Optical fiber impulse sensor fabricating method

a technology of optical fiber and impulse sensor, which is applied in the direction of instruments, other domestic objects, optical elements, etc., can solve the problems of time-consuming insertion of hpof into the cavity and poor workability, and achieve the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

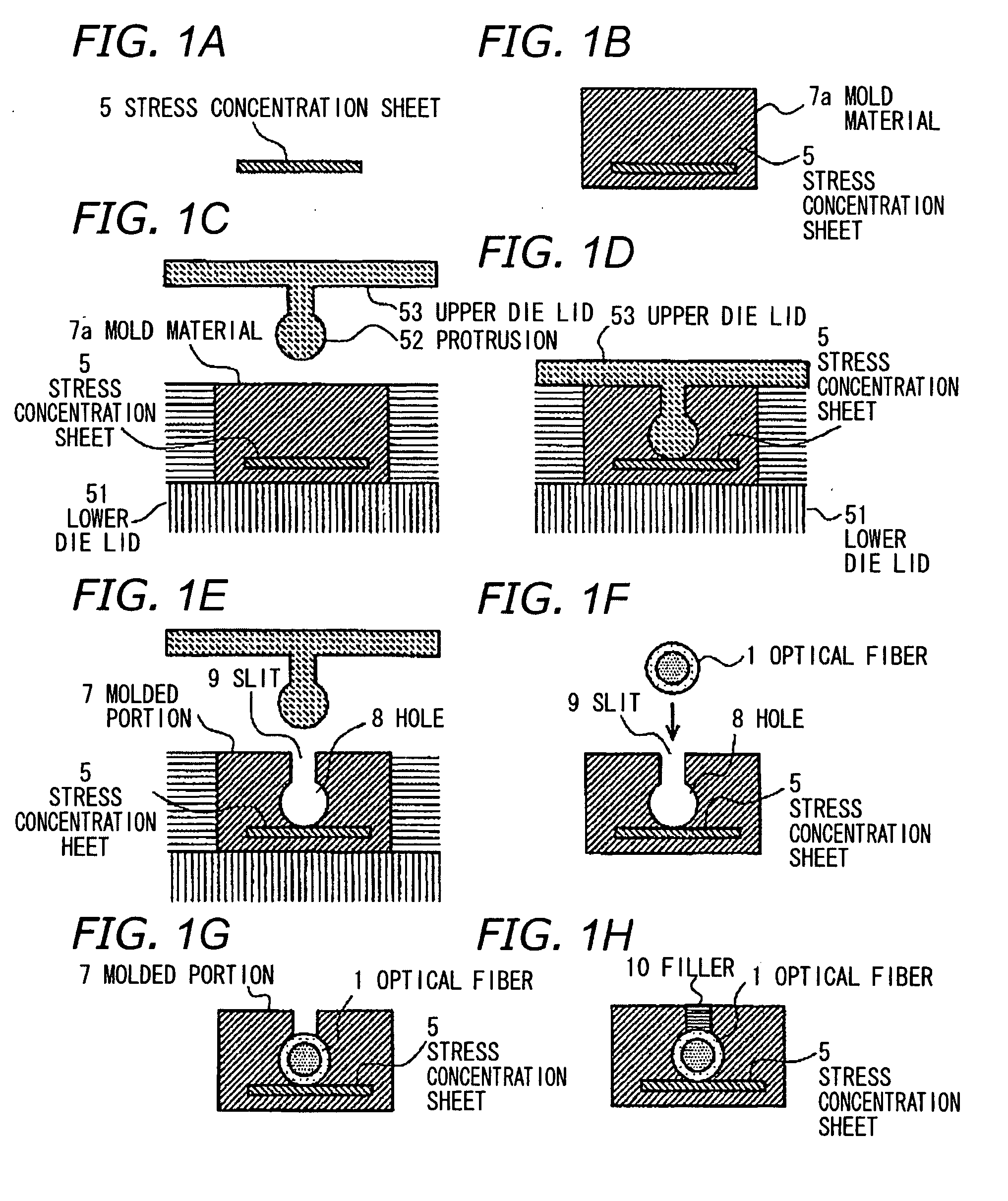

Optical Fiber Impulse Sensor Fabrication Method FIGS. 1A-1H show a process for fabricating an optical fiber impulse sensor according to the present invention.

[0027] Around the perimeter of a stress concentration sheet 5 shown in FIG. 1A, is extruded and molded a mold material 7a, as shown in FIG. 1B. It should be noted, however, that this invention is applicable even in the case of no stress concentration sheet 5.

[0028] As shown in FIG. 1C, this is followed by mounting the mold material 7a to a lower die lid 51 for pressing and molding. An upper die lid 53 for pressing and molding, which has a protrusion 52 formed in an integral shape of an optical fiber insertion hole 8 and an insertion slit 9 (in the figure, a shape having a substantially keyhole-shaped cross section) is caused to face the lower die lid 51 for pressing and molding.

[0029] As shown in FIG. 1D, the upper die lid 53 is pressed down and fitted on the lower die lid 51, and as shown in FIG. 1E, is then removed upward th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap