Limestone-cement liquid grinding aid and preparation method thereof

A limestone and grinding aid technology, applied in the field of grinding aids, can solve the problems of low output, long cement setting time, low cement strength, etc., and achieve the effects of increasing output, improving cement workability, and improving grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: a kind of limestone cement liquid grinding aid, composition is as follows:

[0014] polymeric polyol 12%,

[0015] Triisopropanolamine 12%,

[0016] Sodium Hexametaphosphate 12%,

[0017] Sodium sulfamate 8%,

[0018] The balance is water, and the total amount is 100%.

[0019] The preparation method of the limestone cement liquid grinding aid, the steps are: according to the formula ratio, pour a sufficient amount of water into the reaction kettle, heat to 50°C and keep the temperature constant, add sodium hexametaphosphate and stir for 30 minutes, then add sodium sulfamate and stir for 30 minutes, and cool down After reaching room temperature, add polymeric polyol and triisopropanolamine and stir for 20 minutes, and then filter impurities through a 150-mesh stainless steel sieve to obtain product 1.

Embodiment 2 to Embodiment 5

[0021] Repeat the method of Experimental Example 1 by each component content specified in the following table 1, obtain the limestone cement liquid grinding aid product 2 to product 5 of different component content respectively:

[0022] Table 1

[0023] Component (%)

Example 1

Example 2

Example 3

Example 4

Example 5

polymer polyol

12

15

12

12

10

12

10

13

14

15

Hexametaphosphate

12

15

12

10

10

Sodium sulfamate

8

10

5

8

7

get

Product 1

Product 2

Product 3

Product 4

Product 5

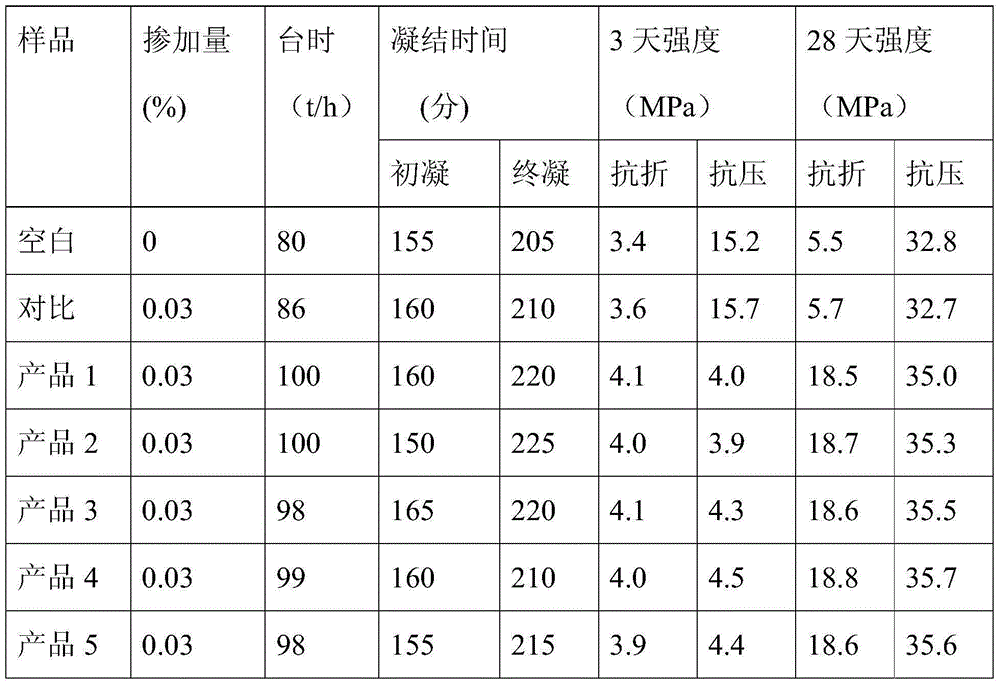

[0024] With the limestone cement liquid grinding aid product that makes among the embodiment 1 to embodiment 5, in addition amount is 0.03% of cement quality, carry out the comparative experiment and the blank experiment of adding limestone cement liquid grinding aid and common grinding aid , the experimental result...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap