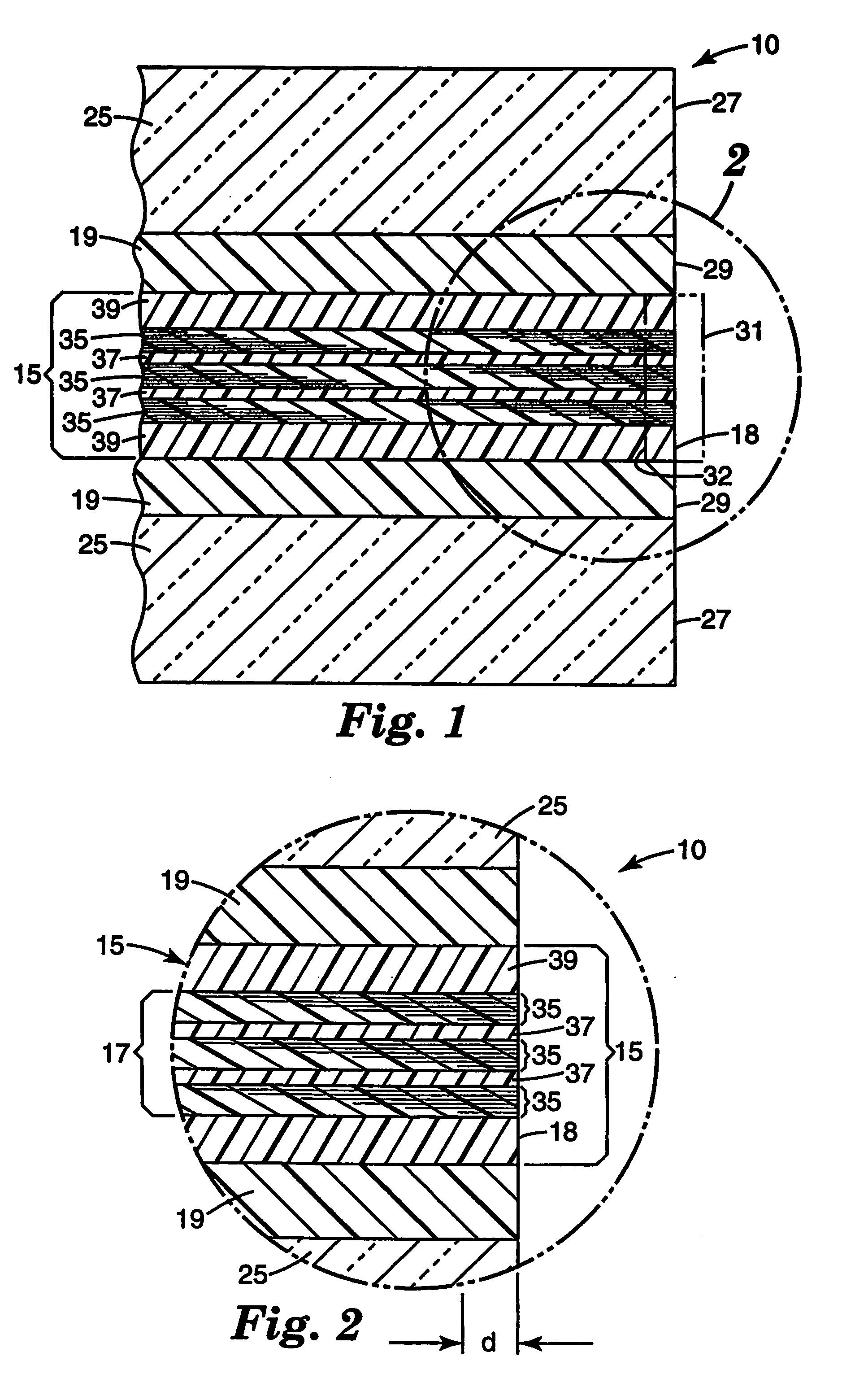

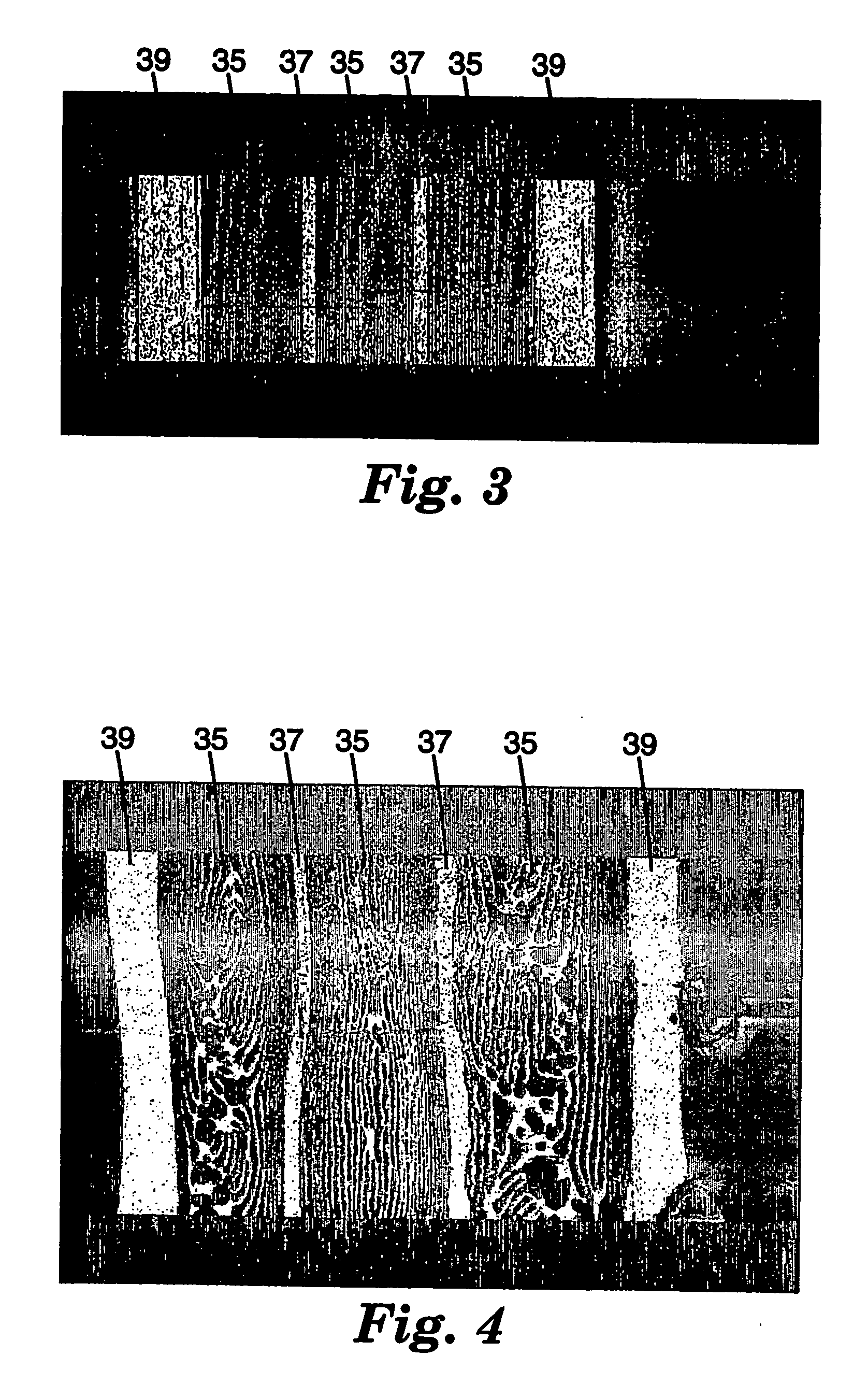

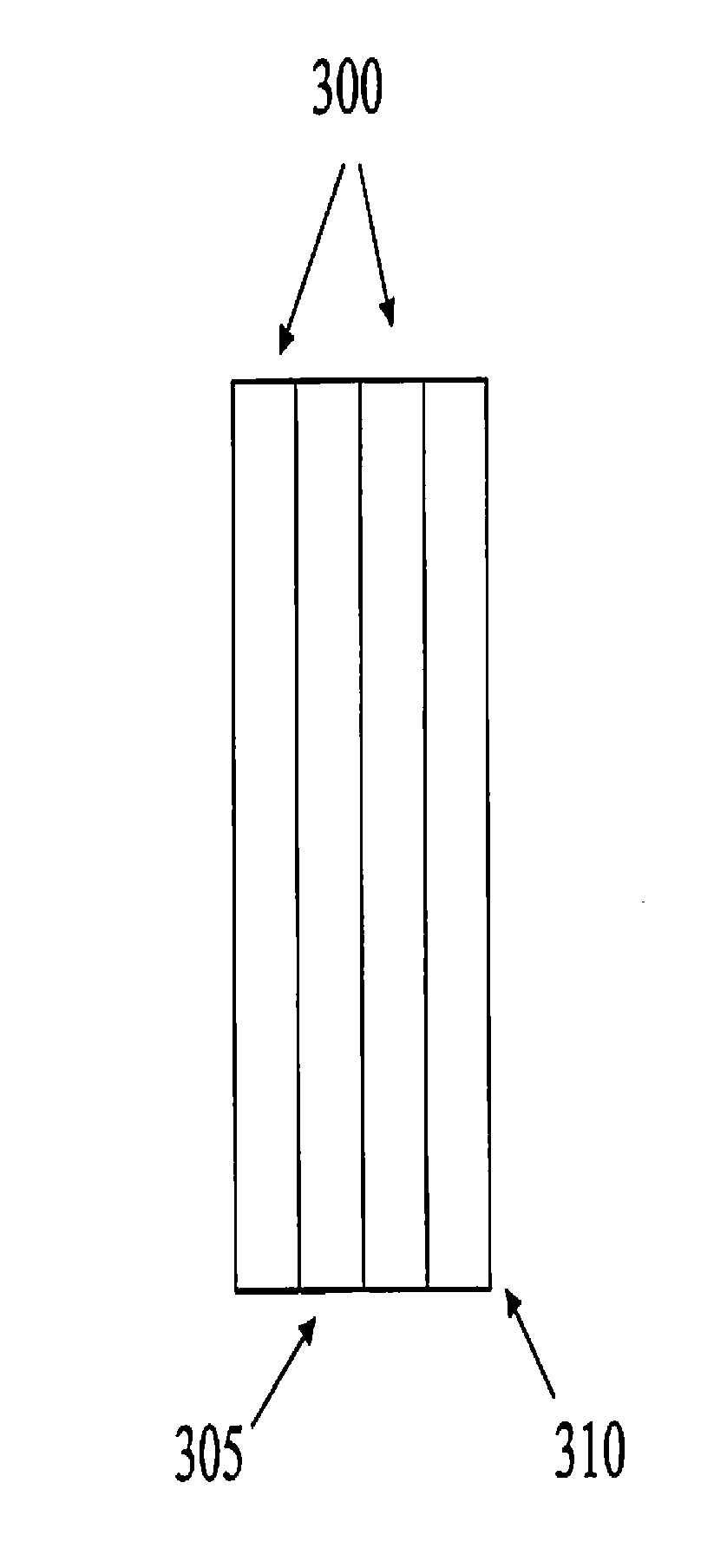

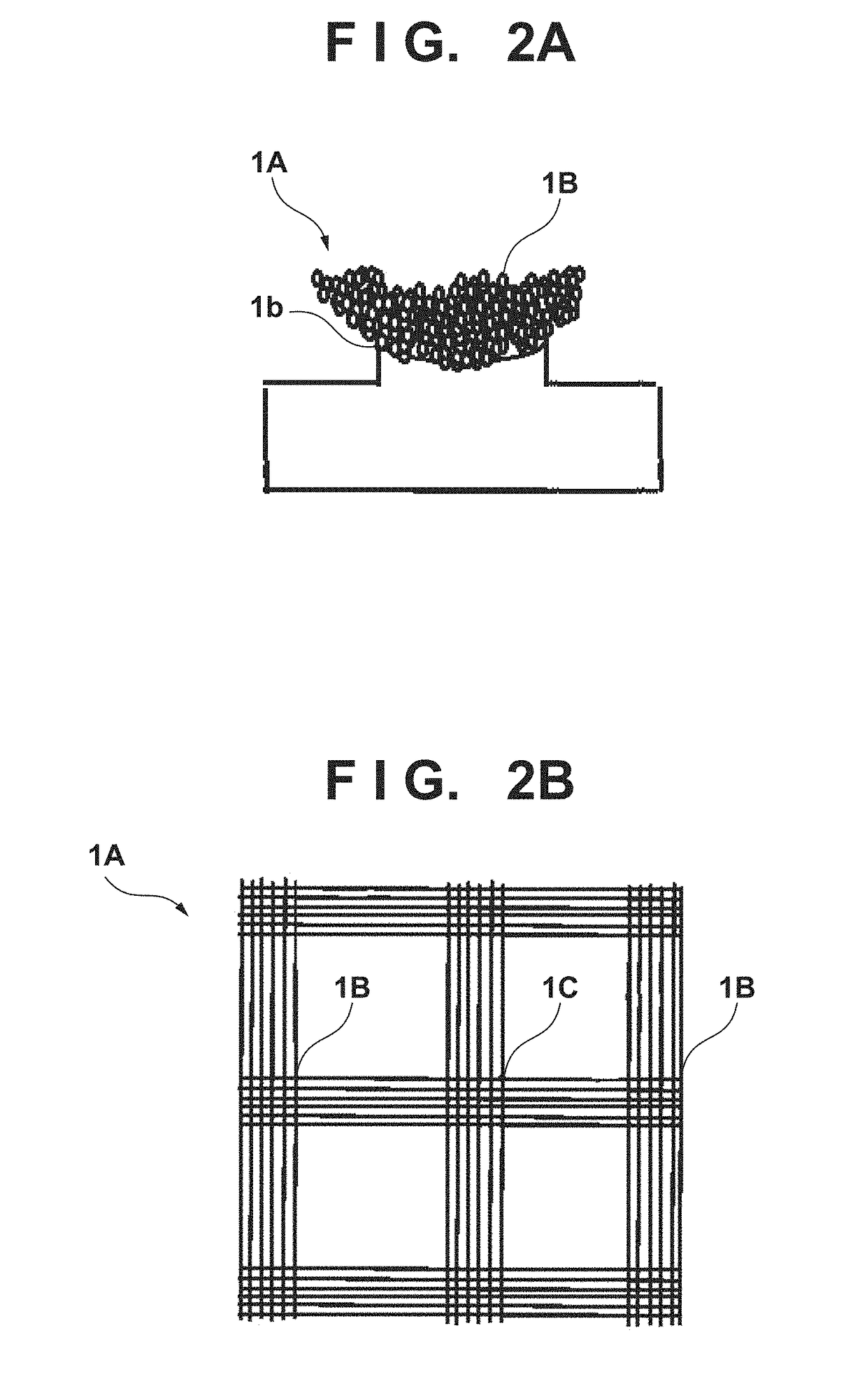

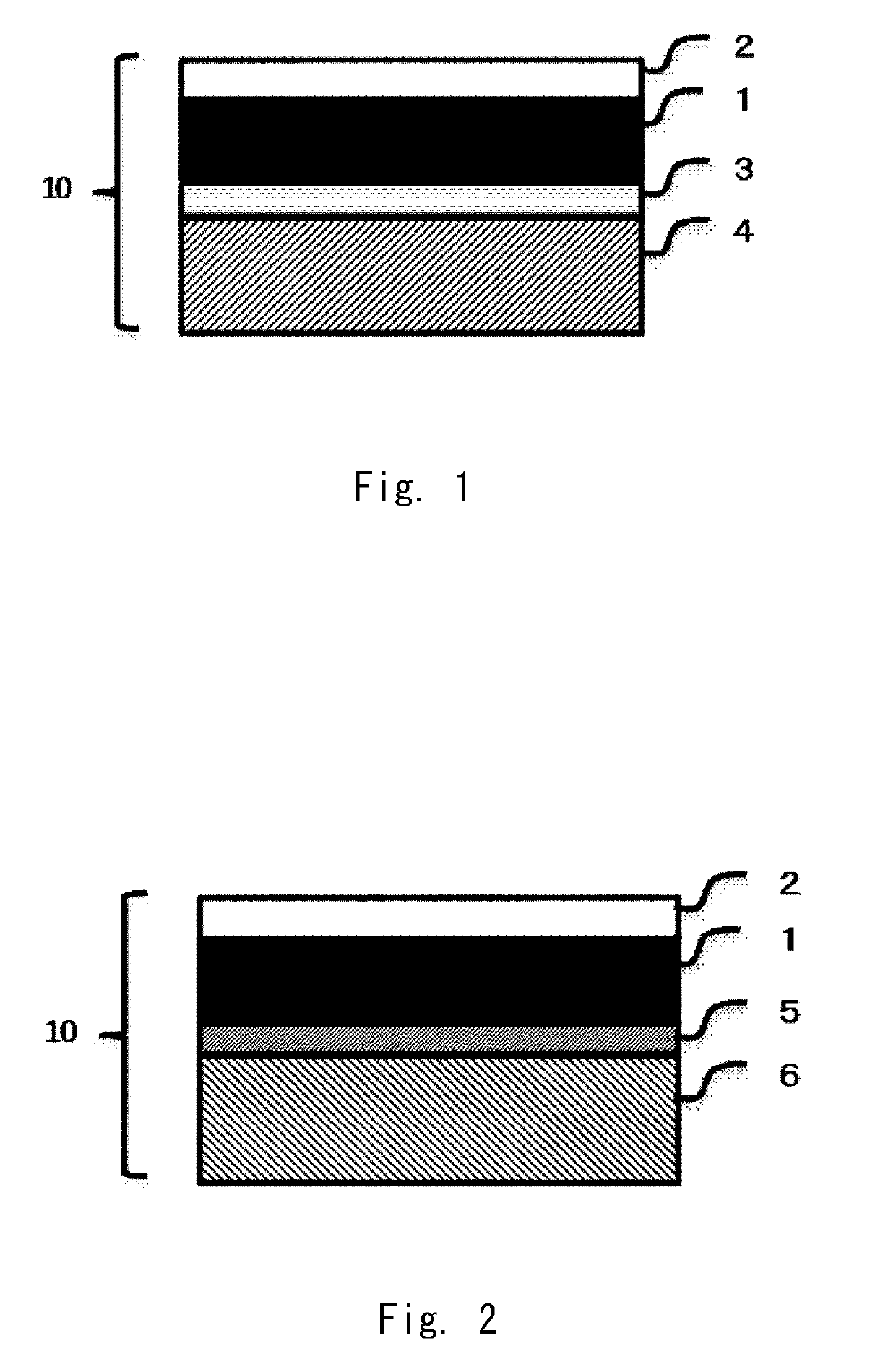

Laminates and methods of making same

InactiveUS20070053088A1Reduce decreaseAvoid layeringMirrorsSynthetic resin layered productsEngineeringMultiple layer

Owner:3M INNOVATIVE PROPERTIES CO

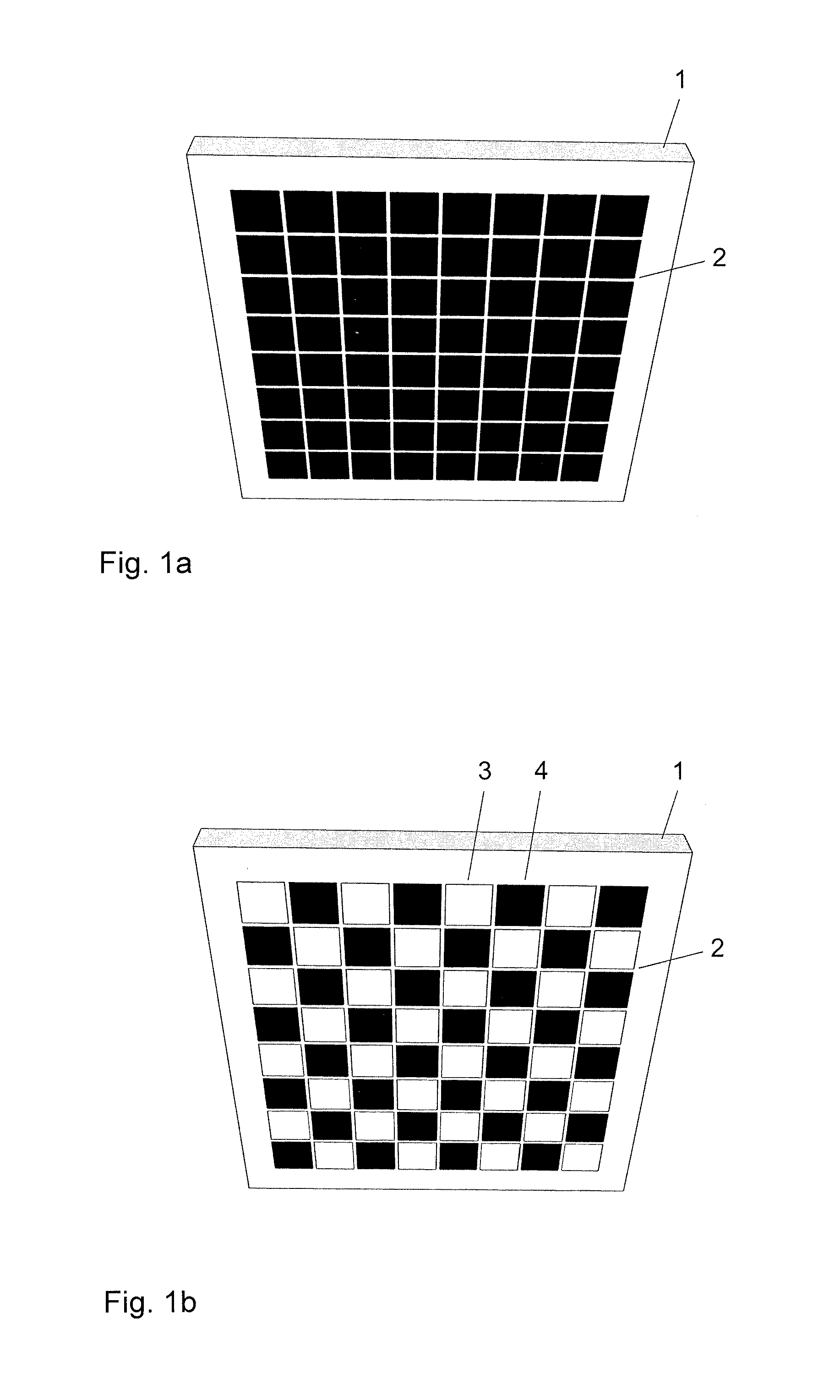

Fast generation of elements with individually patterned anisotropy

ActiveUS20150109597A1Rapid productionOptical articlesPhotomechanical exposure apparatusPolarization planeAnisotropy

Owner:ROLIC AG

Printed lenticules for lenticular printing

Owner:XEROX CORP

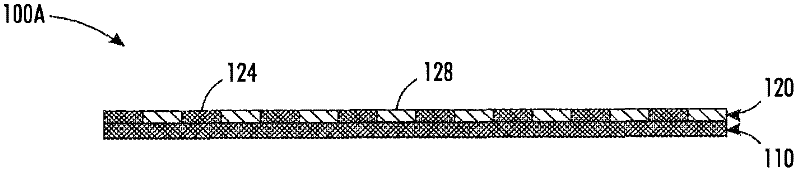

Smoothing of 3D printed lenses

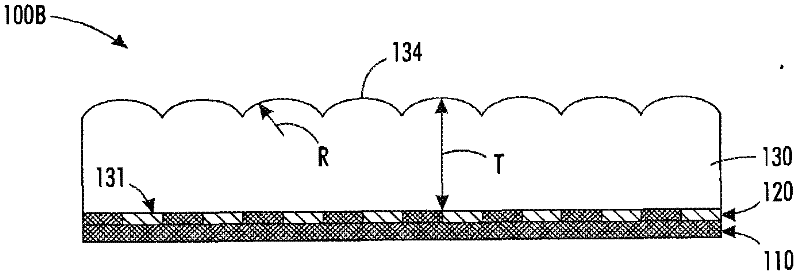

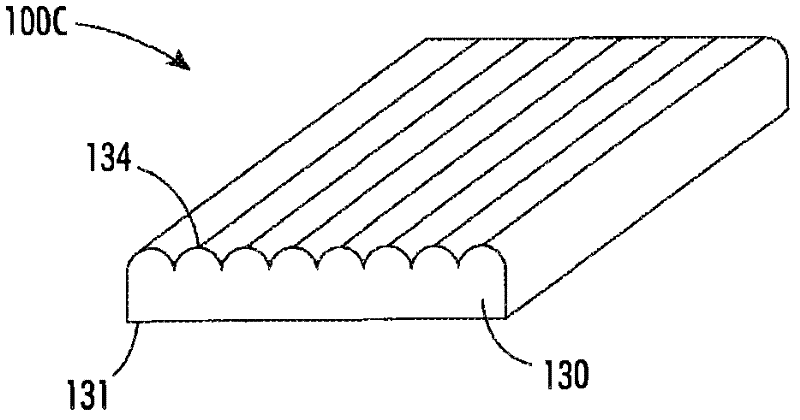

ActiveUS20170100903A1Improved additive processSimple processAdditive manufacturing apparatusOptical articlesPolymer sciencePolymer coatings

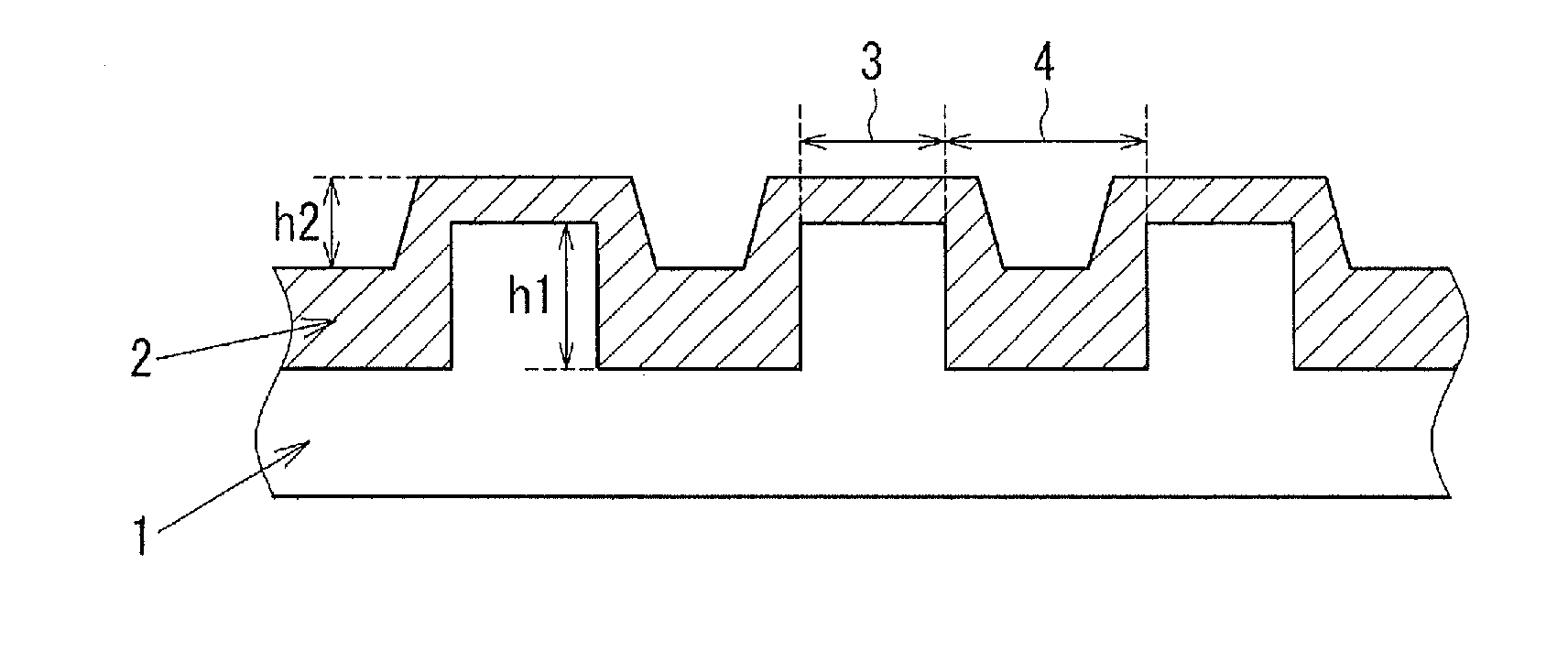

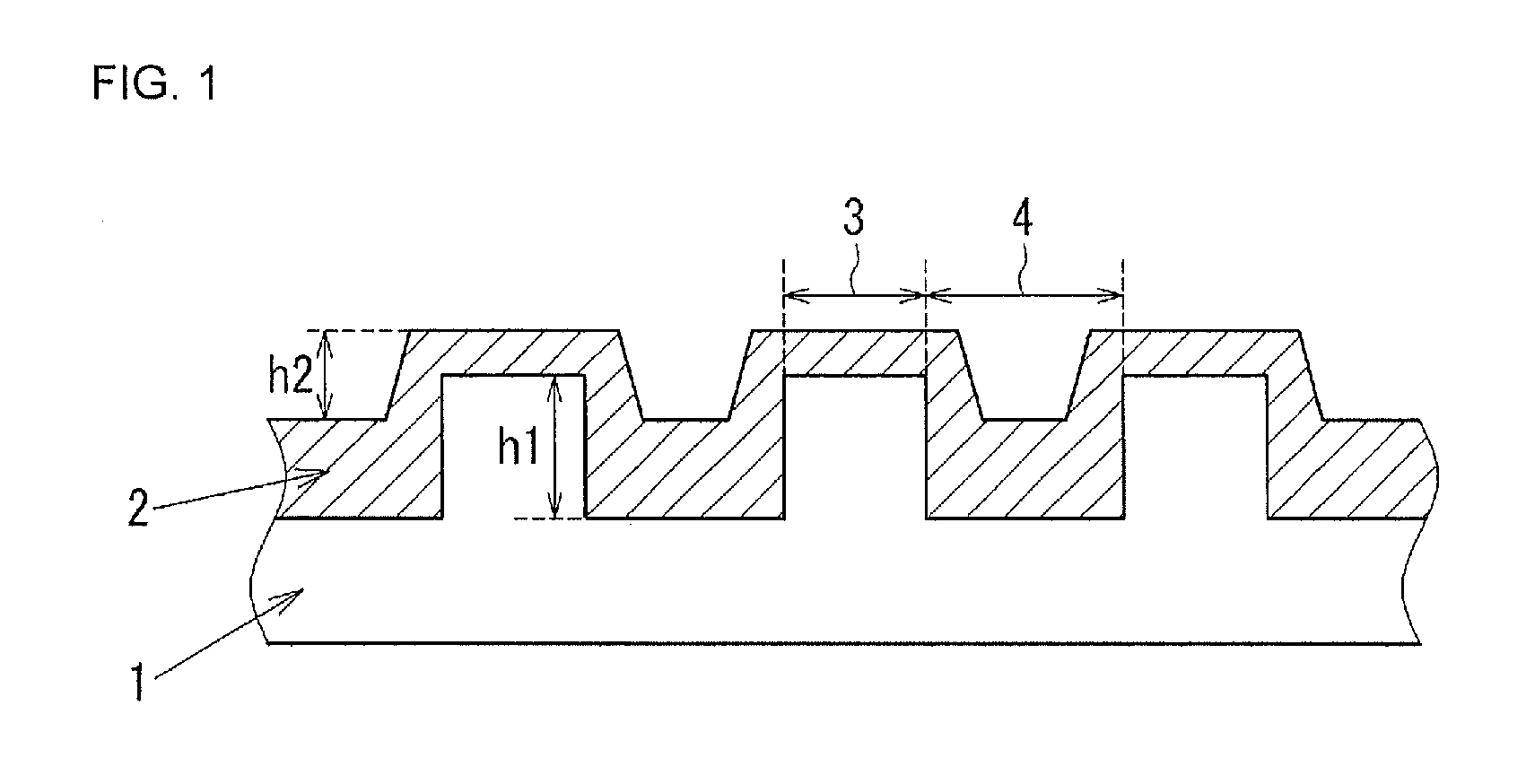

Systems and methods for smoothing a lens are disclosed herein. A monomer used to make or augment the lens according to an additive method is deposited on the lens surface to be smoothed. A film or membrane with certain elastic properties is pressed against the layered (stepped) surface, with the monomer in between the lens and the membrane. The pressure of the membrane spreads the monomer over the surface of the lens, filling the spaces between the layered (stepped) surface and the membrane. A curing agent is applied to transition the monomer into a polymer coating matching the curve of the membrane. The membrane is removed, leaving a clean, smooth lens surface.

Owner:INDIZEN OPTICAL TECH OF AMERICA LLC

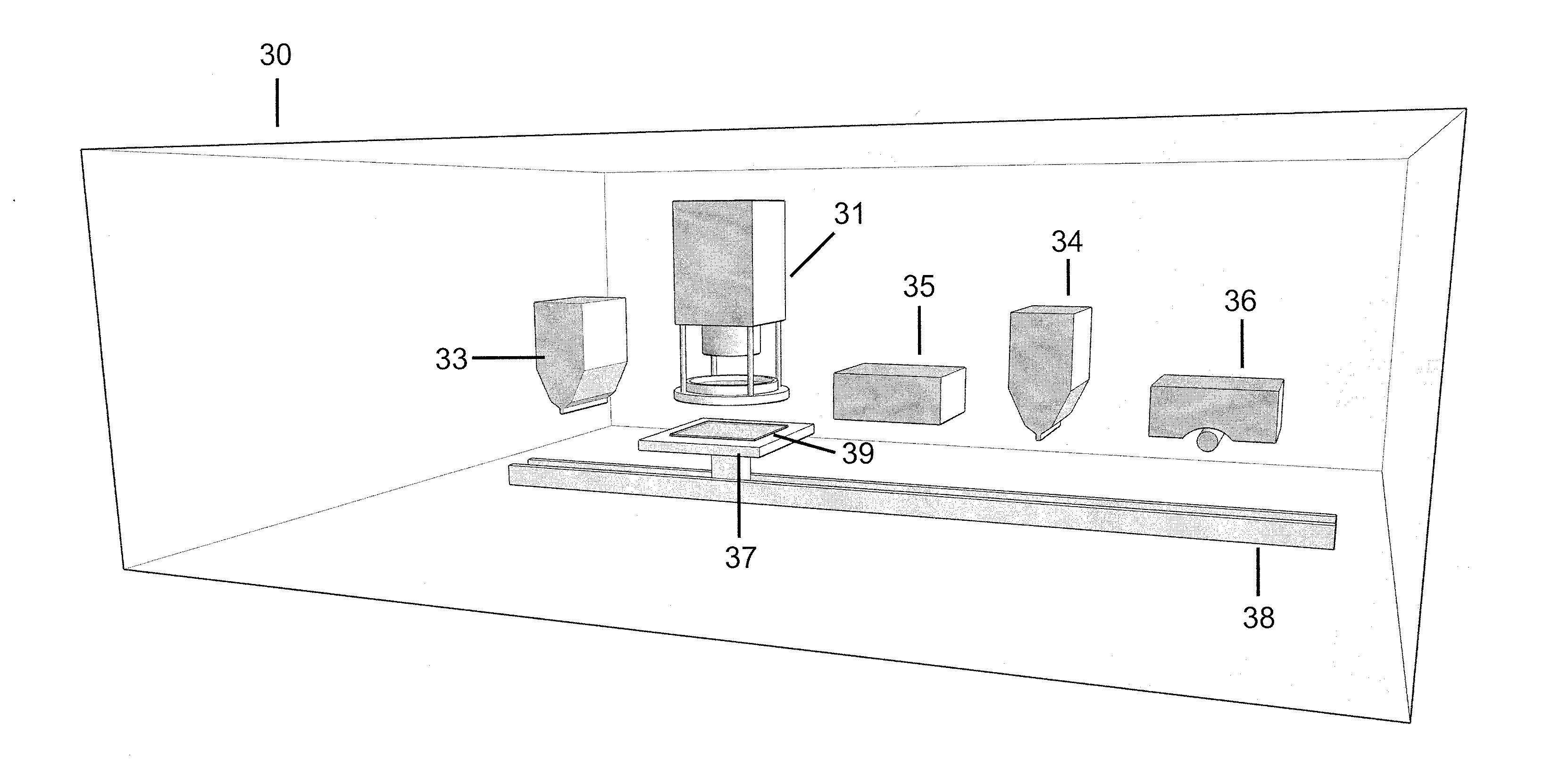

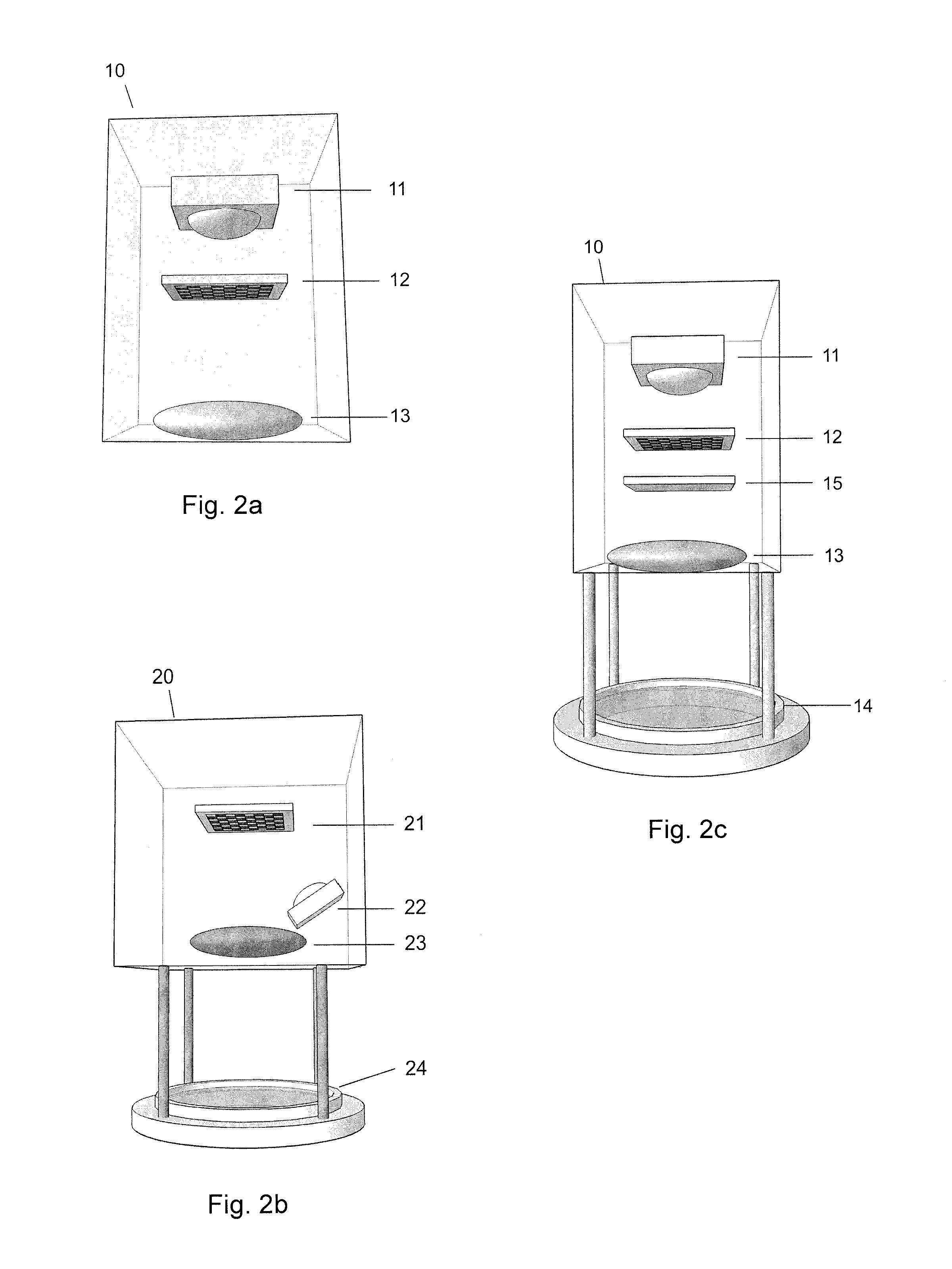

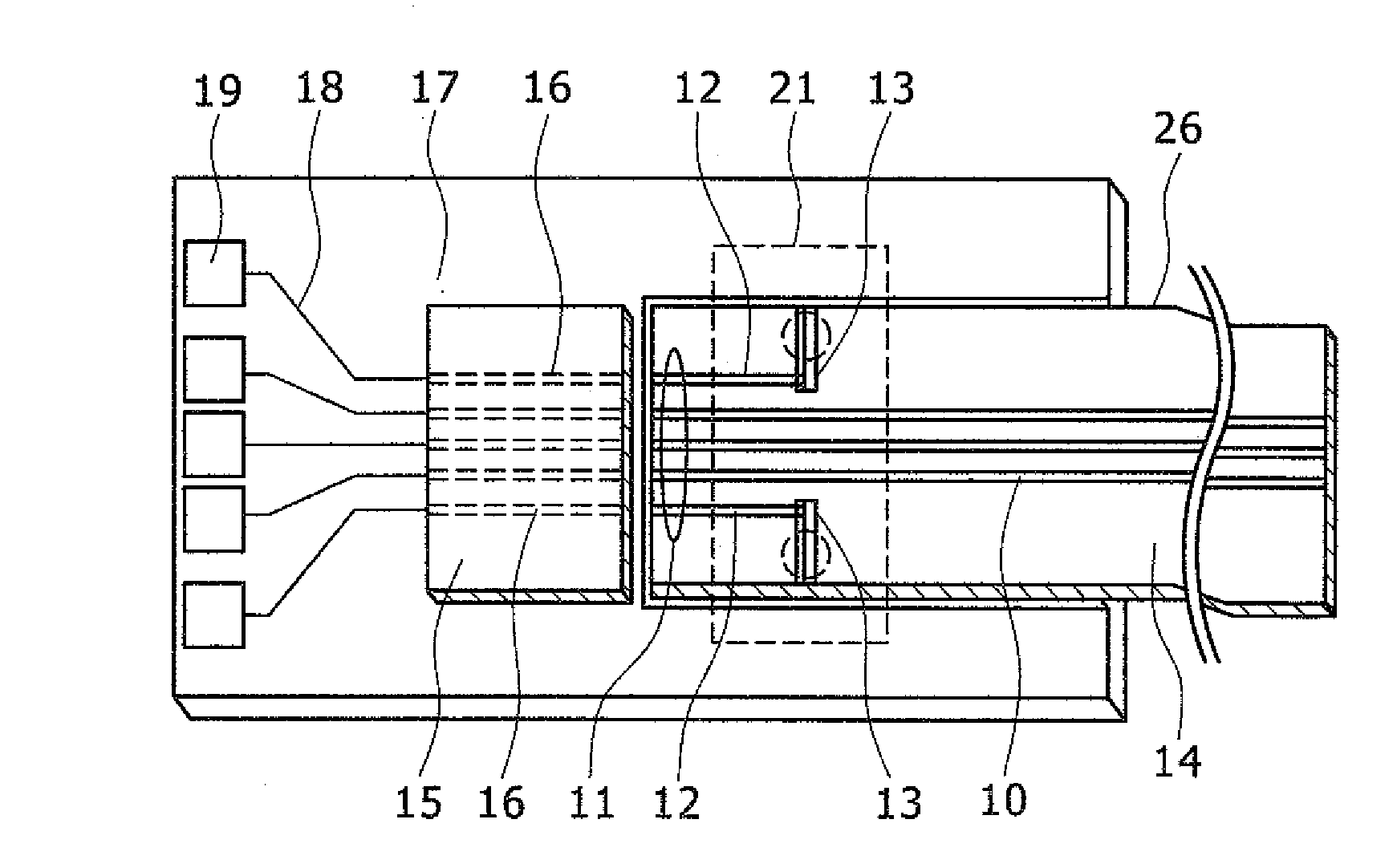

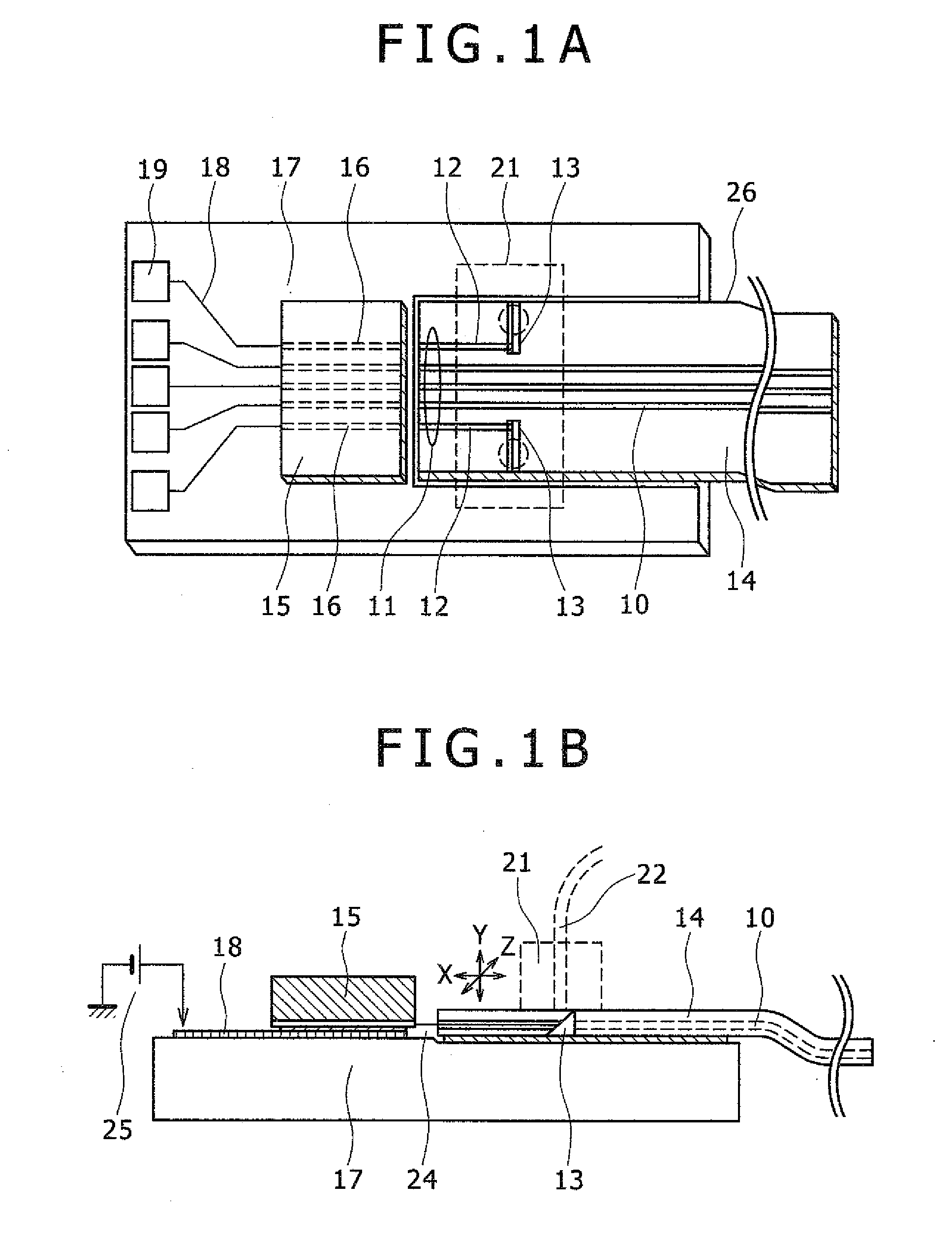

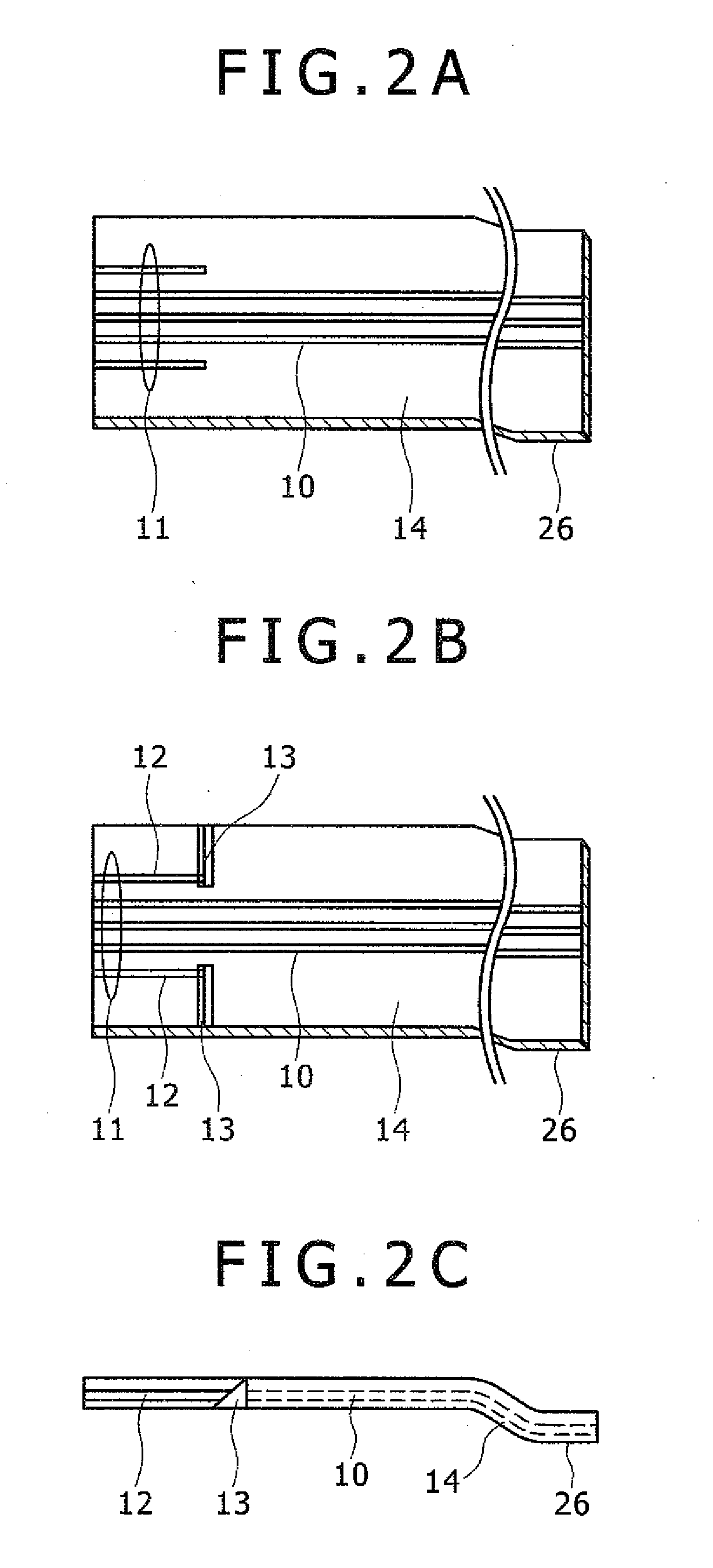

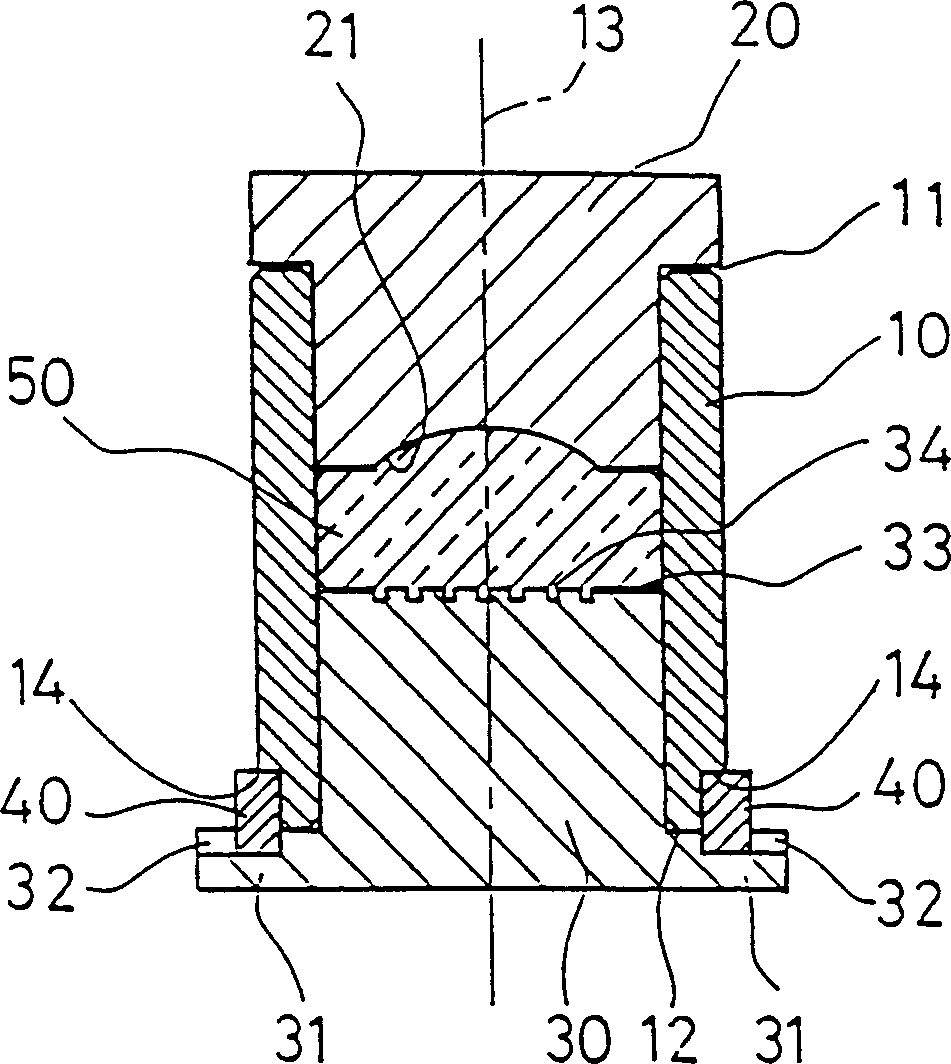

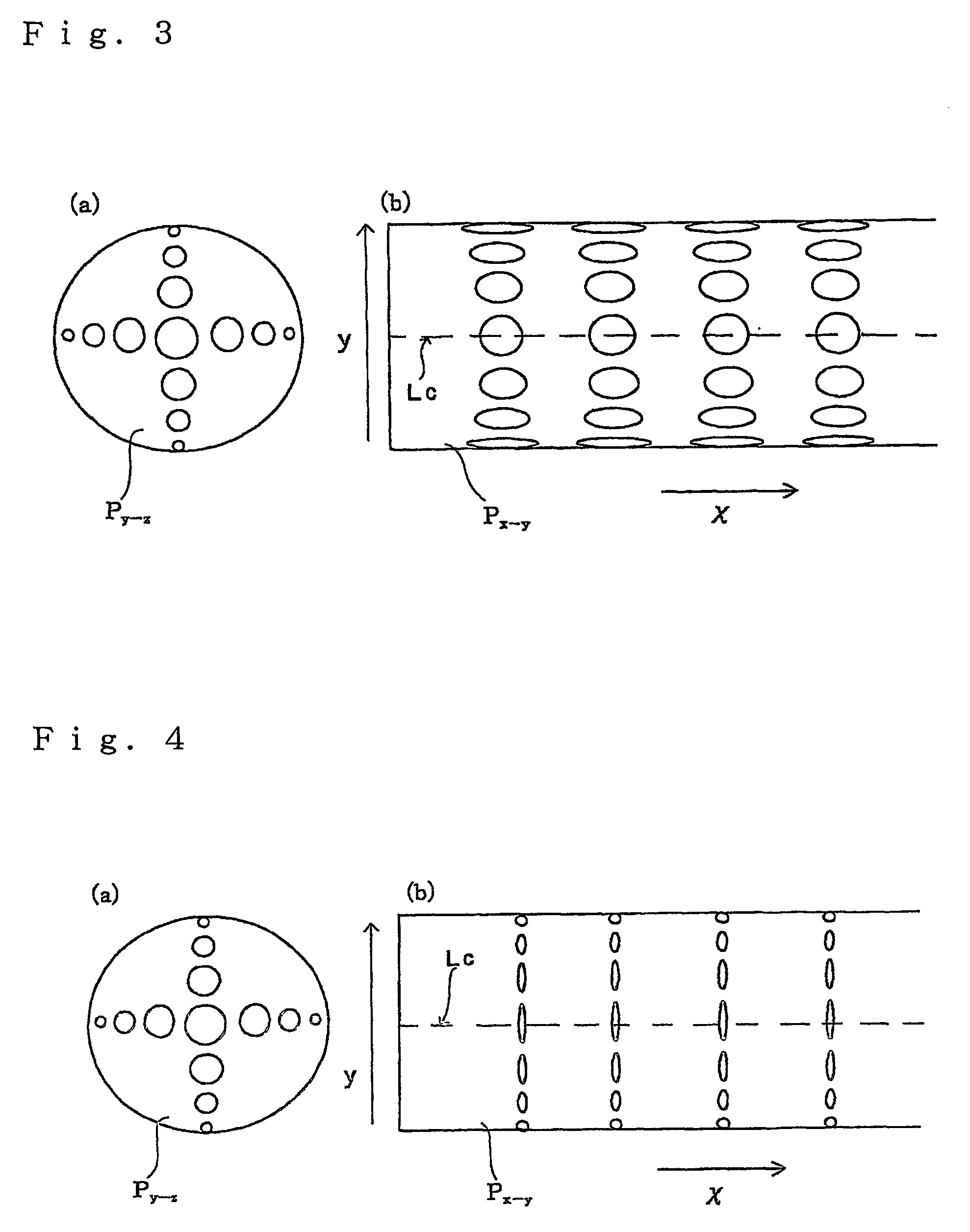

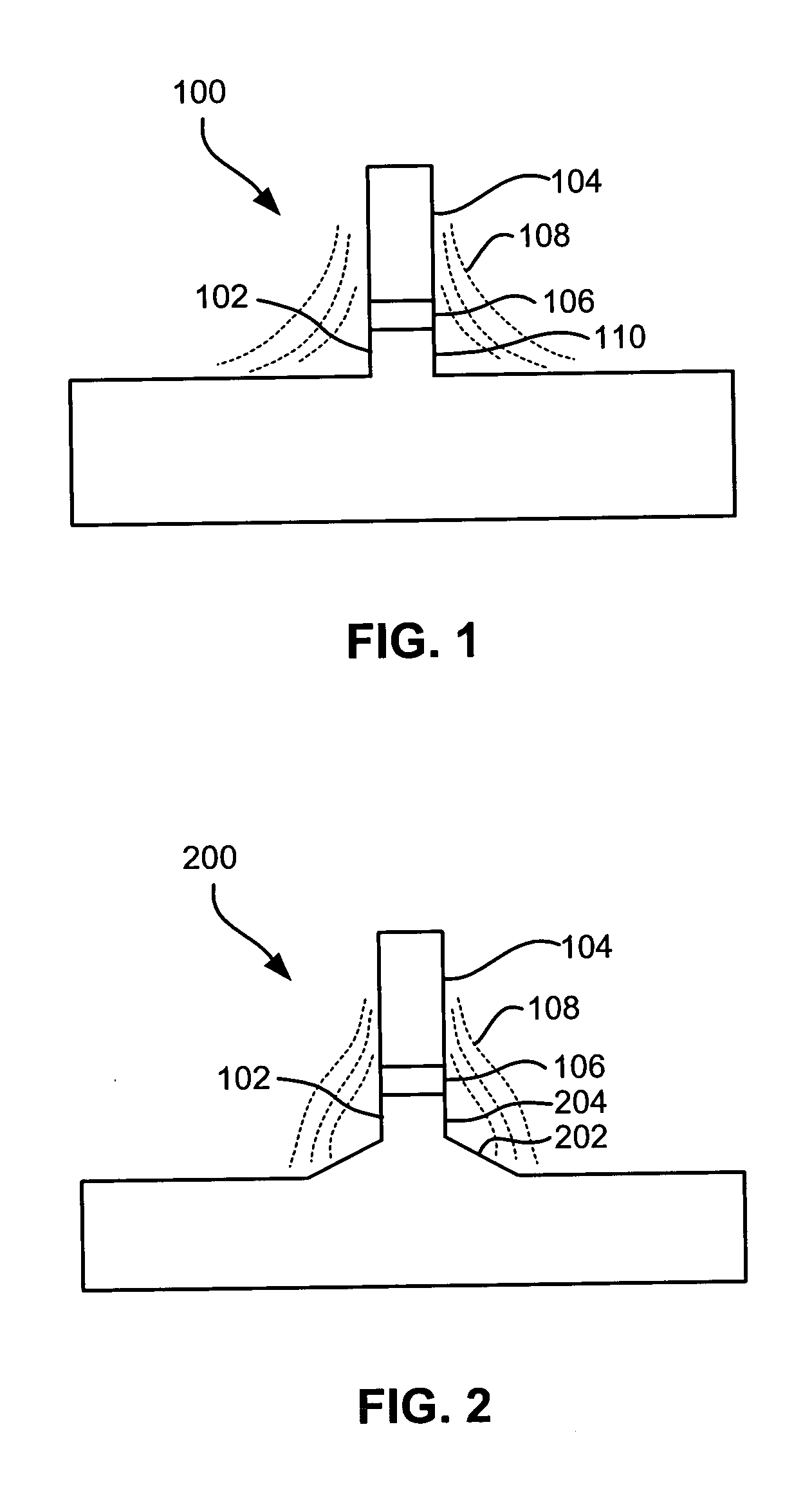

Planar optical waveguide array module and method of fabricating the same

InactiveUS20090297095A1Effective connectionMounted with easeOptical articlesCoupling light guidesWaveguide channelPlanar optical waveguide

The optical element array and an optical waveguide array are optically connected on the substrate. The optical waveguide array includes optical waveguide channels which are the outermost optical waveguide channels on both sides of optical waveguide array channels and each of which is provided with a mirror structure for light redirection. With the optical element array driven by a bias applied thereto, the optical waveguide array is brought near the optical element array. The optical axes of the optical waveguide array channels and the optical element array are aligned while monitoring optical signals outputted from the outermost optical waveguide channels on both sides of the optical waveguide array channels via the mirror structures for light redirection. The optical waveguide array is fixed to the substrate in such a position that the optical signals have a desired output value.

Owner:HITACHI LTD

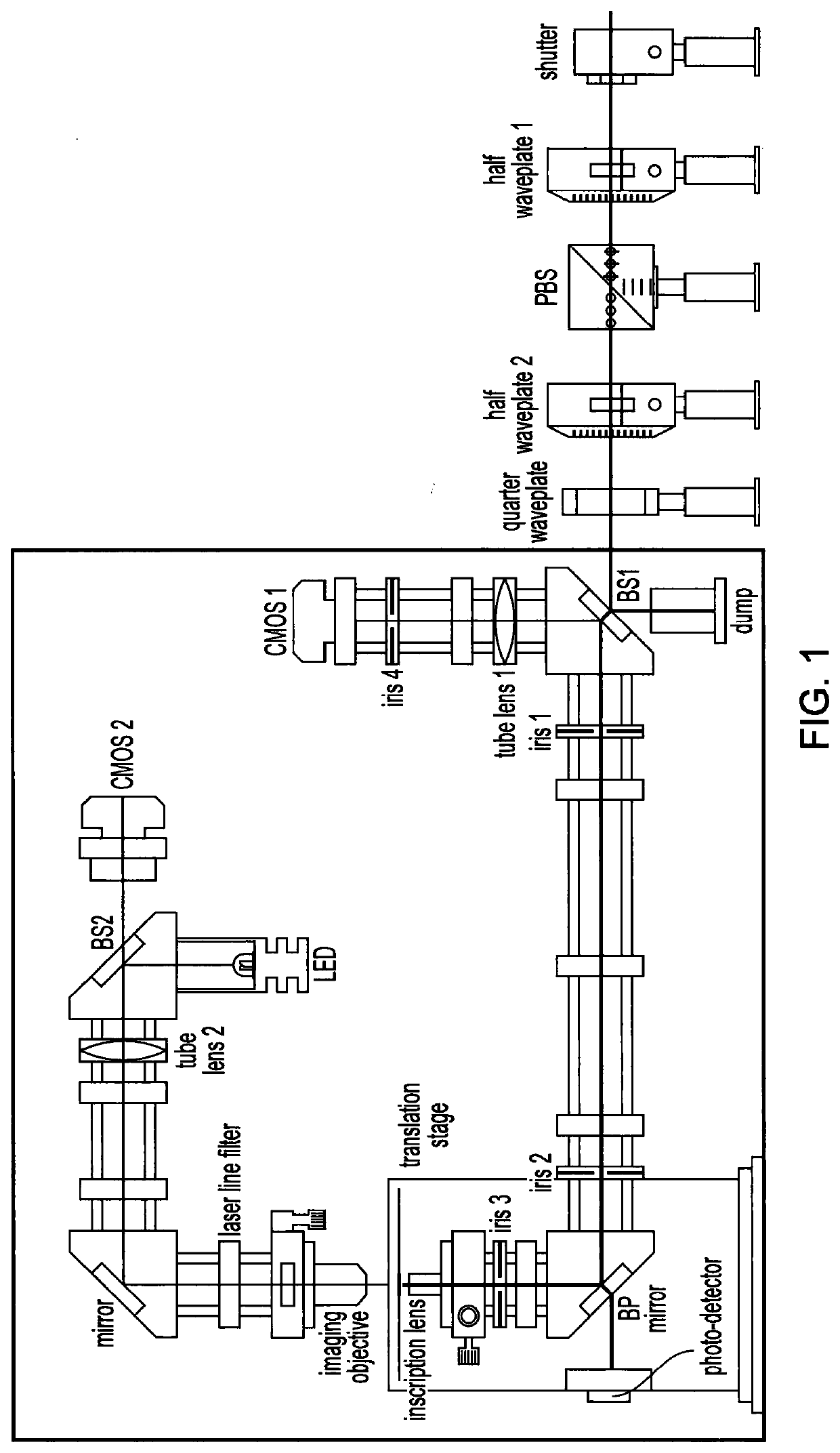

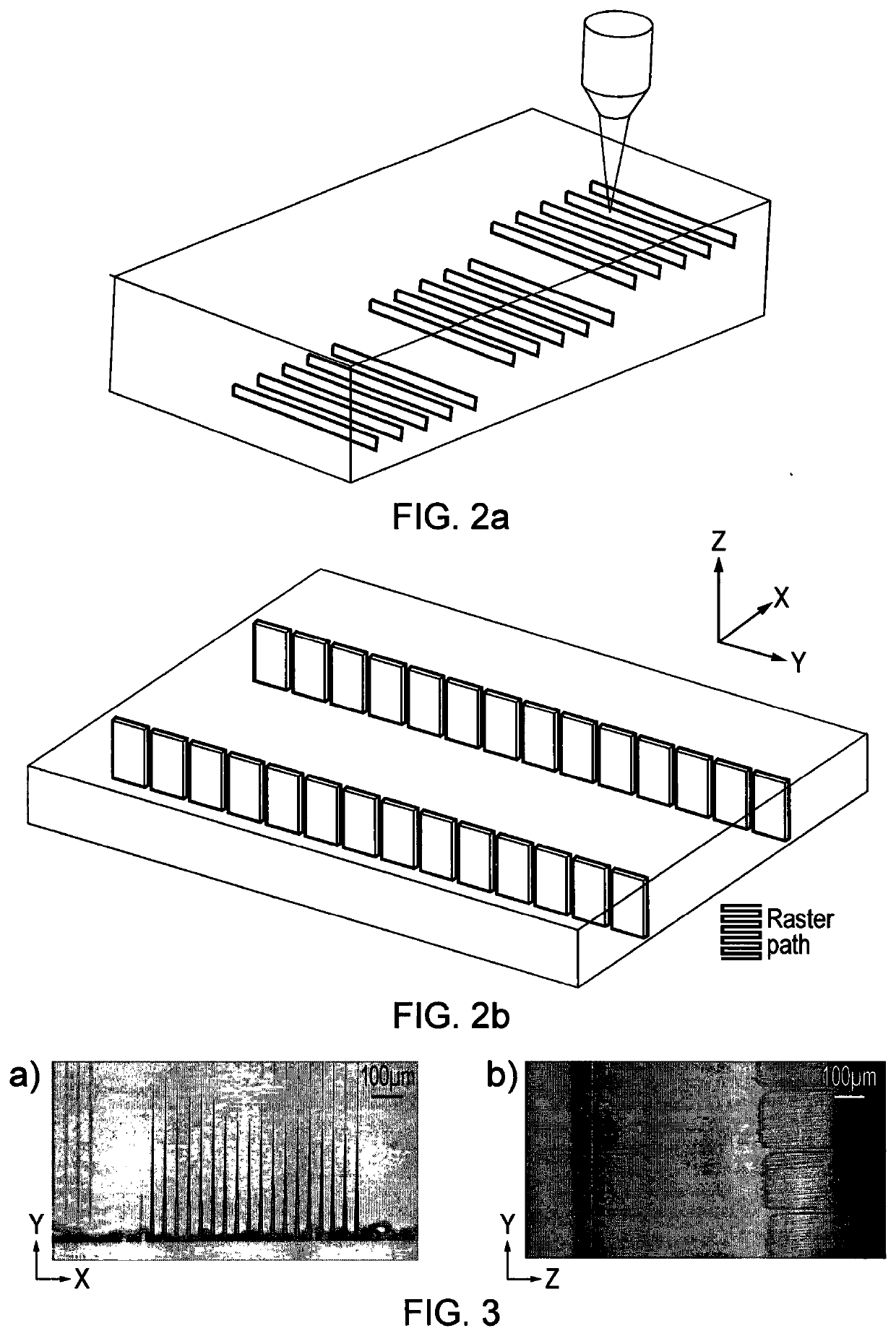

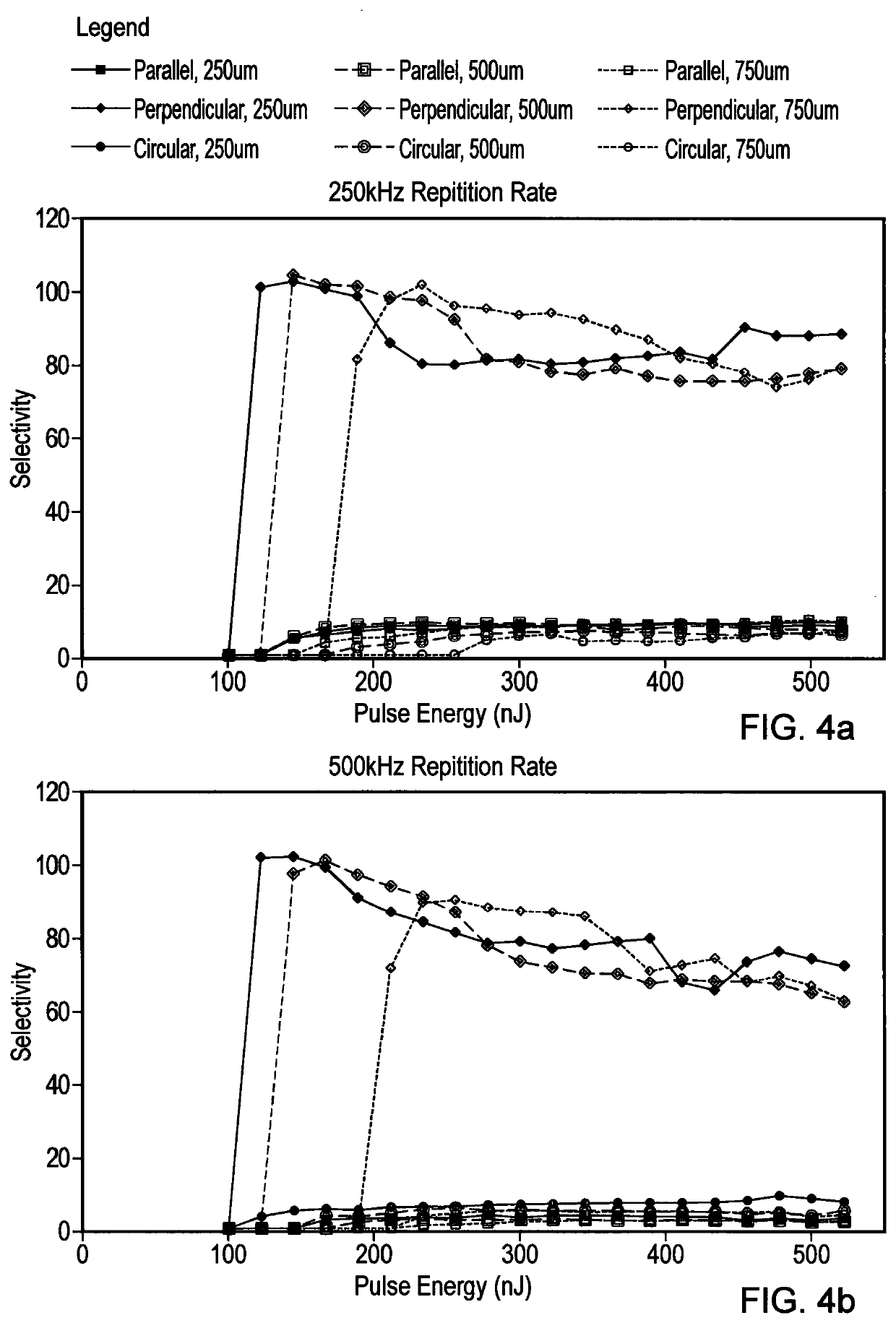

Direct laser writing and chemical etching and optical devices

ActiveUS20190361174A1Increase the area ratioSimplify polishingOptical articlesEndoscopesPhysicsEtching

Owner:HEROIT WATT UNIV

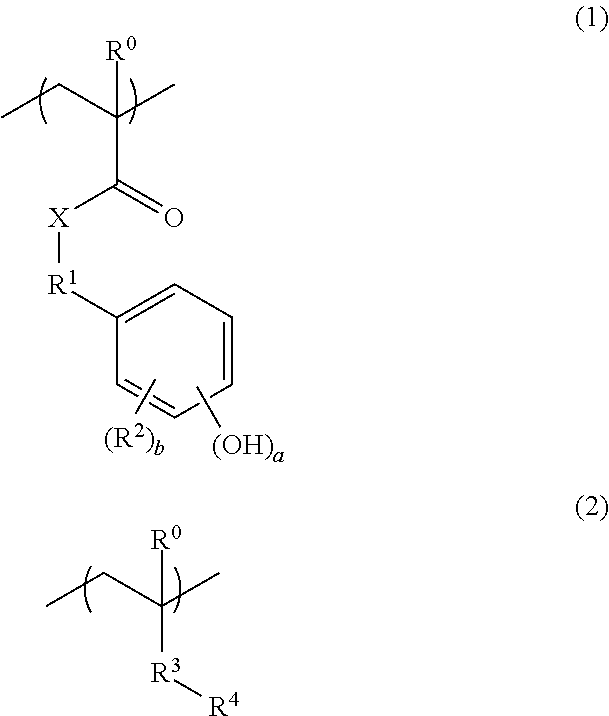

Process for production of water-soluble (meth)acrylic polymers, water-soluble (meth)acrylic polymers, and use thereof

InactiveUS7230061B2Avoid bumpingInhibiting other uncontrollable anomalous reactionSurgical adhesivesOptical articlesMeth-Ultraviolet

Owner:NIPPON SHOKUBAI CO LTD

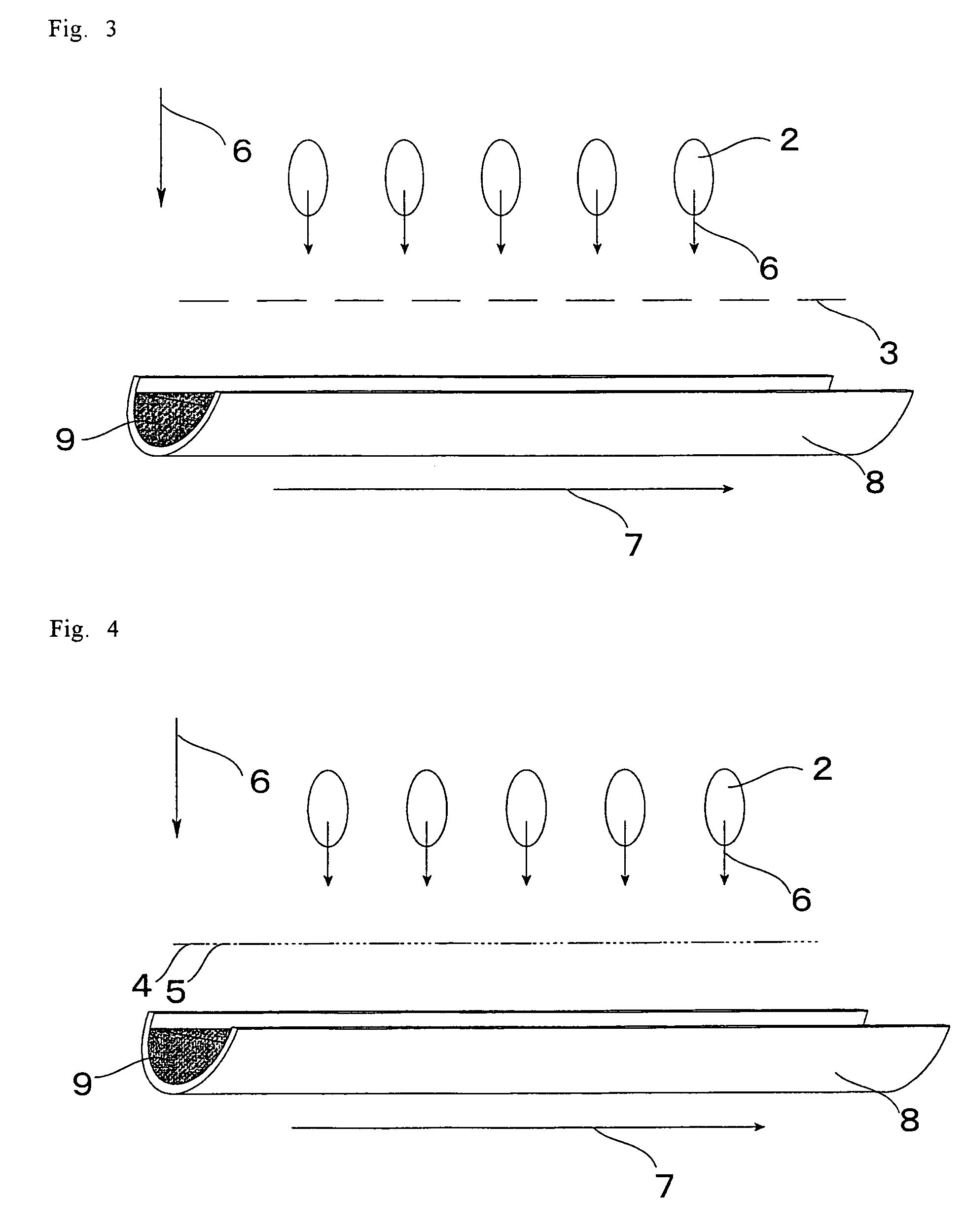

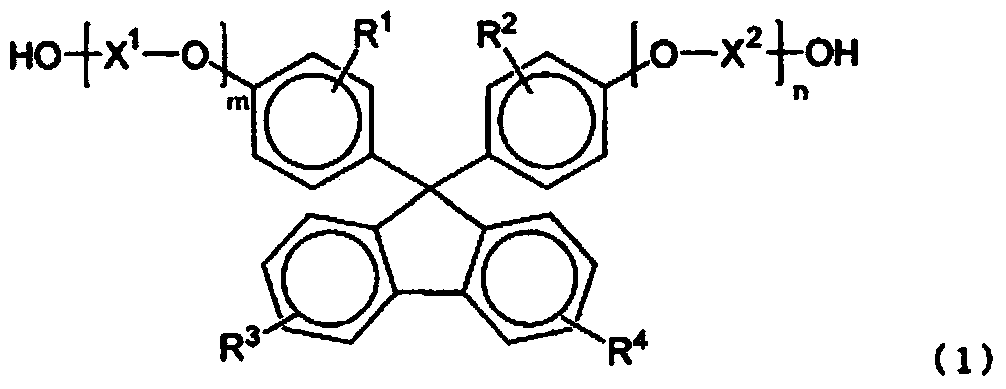

Wire grid polarizer, display device including the same, and method of fabricating the wire grid polarizer

Owner:SAMSUNG DISPLAY CO LTD

Process for produicng stamper for direct mastering, and stamper produced by such process and optical disc

InactiveUS20060290018A1Increased durabilityWeaken energyOptical articlesRecord information storageEngineeringInjection molding machine

In producing a stamper for molding an optical disc, a master disc which can be obtained from the steps of forming a thermosensitive material layer capable of acting as a negative type by a laser beam on a substrate, irradiating a laser beam to predetermined areas of the thermosensitive material layer so as to partially perform exposure and wet-etching the partially exposed thermosensitive material layer so as to form a fine pits-and-bumps pattern is used as a stamper for injection molding machine. Therefore, minute pits each having a size smaller than the spot of the laser beam of optical limit are formed, thereby providing a stamper with the small number of deficiencies.

Owner:PANASONIC CORP

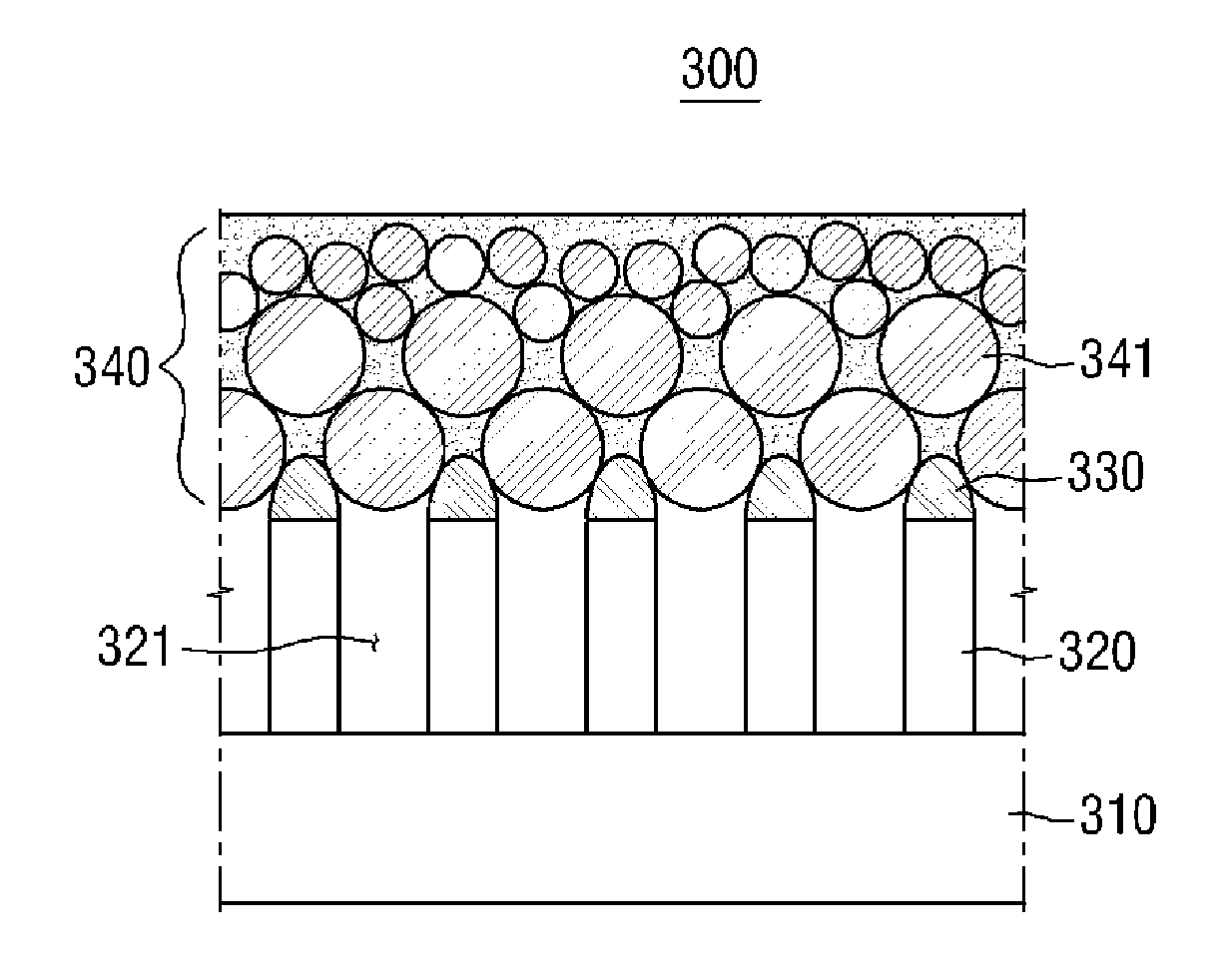

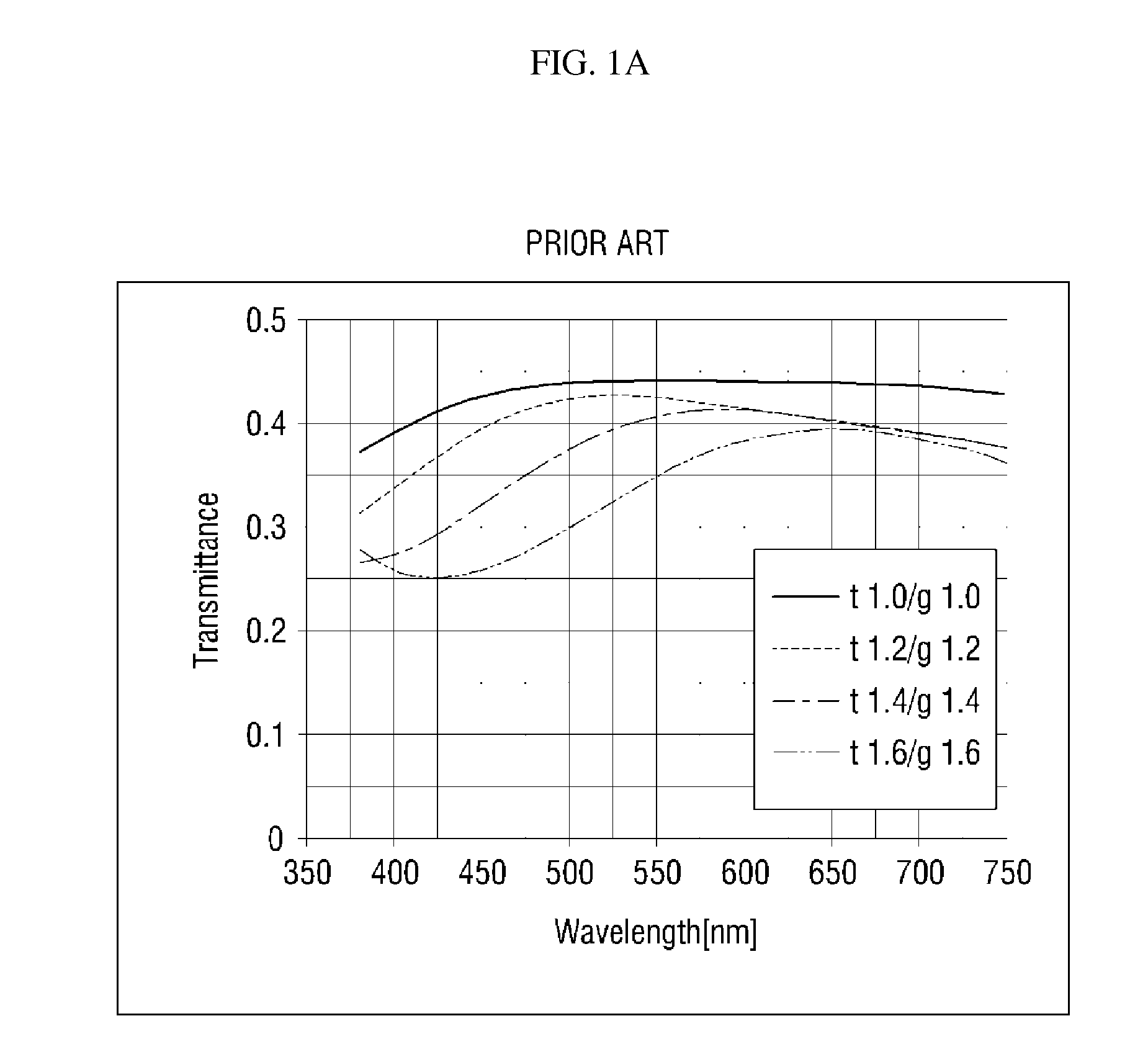

Phase difference film, circularly polarizing plate using same, and image display device

ActiveCN104067151AReduce loadNot prone to decolorizationSolid-state devicesElectroluminescent light sourcesColor shiftPhase difference

Owner:MITSUBISHI RAYON CO LTD +1

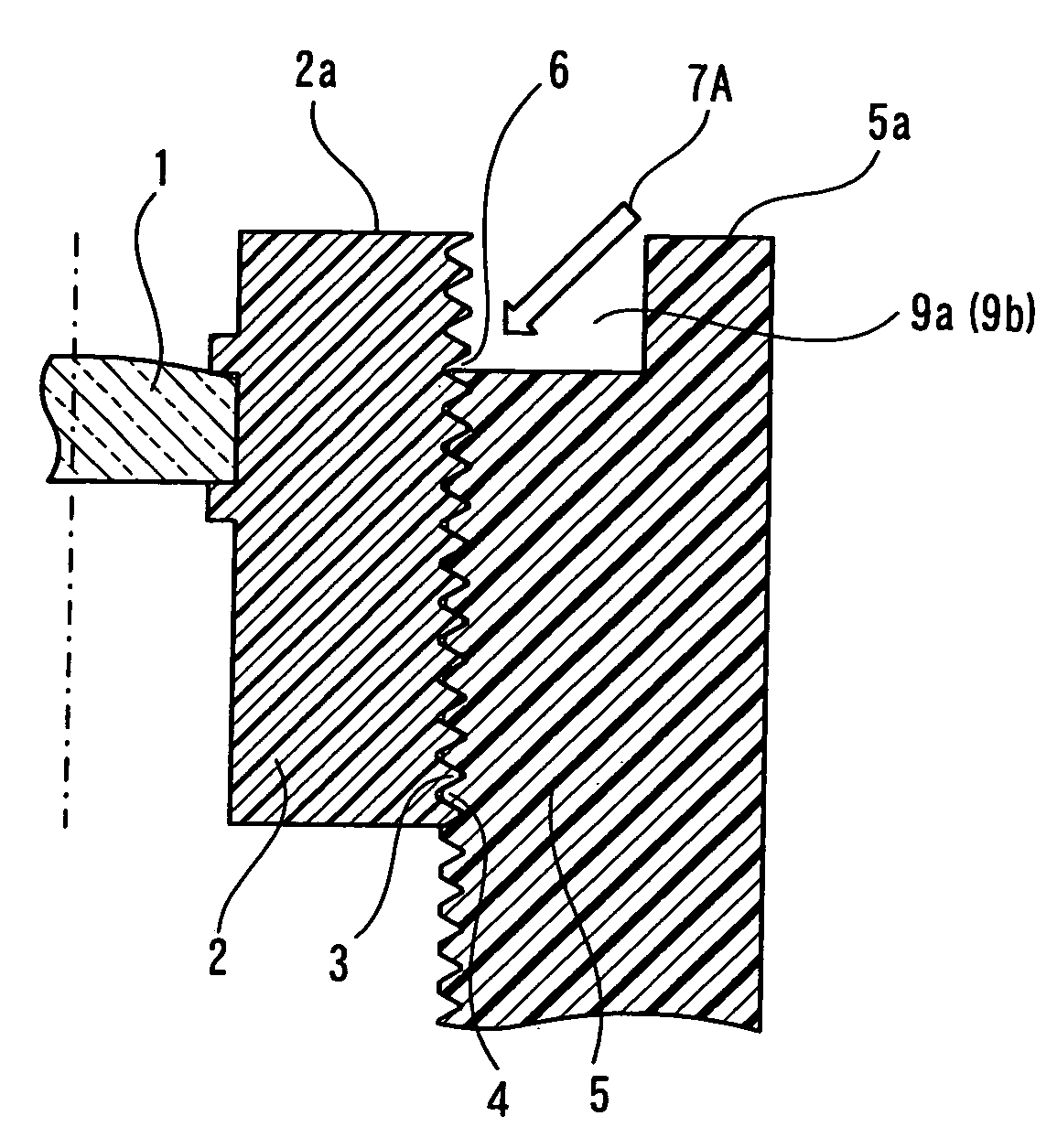

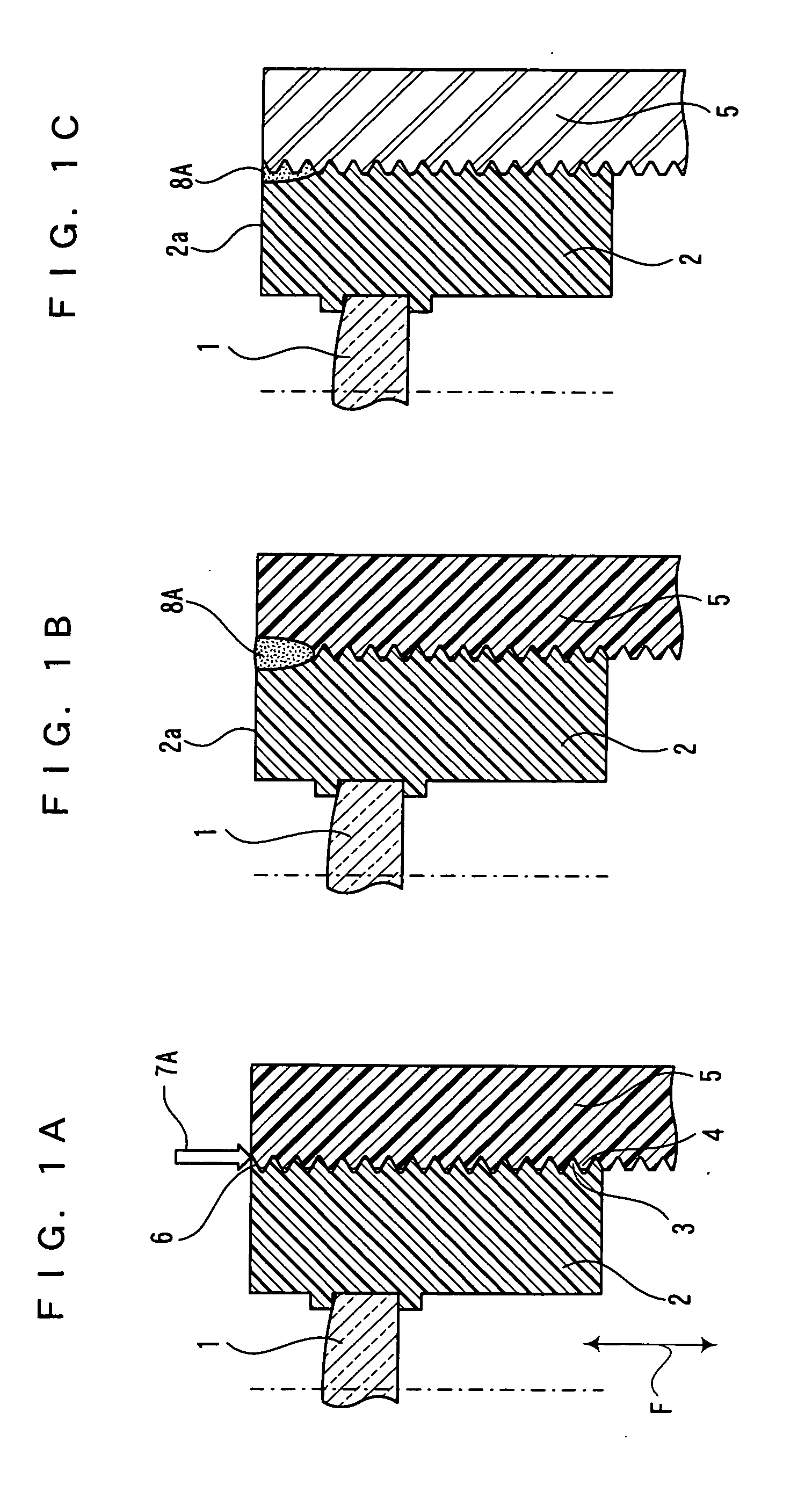

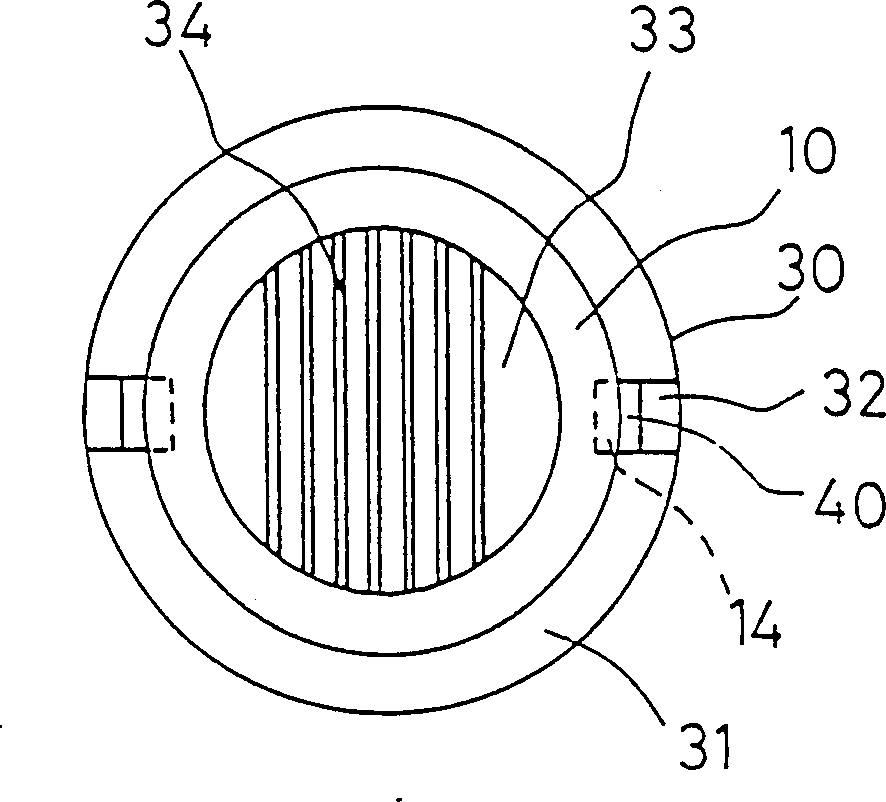

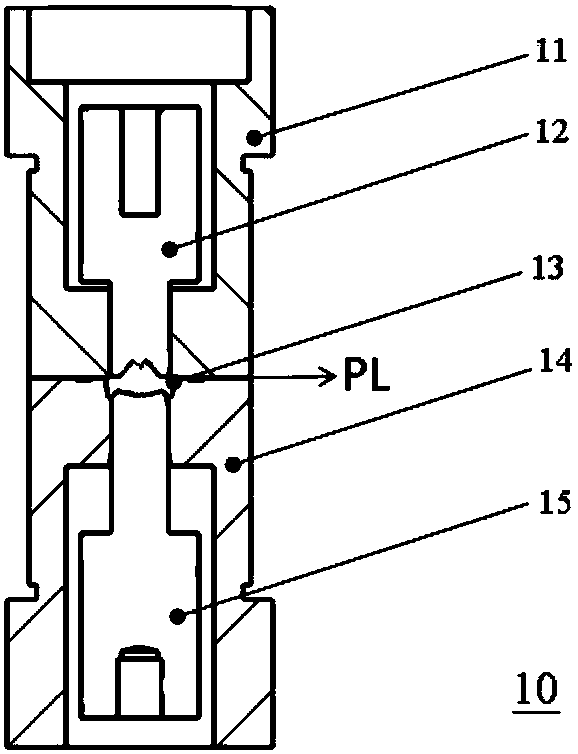

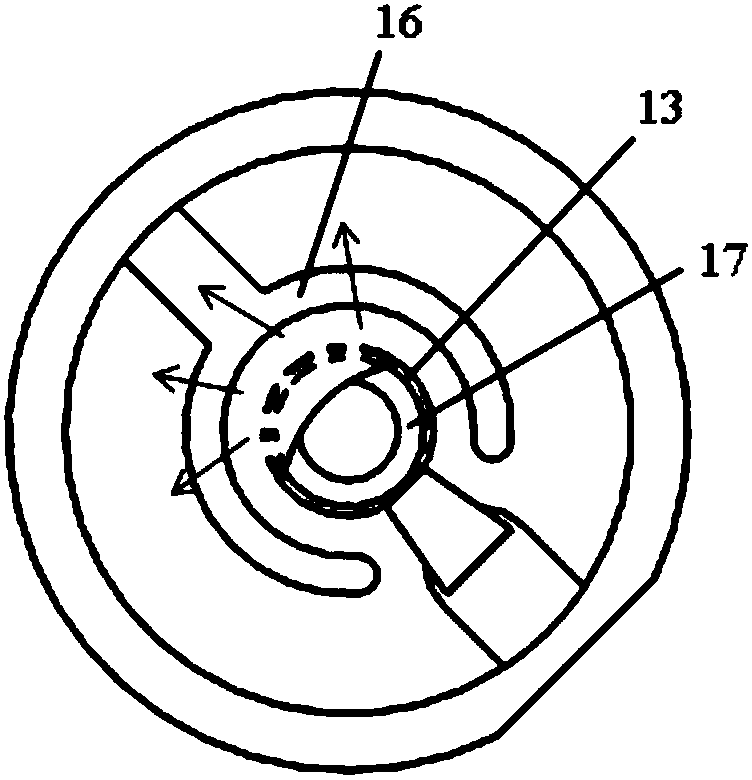

Optical element, optical-element formation mould and method thereof

InactiveCN1405104AOptical performance degradationPrevent rotationPrismsOptical articlesGratingOptical instrument

Owner:PANASONIC CORP

Curved lenses configued to decode three-dimensional content

Owner:SCHLUMBERGER TECH CORP

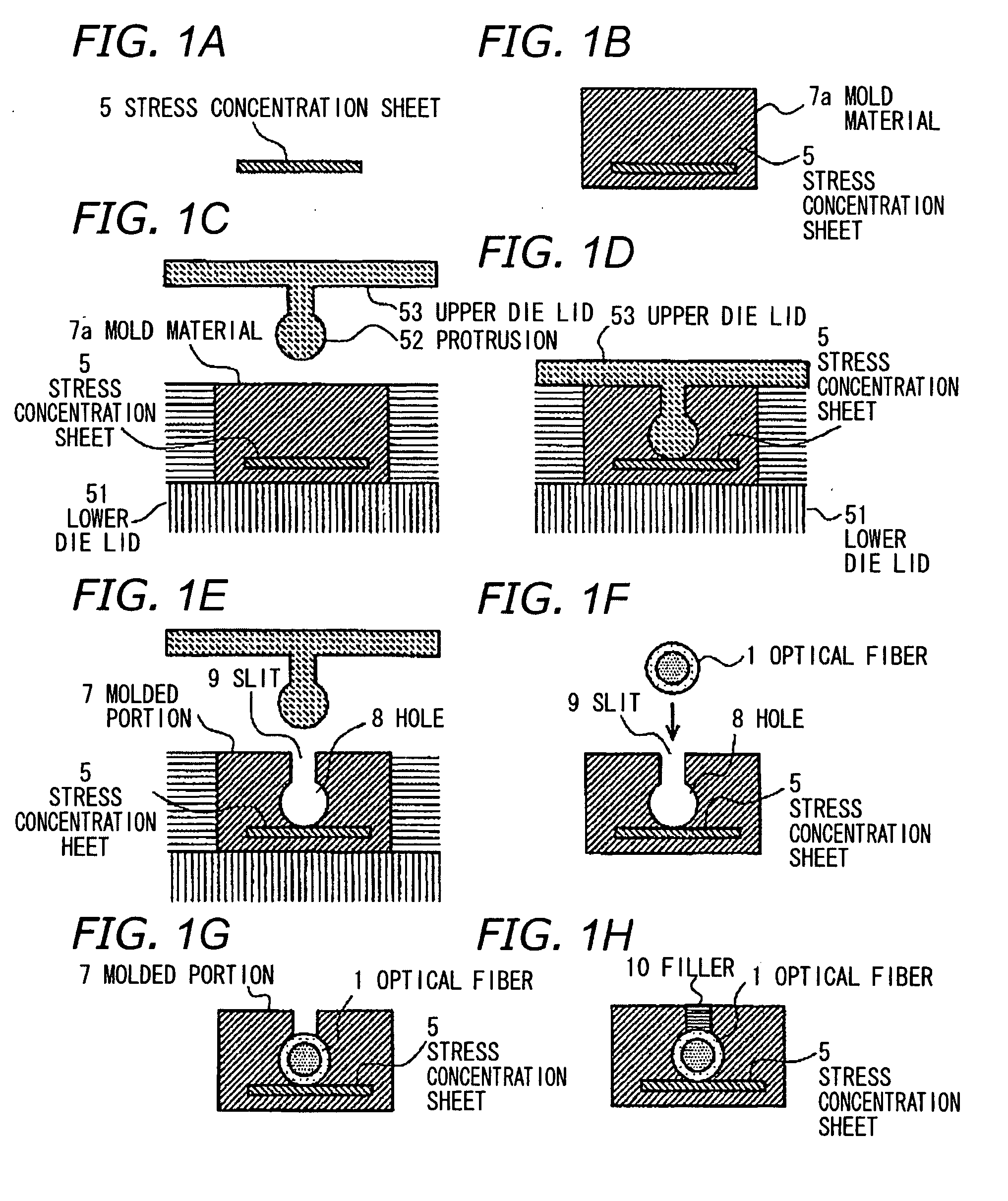

Optical fiber impulse sensor fabricating method

Owner:HITACHI CABLE +1

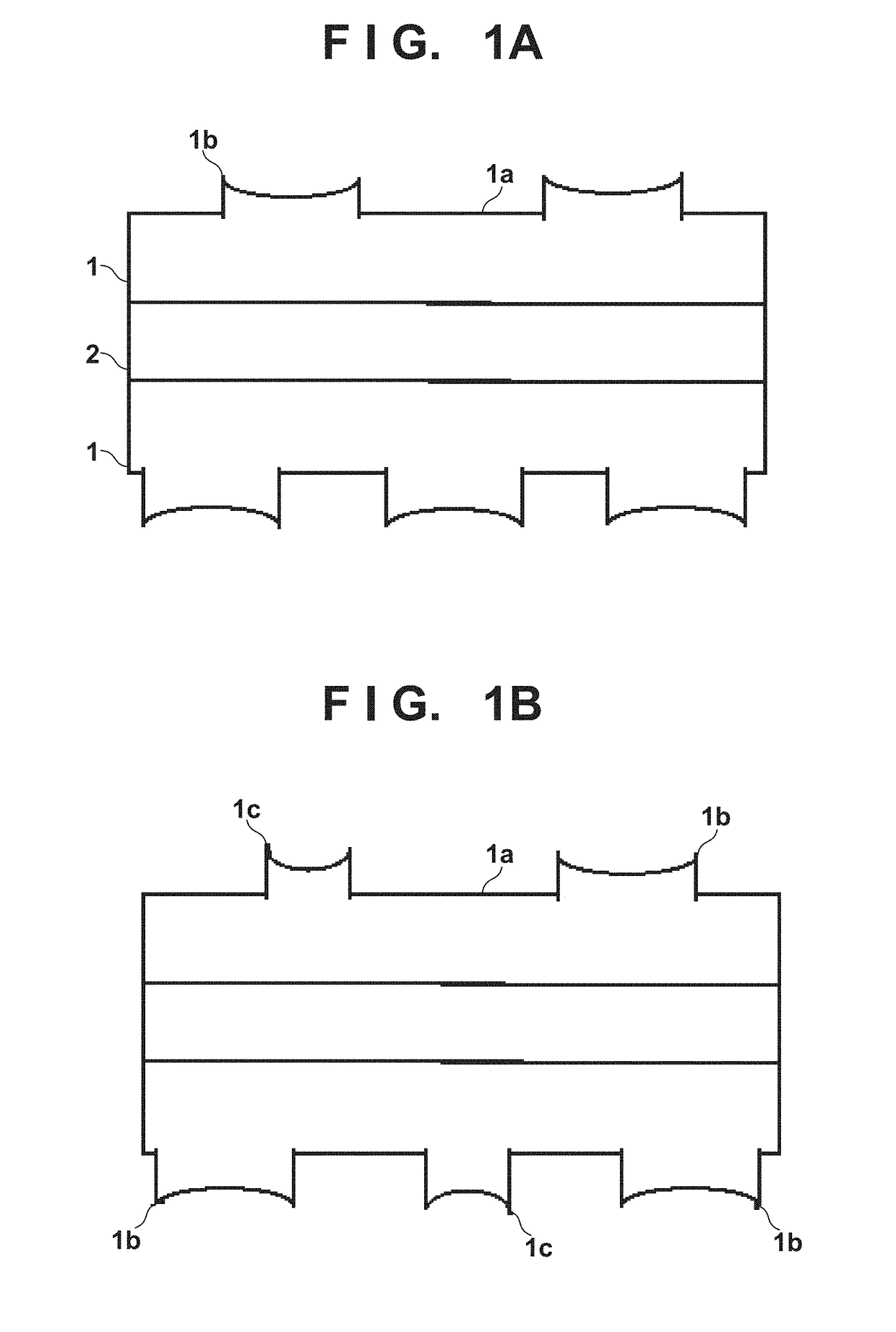

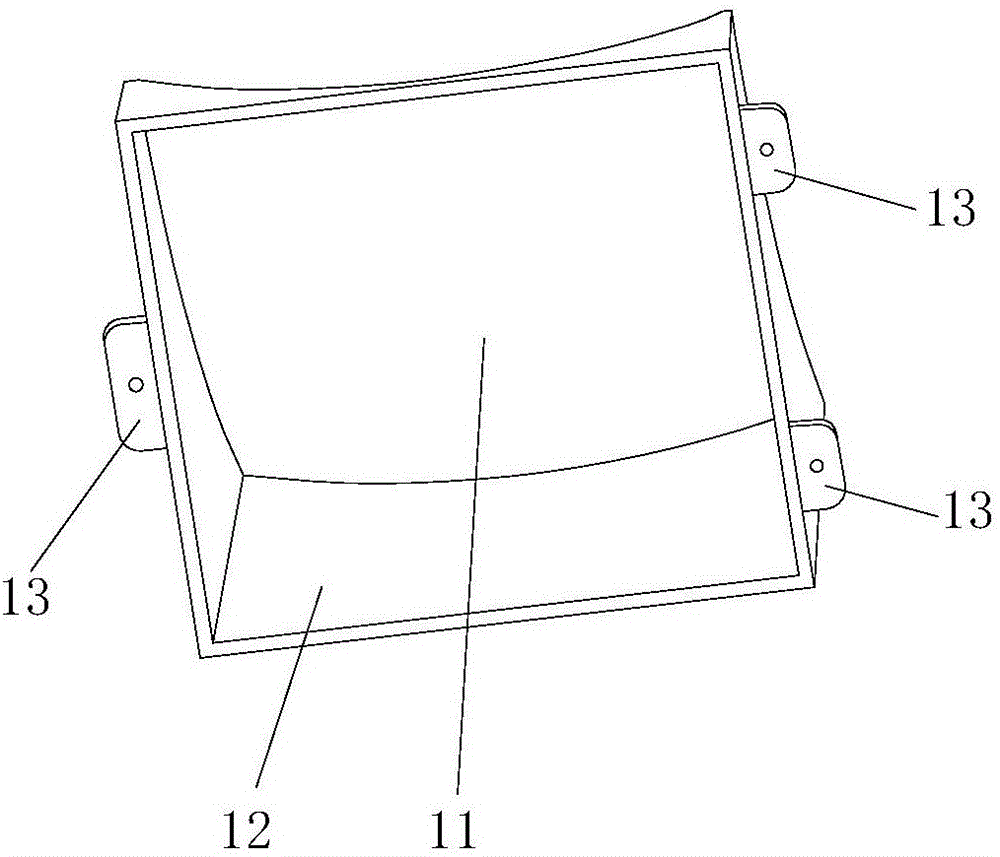

Fiber reinforced laminate, shutter device and optical apparatus

Owner:CANON DENSHI KK

Non-photosensitive resin composition

ActiveUS20150338556A1Good chemical resistanceImprove heat resistanceOptical filtersOptical articlesEpoxyOrganic group

Owner:NISSAN CHEM IND LTD

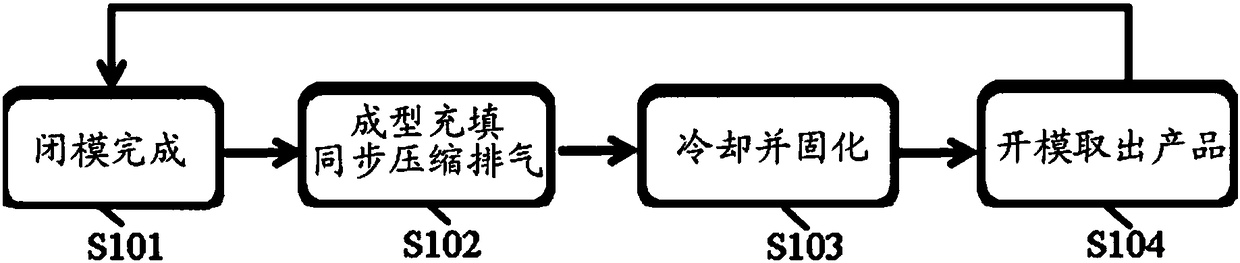

Injection molding hyperboloid reflector and injection molding method thereof

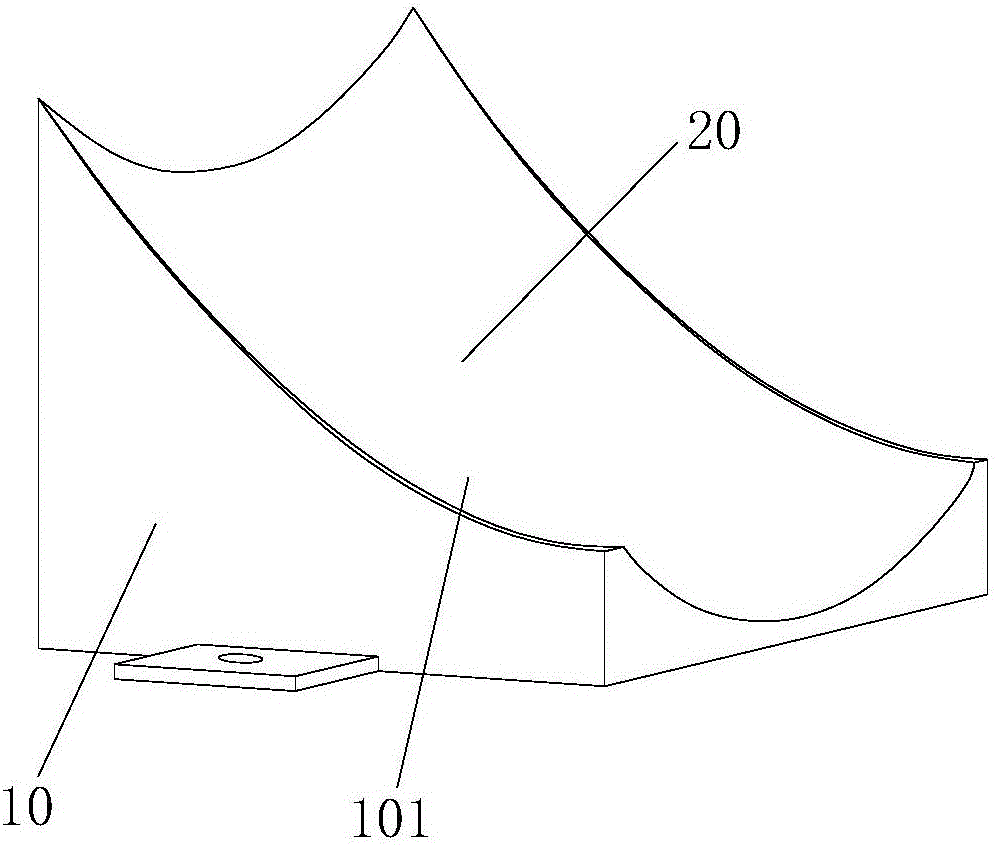

InactiveCN106094078AGood formabilityEasy to installMirrorsOptical articlesInjection molding processConcave surface

The invention provides an injection molding hyperboloid reflector and an injection molding method thereof. The injection molding hyperboloid reflector comprises a pedestal which is obtained by employing an injection molding process and provided with a hyperboloid concave surface, and a reflecting layer connected to the concave surface. The pedestal is integrated through injection molding; the reflecting layer is connected to the pedestal concave surface through the vacuum coating technology. The pedestal which is obtained through injection molding and provided with a hyperboloid concave surface has sound moldability, is convenient to install and transport, and can better protect the reflecting layer in a transportation process. The pedestal preferably employs engineering plastics capable of injection molding, has great weatherability, is hard to deform, guarantees the service life of the hyperboloid reflector, and is light; meanwhile, the tolerance between the dimension of the hyperboloid concave surface of the hyperboloid reflector and the dimension of a theoretically calculated curved surface is small, and the hyperboloid concave surface is almost identical with a designed curved surface, has excellent light condensing effects, and can improve a light utilization rate. The injection molding method is simple to operate.

Owner:SHENZHEN ANGTEER SOLAR ENERGY INVESTMENT

Machine-learning-based quality prediction of manufactured fiber optic cable

According to an aspect, there is provided a method for monitoring quality of loose tube fiber optic cable during manufacture in a secondary coating line. Initially, a trained machine-learning algorithm for calculating expected values of one or more quality metrics of manufactured loose tube fiber optic cable based on values of the one or more production process parameters of the secondary coating line is maintained in a machine-learning database. A computing system monitors one or more values of the one or more production process parameters during miming of the secondary coating line and calculates, in real-time during the monitoring, one or more expected values of the one or more quality metrics using the trained machine-learning algorithm with the monitored values of the one or more production process parameters as input. The computing system outputs at least the one or more expected values of the one or more quality metrics to a user device.

Owner:MAILLEFER EXTRUSION

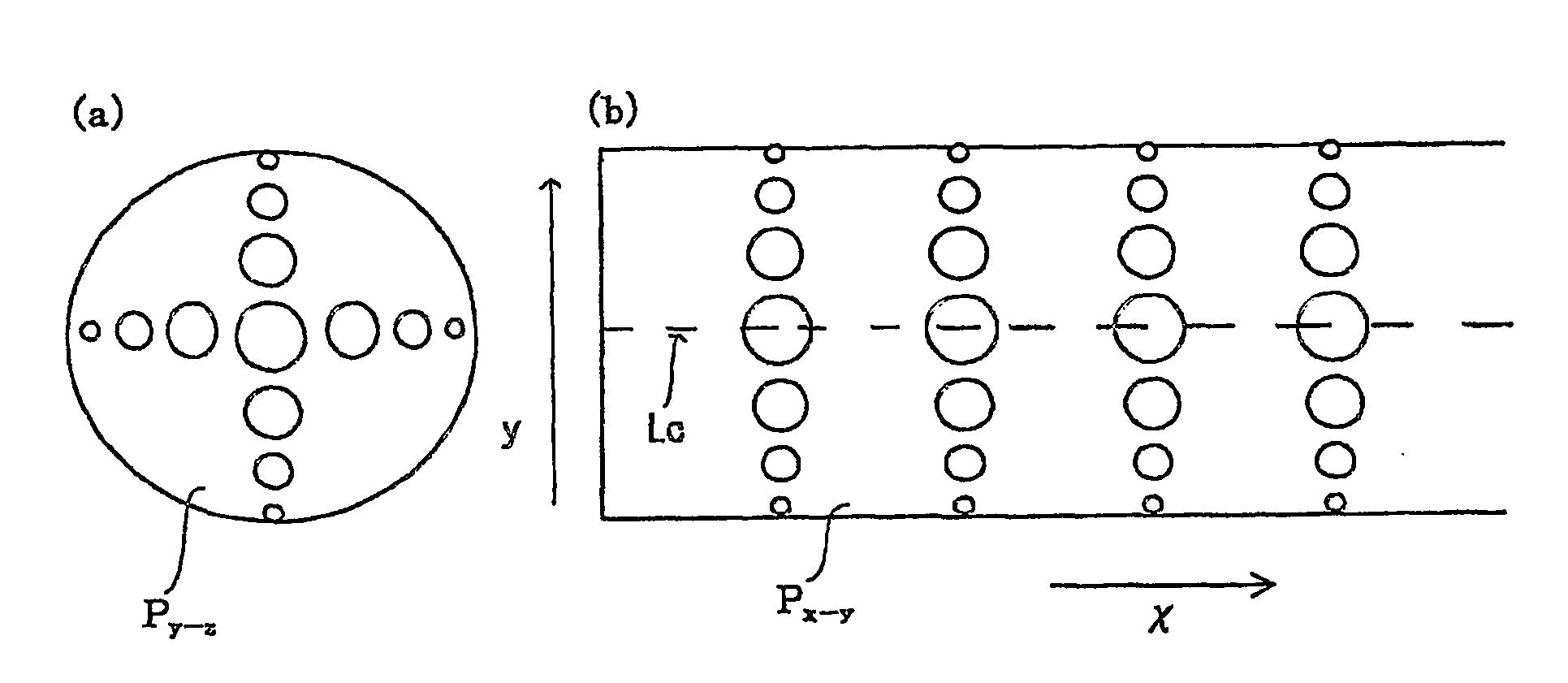

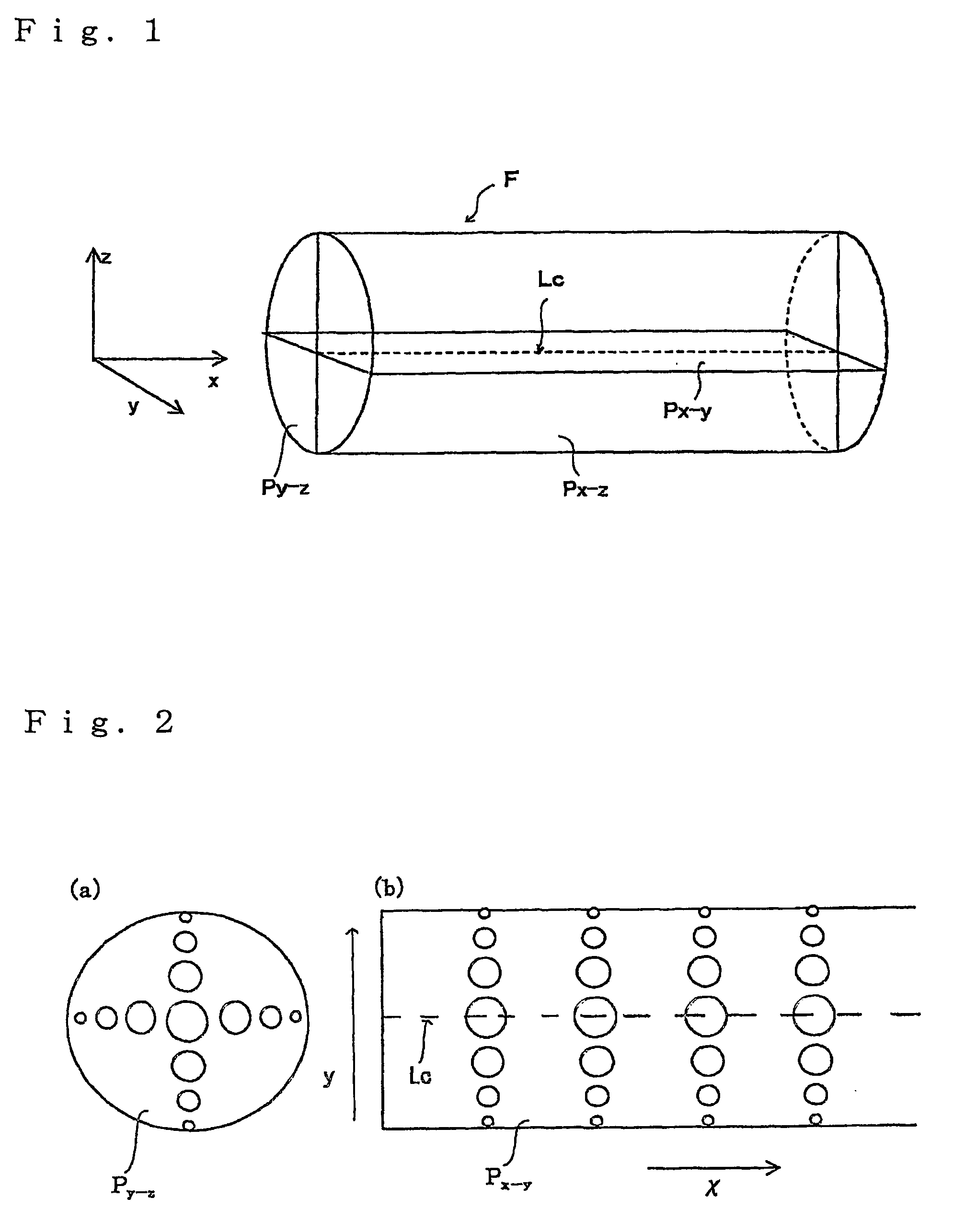

Plastic optical fibers and processes for producing them

InactiveUS20060228082A1Shorten the timeLow costOptical fibre with graded refractive index core/claddingOptical articlesEngineeringRefractive index

Owner:FUJIFILM HLDG CORP +1

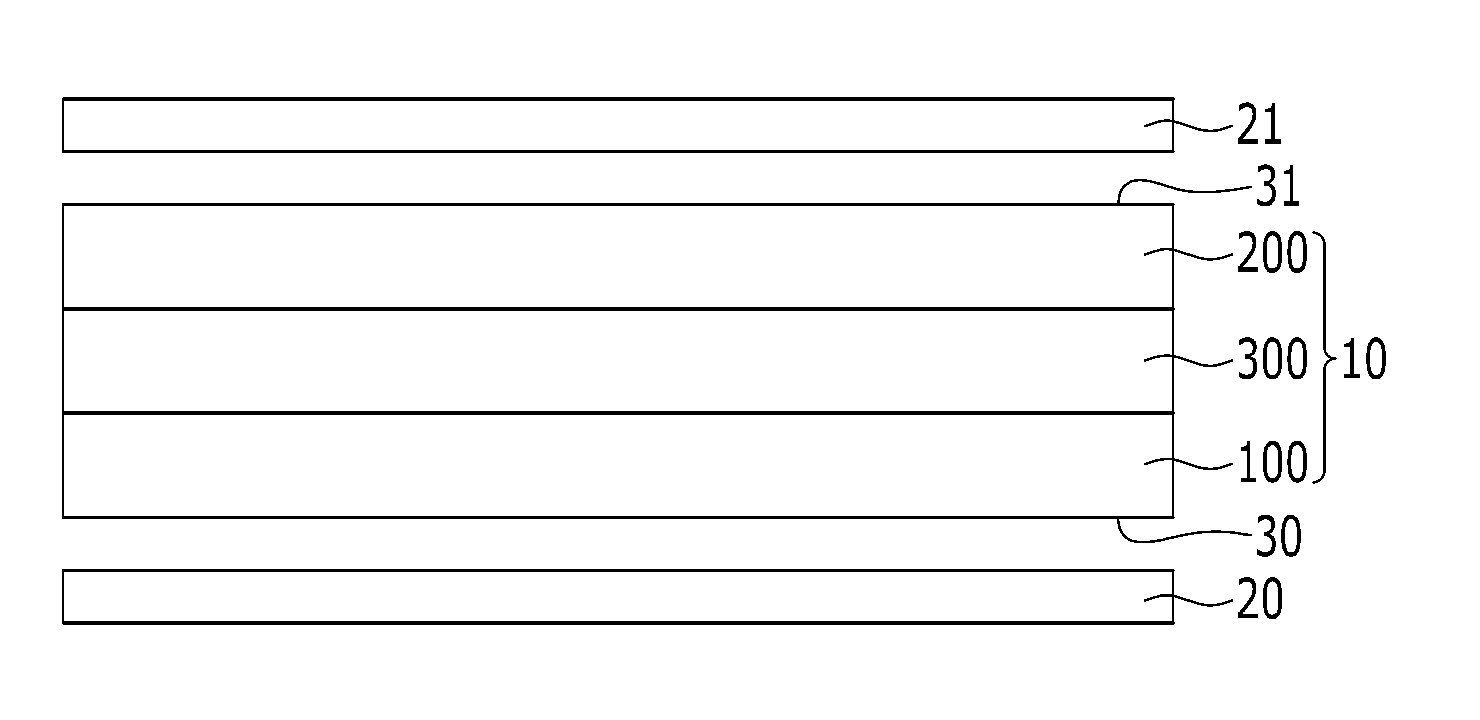

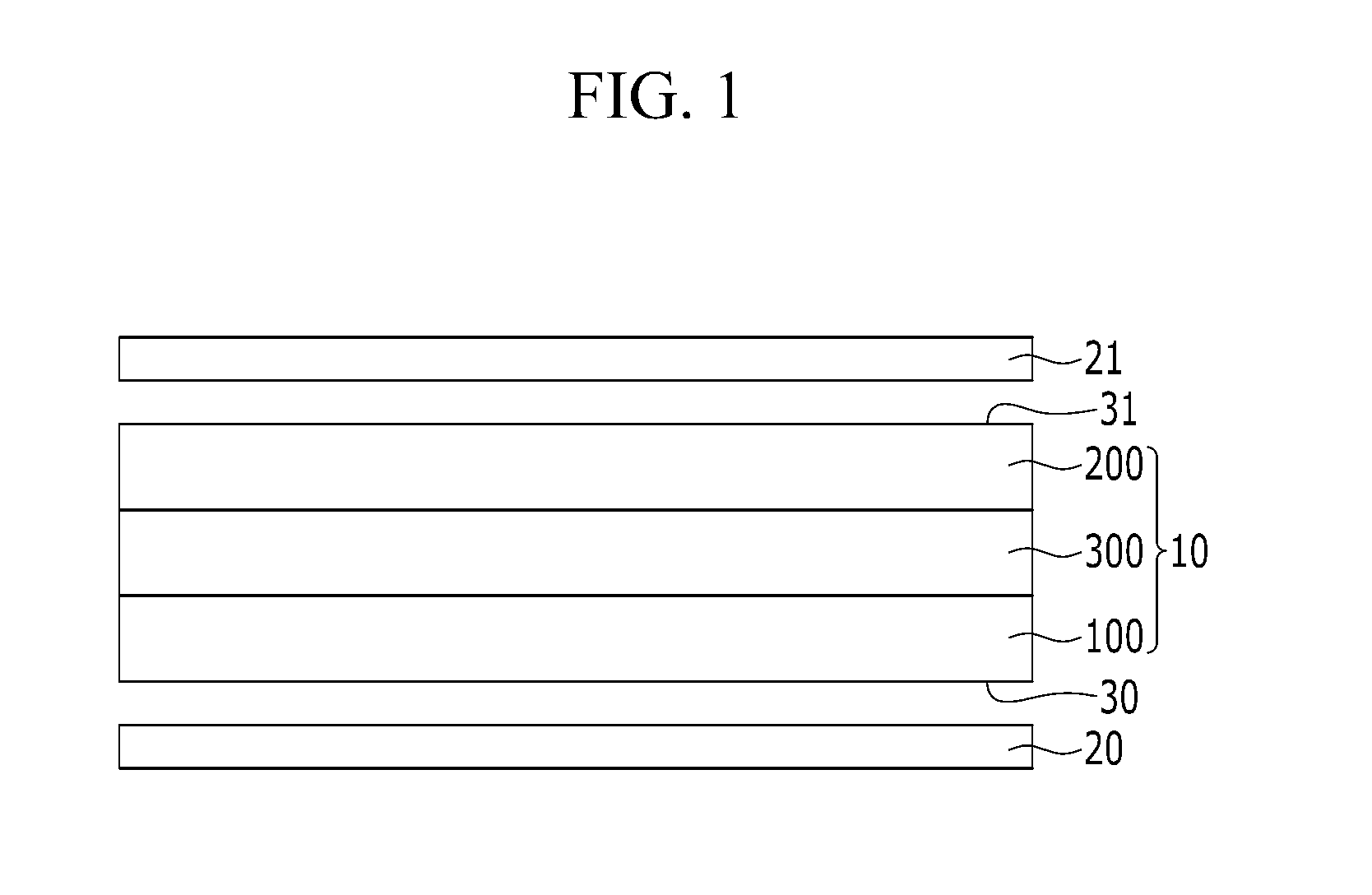

Spectacle lens and spectacles

InactiveUS20180299700A1Improve heat resistanceQuality improvementSpectales/gogglesOptical articlesEyewearLens plate

Provided is a spectacles lens that includes a multilayer film disposed on a surface of a lens base material directly or via one or more other layers, wherein the multilayer film includes a plurality of high refractive index material layers and a plurality of low refractive index material layers, and a thickness of the thickest high refractive index material layer among the plurality of high refractive index material layers is greater than a thickness of the thickest low refractive index material layer among the plurality of low refractive index material layers.

Owner:HOYA LENS THAILAND LTD

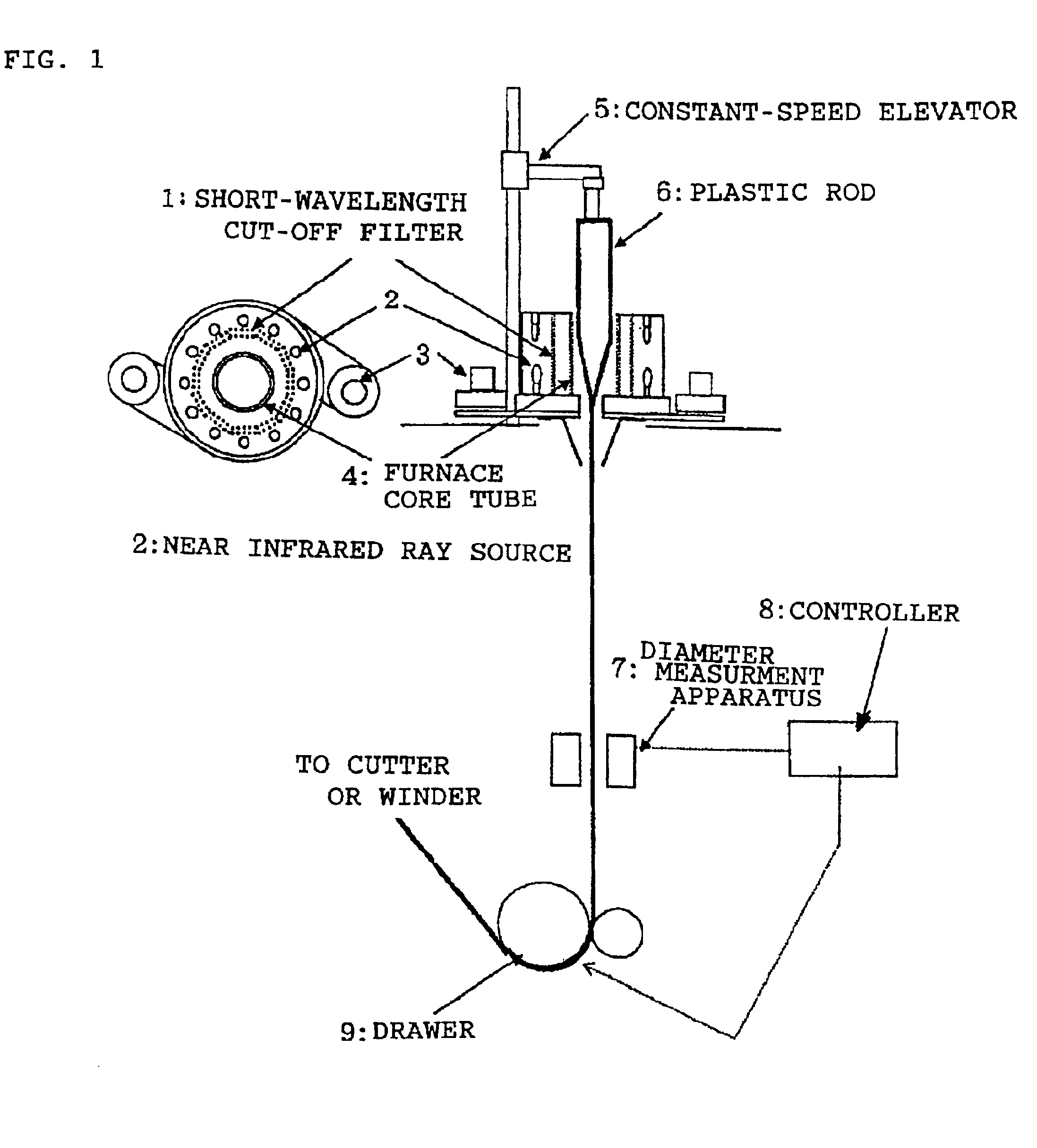

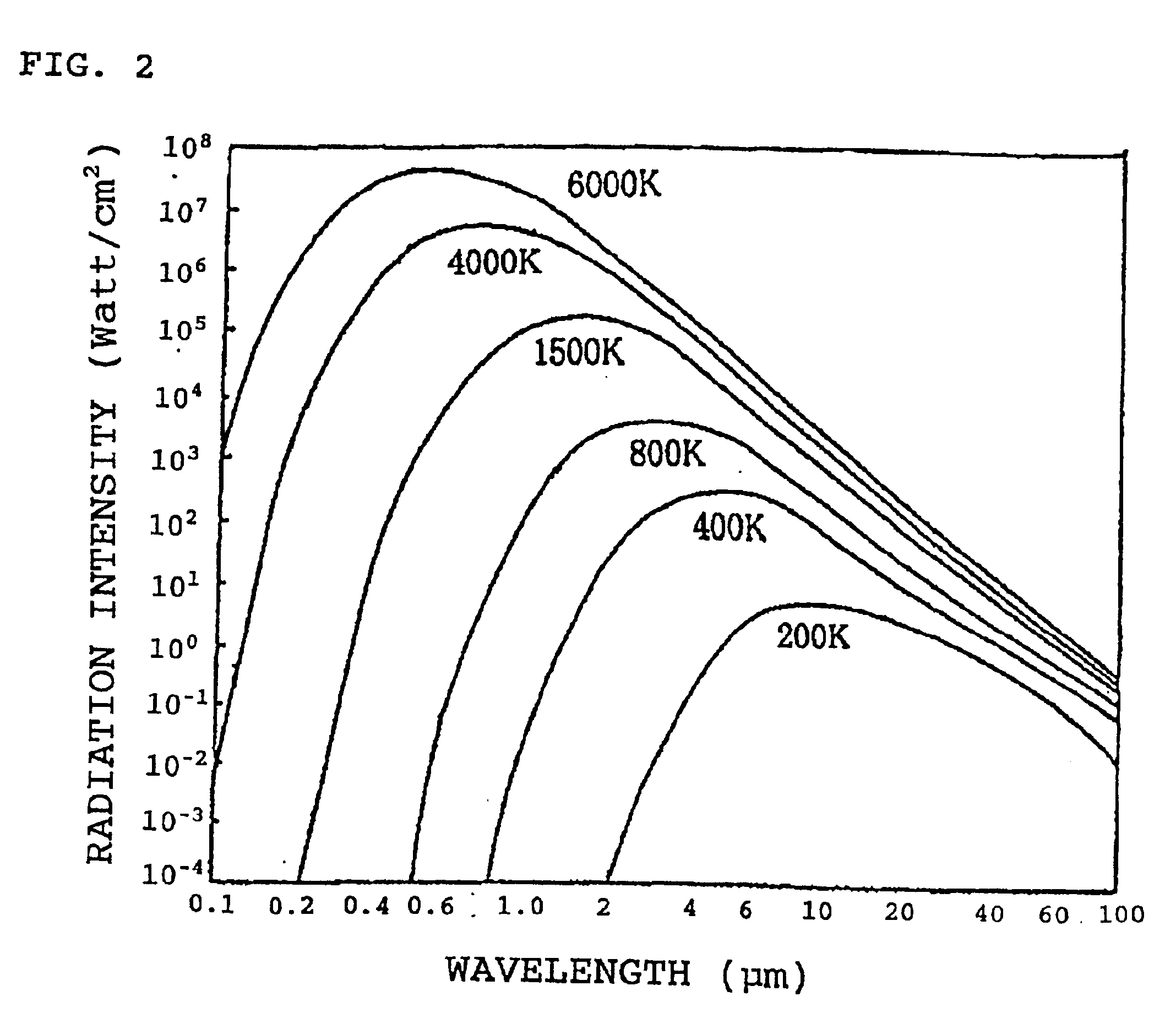

Method of manufacturing plastic optical fiber

InactiveUS6908576B2Fast productionQuality improvementOptical articlesOptical light guidesEngineeringPlastic optical fiber

Owner:KURARAY CO LTD

Medical devices having antimicrobial coatings thereon

ActiveUS8172395B2Improve antibacterial propertiesLow cytotoxicitySurgeryOptical articlesOptical propertyExtended wear contact lenses

Owner:ALCON INC

Nanoprocessing and heterostructuring of silk

InactiveUS20180354066A1Improve surface smoothnessEasy to controlOptical articlesDomestic articlesEngineeringAbnormal shaped

The present invention relates to nanoprocessing and heterostructuring of silk. It has been shown that few-cycle femtosecond pulses are ideal for controlled nanoprocessing and heterostructuring of silk in air. Two qualitatively different responses, ablation and bulging, were observed for high and low laser fluence, respectively. Using this approach, new classes of silk-based functional topological microstructures and heterostructures which can be optically propelled in air as well as on fluids remotely with good control have been fabricated.

Owner:INDIAN INST OF SCI EDUCATION & RES

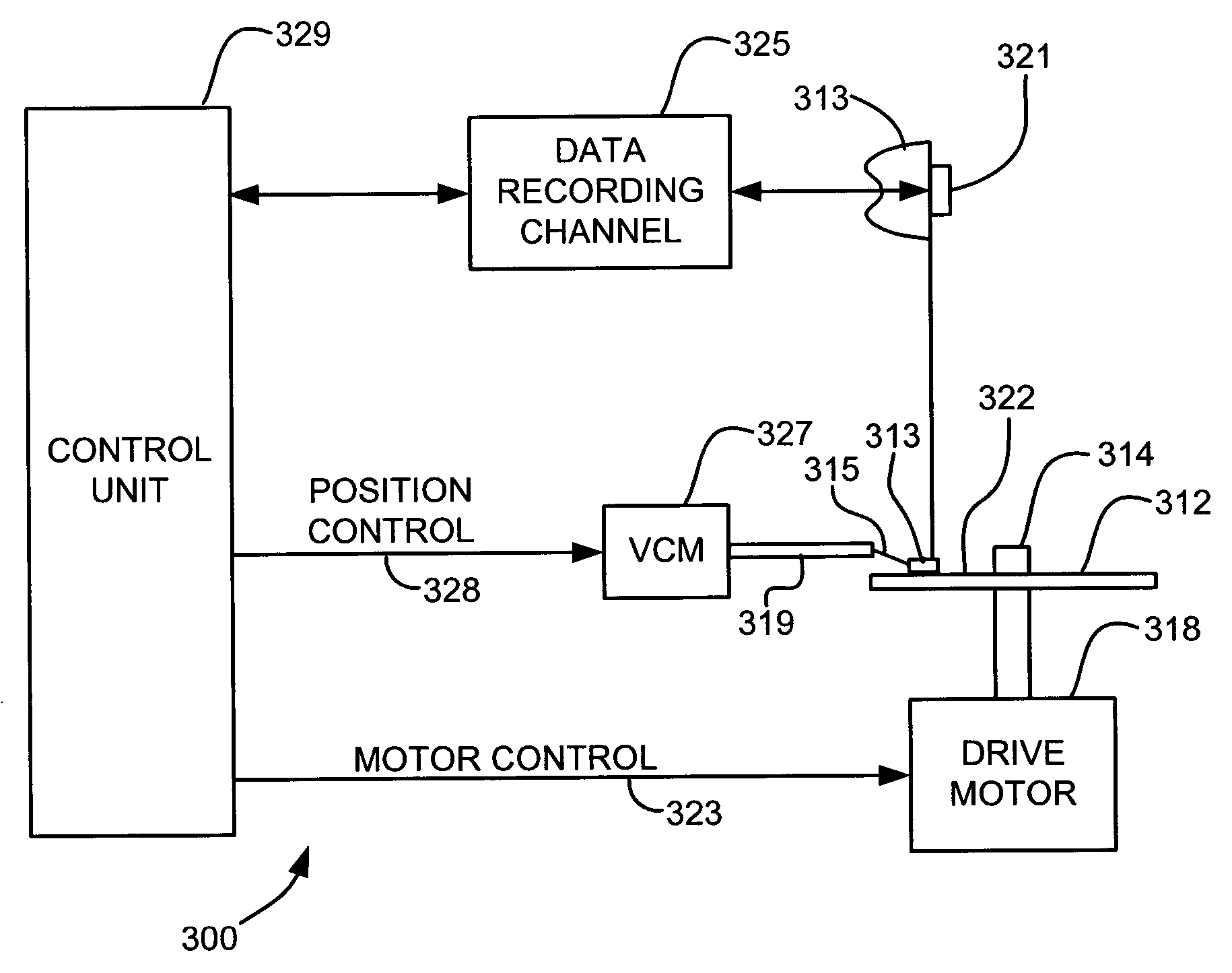

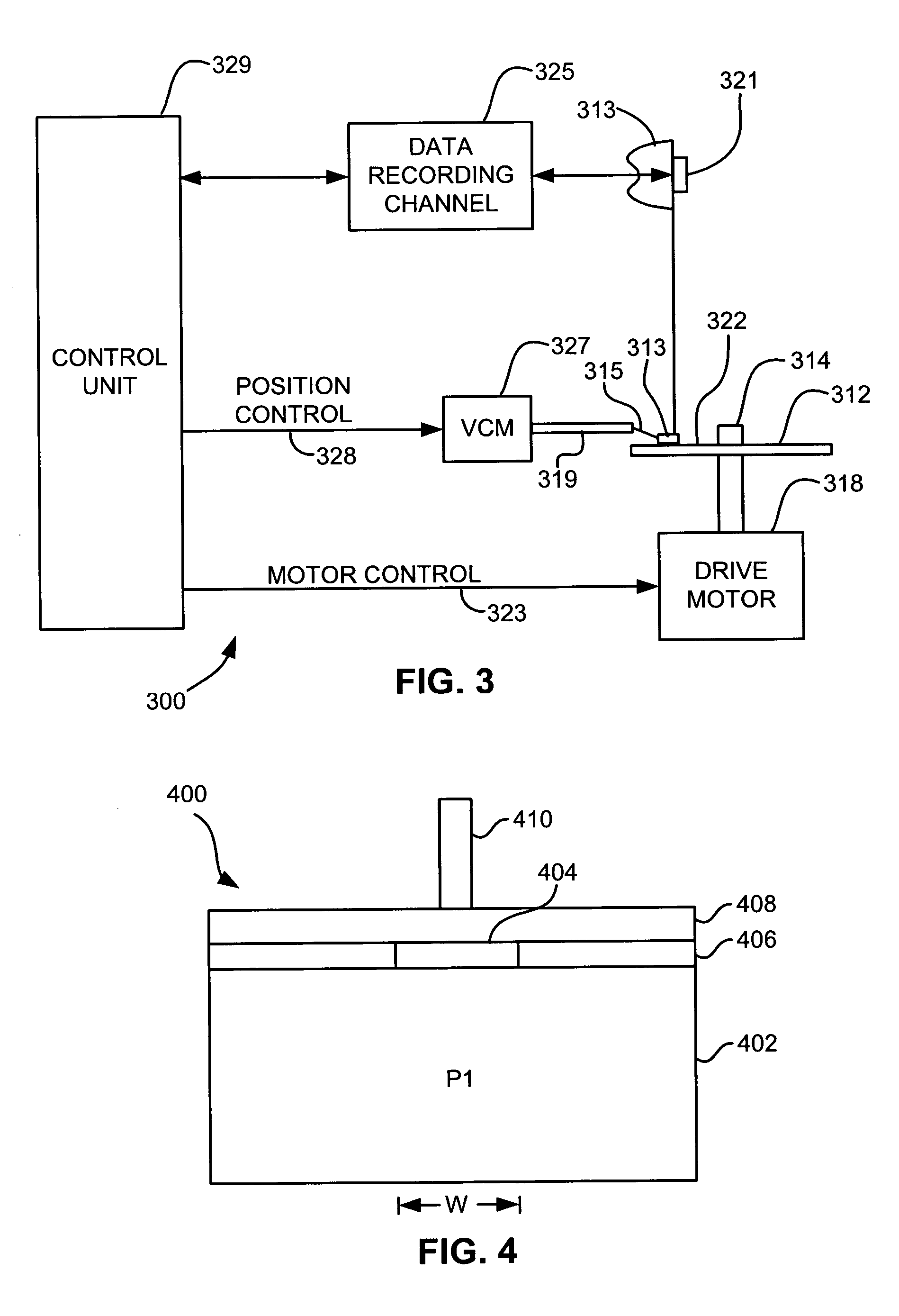

Method for creating inductive write head with steep shoulder at notch

InactiveUS20050023243A1High momentManufacture head surfaceDecorative surface effectsEngineeringPhotoresist

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

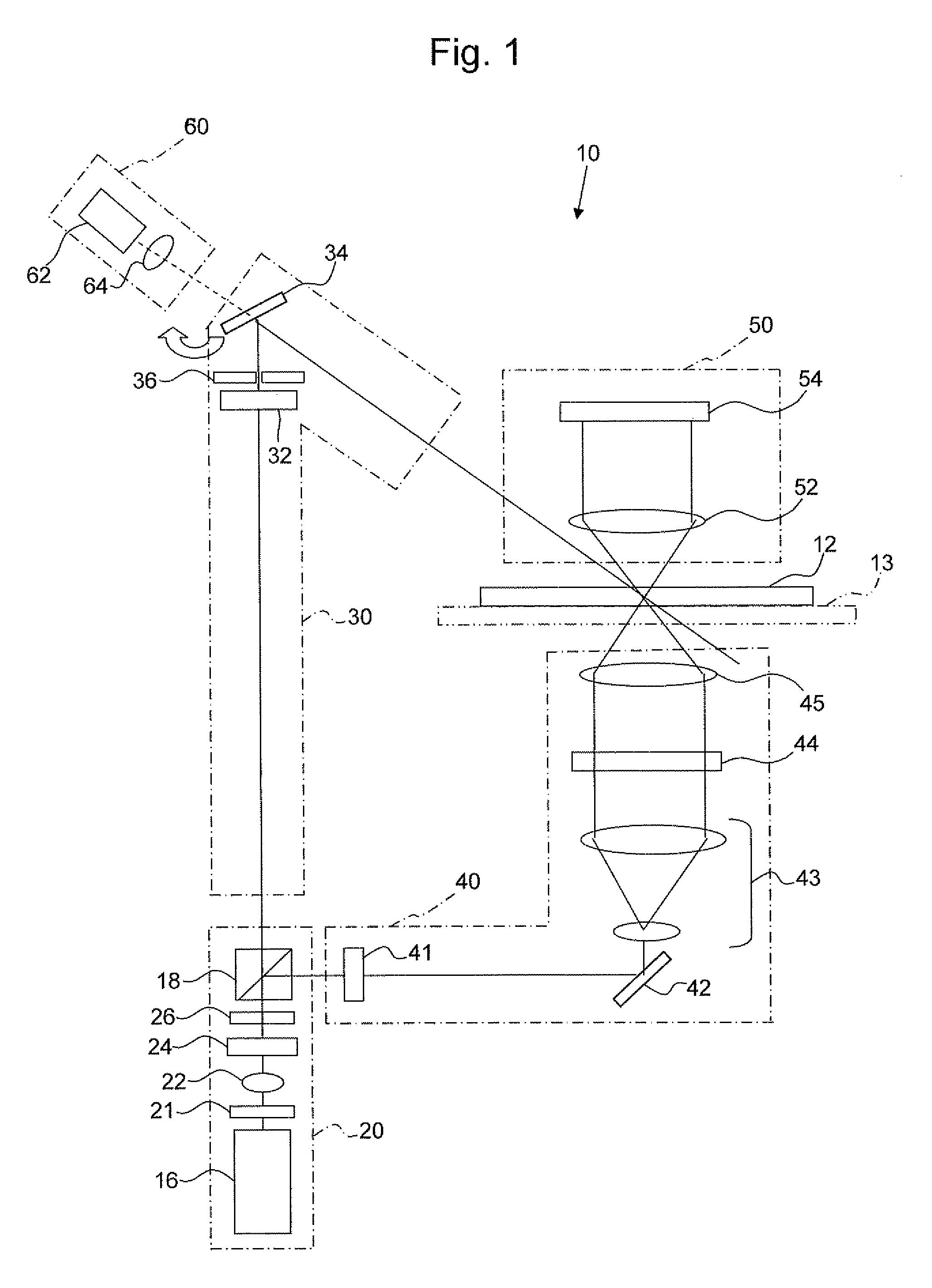

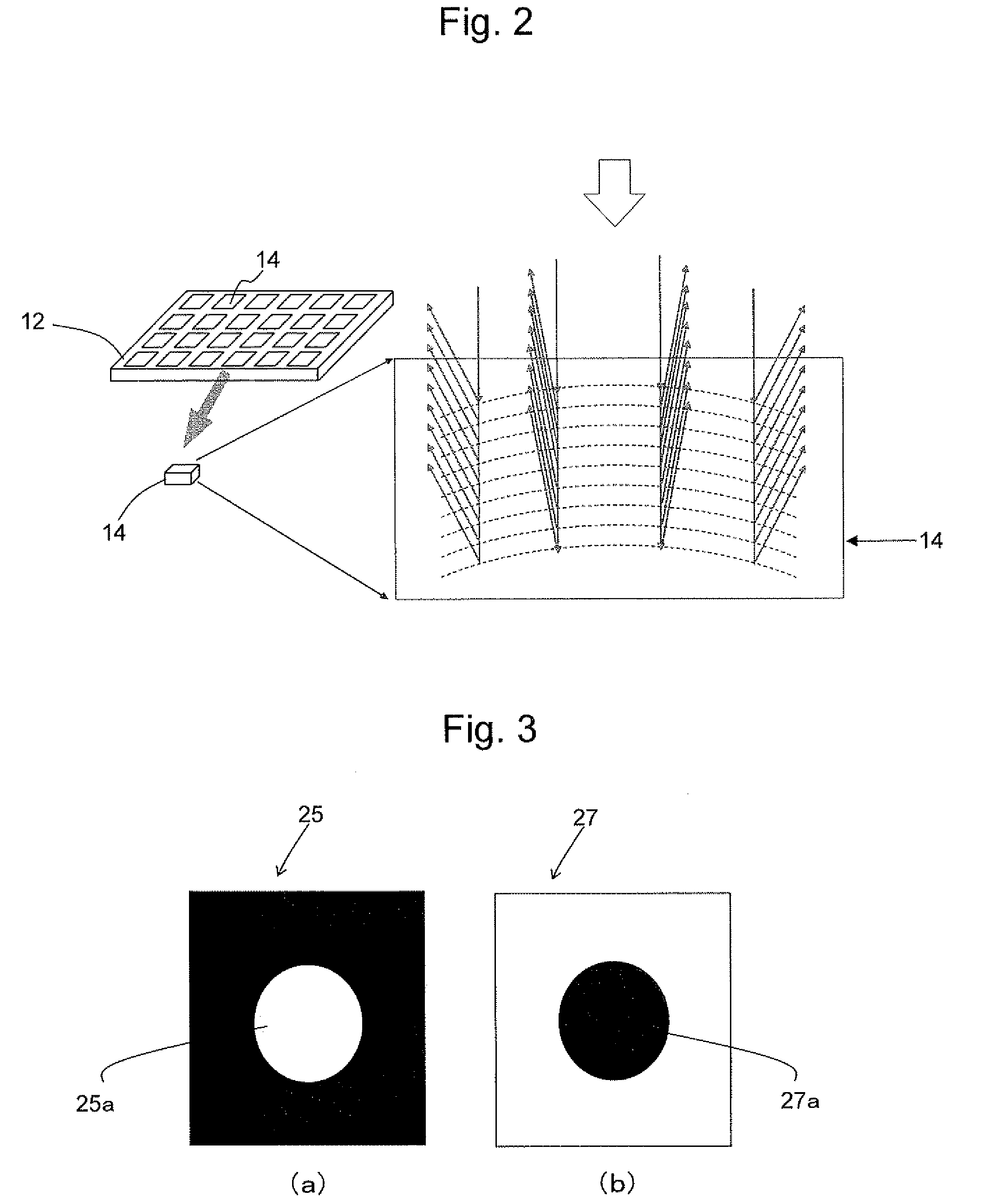

Method for determining recording exposure for holographic recording medium and method for recording thereon

InactiveUS20120256334A1Short timePhotomechanical apparatusOptical articlesLaser beamsHolographic recording

Owner:TDK CORPARATION

Camera package, method for manufacturing camera package, and electronic device

PendingUS20220130880A1Increase in sizeReduce manufacturing costSolid-state devicesOptical articlesEngineeringMechanical engineering

The present disclosure relates to a camera package, a method for manufacturing a camera package, and an electronic device with which it is possible to reduce manufacturing cost for lens formation.The camera package according to the present disclosure includes: a solid-state imaging element; and a lens formed above a transparent substrate that protects the solid-state imaging element. A lens formation region in which the lens is formed above the transparent substrate and a lens free region around the lens formation region differ in contact angle. The present disclosure can be applied to, for example, a camera package in which a lens is disposed above a solid-state imaging element, or the like.

Owner:SONY SEMICON SOLUTIONS CORP

Black film

Owner:KURARAY CO LTD

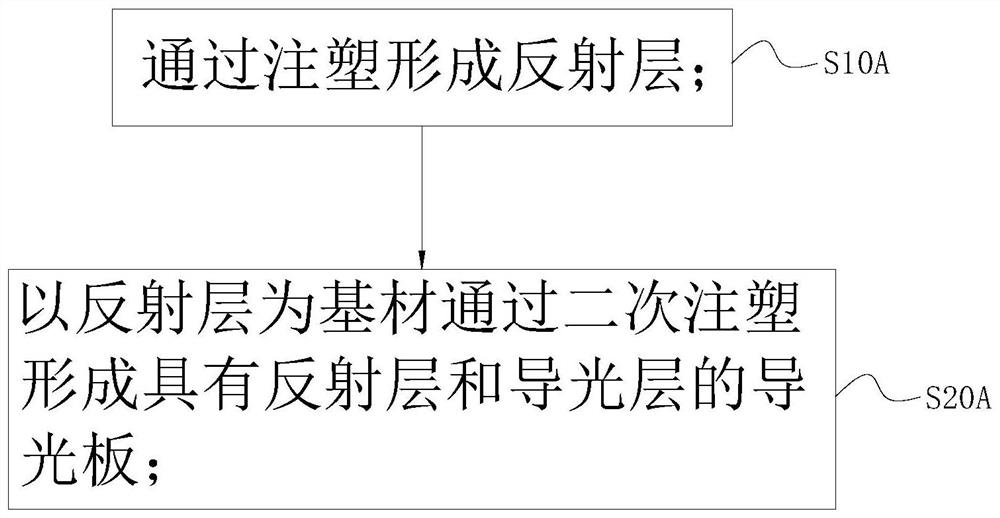

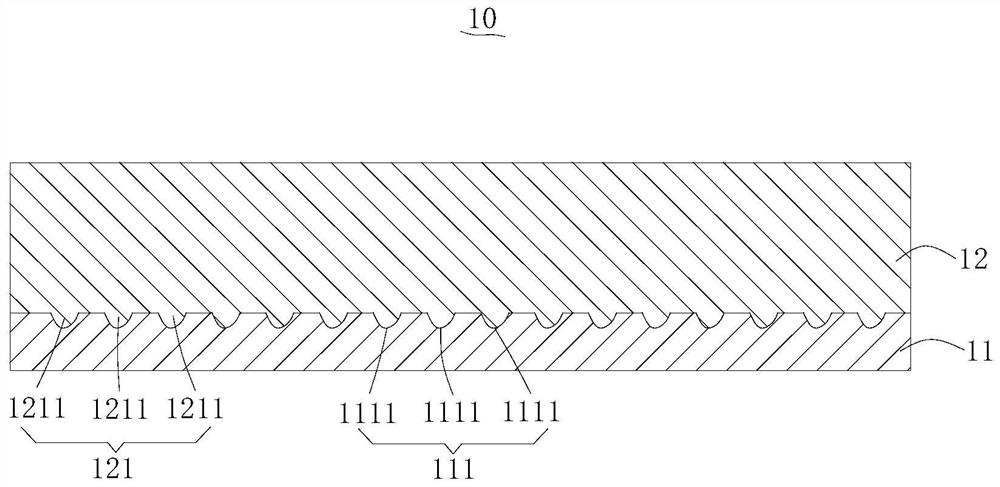

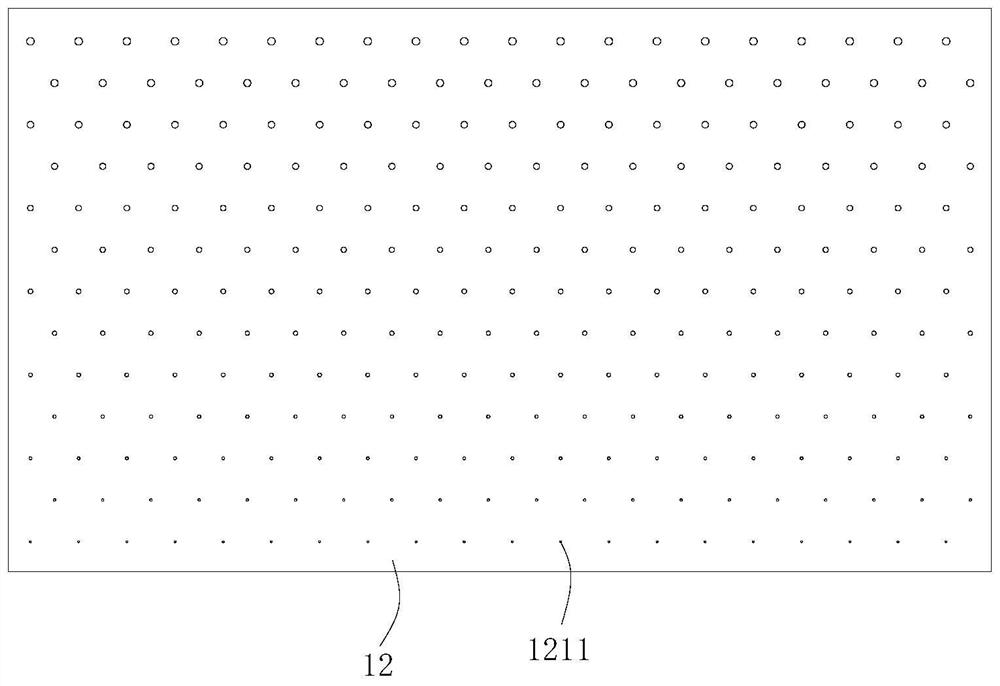

Light guide plate making method, light guide plate and side-entering backlight module

InactiveCN111703015AReduce manufacturing process stepsShorten the design and production cycleMechanical apparatusOptical articlesLight guideEngineering

Owner:HEFEI HUIKE JINYANG TECH

Die

Owner:NINGBO SUNNY AUTOMOTIVE OPTECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap