Anti-radiation cracking large-volume heavy concrete as well as preparation method and construction method thereof

A heavy-concrete, large-volume technology used in the field of concrete to reduce adverse effects, optimize heat release history, and improve work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0074] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

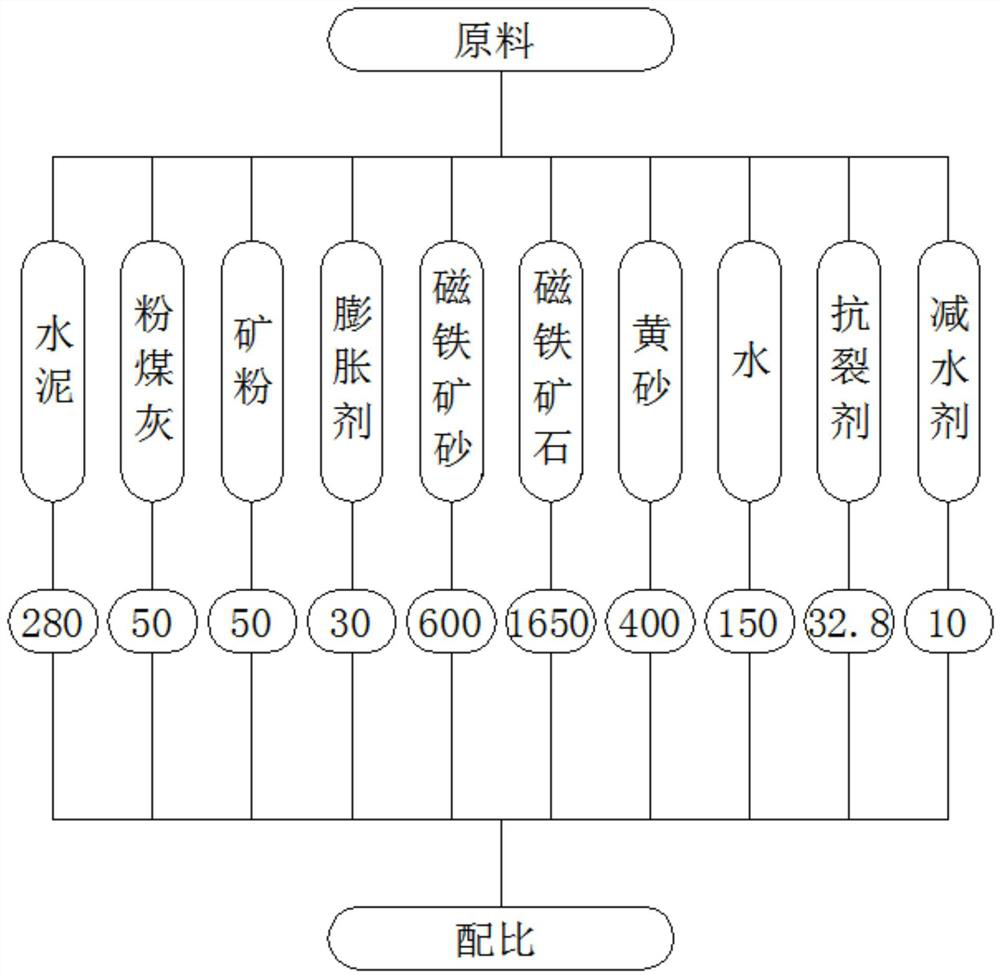

[0075] see Figure 1 to Figure 4 , The present invention provides a technical solution: a large-volume heavy concrete for preventing radiation cracking, the formula and proportion are as follows: cement 280, fly ash 50, mineral powder 50, expansion agent 30, magnetite sand 600, magnetite 1650, yellow sand 400, water 150, anti-cracking agent 32.8, water reducing agent 10.

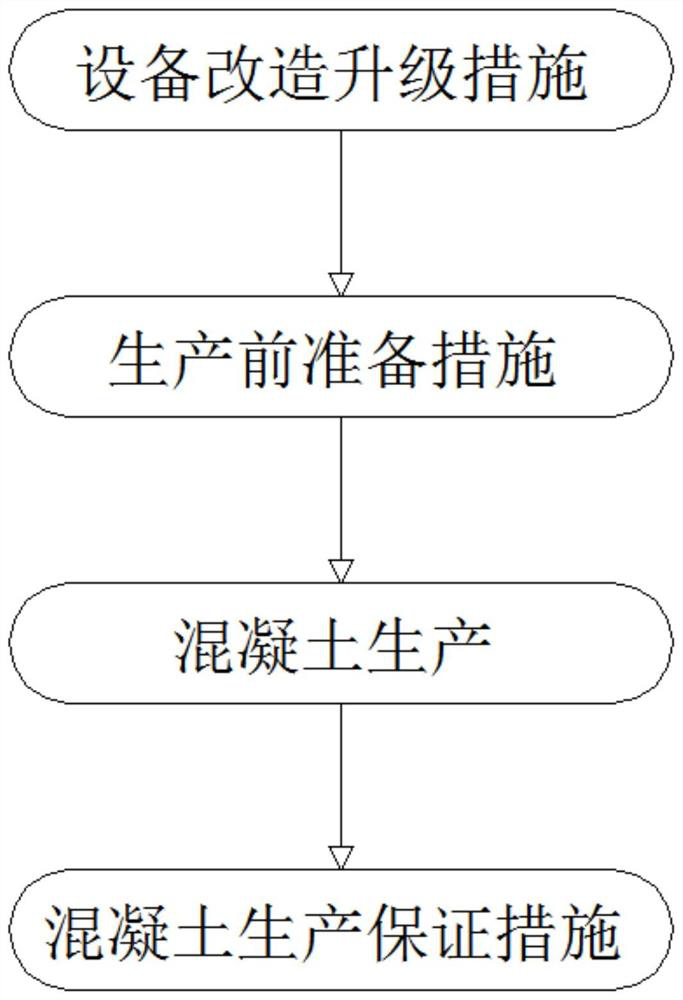

[0076] A preparation method of large-volume heavy concrete for preventing radiation cracking, the specific steps are as follows:

[0077] Step 1: Equipment transformation and upgrading measures; the specific steps are as follows:

[0078] ①: All mixer blades of the production line are replaced with new wear-resistant blades, which are specially used for heavy concre

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap