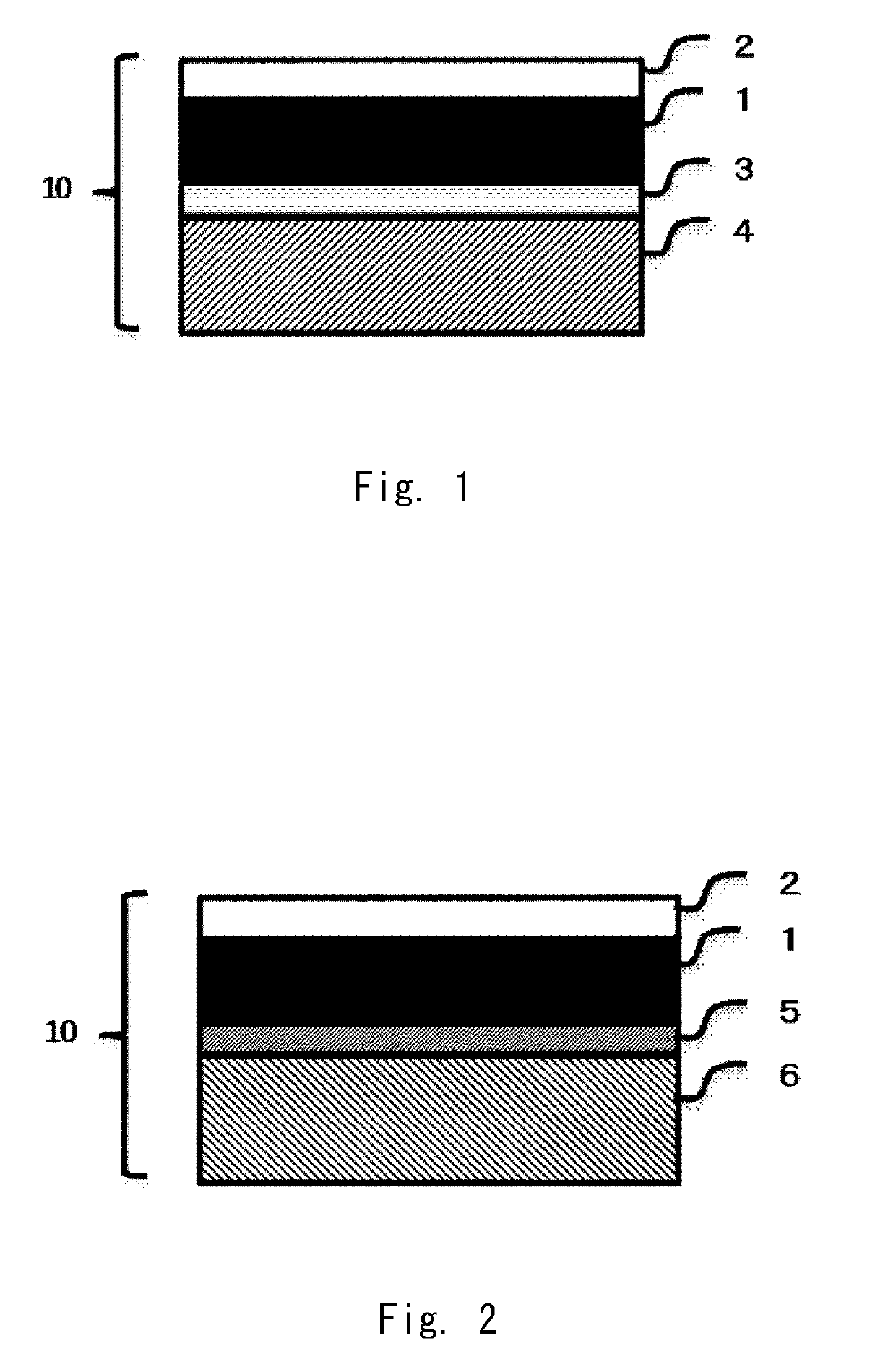

Black film

a black film, black technology, applied in the direction of synthetic resin layered products, protective garments, furniture parts, etc., can solve the problems of whitish hue, inability to obtain film that excels in deep and clear coal blackness, and notably lose the design sophistication of decorative molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

manufacturing example 1

[Preparation of Organic Dye-Containing Resin (P-1)]

[0134]The following materials were melt-compounded, and an organic dye-containing resin (P-1), which was a black acrylic resin, was obtained.

[0135]methacrylic resin (X-1): 70.64 mass %

[0136]multilayer structure rubber particle (Y): 27.66 mass %

[0137]Solvent Green 28: 0.50 mass %

[0138]Solvent Green 3: 0.90 mass %

[0139]Solvent Violet 36: 0.30 mass %

[0140]In the organic dye-containing resin (P-1), the content of a structural unit derived from an acrylic acid alkyl ester having a carbon number of 6 to 12 was 10.14 mass %.

manufacturing examples 2 to 11

[Preparation of Organic Dye-Containing Resins (P-2) to (P11)]

[0141]Organic dye-containing resins (P-2) to (P-8) and (P-11), which were black acrylic resins, an organic dye-containing resin (P-9), which was a black polycarbonate resin, and an organic dye-containing resin (P-10), which was a black ABS resin, were obtained in a similar manner to that in Manufacturing Example 1 except that the source materials and the mixing ratios were changed in accordance with Table 1.

manufacturing example 12

[Preparation of Acrylic Resin (Q)]

[0142]The following materials were melt-compounded, and a transparent acrylic resin (Q) was obtained.

[0143]methacrylic resin (X-2): 79.20 mass %

[0144]block copolymer (Z): 19.80 mass %

[0145]TINUVIN 479 (manufactured by Toyotsu Chemiplas Corporation): 1.0 mass %

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

- where in a L*a*b* color system measurement compliant with HS Z 8781-4, L* (lightness) is no more than 10, an absolute value of a* is no more than 2.0, and an absolute value of b* is no more than 2.0, and a total light transmittance obtained after the black film is stretched twofold in one axial direction at a temperature higher than a glass transition temperature by 20° C. is no more than 3.0%.

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap